width HONDA CIVIC 2002 7.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 2002, Model line: CIVIC, Model: HONDA CIVIC 2002 7.GPages: 1139, PDF Size: 28.19 MB

Page 20 of 1139

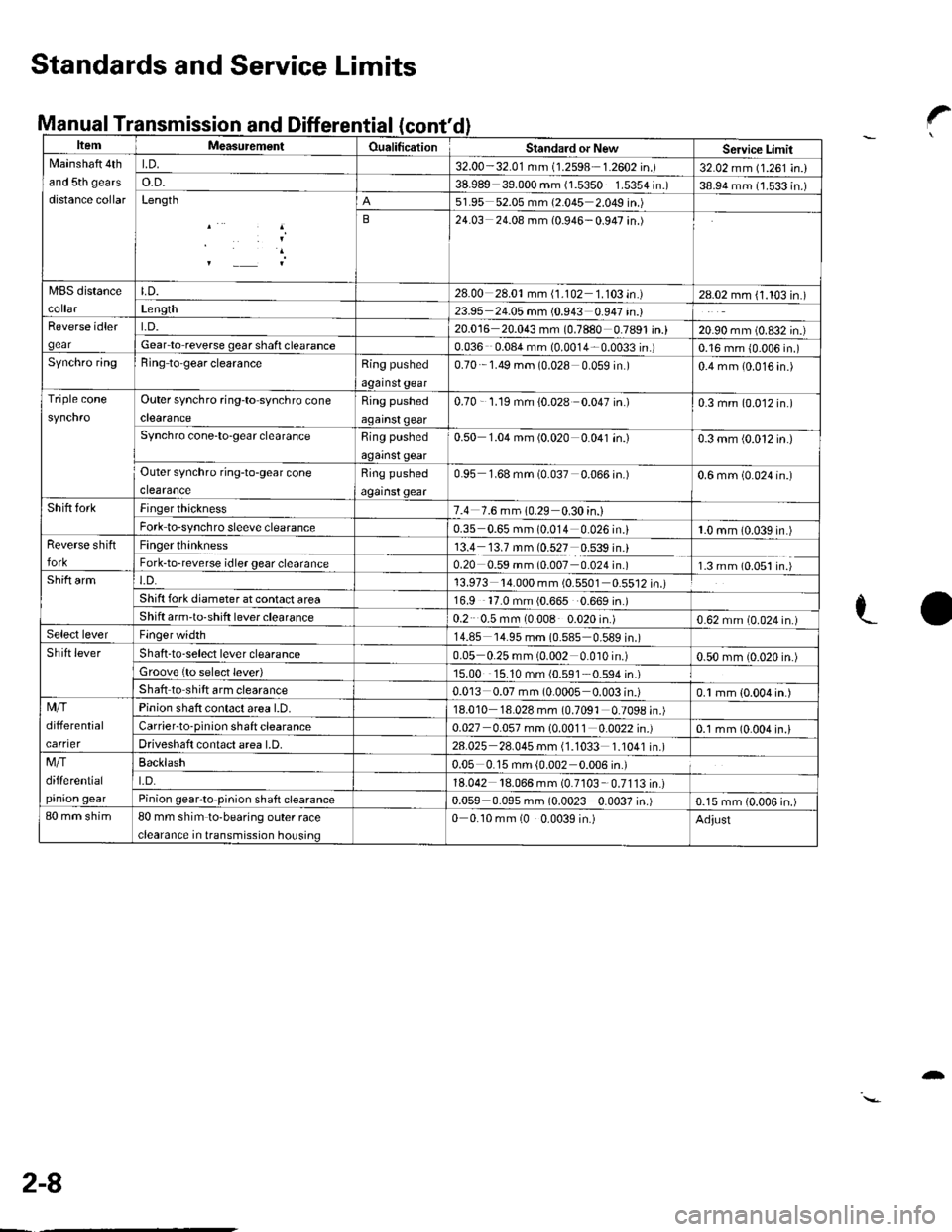

anuat I ransmcont'

ItemMeasutemenlOualificationStandard or NewServicc LimitNlainshaft 4th

and 5th gears

distance collar

LD.32.00-32.01 mm (1.2598 1.2602 in.)32.02 mm (1.261 in.)o.D.38.989 39.000 mm (1.5350 1.5354 in.)38.94 mm (1.533 in.)Length51.95 52.05 mm (2.045 2.049 in.)

