starter HONDA CIVIC 2003 7.G User Guide

[x] Cancel search | Manufacturer: HONDA, Model Year: 2003, Model line: CIVIC, Model: HONDA CIVIC 2003 7.GPages: 1139, PDF Size: 28.19 MB

Page 45 of 1139

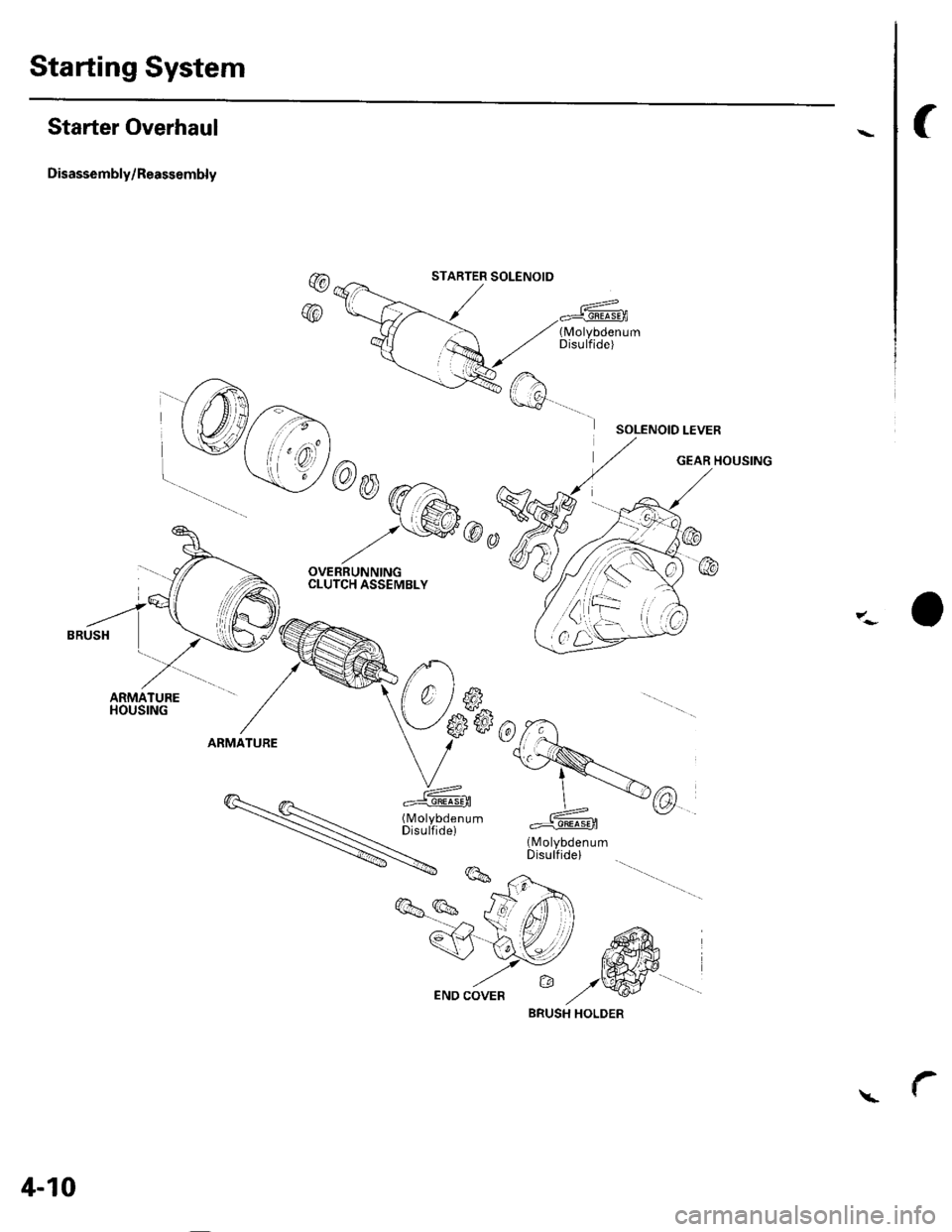

Starting System

Starter Overhaul

Disassembly/Reassembly

f

@

@

,-- ----_2<-

; ,/ 1(-\

rw.h

\:!@a

-

@-A

q -z\hsc6

b-.- ,"OVERRUNNINGCLUTCH ASSEMBLY

G

SOLENOID LEVER

o*"lu*.

V*rN*

\#. A*@

c^)* -#""Jli[X:""

