air condition HONDA CIVIC 2002 7.G Owner's Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 2002, Model line: CIVIC, Model: HONDA CIVIC 2002 7.GPages: 1139, PDF Size: 28.19 MB

Page 345 of 1139

ldle Control System

ldle Speed lnspection

NOTE:' Leave the idle air control (lAC) valve connecled.. Before checking the idle speed, check these items:- The malfunction indicator lamp (MlL) has not been

reported on.- lgnition timing- Spark plugs- Air cleaner- PCV system. Pullthe parking brake lever up. Start the engine, and

make sure the headlights are off.

1. Disconnect the evaporative emission (EVAP)

canister purge valve 2P connector.

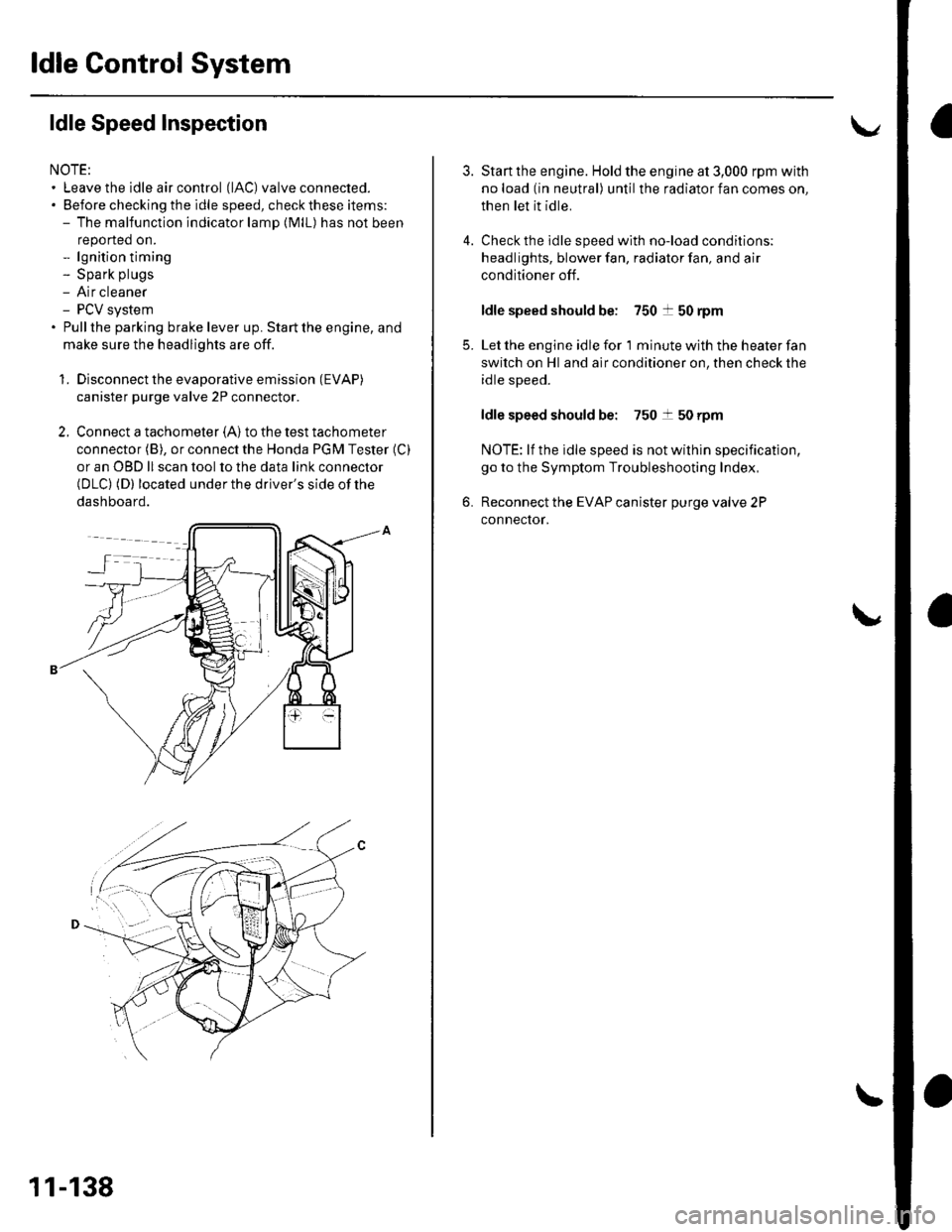

2. Connect a tachometer (A)to the test tachometer

connector (B), or connect the Honda PGM Tester (C)

or an OBD ll scan tool to the data link connector(DLC) (D) located under the driver's side of the

dashboard.

11-138

4.

3.

5.

6.

Start the engine. Hold the engine at 3,000 rpm with

no load (in neutral) until the radiator fan comes on,

then let it idle.

Check the idle speed with no-load conditions;

headlights, blower fan, radiator fan, and air

conditioner off.

ldle speed should be: 750 t 50 rpm

Let the engine idle for 1 minute with the heater fan

switch on Hl and air conditioner on, then check the

idle speed.

ldle speed should be: 750 t 50 rpm

NOTE: lf the idle speed is not wilhin specification,

go to the Symptom Troubleshooting Index,

Reconnect the EVAP canister purge valve 2P

connector.

Page 387 of 1139

EVAP System

DTC Troubleshooting (cont'd)

DTC Pl457: EVAP Control System(EVAP Canister System)

Leakage

The fuel system is designed to allow specified

maximum vacuum and pressure conditions. Do not

deviate from the vacuum and pressure tests as

indicated in these procedures. Excessive pressure/

vacuum would damage the EVAP components or

cause eventual fuel tank system failure.

SpecialTools Required

Vacuum pump/gauge, 0-30 in.Hg A973X-041-XXXXX

This is a two-trip code. Once cleared, it cannot be

reproduced in one trip. Also, certain specific driving

and ambient conditions must occur before the ECfM will

complete the system checks, Additional test drives may

still not meet the specific conditions needed to16^r^.1' '^6 rh6 ^^.16

Follow these troubleshooting procedures carefully to

ensure the integrity of the system and to confirm the

cause of the problem or code.

NOTE: Fresh fuel has a higher volatility lhat creates

greater pressure/vacuum. The optimum condition for

testing is fresh fuel, and there must be less than a full

tank. lf possible, to assist in leak detection, add I gallon

of fresh fuel to the tank (as long as it will not fill the

tank), just before starting these procedures.

