COIL HONDA CIVIC 2003 7.G Owner's Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 2003, Model line: CIVIC, Model: HONDA CIVIC 2003 7.GPages: 1139, PDF Size: 28.19 MB

Page 280 of 1139

16.Test-drive the vehicle for several minutes in the

range of the freeze data or under various

conditions if there was no freeze data.

Check for a DTC or a Temporary DTC with the scan

Tool.

ls DTC or Temporary DTC P0301, P0302, P0303

or P0304 indicated?

YES Go to step 18.

NO lntermittent misfire due to bad contact at the

injector connector (no misfire at this time). Make

sure the injector connection is secure. Check for

poor connections or loose terminals at the

injector.l

Determine which cylinder(s) had the misfire.

Does the misf ire occur in the cylinder where the

i njector w as exchanged ?

YES- Replace the faulty injector.I

NO-Go to step 19.

Turn the ignition switch OFF.

Disconnect the ignition coil 3P connector from the

problem cylinder.

Turn the ignition switch ON (ll).

't7 .

18.

19.

20.

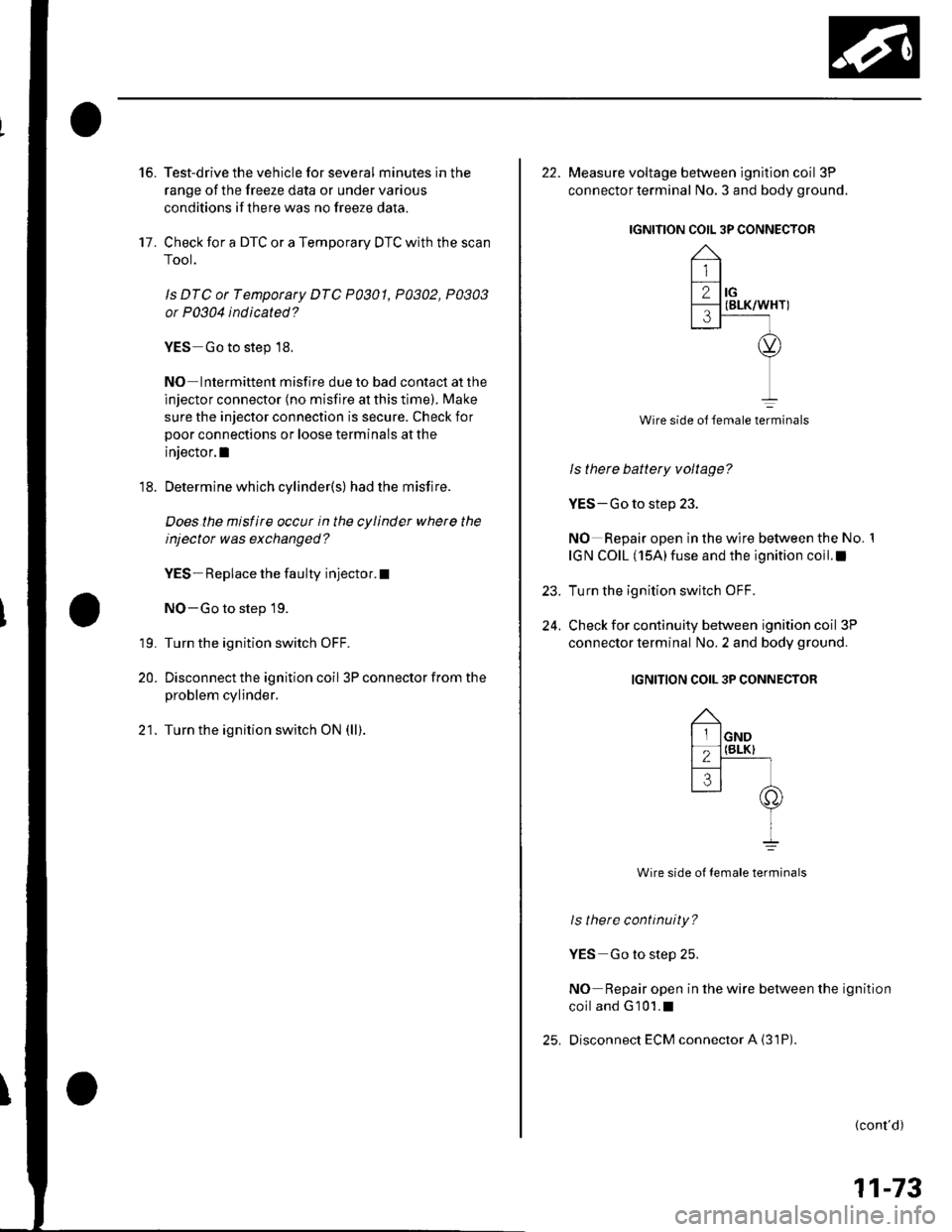

22. Measure voltage between ignition coil 3P

connector terminal No. 3 and body ground.

IGNITION COIL 3P CONNECTOR

Wire side ol female terminals

ls there battery voltage?

YES-Go to step 23.

NO Repair open in the wire between the No. 1

IGN COIL (15A)fuse and the ignition coil.I

Turn the ignition switch OFF.

Check for continuity between ignition coil 3P

connector terminal No. 2 and body ground.

IGNITION COIL 3P CONNECTOR

Wire side ot female terminals

ls there continuity?

YES Go to step 25.

NO Repair open in the wire between the ignition

coiland G101.1

Disconnect ECM connector A {31P)

23.

24.

(cont'd)