S#o

7:- o

a<-4 t^ fr/ / ffiA-v

9\:-/ ffitr,.. D lWEND COVER t/ '!4/

STARTER SOLENOID

4-10

BRUSH HOLDER

Page 46 of 1139

\

?.-

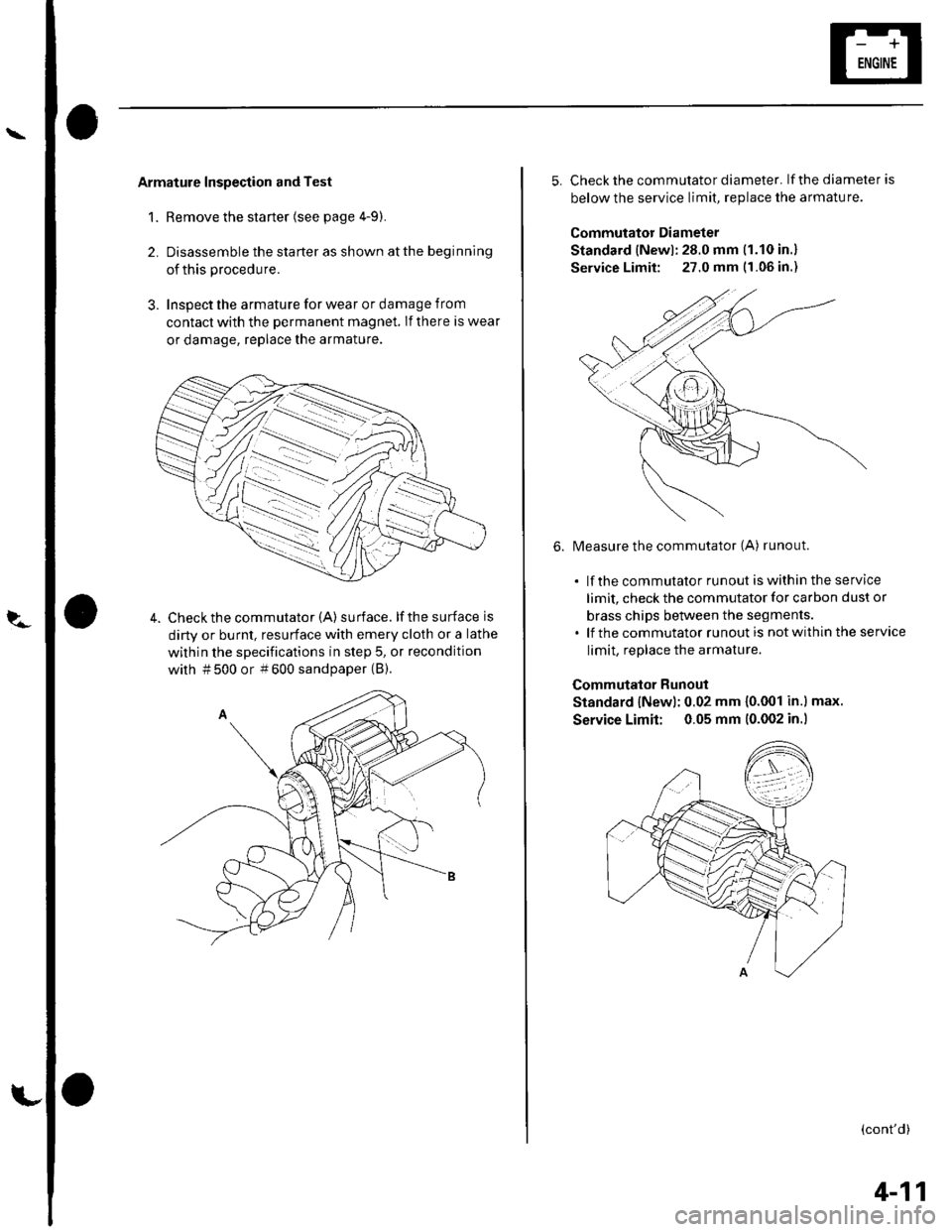

Armature Inspection and Test

1. Remove the starter (see page 4-9).

2. Disassemble the starter as shown atthe beginning

of this procedure.

3. Inspect the armature for wear or damage from

contact with the permanent magnet. lf there is wear

or damage, replace the armature.

Check the commutator (A) surface. lf the surface is

dirty or burnt, resurface with emery cloth or a lathe

within the specifications in step 5, or recondition

with # 500 or # 600 sandpaper (B).

6.

5. Check the commutator diameter. lf the diameter is

below the service limit, replace the armature.

Commutator Diameter

Standard (Newl: 28.0 mm (1.10 in.l

Service Limit: 27.0 mm (1.06 in.)

Measure the commutator (A) runout.

. lf the commutator runout is within the service

limit, check the commutator for carbon dust or

brass chips between the segments.. lf the commutator runout is not within the service

limit, reolace the armature.

Commutator Runout

Standard lNew): 0.02 mm 10.001 in.) max.

Service Limit: 0.05 mm (0.002 in.)

(cont'd)

4-11

Page 47 of 1139

Starting System

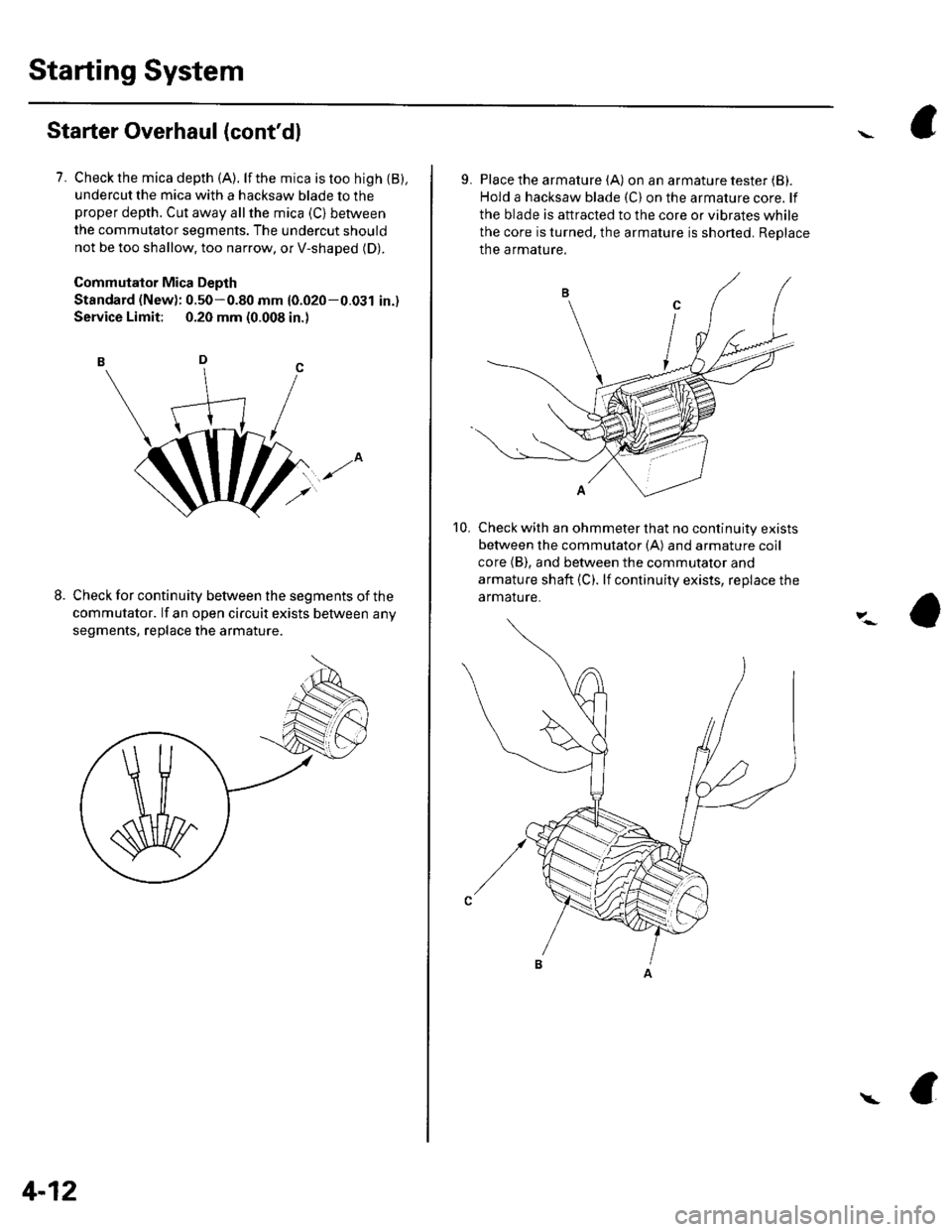

Starter Overhaul (cont'dl

7. Check the mica depth (A). lf the mica is too high {B),undercut the mica with a hacksaw blade to theproper depth. Cut away allthe mica (C) between

