check engine light HONDA CIVIC 2002 7.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 2002, Model line: CIVIC, Model: HONDA CIVIC 2002 7.GPages: 1139, PDF Size: 28.19 MB

Page 33 of 1139

L

A

I

Do the items in parts A, B, C, D, E, F, and G as required for mileage/time interval listed.

Feplace engine oil(see pageS 5). Capacity withoutlilter change:4.0 q (4.2 US qt,3.5lmp qt)

Replace engjne oil filter (see page I 6). Capacity with filter change: 4.2 0 14.4 US qt, 3.7 lmp qt)Insoect front and rear brakes,. Check pads and discsforwearlthickness), damage, andcracks.. Check calipers for damage, leaks, and tightness of mount bolts.Lubricate door locks, latches and hinges with Honda white lithium grease.Rotate tires, if the vehicle has been driven the distance listed. Follow the pattern shown in the Owner's Manual-Check tire inflaron aoocondition,Inspecttie rod ends, steering gearbox, and boots (see page 17,5).. Check rack grease and steering linkage.. Check boots for damage and leaking grease.. Checklluid linefordamage and leaks.Inspect suspensron components. Check bolts for tightness.. Check condition of ball joint boots for deterioration and damage.Inspect driveshaft boots. Check boots for cracks and boot bands for tightness (see page 16-3).

Check parking brake adjustment. Should be fully applied within 7 to 9 clicks.Insp€ct brake hoses and lioes. (including ABS). Check the master cylinder, proportioning control valve, and ABS modulator for damageand leakage (see page 19-24).Check all fluid levels and condition ot lluids; check for leaks. lf necessary, add MTF (see page 13 3), engine coolant, brake fluid, andwindshield washer f luid.Inspect exhaust system*. Check catalytic converter heat shield, exhaust pipe and muffler for damage, leaks, and tightness (see page 9 8).Inspect fuel lines and connections*. Check for loose connections, cracks and deterioration; retighten loose connections and replacedamaged pans (seo page 11'146).Check alllights. Checkfunction otallinterior and exterior lights, andthe position ofthe headlights (see page 22-68).Inspect the v€hicle underbody. Check the paint for damage, scratches, stone chippin0, and dents.

L

D

E

F

H

InsDect and adiust drive belt.. Look tor cracks and damage, and inspect auto tensioner {needs no adjustment).Reolace dust and oollen filter.

Replace air cleaner element every 15,000 miles 124,000 km) in dustv condition {independent ol timei otherwise use Normal Conditionsscredule (see page 11-162).

lReplaceaircleanerelementevery30,000miles(48,000km)(independento{timei(seepagell-162).

Replace brake fluid every 3 years (independent oJ mileagei.

Replacethe dust and pollen Iilter every 15,000 miles ifvehicle is driven mostlywhere air has high concentration olsootfrom industryanddiesel powered vehiclesj also replace the dust and pollen filter anytime aarflow is less than ussal (see pags 21-39).

According to state and federal regulations, failure to do the maintenance items marked with asterisk (*) will not void customer's emissionswarranties. However, Honda recommends that all maintenance services be done at the recommended interval to ensure long-term reliability,

3-7

Page 35 of 1139

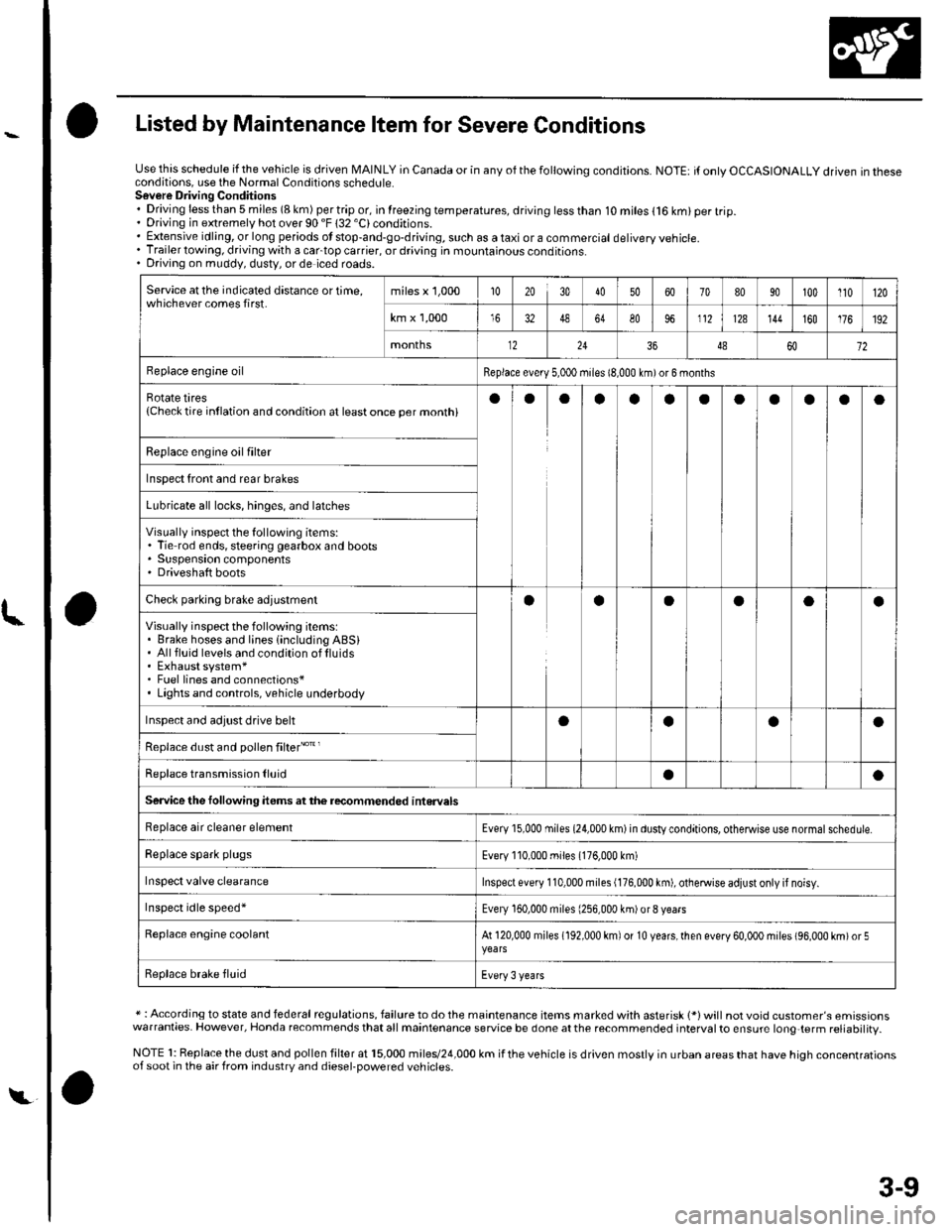

Listed by Maintenance ltem for Severe Conditions

Use this schedule if the vehicle is driven MAINLY in Canada or in anv of the followina conditions.NOTE: it only OCCASIONALLY driven in theseconditions, use the Normal Conditions schedute.Sovere Driving Conditions. Driving less than 5 miles (8 km) per trip or, in lreezing temperatures, driving less than. Driving in extremely hot over 90 "F 132 'C)conditions.10 miles (16 km) per trip.

