light HONDA CIVIC 2002 7.G Repair Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 2002, Model line: CIVIC, Model: HONDA CIVIC 2002 7.GPages: 1139, PDF Size: 28.19 MB

Page 601 of 1139

Conventional Brake Components

Brake Pedaland Brake PedalPosition Switch Adjustment

Pedal Height

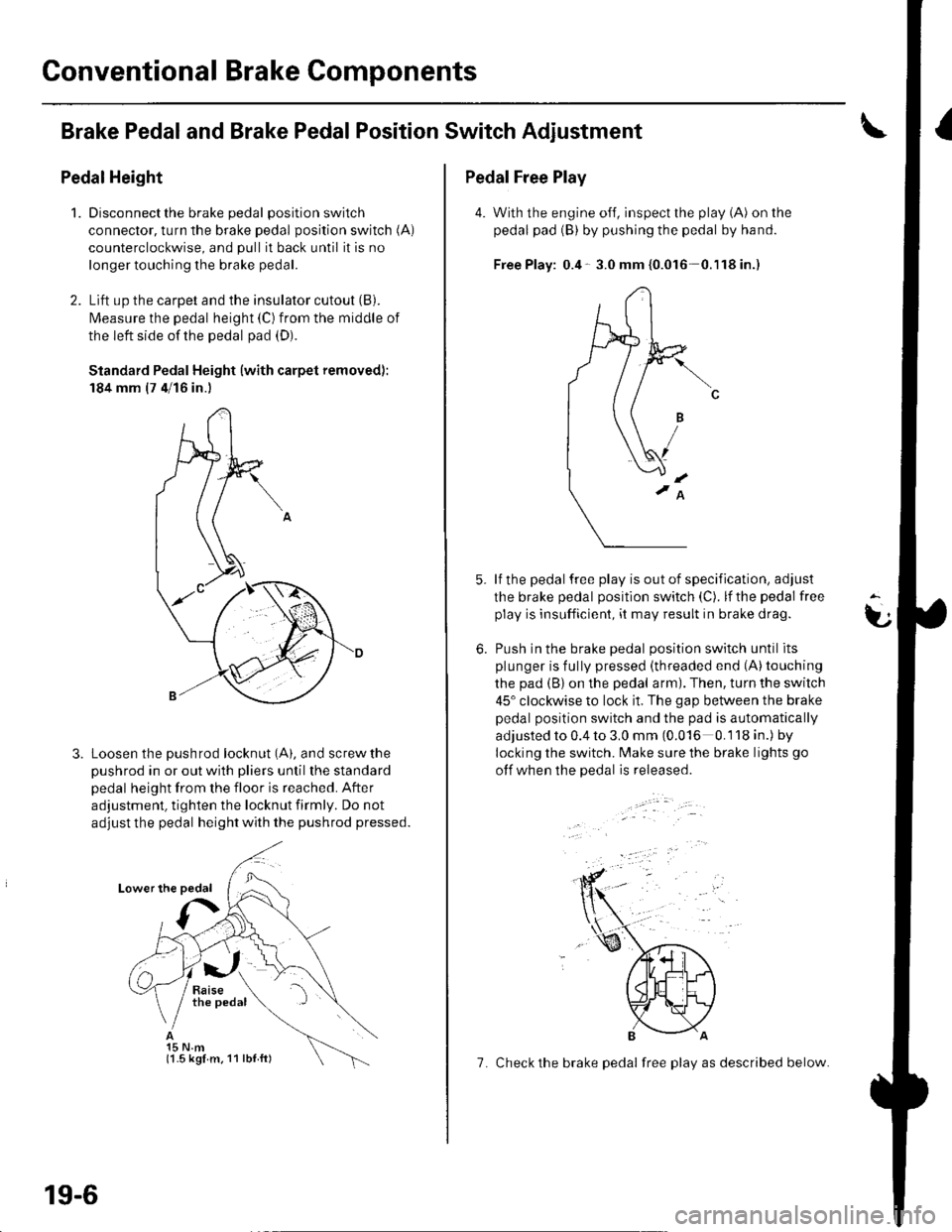

1.Disconnect the brake pedal position switch

connector, turn the brake pedal position switch (A)

counterclockwise, and pull it back until it is no

longer touching the brake pedal.

Lift up the carpet and the insulator cutout (B).

l\4easure the pedal height (C) from the middle of

the left side of the pedal pad (D).

Standard Pedal Height (with carpet removed):

184 mm (7 4/16 in.)

Loosen the pushrod locknut (A), and screw the

pushrod in or out with pliers until the standard

pedal height from the floor is reached. After

adjustment, tighten the locknut firmly. Do not

adjust the pedal height with the pushrod pressed.

15 N.m(1.5 kgl m. 11 lbl ft)

19-6

7. Check the brake pedal free play as described below.

Pedal Free Play

4. With the engine off, inspect the play (A) on the

pedal pad (B) by pushing the pedal by hand.

Free Play: 0.4- 3.0 mm {0.016 0.'l18in.)

lf the pedal free play is out of specification, adjust

the brake pedal position switch (C). lf the pedal free

play is insufficient, it may result in brake drag.

Push in the brake oedal oosition switch until its

plunger is fully pressed (threaded end (A)touching

the pad (B) on the pedal arm). Then, turn the switch

45" clockwise to lock it. The gap between the brake

pedal position switch and the pad is automatically

adjusted to 0.4 to 3.0 mm (0.016 0.118 in.) by

locking the switch. Make sure the brake lights go

otf when the pedal is released.

t

6.