EVAP Canister Purge Valve Test

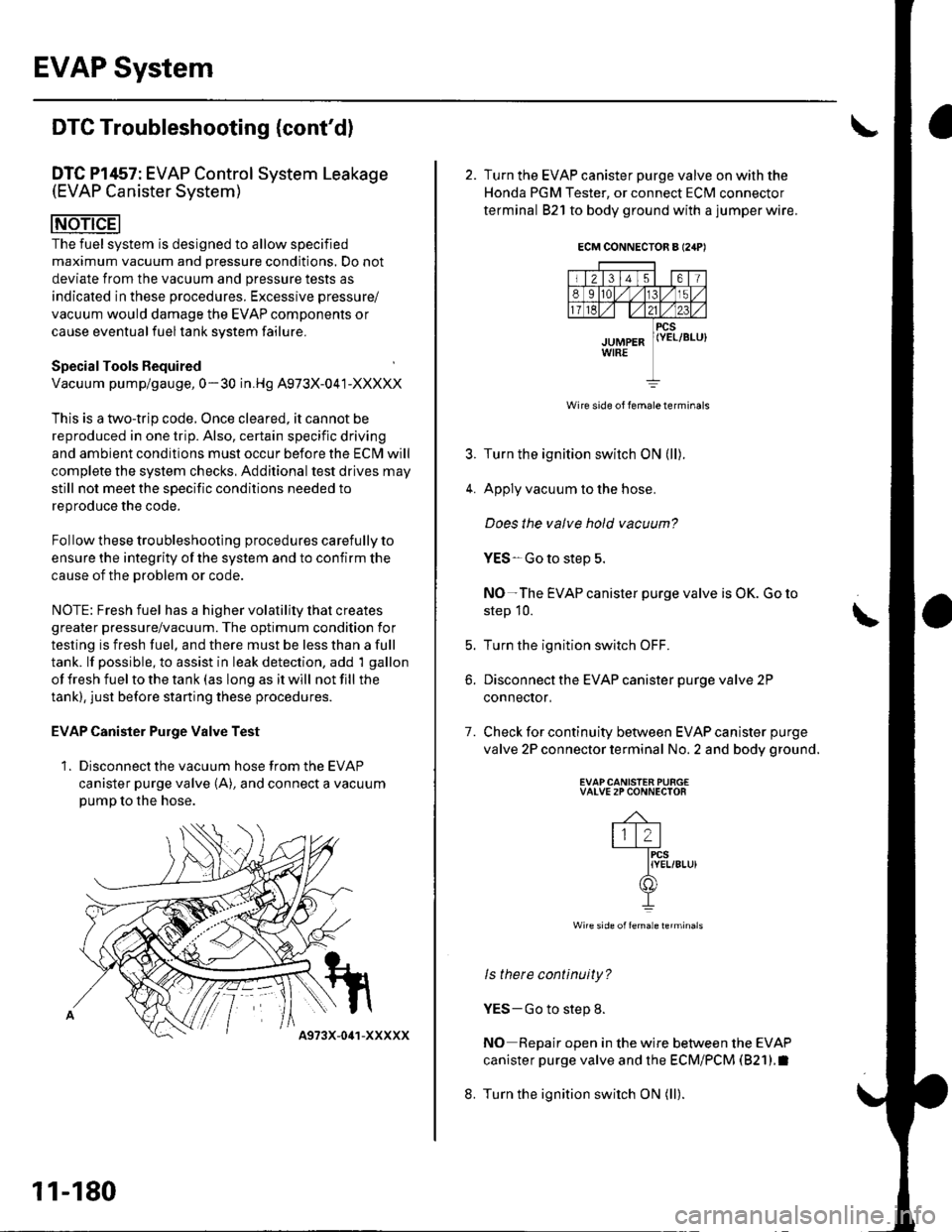

1. Disconnect the vacuum hose from the EVAP

canister purge valve (A), and connect a vacuumpump to the hose.

11-180

4973X-041-XXXXX

ECM CONNECTOR A I24P'

Wire side of lemale terminals

4.

7.

2. Turn the EVAP canister purge valve on with the

Honda PGM Tester, or connect ECM connector

terminal 821 to body ground with a jumper wire.

Turn the ignition switch ON (ll).

Apply vacuum to the hose.

Does the valve hold vacuum?

YES-Go to step 5.

NO-The EVAP canister purge valve is OK. Go to

step 10.

Turn the ignition switch OFF.

Disconnect the EVAP canister purge valve 2P

conneclor,

Check for continuity between EVAP canister purge

valve 2P connector terminal No. 2 and body ground.

EVAPCANISTEN PURG€VALVE 2P CONNECTOR

-4-

lll2l-fircs

IYEL/8Lu)(f])

I

Wire side offemale lerminals

ls there continuity?

YES-Go to step 8.

NO Repair open in the wire between the EVAP

canister purge valve and the ECM/PCM (821).I

Turn the ignition switch ON (ll).

t

b.

8.

Page 524 of 1139

DTC 22: Vehicle Speed Sensor Signal

DTC 23: Engine Speed Signal

NOTE:. lf the MIL indicator is ON, troubleshoot the PGIVI-Fl

system first.. Even though the system is operating normally, the

EPS indicator will come on under the following

conditions.

- Condition 1:. The vehicle was traveling at least '12.4 mph(20 km/h), then. A rapld change in vehicle speed was detected,

then. The vehicle (or the vehicle speed sensor signal)

stopped for at least 5 seconds, and. The engine speed was still 1,640 rpm or higher for

at least 5 seconds- Condition 2:

After the vehicle (or the vehicle speed sensor

signal) has stopped for at least 10 seconds, yetthe

engine speed was still 1,640 rpm or higher for at

least 20 seconds.- Condition 3:

When the vehicle speed is 10 km/h (6.2 mph) or

above and the engine is running at 280 rpm or

below for 3 seconds.

1. Start the engine and check the tachometer.

ls the tachometer working correctly?

YES- Go to step 2.

NO-Go to step 9.

2. Test-drive the vehicle above 15 km/h {9.3 mph).

ls the speedometer working correctly?

YES Go to step 3.

NO-Perform the speedometer system

troubleshooting {see page 22-651.a

3.Block the rear wheels and raise the vehicle, and

make sure it is securely supported.

Turn the ignition switch ON (ll).