B24.03 24.08 mm (0.946-0.947 in.)

MBS distanceLD.28.00 28.01mm (1.102 1.103 in.)28.02 mm (1.103 in.)Len9th23.95 24.05 mm (0.943 0.947 in.)Reverse idler

gear

t.D.20.016 20.043 mm (0.7880 0.7891 in.)20.90 mm (0.832 in.)Gear lo reverse gear shafi clearance0.036 0.08a mm (0.0014 0.0033 in.)0.16 mm {0.006 in.)Synchro ringBing to'gear clearanceRing pushed

against gear

0.70 1.49 mm (0.028 0 059 in )0.4 mm (0.016 4n.)

Triple coneOuter synchro ring-to synchro cone

clearance

Ring pushed

against qear

0.70 - '1.19 mm {0.028 0.047 in.)0.3 mm (0.012 in.)

Synchro cone-to-gear clearanceRing pushed

against gear

0.50 1.04 mm (0.020 0.041 in.)0.3 mm (0.012 in.)

Outer synchro ring-to-gear cone

clearance

Ring pushed

against gear

0.95 1.68 mm (0.037 0.066 in.)0.6 mm (0.024 in.)

Shift forkFinger thickness7.4 7.6 mm 10.29 0.30 in.)Fork to-synchro sleeve clearance0.35 0.65 mm (0.014 0.026 in.i1.0 mm (0.039 in.)Reverse shift

fork

Finger thinkness13.4 13.7 mm (0.527 0.539 in.)Fork-to-reverse idler gear clearance0.20 0.59 mm (0.007 0.024 in.)1.3 mm (0.051 in.)Shift armt.D.13.973 '14.000 mm (0.5501 0.5512 in.)Shift fork diameter at conlact area16.9 '17.0 mm (0.665 0.669 in.)Shift arm'to-shift lever clearance0.2 0.5 mm (0.008 0.020 in.)0.62 mm (0.024 in.)Select leverFinger width14.85 '14.95 mm (0.585 0.589 in.)Shift leverShaft -to-select lever clearance0.05 0.25 mm (0.002 0.010 in.)0.50 mm (0.020 in.)Groove {to select lever)15.00 15.10 mm {0.591 0.594 in.)

Shaft to shift arm clearance0.013 0.07 mm (0.0005 0.003 in.)0.1 mm {0.004 in.)Mfi

differential

carrier

Pinion shaft contact area l.D.18.010 18.028 mm (0.7091 0.7098 in.)Carrier-to-pinion shaft clearance0.027 0.057 mm (0.0011 0.0022 in.)0.1 mm (0.004 in.lDriveshaft contact area LD.28.025 28.045 mm (1.1033 1.1041 in.)Mfi

differential

pinion qear

Backlash0.05 0.15 mm {0.002 0.006 in.)

t.D.18.042 18.066 mm (0.7103 0.7113in.)Pinion gearto pinion shaft clearance0.059 0.095 mm (0.0023 0.0037 in.)0.15 mm (0.006 in.)80 mm shim80 mm shim to-bearing outer race

clearance in transmission housing

0 0.10 mm (0 0.0039 in.)Adjust

Standards and Service Limits

Manual Transmission and Differential?