11-73

Page 281 of 1139

PGM-FI System

aDTC Troubleshooting (cont'dl

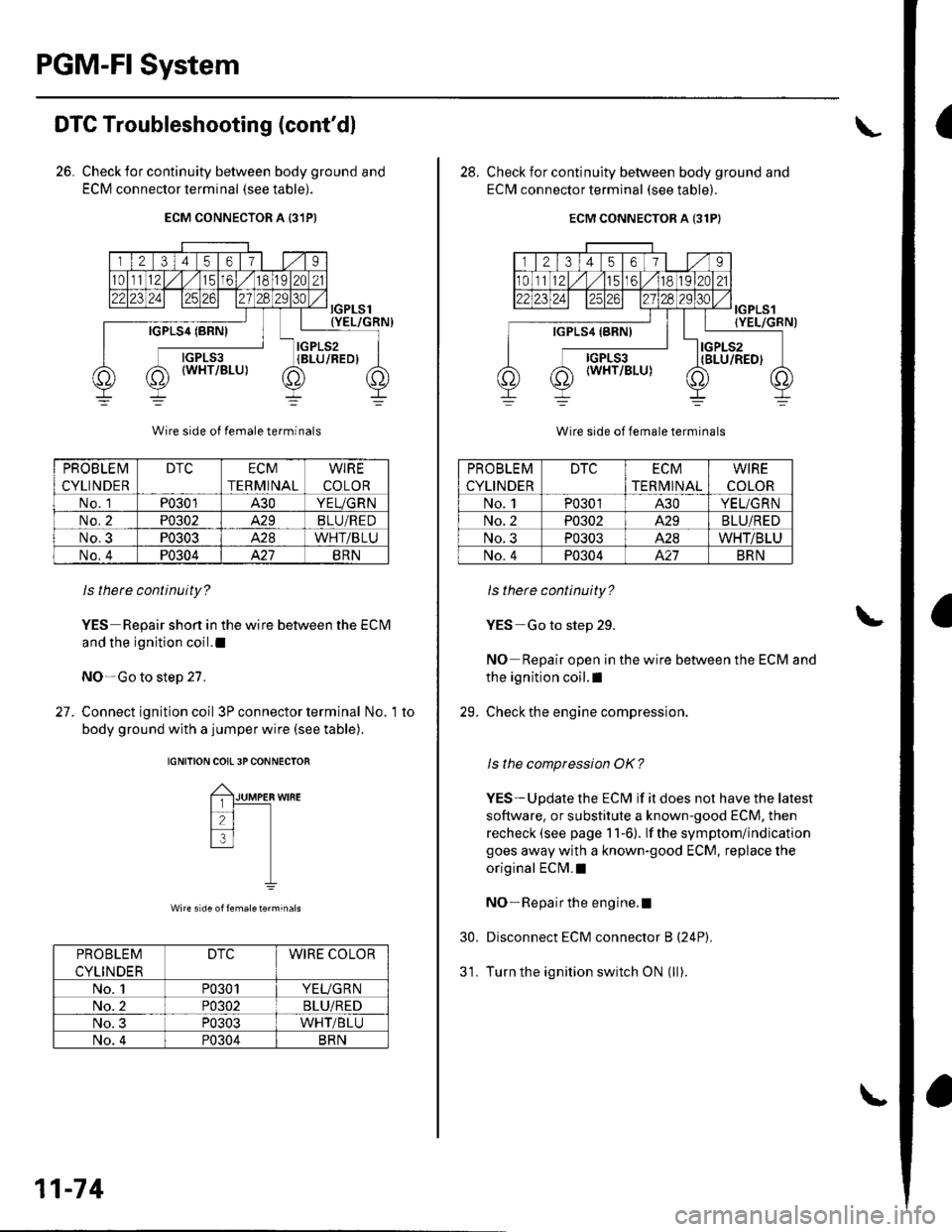

26. Check for continuity between body ground and

ECM connector terminal (see table).

ECM CONNECTOR A {31PI

PROB LE IVI

CYLINDER

DTCECM

TERMINAL

WIRE

COLOR

No. 1P0301430YEUGRN

No.2P0302A.29BLU/RED

No.3P0303428WHT/BLU

No,4P0304421BRN

ls there continuity?

YES Repair shon in the wire between the EClvl

and the ignition coil.l

NO-Go to step 27.

27. Connect ignition coil 3P con nector term inal No. 1to

body ground with a jumper wire (see table).

IGNITION COII 3PCONNECTOR

Wire s de of femaleterminals

PROBLEM

CYLINDER

DTCWIRE COLOR

No. 1P0301YEUGR N

No. 2P0302BLU/RED

No. 3P0303WHT/BLU

No. 4P0304BRN

11-74

28. Check for continuity between body ground and

ECM connector terminal (see table).

ECM CONNECTOR A {31P}

PROBLEM

CYLINDER

DTCECM

TERI\4INAL

WIRE

COLOR

No. 1P0301A30YEL/GRN

No. 2P0302429BLU/RED

No. 3P0303A.28WHT/BLU

No. 4P0304A.21BRN

ls there continuity?

YES-Go to step 29.

NO Repair open in the wire between the ECM and

the ignition coil.l

29. Check the engine compression

ls the compression OK?

YES-Update the ECM if it does not have the latest

software, or substitute a known-good ECM, then

recheck (see page 11-6). lf the symptom/indication

goes away with a known-good ECM, replace the

original ECI\4.I

NO- Repair the engine.l

Disconnect ECM connector B (24P).

Turn the ignition switch ON (ll).

30.