Page 602 of 1139

Parking Brake Check and Adiustment

Check

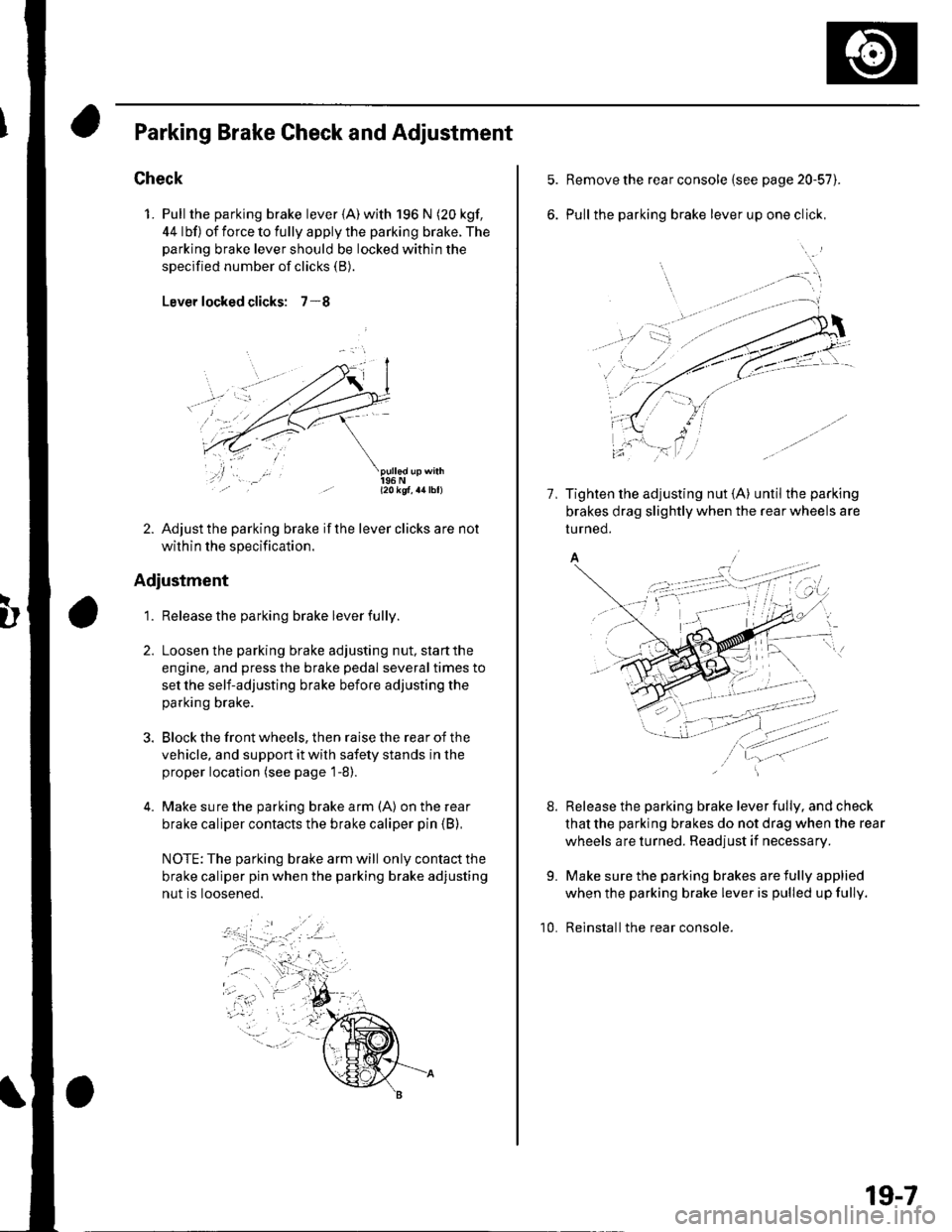

1. Pull the parking brake lever {A) with 196 N (20 kgf,

44 lbf) of force to fully apply the parking brake. The

parking brake lever should be locked within the

specified number of clicks (B).

Lever locked clicks: 7-8

- l2okqf, a4lbl)

2. Adjust the parking brake if the lever clicks are not

within the specification.

Adjustment

1. Release the parking brake lever fully.

Loosen the parking brake adjusting nut, start the

engine, and press the brake pedal several times to

set the self-adjusting brake before adjusting the

parking brake.

Block the front wheels, then raise the rear of the

vehicle, and support it with safety stands in the

proper location (see page 1-8).

Make sure the parking brake arm (A) on the rear

brake caliper contacts the brake caliper pin (B),

NOTE: The parking brake arm will only contact the

brake caliper pin when the parking brake adjusting

nut is loosened.

Remove the rear console {see page 20-57).

Pull the parking brake lever up one click,

7, Tighten the adjusting nut {A} until the parking

brakes drag slightly when the rear wheels are

tu rned.

A/

Release the parking brake lever fully, and check

that the parking brakes do not drag when the rear

wheels are turned. Readjust if necessary.

Make sure the parking brakes are fully applied

when the parking brake lever is pulled up fully.

Reinstall the rear console.

8.

9.

10.

19-7

Page 613 of 1139

Gonventional Brake Components

IBrake Booster Test

Functional Test

1. With the engine stopped, press the brake pedal

several times to deplete the vacuum reservoir, thenpress the pedal hard, and hold itfor 15 seconds. lfthe pedal sinks, either the master cylinder is

bypassing internally, or the brake system (master

cylinder, lines. modulator, or calipers) is leaking.

2. Start the engine with the brake pedal pressed. lf thepedal sinks slightly, the vacuum booster is workingproperly. lf the pedal height does not vary, thebooster or check valve is faulty.

3. With the engine running, press the brake pedal

lightly. lfthe brake pedal sinks more than 1O mm

{3/8 in, ) in 3 minutes, the master cylinder is faulty.A slight change in pedal height when the Ay'C

compressor cycles on and off is normal. (The A,/C

compressor load changes the vacuum available tothe booster.)

Leak Test

1. Press the brake pedal with the engine running, thenstop the engine. lf the pedal height does not vary

while pressed for 30 seconds, the vacuum boosteris OK. lf the pedal rises, the booster is faulty.

2. With the engine stopped, press the brake pedal

several times using normal pressure. When thepedal is first pressed, it should oe row.

On consecutive applications, the pedal height

should gradually rise. lfthe pedal position does notvarv, check the booster check valve.

