ABS HONDA CIVIC 2002 7.G Owner's Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 2002, Model line: CIVIC, Model: HONDA CIVIC 2002 7.GPages: 1139, PDF Size: 28.19 MB

Page 311 of 1139

PGM-FI System

MIL Circuit Troubleshooting (cont'dl

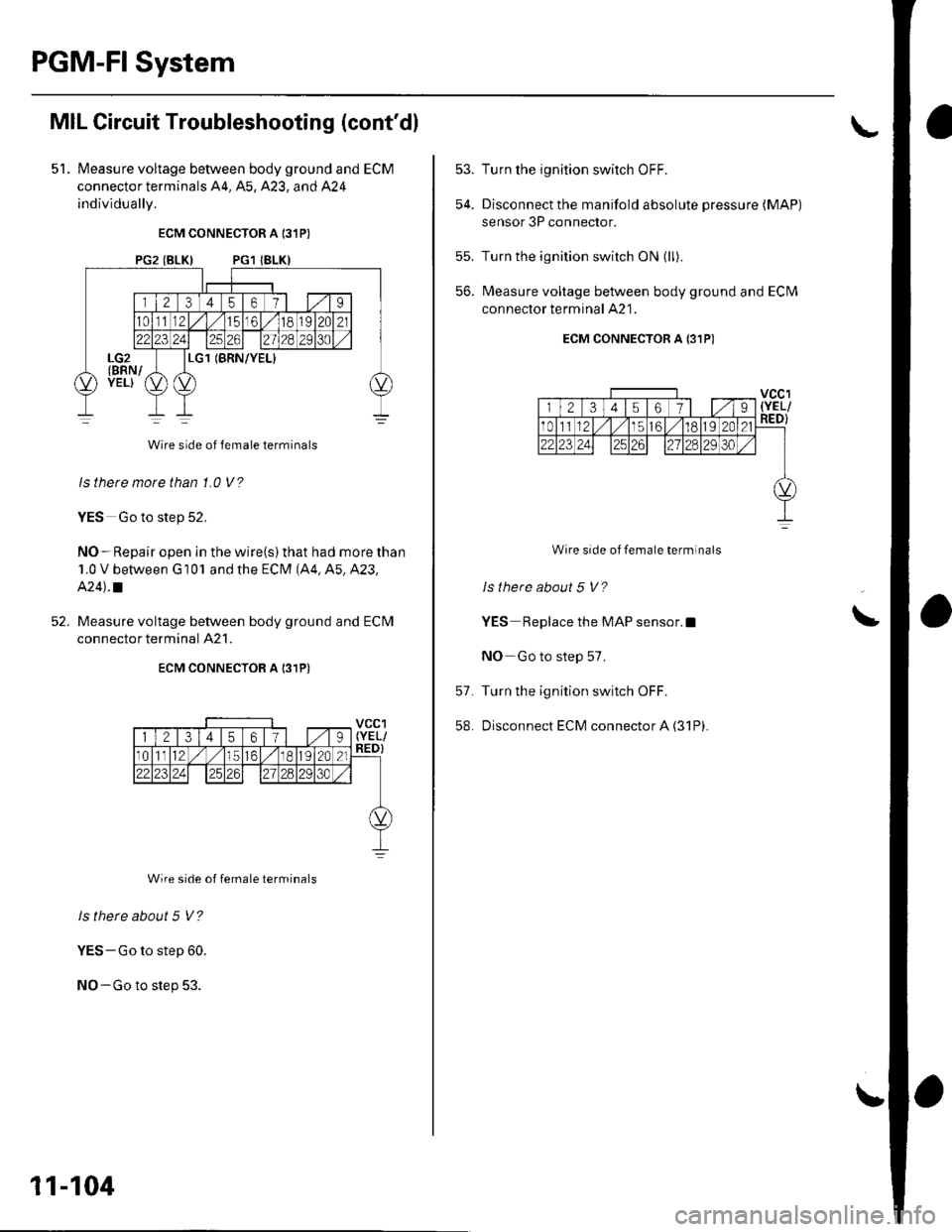

51. Measure voltage between body ground and ECM

connector terminals 44, A5, 423, and 424

individuallv.

ECM CONNECTOR A 131P)

PG2 (BLK) PG1 IBLKI

Wire side of female terminals

ls there morc than 1.0 V ?

YES Go to step 52.

NO-Repair open in the wire(s) that had more than

1.0 V between G 10'l and the ECM (A4, A5, A23,

A24l.a

Measure voltage between body ground and ECM

connector terminal 421.

ECM CONNECTOR A 131P)

Wire side of female terminals

ls there about 5 V?

YES-Go to step 60.

NO-Go to step 53.

11-104

53.

54.

Turn the ignition switch OFF.

Disconnect the manifold absolute pressure (MAP)

sensor 3P connector.

Turn the ignition switch ON (ll).

Measure voltage between body ground and ECM

connector terminal A21.

ECM CONNECTOR A {31P)

Wire side of female terminals

ls there about 5 V?

YES Replace the MAP sensor.l

NO Go to step 57.

Turn the ignition switch OFF.

Disconnect ECM connector A (31P).

55.

56.

\

57.

58.

