starter HONDA CIVIC 2003 7.G Owner's Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 2003, Model line: CIVIC, Model: HONDA CIVIC 2003 7.GPages: 1139, PDF Size: 28.19 MB

Page 101 of 1139

Cylinder Head

Engine Compression Inspection

1. Warm up the engine to normal operating

temperature (cooling fan comes on).

2. Turn the ignition switch OFF.

3. Remove the intake manifold cover (see step 1 onpage 6-22).

4, Disconnect all four injector connectors.

5. Start the engine, and let it run until it stalls.

6. Remove the iour ignition coils (see page 4-18).

7. Remove the four spark plugs.

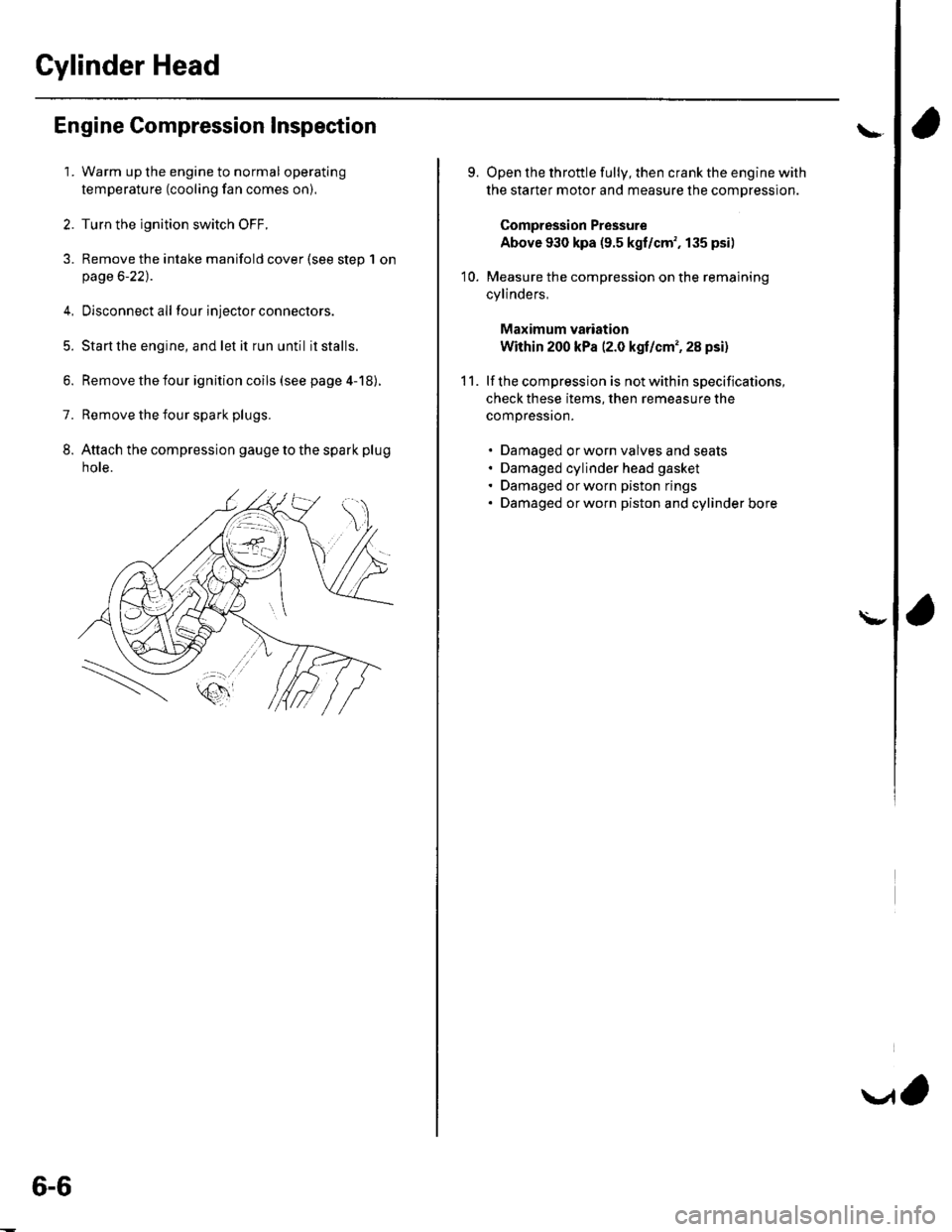

8. Attach the compression gauge to the spark plug

note.

6-6

V,

\

9.

10.

Open the throttle fully, then crank the engine with

the starter motor and measure the compression.

Compression Pressure

Above 930 kpa (9.5 kgf/cm', 135 psi)

Measure the compression on the remaining

cylinders,

Maximum vadation

Within 200 kPa (2.0 kgf/cm', 28 psi)

lf the compression is not within specifications,

check these items, then remeasure the

compressron.

. Damaged orworn valves and seats. Damaged cylinder head gasket. Damaged or worn piston rings. Damaged orworn piston and cylinder bore

11.

\-

Page 136 of 1139

14. Installthe water bvpass hose.

15. Installthe air cleaner housing (see step 37 on page

5-15).

16. Installthe intake manifold (see page 9-5).

17. Installthe exhaust manifold (see page 9-7).

'18. Installthe cam chain (see page 6-15).

19. Adjust the valve clearance (seepage6-9).

20. Installthe drive belt (see page 4-26).

21. Clean the battery posts and cable terminals with

sandpaper, then assemble them and apply grease

to prevent corrosion.

22. After installation, checkthatall tubes, hosesand

connectors are installed correctly.

23. Inspectforfuel leaks. Turn the ignition switch ON

{ll) {do not operate the starter) so that the fuel pump

runs for about 2 seconds and pressurizes the fuel

line. Repeat thls operation two or three times, then

check for fuel leakage at any point in the fuel line.

24. Refillthe radiator with engine coolant, and bleed

air from the cooling system with the heater valve

open (see page 10-6).

25. Inspect the idle speed (see page 11-'138).

26. Inspect the ignition timing (see page 4-17).

Gylinder Head Cover lnstallation

1. Thoroughly clean the head cover gasket and the

groove.

