trans HONDA CIVIC 2002 7.G Manual Online

[x] Cancel search | Manufacturer: HONDA, Model Year: 2002, Model line: CIVIC, Model: HONDA CIVIC 2002 7.GPages: 1139, PDF Size: 28.19 MB

Page 770 of 1139

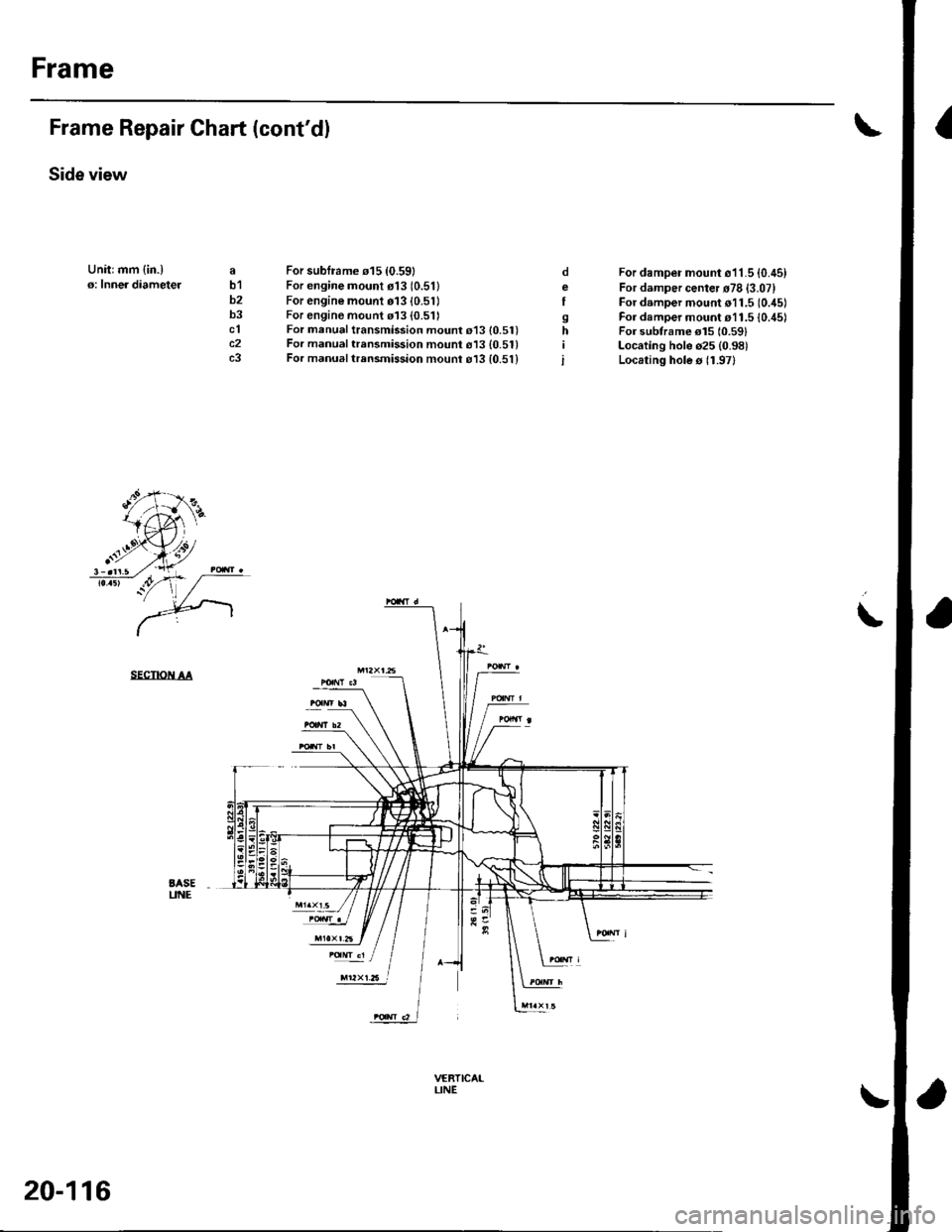

Frame

IFrame Repair Chart (cont'dl

Side view

Unitrmm {in.)o: Inner diameteJab1b2b3clc2c3

For subframe 015 {0.59}For engine mount o13 (0.511

For engine mount 01310.51)For engine mount 113 (0.511For manual transmission mount 013 {0.51)For manual trensmission mount 613 {0.51}For manual trrnsmission mounr o13 {0.51}

For damper mount o11.5 {0.45)For damper center r78 {3.07}For damper mount o11.5 (0.45)

For damper mount r11.5 {0./t5lFor subtrame el5 10.591Locating hole o25 (0.98)

Locating hole s 11.97)

oeI

sh

i

\

SECTIOiI AA

BASEUNE

trr2xt.6 l

VERTICAILINE

20-116

Page 771 of 1139

Frame

IFrame Repair Chart (cont'dl

Side view

Unitrmm {in.)o: Inner diameteJab1b2b3clc2c3

For subframe 015 {0.59}For engine mount o13 (0.511

For engine mount 01310.51)For engine mount 113 (0.511For manual transmission mount 013 {0.51)For manual trensmission mount 613 {0.51}For manual trrnsmission mounr o13 {0.51}

For damper mount o11.5 {0.45)For damper center r78 {3.07}For damper mount o11.5 (0.45)

For damper mount r11.5 {0./t5lFor subtrame el5 10.591Locating hole o25 (0.98)