Page 351 of 1139

FuelSupply System

Fuel Pressure Relieving

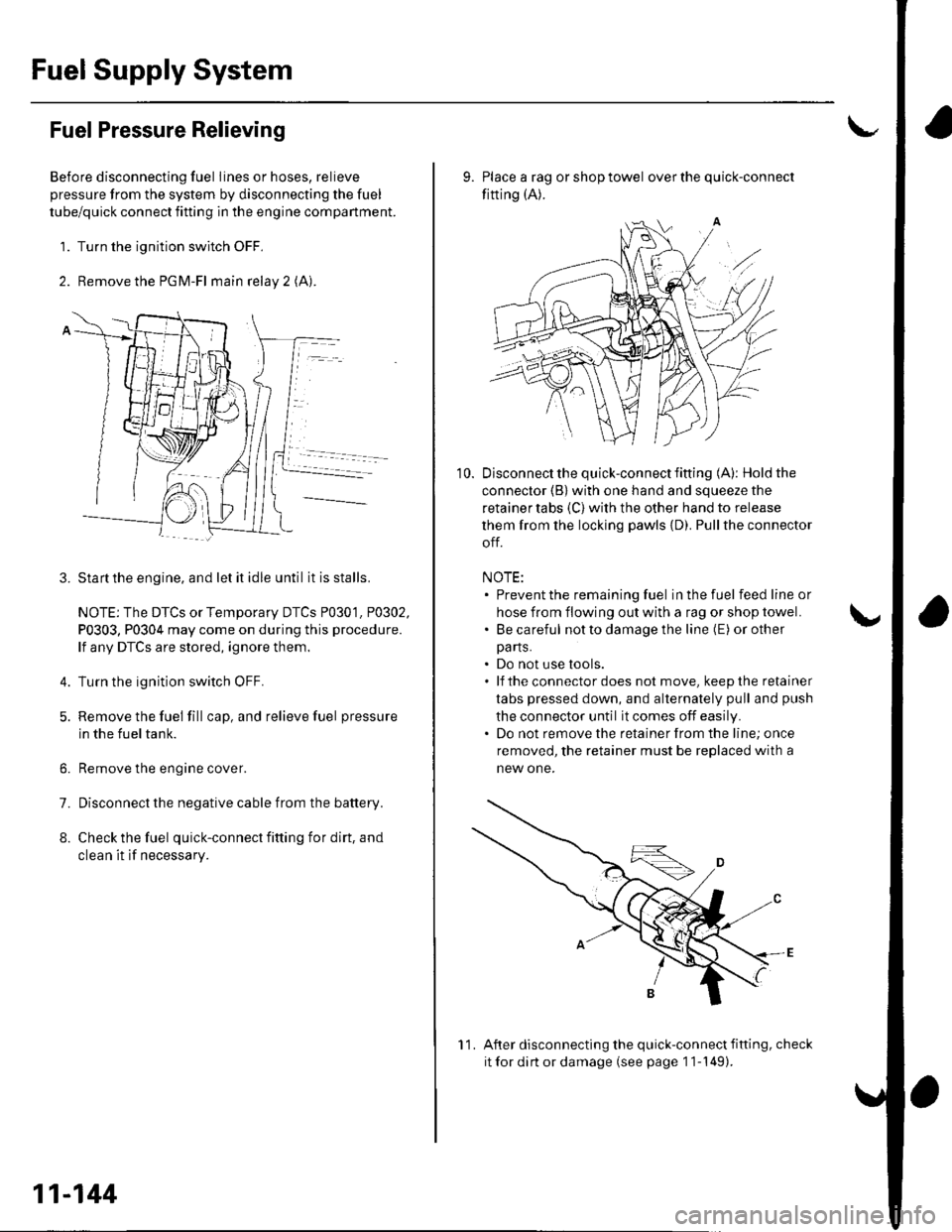

Before disconnecting fuel lines or hoses, relieve

pressure from the system by disconnecting the fuel

tube/quick connect fitting in the engine compartment.

1. Turn the ignition switch OFF,

2. Remove the PGM-Fl main relay 2 (A).

Startthe engine, and let it idle until it is stalls.

NOTE: The DTCS or Temporary DTCS P0301. P0302,

P0303, P0304 may come on during this procedure.

lf any DTCS are stored, ignore them.

Turn the ignition switch OFF.

Remove the fuel fill cap, and relieve fuel pressure

in the fueltank.

Remove the engine cover.

Disconnect the negative cable from the battery.

Check the fuel quick-connect fitting for dirt, and

clean it if necessary.

3.

4.

6.

7.

8.

11-144

11

10.

9. Place a rag or shop towel over the quick-connect

fitting (A).

Disconnect the quick-connect fifting (A): Hold the

connector (B) with one hand and squeeze the

retainer tabs (C) with the other hand to release

them from the locking pawls {D). Pullthe connector

off.

NOTE:. Prevent the remaining fuel in the fuel feedlineor

hose from flowing out with a rag or shop towel.. Be careful notto damage the line (E) or other

pa rts.. Do not use tools.. lf theconnectordoes not move, keepthe retainer

tabs pressed down, and alternately pull and push

the connector until it comes off easily.. Do not remove the retainer from the line; once

removed, the retainer must be replaced with a

new one.

After disconnecting the quick-connect fifting, check

it for dirt or damage (see page 1 1-149).

Page 356 of 1139

2.

