trans HONDA CIVIC 2002 7.G Manual PDF

[x] Cancel search | Manufacturer: HONDA, Model Year: 2002, Model line: CIVIC, Model: HONDA CIVIC 2002 7.GPages: 1139, PDF Size: 28.19 MB

Page 465 of 1139

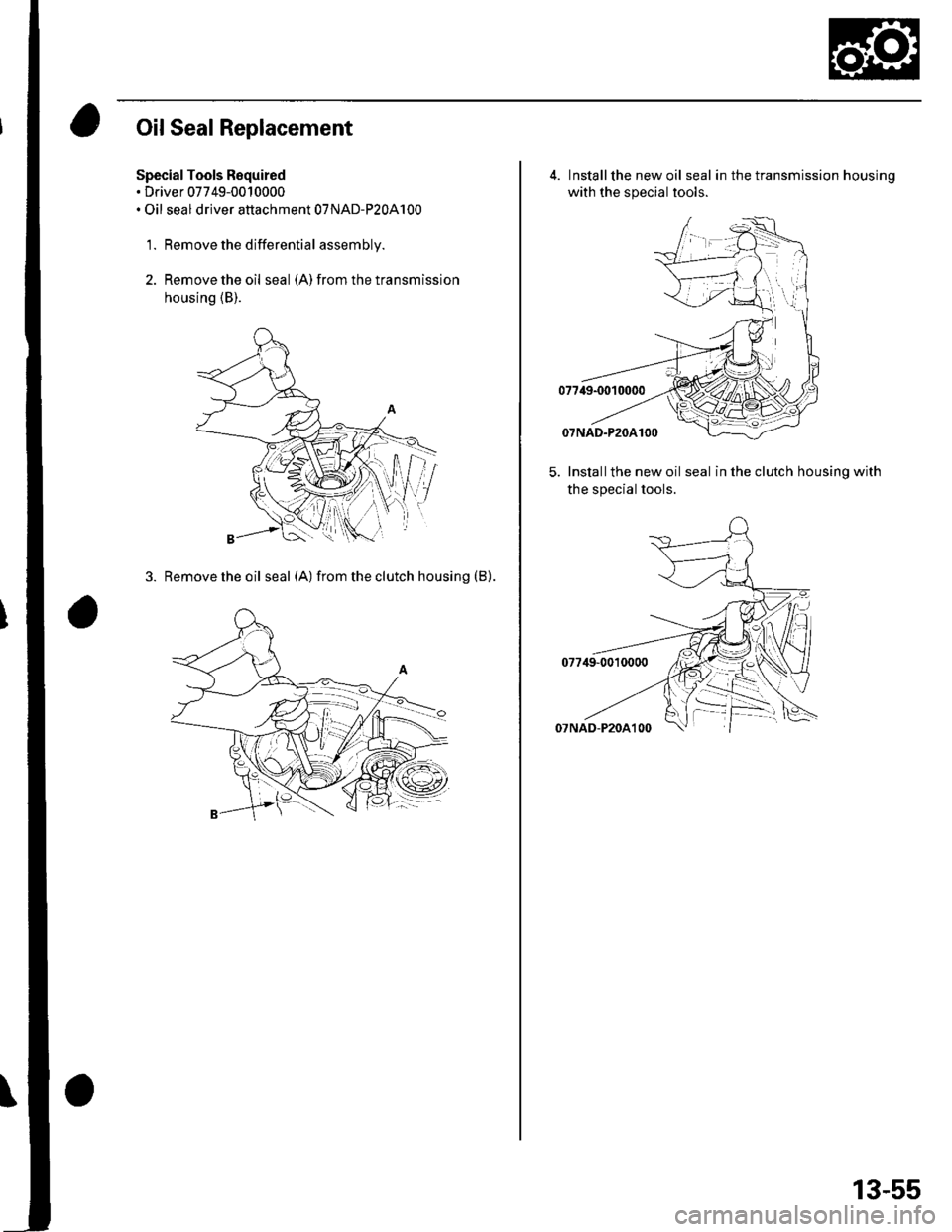

Oil Seal Replacement

Special Tools Required. Driver 07749-0010000. Oil seal driver attachment 07NAD-P20A100

1. Remove the differential assembly.

2. Remove the oil seal (A) from the transmission

housing (B).

3. Removetheoil seal (A) fromtheclutch housing (B).

4. Installthe new oil seal in the transmission housinq

with the special tools.

5. Installthe new oil seal in the clutch housing with

the special tools.