Page 635 of 1139

t

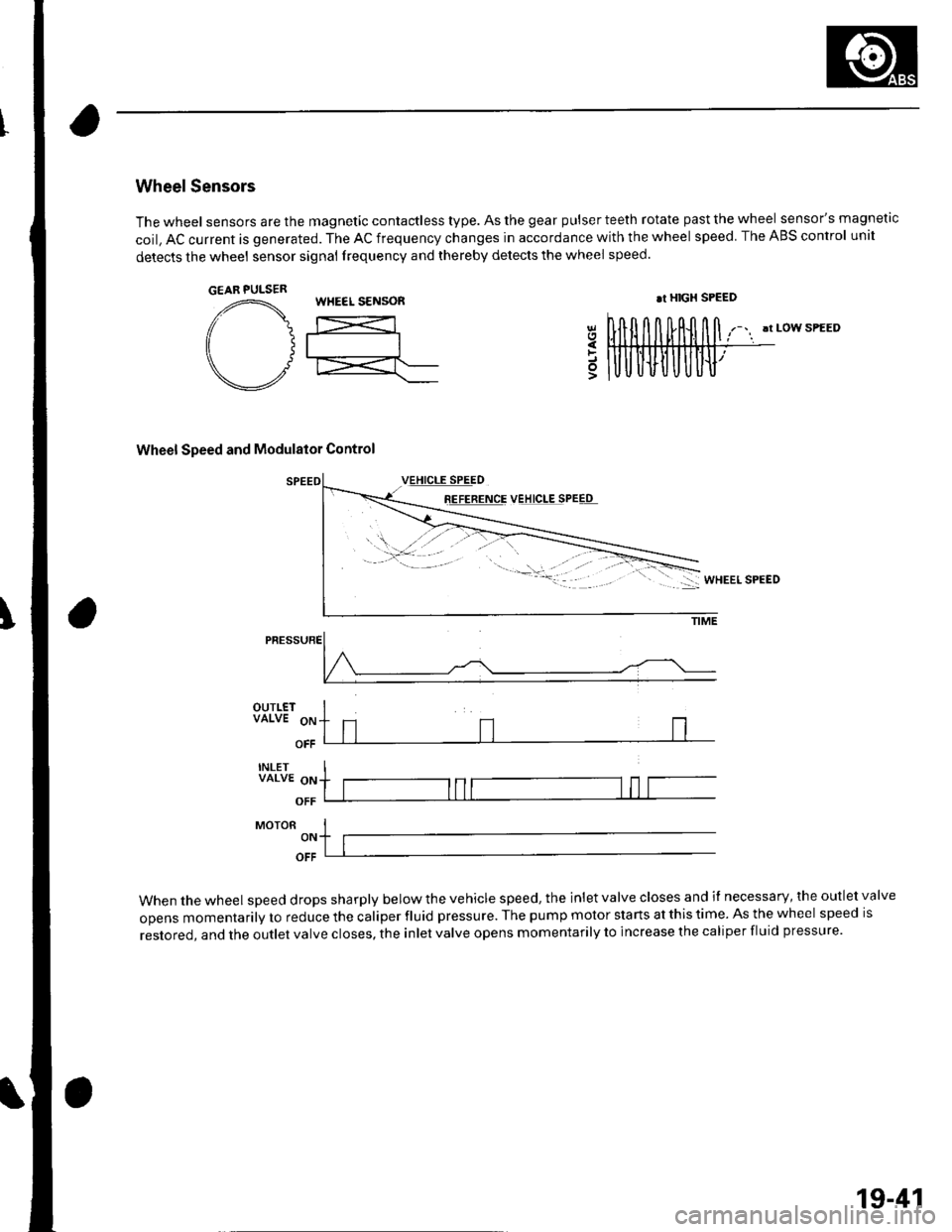

Wheel Sensors

The wheel sensors are the magnetic contactless type. As the gear pulser teeth rotate past the wheel sensor's magnetic

coil, AC current is generated. The AC frequency changes in accordance with the wheel speed. The ABS control unit

detects the wheel sensor signal frequency and thereby detects the wheel speed.

!t LOW SPEED

Wheel Speed and Modulator Control

8E!EEETqE VEJ!q!ESPEEq

5

PRESSURE

OUTLETVALVE 9p

OFF

INLETVALVE oN

OFF

MoroR I-,. ltlOFF

When the wheel speed drops sharply below the vehicle speed, the inlet valve closes and il necessary, the outlet valve

opens momentarily to reduce the caliper fluid pressure. The pump motor starts at this time. As the wheel speed is

restored, and the outlet valve closes, the inlet valve opens momentarily to increase the caliper fluid pressure.

GEAR PULSERWHEEL S€NSOR.r HIGX SPEED

19-41

Page 803 of 1139

Heating and Air Conditioning

Compressor Clutch Circuit

Troubleshooting (cont'dl

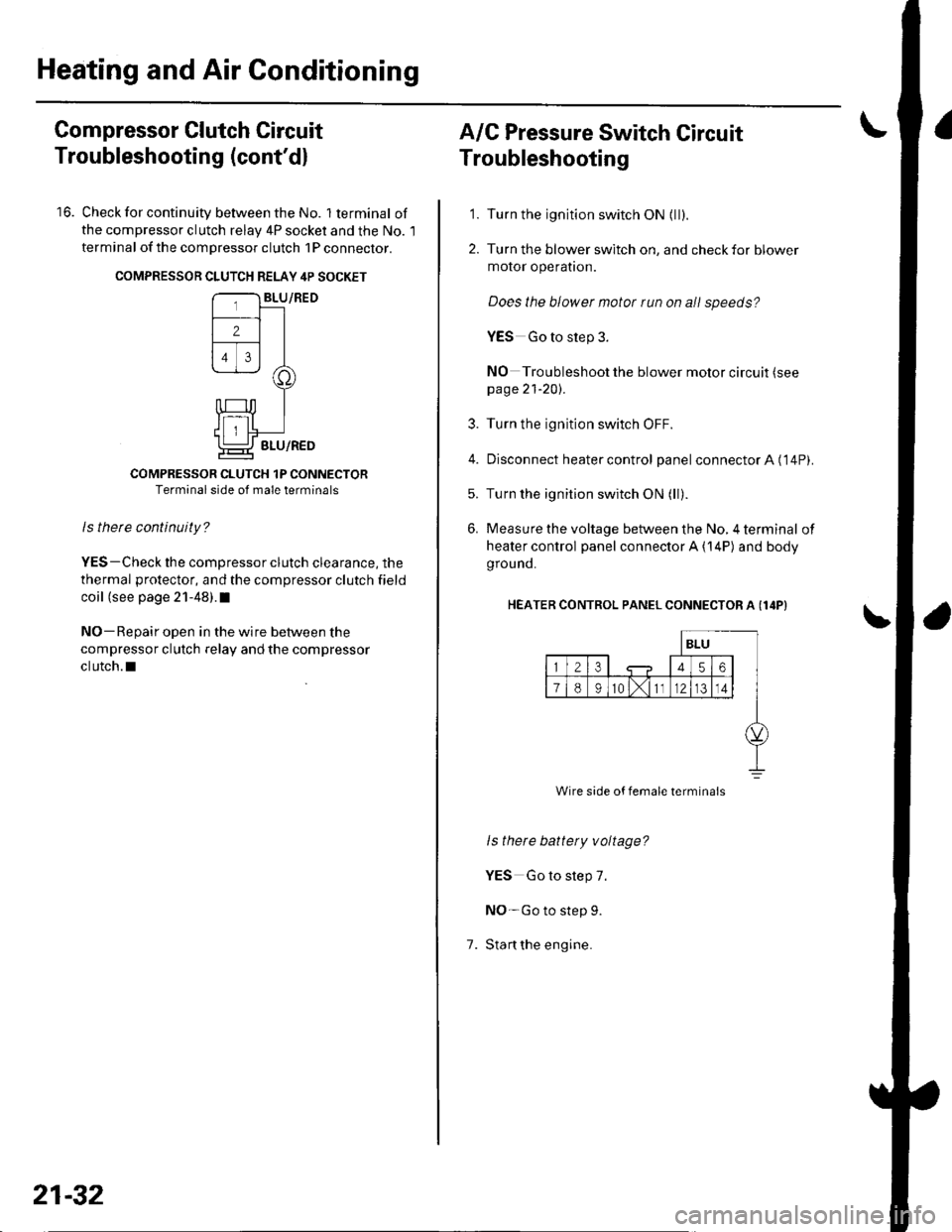

16. Check for continuity between the No. lterminal of

the compressor clutch relav 4P socket and the No. l

terminal of the compressor clutch 1P conneclor.

