steering HONDA CIVIC 2002 7.G Owner's Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 2002, Model line: CIVIC, Model: HONDA CIVIC 2002 7.GPages: 1139, PDF Size: 28.19 MB

Page 503 of 1139

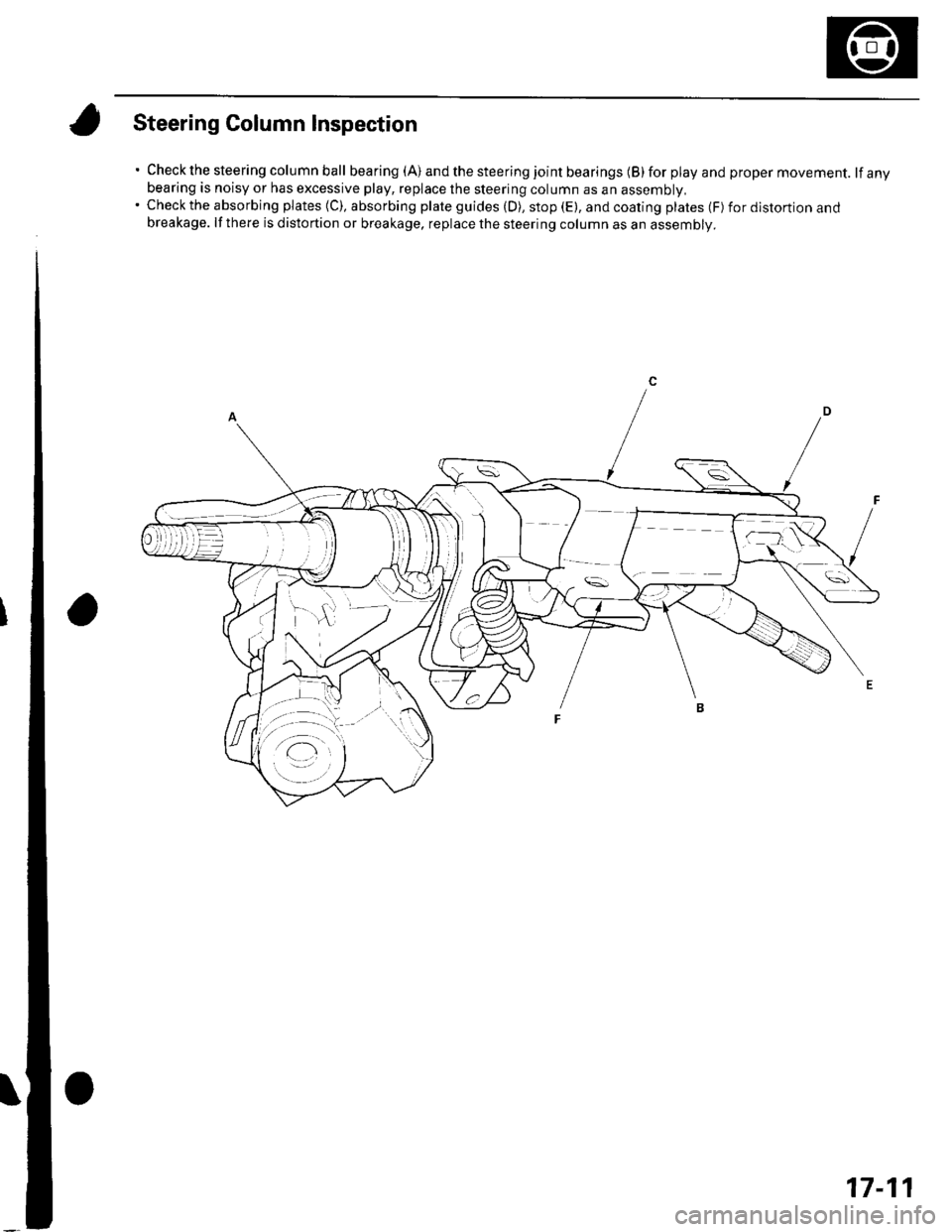

Steering Column Inspection

. Check the steering column ball bearing(A) andthesteeringjointbearings(B)forplayandpropermovement. lfanybearing is noisy or has excessive play, replace the steering column as an assembly,'Checktheabsorbingplates(C),absorbingplateguides(D),stop(E),andcoatingplates(F) for distortion andbreakage. lf there is distortion or breakage, replace the steering column as an assembly.