13-55

Page 466 of 1139

M/T Differential

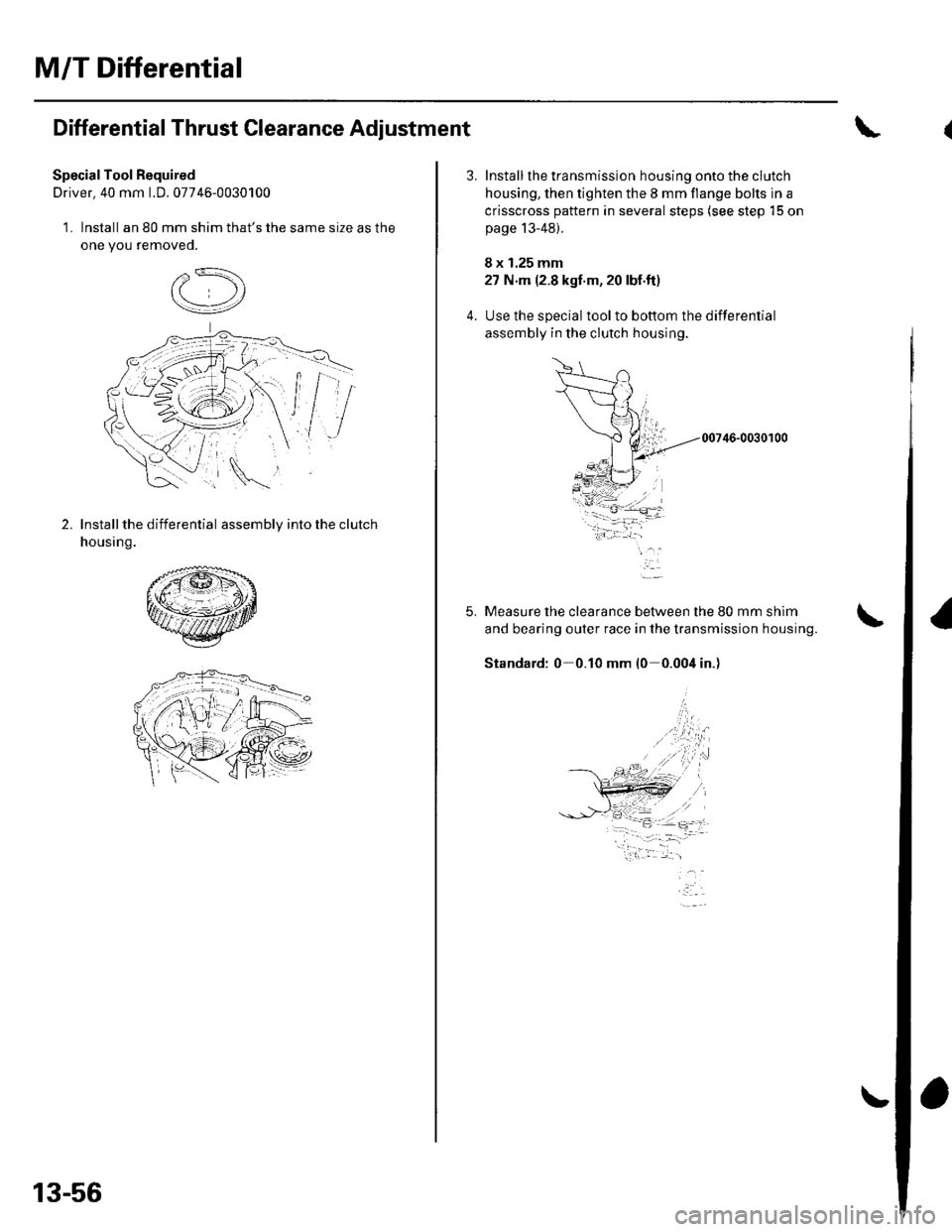

Differential Thrust Clearance Adjustment

SpecialTool Required

Driver. 40 mm LD. 07746-0030100

1. Install an 80 mm shim that's the same size as the

one you removeo.

2.Install the differential assembly into the clutch

housing.

13-56

5.

Install the transmission housing onto the clutch

housing, then tighten the 8 mm flange bolts in a

crisscross pattern in several steps (see step 15 on

page 13-48).

8 x 1.25 mm

27 N m (2.8 kgf'm, 20 lbf.ft)

Use the special toolto bottom the differential

assembly in the clutch housing.

00746-0030100

Measure the clearance between the 80 mm shim

and bearing outer race in the transmission housing.

Standard: 0 0.10 mm l0 0.004 in.)

-i.w.t ..1-- -- :,- -=.