COMPRESSON CLUTCH RELAY 4P SOCKET

COMPRESSOR CLUTCH 1P CONNECTORTerminal side of male terminals

ls therc continuity?

YES-Check the compressor clutch clearance, the

thermal protector, and the compressor clutch field

coil (see page 21-48).I

NO-Repair open in the wire between the

compressor clutch relay and the compressor

clutch.l

21-32

A/C Pressure Switch Circuit

Troubleshooting

'1. Turn the ignition switch ON {ll).

2. Turn the blower switch on, and check for blower

motor operatron.

Does the blower motor run on all speeds?

YES Go to step 3.

NO Troubleshoot the blower motor circuit (see

page 21-20).

3. Turn the ignition switch OFF.

4. Disconnect heater control panel connectorA ('14P).

5. Turn the ignition switch ON (ll).

6. Measure the voltage between the No, 4 terminal of

heater control panel connector A {14P) and body

grou nd.

HEATER CONTROL PANEL CONNECTOR A (I4P}

1.

ls there battety voltage?

YES Go to step 7.

NO-Go to step 9.

Stan the engine.

Wire side of female termina's

Page 819 of 1139

Heating and Air Gonditioning

1.

Compressor Clutch Check

Check the armature plate for discoloration, peeling,

or other damage. lf there is damage, replace the

clutch set (see page 21-49),

Check the rotor pulley bearing play and drag by

rotating the rotor pulley by hand. Beplace the

clutch set with a new one if it is noisy or has

excessive play/drag (see page 21-49).

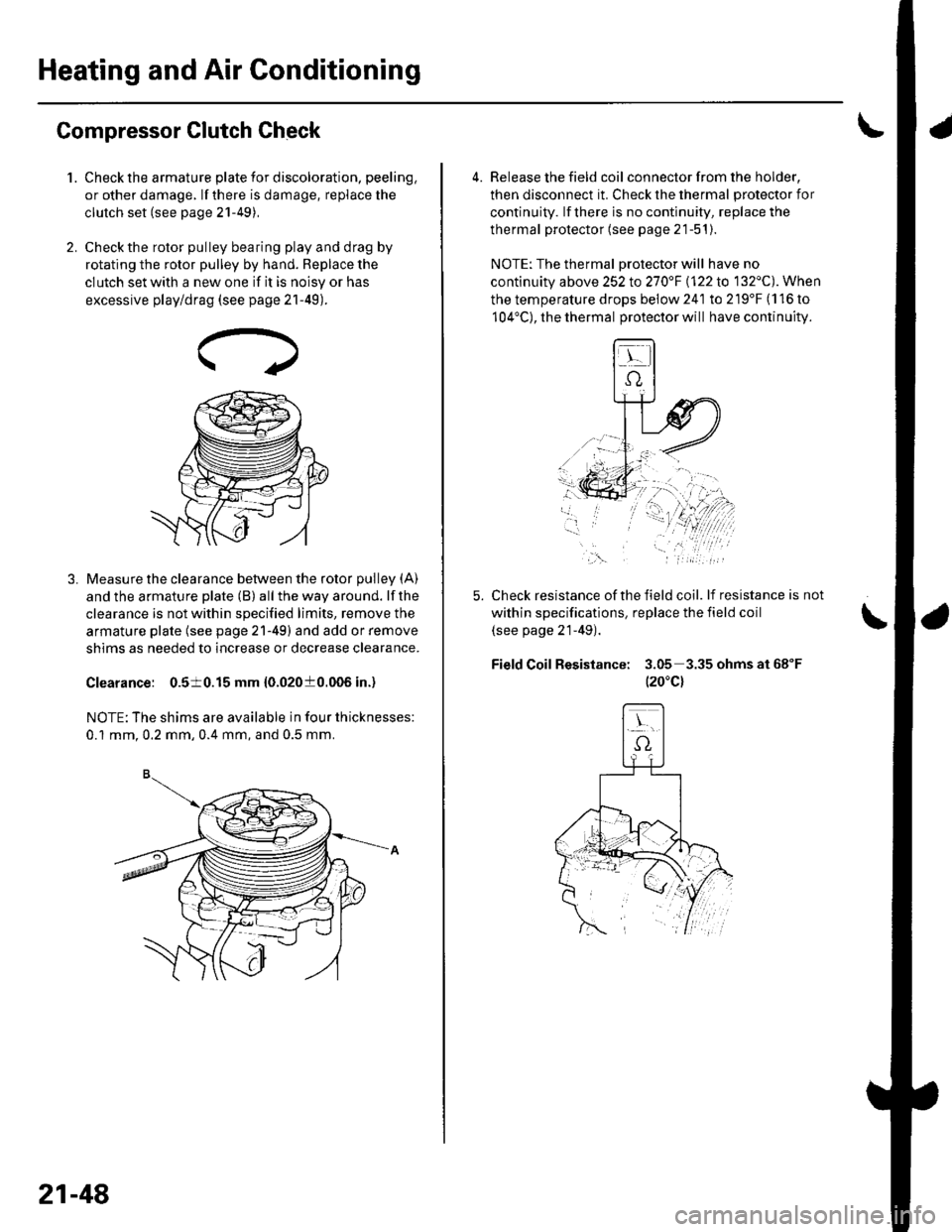

Measure the clearance between the rotor pulley (A)

and the armature plate (B) all the way around. lf the

clearance is not within specified limits, remove the

armature plate (see page 21-49) and add or remove

shims as needed to increase or decrease clearance.

Clearance: 0.510.15 mm {0.02010.006 in.)

NOTE: The shims are available in four thicknesses:

0.1 mm.0.2 mm,0.4 mm, and 0.5 mm.