Locating hole s 11.97)

oeI

sh

i

\

SECTIOiI AA

BASEUNE

trr2xt.6 l

VERTICAILINE

20-116

Page 773 of 1139

21-2

z t-'5

z t-o

z t-o

21-8

21-9

21-10

21-11

21-14

z t- to

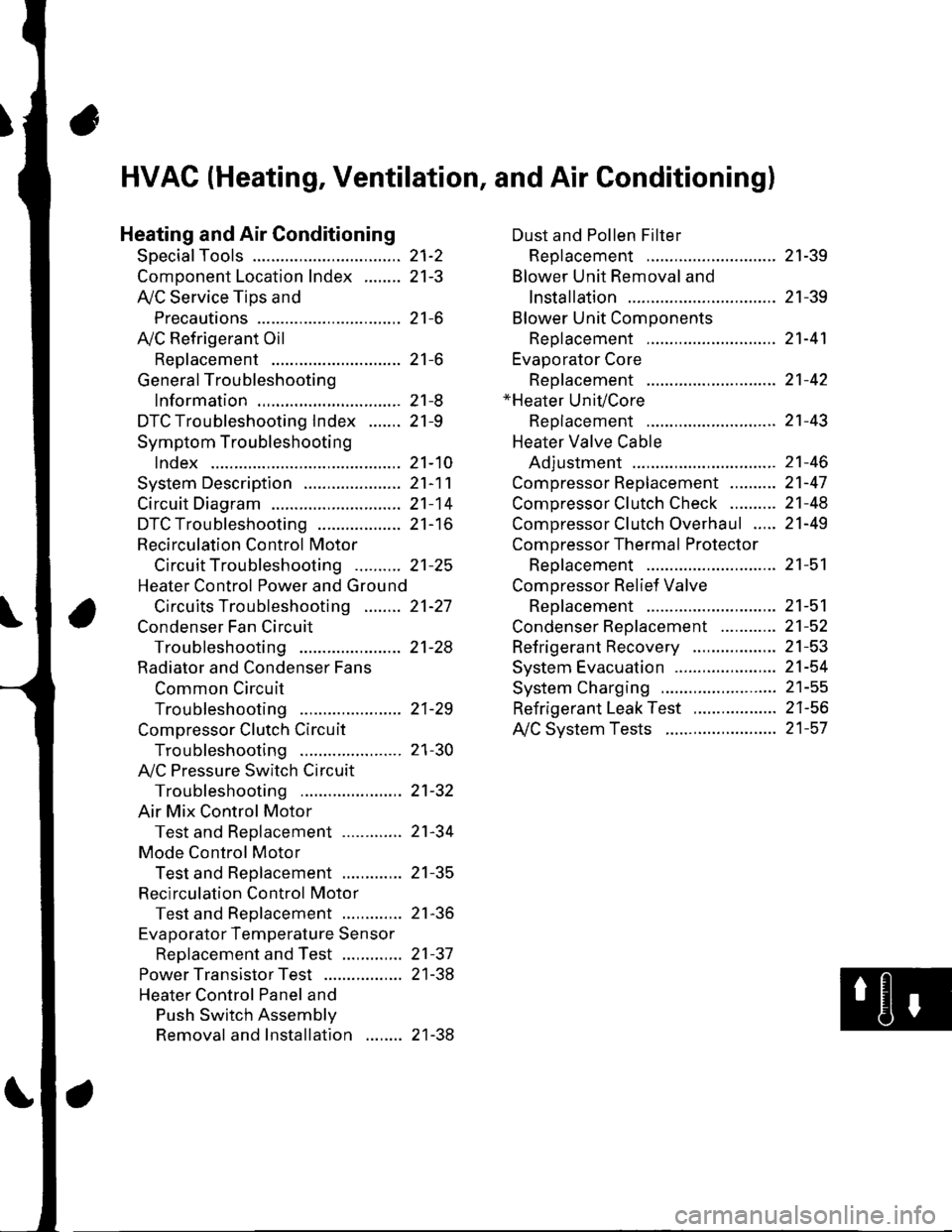

HVAC (Heating, Ventilation, and Air Gonditioningl

Heating and Air Conditioning

SpecialTools

Comoonent Location lndex ........

A/C Service Tios and

Precautions

A,/C Refrigerant Oil

ReDlacement

General Troubleshooting

lnformation

DTC Troubleshooting Index .......

Symptom Troubleshooting

1ndex..............

System Description .....................

Circuit Diagram

DTC Troubleshooting ..................