Page 467 of 1139

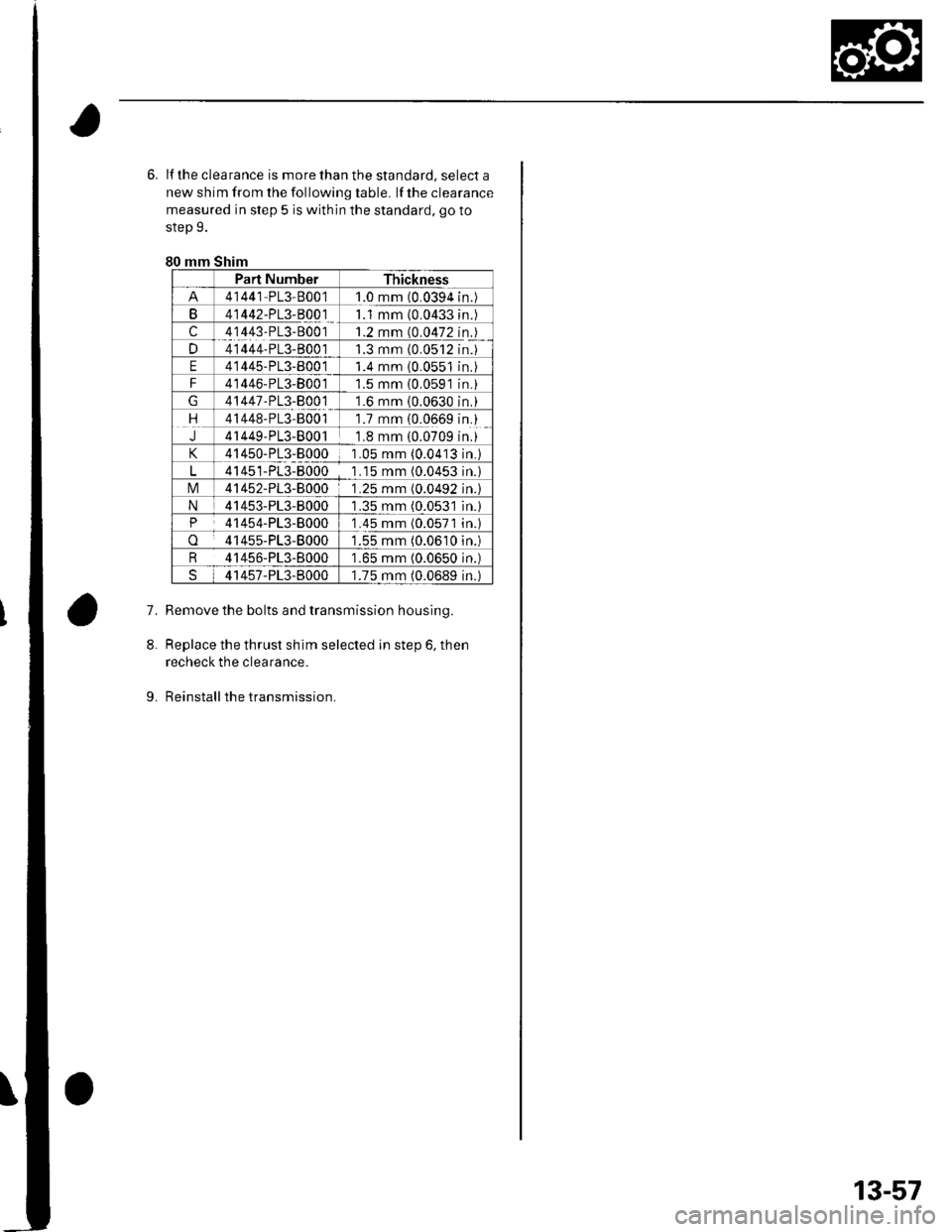

6. lf the clea rance is more than the standard, select a

new shim from the following table. lf the clearance

measured in step 5 is within the standard, go to

step 9.

80 mm Shim

Part NumberThickness

41441 PL3-80011.0 mm (0.0394n.

B41442-PL3-B00111 mm (0.0433n.

c41443-PL3-80011.2 mm (0.0472n.

D41444-PL3-B0011.3 mm {0.0512n.

E41445-PL3-800 11.4 mm 10.0551n.

F41446-PL3-80011.5 mm {0.0591n.

41447-PL3-800 11.6 mm (0.0630n.

rt41448-PL3-B0011.7 mm {0.0669n.

J41449-PL3-80011.8 mm (0.0709n.

41450-PL3-80001 .05 mm (0.0413n.)

41451-PL3-80001 .15 mm (0.0453n.l

tvl41452-PL3-80001.25 mm (0.0492n.l

N41453-PL3-80001.35 mm (0.053'ln.)

P41454-PL3-80001 .45 mm (0.0571n.l

o41455-PL3-80001.55 mm (0.0610n.)

R 41456-PL3-8000'1.65 mm (0.0650 in.)

41457-PL3-80001.75 mm (0.0689 in.)

7.Remove the bolts and transmission housing.

Replace the thrust shim selected in step 6, then

recheck the clearance.

Reinstall the transmission.

8.

9.