the commutator segments. The undercut should

not be too shallow, too narrow, or V-shaped (D).

Commutator Mica Depth

Standard (New): 0.50-0.80 mm {0.020-0.031 in.)

Service Limit: 0.20 mm (0.008 in.)

Check for continuity between the segments of the

commutator. lf an open circuit exists between any

segments, replace the armature.

M

4-12

\

9. Place the armature (A) on an armature tester (B).

Hold a hacksaw blade (C) on the armature core. lf

the blade is attracted to the core or vibrates while

the core is turned, the armature is shoned. Replace

the armature.

Check with an ohmmeter that no continuity exists

between the commutator (A) and armature coll

core (B), and between the commutator and

armature shaft (C). lf continuity exists, replace the

armature.

10,

Page 48 of 1139

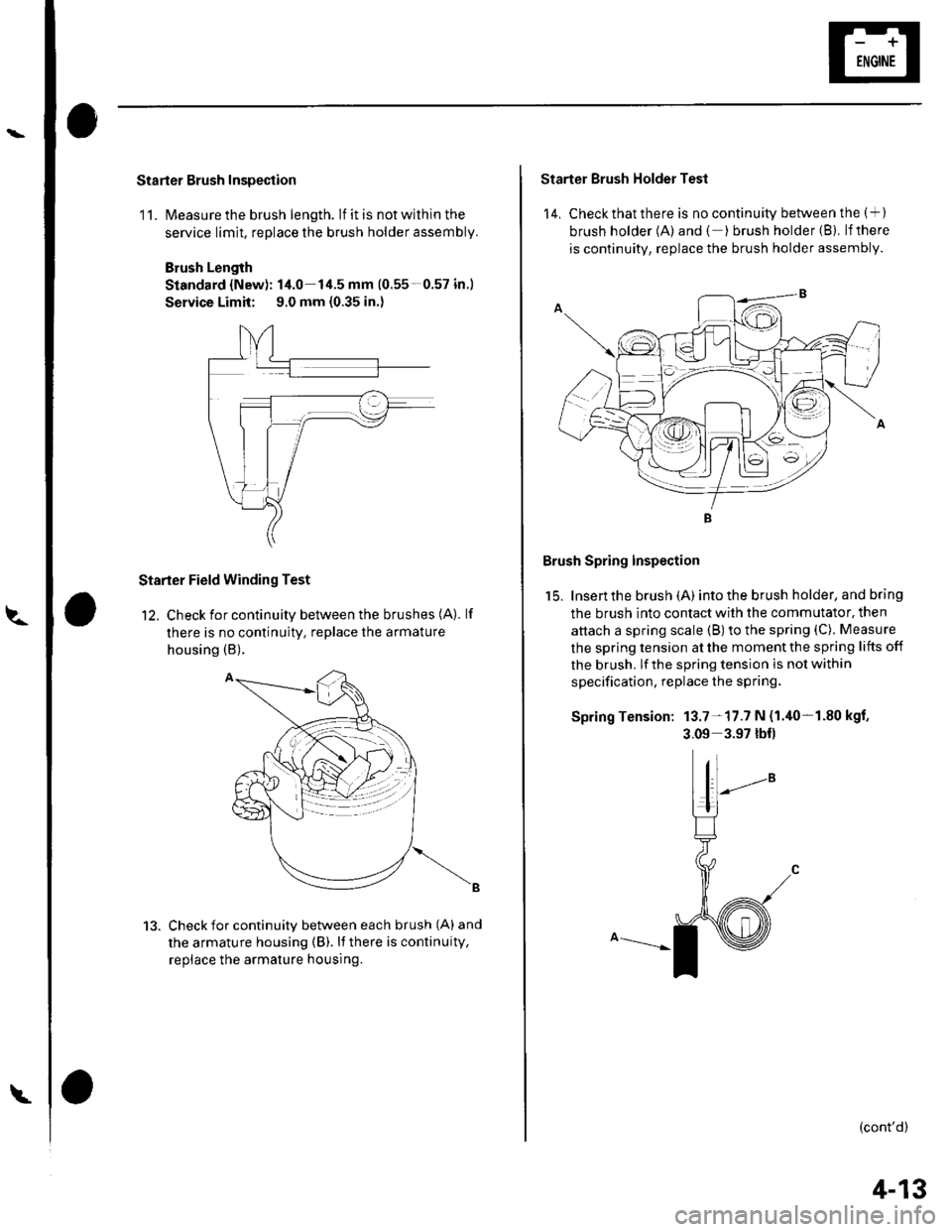

Starter Brush Inspection

11. lvleasure the brush length. lf it is not within the

service limit, replace the brush holder assembly.

Brush Length

Standard {New): 14.0-14.5 mm (0.55-0.57 in.)

Service Limit: 9.0 mm {0.35 in.)

Starter Field Winding Test

12. Check for continuity between the brushes (A). lf

there is no continuity. replace the armature

housing (B).

Check for continuity between each brush (A) and

the armature housing (B). li there is continuity,

replace the armature housing.

13.

Starter Brush Holder Test

14, Check that there is no continuity between the (+ )

brush holder {A) and ( ) brush holder (B}. lfthere

is continuity, replace the brush holder assembly.

Brush Spring Inspection

15. Insen the brush (A) into the brush holder, and bring

the brush into contact with the commutator, then

attach a spring scale (B) to the spring (C). Measure

the spring tension at the moment the spring lifts off

the brush. lf the spring tension is not within

specification, replace the spring.