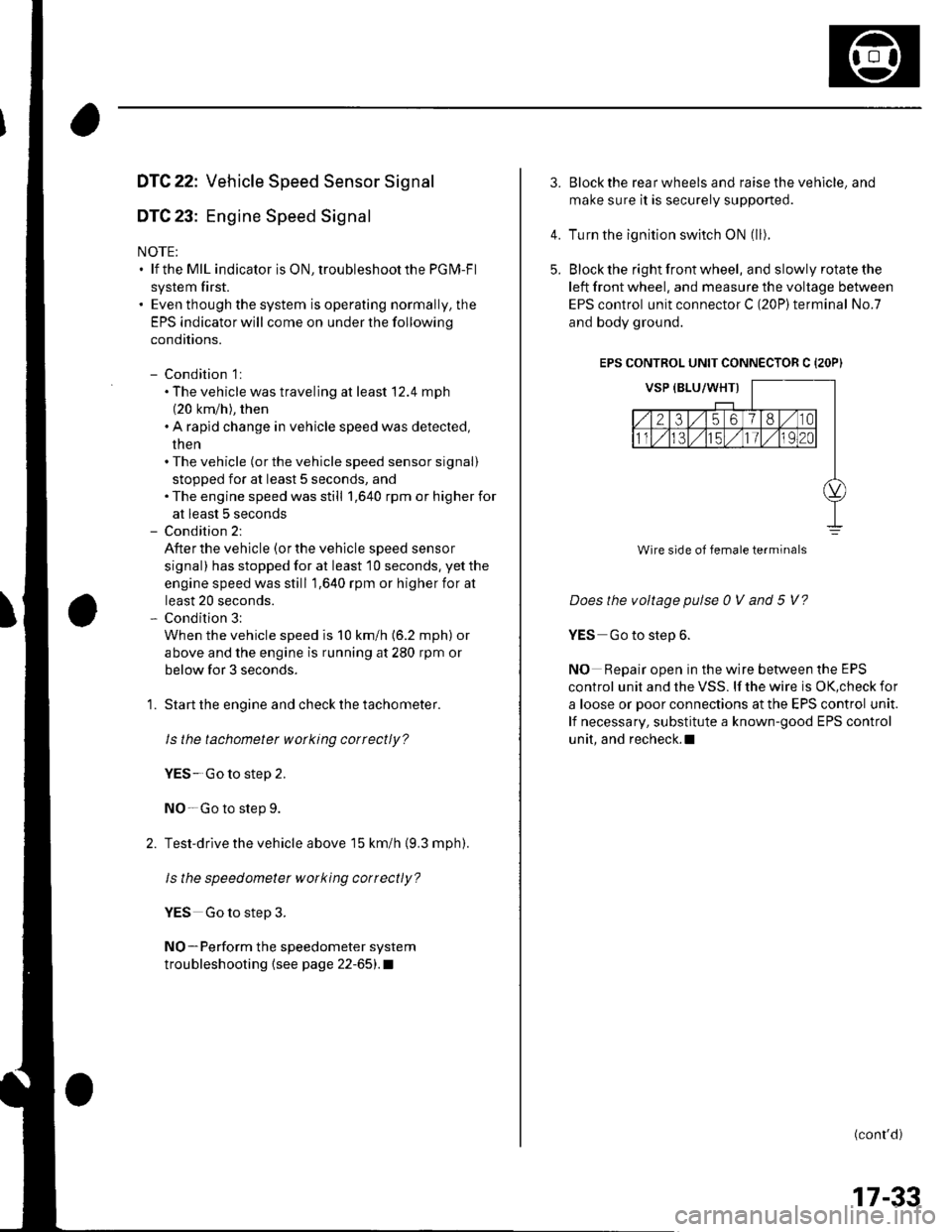

Block the right front wheel, and slowly rotate the

left front wheel, and measure the voltage between

EPS control unit connector C (20P)terminal No.7

and body ground.

EPS CONTROL UNIT CONNECTOR C {2OP)

Does the voltage pulse 0 V and 5 V?

YES Go to step 6.

NO Repair open in the wire between the EPS

control unit and the VSS. lf the wire is OK,check for

a loose or poor connections at the EPS control unit.

lf necessary, substitute a known-good EPS control

unit, and recheck.l

(conr'd)

4.

5.