17-11

Page 504 of 1139

Steering

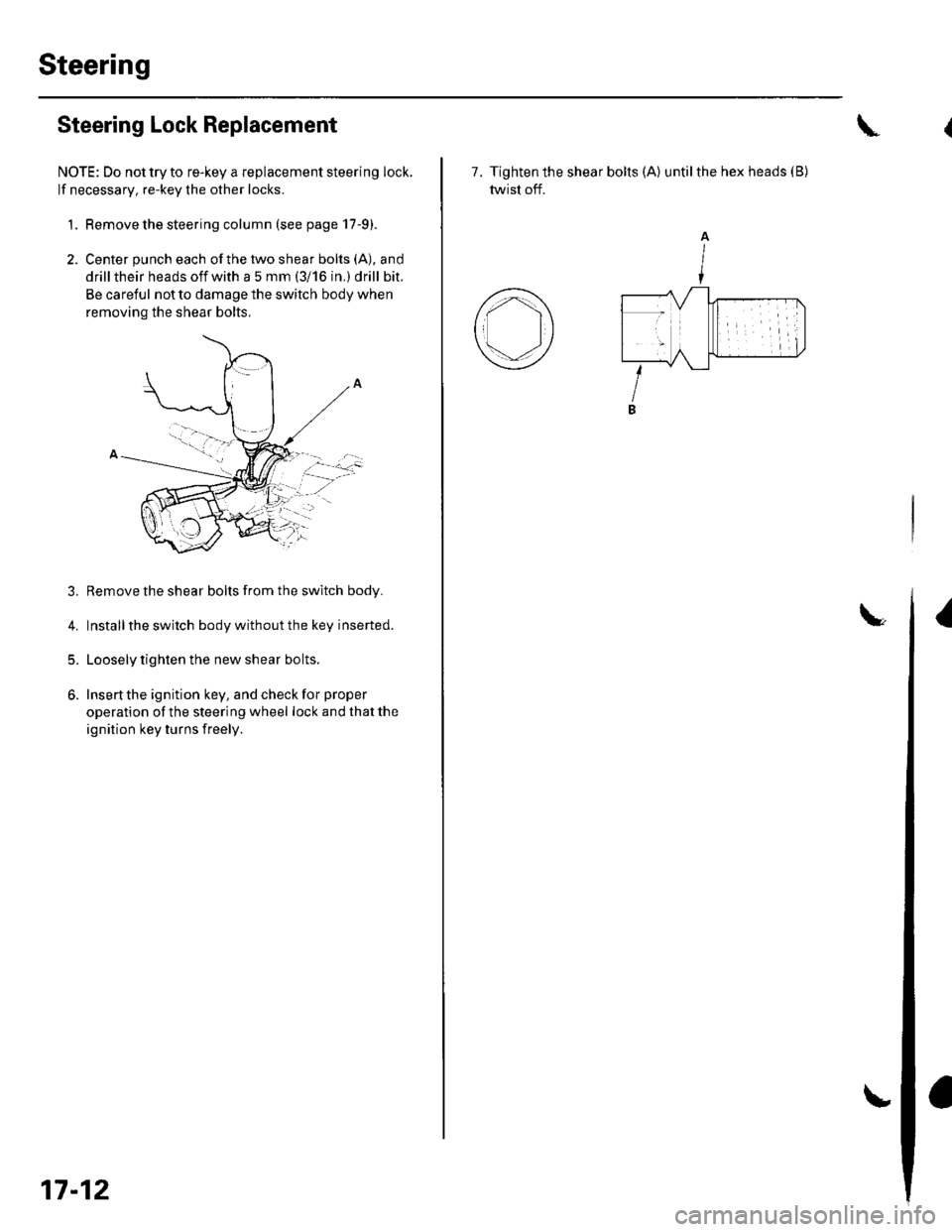

Steering Lock Replacement

NOTE: Do not try to re-key a replacement steering lock.

lf necessary, re-key the other locks.

1. Remove the steering column (see page 17-9).

2. Center punch each ofthe two shear bolts (A), and

drill their heads off with a 5 mm (3i 16 in.) drill bit.

Be careful not to damage the switch body when

removing the shear bolts,

3. Remove the shear bolts from the switch body.

4. Installthe switch body without the key inserted.

5. Loosely tighten the new shear bolts.

6. Insert the ignition key, and check for proper

operation of the steering wheel lock and that the

ignition key turns freely.

:..'-":'

17-12

7. Tighten the shear bolts (A) untilthe hex heads (B)

twist off.