Recirculation Control Motor

CircuitTroubleshooting .......... 21-25

Heater Control Power and Ground

Circuits Troubleshooting ........ 21-27

Condenser Fan Circuit

Troubleshooting ...................... 21-28

Radiator and Condenser Fans

Common Circuit

Troubfeshooting ...................... 21-29

Compressor Clutch Circuit

Troubleshooting ...................... 21-30

A,/C Pressure Switch Circuit

Troubleshooting ...................... 21-32

Air Mix Control Motor

Test and Reolacement ............. 21-34

Mode Control Motor

Test and Replacement ............. 21-35

Recirculation Control Motor

Test and Reolacement ............. 21-36

Evaporator Temperature Sensor

Reolacement and Test ............. 21-31

Power Transistor Test ................. 21 -38

Heater Control Panel and

Push Switch Assemblv

Removal and Installation ........ 21-38

Dust and Pollen Filter

Reolacement ..21-39

Blower Unit Removal and

lnstallation ...... 21-39

Blower Unit Comoonents

ReDlacement ............................ 21-41

Evaporator Core

Reolacement ..21-42*Heater Unit/Core

ReDlacement ..21-43

Heater Valve Cable

Adjustment .....21-46

CompressorReplacement .......... 21-47

Comoressor Clutch Check .......... 21-48

Comoressor Clutch Overhaul ..... 21-49

Compressor Thermal Protector

Reo1acement ............................ 21-51

Comoressor Relief Valve

Reolacement ............................ 21-51

Condenser Reolacement ............ 21-52

Refrigerant Recovery .................. 21-53

System Evacuation ...................... 21-54

System CharginS ......................... 21-55

Refrigerant LeakTest .................. 21-56

A,/C Svstem Tests ........................ 21-57

Page 777 of 1139

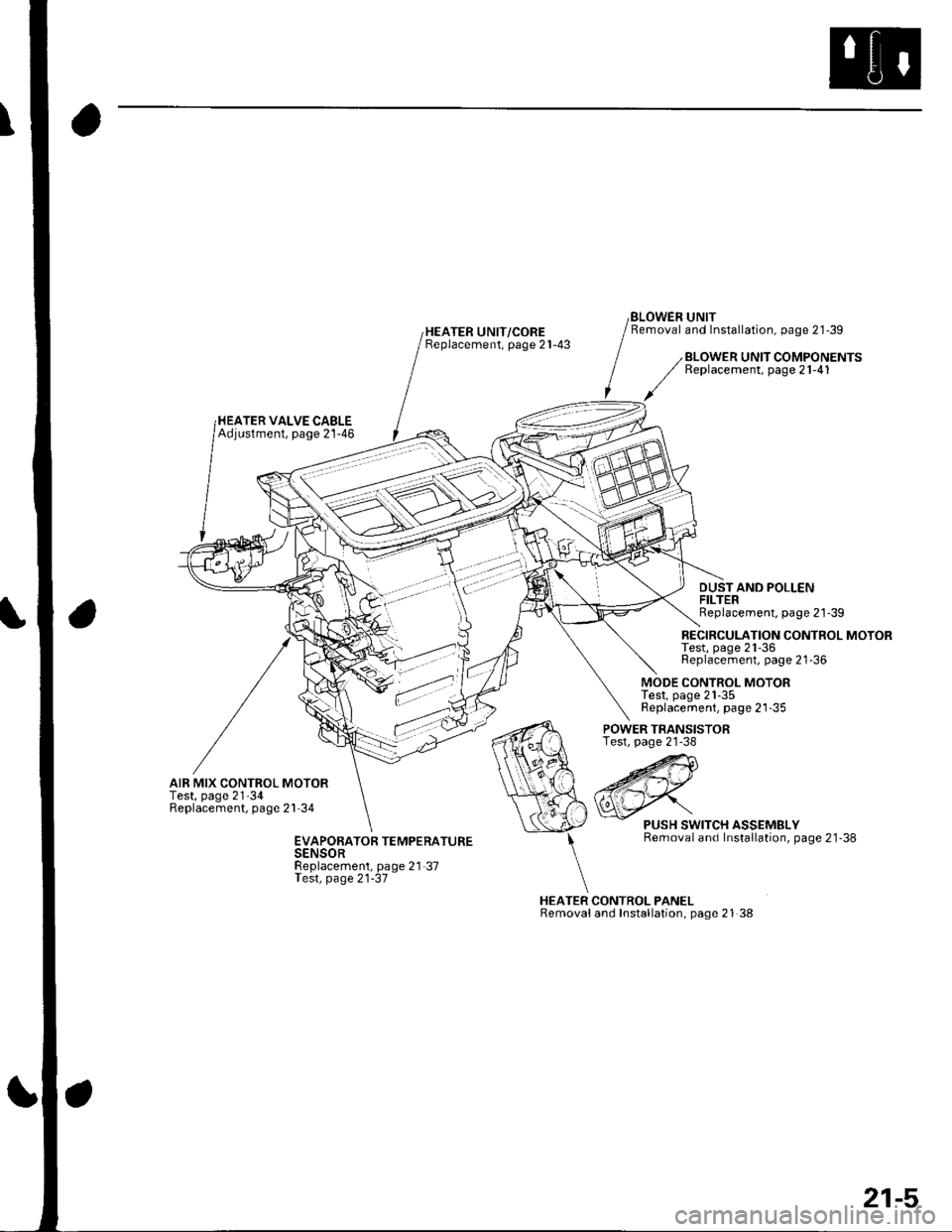

HEATER UNIT/COREBeplacement, page 21-43

BLOWEN UNITRemoval and Installation, page 21-39

HEATER VALVE CABLEAdjustment, page 21-46

BLOWER UNIT COMPONENTSReplacement, page 21-41

DUSTAND POLLENFILTERReplacement, page 21'39

RECIRCULATION CONTROL MOTORTest, page 21-36Replacement, page 21-36

MODE CONTROL MOTORTest, page 21-35Replacement, page 21-35

AIR MIX CONTROL MOTORTest, page 21'34Replacement, page 21'34

POWER TRANSISTORTest, page 21-38

HEATER CONTROL PANELRemovaland Installation, page 21 38

PUSH SWITCH ASSEMBLYRemoval and Installation, page 21'38EVAPORATOR TEMPERATURESENSORReplacement, page 21-37Test, page 21-37