Spring Tension: 13.7-17.7 N {1.40-1.80 kgf,

3.09 3.97 lbf)

(cont'd)

4-13

Page 49 of 1139

Starting System

Starter Overhaul (cont'dl

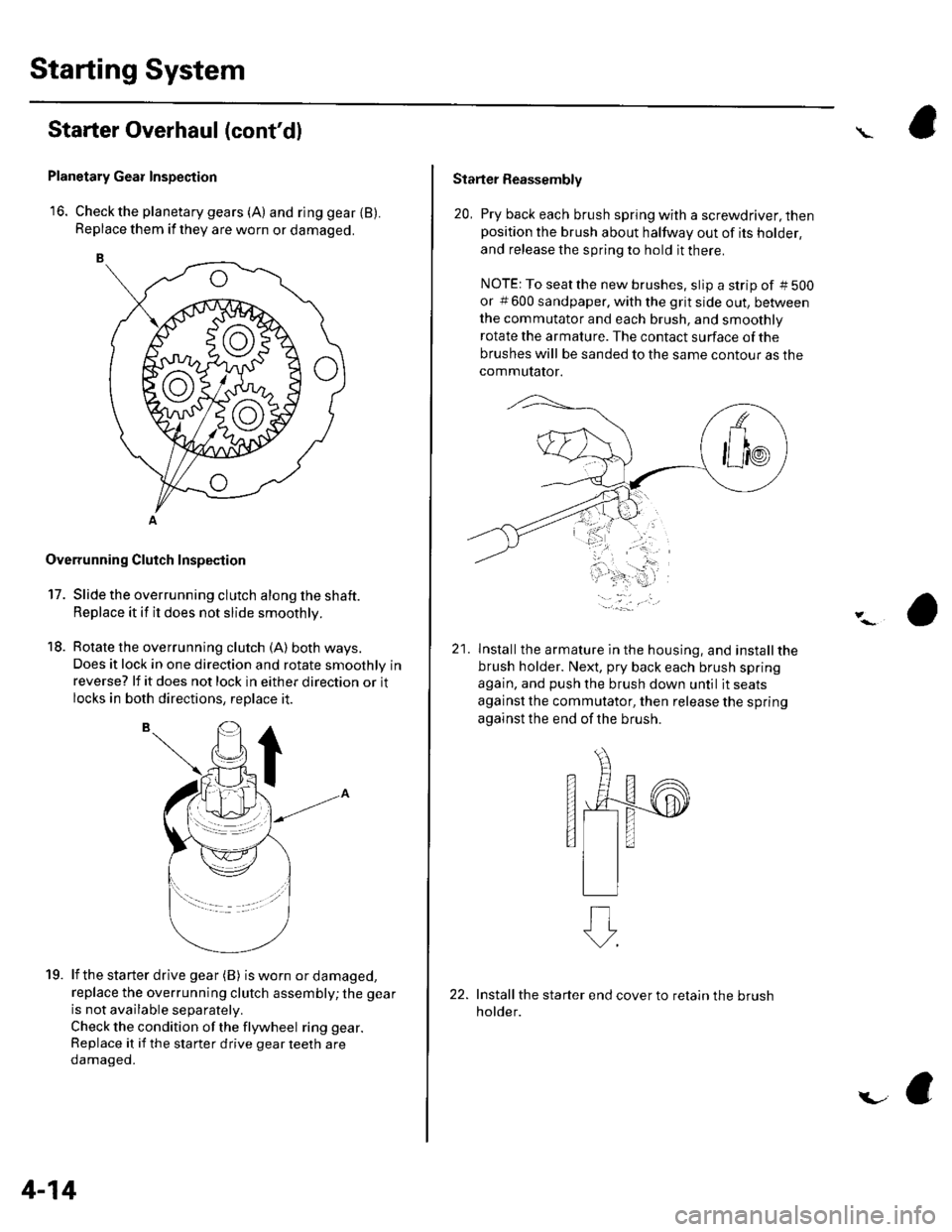

Planetary Gear Inspection

16. Check the planetary gears (A) and ring gear {B).Replace them if they are worn or damaged.

Overrunning Cluich Inspection

17. Slide the overrunning clutch along the shaft.

Replace it if it does not slide smoothly.

18. Rotate the overrunning clutch (A) both ways.

Does it lock in one direction and rotate smoothly inreverse? lf it does not lock in either direction or it

locks in both directions, replace it.

lf the starter drive gear (B) is worn or damaged,

replace the overrunning clutch assembly; the gear

is not available separately.

Check the condition of the flywheel ring gear.

Replace it if the starter drive gear teeth are

oamageo.

19.