I

A

I

Page 505 of 1139

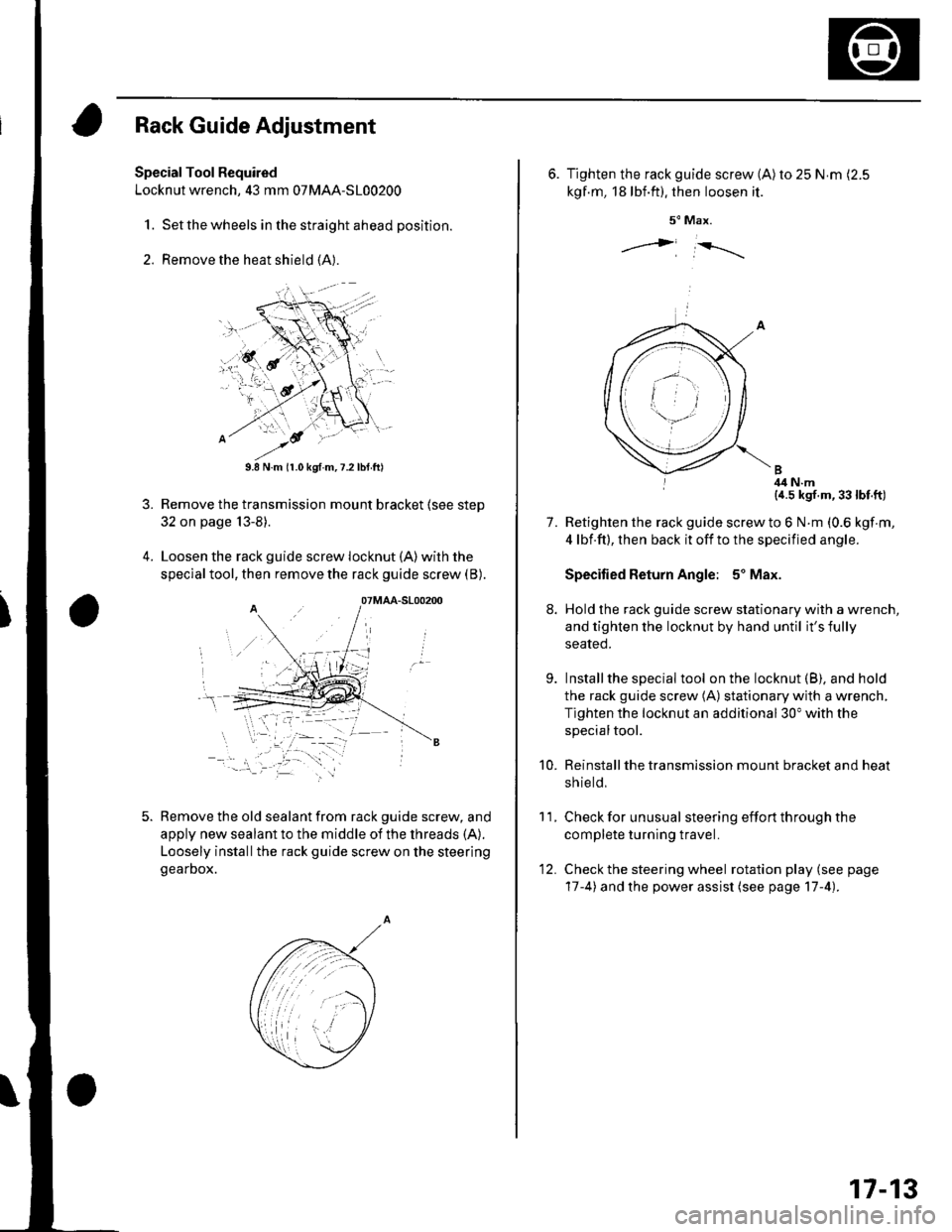

Rack Guide Adjustment

Special Tool Required

Locknut wrench, 43 mm 07MAA-S100200

1. Set the wheels in the straight ahead position.

2. Remove the heat shield (A).

3.

9.8 N.m (r.0 kgf.m,7.2lbtft)

Remove the transmission mount bracket (see step

32 on page 13-8).

Loosen the rack guide screw locknut (A)with the

special tool, then remove the rack guide screw (B).

Remove the old sealant from rack guide screw, and

apply new sealant to the middle of the threads (A).

Loosely installthe rack guide screw on the steering

gearDox.

'-.i. '' '

07MAA-S100200

6. Tighten the rack guide screw (A)ro 25 N.m (2.5

kgf.m, 18lbf.ft). then loosen it.

5" Max.

j i-rrrr-,

I 4il N.m{a.5 kgf.m,33lbt.ft)

Retighten the rack guide screw to 6 N.m (0.6 kgf m,

4 lbf.ft), then back it off to the specified angle.

Specified Return Angle: 5' Max.

Hold the rack guide screw stationary with a wrench,

and tighten the locknut by hand until it's fully

seated.

Installthe special tool on the locknut (B), and hold

the rack guide screw (A) stationary with a wrench,

Tighten the locknut an additional 30" with the

specialtool.

Reinstall the transmission mount bracket and heat

sh ie ld,

Check for unusual steering effort through the

complete turning travel.

Check the steering wheel rotation play (see page

17-4) and the power assist (see page 17-4).

11.

7.

9.

10.

12.