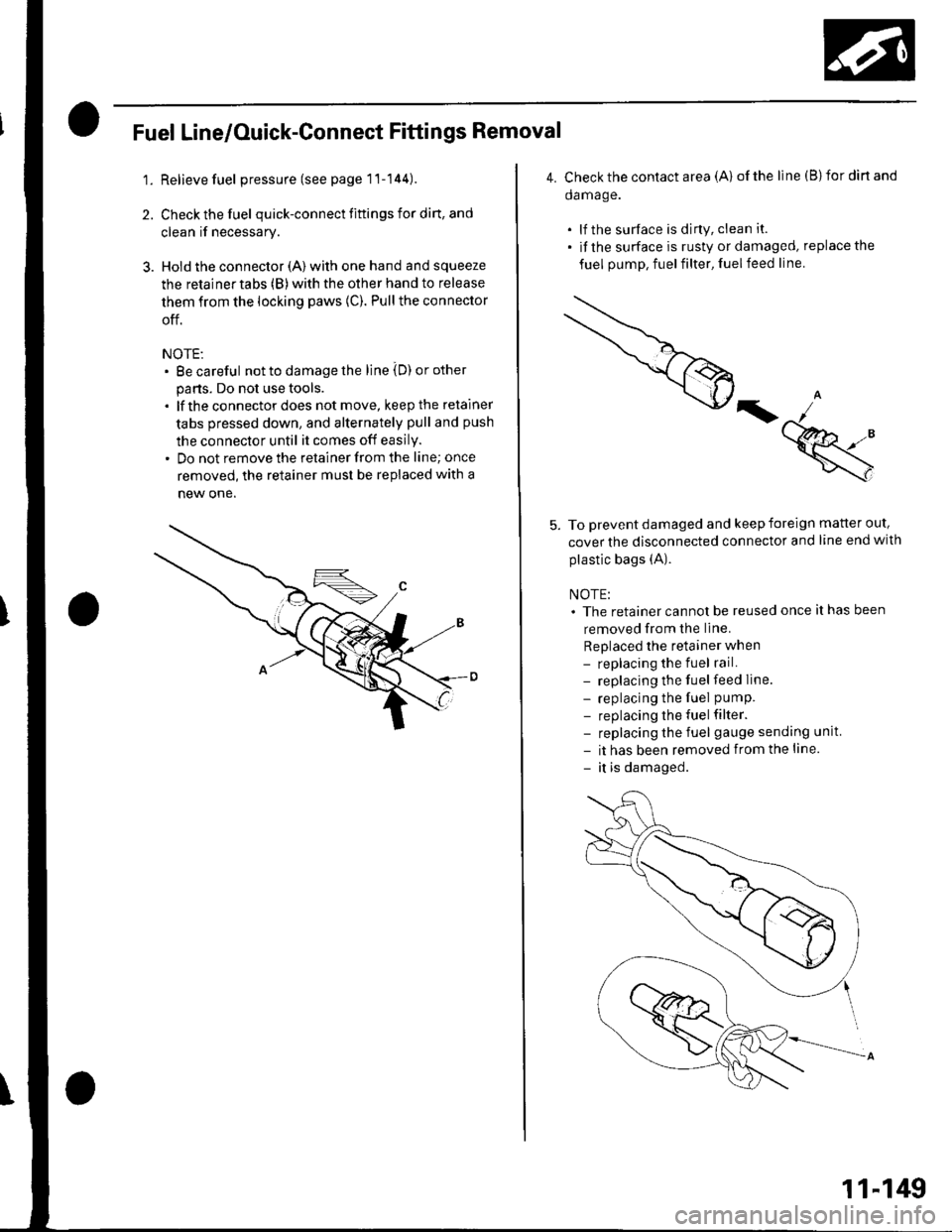

Fuel Line/Ouick-Gonnect Fittings Removal

1. Relieve fuel pressure (see page 1'l-144).

Check the fuel quick-connect fiftings for din, and

clean if necessary.

Hold the connector (A) with one hand and squeeze

the retainertabs (B)with the other hand to release

them from the locking paws (C). Pull the connector

off.

NOTE:. Be careful not to damage the line iD) or other

parts. Do not use tools.. lf the connectordoes not move, keep the retainer

tabs pressed down, and alternately pull and push

the connector until it comes off easily.. Do not remove the retainer from the line; once

removed, the retainer must be replaced with a

new one.

4. C heck the contact a rea (A) of the line (B)for dirt and

da mage.

. lf the surface is dirty, clean it.. if the surface is rusty or damaged, replace the

fuel pump, fuelfilter, fuelfeed line.

=k

To prevent damaged and keep foreign matter out,

cover the disconnected connector and line end with

plastic bags (A).

NOTE:. The retainer cannot be reused once it has been

removed from the line.

Replaced the retainer when- replacing the fuel rail.- replacing the fuel feed Iine.

- replacing the fuel pumP.

- replacing the fuel filter.- replacing the fuel gauge sending unit

- it has been removed from the line.

- it is damaged.