19-18

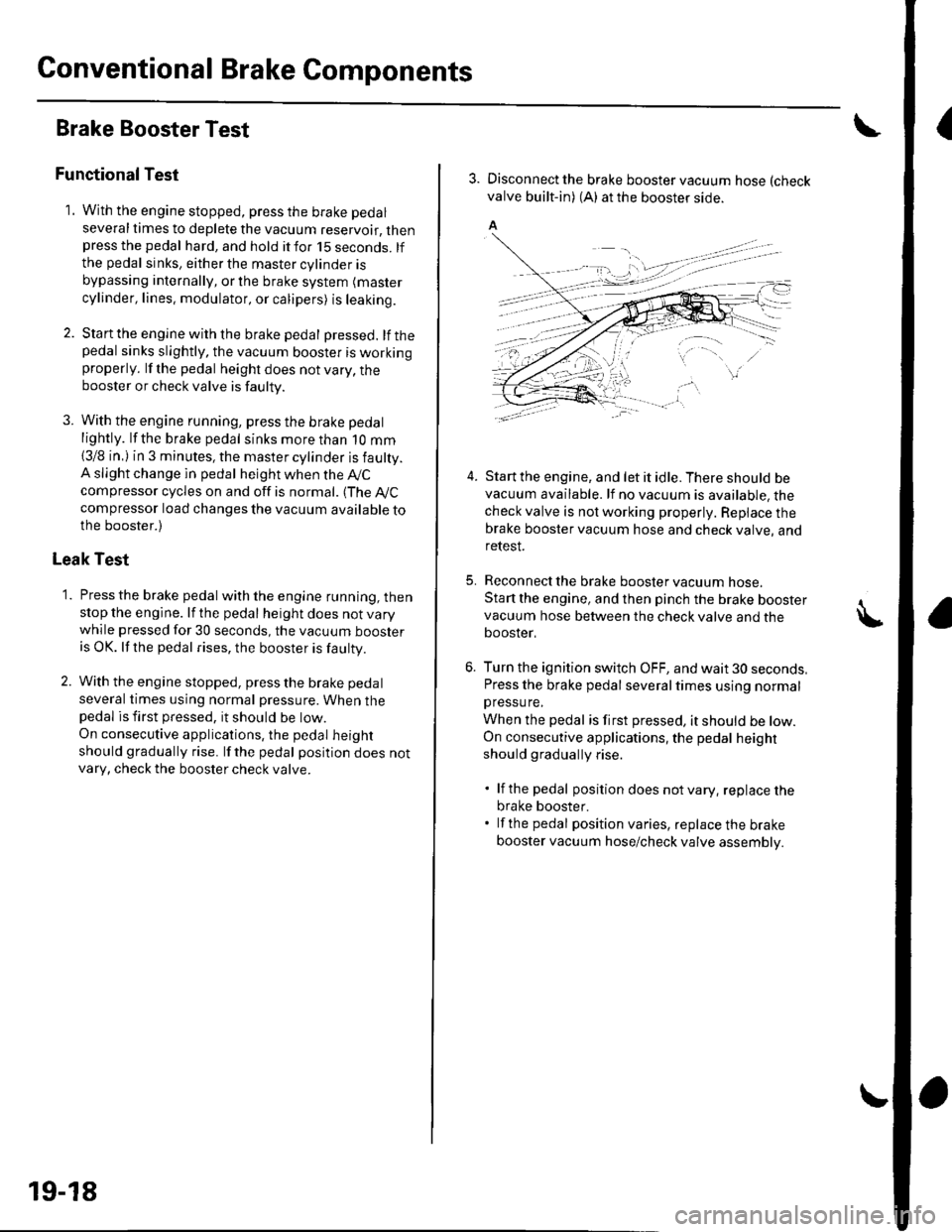

3. Disconnect the brake booster vacuum hose (check

valve built-in) (A) at the booster side.

5.

4.Start the engine, and let it idle. There should bevacuum available. lf no vacuum is available, thecheck valve is not working properly. Repiace thebrake booster vacuum hose and check valve, andrelesI.

Reconnect the brake booster vacuum nose.

Start the engine, and then pinch the brake boostervacuum hose between the check valve and thebooster,

Turn the ignition switch OFF, and wait 30 seconds,Press the brake pedal several times using normalpressu re,

When the pedal is first pressed, it should be low.On consecutive applications, the pedal height

should gradually rise.

. lf the pedal position does notvary, replacethe

brake booster.. lf the pedal position varies, replace the brake

booster vacuum hose/check valve assembly.

Page 666 of 1139

Doors

Door Glass Adiustment {cont'd)