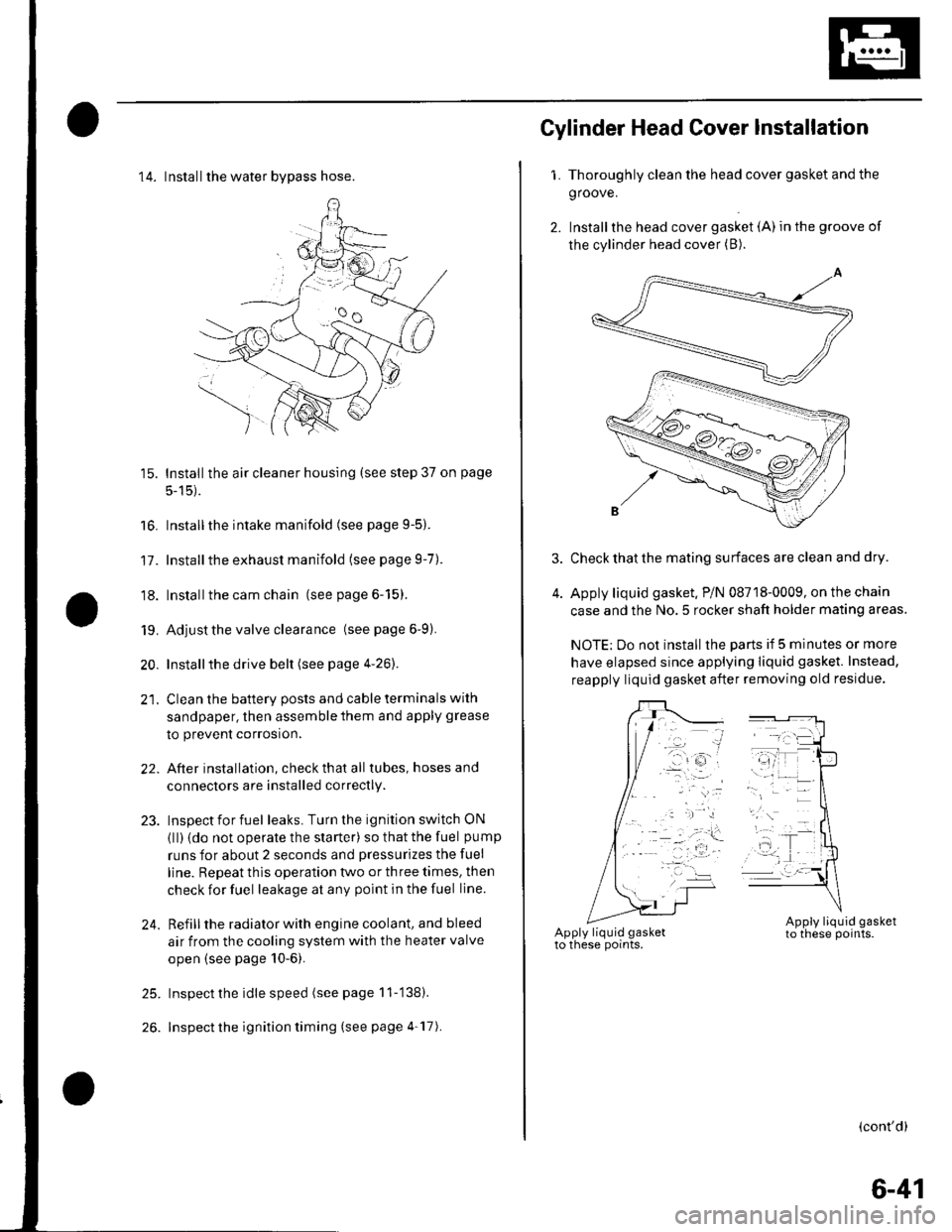

2. Installthe head cover gasket (A) in the groove of

the cylinder head cover (B).

Check that the mating surfaces are clean and dry.

Apply liquid gasket. P/N 08718-0009, on the chain

case and the No.5 rocker shaft holder mating areas.

NOTE: Do not install the parts if 5 minutes or more

have elapsed since applying liquid gasket. Instead,

reapply liquid gasket after removing old residue.

(cont'd)

6-41

Page 188 of 1139

lntake Manifold and Exhaust System

Intake Manifold Removal and Installation (cont'd)