4-14

i.-

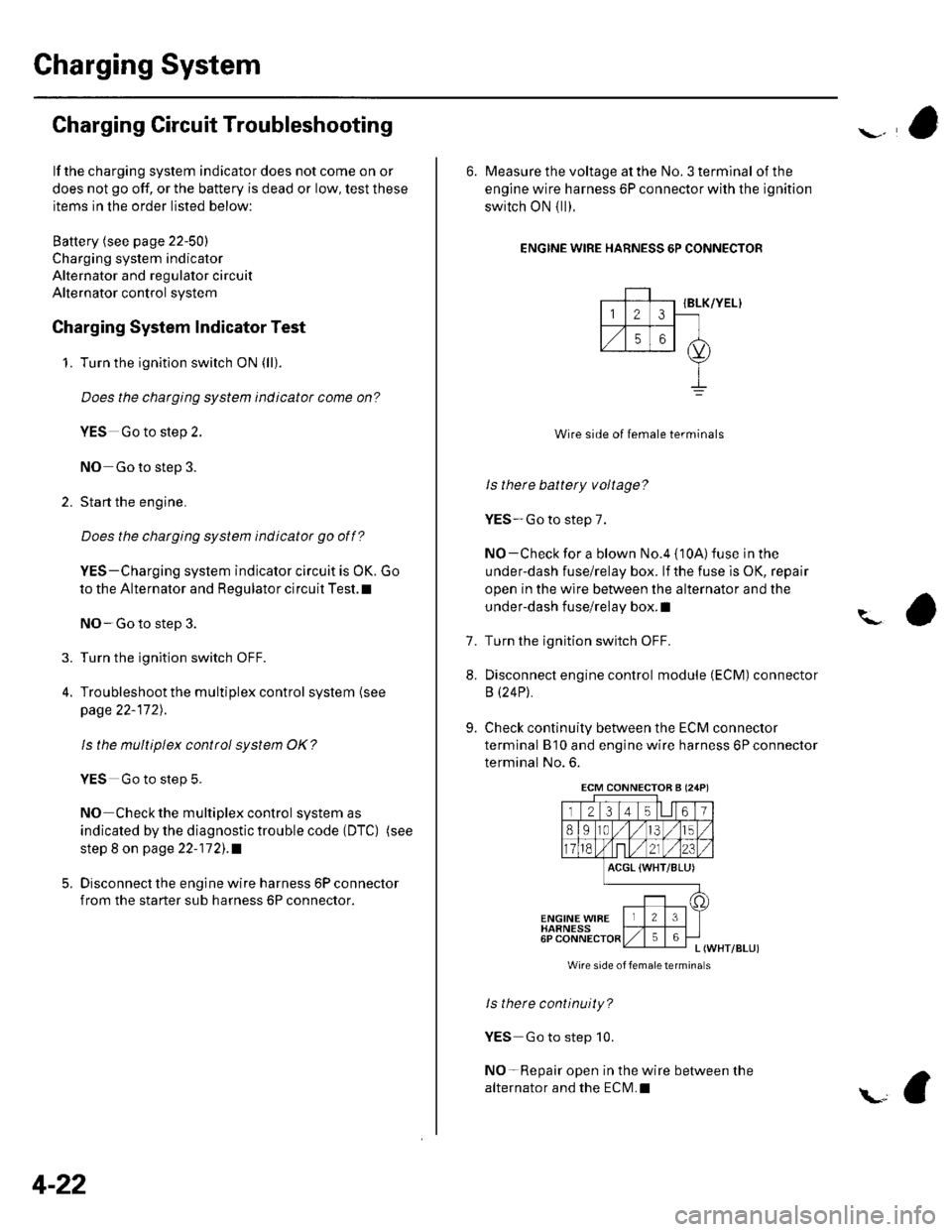

Starter Reassembly

20, Pry back each brush spring with a screwdriver, thenposition the brush about halfway out of its holder,

and release the spring to hold it there.

NOTE: To seatthe new brushes. slip a strip of #5OO

or # 600 sandpaper. with the grit side out, be&veen

the commutator and each brush, and smoothly

rotate the armature. The contact surface of the

brushes will be sanded to the same contour as the

commutator.

21lnstallthe armature in the housing, and installthe

brush holder. Next, pry back each brush spring

again, and push the brush down until it seats

against the commutator, then release the spring

against the end of the brush.

s

Install the starter end cover to retain the brush

holder.

Page 57 of 1139

Gharging System

Charging Circuit Troubleshooting

lf the charging system indicator does not come on or

does not go off, or the battery is dead or low, test these

items in the order listed below:

Battery (see page 22-50)

Charging system indicator

Alternator and regulator circuit

Alternator control system

Charging System Indicator Test

1. Turn the ignition switch ON {ll).

Does the chatging system indicator come on?

YES Go to step 2.

NO Go to step 3.

2. Start the engine.

Does the charging system indicator go off?

YES-Charging system indicator circuit is OK. Go

to the Alternator and Regulator circuit Test. t

NO-Go to step 3.

3. Turn the ignition switch OFF.

4. Troubleshoot the multiplex control system (see

page 22 172).

ls the multiplex control system OK?

YES Go to step 5.

NO Check the multiplex control system as

indicated by the diagnostic trouble code (DTC) (see

step 8 on page 22-172).1

5. Disconnect the engine wire harness 6P connector

from the starter sub harness 6P connector.

4-22

\"4

6. Measure the voltage at the No. 3 terminal of the

engine wire harness 6P connector with the ignition

switch ON { ll).

ENGINE WIRE HARNESS 6P CONNECTOR

IBLK/YEL}

Wire side of female terminals

ls there battery voltage?

YES-Go to step 7.

NO-Check for a blown No.4 {10A) fuse in the

under-dash fuse/relay box. lf the fuse is OK, repair

open in the wire between the alternator and the

under-dash fuse/relay box. I

Turn the ignition switch OFF.

Disconnect engine control module (ECM) connector

B (24P).

Check continuity between the ECM connector

terminal B'10 and engine wire harness 6P connector

terminal No. 6.

?

7.

8.

9.

ACGL {WHT/BLU)

ENGINE WIBEHARNESS6PL (WHT/BLUI

Wire side of femaletermina s

ls there continuity?

YES Go to step 10.

NO-Repair open in the wire between the

alternator and the ECN4.I

ECM CONNECTOB A (24P)

Page 58 of 1139

'10. Check continuity between the ECM connector

terminal 810 and body ground.

ECM CONNECTOR S I24PI

23 t4 t567

8I10,/1,/315

118,Nnt,/2123

ACGL (WHT/BLUI

t1'

Wire side ol female terminals

ls there continuity?

YES- Repair short to ground in the wire between

the ECM and the engine wire harness 6P connector.

t

NO-Go to alternator and regulator test.