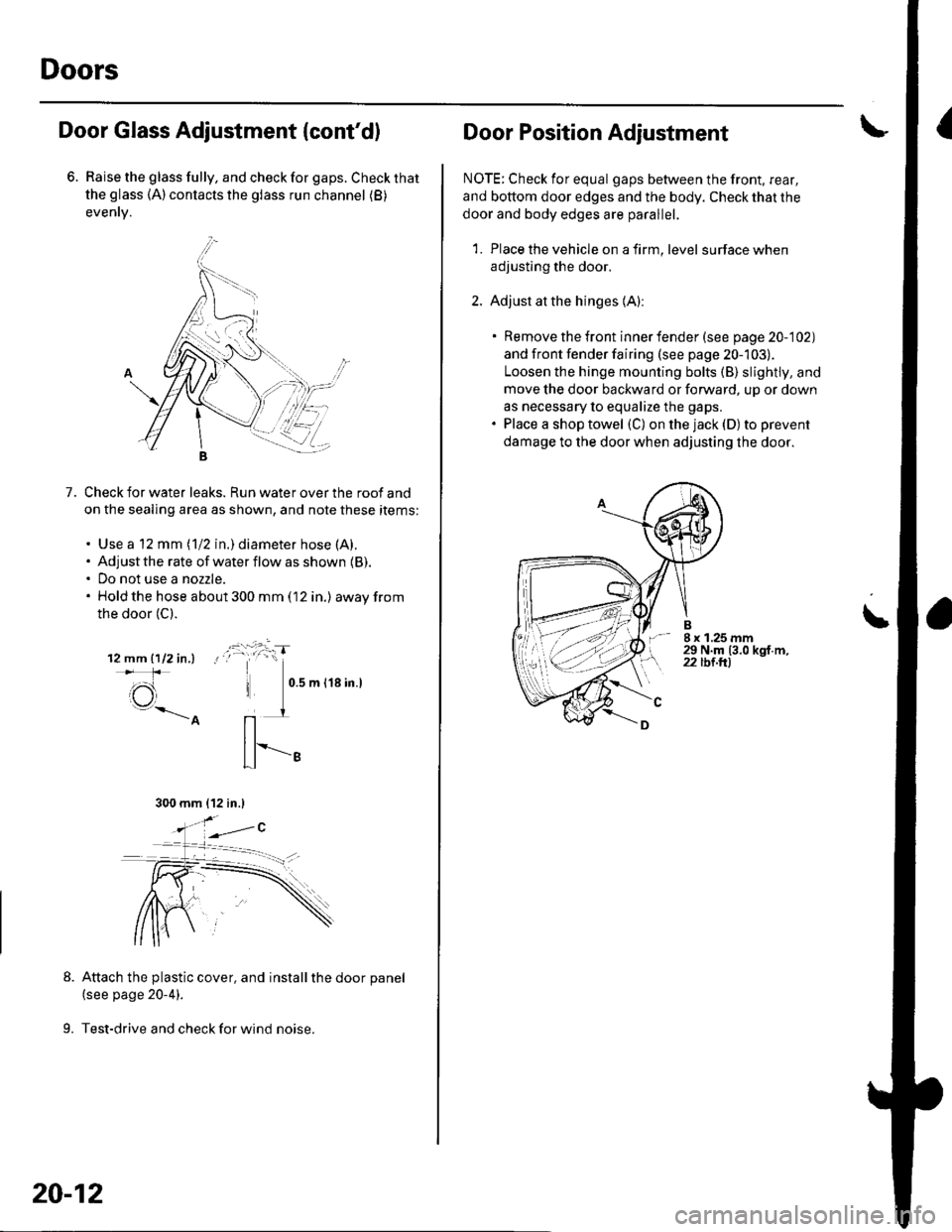

6. Raise the glass fully, and check for gaps. Check that

the glass (A) contacts the glass run channel (B)

evenrv.

7.Check for water leaks. Run water over the roof and

on the sealing area as shown, and note these items:

. Use a 12 mm (1/2 in.) diameter hose (A).. Adjust the rate of water flow as shown {B).. Do not use a nozzle.. Hold the hose about 300 mm (12 in.) awayfrom

the door (C).

12mm1112in,l !

\e

Attach the plastic cover, and installthe door panel(see page 20-4).

9. Test-drive and check for wind noise.

300 mm {12 in.l

20-12

Door Position Adiustment\

NOTE; Check for equal gaps between the front, rear,

and bottom door edges and the body. Check that the

door and body edges are parallel.

1. Place the vehicle on a firm, level surface when

adjusting the door.

2. Adjust at the hinges {A):

. Remove the front inner fender (see page 20-102)

and front fender fairing (see page 20-103).

Loosen the hinge mounting bolts (B) slightly, and

move the door backward or forward, uD or down

as necessary to equalize the gaps.. Place a shop towel (C) on the jack (D) to prevent

damage to the door when adjusting the door.

t, 8x1.25mm29 N.m (3.0 kgf.m,22 tbt.trl

\

Page 667 of 1139

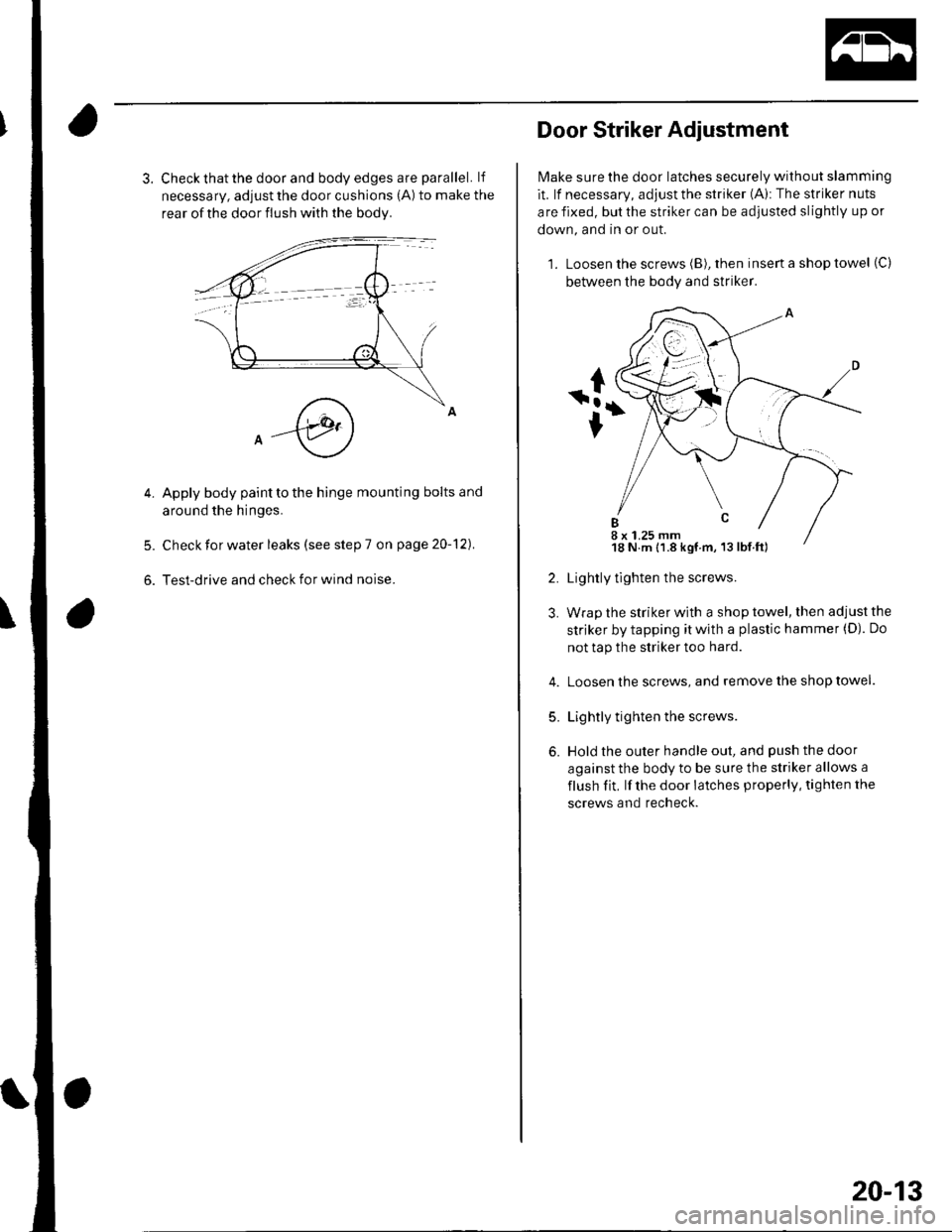

3. Check that the door and body edges are parallel. lf

necessary, adjust the door cushions (A) to make the

rear of the door flush with the bodv.

Apply body paint to the hinge mounting bolts and

around the hinges.