17-13

Page 506 of 1139

Electrical Power Steering (EPSI

SpecialTools ............. 17 -16

Component Location Index ......................................... 17-17

General Troubleshooting Information ....................... 17-18

DTC Troubleshooting Index .............. 17-22

Symptom Troubleshooting Index ............................... 17 -23

System Description ................. ........... 17-24

Circuit Diagram ......... 17-26

DTC Troubleshooting ............... .......... 17-28

EPS lndicator Circuit Troubleshooting ....................... 17-47

Motor Removal/lnstallation ............... 17-49

Steering Gearbox Removal ............... 17-51

Steering Gearbox Overhaul ............... 17-55

Steering Gearbox Installation ........... 17-63

EPS Control Unit Remova l/lnsta llation ....................... 17-67

Tie-rod Ball Joint Boot Replacement .......................... 17-67

Page 508 of 1139

![HONDA CIVIC 2002 7.G Owners Manual Component Location Index

UNDER.HOODFUSE/RELAY BOX

EPS CONTROL UNITEPS Control Unit Removal/lnstallation,page 17 -67

UNDER.DASH FUSE/RELAY BOX

-,/.,....

.,i,

X ]

DATA LINK CONNECTOR I16P)

TOROUE SENS HONDA CIVIC 2002 7.G Owners Manual Component Location Index

UNDER.HOODFUSE/RELAY BOX

EPS CONTROL UNITEPS Control Unit Removal/lnstallation,page 17 -67

UNDER.DASH FUSE/RELAY BOX

-,/.,....

.,i,

X ]

DATA LINK CONNECTOR I16P)

TOROUE SENS](/img/13/5744/w960_5744-507.png)

Component Location Index

UNDER.HOODFUSE/RELAY BOX

EPS CONTROL UNITEPS Control Unit Removal/lnstallation,page 17 -67

UNDER.DASH FUSE/RELAY BOX

-,'/.,....

'.,i,

X ]

DATA LINK CONNECTOR I16P)

TOROUE SENSOR

STEERING GEARBOXSteering Gearbox Removal, page 17-51Steering Gearbox Overhaul, page 17-55Steering Gearbox Installation, page 17-63

Removal/lnstallation,page l7-49

GAUGE ASSEMBLY

MOTOR

17-17

Page 509 of 1139

EPS Components

aGeneral Troubleshooting Information

EPS Indicator

Under normal conditions, the EPS indicator comes on when

the ignitlon switch is turned to the ON (ll) position, then goes

off after the engine is started. This indicates that the bulb and

its circuit are operating correctly.

lf there is any trouble in the system after the engine is started,

the EPS indicator will stay on, and the power assist is turned

off.

When EPS indicator light comes on, the control unit

memorizes the DTC. In this case, the control unit will not

activate the EPS system after the engine starts again, but it

keeps the EPS indicator on.

When DTC 12, 16, 17, 18 or 67 is stored in the control unit, the

EPS indicator will stay on until the DTC is erased. When a

problem is detected and the EPS indicator comes on, there are

cases when the indicator stays on untilthe ignition switch is

turned 0FF, and cases when the indicator goes off

automatically when the system returns to normal. Even though

the system is operating normally, the EPS indicator will come

on under the following conditions:

Condition '1:

. The vehicle was traveling at least 12.4 mph (20 km/h), then. A rapid change in vehicle speed was detected, then. The vehicle (or the vehicle speed sensor signal) stopped for

at least 5 seconds. The engine speed was still 'l,640rpmorhigherforatleastS

seconds

Condition 2:

After the vehicle (or the vehicle speed sensor signal) has

stopped for at least 10 seconds, yet the engine speed was still

1,640 rpm or higherfor at least 20 seconds.

Condition 3:

When the engine speed is 280 rpm or less, and the vehicle is traveling at

a speed of 6,2 mph (10 km/h) or more for 3 seconds.

To determine the actual cause ofthe problem, question the

customer about the conditions during which the problem

occured, taking the above conditions into consideration.

Diagnostic Trouble Code (DTCI

. lf the CPU cannot be activated, or itfails,the EPS indicator

comes on, but the DTC is not memorized.. The memory can hold any number of DTCS. However, when

the same DTC is detected more than once, the most recent

DTC is written over the prior DTC, therefore only one

occurrence is memorized.. The DTCS are indicated repeatedly untilthe ignition switch is

turned OFF.. lf the DTC is not memorized,the EPS indicator blinks.

. The DTCS are memorized in the EEPRO| (non-volatile

memory) therefore the memorized DTCS cannot be erased

by disconnecting the battery. Perform the specified

procedures to clear DTCS.

Self-diagnosis

Self-diagnosis can be classified into two categories:.Initial diagnosis: performed right after the engine

starts and until the EPS indicator goes off.. Regular diagnosis: performed right after the initial

diagnosis until the ignition switch is turned OFF.

The EPS control unit performs the following functions

when a problem is detected by self-diagnosis;

'1. Turns on the EPS indicator.