21-5

Page 783 of 1139

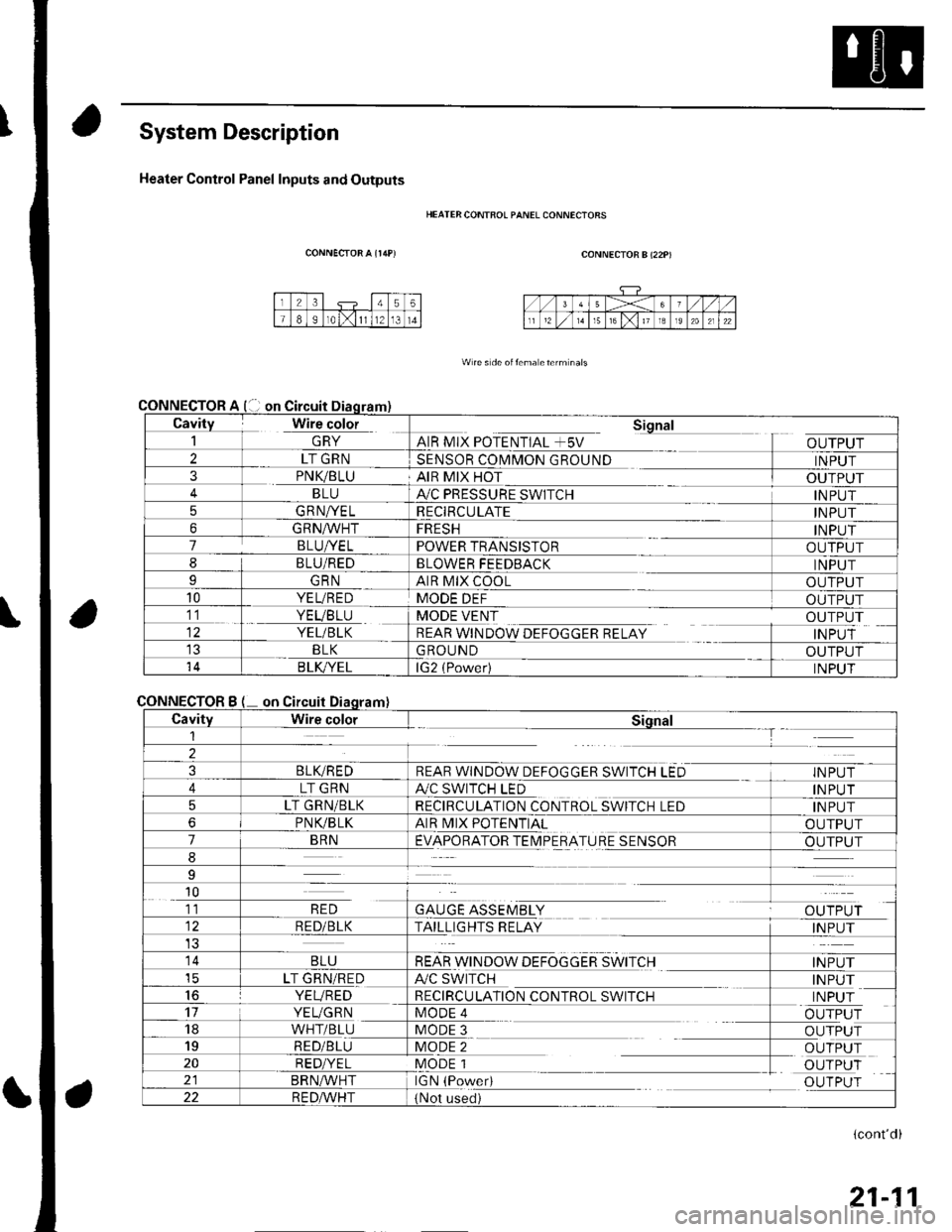

System Description

Heater Control Panel Inputs and Outputs

CONNECTOR A {r/rP)

CONNECTOR

CONNECTOR

HEATER CONTFOL PANEL CONNECIORS

CONNECTOR B (22P)

W re s de oitema eterm nals

Cavity Wire color_| \ln YAIR MIX POTENTIAL +5V

Sional

OUTPUT2LT GRNSENSOR COMMON GROUNDINPUT3PNK/BLUAIR MIX HOTOUTPUTBLUA,/C PRESSURE SWITCHINPUT5GRNA/ELRECIRCULATEINPUT6GRNA/VHTFRESHINPUT7BLUI/ELPOWER TRANSISTOROUTPUT8BLU/REDBLOWER FEEDBACKINPUTIGRNAIR MIX COOLOUTPUT10YEL/REDMODE DEFOUTPUT11. YEVBTU

YEL/BLK

MODE VENT

REAR WINDOW DEFOGGER RELAY

OUTPUT

INPUTBLKGROUNDOUTPUT14B LK/YELlG2 (Power)INPUT

Bon

CavityWire colorSiqnal1--T

2

3BLIVREDREAR WINDOW DEFOGGER SWITCH LEDINPUT

4LT GRNA./C SWITCH LEDINPUT

5LT GRN/BLKRECIRCULATION CONTROL SWITCH LEDINPUT

6PNVBLKAIR MIX POTENTIALOUTPUT

7BRNEVAPORATOR TEIMPERATURE SENSOROUTPUT

8

9

10

GAUGE ASSEMBLYal' 'TDr ri11RED

RED/BLKTAILLIGHTS RELAYINPUT

14BLUREAR WINDOW DEFOGGER SWITCHINPUTicLT GRN/REDA/C SWITCHINPUT16YEVREDRECIRCULATION CONTROL SWITCHINPUT17YEUGRNMODE 4OUTPUT18WHT/BLUMODE 3OUTPUT19RED/BLUMODE 2OUTPUT20RED/YELMODE 1OUTPUTBRN^,^/HTIGN (PowedOUTPUT22R E DA/r'HT(Not used)

(cont'd)

21-11

Page 791 of 1139

Heating and Air Gonditioning

DTC Troubleshooting {cont'd)