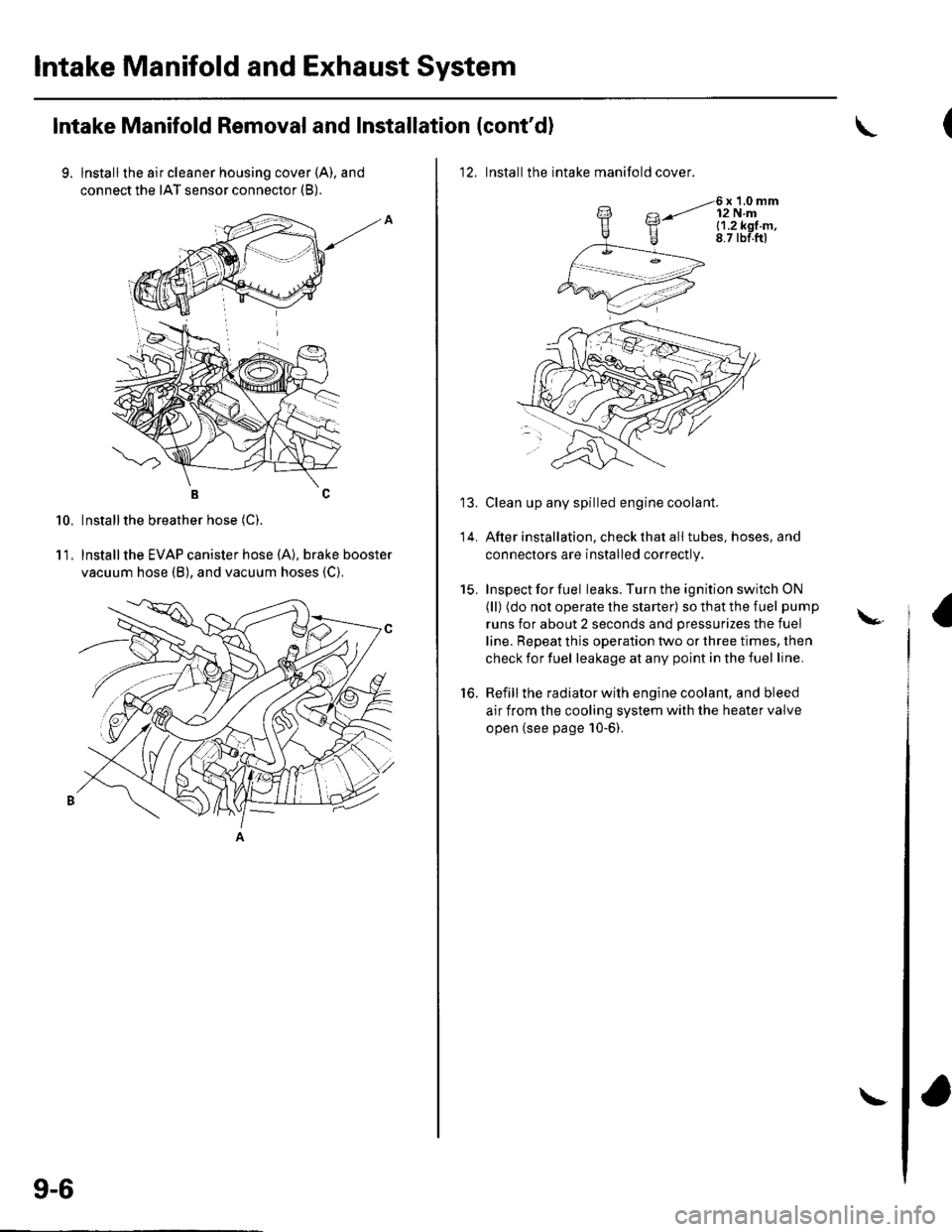

9. lnstallthe air cleaner housing cover (A), and

connect the IAT sensor connector (B).

BC

Installthe breather hose (C).

lnstallthe EVAP canister hose (A), brake booster

vacuum hose (B), and vacuum hoses {C).

10.

11.

9-6

\

12. Installthe intake manifold cover.

6x1.0mm12 N.ml.1.2k91.m,8.7 tbf.ftl

Clean up any spilled engine coolant.

After installation, check that all tubes, hoses, and

connectors are installed correctly.

Inspect for fuel leaks. Turn the ignition switch ON

(ll) (do not operate the starter) so that the fuel pump

runs for about 2 seconds and pressurizes the fuel

line. Repeat this operation two or three times, then

check for fuel leakage at any point in the fuel line.

Refill the radiator with engine coolant, and bleed

air from the cooling system with the heater valve

open (see page 10-6).

to.

\-

Page 217 of 1139

Fuel and Emissions Systems

Symptom Troubleshooting Index

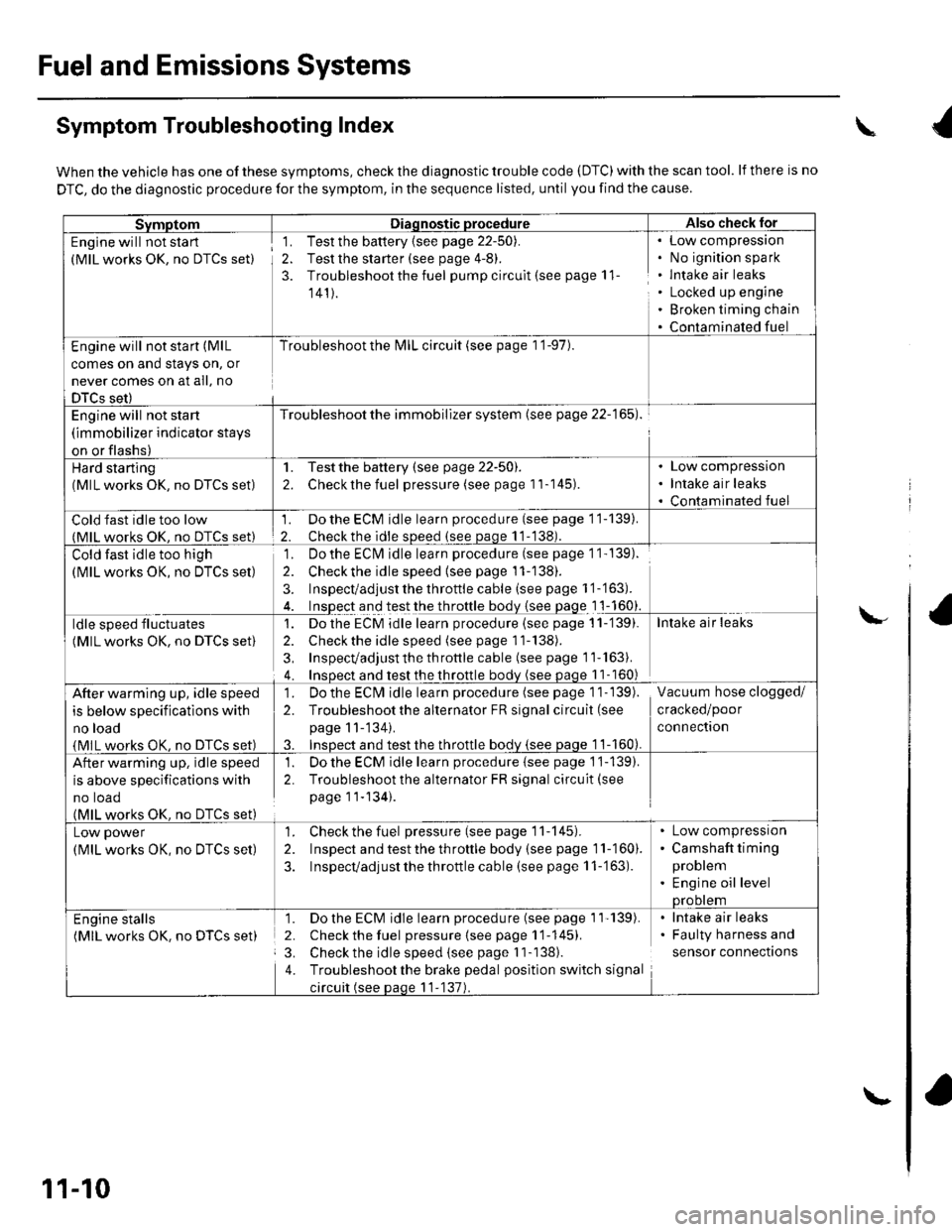

When the vehicle has one of these symptoms, check the diagnostic trouble code (DTC) with the scan tool. lf there is no

DTC, do the diagnostic procedure for the symptom, in the sequence listed, until you find the cause.

SvmotomDiaqnostic procedureAlso check lor

Engine will not sta rt

(MlL works OK, no DTCS set)

1. Test the battery {see page 22-50).

2. Test the starter (see page 4-8).

3. Troubleshoot the fuel pump circult (see page 11

141).

Low compressron

No ignition spark

lntake air leaks

Locked up engine

Broken timing chain

Contaminated fuel

Engine will not start (MlL

comes on and stays on, or

never comes on at all, no

DTCS set)

Troubleshoot the l\4lL circuit (see page 1 '1-97).

Engine will not start

(immobilizer indicator stays

on or flashs)

Troubleshoot the immobilizer system (see page 22-165).