Check for water leaks (see step 7 on page 20-12).

Test-drive and check for wind noise.

5.

Door Striker Adjustment

Make sure the door latches securely without slamming

it. lf necessary, adjust the striker (A): The striker nuts

are fixed, but the striker can be adjusted slightly up or

down, and in or out.

1. Loosen the screws (B), rhen insert a shop towel (C)

between the body and striker.

Lightly tlghten the screws.

Wrap the striker with a shop towel, then adjust the

striker by tapping it with a plastic hammer (D). Do

not tap the striker too hard.

Loosen the screws, and remove the shop towel.

Lightly tighten the screws.

Hold the outer handle out, and push the door

against the body to be sure the striker allows a

flush fit, lf the door latches properly, tighten the

screws and recheck.

5.

6.

8 x 1.25 mm18 N.m 11.8 kgf m, 13 lbf.ft)

20-13

Page 676 of 1139

Glass

to.

Windshield Replacement (cont'dl

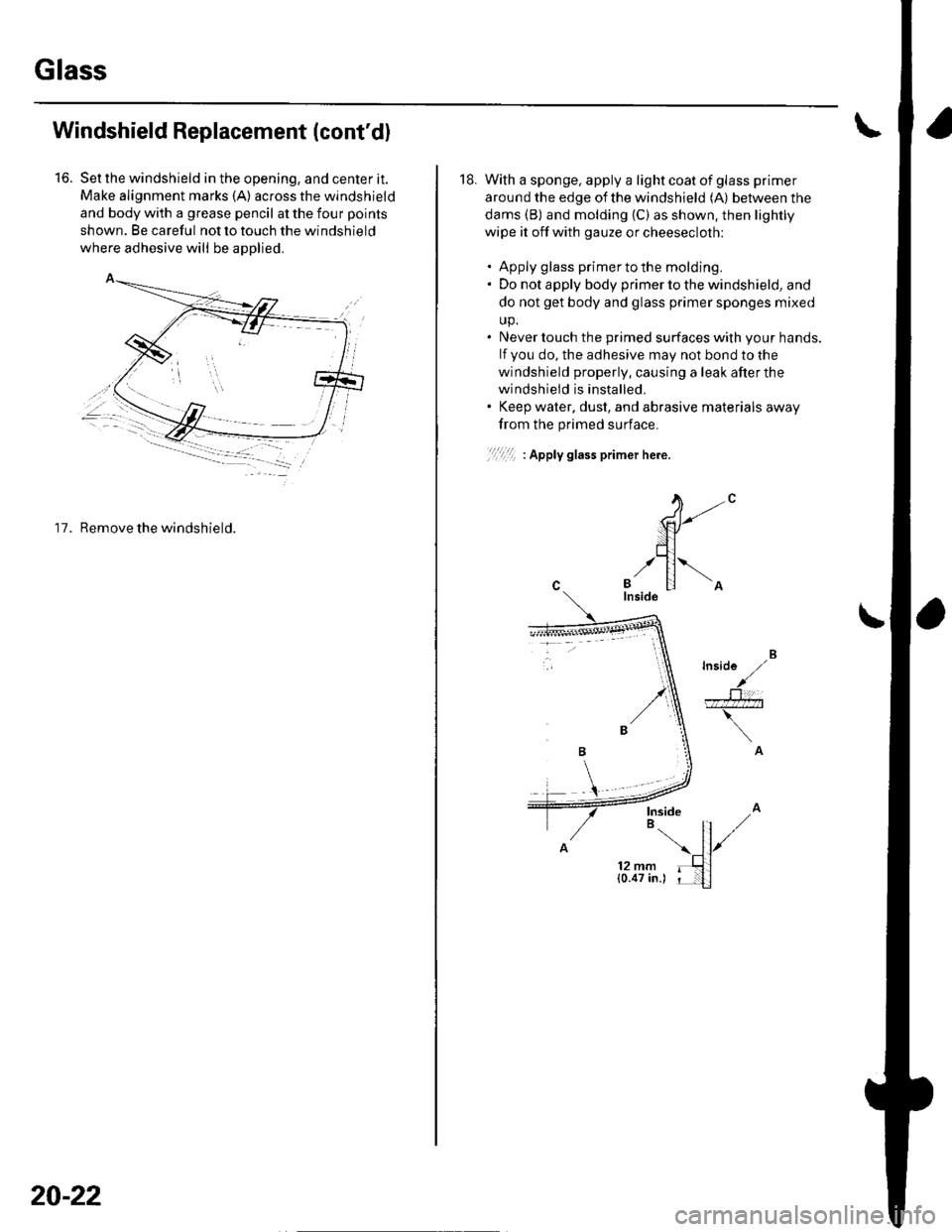

Set the windshield in the opening, and center it.

Make alignment marks (A) across the windshield

and body with a grease pencil at the four points

shown. Be careful not to touch the windshield

where adhesive will be applied.

17. Remove the windshield.

20-22

18. With a sponge, apply a light coat of glass primer

around the edge of the windshield (A) between the

dams (B) and molding {C) as shown, then lightly

wipe it off with gauze or cheesecloth:

. Apply glass primer to the molding.. Do not apply body primer to the windshield, and

do not get body and glass primer sponges mixed

up.. Never touch the primed surfaces with your hands.

lf you do, the adhesive may not bond to the

windshield properly. causing a leak afterthe

windshield is installed.. Keep water. dust, and abrasive materials away

from the primed surface.

'l',,1r- r Apply glass primer here.