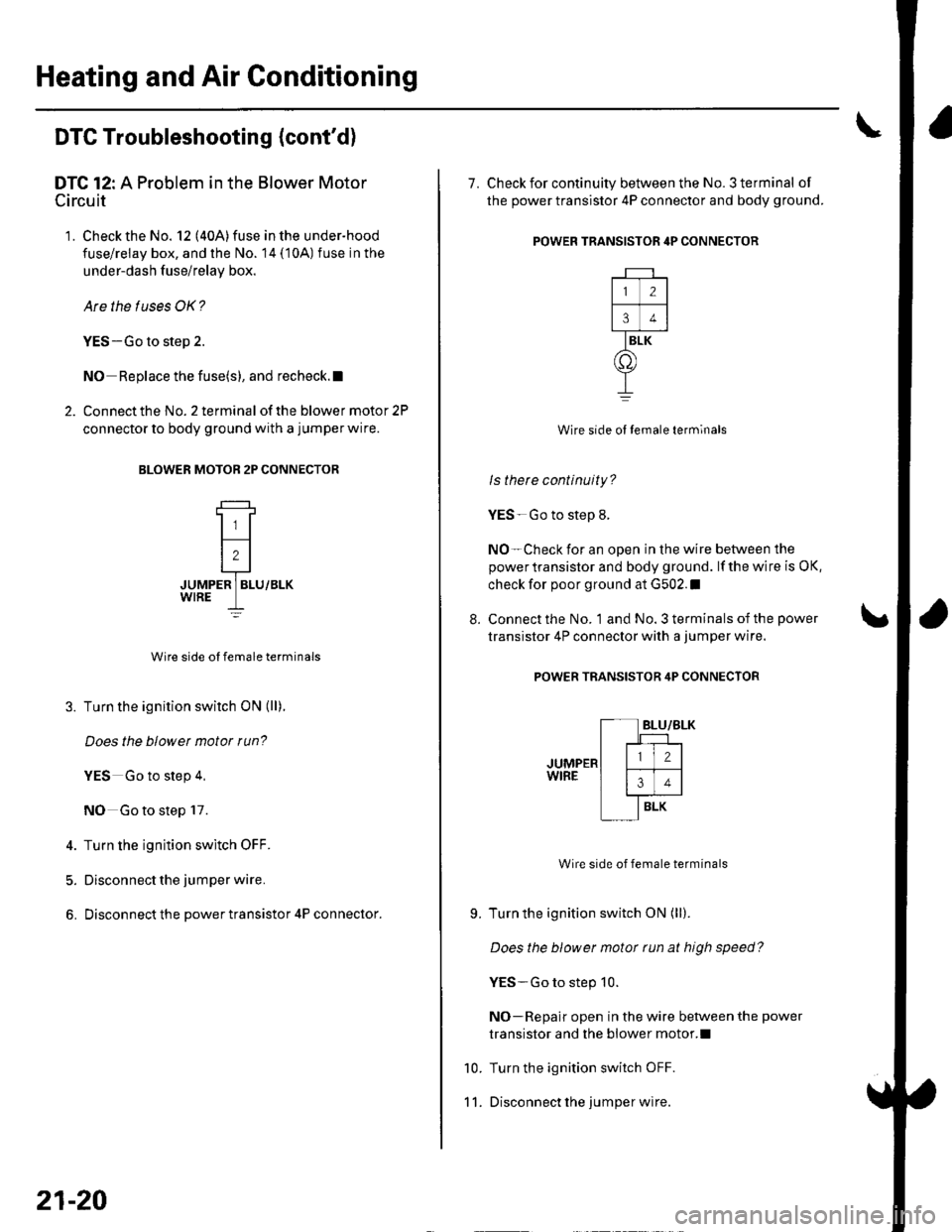

DTC 12: A Problem in the Blower Motor

Circuit

'1. Check the No. 12 (40A)fuse inthe under-hood

fuse/relay box, and the No. 14 (10A) fuse in the

under-dash f use/relay box.

Are the tuses OK?

YES-Go to step 2.

NO Replace the fuse(s), and recheck.l

2. Connect the No. 2 terminal of the blower motor 2P

connector to body ground with a jumper wire.

BLOWER MOTOB 2P CONNECTOR

JUMPER ] BLU/BLK

Wire side ol female terminals

3. Turn the ignition switch ON (ll).

Does the blowet motor run?

YES Go to step 4,

NO Go to step 17.

4. Turn the ignition switch OFF.

5. Disconnect the jumper wire.

6. Disconnect the power transistor 4P connector.

21-20

8.

7. Check for continuity between the No. 3 terminal of

the power transistor 4P connector and body ground.

POWER TRANSISTOR 4P CONNECTOR

Wire side ol temale terminals

ls there continuity?

YES-Go to step 8.

NO-Check for an open in the wire between the

power transistor and body ground. lf the wire is OK,

check for poor ground at G502.I

Connect the No. 1 and No. 3 terminals of the power

transistor 4P connector with a jumper wire.

POWER TRANSISTOR 4P CONNECTOR

Wire side of female terminals

Turn the ignition switch ON (ll).

Does the blower motor tun at high speed?

YES-Go to step 10.

NO-Repair open in the wire between the power

transistor and the blower motor.l

Turn the ignition switch OFF.

Disconnect lhe jumper wire.

9.

10.

11.