Hard starting(MlL works OK, no DTCS set)

1. Testthe battery (see page 22-50).

2. Checkthe fuel pressure (see page 11-145).

Low compression

Intake air leaks

Contaminated fuel

Cold fast idle too low(MlL works OK. no DTCS set)

1. Do the ECM idle learn procedure (see page 11-139).

2. Checkthe idle sDeed (see paqe 11-138).

Cold fast idle too high

(MlL works OK, no DTCS set)

Do the ECI\4 idle learn procedure (see page 1 1- 139).

Checkthe idle speed {see page 11-138).

Inspect/adjust the throttle cable (see page 1 '1-'163).

Inspect and test the throttle body {see page 1 1-160}.

']�

2.

3.

ldle speed fluctuates

(MlL works OK, no DTCS set)

1. Dothe ECM idle learn procedure (see page 11-'139).

2. Check the idle speed (see page 11-138).

3, Inspecvadjust th e throttle cable (see page 11''163).

4. Insoect and test the throttle bodv (see paqe 11- 160)

Intake air leaks

After warming up, idle speed

is below specifications with

no load

{MlL works OK, no DTCS set)

1. Do the ECIVI idle learn procedure (see page 1 1- 139).

2. Troubleshootthe alternator FR signal circuit (see

page 11-'134).

3. InsDect and test the throttle bodv {see paqe 1 1-160).

Vacuum hose clogged/

cracked/poor

connectron

After warming up, idle speed

is above specifications with

no toao(MlL works OK. no DTCS set)

1. Do the ECM idle learn procedure {see page 1'j-139).

2. Troubleshoot the alternator FR signal circuit(see

page 11-134).

Low power

(MlL works OK, no DTCS set)

1. Check the fuel pressure(seepagell-145).

2. Inspect and test the th roftle body (see page 11-160).

3. Inspecvadjust the throttle cable (see page 11-'163).

Low compressron

Camshaft timing

problem

Engine oil levelprootem

Engine stalls(MlL works OK. no DTCS set)

1. Do the ECM idle learn procedure (see page 1'l'139).

2. Check the fuel pressure{seepagell-145).

3. Check the idle speed (see page I 1-138).

4. Troubleshootthe brake pedal position switch signal

circuit (see paqe 11-137).

lntake air leaks

Faulty harness and

sensor connections

\

\-

11-10

\-

Page 284 of 1139

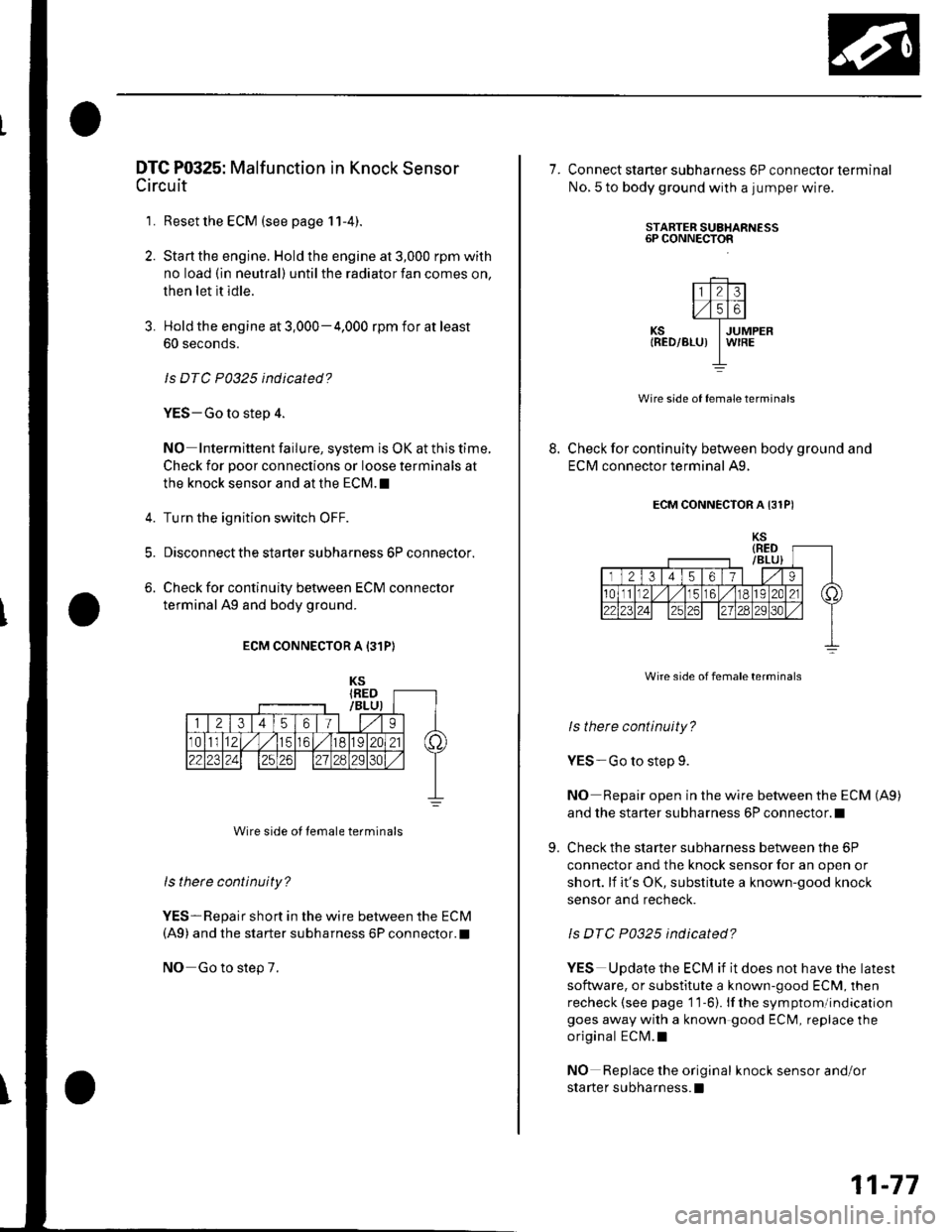

DTG P0325: Malfunction in Knock Sensor

Circu it

1. Reset the ECM (see page 11-4).

2. Start the engine. Hold the engine at 3,000 rpm with

no load (in neutral) until the radiator fan comes on,

then let it idle.

3. Hold the engine at 3,000-4,000 rpm for at least

60 seconds.

ls DTC P0325 indicated?

YES-Go to step 4.

NO Intermittent failure, system is OK at this time.