. Extensive idling, or long periods ot stop-and-go-driving, such as a taxi or a commercial delivery vehicle.. Trailer towing, driving with a cartop carrier, or driving in mountainous conditions.. Driving on muddy, dusty, or de iced roads.

Service at the indicated distance or time,whichever comes first.miles x 1,000102030405060708090100110120

km x 1,0001648648096112128144160176192

months122436486072

Replace engine oilReplace every 5,000 miies 18,000 km)or 6 months

Rotate tires{Checktire intlation and condition at leastonce per monthiaoaaoaaoaaao

Replace engine oil fiher

Inspect front and rear brakes

Lubricate all locks, hinges, and latches

Visually inspect the following items:. Tie rod ends, steering gearbox and boots. Suspension components' Driveshaft boots

Checl parking brale adjuslmentaaOaoa

Visually inspect the following items:. Brake hoses and lines {including ABSi. Allfluid levels and condition oflluids. Exhaust system*. Fuel lines and connections*. Lights and controls, vehicle underbody

Inspect and adjust drive behoaoa

Replace dust and pollen filter"o't'

Replace transmission lluidaa

Service the following items atthe recommended interuals

Replace air cleaner elementEvery 15,000 miies (24,000 km) in dusty conditions, otheMise use normal schedule.

Replace spark plugsEvery 110,000 miles (176,000 km)

Inspect valve clearanceInspect every 110,000 miles (176,000 km), otheMise adiust only if noisy.

Inspect idle speed'Every 160,000 miles (256,000 km)or8 vears

Replace engine coolantAt 120,000 miles (192,000 km) of 10 years,lhen every 60,000 miles (96,000 km)or 5

Replace brake fluidEvery 3 years

* : According to state and federal regulations, failure to do the maintenance items marked with asterisk 1*)will not void customer's emissionswarranties. However, Honda recommends that all maintenance service be done at the recommended interval to ensure long{erm reliabilitv.

NOTE 1: Replace the dust and pollen filter at 15,000 miles/24,000 km if the vehicle is driven mostly in urban areas that have high concentrationsof soot in the air from industrv and diesel-Dowered vehicles.

t,

3-9

Page 52 of 1139

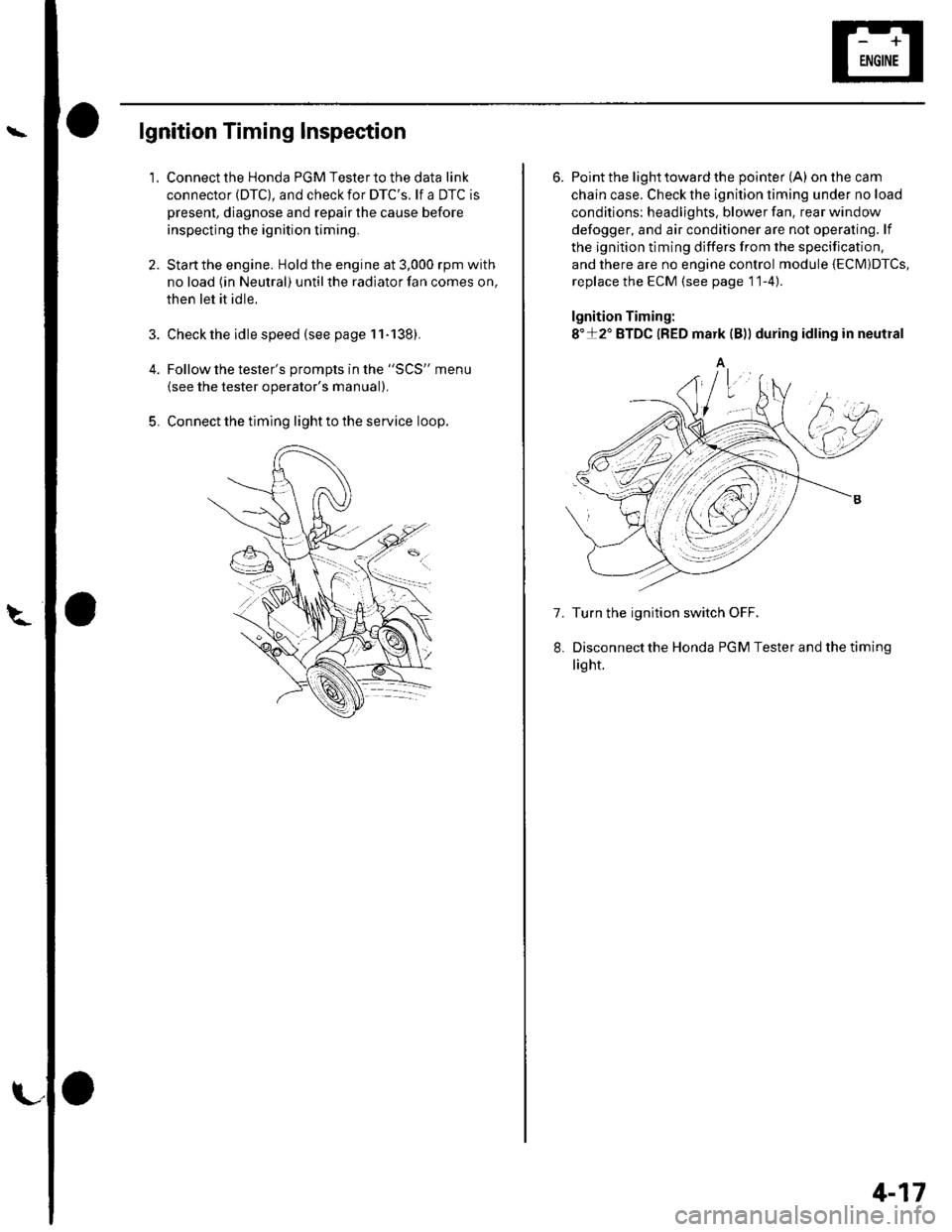

lgnition Timing Inspection

1.