)-'

G1)'r'llol

,,/ ll\B tl -A

lnside

Page 677 of 1139

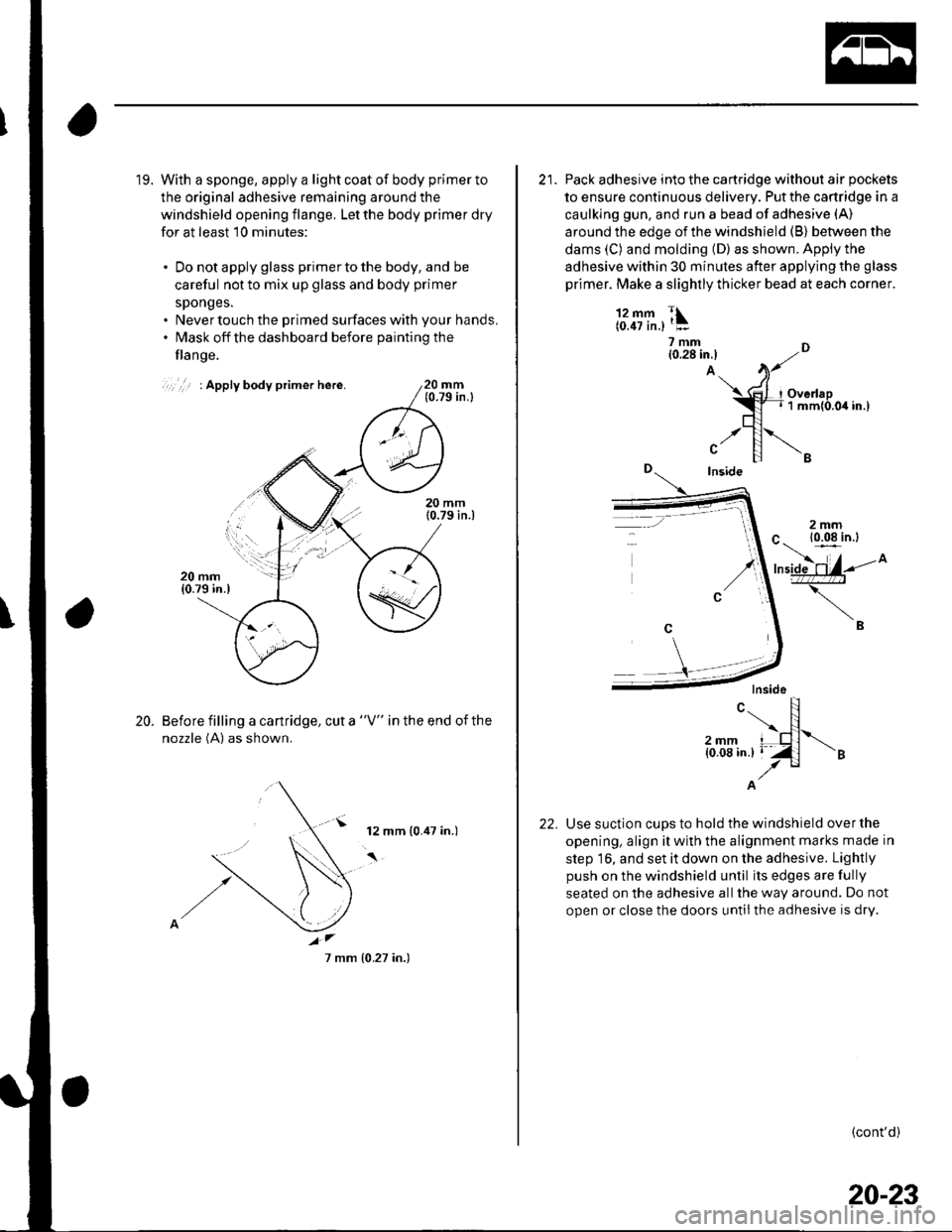

19. With a sponge, apply a light coat of body primer to

the original adhesive remaining around the

windshield opening flange, Let the body primer dry

for at least 10 minutes:

. Do not apply glass primer to the body, and be

careful not to mix up glass and body primer

sponges.. Never touch the primed surfaces with your hands.. l\4ask off the dashboard before paintingthe

flange.

20 mm(0.79 in.l

Before filling a cartridge, cut a "V" in the end of the

nozzle (A) as shown.

20.

12 mm (0.47 in.)

7 mm {0.27 in.)

21. Pack adhesive into the cartridge without air pockets

to ensure continuous delivery. Put the cartridge in a

caulking gun, and run a bead of adhesive (A)

around the edge of the windshield (B) between the

dams (C) and molding (D) as shown. Apply the

adhesive within 30 minutes after applying the glass

primer. Make a slightly thicker bead at each corner.

l'1fifr.,1:?mm n10.28 in.l ,..-A.. )t

$?I.",x1"u.80.".,trl

.,r []\"Inside

-'

A

Use suction cups to hold the windshield over the

opening, align it with the alignment marks made in

step 16, and set it down on the adhesive. Lightly

push on the windshield until its edges are fully

seated on the adhesive allthe way around. Do not

open or close the doors until the adhesive is dry.

c.. N\F12mm I nl{0.08 in.} I 'Z l

./"

(cont'd)