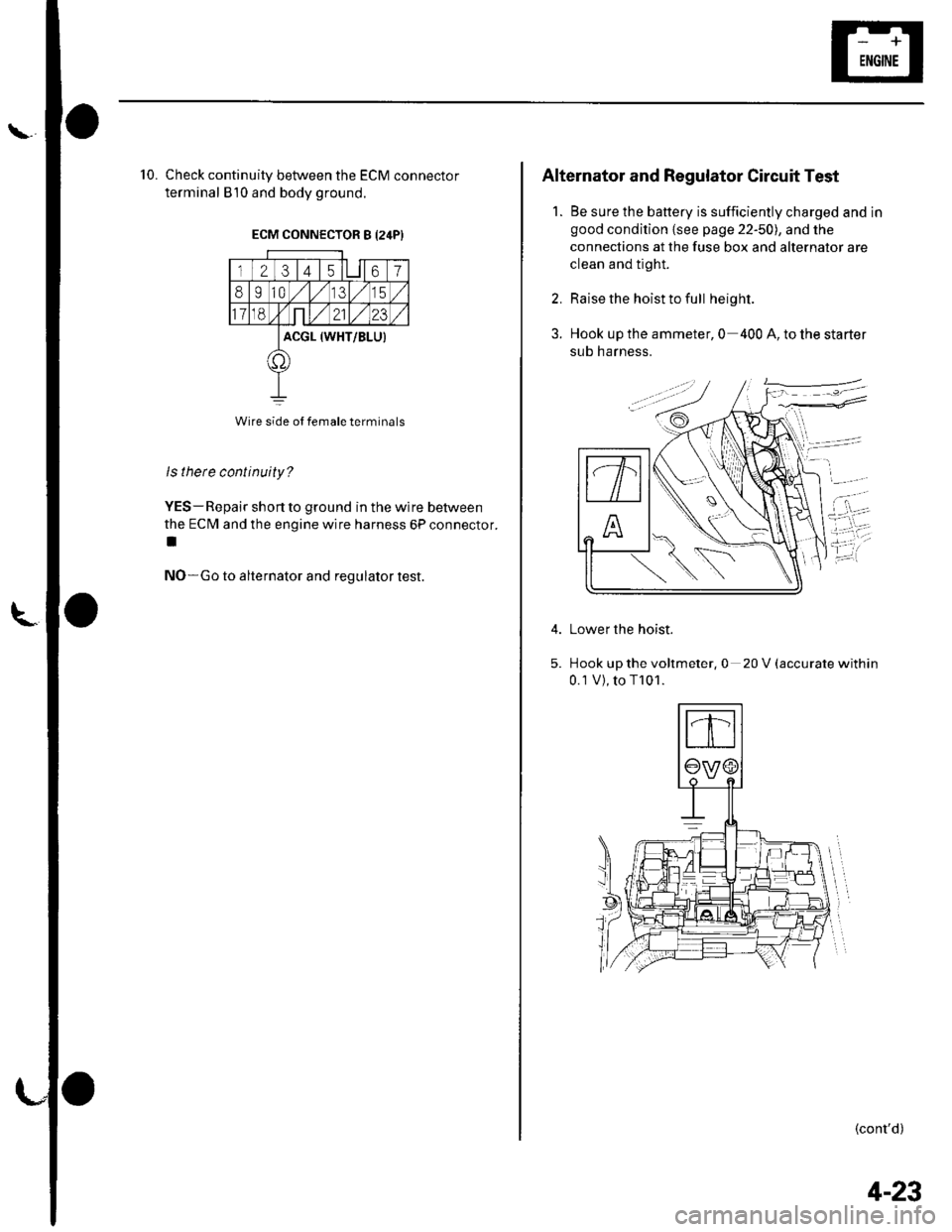

Alternator and Regulator Circuit Test

1. Be sure the battery is sufficiently charged and in

good condition {see page 22-50), and the

connections at the fuse box and alternator are

clean and tight.

2. Raise the hoist to full height.

3. Hook up the ammeter, 0 400 A, to the starter

sub harness.

Lower the hoist.

Hook up the voltmeter, 0 20 V (accurate within

0.1V),toT101.

(cont'd)

4-23

Page 59 of 1139

Gharging System

Charging Circuit Troubleshooting (cont'd)

6. Start the engine. Hold the engine at 3,000 rpm with

no load (in Neutral) until the radiator fan comes on,

then let it idle.

7. Raise the engine speed to 2,000 rpm, and hold it

there.

8. Turn the headlights (high beam) on, and measure

voltage at the under-hood fuse/relay box terminal.

ls the voltage between 13.9 and 15.1 v?

YES-Go to step 9.

NO Repair or replace the alternator components

(see page 4-30).1

9. Read the amperage at '13.5 V.

NOTE: Adjust the voltage by turning the blower

motor, rear window defogger, brake lights. etc. ON.

ls the amperage 604 ot morc?