LO

2-8

-

Page 23 of 1139

L

v

2-11

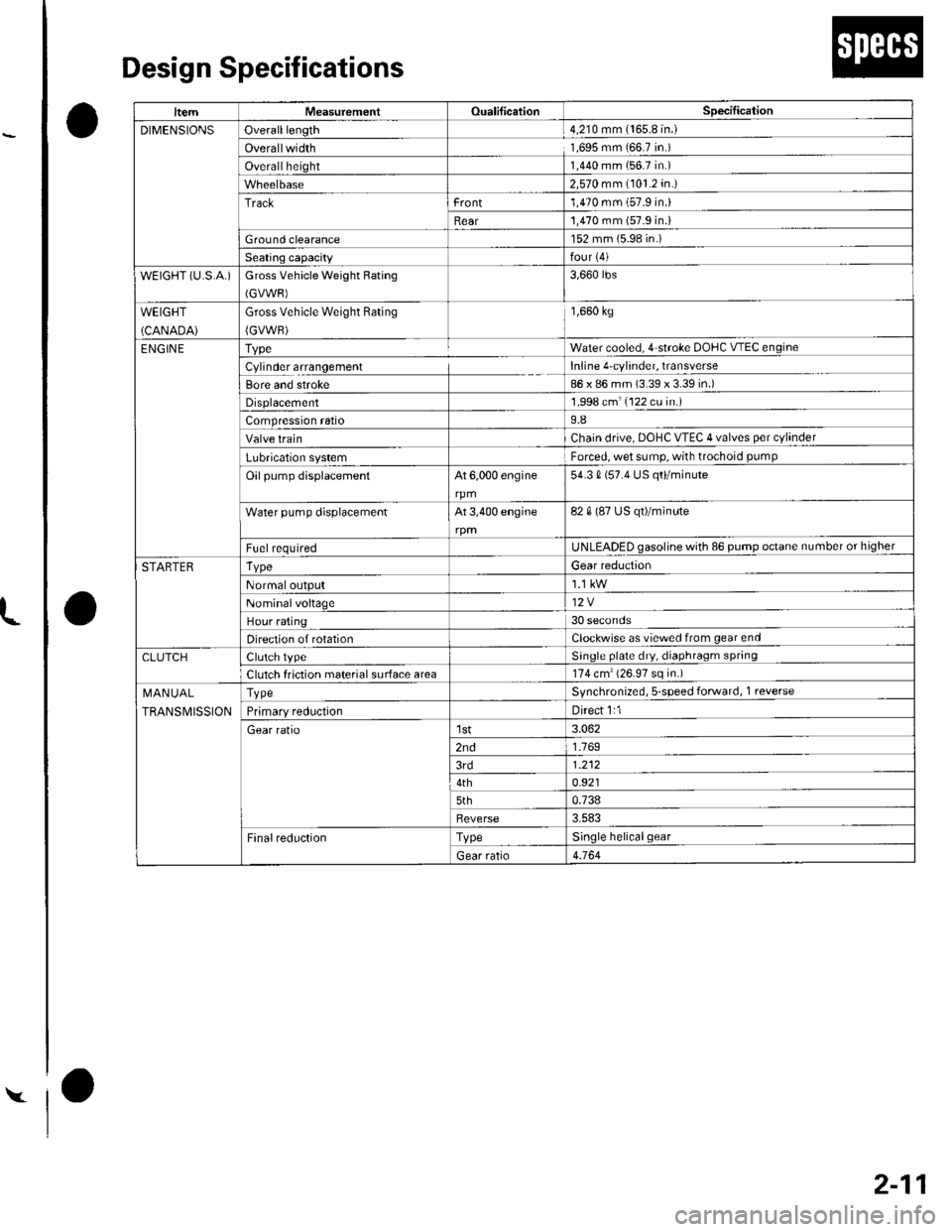

Design Specifications

O

o

o

|temMeasurementOualificationSpecilication

DIMENSIONSOveralllength4,210 mm {165.8 in.)

Overallwidth1,695 mm 166.7 in.)

Overallheight1,440 mm (56.7 in.)

2,570 mm (101.2 in.)

Trackrront1,470 mm (57.9 in.)

Rear'1,470 mm (57.9 in.i

Ground clearance152 mm (5.98 in.)

Seating capacityfour {4)

wEtGt-iT {u.s.A.)Gross Vehicle Weight Rating

(GVWR)

3,660 rbs

WEIGHT

(CANADA)

Gross Vehicle Weight Rating

{GVWR)

1,660 kg

ENGIN ETvpeWater cooled. 4 stroke DOHC V-EC engin(

Cylinder arrangementInline 4'cylinder, transverse

Bore and stroke86 x 86 mm (3.39 x 3.39 in.)

Displacement1,998 cm'(122 cu in.)