13-57

Page 470 of 1139

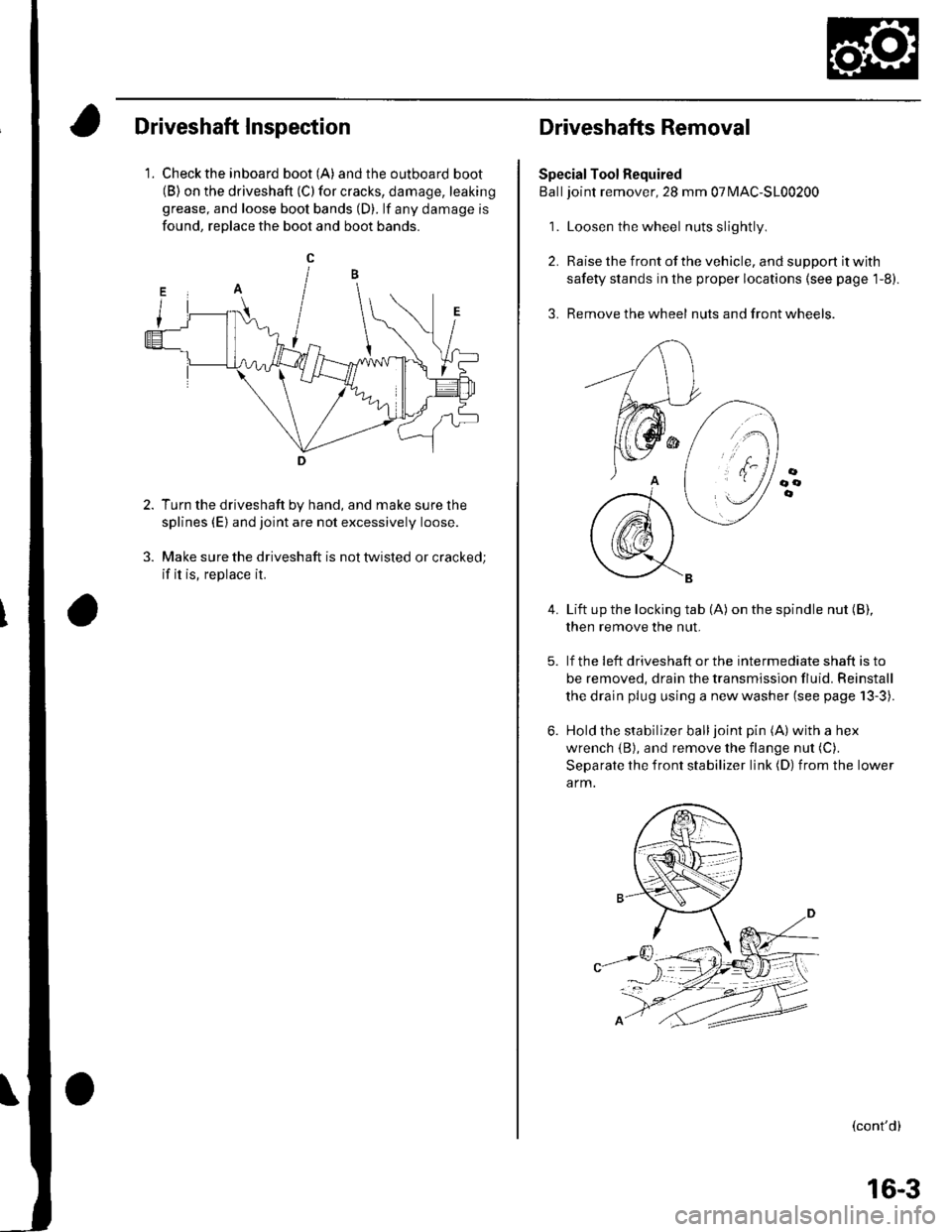

Driveshaft Inspection

1. Check the inboard boot (A) andthe outboard boot(B) on the driveshaft (C) for cracks, damage, leaking

grease, and loose boot bands (D). lf any damage is

found, reDlace the boot and boot bands.

Turn the driveshaft by hand, and make sure the

splines (E) and joint are not excessively loose.

Make sure the driveshaft is not twisted or cracked;

if it is, replace it.

Driveshafts Removal

Special Tool Required

Balljoint remover, 28 mm 07MAC-S100200

1. Loosen the wheel nuts slightly

2. Raise the front of the vehicle, and support it with

safety stands in the proper locations (see page 1-8).

3. Remove the wheel nuts and front wheels.

4.Lift up the locking tab (A) on the spindle nut (B),

then remove the nut.

lf the !eft driveshaft or the intermediate shaft is to

be removed, drain the transmission fluid. Reinstall

the drain plug using a new washer (see page 13-3).

Hold the stabilizer balljoint pin (A) with a hex

wrench {B), and remove the flange nut (C).

Separate the front stabilizer link (D) from the lower

a rm.

(cont'd)

16-3

Page 486 of 1139

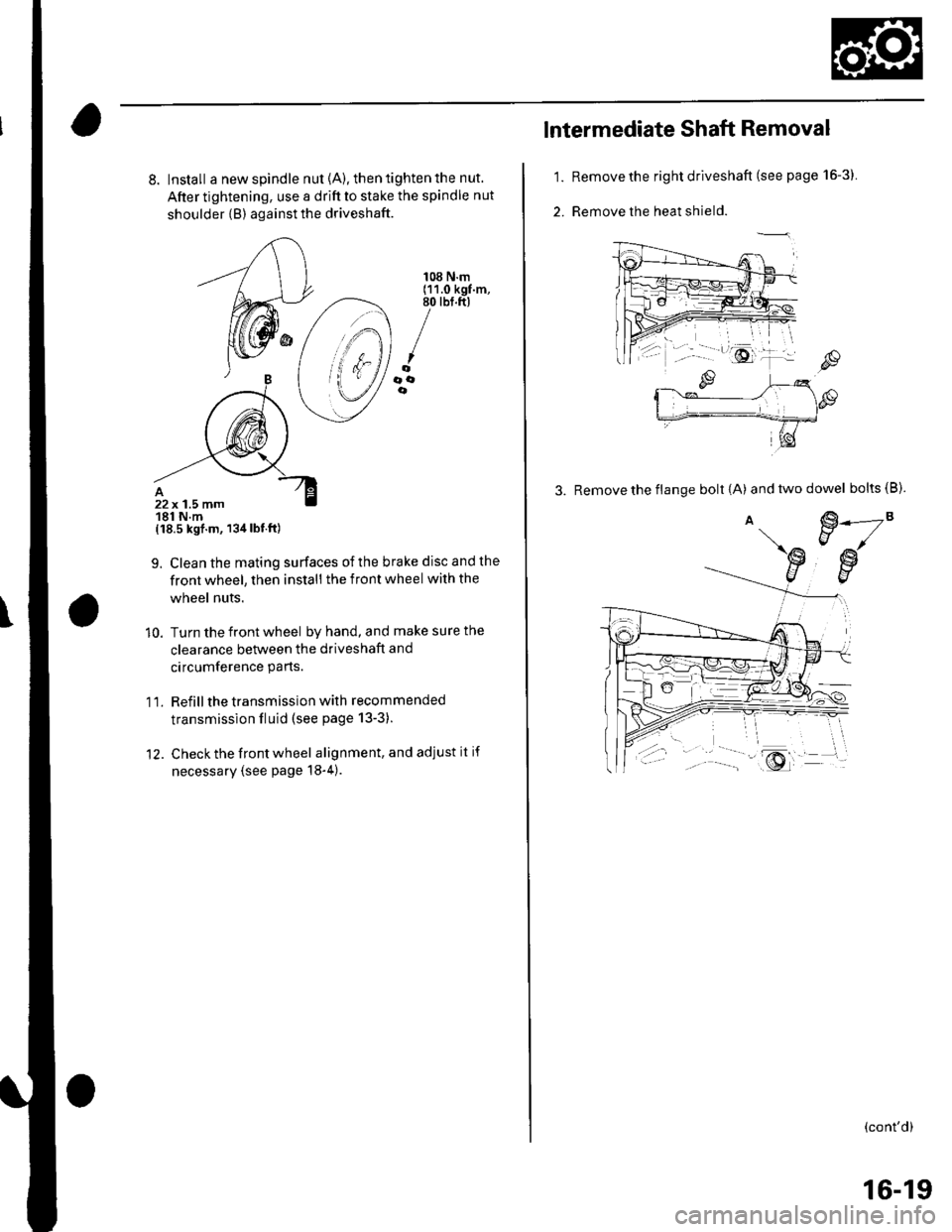

8. Install a new spindle nut {A), then tighten the nut.

After tightening, use a drift to stake the spindle nut

shoulder {B) against the driveshaft.