Wire side of female terminals

17-33

Page 640 of 1139

ABS Components

DTC Troubleshooting (cont'dl

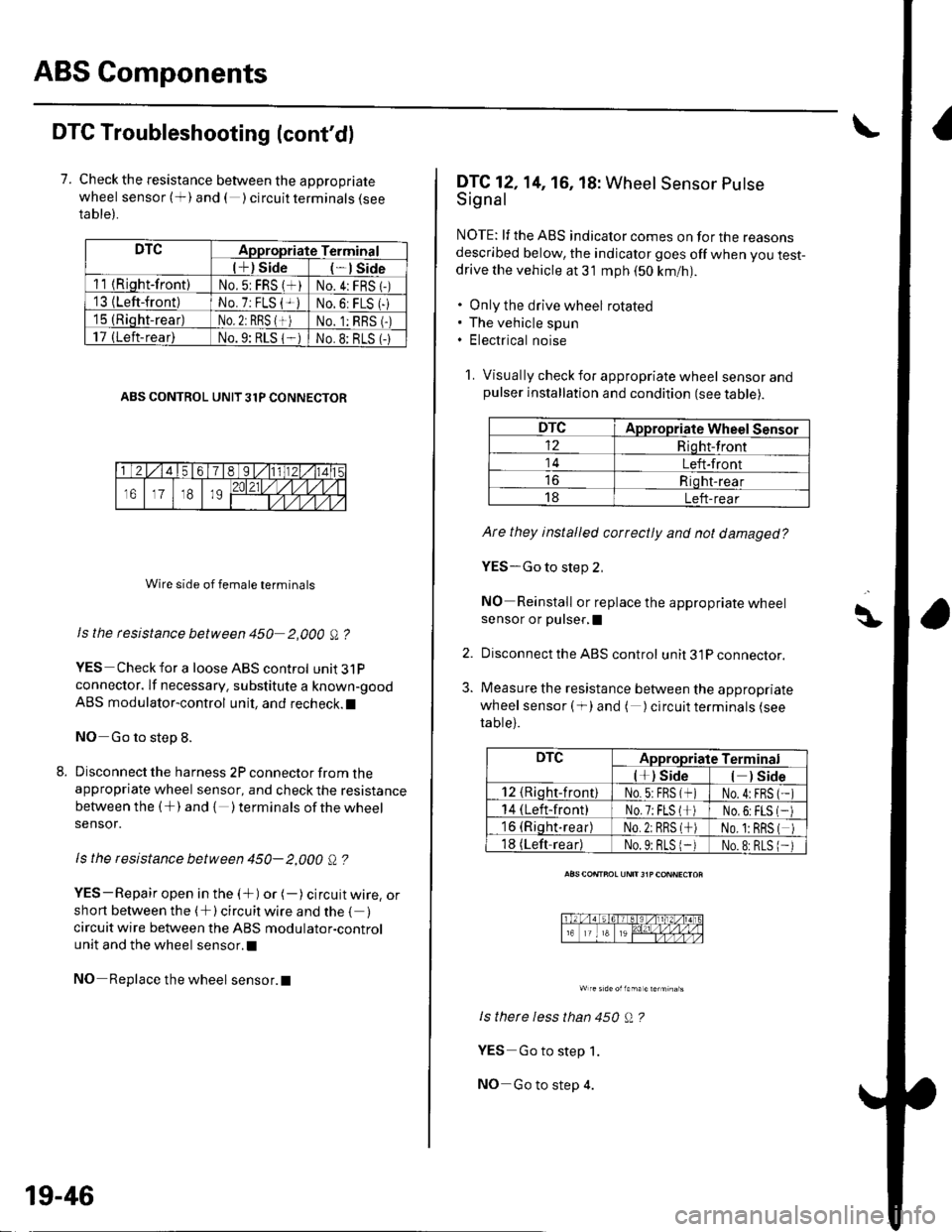

7. Check the resistance between the appropriate

wheel sensor (+) and ( ) circuit terminals {seeta ble).

DTCAppropriate Terminal

l+) Side*lSide

11 {Riqht-front)No.5: FRS (*)No.4:FRS 1-)'13 {Left-front)No. 7: FLS {+iNo.6: FLS (-

15 (Rioht-rear)No. 2: RBS {+)No. 1:RBS (-)

17 (Left-rear)No.9: RLS 1-No.8: BLS (-

ABS CONTROL UNIT 31P CONNECTOR

Wire side of female terminals

Is the rcsistance between 450 2,000 A ?

YES Check for a loose ABS control unit3lP

connector. lf necessary. substitute a known-good

ABS modulator-control unit, and recheck.l

NO Go to step 8.

Disconnect the harness 2P connector from theappropriate wheel sensor, and check the resistance

between the (+) and { )terminalsof thewheel

sensor.

ls the resistance between 450- 2,000 Q ?

YES-Repair open in the (+) or (-) circuit wire, orshort between the (+) circuit wire and the { )circuit wire between the ABS modulator-control

unit and the wheel sensor.l

NO Replace the wheel sensor.l

19-46

DTC12,14, 16, 18: Wheel Sensor Putse

Signal

NOTE: lf the ABS indicator comes on for the reasonsdescribed below, the indicator goes off when you test-drive the vehicle at 31 mph (50 km/nl.

. Only the drive wheel rotated. The vehicle spun. Electrical noise

1. Visually check for appropriate wheel sensorandpulser installation and condition (see table).

DTCAppropriate Wheel Sensor

12Riqht-front

14Left-front

Riqht-rear

18Left-rear

Ate they installed correctly and not damaged?

YES-Go to step 2,

NO Reinstall or replace the appropriate wheelsensor or pulser,I

Disconnect the ABS control unit 31P connector.

Measure the resistance between the appropriate

wheel sensor ( f) and ( ) circuit terminals (see

table).

ls therc less than 450 Q ?

YES Go to step 1.

NO-Go to step 4.

\\|D

2.

3.