21-48

a

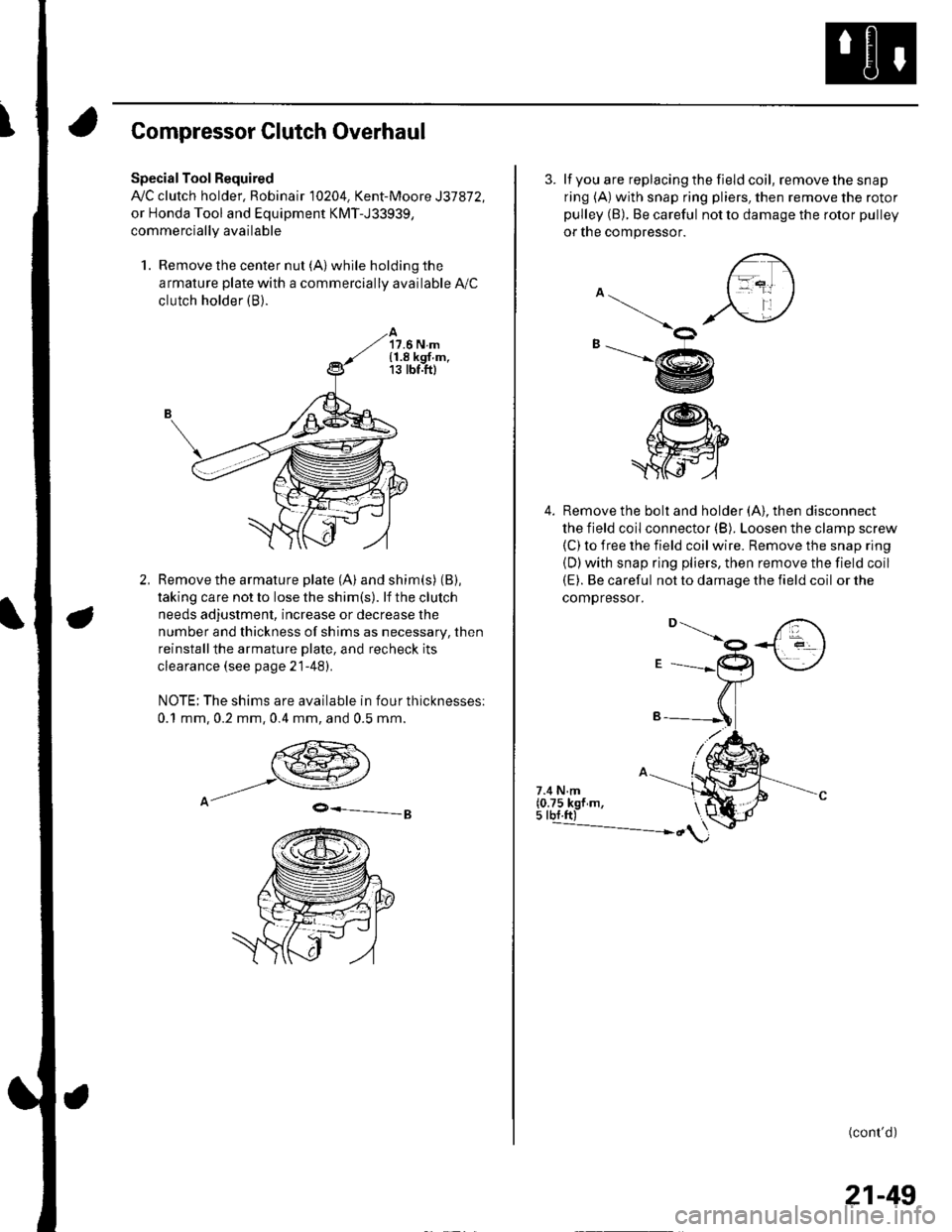

4. Release the field coil con nector f rom the holder,

then disconnect it. Check the thermal protector for

continuity. lf there is no continuity, replace the

thermal protector (see page 21-51).

NOTE: The thermal Drotector will have no

continuity above 252to270"F \122lo 132'C). When

the temperature drops below 241 to 219'F (116 to

104'C), the thermal protector will have continuity.

Check resistance of the field coil. lf resistance is not

within specifications, replace the field coil

(see page 21-49).

Field Coil Resistance: 3.05 3.35ohmsat68"F

t20"c)

,\.