Check for poor connections or loose terminals at

the knock sensor and at the ECM.I

4. Turn the ignition switch OFF.

5. Disconnect the starter subharness 6P connector.

6. Check for continuity between ECM connector

terminal Ag and body ground.

ECM CONNECTOR A 131P)

Wire side of lemale terminals

ls there continuity?

YES-Repair short in the wire between the ECM(A9) and the starter subharness 6P connector.l

NO Go to step 7.

7. Connect staner subharness 6P connector terminal

No. 5 to body ground with a jumper wire.

8.

STARTER SUAHARNESS6P CONNECTOR

l1l213ll,/l5l6l._

KS IJUMPER|RED/BLU) IW|REI

Wire side of female terminals

Check for continuity between body ground and

ECM connector terminal A9.

9.

ECM CONNECTOR A {31PI

Wire side of female terminals

ls there continuity?

YES-Go to step 9.

NO Repair open in the wire between the ECM (A9)

and the starter subharness 6P connector.l

Check the starter subharness between the 6P

connector and the knock sensor for an open or

short. lf it's OK, substitute a known-good knock

sensor and recheck.

ls DTC P0325 indicated?

YES Update the ECM if it does not have the latest

software. or substitute a known-good ECM, then

recheck {see page '11-6). lf the sym ptomlindication

goes away with a known good ECM, replace the

original ECM.I

NO Replace the original knock sensor and/or

sta rte r subharness.l

11-77

Page 319 of 1139

PGM-FI System

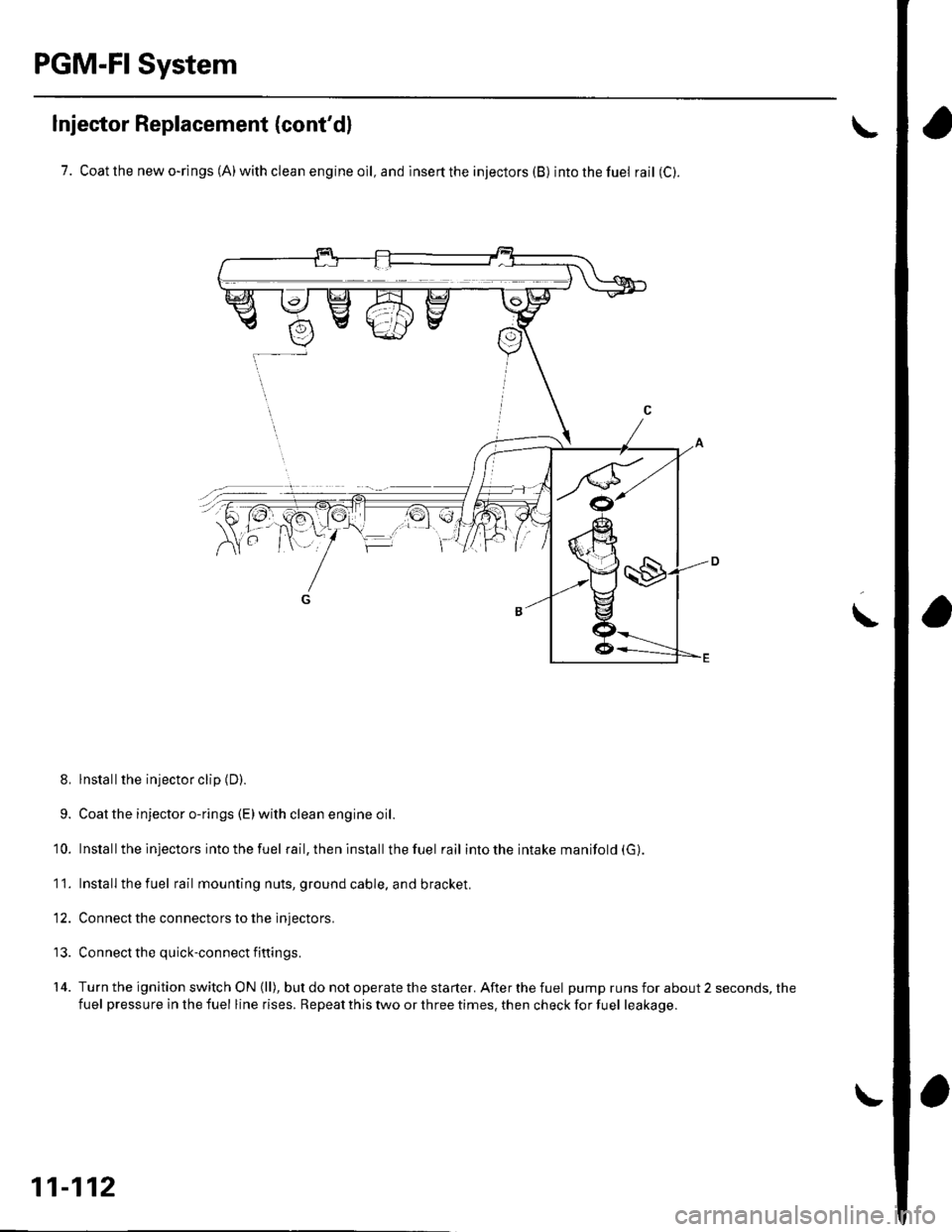

Injector Replacement (cont'd)

7. Coatthenewo-rings(A)withcleanengineoll,andinserttheinjectors(B) intothefuel rail (C).

8, lnstall the injector clip {D).

9. Coat the injector o-rings (E)with clean engine oil.

10. Installthe injectors intothefuel rail, then install the fuel rail intotheintakemanifold(G).

1 '1. Install the fuel rail mounting nuts, ground cable. and bracket.

12. Connect the connectors to the injectors.

13. Connect the quick-connect fittings.

14. Turnthe ignition switch ON (ll), butdo notoperatethe starter. Afterthefuel pump runs for about 2 seconds, the

fuel pressure in the fuel line rises. Repeat this two or three times. then check for fuel leakage.