{18.5 kgf.m, 134lbt.ft)

9. Clean the mating surfaces ofthe brake disc and the

front wheel, then install the front wheel with the

wheel nuts.

10. Turn the front wheel by hand, and make sure the

clearance between the driveshaft and

circumference parts.

1 l. Refill the transmission with recommended

transmission fluid (see page 13-3).

12. Check the front wheel alignment, and adjust it if

necessary (see page 18-4).

108 N.m(11.0 kgf.m,80 tbt.ft)

/oooe

22x 1.5 mm181 N.m

1.

2.

lntermediate Shaft Removal

Remove the right driveshaft (see page 16-3).

Remove the heat shield.

3. Remove the flange bolt {A) andtwodowel bolts(B).

€.---2"EJ/

€w

(cont'd)

16-19

Page 491 of 1139

Driveline/Axle

Intermediate Shaft Reassembly

(cont'd)

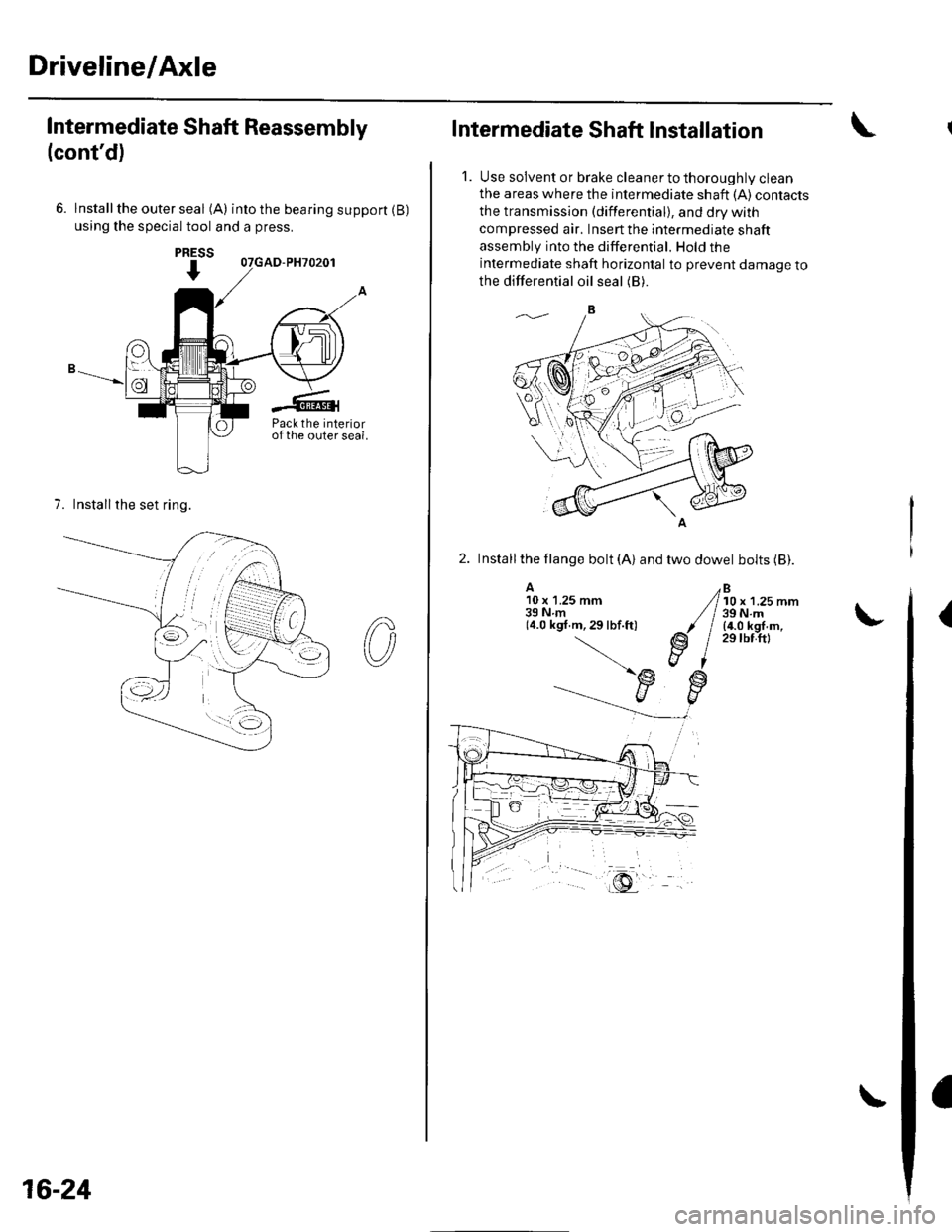

6. lnstallthe outer seal (A) intothebearingsupport(B)

using the special tool and a press.

7. Installthe set ring.

PRESS

I

Pack the interiorofthe outer seal.