4.

5.

Connect the Honda PGM Tester to the data link

connector (DTC), and check for DTC'S. lf a DTC is

present, diagnose and repair the cause before

inspecting the ignition timing.

Startthe engine. Hold the engine at 3,000 rpm with

no load (in Neutral) until the radiator fan comes on,

then let it idle.

Check the idle speed (see page 11-138).

Follow the tester's prompts in the "SCS" menu

{see the tester operator's manual),

Connect the timing light to the service loop.

o

6. Point the light toward the pointer (A) on the cam

chain case. Check the ignition timing under no load

conditions: headlights, blower fan. rear window

defogger, and air conditioner are not operaling. lf

the ignition timing differs from the specification,

and there are no engine control module {ECM)DTcs,

replace the ECM (see page 11-4)

lgnition Timing:

8"+2" BTDC {RED mark {B)) during idling in neutral

A

7. Turn the ignition switch OFF.

Disconnectthe Honda PGM Tester and thetiming

light.

4-17

Page 59 of 1139

Gharging System

Charging Circuit Troubleshooting (cont'd)

6. Start the engine. Hold the engine at 3,000 rpm with

no load (in Neutral) until the radiator fan comes on,

then let it idle.

7. Raise the engine speed to 2,000 rpm, and hold it

there.

8. Turn the headlights (high beam) on, and measure

voltage at the under-hood fuse/relay box terminal.

ls the voltage between 13.9 and 15.1 v?

YES-Go to step 9.

NO Repair or replace the alternator components

(see page 4-30).1

9. Read the amperage at '13.5 V.

NOTE: Adjust the voltage by turning the blower

motor, rear window defogger, brake lights. etc. ON.

ls the amperage 604 ot morc?

YES-Alternator/regulator operation is OK. I

NO Repair or replace the alternator components(see page 4-30).1

4-24

\,

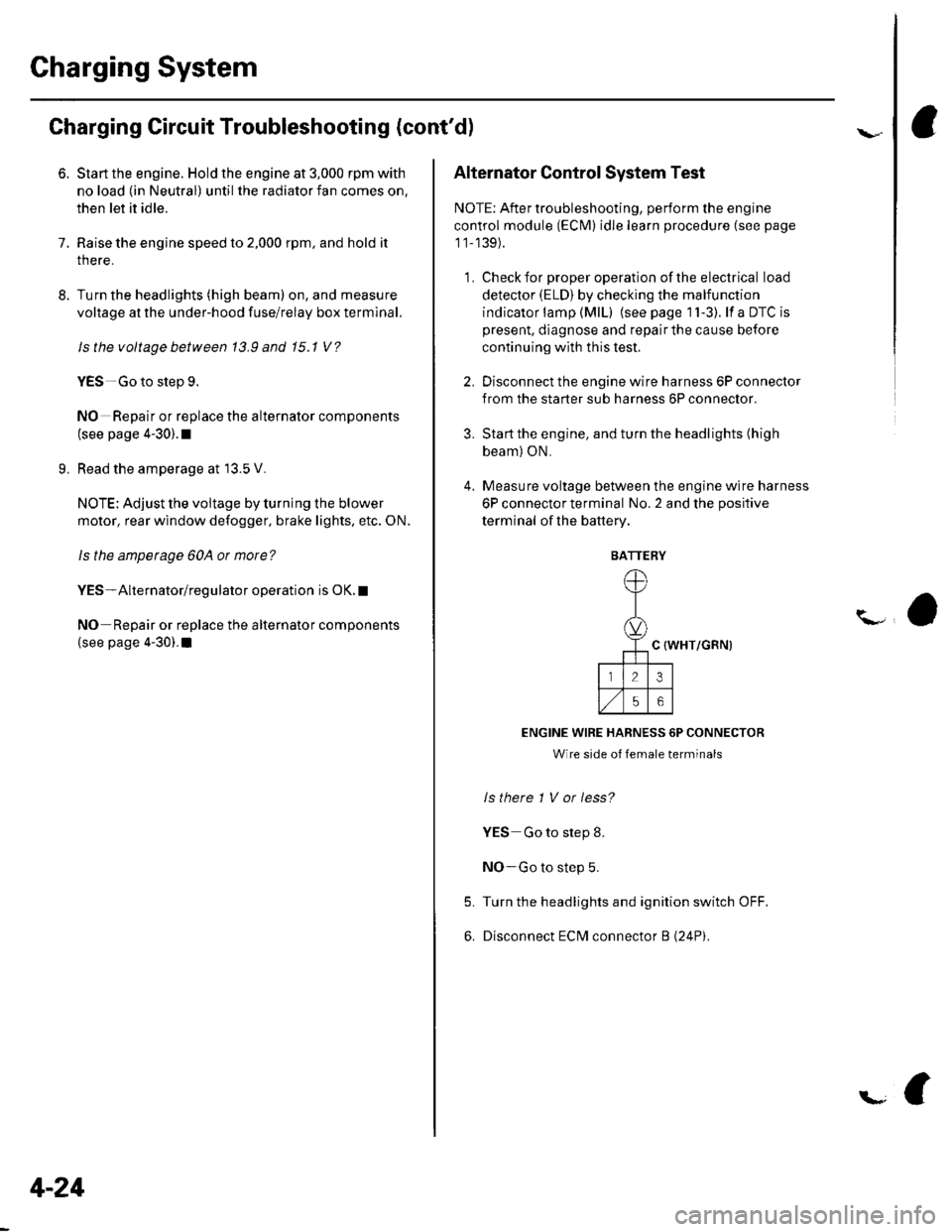

Alternator Control System Test

NOTE: After troubleshooting, perform the engine

control module (ECM) idle learn procedure (see page

11-139).

1 . Check for proper operation of the electrical load

detector (ELD) by checking the malfunction

indicator lamp (MlL) (see page 1 l-3). lf a DTC is

present, diagnose and repair the cause before

continuing with this test.

2. Disconnect the engine wire harness 6P connector

from the starter sub harness 6P connector.

3. Start the engine, and turn the headlights (high

beam) ON,

4. Measure voltage between the engine wire harness

6P connector terminal No. 2 and the positive

terminal of lhe battery.