11-149

Page 372 of 1139

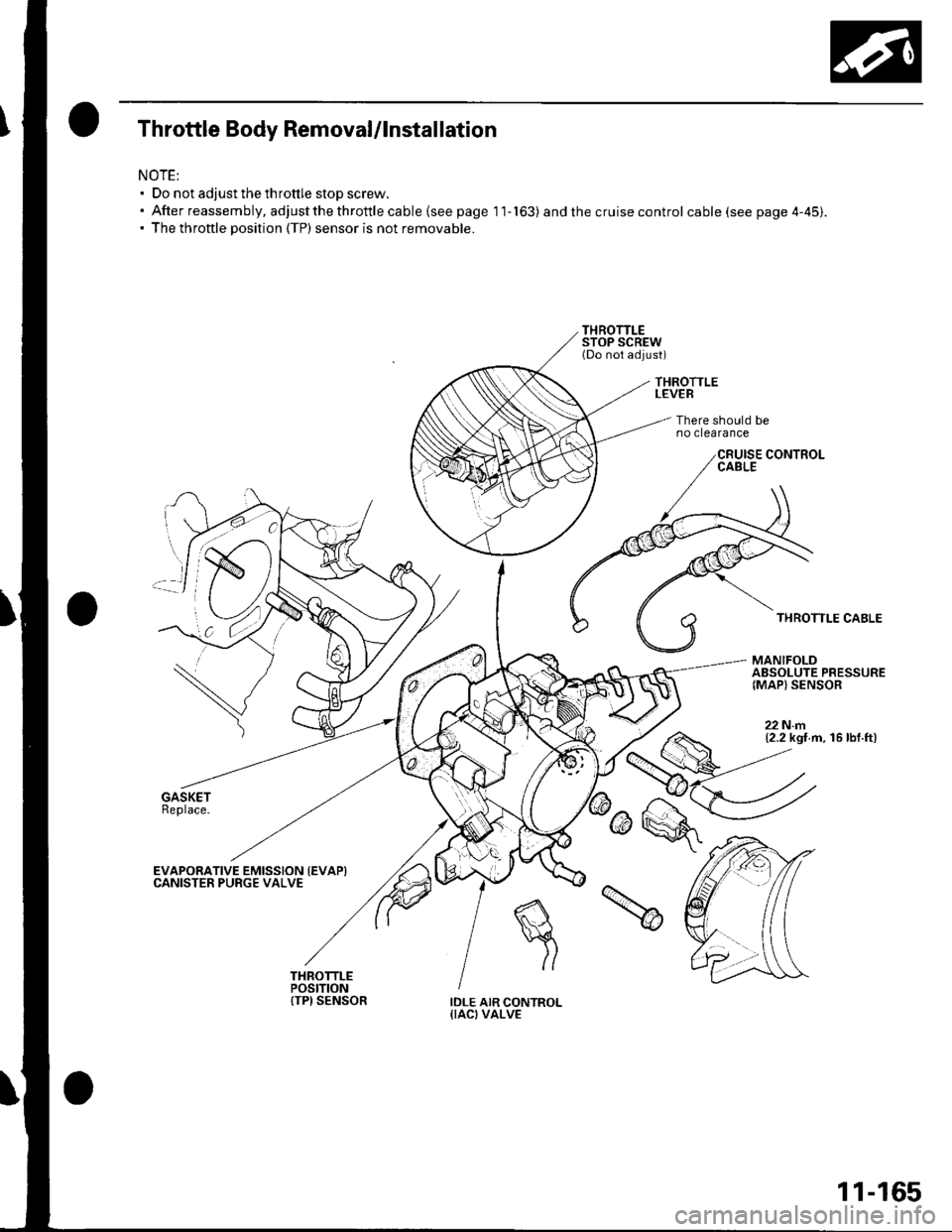

Throttle Body Removal/lnstallation

NOTE:' Do not adjust the throttle stop screw.. Afterreassembly,adjustthethrottlecable{seepagell-163) and the cruise control cable (see page 4-45).. The throttle position (TP) sensor is not removable.

THROTTLELEVER

There should beno clearance

THROTTLE CABLE

MANIFOLDABSOLUTE PRESSURE{MAP} SENSOR

22Nm(2.2 kgt.m, 16 lbf.ft)

EVAPORATIVE EMISSION {EVAPICANISTER PURGE VALVE

IDLE AIR CONTROL{IACI VALVE

11-165

Page 474 of 1139

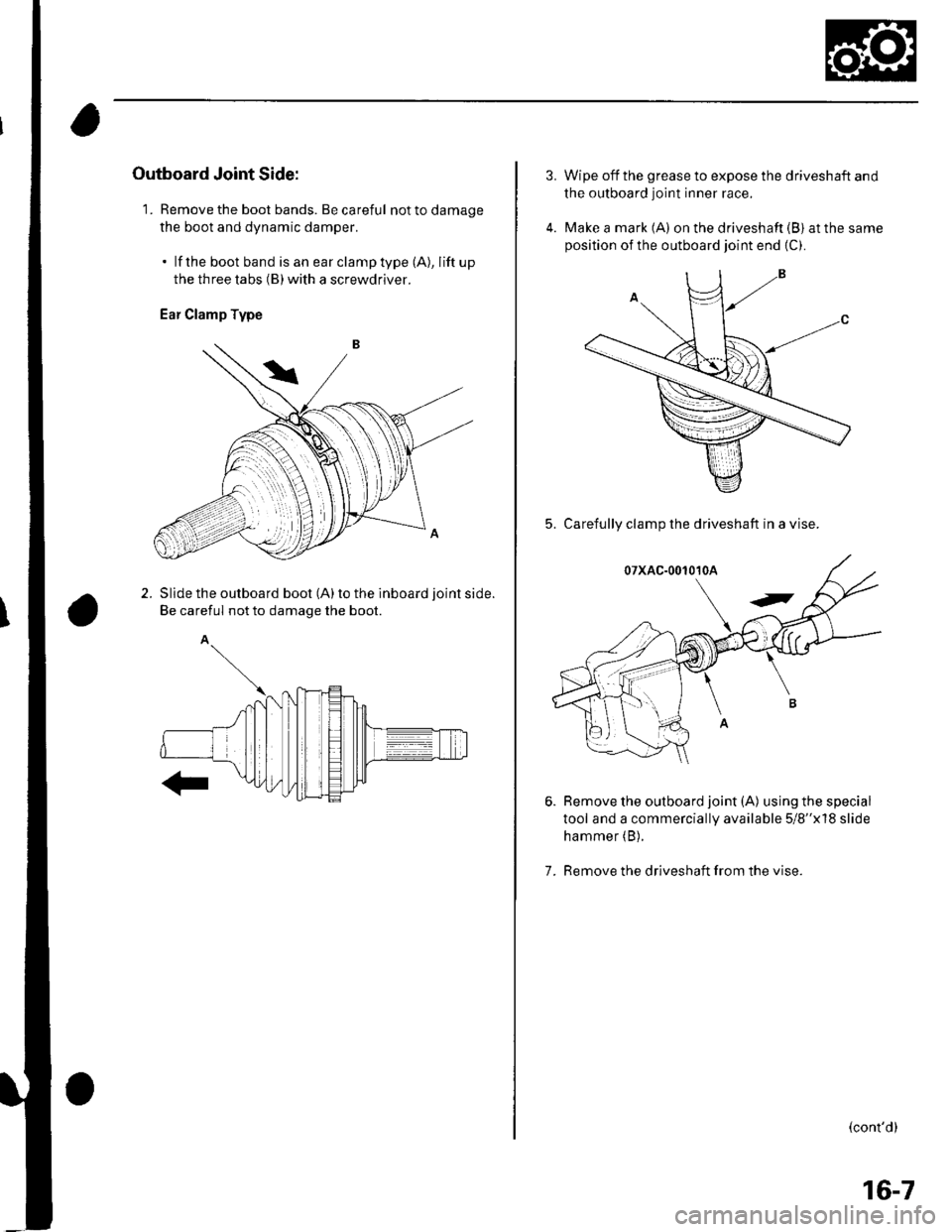

Outboard Joint Side:

1. Remove the boot bands. Be careful nottodamage

the boot and dynamic damper.

. lf the boot band is an earclamptype (A), lift up

the three tabs (B) with a screwdriver.

Ear Clamp Type

Slide the outboard boot (A) to the inboard ioint side.

Be careful not to damaoe the boot.

2.

4.

Wipe off the grease to expose the driveshaft and

the outboard joint inner race.