Compression ratio9.8

Valve trainChain drive. DOHC VTEC 4 valves per cylinder

Lubrication systemForced, wet sump, with trochoid pumP

Oil pump displacementAt 6,000 engine

rpm

54.3 0 (57.4 US qo/minute

Water pump displacementAt 3,400 engine82 0 (87 US qt)/minute

F!el requiredUNLEADED gasoline with 86 pump octane number or higher

STARTERTvpeGear reduction

Normaloutput

Nominalvoltage12V

Hour rating30 seconds

Direction of rotationClockwise as viewecl from gear end

CLUTCHClutch tvpeSinqle plate dry, diaphragm spring

Clutch friction material surface area174 cm'{26.97 sq in.)

I\,1AN UAL

TRANSMISSION

TvpeSvnchronized, s-speed forward, 1 reverse

Primarv reductionDirect 1:1

Gear ratiolst3.062

2nd1.769

3rd1.212

4th0.921

5th0.738

Reverse3.583

FinalreductionTypeSinole helicalgear

Gear ratio4.164

Page 130 of 1139

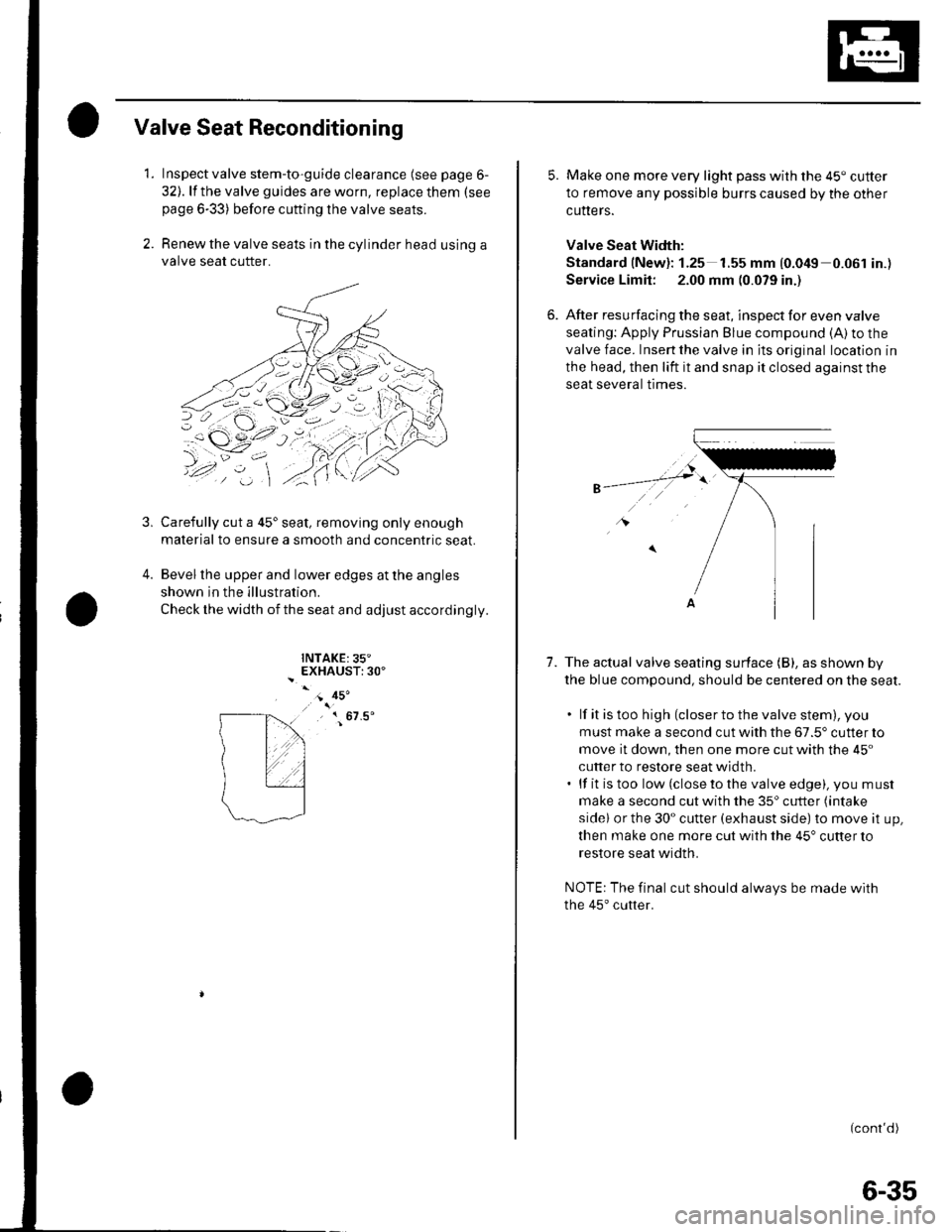

Valve Seat Reconditioning

1. Inspect valve stem-to-guide clearance (see page 6-

32). lf the valve guides are worn, replace them (see

page 6-33) before cutting the valve seats.

2. Renew the valve seats in the cylinder head using a

valve seat cutter.

Carefully cut a 45'seat, removing only enough

material to ensure a smooth and concentric seat.

Bevel the upper and lower edges at the angles

shown in the illustration.

Check the width of the seat and adjust accordingly.

INTAKE:35"EXHAUST:30'

3,

4.

- 45'

, { 67.5'

5. Make one more very light pass with the 45" cutter

to remove any possible burrs caused by the other

cutters.

Valve Seat Width:

Standard (New): 1.25 1.55 mm {0.049 0.061 in.)

Service Limit: 2.00 mm (0.079 in.)

6. After resurfacing the seat, inspect for even valve

seating: Apply Prussian Blue compound (A) to the

valve face. Insert the valve in its original location in

the head, then lift it and snap it closed against the

seat several trmes.

1.The actual valve seating surface (B), as shown by

the blue compound, should be centered on the seat.

. lf it is too high (closer to the valve stem), you

must make a second cut with the 67.5' cutter to

move it down, then one more cut with the 45"

cutter to restore seat width.. lf it is too low (close to the valve edge), you must

make a second cut with the 35'cutter (intake

sidel or the 30" cutter (exhaust side) to move it up,

then make one more cut with the 45" cutter to

restore seat width.

NOTE: The final cut should always be made with

the 45'cutter.

(cont'd)