YES-Alternator/regulator operation is OK. I

NO Repair or replace the alternator components(see page 4-30).1

4-24

\,

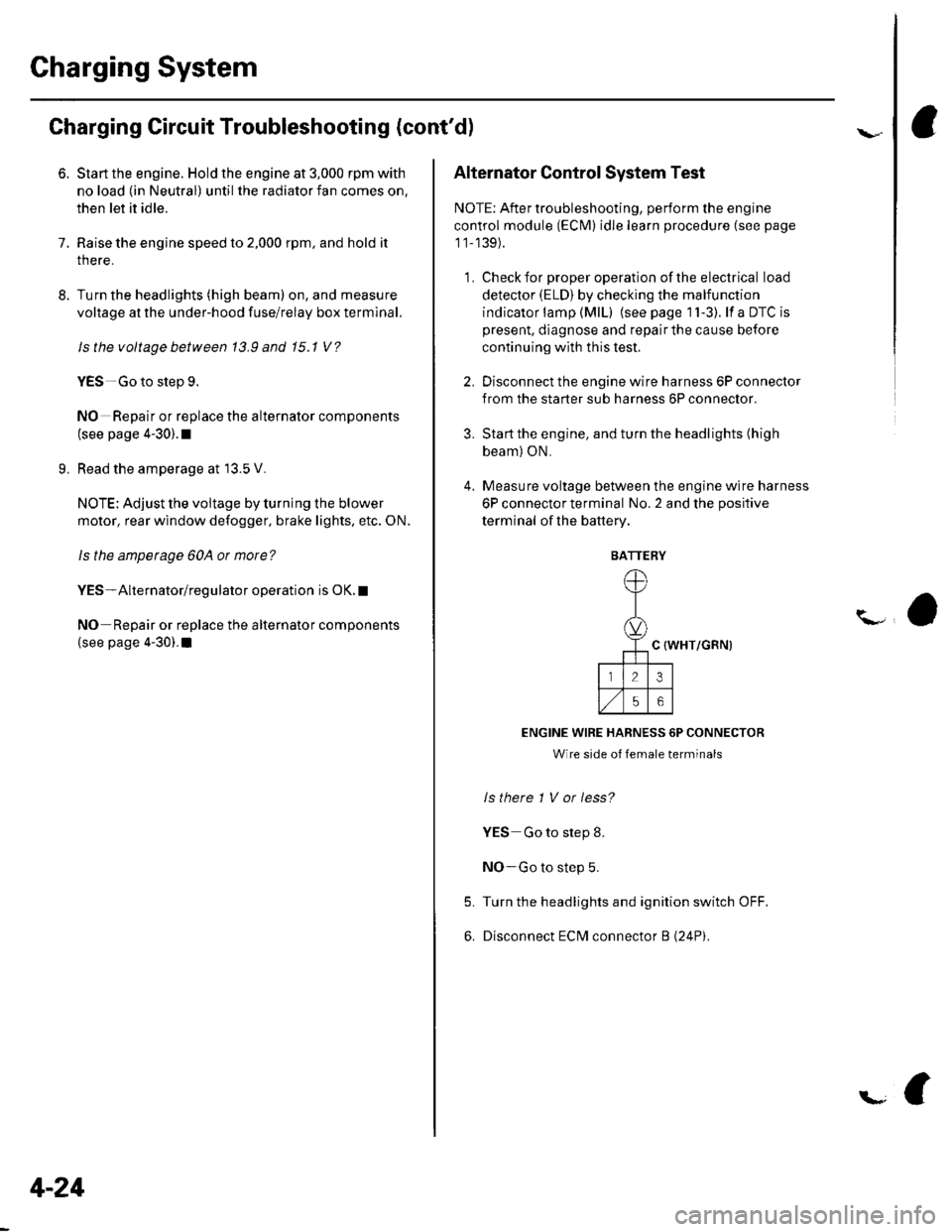

Alternator Control System Test

NOTE: After troubleshooting, perform the engine

control module (ECM) idle learn procedure (see page

11-139).

1 . Check for proper operation of the electrical load

detector (ELD) by checking the malfunction

indicator lamp (MlL) (see page 1 l-3). lf a DTC is

present, diagnose and repair the cause before

continuing with this test.

2. Disconnect the engine wire harness 6P connector

from the starter sub harness 6P connector.

3. Start the engine, and turn the headlights (high

beam) ON,

4. Measure voltage between the engine wire harness

6P connector terminal No. 2 and the positive

terminal of lhe battery.

C {WHT/GRN)

ENGINE WIRE HARNESS 6P CONNECTOR

Wire side of female terminals

ls there 1 V or less?

YES Go to step 8.

NO-Go to step 5.

Turn the headlights and ignition switch OFF.

Disconnect ECM connector B (24P).

5.

6.

BATTERY

Page 60 of 1139

\

L

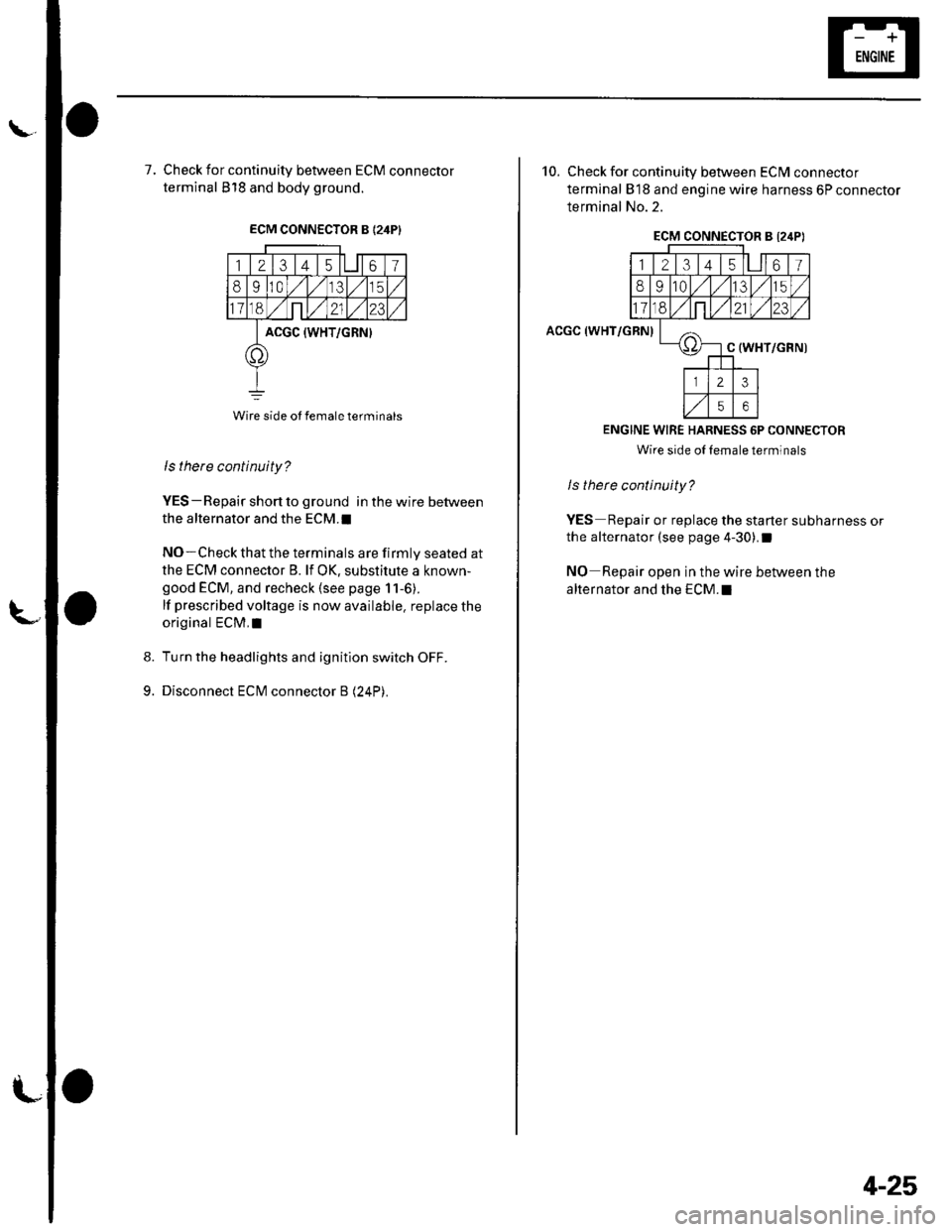

7, Check for continuity between ECM connector

terminal 818 and body ground.