DTCAppropriate Terminal

l*) Side) Side

12 {Rioht-front)No.5:FBS (*No.4:FBS

14 (Left-front)No.7;FLS l*No,6:FLS

16 (Riqht.rear)No.2: RRS (*No. 1:BRS

18 (Left-readNo.9: BLS 1-No.8:RLS

Page 773 of 1139

21-2

z t-'5

z t-o

z t-o

21-8

21-9

21-10

21-11

21-14

z t- to

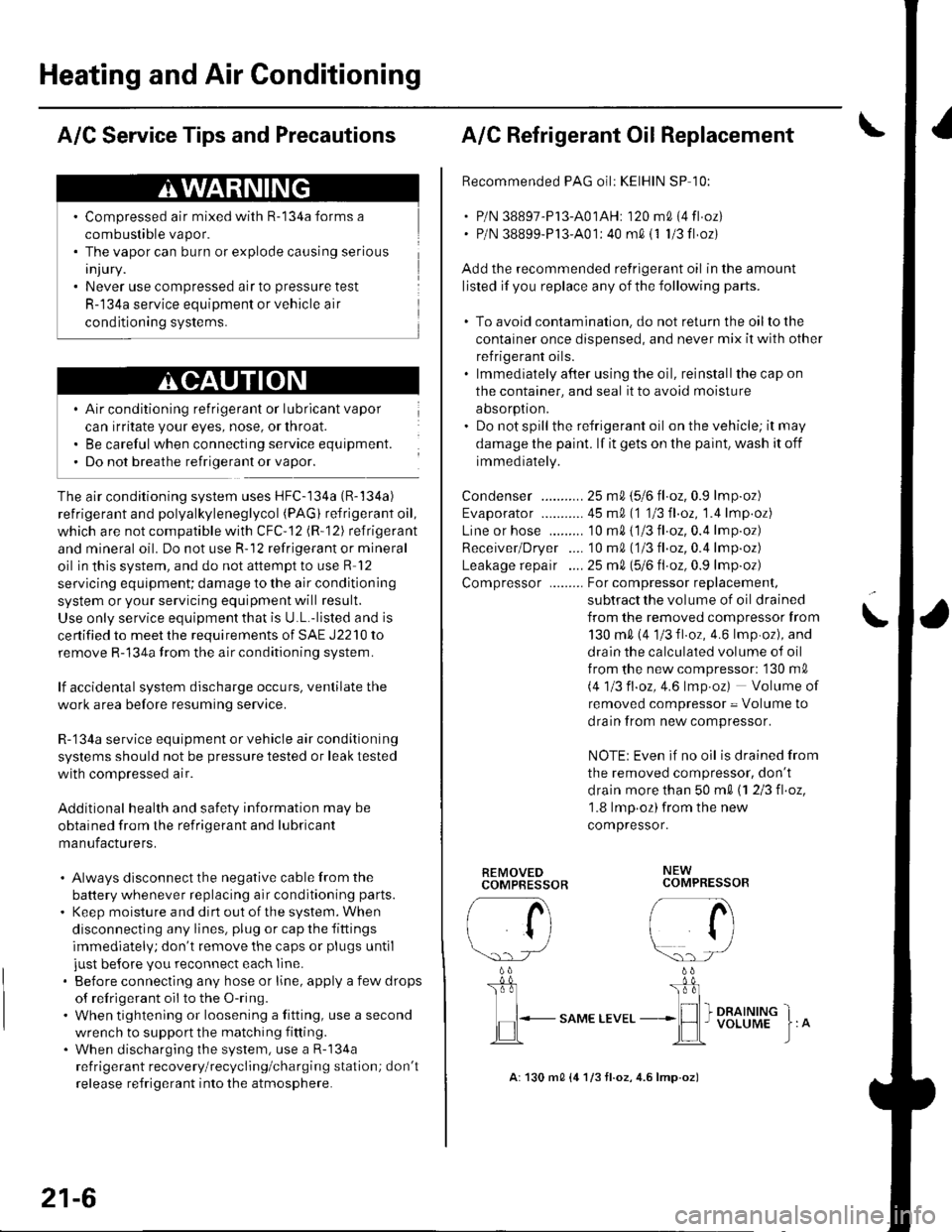

HVAC (Heating, Ventilation, and Air Gonditioningl

Heating and Air Conditioning

SpecialTools

Comoonent Location lndex ........

A/C Service Tios and

Precautions

A,/C Refrigerant Oil

ReDlacement

General Troubleshooting

lnformation

DTC Troubleshooting Index .......

Symptom Troubleshooting

1ndex..............

System Description .....................

Circuit Diagram

DTC Troubleshooting ..................

Recirculation Control Motor

CircuitTroubleshooting .......... 21-25

Heater Control Power and Ground

Circuits Troubleshooting ........ 21-27

Condenser Fan Circuit

Troubleshooting ...................... 21-28

Radiator and Condenser Fans

Common Circuit

Troubfeshooting ...................... 21-29

Compressor Clutch Circuit

Troubleshooting ...................... 21-30

A,/C Pressure Switch Circuit

Troubleshooting ...................... 21-32

Air Mix Control Motor

Test and Reolacement ............. 21-34

Mode Control Motor

Test and Replacement ............. 21-35

Recirculation Control Motor

Test and Reolacement ............. 21-36

Evaporator Temperature Sensor

Reolacement and Test ............. 21-31

Power Transistor Test ................. 21 -38

Heater Control Panel and

Push Switch Assemblv

Removal and Installation ........ 21-38

Dust and Pollen Filter

Reolacement ..21-39

Blower Unit Removal and

lnstallation ...... 21-39

Blower Unit Comoonents

ReDlacement ............................ 21-41

Evaporator Core

Reolacement ..21-42*Heater Unit/Core

ReDlacement ..21-43

Heater Valve Cable

Adjustment .....21-46

CompressorReplacement .......... 21-47

Comoressor Clutch Check .......... 21-48

Comoressor Clutch Overhaul ..... 21-49

Compressor Thermal Protector

Reo1acement ............................ 21-51

Comoressor Relief Valve

Reolacement ............................ 21-51

Condenser Reolacement ............ 21-52

Refrigerant Recovery .................. 21-53

System Evacuation ...................... 21-54

System CharginS ......................... 21-55

Refrigerant LeakTest .................. 21-56

A,/C Svstem Tests ........................ 21-57

Page 774 of 1139

HVAC {Heating, Ventilation, and Air Conditioning)

SpecialTools

Ret.No.Tool NumberDescriDtion Otv

o07sAz-001000ABackprobe Set 2

---2

att-,,- KCe

/'Tt "-t--'

e^t"'