2. Memorizes the DTC.

3. Stops power assist and manual steering operation

begrns.

NOTE:. When DTC 23 (a problem with the circuit for

engine speed signal) is detected, the power

assist will return to normal when the vehicle

speed is 0.62 mph (1 km/h) or above.. Fot DfCs 22,23, 64, or 66 the EPS indicator goes

off automatically when the system relurns to

normal. For all other codes, the EPS indicator

goes off when the system is OK after the ignition

switch is turned from OFF to ON (ll).

Restriction on Power Assist Operation

Repeated extreme steering force. such as turning the

steering wheel continuously back-and-forth with the

vehicle stopped, causes an increase of power

consumption in the EPS motor. The increase of electric

current causes the motor to heat up. Because this heat

adversely affects the system, the control unit monitors

the electric current of the motor.

When the control unit detects heat build-up in the motor,

it reduces the electric current to the motor gradually to

protect the system, and it restricts the power assist

operation. The EPS indicator does not come on during

this function.

When steering torque is not applied to the steering

wheel, or when the ignition is turned off, and the motor

cools, the control unit will restore the power assist

gradually until it's fully restored (after approximately 15

minutes maximum).

17-18

Page 512 of 1139

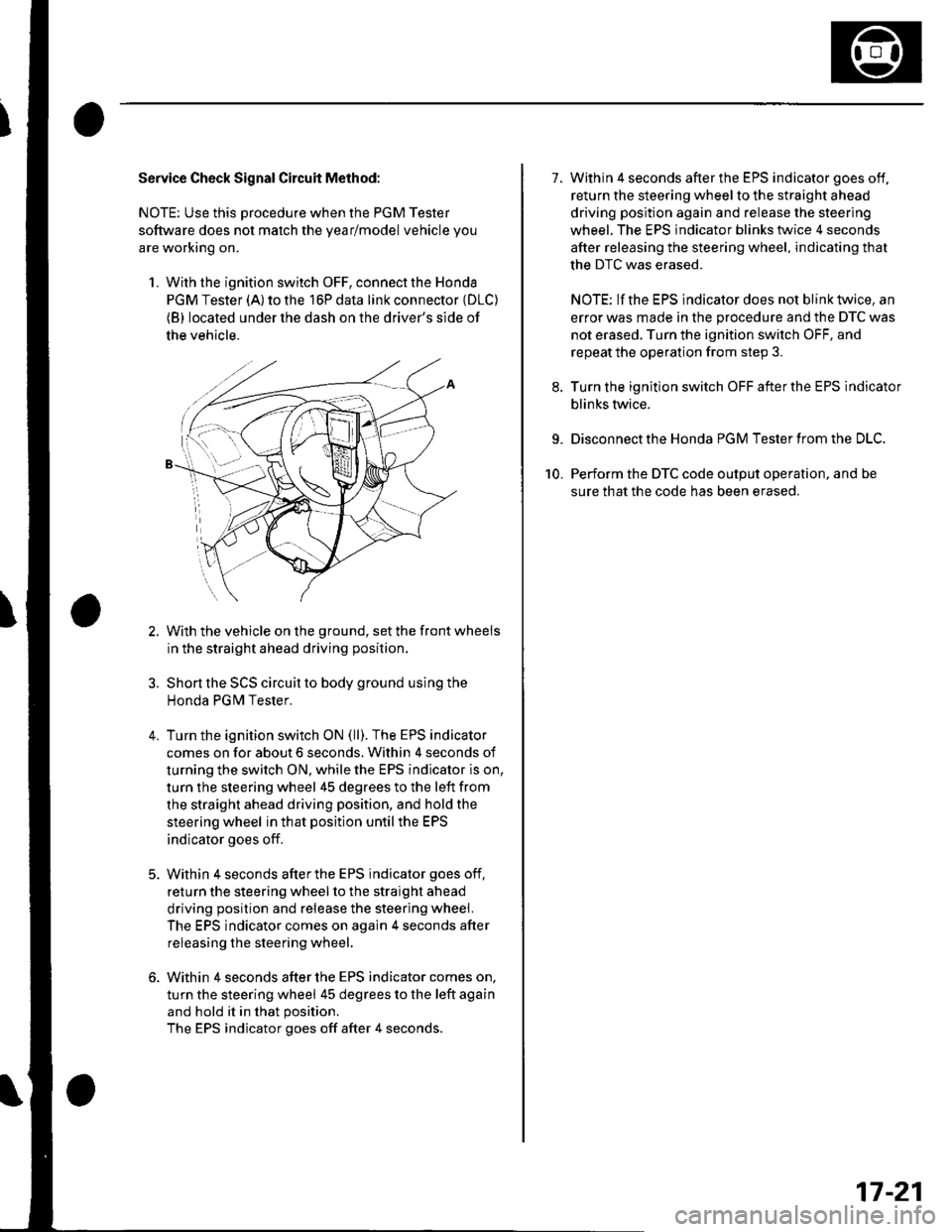

Service Check Signal Circuit Method:

NOTE: Use this procedure when the PGM Tester

software does not match the yearlmodel vehicle you

are working on.