\

11-112

Page 844 of 1139

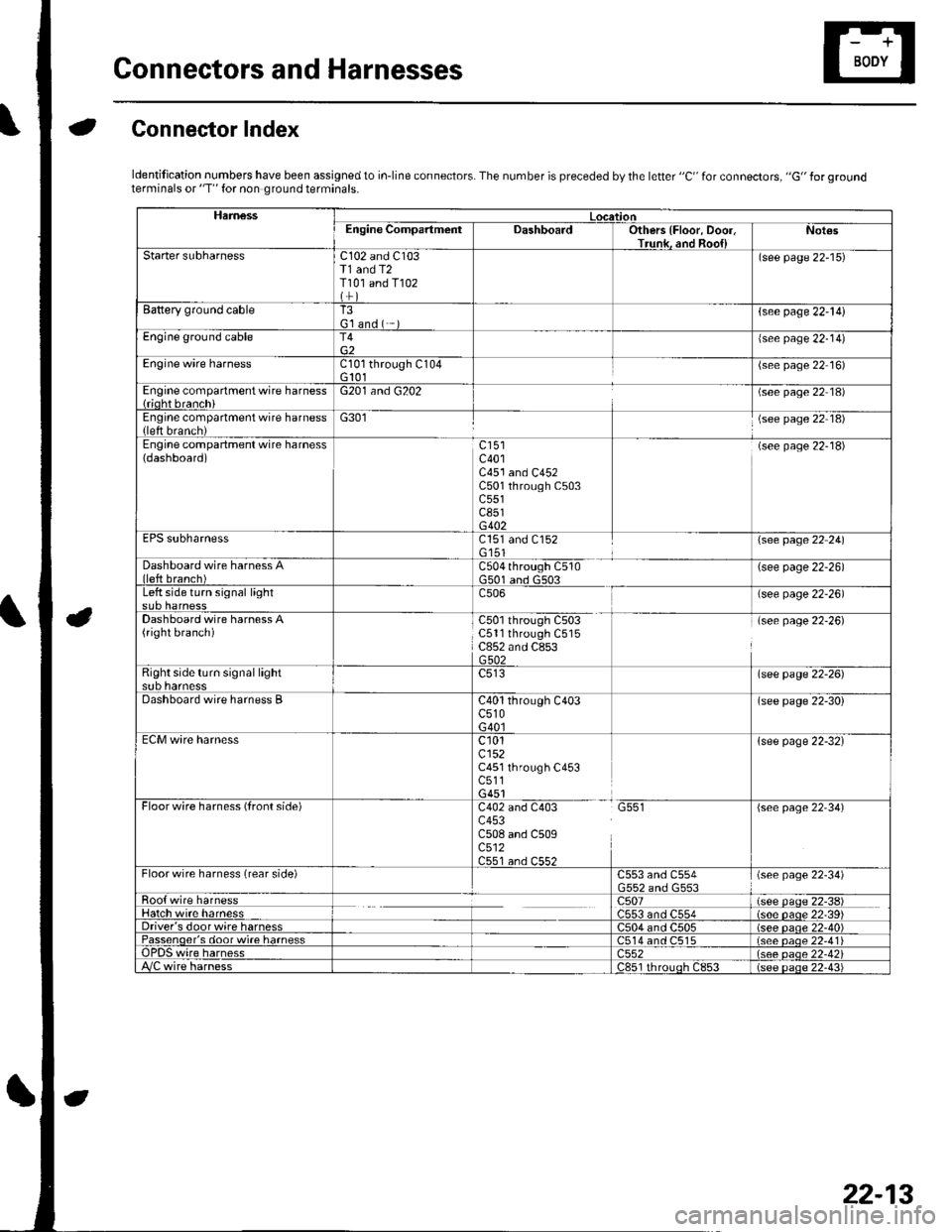

Gonnectors and Harnesses

aGonnector Index

ldentification numbers have been assigned to in-line connectors. The number is preceded by the letter "C" for connectors, "G" for groundterminals or "T" for non ground terminals.

HamessLocationEngine CompartmentDashboardOthers {Floor, Door,Trunk. and Roo{lNot€s

Starter subharnessC102 and C103T1 and T2T101 and T102

(see page 22-15)

Battery ground cableT3G'l and ( -{see page 22-l!)

Engine ground cableT4{see page 22-14)

Engine wire harnessCl0l through C104G 101(see page 22 16)

Engine compartment wire harness{rioht branchiG201 and G202(see page 22 18)

Engine compartment wire harness(left brench)G301(see page 22 18)

Engine compartment wire harness(dashboard)c401C451 and C452C501 through C503c551c851G402

(see page 22-18)

EPS subharnessC151 and C152G'151\see page 22 241

Dashboard wire harness Alleft branch)C504 through C510G501 and G503(see page 22-26)

Left side turn signal lightc506(see page 22-26)

Dashboard wire harness A(right branch)C50l through C503C5ll through C515C852 and C853G502

(see page 22-26)

Right side turn si9nal lightsub harnesslsee page 22-26)

Dashboard wire harness BC40l through C403c510G40l

(see page 22-30)

ECM wire harnessc101cl52C451 through C453c511G451

{see page 22-32}

Floorwire harness (front side)C402 and C403 G551c453C508 and C509c512C551 an.l C55?

(see page 22'34)

Floor wire harness (rear side)C553 and C554(see page 22-34)

Roo{ wire harnessc507(see paqe 22-38)Hatch wire harnessC553 and C554(s6e paqe 22'39)Driver's door wire harnessC504 and C505(see paqe 22-40)Passenqer's door wi.e harness514 and C515(see oaoe 22-41Te harness)552(see oaqe 22-42i/C wire harnessc851 rhrouoh c853(see paqe 22.43i