T

21-2

Page 776 of 1139

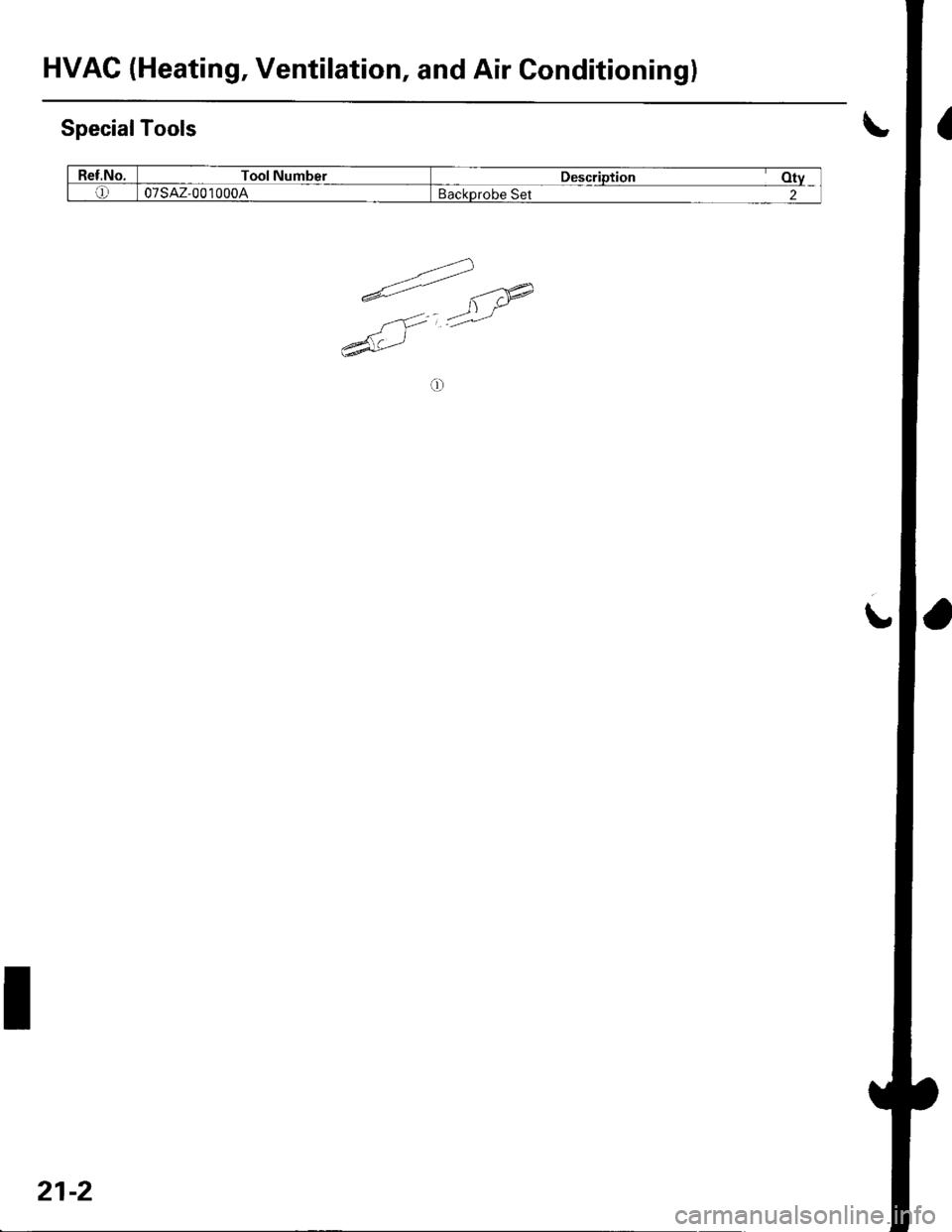

Heating and Air Conditioning

Component Location Index (cont'dl

CONDENSER FANTest, page 22-51

RADIATOR FAN RELAYTest, page 22-51

Tesl, page 22-51CLUTCH RELAY

MOTOR RELAYTest, page 22-5I

UNDER.HOOD FUSE/RELAY BOX

... A/C PRESSURE SWITCH

RADIATOR FAN

\

.\

-

'-t t_]]l

/l I T I --::--

l- -l -

CONOENSER FAN

21-4

Page 778 of 1139

Heating and Air Conditioning

A/C Service Tips and Precautions

Compressed air mixed with R- 134a forms a

combustible vapor.

The vapor can burn or explode causing serious

injury.

Never use compressed air to pressure test

R-134a service equipment or vehicle air

conditioning systems.

Air conditioning refrigerant or lubricant vapor

can irritate your eyes, nose, or throat.

Be careful when connecting service equipment.

Do not breathe refrigerant or vapor.

The air conditioning system uses HFC-134a (R-134a)

ref rigerant and polyalkyleneglycol (PAG) ref rigerant oil,

which are not compatible with CFC'12 (R-12) refrigerant

and mineral oil. Do not use R-'12 refrigerant or mineral

oil in this system, and do not aftempt to use R 12

servicing equipment; damage to the air conditioning

system or your servicing equipment will result.

Use only service equipment that is U.L.-listed and is

certified to meet the requirements of SAE J2210 to

remove R-134a from the air conditioning system.

lf accidental system discharge occurs, ventilate the

work area before resuming service.

R-134a service equipment or vehicle air conditioning

systems should not be pressure tested or leak tested

with compressed air.

Additional health and safety information may be

obtained from the refrigerant and lubricant

manufacturers.

. Always disconnect the negative cable from the

battery whenever replacing air conditioning parts.

. Keep moisture and dirt out of the system. When

disconnecting any lines, plug or cap the fittings

immediately; don't remove the caps or plugs until

iust be{ore you reconnect each line.' Before connecting any hose or line, apply a few drops

of relrigerant oil to the O-ring.. When tightening or loosening a fitting, use a second

wrench to support the matching fitting.. When discharging the system, use a R-'134a

ref rigerant recovery/recycling/charging station; don't

release refrigerant into the atmosphere.

21-6

A: 130 m0 {4 l/3 tl.oz,4.6 lmp.oz)

],^

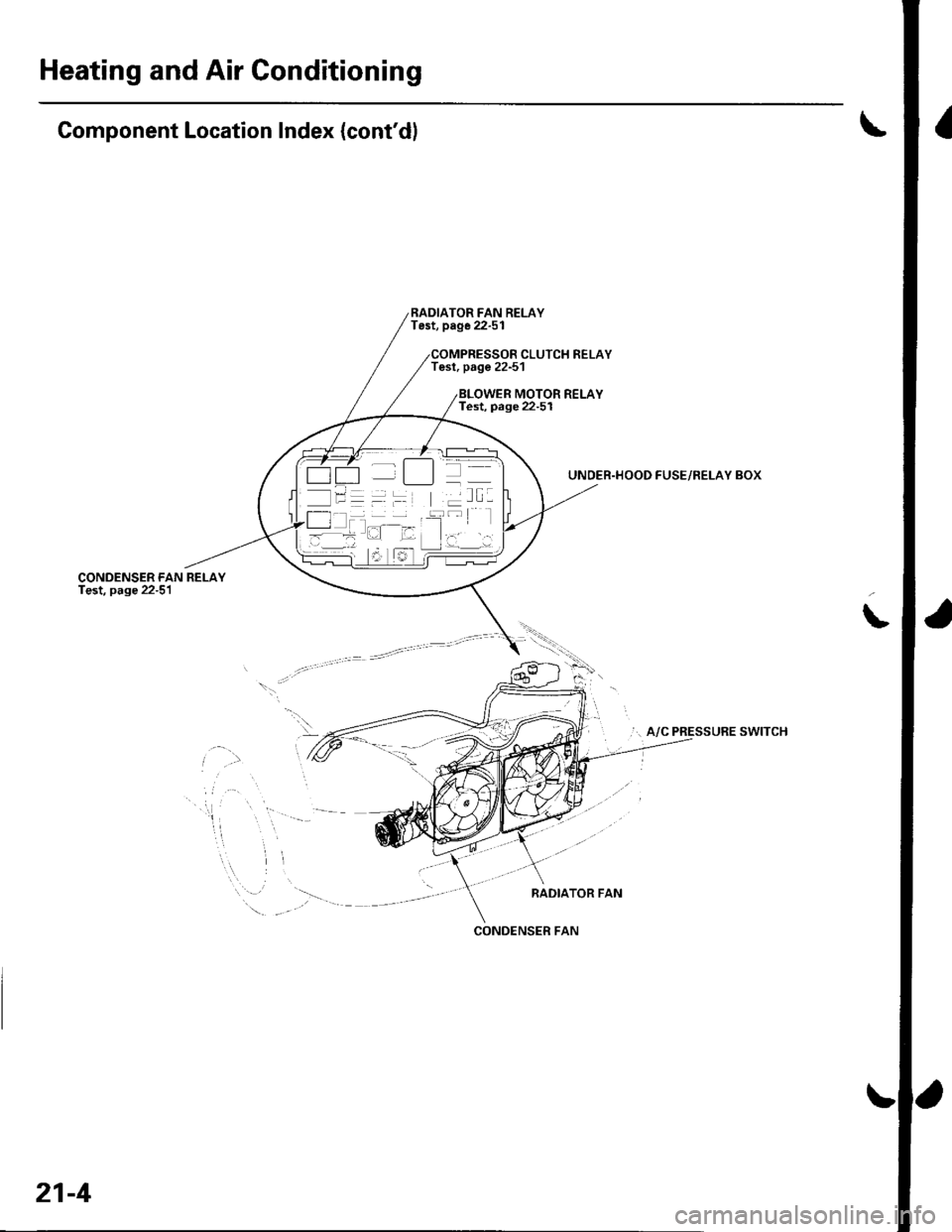

A/C Refrigerant Oll Replacement

Recommended PAG oil: KEIHIN SP 10:

. P/N 38897-P l3-A01AH: '120 m0 i4 fl oz). P/N 38899-P13'A01: 40 m0 i1 1/3 fl oz)

Add the recommended refrigerant oil in the amount

listed if you replace any of the following parts.