ECM CONNECTOR B {24PI

123 t4 t561

8910,/1,/35

11ont,/2123

ACGC {WHT/GRN}

o

Wire side ot female terminals

9.

ls there continuity?

YES-Repair short to ground in the wire between

the alternator and the ECM.I

NO-Check that the terminals are firmly seated at

the ECM connector B. lf OK, substitute a known-

good ECM, and recheck (see page 11-6).

lf prescribed voltage is now available. replace the

original ECM,I

Turn the headlights and ignition switch OFF.

Disconnect ECM connector B (24P).

10. Check for continuity between ECM connector

terminal 818 and engine wire harness 6P connector

terminal No.2.

ACGC (WHT/GRN)

ECM CONNECTOR B l2,lPI

12314l5lll67

8910t.)15

11on2123

oC (WHT/GRN)

23

56

ENGINE WIRE HARNESS 6P CONNECTOR

Wire side oI lemale terminals

ls therc continuity?

YES Repair or replace the starter subharness or

the alternator (see page 4-30).I

NO Repair open in the wire between the

alternator and the ECM.I

4-25

Page 95 of 1139

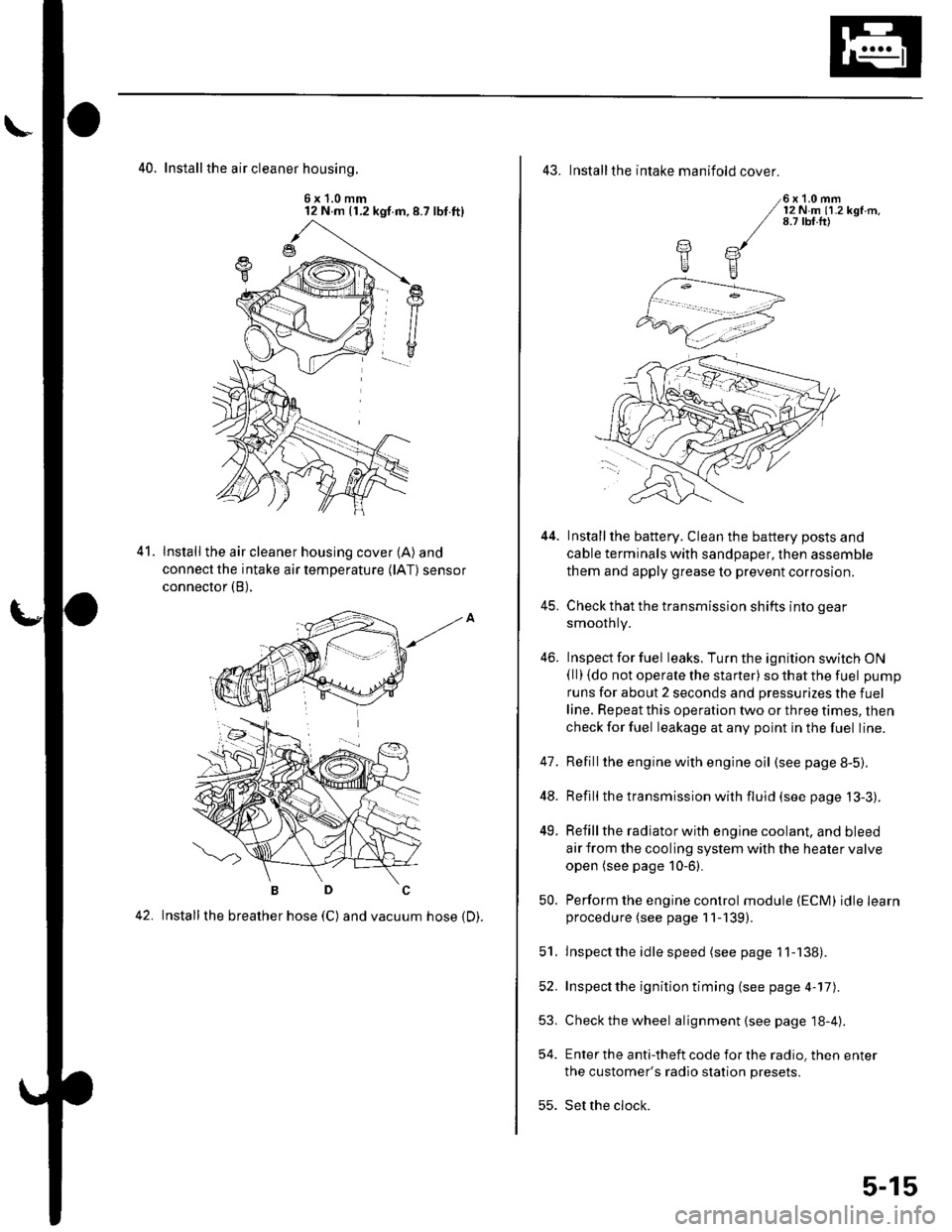

40. Install the air cleaner housinq.

6x1.0mm12 N m (1.2 kgf.m,8.7 lbt.ft)

Install the air cleaner housing cover (A) and

connect the intake air temperature (lAT) sensor

connector (B),

42. Installthe breather hose (C) and vacuum hose 1D).

41.

43. Installthe intake manifold cover.

6x1.0mm12Nm11.2kgf.m.8.7 tbf.ft)

Installthe battery. Clean the battery posts and

cable terminals with sandpaper, then assemble

them and apply grease to prevent corrosion.

Check that the transmission shifts into gear

smoothly.

Inspect for fuel leaks. Turn the ignition switch ON(ll) {do not operate the starter) so that the fuel pump

runs for about 2 seconds and pressurizes the fuel

line. Repeat this operation two or three times, then

check for fuel leakage at any point in the fuel line.

Refillthe engine with engine oil (see page 8-5).

Refill the transmission with fluid (see page 13-3).

Refill the radiator with engine coolant, and bleed

air from the cooling system with the heater valve

open (see page 10-6).

Perform the engine control module (ECM) idle learnprocedure (see page 11-139).

Inspect the idle speed (see page 1 1-138).

Inspect the ignition timing (see page 4-17).

Check the wheel alignment {see page 18-4).

Enter the anti-theft code for the radio, then enter

the customer's radio station presets.

Set the clock.

YE

44.

41.

]tE

46.

48.

49.

52.

53.

54.

50.

51.

55.

5-15