22-13

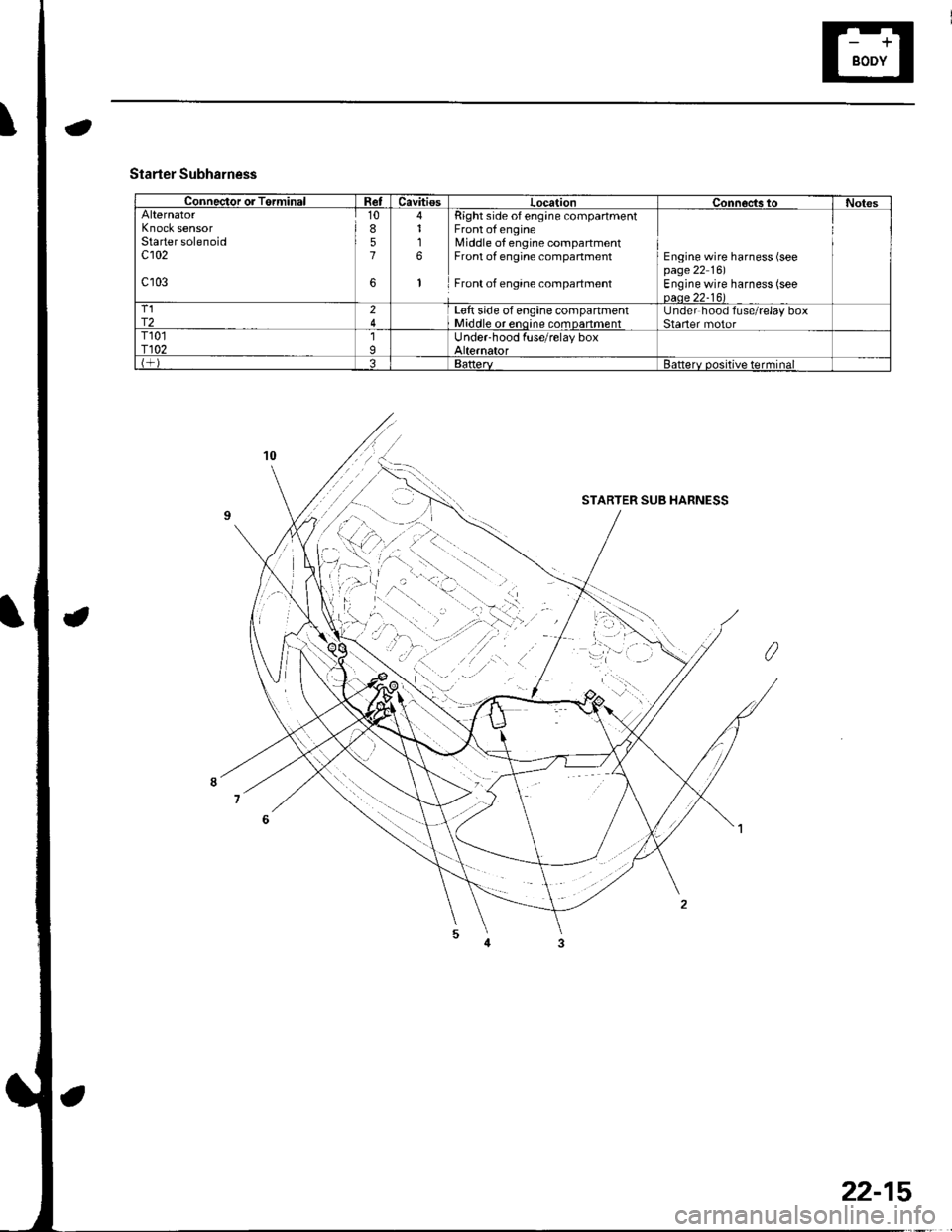

Page 846 of 1139

Connector or TerminalRetCavitiesLocationConnoc,ts toNotesAlternatorKnock sensorStarter solenoidc102

c103

10857

6

4116

1

Right side of eng;ne compartmentFront of engineMiddle of engine compartmentFront of engine compartment

Front of engane compartment

Engine wire harness (seepage 22 16)Engine wire harness (seeoaae 22-16)T1r224L€tt side of engine compartmentMiddle or enoine comDanmentUnder hood fuse/relay boxStaner motorT101r1021IUnder-hood fuse/relay boxAlternatorBattervBatterv positive terminal

Starter Subharness

STARTER SUB HARNESS

22-15

Page 847 of 1139

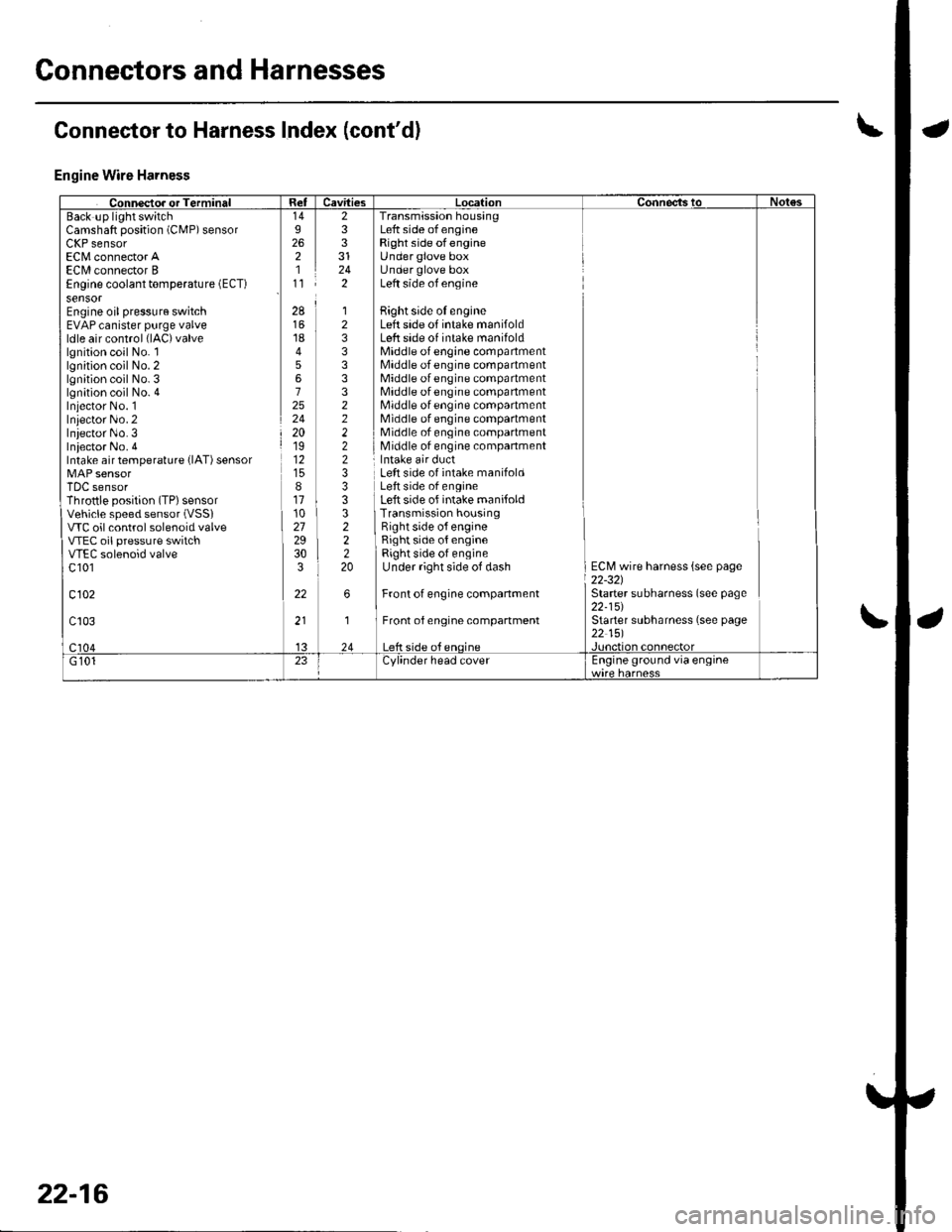

Connectors and Harnesses

Engine Wire Harness

Camshaft position (CMP) sensorLllr sensorEC[,4 connector AECI/l connector BEngine coolant temperature (ECT)

sensorEngine oil pressure switchEVAP canister purge valveldle air control (lAC)valve

lgnition coil No. llgnition coil No. 2lgnition coil No. 3lgnition coil No. 4Iniector No. 1Inlector No.2Iniector No.3Iniector No. 4Intake air temperature {lAT) sensor