2

34

BLK

o

Page 792 of 1139

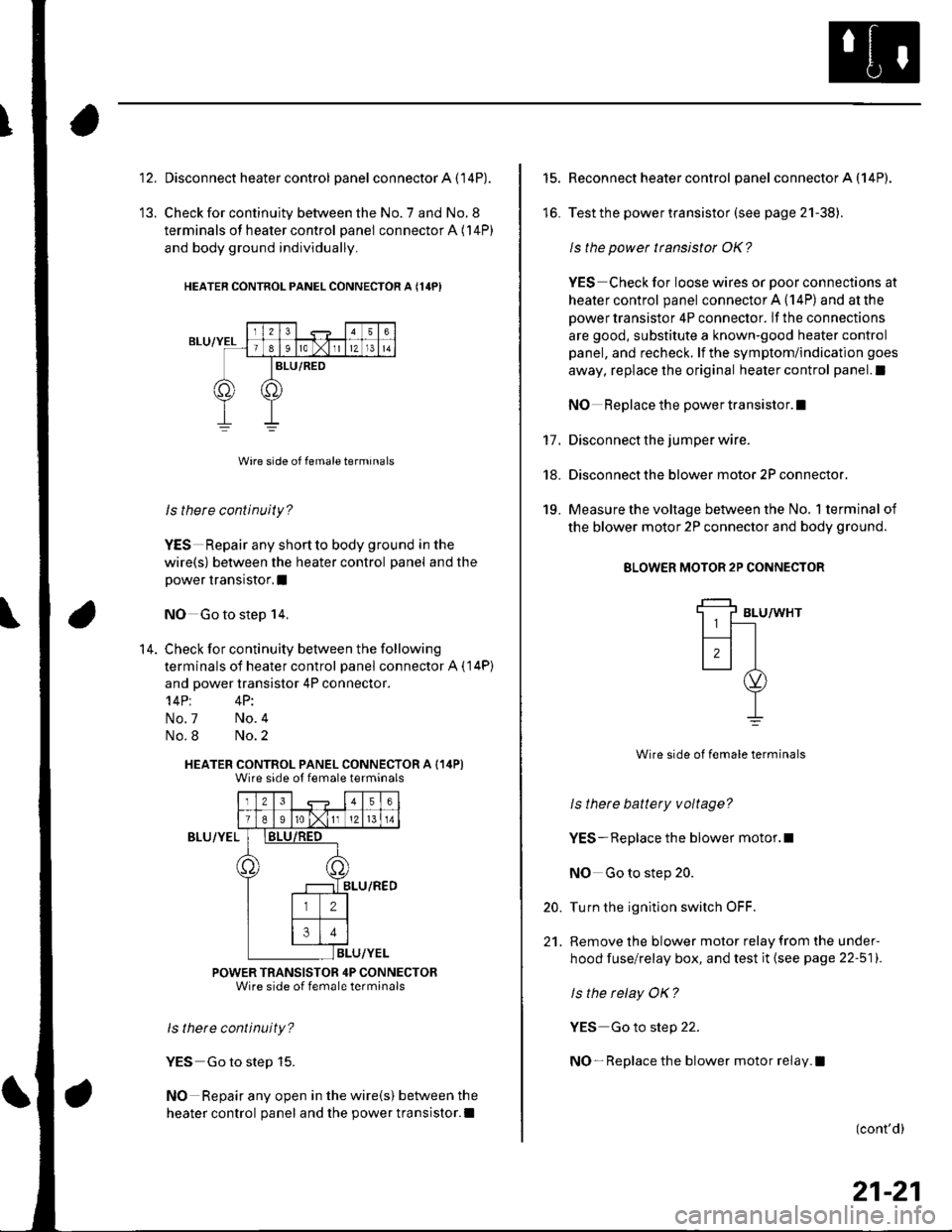

1a

13.

Disconnect heater control panel connector A (14P).

Check for continuity between the No. 7 and No. 8

terminals of heater control panel connector A (14P)

and body ground individually.

HEATER CONTNOL PANEL CONNECTOR A {14PI

ls there continuity?

YES Repair any shortto body ground in the

wire(s) between the heater control panel and the

power transistor.I

NO Go to step 14,

Check for continuity between the following

terminals of heater control panel connector A ( 14P)

and power transistor 4P connector.'l4Pt 4P:

No.7 No.4

No.8 No.2

HEATER CONTROL PANEL CONNECTOR A (14P)Wire side ot female terminals

Iz341516

T89ro lxlI12l 13 l 14

)8LU/RED

ILU/YEL

POWER TRANSISTOR 4P CONNECTORWire side of female terminals

ls thete continuity?

YES Go to step 15.

NO Repair any open in the wire(s) between the

heater control panel and the power transistor.l

14.

BLU/YEL

15.

lo.

17.

18.

19.

Reconnect heater control panel connector A (14P).

Test the power transistor (see page 21-38).

ls the power transistor OK?

YES Check for loose wires or poor connections at

heater control panel connector A (14P) and at the

power transistor 4P connector. lf the connections

are good, substitute a known-good heater control

panel, and recheck. lf the symptom/indication goes

away, replace the original heater control panel.l

NO Replace the power transistor.I

Disconnect the jumper wire.

Disconnect the blower motor 2P connector.

Measure the voltage between the No, 1 terminal of

the blower motor 2P connector and body ground.

BLOWER MOTOR 2P CONNECTOR

BLU/WHT

Wire side of female terminals

ls thete battery voltage?

YES- Replace the blower motor.l

NO Go to step 20.

Turn the ignition switch OFF.

Remove the blower motor relay from the under-

hood fuse/relay box, and test it (see page 22-511.

ls the relay OK?

YES Go to step 22.

NO- Replace the blower motor relay.l

20.

21.

(cont'd)