C {WHT/GRN)

ENGINE WIRE HARNESS 6P CONNECTOR

Wire side of female terminals

ls there 1 V or less?

YES Go to step 8.

NO-Go to step 5.

Turn the headlights and ignition switch OFF.

Disconnect ECM connector B (24P).

5.

6.

BATTERY

Page 60 of 1139

\

L

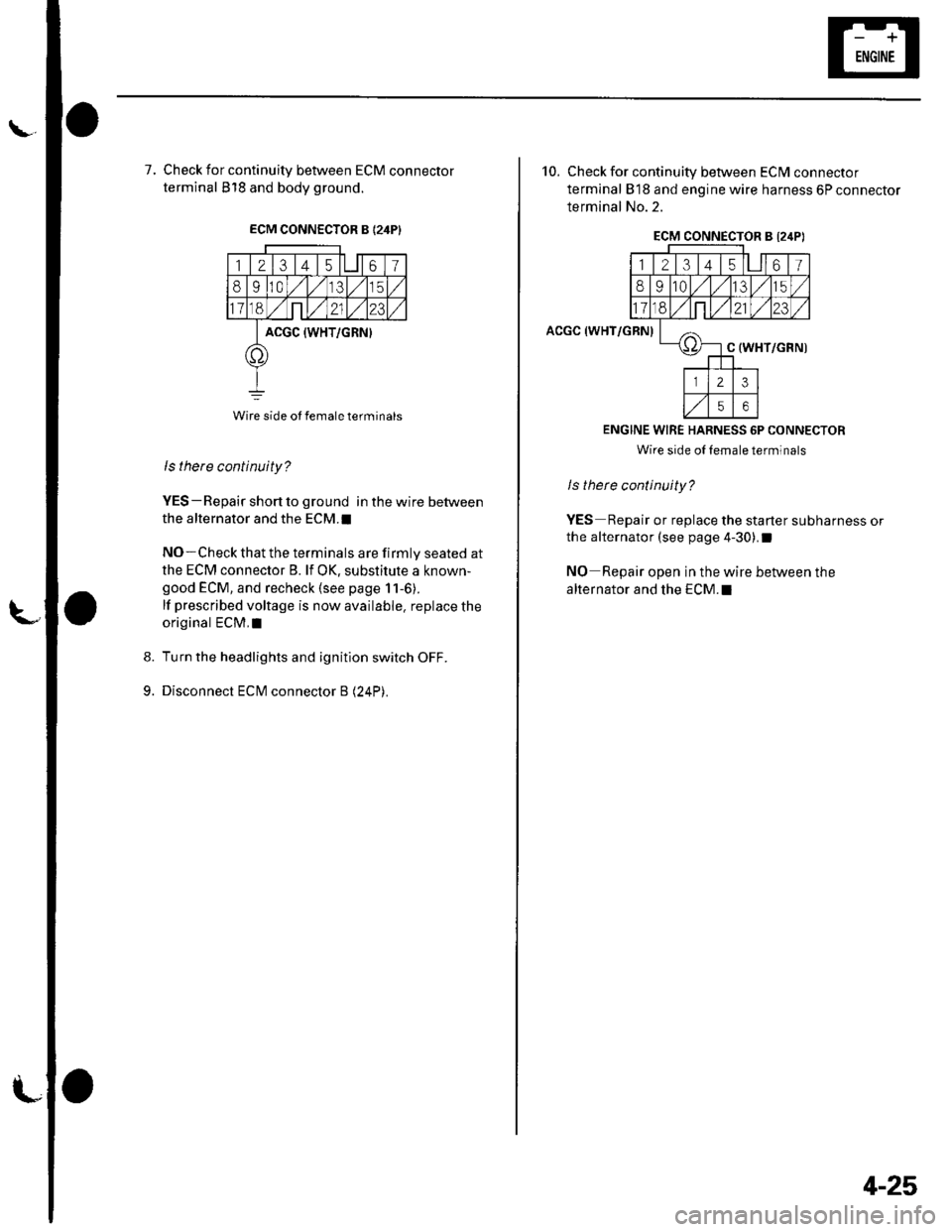

7, Check for continuity between ECM connector

terminal 818 and body ground.

ECM CONNECTOR B {24PI

123 t4 t561

8910,/1,/35

11ont,/2123

ACGC {WHT/GRN}

o

Wire side ot female terminals

9.

ls there continuity?

YES-Repair short to ground in the wire between

the alternator and the ECM.I

NO-Check that the terminals are firmly seated at

the ECM connector B. lf OK, substitute a known-

good ECM, and recheck (see page 11-6).

lf prescribed voltage is now available. replace the

original ECM,I

Turn the headlights and ignition switch OFF.

Disconnect ECM connector B (24P).

10. Check for continuity between ECM connector

terminal 818 and engine wire harness 6P connector

terminal No.2.

ACGC (WHT/GRN)

ECM CONNECTOR B l2,lPI

12314l5lll67

8910t.)15

11on2123

oC (WHT/GRN)

23

56

ENGINE WIRE HARNESS 6P CONNECTOR

Wire side oI lemale terminals

ls therc continuity?