Page 820 of 1139

Compressor Clutch Overhaul

Special Tool Required

A,/C clutch holder, Robinair 10204. Kent-Moore J37872,

or Honda Tool and Equipment KMT-J33939,

commercially available

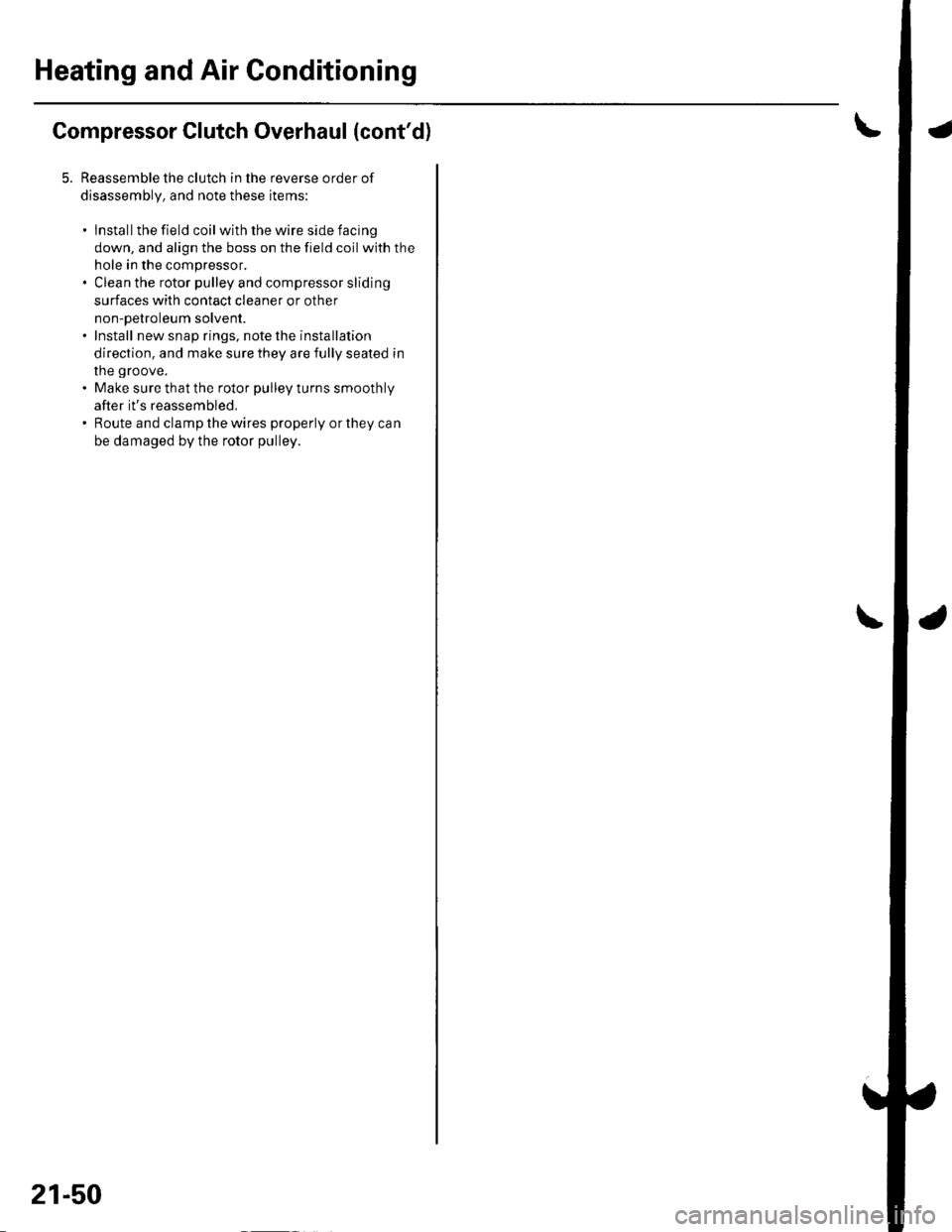

1. Remove the center nut (A) while holding the

armature plate with a commercially available A,/C

clutch holder (B).

17.6 N.m{1.8 kgf.m,13 tbt.ft)

Remove the armature plate (A) and shim(s) (B),

taking care not to lose the shim(s). lf the clutch

needs adjustment, increase or decrease the

number and thickness of shims as necessary, then

reinstallthe armature Dlate, and recheck its

clearance (see page 21-481.

NOTE: The shims are available in four thicknesses:

0.1 mm,0.2 mm,0.4 mm, and 0.5 mm.

9-=-g

3. lf you are replacing the field coil, remove the snap

ring (A) with snap ring pliers, then remove the rotor

pulley (B). Be careful not to damage the rotor pulley

or tne compressor.

4. Remove the bolt and holder (A). then disconnect

the field coil connector (B). Loosen the clamp screw(C) to iree the field coil wire. Remove the snap ring

{D)with snap ring pliers, then remove the field coil(E). Be careful not to damage the field coil or the

comoressor.

\ot

-@

/@h"

.ffi

7.4 N.m(0.75 kgf m,5 tbf.ft)---------------- ")

(cont'd)

21-49

Page 821 of 1139

Heating and Air Gonditioning

Compressor Clutch Overhaul (cont'd)

5. Reassemble the clutch in the reverse order of

disassembly, and note these items:

. Installthe field coil with the wire side facing

down, and align the boss on the field coil with the

hole in the compressor.. Clean the rotor pulley and compressor sliding

surfaces with contact cleaner or other

non-petroleum solvent..Install new snap rings, note the installation

direction, and make sure they are fully seated in

the groove.

. Make sure that the rotor pulley turns smoothly

after it's reassembled,. Route and clamp the wires properly or they can

be damaged by the rotor pulley.

21-50

Page 822 of 1139

Compressor Thermal Protector

Replacement

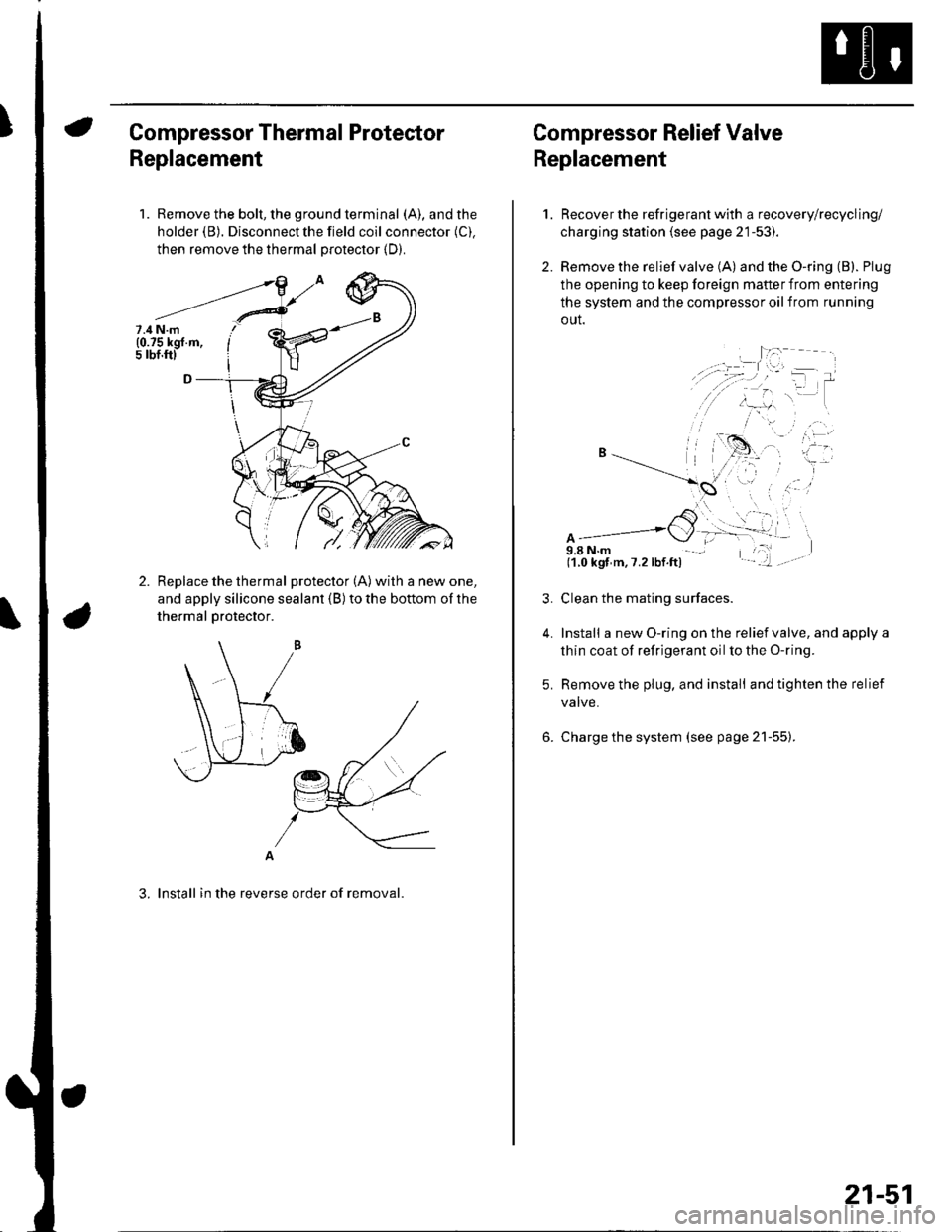

1. Remove the bolt, the ground terminal (A), and the

holder (B). Disconnect the field coil connector (C).

then remove the thermal protector (D).