Make a mark (A) on the driveshaft (B) at the same

position of the outboard joint end {C).

5. Carefullv clamp the driveshaft in a vise.

Remove the outboard joint (A) using the special

tool and a commercially available 5/8"x18 slide

hammer (B).

Remove the driveshaft from the vise.

(cont'd)

7.

16-7

Page 479 of 1139

Driveline/Axle

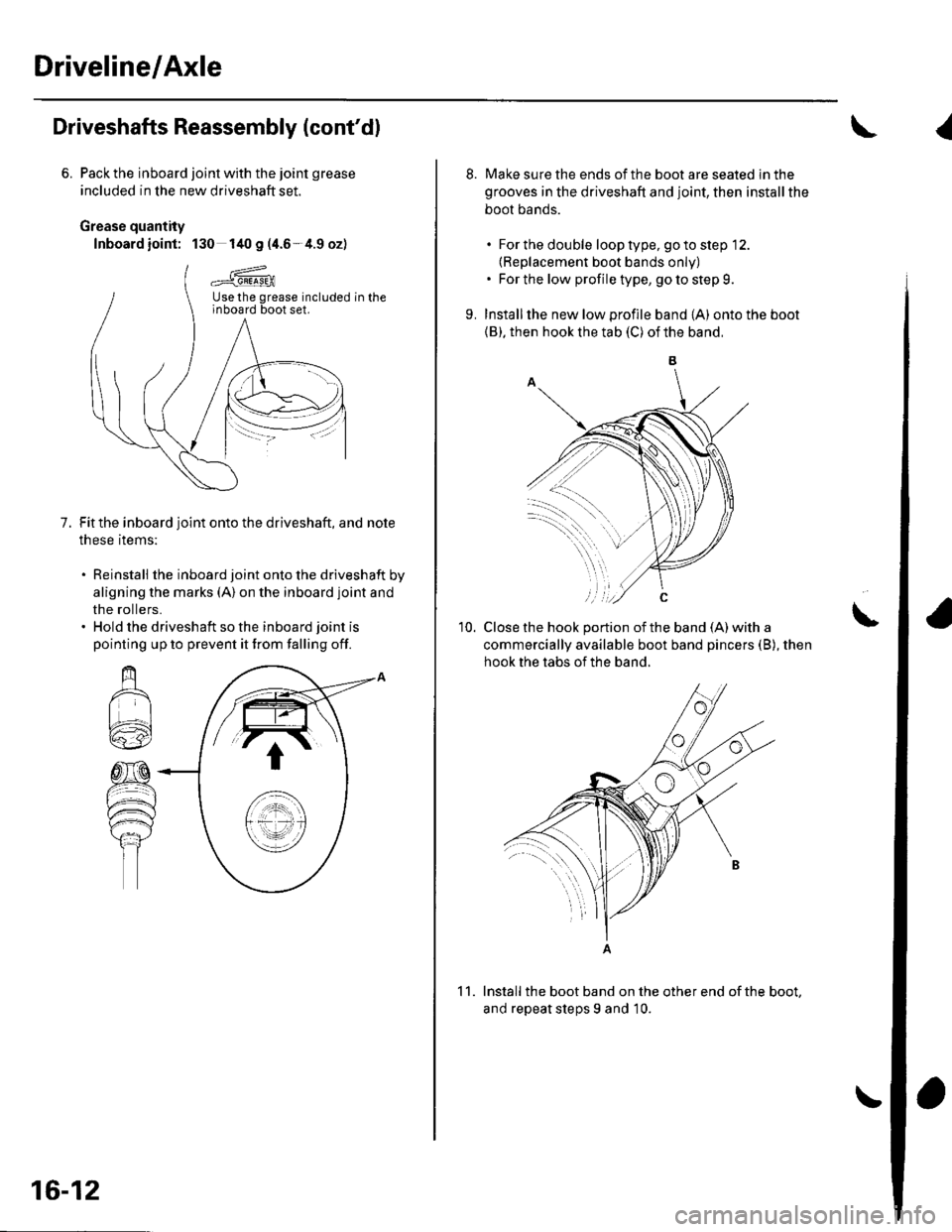

6.

Driveshafts Reassembly (cont'd)

Pack the inboard joint with the joint grease

included in the new driveshaft set.

Grease quantity

Inboard ioint: 130 140 g (4.6-4.9 oz)

Use the grease included in theinboard boot set.

Fit the inboard joint onto the driveshaft, and note

these items:

. Reinstall the inboard joint onto the driveshaft by

aligning the marks (A) on the inboard joint and

the rollers.. Hold the driveshaft so the inboard joint is

pointing up to prevent it trom falling off.

7.

16-12

11.

8.Make sure the ends of the boot are sealed in the

grooves in the driveshaft and joint, then installthe

boot bands.

. For the double loop type, go to step 12.(Replacement boot bands only). For the low profile type, go to step 9.

Installthe new low profile band {A) onto the boot

{B). then hook the tab (C) of the band,

Close the hook portion of the band (A) with a

commercially available boot band pincers (B), then

hook the tabs of the band.

Install the boot band on the other end of the boot,

and reoeat steos 9 and 10.

9.

\10.