YES Repair or replace the starter subharness or

the alternator (see page 4-30).I

NO Repair open in the wire between the

alternator and the ECM.I

4-25

Page 73 of 1139

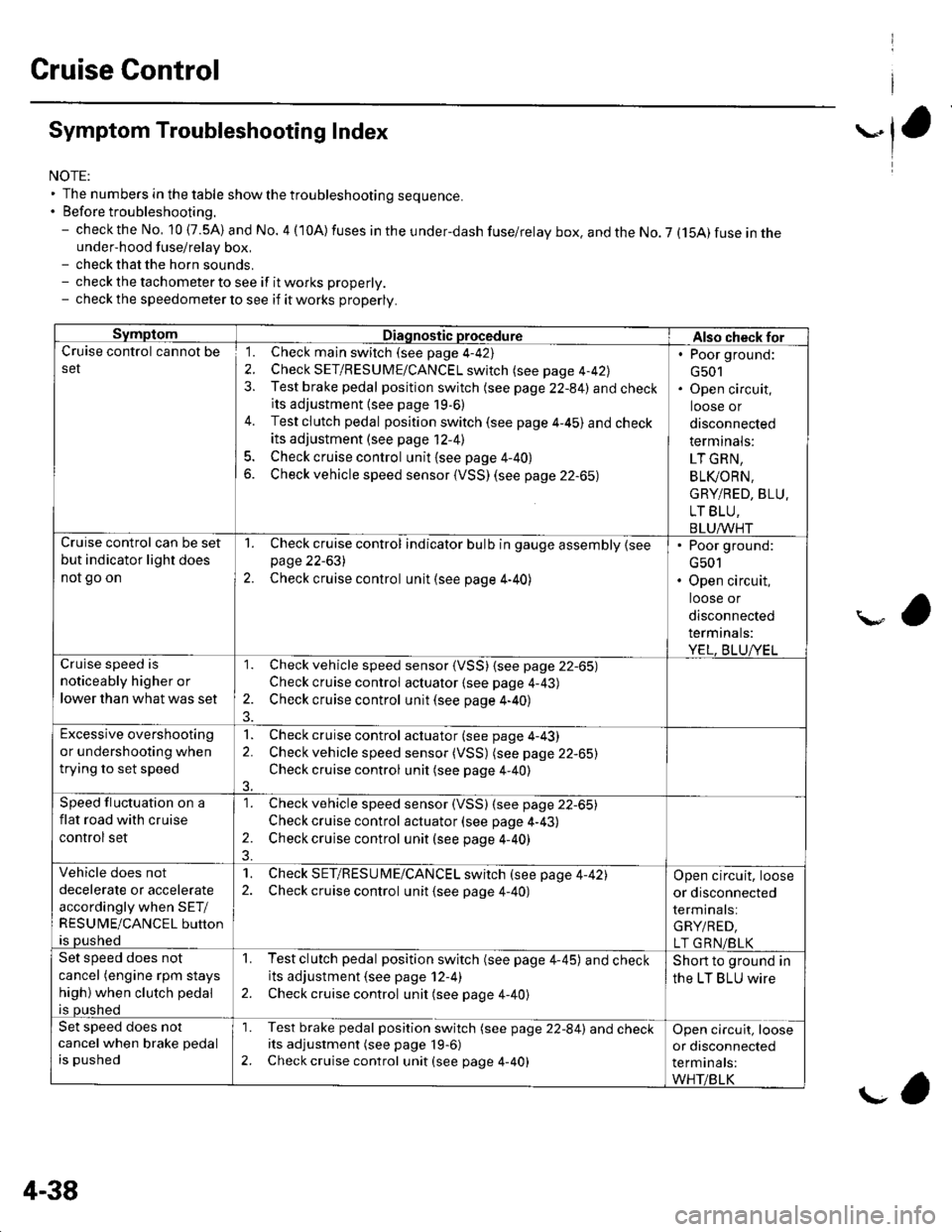

Cruise Control

Symptom Troubleshooting Index

NOTE:' The numbers in the table showthetroubleshooting sequence.. Before troubleshooting.- check the No, 10 (7.5A) and No. 4 (10A) fuses in the under-dash fuse/relay box. and the No. 7 (15A) fuse in theunder-hood fuse/relay box,- check that the horn sounds.- check the tachometer to see if it works properly.- check the speedometer lo see if it works properly.

SymptomDiagnostic procedureAlso check forCruise control cannot be

set

1. Check main switch (see page 4-42)

2. Check SET/RESUME/CANCEL switch (see page 4-42)

3. Test brake pedal position switch (see page 22-84) and checkits adjustment {see page 19,6)

4. Test clutch pedal position switch (see page 4-45) and check

its adjustment (see page 12-41

5. Check cruise control unit {see page 4-40}

6. Check vehicle speed sensor (VSS) (see page 22-65)

. Poor ground:

G501. Open circuit,

loose or

disconnected

term inals:

LT GRN,

BLI(ORN.

GRY/RED, BLU.

LT BLU,

BLUAA/HTCruise control can be set

but indicator light does

not go on

1. Check cruise control indicator bulb in gauge assembly {seepage 22-631

2. Check cruise control unit (see page 4-40)

. Poor ground:

G501. Open circuit,

loose or

disconnected

termrnats:

YEL, BLUA/ELar, 'i.a c^aa.l ic

noticeably higher or

lower than what was set

1. Check vehicle speed sensor (VSS) {see page 22-65)

Check cruise control actuator {see page 4-43)

2. Check cruise control unit (see page 4-40)

Excessive overshooting

or undershooting when

trying to set speed

1. Check cruise control actuator (see page 4-43)

2. Check vehicle speed sensor (VSS) (see page 22-65)

Check cruise control unit (see page 4-40)

3.

Speed fluctuation on a

flat road with cruise

control set

1. Check vehicle speed sensor (VSS) (see page 22-65)

Check cruise control actuator (see page 4-43)

2. Check cruise control unit (see page 4-40)

Vehicle does not

decelerate or accelerate

accordingly when SET/

RESUME/CANCEL button

is pushed

1. Check SET/RESU ME/CANCEL switch (see page 4-42)2. Check cruise control unit {see page 4-40)

Open circuit, loose

or disconnected

terminals:

GRY/RED,

LT GRN/BLKSet speed does not

cancel (engine rpm stays

high) when clutch pedal

is pushed

1. Testclutch pedal position switch (see page 4-45) and checkits adjustment (see page 12-4)

2. Check cruise control unit (see page 4-40)

Short to ground in

the LT BLU wire

Set speed does not

cancel when brake pedal

is pushed

'1. Test brake pedal position switch (see page 22-84) and checkits adjustment (see page 19-6)

2. Check cruise control unit (see page 4-40)

Open circuit, loose

or disconnected

terminals:

