Throttle HONDA CIVIC 2003 7.G Owner's Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 2003, Model line: CIVIC, Model: HONDA CIVIC 2003 7.GPages: 1139, PDF Size: 28.19 MB

Page 256 of 1139

![HONDA CIVIC 2003 7.G Owners Manual PGM-FI System

Component Location Index

CAMSHAFT POS]TION {CMP) SENSOR B(TOP DEAD CENTER (TDC}SENSORITroubleshootina. oaoe 1 1-95Replacement, p;ge 1-1.1 14

ELECTRICAL LOADDETECTOR {ELDITroubleshooting, HONDA CIVIC 2003 7.G Owners Manual PGM-FI System

Component Location Index

CAMSHAFT POS]TION {CMP) SENSOR B(TOP DEAD CENTER (TDC}SENSORITroubleshootina. oaoe 1 1-95Replacement, p;ge 1-1.1 14

ELECTRICAL LOADDETECTOR {ELDITroubleshooting,](/img/13/5744/w960_5744-255.png)

PGM-FI System

Component Location Index

CAMSHAFT POS]TION {CMP) SENSOR B(TOP DEAD CENTER (TDC}SENSORITroubleshootina. oaoe 1 1-95Replacement, p;ge 1-1.1 14

ELECTRICAL LOADDETECTOR {ELDITroubleshooting,page 1'l -92

INTAKE AIR TEMPERATURE{IATI SENSORTroubleshooting,page 'l'l-55

Replacement, page 11-'l 15

f- \

rl

KNOCK SENSORTroubleshooting, page 1 1-77Beplacement, page 11 115

ENGINE COOLANT TEMPERATURE(ECTI SENSORTroubleshooting, page 1 1-57Replacement, page 11 114

MANIFOLD ABSOLUTE PRESSURE(MAP) SENSORTroubleshooting, page 1 1-52

THROTTLE POSITIONITP} SENSORTroubleshooting, page 11-60CRANKSHAFT POSITIONICKPISENSORTroubleshooting, page'l 1-78Beplacement, page 1 1-'l 16

AIR FUEL RATIO {A/F)SENSOR ISENSOR 1}Trorrbleshooting, page 1 1-84Replacement, page 11- 1 13

{cont'd)

ii'- r'1

.I11 ---:,I''.!,i(..,.?:fir-J-

.....,..:--.

11-49

Page 267 of 1139

PGM-FI System

DTC Troubleshooting (cont'dl

DTC P0122: TP Sensor Circuit Low Voltage

1. Turn the ignition switch oN (111.

2. Check the throttle position with the scan tool.

ls there about 10./. or 0.5 V when the thrcttle is

fully closed and about 90% or 4.5 V when the

throttle is fully opened?

YES Intermittent failure, system is OK at this time.

Check for poor connections or loose terminals at

the TP sensor and at the ECM. t

NO Go to step 3.