1. With the ignition switch OFF, connect the Honda

PGM Tester (A) to the 16P data link connector {DLC)(B) located under the dash on the driver's side of

the vehicle.

With the vehicle on the ground, set the front wheels

in the straight ahead driving position.

Short the SCS circuit to body ground using the

Honda PGM Tester.

Turn the ignition switch ON (ll). The EPS indicator

comes on for about 6 seconds. Within 4 seconds of

turning the switch ON, while the EPS indicator is on,

turn the steering wheel 45 degrees to the left from

the straight ahead driving position, and hold the

steering wheel in that position until the EPS

indicator goes off.

Within 4 seconds afterthe EPS indicator goes off,

return the steering wheel to the straight ahead

driving position and release the steering wheel.

The EPS indicator comes on again 4 seconds after

releasing the steering wheel,

Within 4 seconds after the EPS indicator comes on,

turn the steering wheel 45 degrees to the left again

and hold it in that position.

The EPS indicator goes off after 4 seconds.

4.

1.Within 4 seconds after the EPS indicator goes off,

return the steering wheel to the straight ahead

driving position again and release the steering

wheel. The EPS indicator blinks twice 4 seconds

after releasing the steering wheel, indicating that

the DTC was erased.

NOTE: If the EPS indicator does not blink twice, an

error was made in the procedure and the DTC was

not erased. Turn the ignition switch OFF, and

repeat the operation from step 3.

Turn the ignition switch OFF afterthe EPS indicator

blinks twice.

9. Disconnect the Honda PGM Tester from the DLC.

10. Perform the DTC code output operation, and be

sure that the code has been erased.

17-21

Page 514 of 1139

![HONDA CIVIC 2002 7.G Owners Manual Symptom Troubleshooting Index

SymptomDiagnostic procedureAlso check fo]

EPS indicator does not

come on

EPS lndicator Circuit Troubleshooting (see page 17-47)

EPS indicator does not go

off and no DTC i HONDA CIVIC 2002 7.G Owners Manual Symptom Troubleshooting Index

SymptomDiagnostic procedureAlso check fo]

EPS indicator does not

come on

EPS lndicator Circuit Troubleshooting (see page 17-47)

EPS indicator does not go

off and no DTC i](/img/13/5744/w960_5744-513.png)

Symptom Troubleshooting Index

SymptomDiagnostic procedureAlso check fo]

EPS indicator does not

come on

EPS lndicator Circuit Troubleshooting (see page 17-47)

EPS indicator does not go

off and no DTC is stored

EPS Indicator Circuit Troubleshooting (see page 17-47)

EPS indicator does not stay

on, no DTC is stored, and

there is no power assist

1. Check the motor wires between the EPS control unit and the

motor for a short to ground. Repair as needed.

2. lf the motor wires are OK, replace the steering gearbox

{short in the motor).