WHT/BLK

4-38

g,

Page 132 of 1139

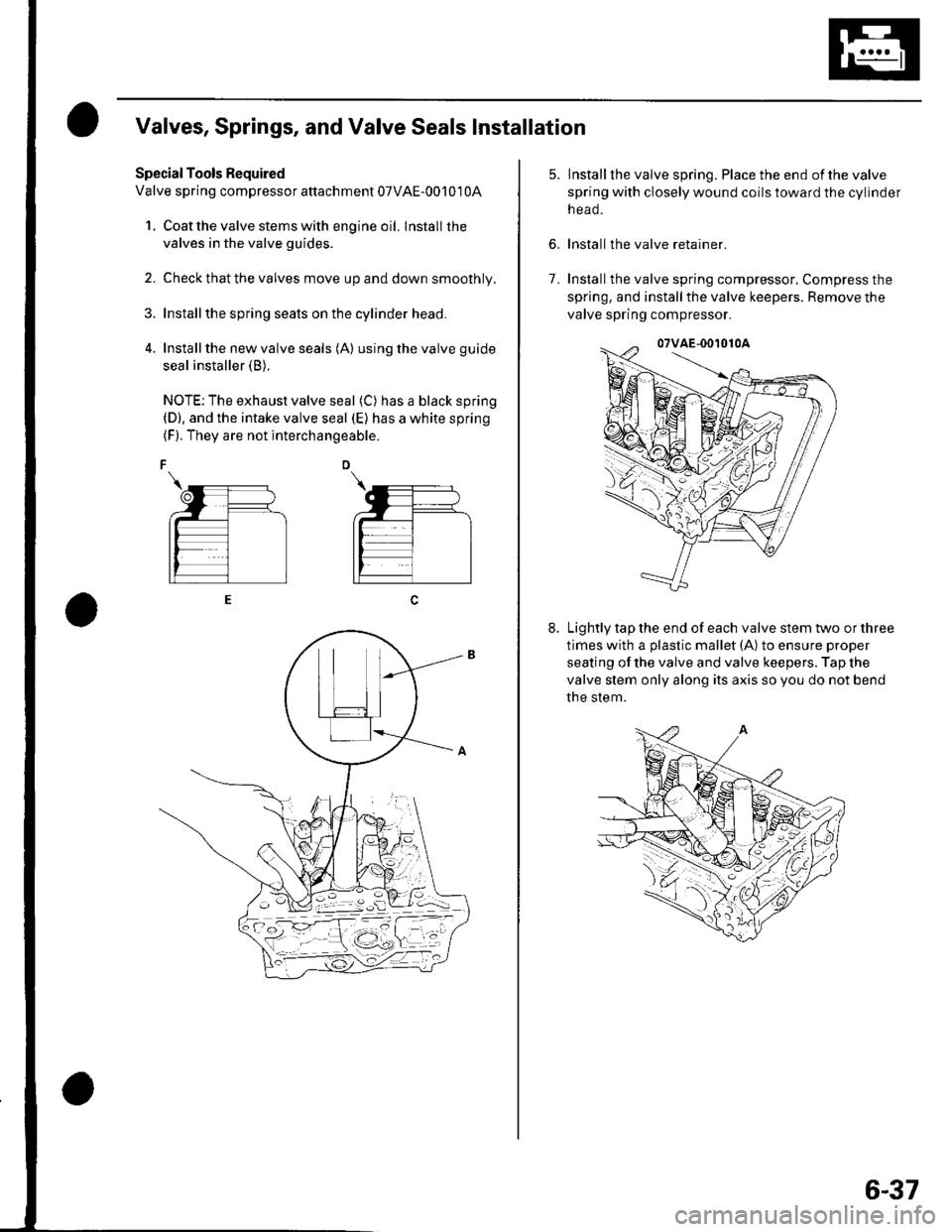

Valves, Springs, and Valve Seals Installation

Special Tools Required

Valve spring compressor attachment 07VAE-00101 0A

1. Coat the valve stems with engine oil. lnstall the

valves in the valve guides.

2. Check that the valves move up and down smoothly.

Installthe spring seats on the cylinder head.

Install the new valve seals (A) using the valve guide

seal installer (B).

NOTE: The exhaust valve seal (C) has a black spring(D), and the intake valve seal (E) has a white spring(F). They are not interchangeable.

6.

lnstallthe valve spring. Place the end ofthe valve

spring with closely wound coils toward the cylinder

n eao.

Install the valve retainer.

Installthe valve spring compressor, Compress the

spring, and install the valve keepers. Remove the

valve spring compressor.

Lightly tap the end of each valve stem two or three

times with a plastic mallet (A) to ensure proper

seating of the valve and valve keepers. Tap the

valve stem only along its axis so you do not bend

the stem.

7.