20-23

Page 679 of 1139

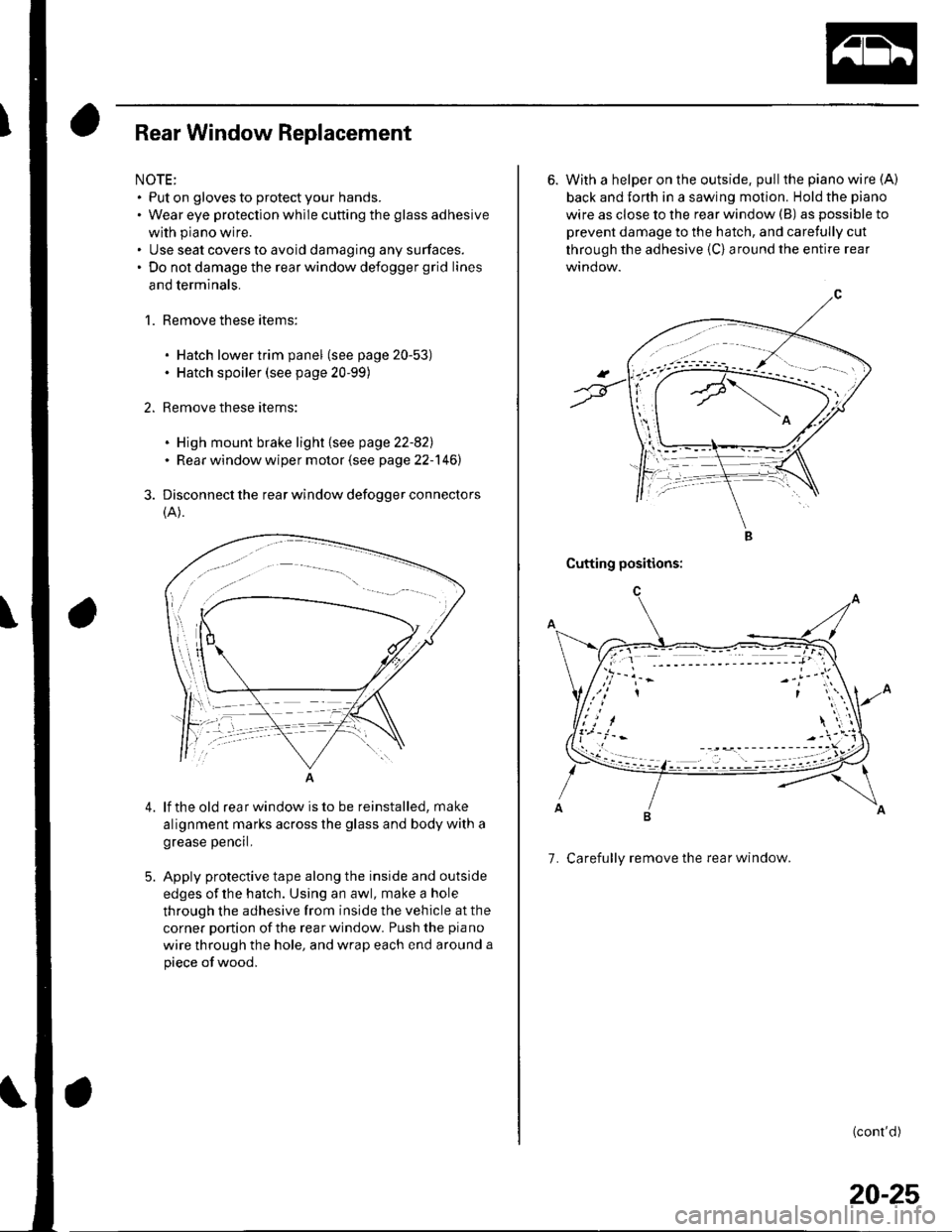

Rear Window Replacement

NOTE:. Put on gloves to protect your hands.. Wear eye protection while cutting the glass adhesive

with piano wire.. Use seat covers to avoid damaging any surfaces.. Do not damage the rear window defogger grid lines

and terminals.

1.Remove these items:

. Hatch lower trim panel (see page 20-53). Hatch spoiler (see page 20-99)

Remove these items:

. High mount brake light {see page 22-821. Rear window wiper motor {see page 22-1461

Disconnect the rear window defogger connectors

(A).

4.lf the old rear window is to be reinstalled, make

alignment marks across the glass and body with a

grease pencrl,

Apply protective tape along the inside and outside

edges of the hatch. Using an awl, make a hole

through the adhesive from inside the vehicle at the

corner portion of the rearwindow. Push the piano

wire through the hole, and wrap each end around a

piece of wood,

6. With a helper on the outside, pull the piano wire (A)

back and Jorth in a sawing motion. Hold the piano

wire as close to the rear window (B) as possible to

prevent damage to the hatch, and carefully cut

through the adhesive {C} around the entire rear

Cutting positions:

7. Carefully remove the rear window.

(cont'd)

20-25

Page 681 of 1139

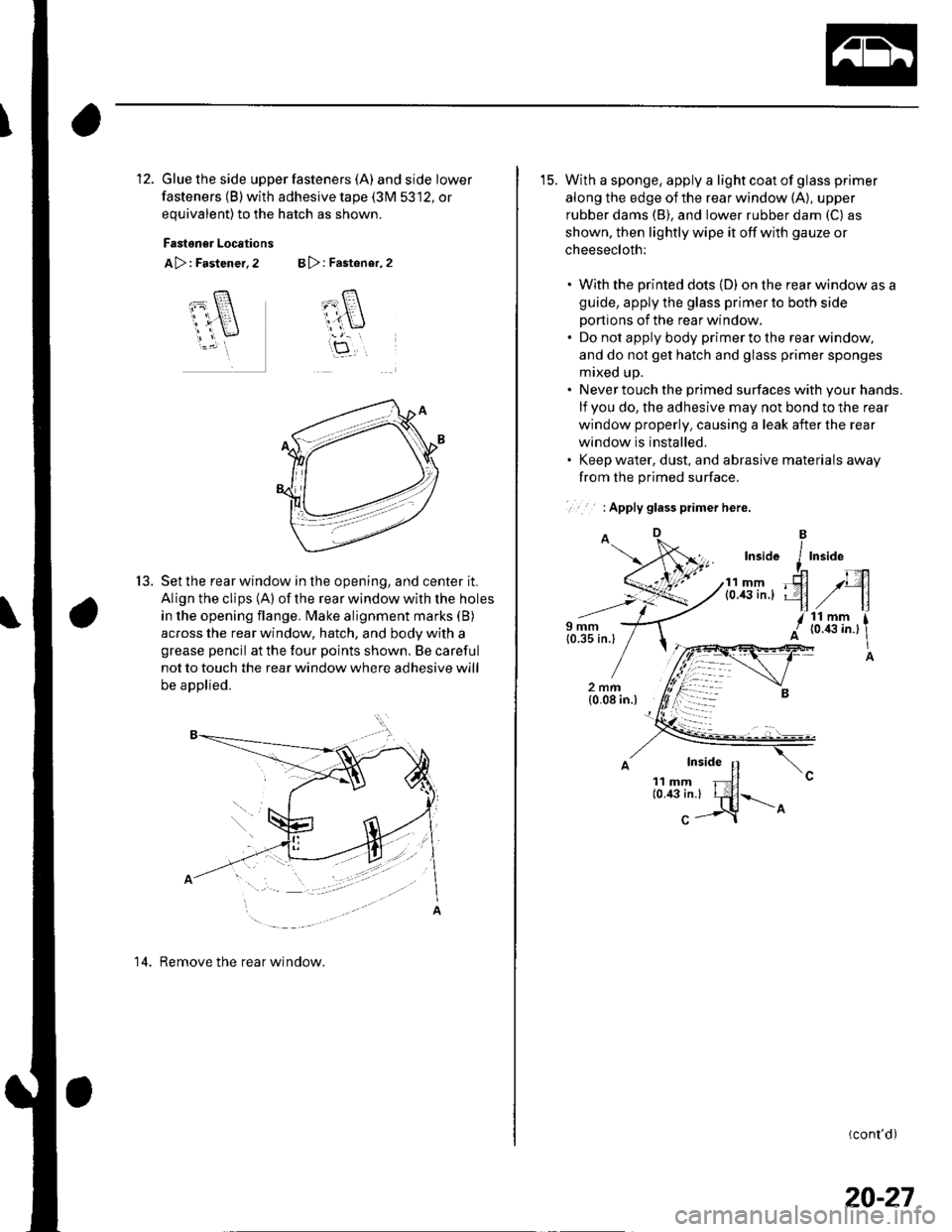

12. Glue the side upper fasteners (A) andsidelower

fasteners (B) with adhesive tape (3M 5312, or

equivalent)to the hatch as shown.