TDC sensorThrottle position (TP) sensorVehicle speed sensor (VSSI

VTC oil control solenoid valveVTEC oil pressure switchVTEC solenoid valvec 101

c102

233

242

Transmission housingLeft side of engineRight side ofengineUnder glove boxUnder glove boxLeft side of engine

Bight side oI engineLeft side of intake manifoldLeft side of intake manifoldMiddle of engine compartmentMiddle of engine compartmentMiddle of engine compartmentMiddle of engine compartmentMiddle of engine compartmentMiddle of engine compartmentMiddle of engine compartmentMiddle of engine companment

28

1845672524201912

811102729303

22

12333332222233

322220

Left side of intake manifoldLeft side of engineLeft side of intake manifoldTransmission housingRight side o{ engineRight side of engineRight side of engineUnder right side of dash

Front of engine companment

Front of engine compartment

ECM wire harness {see page22-321Starter subharness (see page22-15)Starter subharness (see page22 151

Connector to Harness Index (cont'dl

22-16

Page 875 of 1139

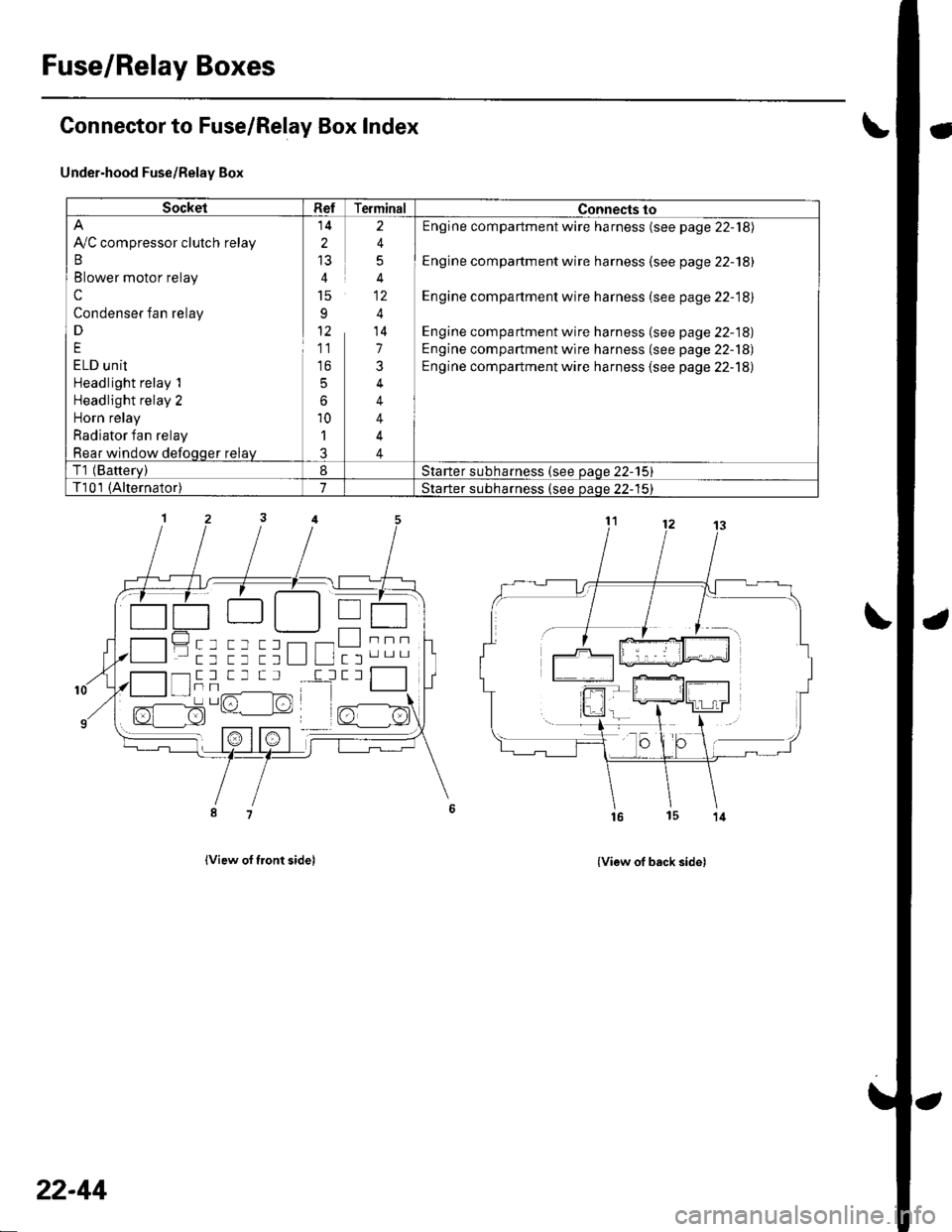

Fuse/Relay Boxes

Connector to Fuse/Relay Box Index

Under-hood Fuse/Relay Box

lview of tront sidel

- a-------) | | T---r .-:-tt || tL__.1 | I

------tttL""tt tt ttL lL ltl'".-

{View of back side)

SocketRefTerminalConnects to

Ay'C compressor clutch relay

B

Blower motor relay

c

Condenser fan relay

D

E

ELD unit

Headlight relay 1

Headlight relay 2

Horn relay

Radiator fan relay

Rear window defoqqer relay

14

2

15

91'

11

to

5

6

10'l

J

2

4

5

4

4

14

7

3

4

4

4

4

Engine compartment wire harness (see page 22-18)

Engine compartment wire harness (see page 22-18)

Engine compartment wire harness (see page 22-18)

Engine compartment wire harness (see page 22-18)

Engine compartment wire harness (see page 22-18)

Engine compartment wire harness {see page 22-18)

T1 (Batterv)8Starter subharness (see oaqe 22-15)

T101 (Alternator)7Starter subharness {see oaoe 22-'15}

""""-l- tr -l T _l T Il

I tTt Tr,/^-------lFrr^l -/1-l sz- l:!)L' lrt

22-44