6-37

Page 172 of 1139

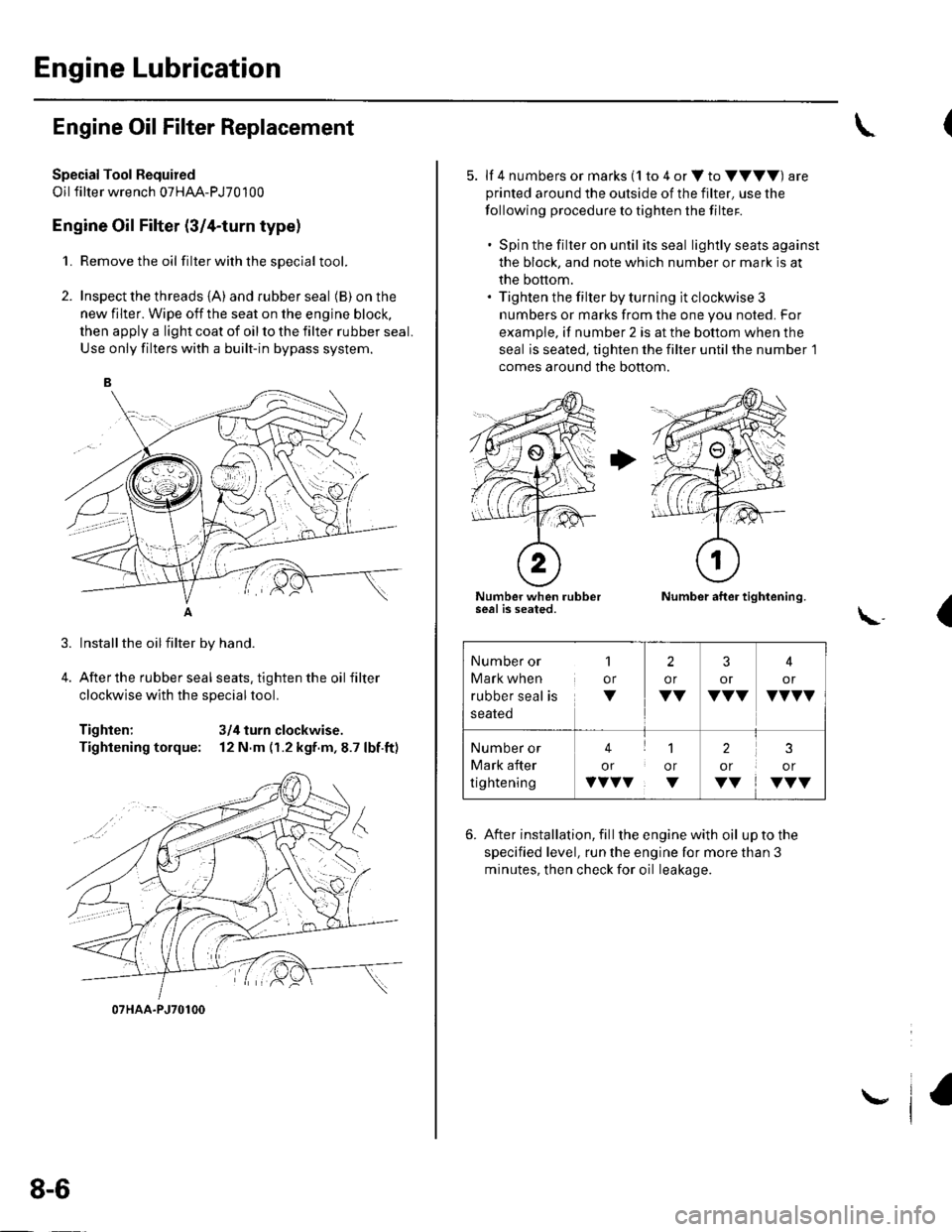

Engine Lubrication

Engine Oil Filter Replacement

Special Tool Fequired

Oil filter wrench 07HAA-PJ70100

Engine Oil Filter (3/4-turn type)

1. Remove the oil filterwiththesDecial tool.

2. Inspect the threads {A) and rubber seal (B) on the

new filter. Wipe off the seat on the engine block,

then apply a light coat of oil to the filter rubber seal.

Use only filters with a built-in bypass system.

Installthe oilfilter by hand.

After the rubber seal seats, tighten the oil filter

clockwise with the special tool.

Tighten: 3/4 turn clockwise.

Tightening torque: 12 N.m (r.2 kgf.m,8.7 lbf.ft)

07HAA-PJ70100

8-6

\,

5. lf 4 numbers or marks (1 to 4 or V to VVVV) are

printed around the outside of the filter, use the

following procedure to tighten the filter.

. Spin the filter on until its seal lightly seats against

the block, and note which number or mark is at

the bottom.. Tighten the filter by turning it clockwise 3

numbers or marks from the one you noted. For

example, if number 2 is at the bottom when the

seal is seated, tighten the filter until the number 1

comes around the bottom.

Number when rubberseal is seated.Number after tightening.

(\..

6. After installation, fill the enginewith oil uptothe

specified level, run the engine for more than 3

minutes, then check for oil leakage.

Number or

Mark when

rubber seal is

1

or

V

2

or

VV

3

or

VVV

4

or

VVVV

Number or

Mark after

tightening

41

or or

vvvv. v

2

or

VV

3

or

VVV

Page 299 of 1139

PGM-FI System

I

a

DTC Troubleshooting (cont'dl

DTC Pl297: ELD Circuit Low Voltage

1. Reset the ECM {see page 11-4).

2. Start the engine.

3. Turn on the headlights.

ls DTC P1297 indicated?

YES Go to step 4.

NO Intermittent failure, system is OK at this time.

Check for poor connections or loose terminals at

the ELD and at the ECM.I

4. Turn the ignition switch and the headlights OFF.

5. Disconnectthe ELD 3P connector.

6. Turn the ignition switch ON {ll).

7. Measure voltage between body ground and ELD 3P

connector terminal No. 3.

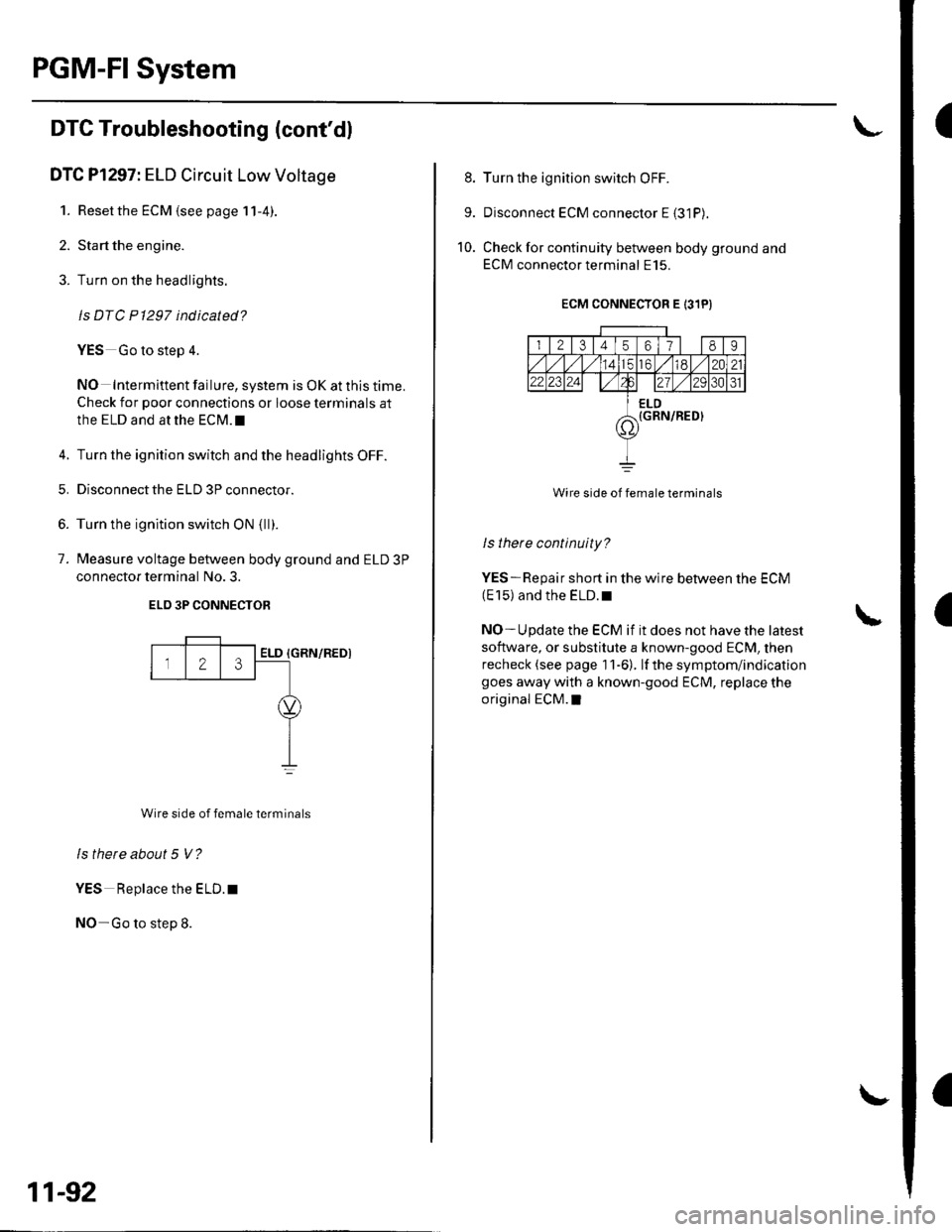

ELO 3P CONNECTOB

{GRN/REDI

Wire side of female terminals

ls there about 5 V?