21-21

Page 809 of 1139

Heating and Air Gonditioning

a

\

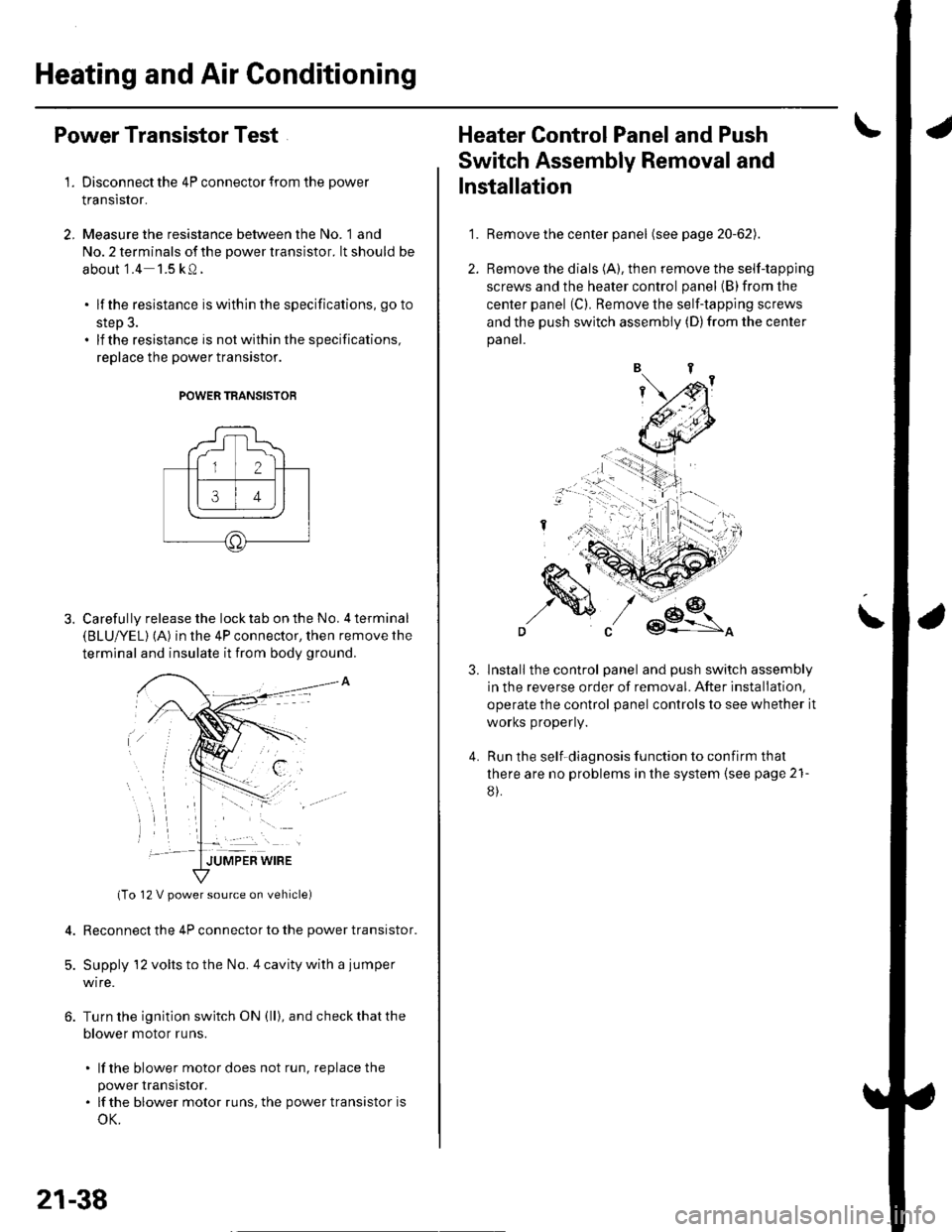

Power Transistor Test

1. Disconnect the 4P connector from the power

Iranslslor.

2, Measure the resistance between the No. 1 and

No. 2 terminals of the power transistor. lt should be

about '1.4 1.5 kQ.

. lf the resistance iswithln the specifications, go to

step 3.. lf the resistance is notwithin the specifications,

replace the power transistor.

POWER TRANSISTOB

Carefully release the lock tab on the No. 4 terminal(BLUI/EL) (A) in the 4P connector, then remove the

terminal and insulate it from body ground.

(To 12 V power source on vehicle)

Reconnect the 4P connector to the power transistor.

Supply 12 volts to the No. 4 cavity with a jumper

wire.

Turn the ignition switch ON (ll), and check that the

blower motor runs.

. lf the blower motor does not run, replace the

power rranstsror.. lf the blower motor runs,the powertransistoris

oK.

12 V power source on vehicle)

21-38

1.

Heater Control Panel and Push

Switch Assembly Removal and

Installation

Remove the center panel (see page 20-62).

Remove the dials (A), then remove the self-tapping

screws and the heater control panel (B)from the

center panel (Cl. Remove the self-tapping screws

and the push switch assembly (D)from the center

panel.

lnstall the control panel and push switch assembly

in the reverse order of removal. After installation,

operate the control panel controls to see whether it

worKs propeny.

Run the self-diagnosis function to confirm that

there are no problems in the system (see page 21-

8).

3.

4.

Page 811 of 1139

Heating and Air Gonditioning

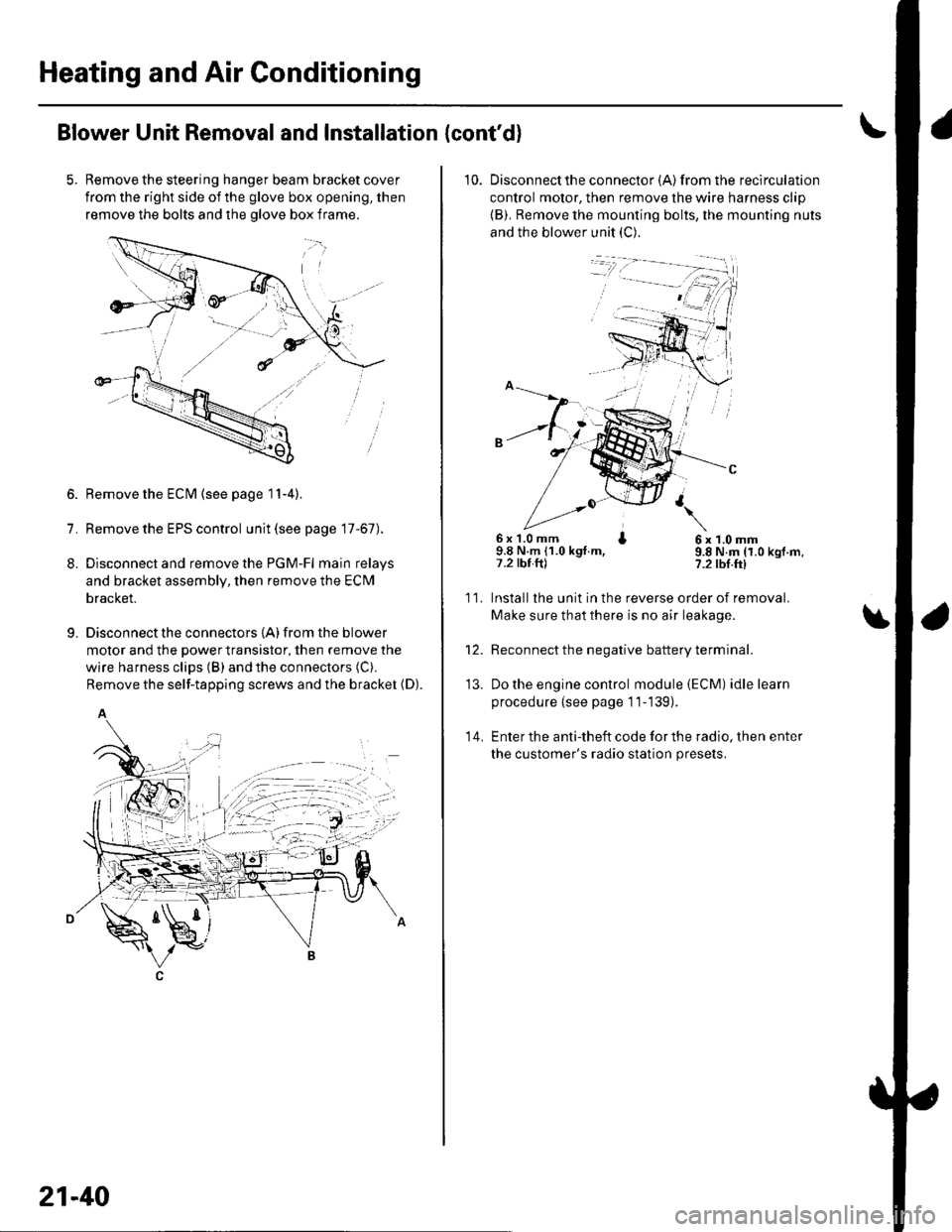

Blower Unit Removal and Installation {cont'd}

Remove the steering hanger beam bracket cover

from the right side of the glove box opening, then

remove the bolts and the olove box frame.