17-23

Page 516 of 1139

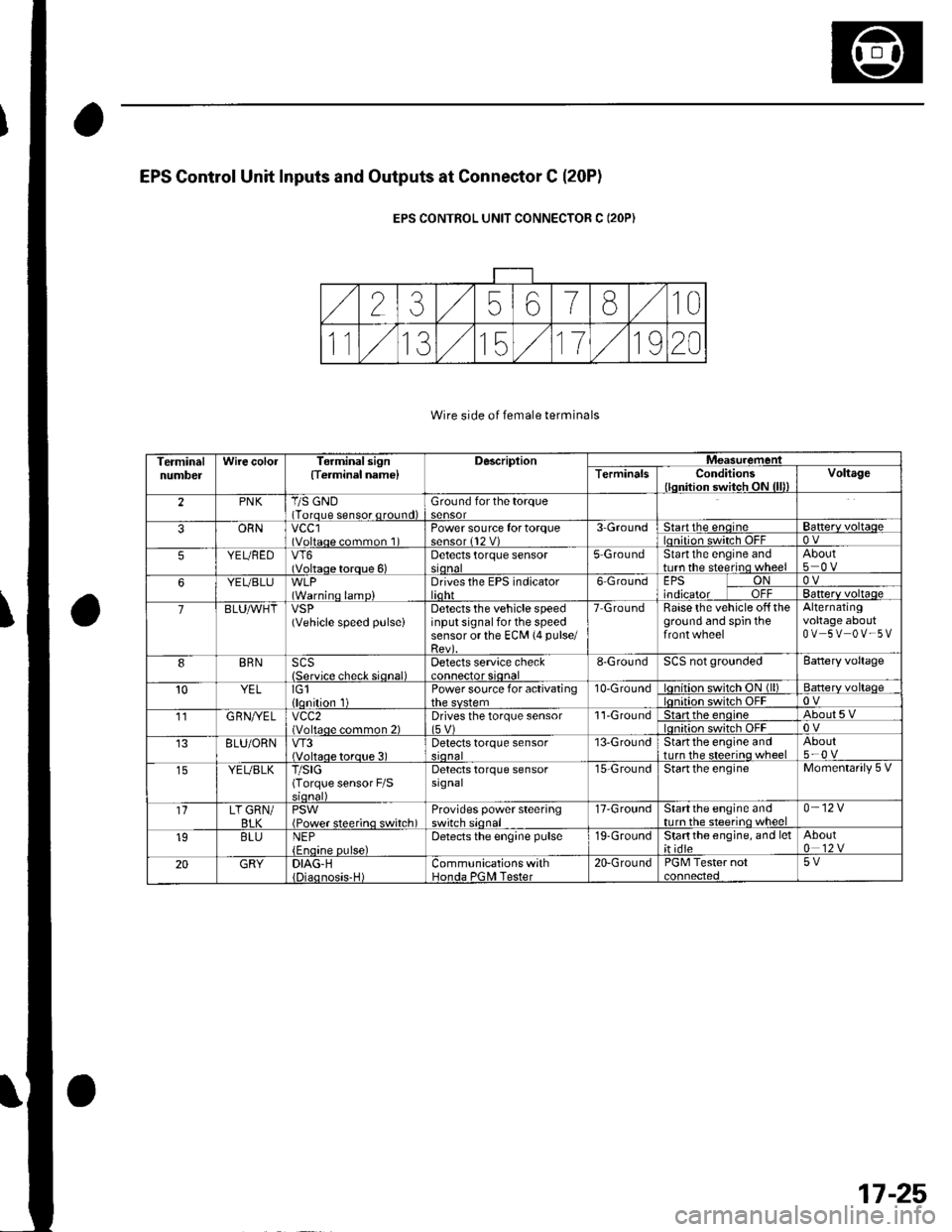

EPS Gontrol Unit Inputs and Outputs at Connestor C (20P1

EPS CONTROL UNIT CONNECTOR C (2OP)

Wire side of female terminals

TerminalnumbelWire colorTerminal sign{Terminel name}DescriplionMeasuremeniTerminalsConditions{lqnition switch ON {lll)Voltage

2PNKT/S GND(Torque sensor qround)Ground for the torque

ORNvccl(Voltaqe common 1Power source fortorque3-Groundtartthe enqrneBa$erv voltaqeOV

5YEUBEDVT6(Voltaqe torque 6)Detects torque sensorstonal5 GroundStartthe engine andturn the steerino wheelAbout

YEUBLU(Warninq lamp)Drives the EPS indicatorlidhr6 GroundEPS ONtnotcatol uTl-OVBanerv voltaqe

7BLUAVHTVSP(Vehicle speed pulseiDetects the vehicle speedinput signal for the speedsensor or the ECM (4 pulse/

Raise the vehicle off theground and spin theAlternatingvoltage aboutOV 5V OV-5V

BRNSCS{Servjco check siqnal)Detects service check8-GroundSCS not groundedBattery voltage

10YELIG1llqnition 1Power source for activating10-Groundon switch ON (ll)Batterv voltaqeon switch OFF11G RN//ELvcc2(Voltaqe common 2)Drives the torque sensor1'l-Groundtan the enoineAbout5Von switch OFF8LU/ORNVT3(Voltaoe toroue 3)Detects torque sensor13-GroundStartthe engine andtrrrn the steerino wheelAbout5-0 v

YEUBLKT/SIG(Torque sensor F/SDetects torque sensorsrgnal15-GroundStartthe engineMomentarily 5 V

1'lLT GRN/BI KPSWiPower steerino switch)Provides power steeringswitch sionall7-GroundStartthe engine andnrrn the steerino wheel0-12V