I

Page 500 of 1139

Steering

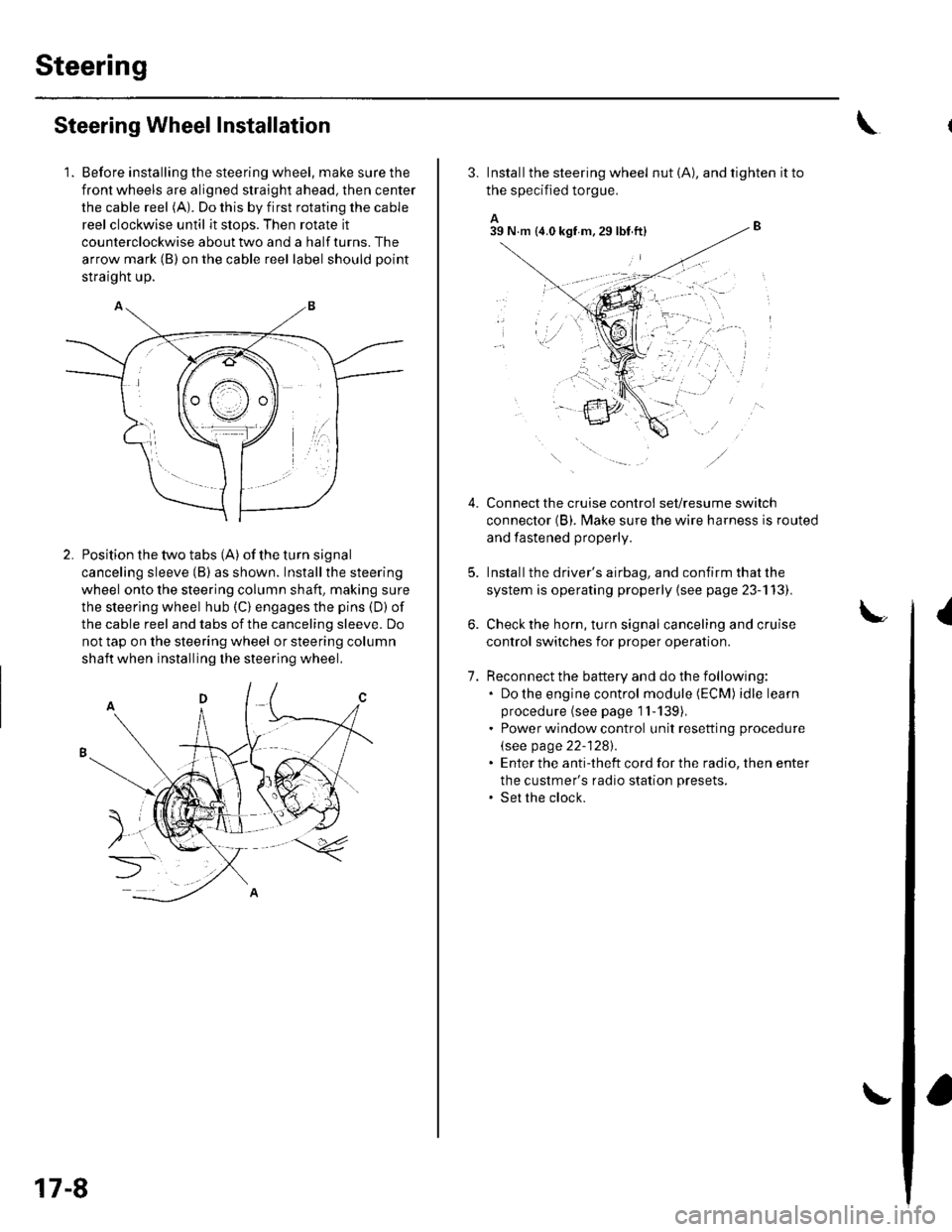

Steering Wheel Installation

1. Before installing the steering wheel, make sure the

front wheels are aligned straight ahead, then center

the cable reel (A). Do this by first rotating the cable

reel clockwise until it stops. Then rotate it

counterclockwise about two and a half turns. The

arrow mark (B) on the cable reel label should point

straight up.

Position the two tabs (A) of the turn signal

canceling sleeve (B) as shown. Installthe steering

wheel onto the steering column shaft, making sure

the steerlng wheel hub (C) engages the pins (D) of

the cable reel and tabs of the canceling sleeve. Do

not tap on the steering wheel or steering column

shaft when installing the steering wheel.

17-8

3. Install the steering wheel nut (A), and tighten it to

the specified torgue.

A_B39 N.m (4.0 kgf m.29lbt ftl

Connect the cruise control set/resume switch

connector (B). fvlake sure the wire harness is routed

and fastened properly.

Install the driver's airbag, and confirm that the

system is operating properly {see page 23-113).

Check the horn, turn signal canceling and cruise

control switches for proper operation.

Reconnect the battery and do the following:. Do the engine control module (ECM) idle learn

procedure (see page 1l-139),. Power window control unit resetting procedure

\see page 22-1281.. Enter the anti-theft cord for the radio, then enter

the custmer's radio station presets.. Set the clock.

{

7.

lr,',,t

;. _,:!