16-24

Intermediate Shaft Installation

1. Use solvent or brake cleaner to thoroughly clean

the areas where the intermediate shaft {A) contacts

the transmission (differential), and dry with

compressed air. Insert the intermediate shaft

assembly into the differential. Hold the

intermediate shaft horizontal to prevent damage to

the differential oil seal (B).

2. Installthe llange bolt (A) and two dowel bolts (Bl.

A10 x 1.25 mm39Nm(4.0 kgf.m,29lbf.ft)

Bl0 x 1.25 mm39 N.m(4.0 kgf.m,29 tbf.ftl

(

Page 505 of 1139

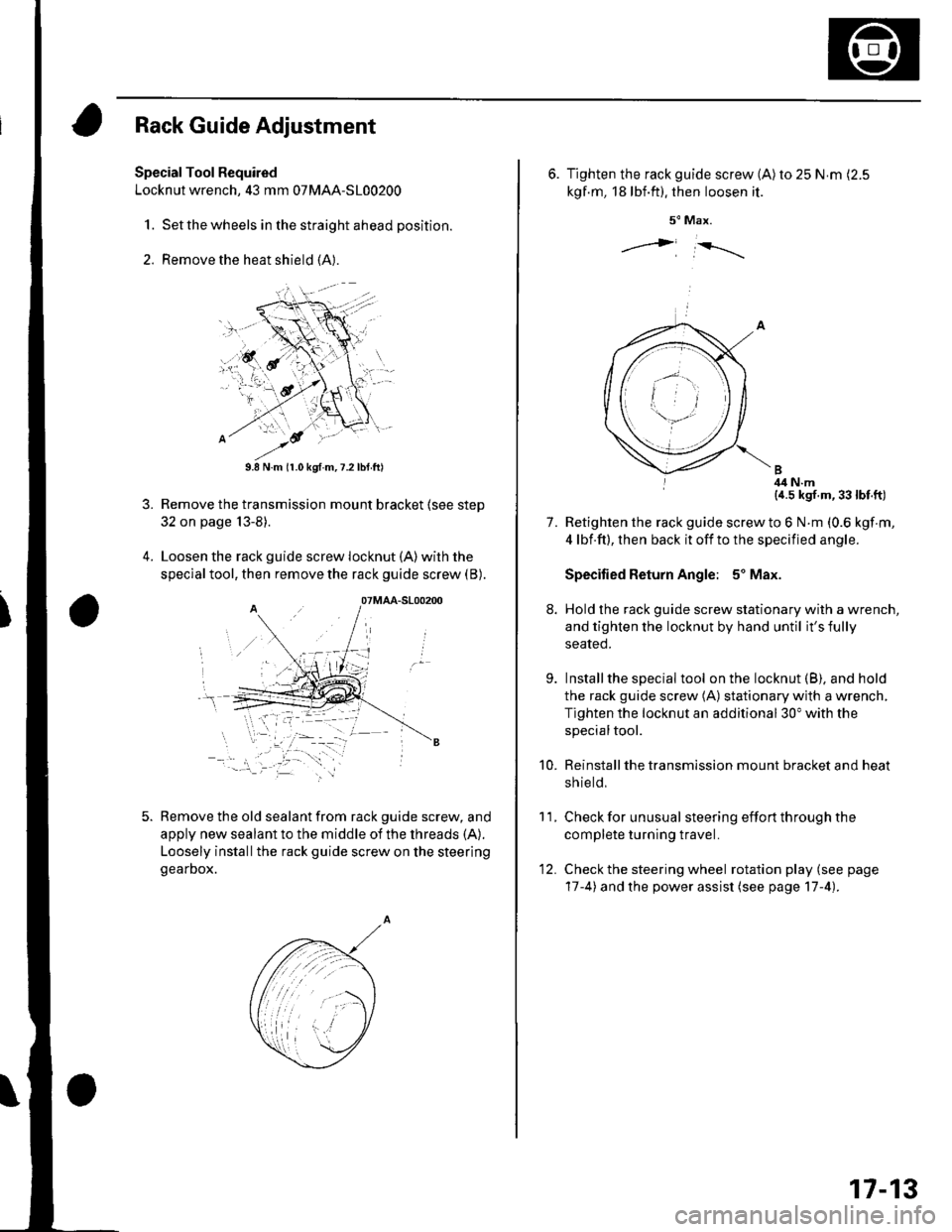

Rack Guide Adjustment

Special Tool Required

Locknut wrench, 43 mm 07MAA-S100200

1. Set the wheels in the straight ahead position.

2. Remove the heat shield (A).

3.

9.8 N.m (r.0 kgf.m,7.2lbtft)

Remove the transmission mount bracket (see step

32 on page 13-8).

Loosen the rack guide screw locknut (A)with the

special tool, then remove the rack guide screw (B).

Remove the old sealant from rack guide screw, and

apply new sealant to the middle of the threads (A).

Loosely installthe rack guide screw on the steering

gearDox.

'-.i. '' '

07MAA-S100200

6. Tighten the rack guide screw (A)ro 25 N.m (2.5

kgf.m, 18lbf.ft). then loosen it.

5" Max.

j i-rrrr-,

I 4il N.m{a.5 kgf.m,33lbt.ft)

Retighten the rack guide screw to 6 N.m (0.6 kgf m,

4 lbf.ft), then back it off to the specified angle.

Specified Return Angle: 5' Max.

Hold the rack guide screw stationary with a wrench,

and tighten the locknut by hand until it's fully

seated.

Installthe special tool on the locknut (B), and hold

the rack guide screw (A) stationary with a wrench,

Tighten the locknut an additional 30" with the

specialtool.