. To avoid contamination. do not return the oilto the

container once dispensed, and never mix it with other

refrigerant oils.. lmmediately af'ter using the oil, reinstallthe cap on

the container, and seal it to avoid moisture

aosorpron.. Donotspill the refrigerant oil on the vehicle; it may

damage the paint. lf it gets on the paint, wash it off

immediately.

Condenser ...........25 mA \516 tl.oz, 0.9 lmp.oz)

Evaporator ........... 45 m0 (1 113Il.oz, '1.4 lmp.oz)

Line or hose ......... '10 m0 {1/3 fl.oz,0.4 lmp.oz)

Receiver/Dryer .... '10 m0 ('113 fl.oz,0.4 lmp.oz)

Leakage repai r .... 25 m0, 1516 Il oz, 0.9 lmp.oz)

Compressor ......... For compressor replacemenl,

subtract the volume of oil drained

from the removed compressor from

130 m0 (4 1/3fl.oz, 4.6lmp.oz), and

drain the calculated volume of oil

f rom the new compressor: '130 m0

i.4113 fl.oz,4.6 lmp.oz) Volume of

removed compressor = Volume to

drain from new compressor.

NOTE: Even if no oil is drained from

the removed compressor, don't

d rain more than 50 m0 \1 2/3 fl.oz,'1.8 lmp oz)from the new

compressor.

\

REMOVEDCOMPBESSOR

rA

li

\.. rJ

b

I

,lEL.-

"o*t ttu"

NEWCOMPRESSOR

/- a\i tl

r/

\:)-) -/

_ 0L'r:l_

I I I DRAINING_*lH I voLUME

Page 780 of 1139

Heating and Air Conditioning

General Troubleshooting Information

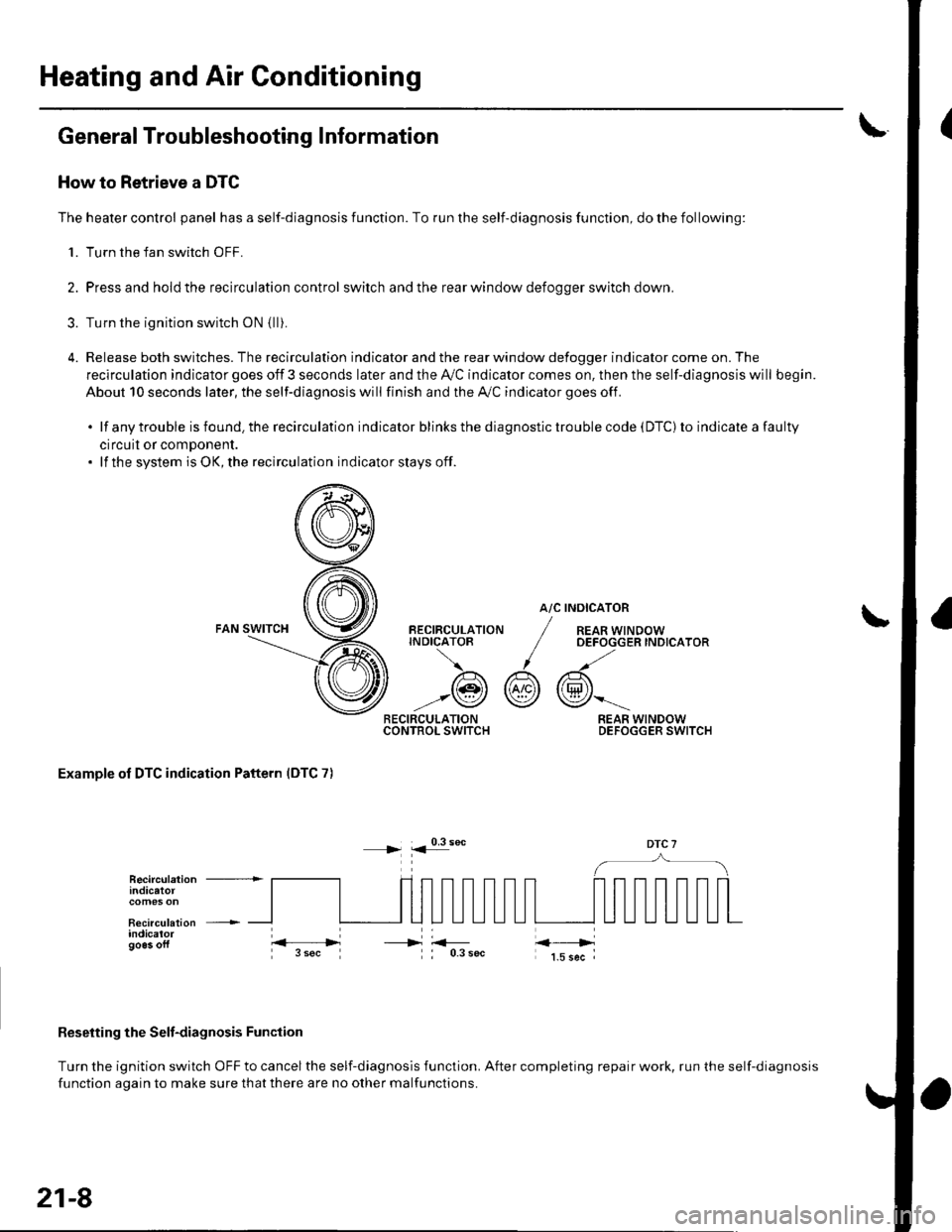

How to Retrieve a DTC

The heater control panel has a self-diagnosis function. To run the self-diagnosis function, do the following:

1. Turn the fan switch OFF.

2. Pressand holdthe recirculation control switch andthe rear window defoooer switch down.

3. Turn the ignition switch oN {lli.

4. Release both switches. The recirculation indicator and the rear window defogger indicator come on. The

recirculation indicator goes off 3 seconds later and the Ay'C indicator comes on. then the self-diagnosis will begin.