Replace the thermal protector (A) with a new one,

and apply silicone sealant (B) to the bottom of the

thermal Drotector.

A

3. lnstall in the reverse order of removal.

7.4 N.m(0.75 kgf.m,5 rbf.ftl

Compressor Relief Valve

Replacement

2.

1.

4.

Recover the refrigerant with a recovery/recycling/

charging station (see page 21-53).

Remove the relief valve (A) and the O-ring (B). Plug

the opening to keep foreign mafter from entering

the system and the compressor oil from running

out.

A9,8 N.m(1.0 kgf m,7.2lbf.ft)

Clean the mating surfaces.

Install a new O-ring on the relief valve, and apply a

thin coat of refrigerant oil to the O-ring.

Remove the plug, and install and tighten the relief

valve.

Charge the system (see page 21-55).

21-51

Page 847 of 1139

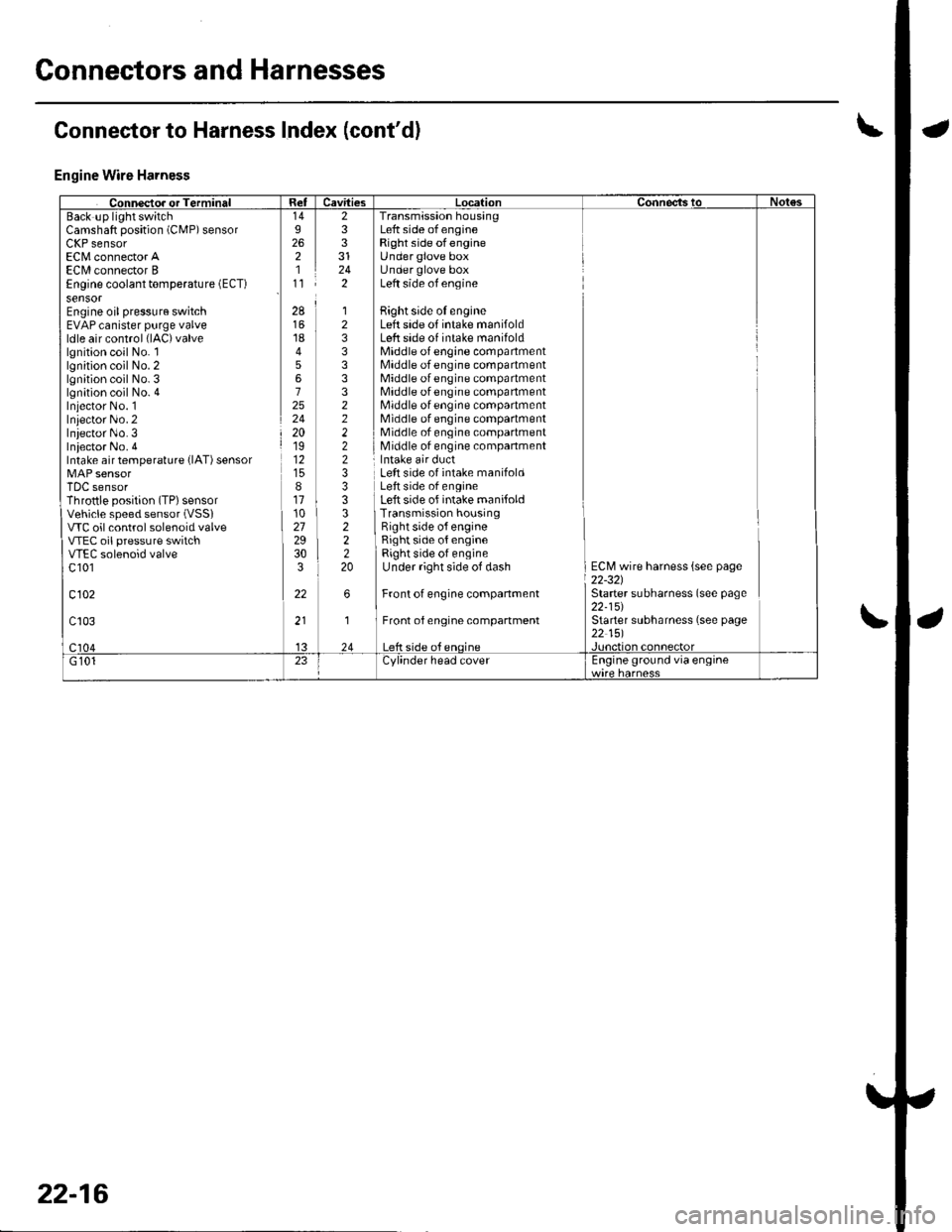

Connectors and Harnesses

Engine Wire Harness

Camshaft position (CMP) sensorLllr sensorEC[,4 connector AECI/l connector BEngine coolant temperature (ECT)

sensorEngine oil pressure switchEVAP canister purge valveldle air control (lAC)valve

lgnition coil No. llgnition coil No. 2lgnition coil No. 3lgnition coil No. 4Iniector No. 1Inlector No.2Iniector No.3Iniector No. 4Intake air temperature {lAT) sensor

TDC sensorThrottle position (TP) sensorVehicle speed sensor (VSSI

VTC oil control solenoid valveVTEC oil pressure switchVTEC solenoid valvec 101

c102

233

242

Transmission housingLeft side of engineRight side ofengineUnder glove boxUnder glove boxLeft side of engine

Bight side oI engineLeft side of intake manifoldLeft side of intake manifoldMiddle of engine compartmentMiddle of engine compartmentMiddle of engine compartmentMiddle of engine compartmentMiddle of engine compartmentMiddle of engine compartmentMiddle of engine compartmentMiddle of engine companment