'' '1i::..'.' l

Page 503 of 1139

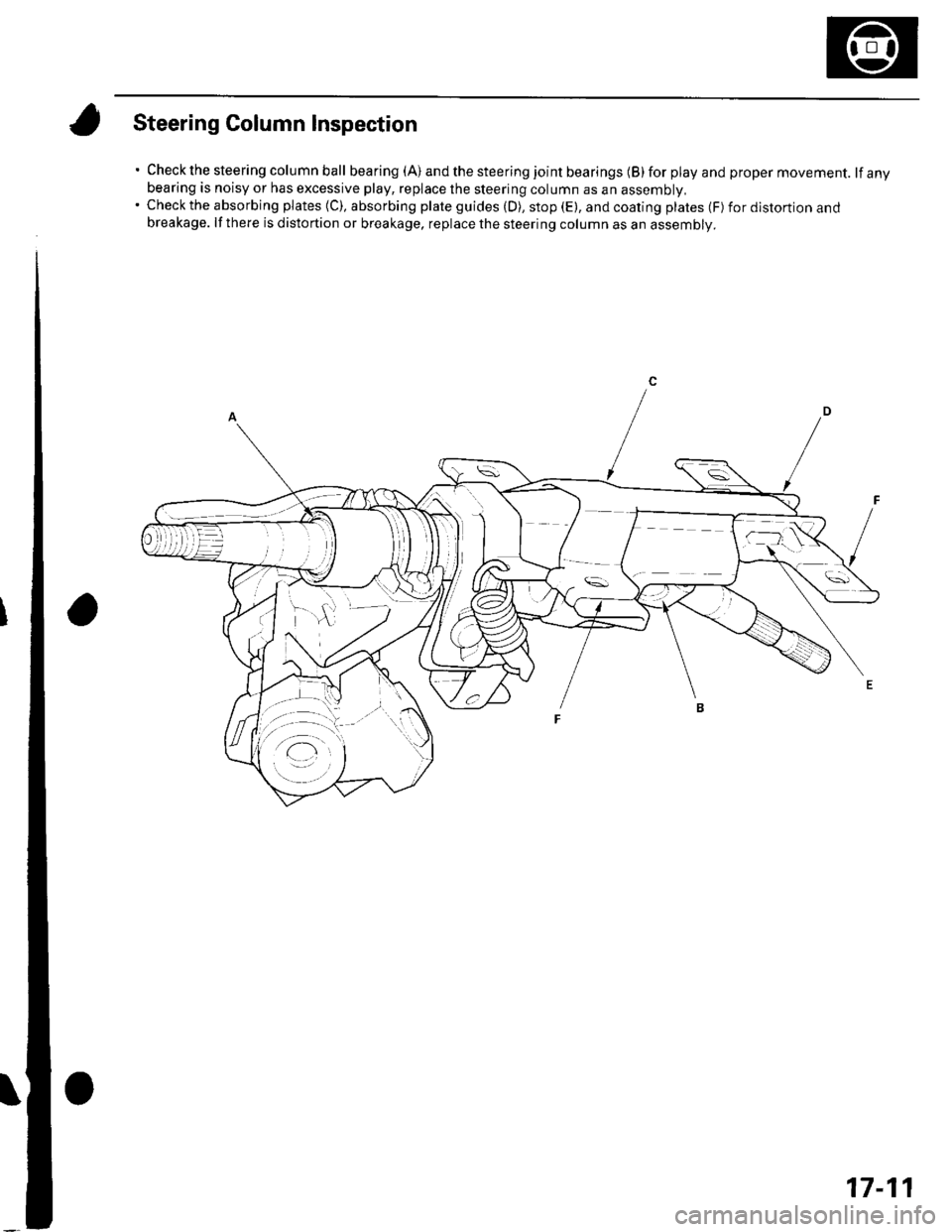

Steering Column Inspection

. Check the steering column ball bearing(A) andthesteeringjointbearings(B)forplayandpropermovement. lfanybearing is noisy or has excessive play, replace the steering column as an assembly,'Checktheabsorbingplates(C),absorbingplateguides(D),stop(E),andcoatingplates(F) for distortion andbreakage. lf there is distortion or breakage, replace the steering column as an assembly.

17-11

Page 550 of 1139

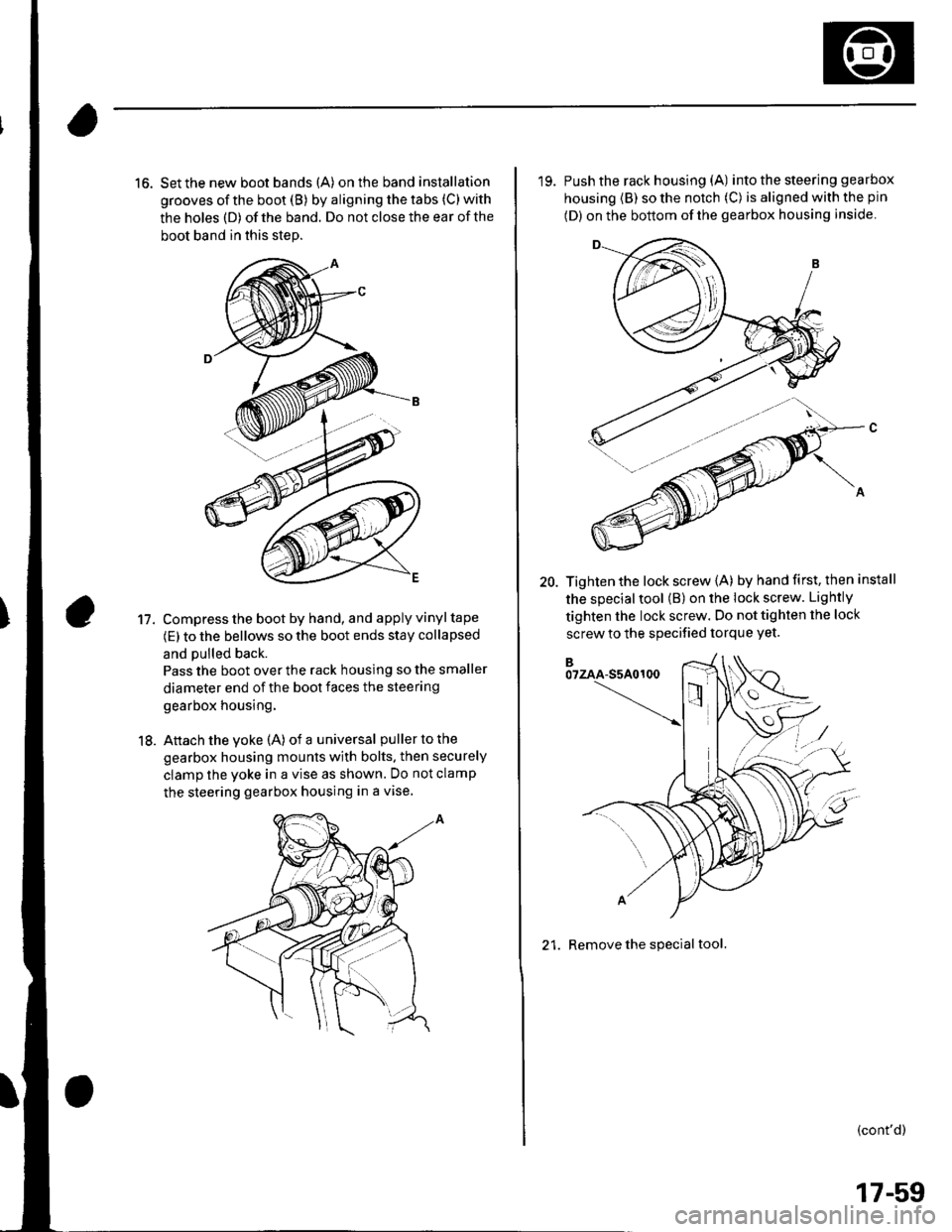

16. Set the new boot bands (A) on the band installation

grooves of the boot (B) by aligning the tabs (C) with

the holes (D) of the band. Do not close the ear of the

boot band in this step.