Reinstall the transmission mount bracket and heat

sh ie ld,

Check for unusual steering effort through the

complete turning travel.

Check the steering wheel rotation play (see page

17-4) and the power assist (see page 17-4).

11.

7.

9.

10.

12.

17-13

Page 599 of 1139

Gonventional Brake Components

ComponentProcedureAlso check for:

l\4aster CylinderLook for damage or signs of fluid leakage at;. Reservoir or reservoir grommets

. Line joints

. Between master cvlinder and booster

Brake HosesLook for damage or signs of fluid leakage at:. Line joints and banjo bolt connections. Hoses and lines. also inspect for twisting or

damaqe

Bulging, twisted or bent lines.

CaliperLook for damage or signs of fluid leakage at:. Piston seal. Banjo bolt connections. Bleeder screw

Seized or sticking caliper pins.

ABS l\ilodulatorLook for damage or signs of fluid leakage at:. Line joints

. Modulator

Brake System Inspection and Tests

Brake System Test

Brake pedal sinks/fades when braking

1. Start the engine, and let it warm up to operating temperature.

2. Attach a 2-inch pieceof masking tape along the bottom of the steering wheel, and draw a horizontal reference

mark across it.

With the transmission in Neutral, press and hold the brake pedal lightly, then release the parking brake.

While still holding the brake pedal, hook the end of the tape measure behind it. Then pull the tape up to the

steering wheel, noting where the tape measure lines up with the reference mark you made on the masking tape.

Apply steady pressure to the brake pedal for 3 minutes.

Watch the tape measure.

. if it moves less than 10 mm, the master cylinder is OK.

. if it moves more than 10 mm replace the master cylinder.

t-

3.

5.

6.

19-4

Page 633 of 1139

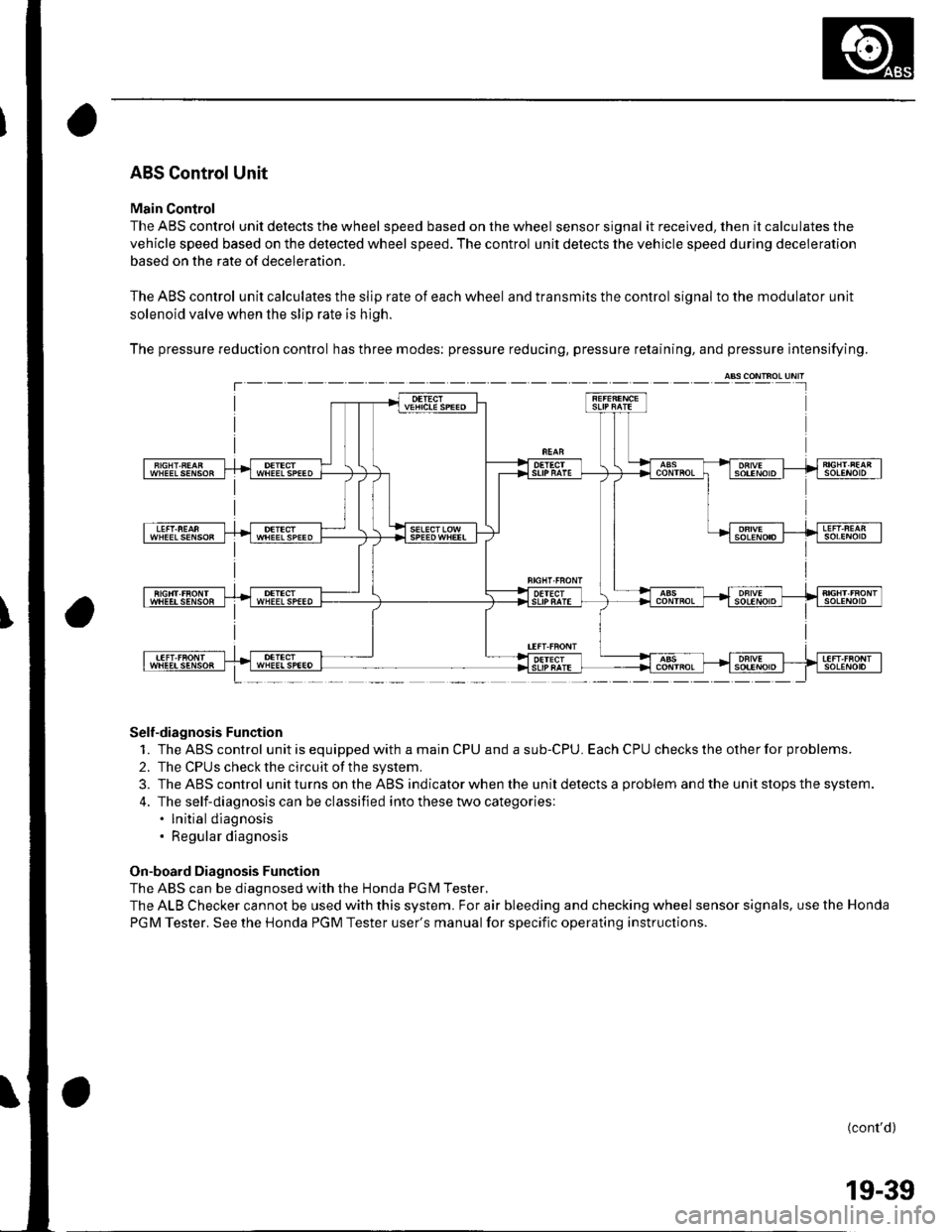

ABS Control Unit

Main Control

The ABS control unit detects the wheel speed based on the wheel sensor signal it received, then it calculates the

vehicle speed based on the detected wheel speed. The control unit detects the vehicle speed during deceleration

based on the rate of deceleration.