1.

8.

9.

Remove the ECM (see page 11-4).

Remove the EPS control unit (see page 17-67).

Disconnect and remove the PGM-Fl main relays

and bracket assembly, then remove the ECM

bracket.

Disconnect the connectors {A) from the blower

motor and the power transistor, then remove the

wire harness clips (B) and the connectors (C).

Remove the self-tapping screws and the bracket (D).

A

21-40

10. Disconnectthe connector {A) from the recirculation

control motor, then remove the wire harness clip

{B). Remove the mounting bolts, the mounting nuts

and the blower unit (C).

6x 1.0 mm I9.8 N.m (1.0 kgt.m,7.2 tbt.ftl

6x1.0mm9.8 N.m (1.0 kgf.m,?.2 tbf.ft)

11.

14.

Installlhe unit in the reverse order of removal.

Make sure that there is no air leakage.

Reconnect the negative battery terminal.

Do the engine control module (ECM) idle learn

procedure {see page 11-139).

Enter the anti-theft code for the radio, then enter

the customer's radio station presets.

\

'13.

Page 812 of 1139

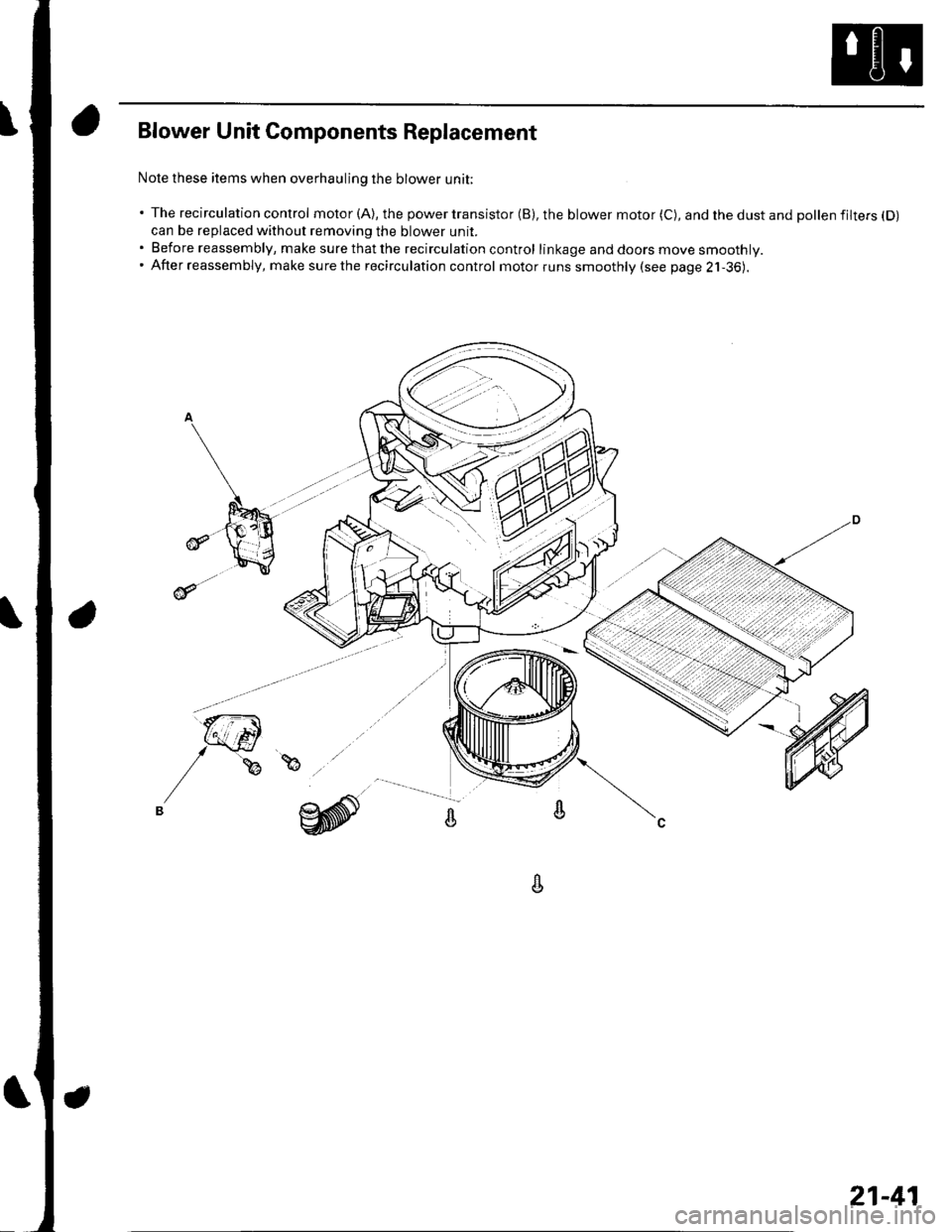

Blower Unit Components Replacement

Nole these items when overhauling the blower unit;

' The recirculation control motor (A), the power transistor (B), the blower motor (C), and the dust and pollen filtefs (D)

can be replaced without removing the blower unit.. Before reassembly, make surethatthe recirculation control linkage and doors move smoothly.. After reassembly, make surethe recirculation control motorruns smoothly (see page 2j-36).

A

21-41