About 10 seconds later, the self-diagnosis will finish and the A,/C indicator goes off.

.lfanytroubleisfound.therecirculationindicatorblinksthediagnostictroublecode(DTC)toindicateafaulty

circuil or comDonent.. lf the system is OK, the recirculation indicator stays off.

atc

@r

RECIRCULATIONCONTROL SWITCH

BECIRCULATIONINDICATOB

/A\

-:@

INOICATOR

REAR WINDOWOEFOGGER INDICATOR

REAR WINDOWDEFOGGER SWITCH

Examole of DTC indication Pattern IDTC 7)

DTC 7

Reseiting the Selt-diagnosis Function

Turn the ignition switch OFF to cancel the self-diagnosis function. After completing repair work, run the self-diagnosis

function aoain to make sure thatthere are no other malfunctions.

Recirculation +indicatot

Recirculation +indicalorgo6s oft----->

21-8

Page 782 of 1139

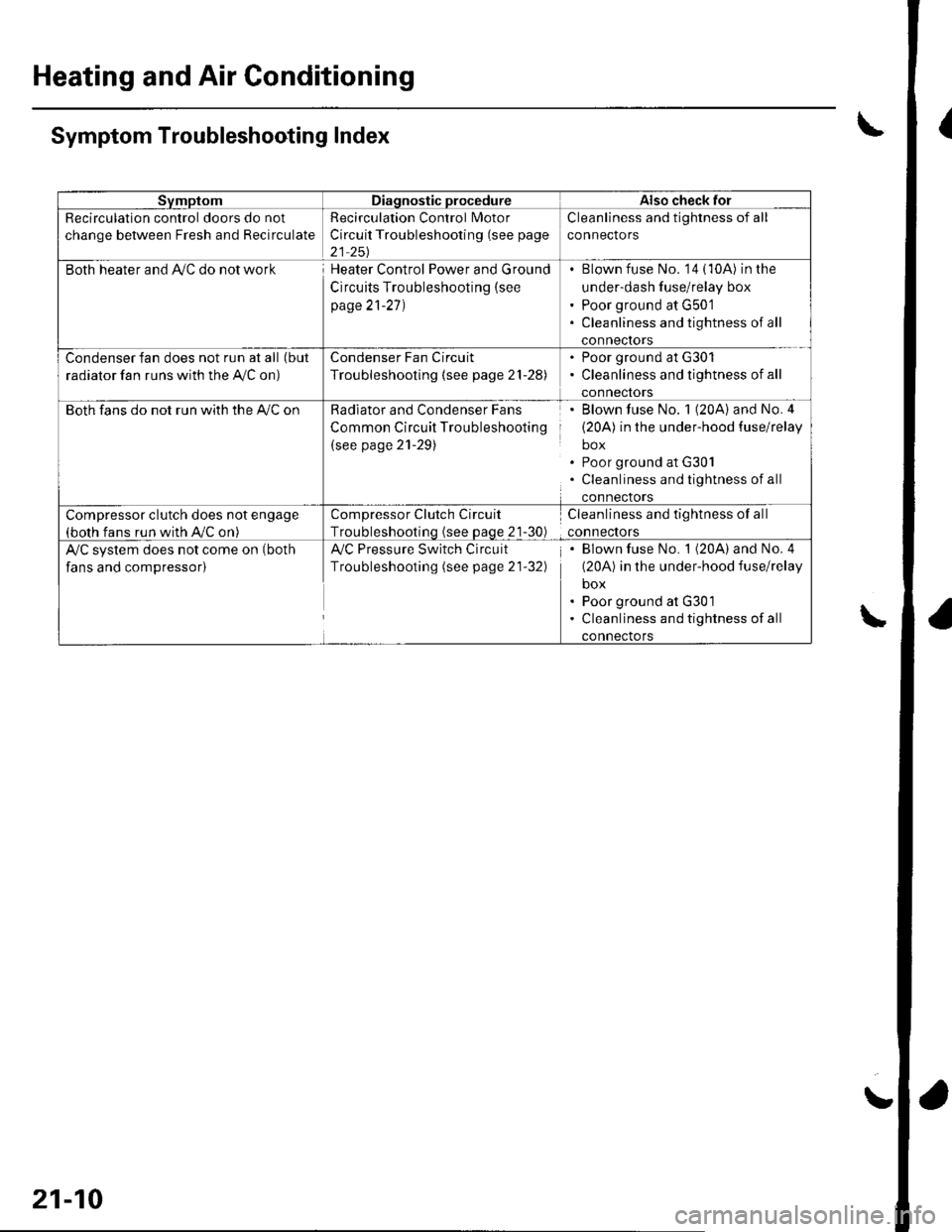

Heating and Air Conditioning

{

a

a

SvmptomDiagnostic procedureAlso check for

Recirculation control doors do not

change between Fresh and Recirculate

Recirculation Control Motor

Circuit Troubleshooting (see page

21 251

Cleanliness and tightness of all

connectors

Both heater and Ay'C do not workHeater Control Power and Ground

Circuits Troubleshooting (see

page 21-27)

Blown fuse No. '14 (10A) in the

under-dash fuse/relay box

Poor ground at G501

Cleanliness and tightness of all

conneclors

Condenser fan does not run at all (but

radiator fan runs with the Ay'C on)

Condenser Fan Circuit

Troubleshooting {see page 21-28)

. Poor ground at G301. Cleanliness and tightness of all

connectors

Both fans do not run with the A,/C onRadiator and Condenser Fans

Common Circuit Troubleshooting

(see page 21-29)

Blown fuse No. 1 (20A) and No.4

(20A) in the under-hood fuse/relay

box

Poor ground at G30l

Cleanliness and tightness of all

connectors

Compressor clutch does not engage(both fans run with A,/C on)

Compressor Clutch Circuit

Troubleshootinq (see Daqe 21-30)

Cleanliness and tightness of all

connectors

A/C system does not come on (both

fans and compressor)

Ay'C Pressure Switch Circuit

Troubleshooting (see page 21-32)

Blown fuse No. 1 (20A) and No. 4

(20A) in the under-hood fuse/relay

box

Poor ground at G301

Cleanliness and tightness of all

connectors

\Symptom Troubleshooting Index

\

21-10

!