YES Replace the ELD. t

NO-Go to step 8.

Z3ELD

11-92

8. Turn the ignition switch OFF.

9. Disconnect ECM connector E {31P).

10. Check for continuity between body ground and

ECM connector terminal E15.

ECM CONNECTOR E 131PI

I l2l3456178I

totd/ 12021,2 2al2/tA31

ELD(GRN/RED}7\'

Wire side of female terminals

ls there continuity?

YES-Repair short in the wire between the ECM(E 15) and the ELD. r

NO- U pdate the ECM if it does not have the latest

software, or substitute a known-good ECM, then

recheck (see page 1 1-6). lf the symptom/indication

goes away with a known-good ECM, replace the

original ECM.I

Page 300 of 1139

DTC Pl298: ELD Circuit High Voltage

1. Resetthe ECM (see page 11-4)

2. Stan the engine.

3. Turn on the headlights.

ls DTC P1298 indicated?

YES-Go to step 4.

NO- Intermittent failure. system is OK at this time.

Check for poor connections or loose terminals at

the ELD and at the ECM.I

4. Turn the ignition switch and headlights OFF.

5. Disconnectthe ELD 3P connector.

6. Turn the ignition switch ON (ll).

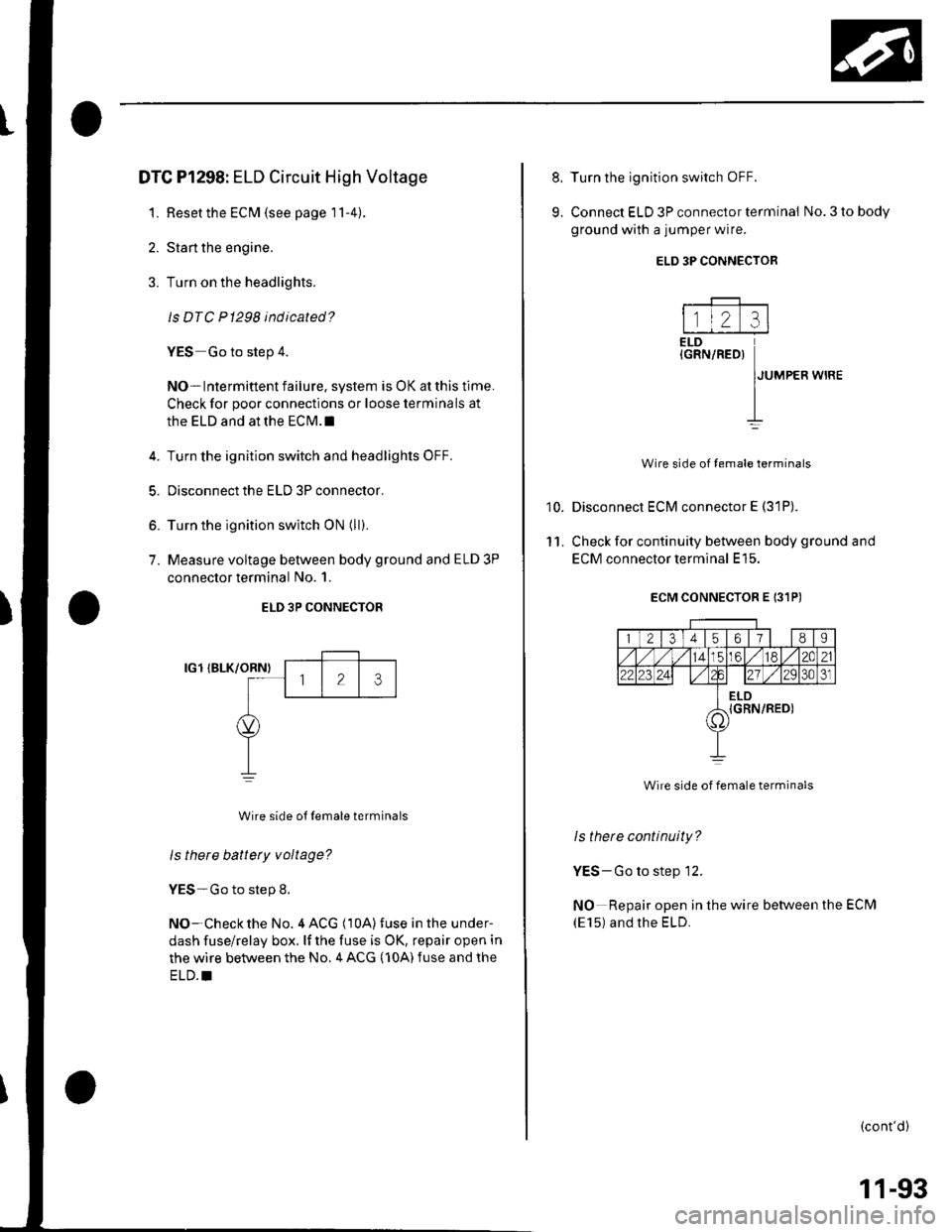

7. Measure voltage between body ground and ELD 3P

connector terminal No. 1.

ELD 3P CONNECTOR

IG1 IBLK/ORNI

Wire side ot {emale terminals

ls there battery voltage?

YES-Go to step 8.

NO-Checkthe No. 4 ACG (10A)fuse in the under-

dash fuse/relay box. lf the fuse is OK, repair open in

the wire between the No. 4 ACG (10A) fuse and the

ELD.I

8.

9.

10.

11.

Turn the ignition switch OFF.

Connect ELD 3P connector terminal No. 3 to body

ground with a jumper wire.

Disconnect ECM connector E (31P).

Check for continuity between body ground and

ECM connector terminal E15.

ECM CONNECTOR E 131PI

1 21345ot/II

14LC6l/ 182C21

22123 2421 ./2Q30J

ELDIGRN/RED)i1'

Wire side of female terminals

Is thete continuity?

YES-Go to step 12.

NO Repair open in the wire between the ECM

(E15) and the ELD.

(cont'd)

ELD 3P CONNECTOR

---F-------

l1l2 :rlELD(GRN/RED)

IJUMPER wrRE

II

Wire side of temale terminals

11-93