Compress the boot by hand, and apply vinyl tape

(E) to the bellows so the boot ends stay collapsed

and pulled back.

Pass the boot over the rack housing so the smaller

diameter end of the boot faces the steering

gearbox housing.

Attach the yoke (A) of a universal puller to the

gearbox housing mounts with bolts. then securely

clamp the yoke in a vise as shown. Do not clamp

the steering gearbox housing in a vise.

11.

18.

'19. Push the rack housing (A) into the steering gea rbox

housing (B) so the notch (C) is aligned with the pin

(D) on the bottom of the gearbox housing inside

20. Tighten the lock screw {A) by hand first, then install

the special tool (B) on the lock screw. Lightly

tighten the lock screw. Do not tighten the lock

screw to the specified torque Yet.

21. Remove the special tool.

(cont'd)

17-59

Page 552 of 1139

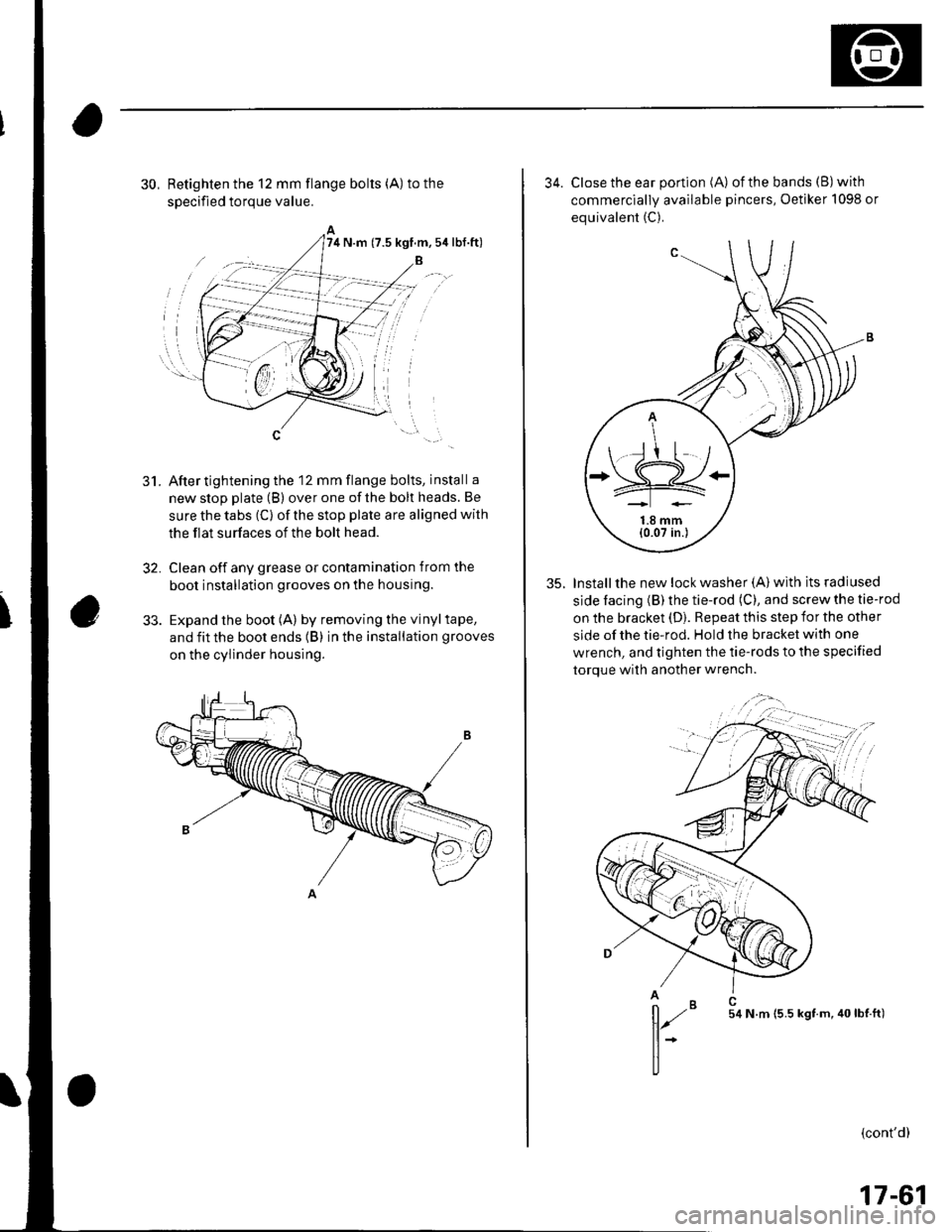

30, Retighten the 12 mm flange bolts (A) to the

soecified toroue value.

After tightening the 12 mm flange bolts, install a

new stop plate (B) over one of the bolt heads. Be

sure the tabs (C) of the stop plate are aligned with

the flat surfaces of the bolt head.

Clean off any grease or contamination from the

boot installation grooves on the housing.

Expand the boot (A) by removing the vinyltape,

and fit the boot ends (B) in the installation grooves

on the cylinder housing.

5t.

32,

74 N.m (7.5 kgf.m,5ir lbf.ft)

34. Close the ear portion (A) ofthe bands (B)with

commerciallv available pincers, Oetiker 1098 or

equivalent (C).

35. Installthe new lock washer (A) with its radiused

side facing (B) the tie-rod (C), and screw the tie-rod

on the bracket (D). Repeat this step for the other

side of the tie-rod. Hold the bracket with one

wrench, and tighten the tie-rods to the specified

torque with another wrench.

,,";=-...,.,

(cont'd)

*=,,',

17-61