28

1845672524201912

811102729303

22

12333332222233

322220

Left side of intake manifoldLeft side of engineLeft side of intake manifoldTransmission housingRight side o{ engineRight side of engineRight side of engineUnder right side of dash

Front of engine companment

Front of engine compartment

ECM wire harness {see page22-321Starter subharness (see page22-15)Starter subharness (see page22 151

Connector to Harness Index (cont'dl

22-16

Page 878 of 1139

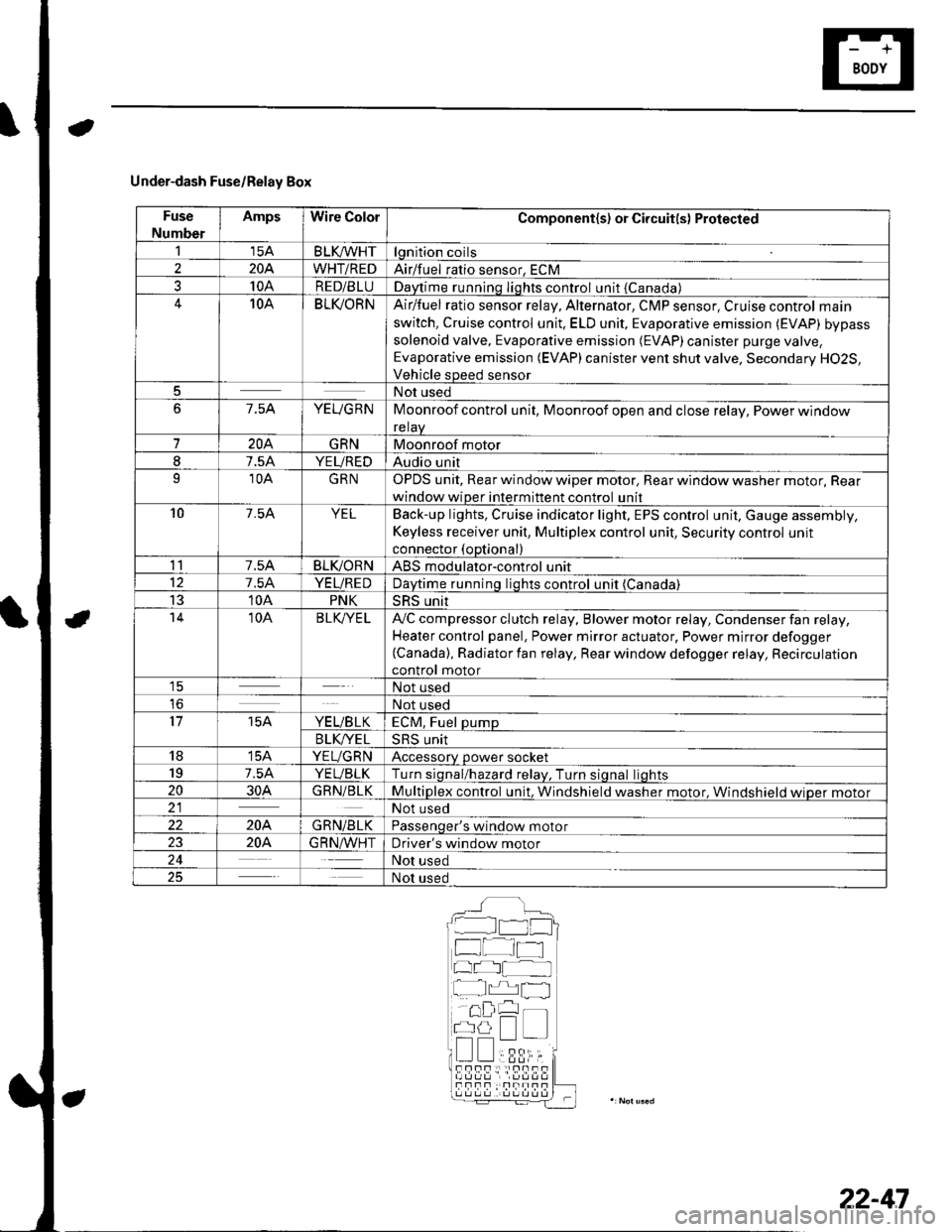

Under-dash Fuse/Relay Box

Fuse

Number

AmpsWire ColorComponent(s) or Circuit(s) Protected

115ABLKA/VHTlgnition coils

2204WHT/REDAirlfuel ratio sensor, ECM

310ARED/BLUDaytime running Iights control unit {Canada)10ABLI(ORNAir/fuel ratio sensor relay, Alternator, CMP sensor, Cruise control main

switch, Cruise control unit. ELD unit, Evaporative emission (EVAP) bypass

solenoid valve, Evaporative emission (EVAP)canister purge valve,

Evaporative emission (EVAP) canister vent shut valve, Secondary H02S,

Vehicle speed sensor

5Not used

67.5AYEUGRNMoonroof control unit, Moonroof open and close relay, Power window

relaV

7204GRNMoonroof motor

I7.5AYEUREDAudio unit

910AGRNOPDS unit, Rear window wiper motor, Rear window washer motor, Rear

window wiper intermittent control unit

107.54YELBack-up lights, Cruise indicator light, EPS control unit, Gauge assembly,

Keyless receiver unit, Multiplex control unit, Security control unit

connector (optional)

117.5ABLIVORNABS modulator-control unit

127.5AYEUREDDaytime runnino liohts control unit (Canada)

1310APNKSRS unit't410ABLK/YE LA,,/C compressor clutch relay, Blower motor relay, Condenser fan relay,

Heater control panel, Power mirror actuator, Power mirror defogger(Canada), Radiator fan relay, Rear window defogger relay, Recirculation

control motor1ENot used

loNot used

1715AYE L/B LKECM, Fuel pump

B LK/YE L>H> Unrr

1815AYEUGRNAccessory power socket

197.5AYEUBLKTurn siqnal/hazard relav, Turn siqnal liohts

2030AGRN/BLKMultiplex control unit, Windshield washer motor. Windshield wioer motor21Not used

22204GRN/BLKPassenqer's window motor

2320A.G R N,A/VHTDriver's window motor

24Not used

25Not used

__^:Hr tl_l

f at-t

at I

r^,rl fl

!!;r -

!339,i;s!!sf Fnf : |rnITf

22-47