6-35

Page 429 of 1139

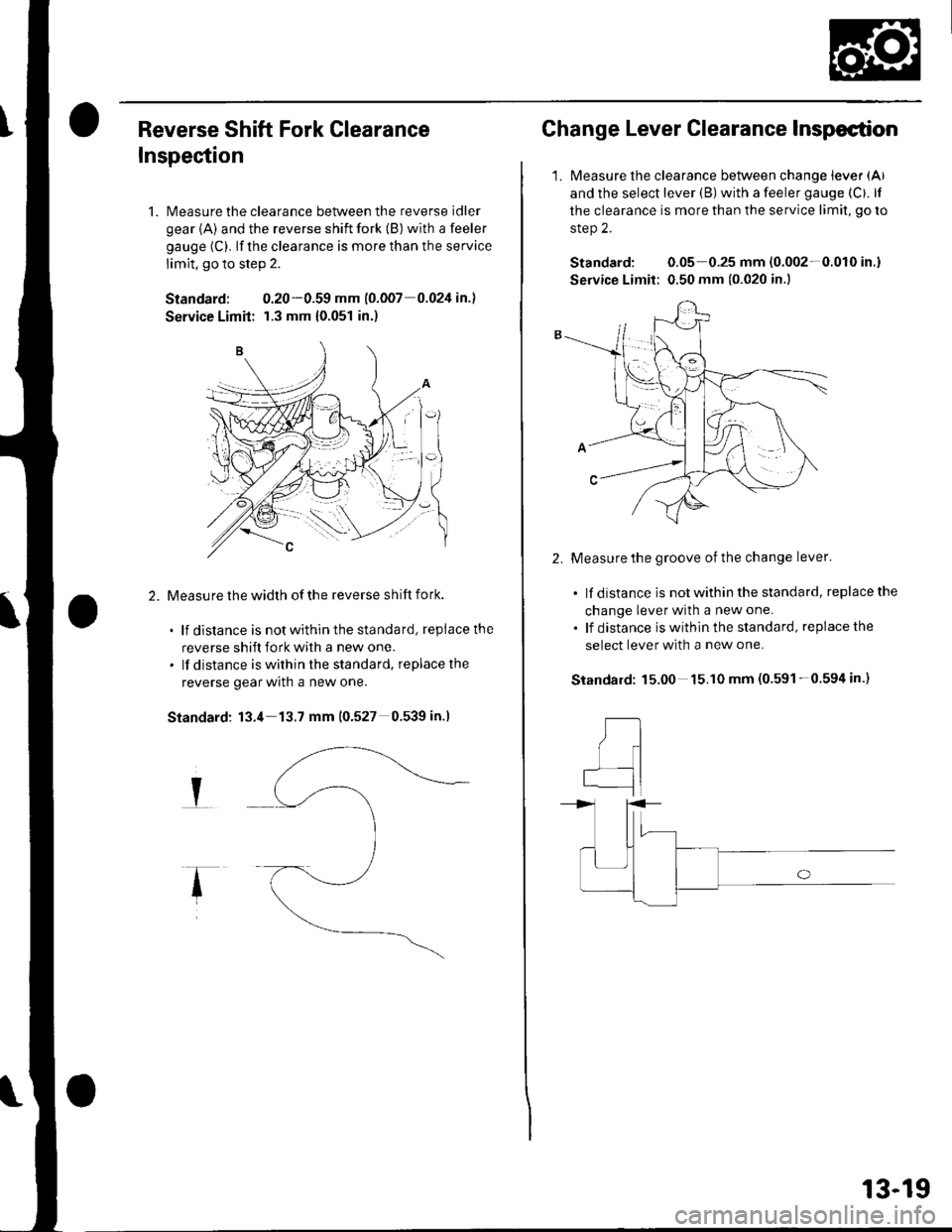

Reverse Shift Fork Clearance

Inspection

1. Measure the clearance between the reverse idler

gear {A) and the reverse shift fork (B) with a feeler

gauge (C). lf the clearance is more than the service

limit, go to step 2.

Standard: 0.20-0.59 mm (o.oo7 0.024 in.l

Service Limit: r.3 mm {0.051 in.)

Measu re the width of the reverse shift fork.

. lf distance is notwithinthestandard, replacethe

reverse shift fork with a new one.. lf distance is within the standard, replacethe

reverse gear wrln a new one.

Standard: 13.4 13.7 mm (0.527 0.539 in.l

I

Change Lever Clearance Inspection

1.Measure the clearance between change lever (Al

and the select lever (B) with a feeler gauge (Cf. lf

the clearance is more than the service limit, go ro

step 2.

Standard: 0.05 0.25 mm (0.002-0.010 in.)

Service Limit: 0.50 mm {0.020 in.)

2.Measure the groove of the change lever'

. lf distance is not within the standard, replace the

change lever with a new one.

. lf distance iswithinthe standard, replacethe

select lever with a new one.

15.00 15.10 mm (0.591-0.594 in.)Standard:

,tl

I

qI

13-19

Page 431 of 1139

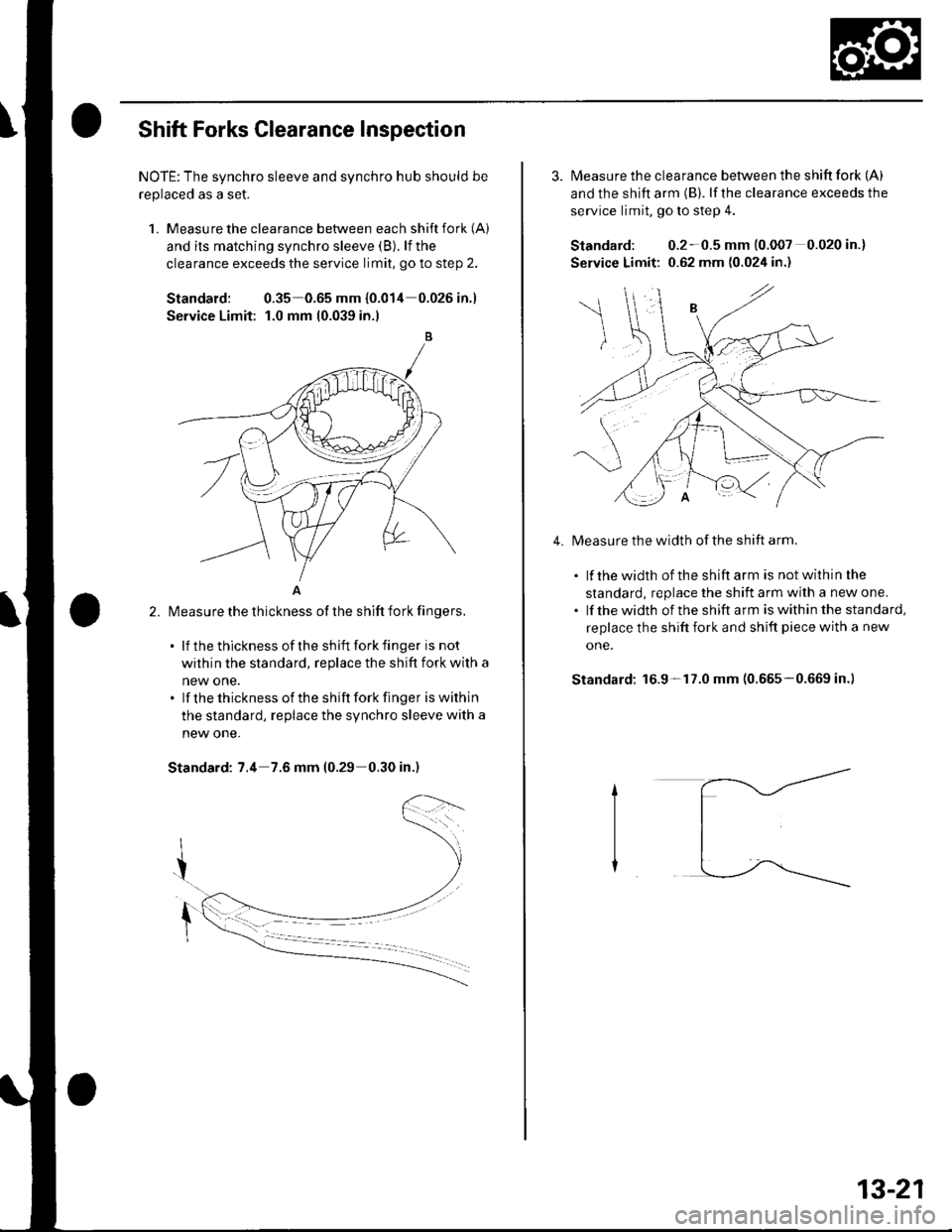

Shift Forks Glearance Inspection

NOTE: The synchro sleeve and synchro hub should be

replaced as a set.

1. Measu re the clearance between each shift fork (A)

and its matching synchro sleeve (B). lf the

clearance exceeds the service limit, go to step 2.

Standard: 0.35 0.65 mm {0.014 0.026in.1

Service Limit: 1.0 mm 10.039 in.l

A

l\4easure the thickness of the shift fork fingers.

. lf thethicknessof theshift forkfinger is not

within the standard, replace the shift fork with a

new one.. lf thethicknessof the shift forkfinger iswithin

the standard, replace the synchro sleeve with a

new one.

Standard: 7.4 7.6 mm (0.29-0.30 in.)

2.

3. Measure the clearance between the shift fork (A)

and the shift arm (B). lf the clearance exceeds the

service limit, go to slep 4.

Standard: 0.2-0.5 mm (0.007 0.020 in.)

Service Limit: 0.62 mm (0.024 in.)

Measure the width of the shift arm.

. lf thewidth of theshiftarm is notwithinthe

standard, replace the shift arm with a new one.. lf thewidth of the shift arm iswithinthe standard,

replace the shift fork and shift piece with a new

one.

Standard: 16.9-17.0 mm (0.665-0.669 in.)

4.

13-21