19BLUNEPDetects the engine pulse19-GroundStartthe engine, and let;t idte

20GRYDIAG-HCommunications withHonda PGNI Tester20-GroundPGM Tester not5V

17-25

Page 520 of 1139

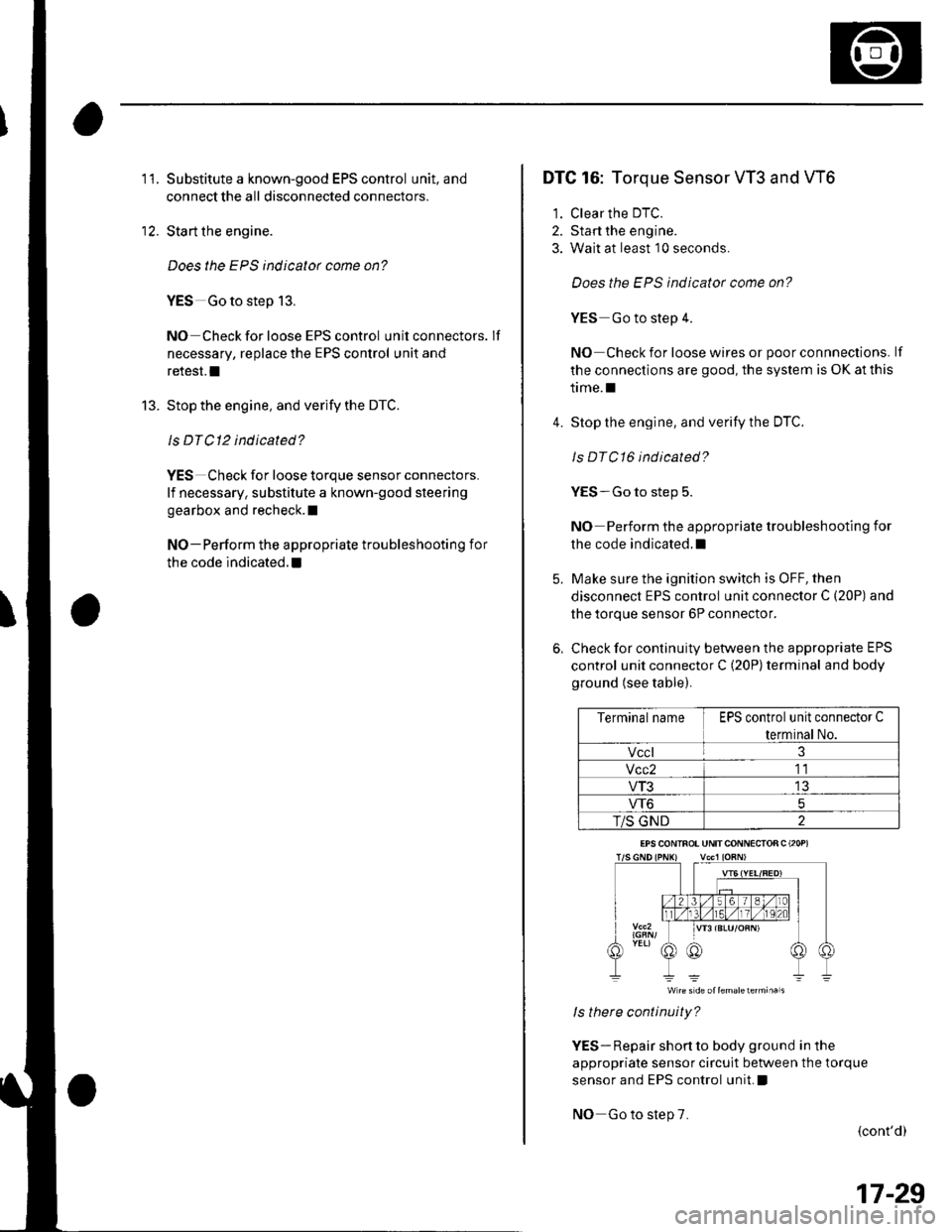

'I 1.Substitute a known-good EPS control unit, and

connect the all disconnected connectors.

Sta rt the engine.

Does the EPS indicator come on?

YES Go to step 13.

NO Check for loose EPS control unitconnectors. lf

necessary, replace the EPS control unit and

retest.l

Stop the engine, and verify the DTC.

ls DTCl2 indicated?

YES Check for loose torque sensor connectors.

lf necessary, substitute a known-good steering

gearbox and recheck.l

NO-Perform the appropriate troubleshooting for

the code indicated. !

12.

13.

DTC 16: Torque Sensor VT3 and W6

1. Clear the DTC.

2. Start the engine.

3. Wait at least 10 seconds.

Does the EPS indicator come on?

YES Go to step 4.

NO Check for loose wires or poor connnections. lf

the connections are good, the system is OK at this

time.l

4. Stop the engine, and verify the DTC.

ls DTC16 indicated?

YES-Go to step 5.

NO Perform the appropriate troubleshooting for

the code indicated. t

5. Make sure the ignition switch is OFF, then

disconnect EPS control unit connector C (20P) and

the torque sensor 6P connector.

6, Check for continuity between the appropriate EPS

control unit connector C (20P) terminal and body

ground (see table).

Terminal nameEPS control unit connector C

terminal No.

Vccl3

Vcc211

VT313

VT65

T/S GND2

W re s d€ oltemalelermi.als

ls there continuity?

YES- Repair short to body ground in the

appropriate sensor circuit between the torque

sensor and EPS control unit, !

NO Go to step 7.

{cont'd)

EPS CONINOT UNITCONNECIOR C (2OP)

17-29