The ABS control unit calculates the slip rate of each wheel and transmits the control signal to the modulator unit

solenoid valve when the slip rate is high.

The pressure reduction control has three modes: pressure reducing, pressure retaining, and pressure intensifying.

Self-diagnosis Function

1. TheABScontrol unitisequippedwithamainCPUandasub-CPU.EachCPUcheckstheotherforproblems.

2. The CPUS check the circuit of the system.

3. TheABScontrol unitturns ontheABS ind icator when the unitdetectsa problem andthe unit stops th e system.

4. The self-diagnosis can be classified into these two categories:. lnitial diagnosis. Regular diagnosis

On-board Diagnosis Function

The ABS can be diagnosed with the Honda PGM Tester.

The ALB Checker cannot be used with this system. For air bleeding and checking wheel sensor signals. use the Honda

PGM Tester. See the Honda PGM Tester user's manual for specific operating instructions.

(cont'd)

T---

19-39

Page 768 of 1139

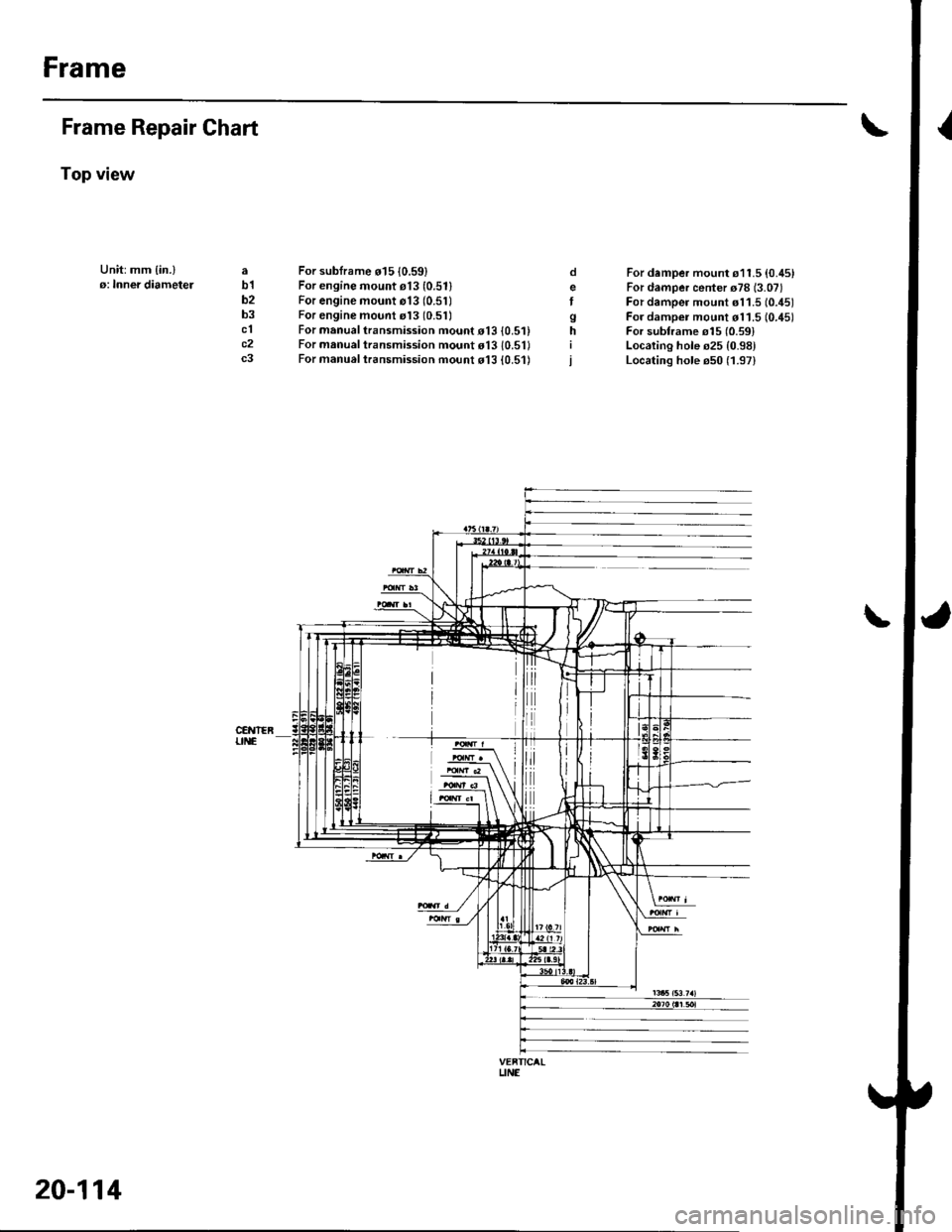

Frame

Frame Repair Chart

Top view

Unit:mm {in.}o: Inner diametelab1b2b3clc2c3

For sublrame o15 10.59)For engine mount e13 (0.511

For engine mount o13 (0.51)For engine mount rl3 (0.51)

For manual transmission mouot o13 {0.5'For manual transmission mount o13 10.5'For manual t.ansmission mo!nt d13 {0.51)

o

Igh

For damper mount s11.5 {0.45}For damper center o78 (3.07)

For damper mount s11.5 (0.451

For dampei mount d11.5 10.45)For subframe o15 {0.591Localing hole s25 {0.98}Locating hole e50 (1.97)

\

VEFTICALUNE

20-114