Fastoner Locations

A>: Fastener, 2 B >: Fastener, 2

T-8.

cl

ar\

itf,

t5.Set the rear window in the opening, and center it.

Align the clips (A) of the rear window with the holes

in the opening flange. Make alignment marks (B)

across the rear window, hatch, and body with a

grease pencil at the four points shown. Be careful

not to touch the rear window where adhesive will

be applied.

14. Remove the rear window.

15. With a sponge, apply a light coat of glass primer

along the edge of the rear window (A), upper

rubber dams (B), and lower rubber dam (C) as

shown, then lightly wipe it off with gauze or

cheesecloth:

. With the printed dots (D) on the rear window as a

guide, apply the glass primer to both side

portions of the rear window.. Do not apply body primer to the rear window,

and do not get hatch and glass primer sponges

mixed up.. Never touch the primed surfaces with your hands.

lf you do, the adhesive may not bond to the rear

window properly. causing a leak after the rear

window is installed.. Keep water, dust, and abrasive materials away

from the primed surface.

.. : Apply glass piimer here.

(cont'd)

20-27

Page 682 of 1139

Glass

16.

Rear Window Replacement (cont'd)

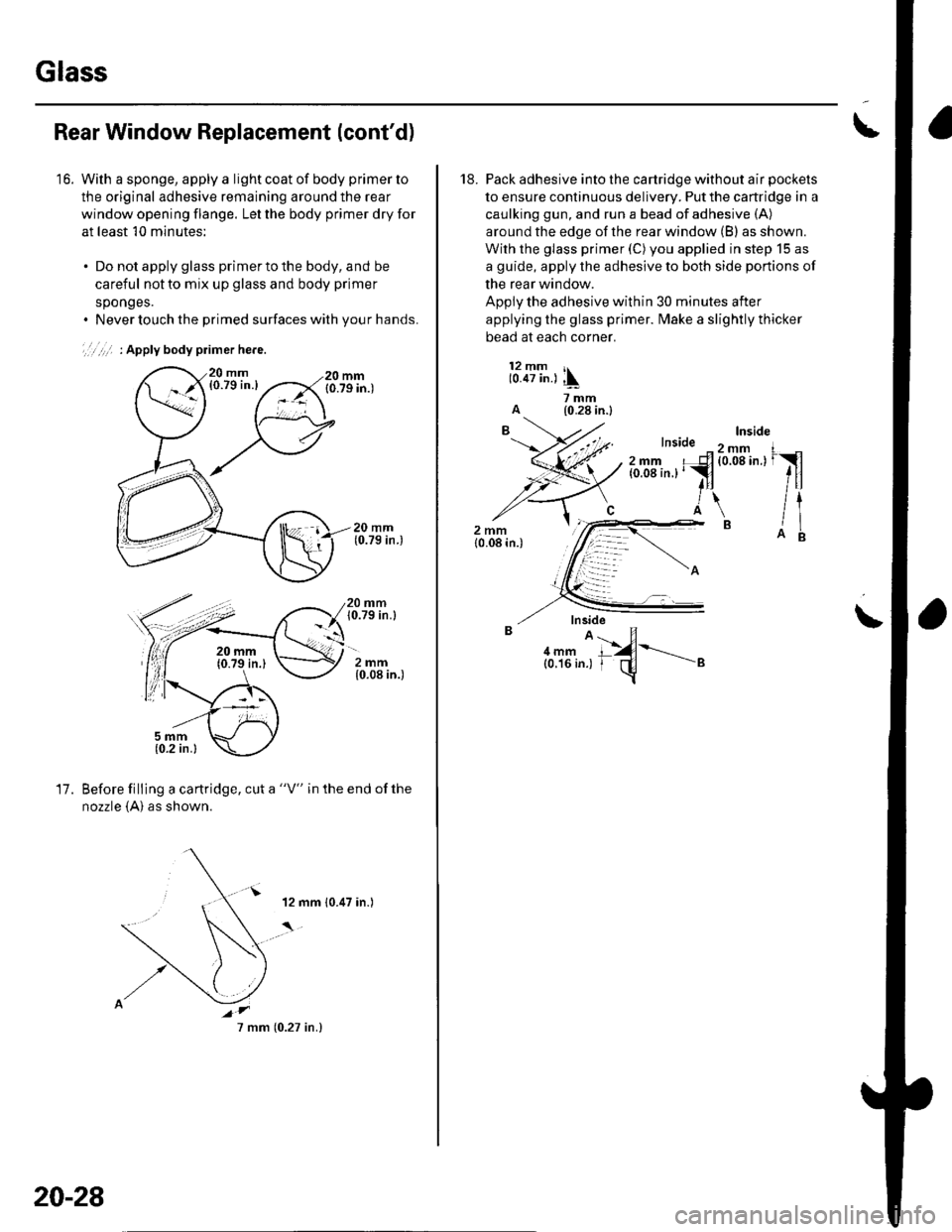

With a sponge, apply a light coat of body primer to

the original adhesive remaining around the rear

window opening flange. Let the body primer dry for

at least 10 minutes;

. Do not apply glass primer to the body, and be

careful not to mix up glass and body primer

sponges.. Never touch the primed surfaces with your hands.

',,,,,' : Apply body primer he.e.

20 mm10.79 in.l

2mm{0.08 in.)

17.Before filling a cartridge, cut a "V" in the end ofthe

nozzle {A} as shown.

20-28

7 mm (0.27 in.)

I

18. Pack adhesive into the cartridge without air pockets

to ensure continuous delivery. Put the cartridge in a

caulking gun, and run a bead of adhesive (A)

around the edge of the rear window (B) as shown.

With the glass primer (C) you applied in step 15 as

a guide, apply the adhesive to both side portions of

the rear window.

Apply the adhesive within 30 minutes after

applying the glass primer. fMake a slightly thicker

bead at each corner.

12 mm r,10.47 in.) ,\

ii'-A (0.28 in.l

\

aru'.1{-----"