3. Turn the ignition switch OFF,

4. Disconnect the TP sensor 3P connector.

5. Turn the ignition switch ON (ll).

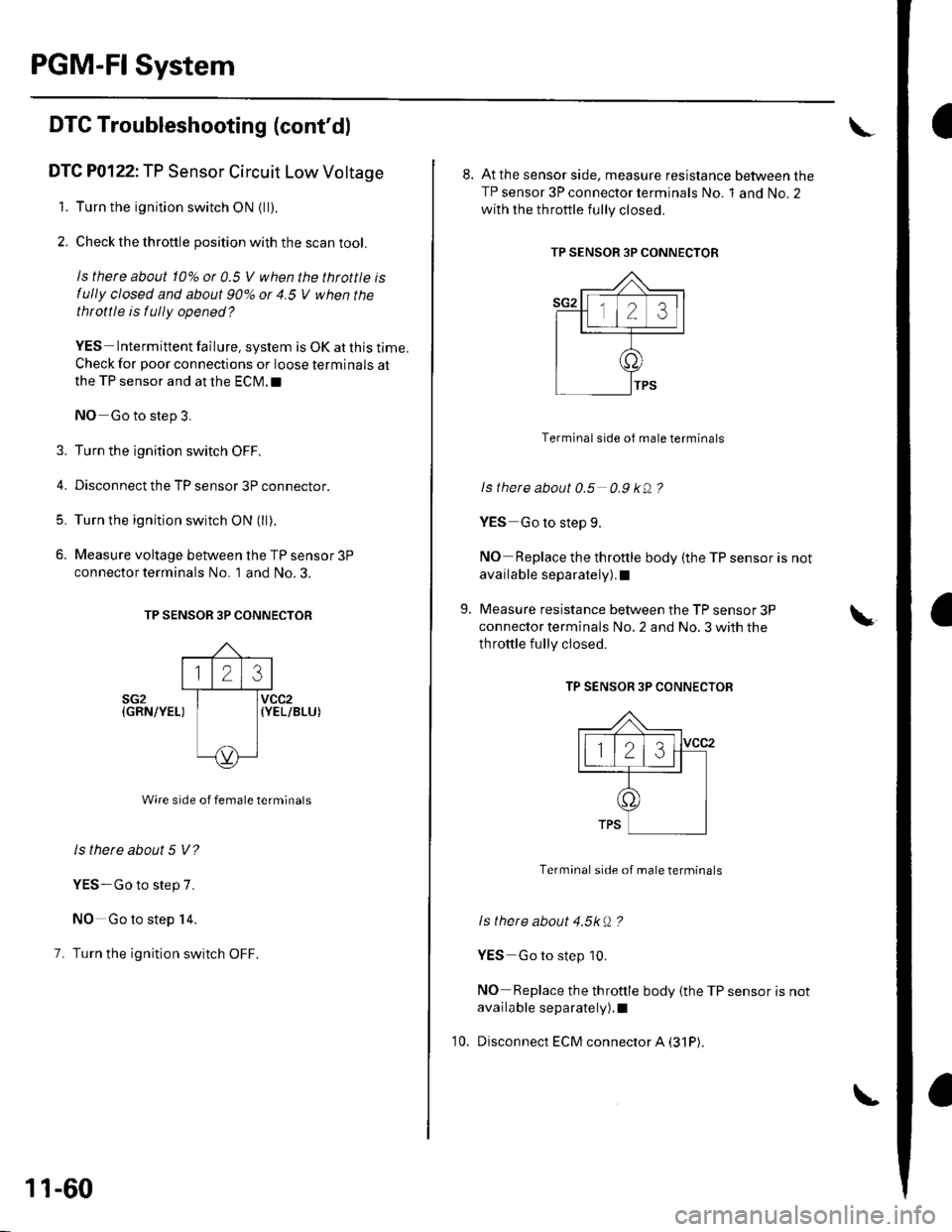

6. Measure voltage between the TP sensor 3P

connector terminals No. 1 and No. 3.

TP SENSOR 3P CONNECTOR

Wire side of female terminals

ls there about 5 V?

YES-Go to step 7.

NO Go to step 14.

Turn the ignition switch OFF.1.

11-60

8. At the sensor side, measure resistance between the

TP sensor 3P connector terminals No. 1 and No. 2

with the throttle fully closed.

TP SENSOR 3P CONNECTOR

Terminal side of male terminals

Is there about 0.5 0.9 kQ ?

YES Go to step 9.

NO Replace the throttle body (the TP sensor is not

available separately). I

Measure resistance between the TP sensor 3P

connector terminals No. 2 and No. 3 with the

throttle fully closed.

TP SENSOR 3P CONNECTOB

Terminal side of male terminals

ls there about 4.5k{l ?

YES Go to step 10.

NO Replace the throttle body (the TP sensor is not

available separately). I

10. Disconnect ECM connector A (31P).

9.\

Page 269 of 1139

PGM-FI System

(

(

DTC Troubleshooting (cont'd)

DTC P0123: TP Sensor Circuit High Voltage

1. Turn the ignition switch oN (ll)

2. Check the throttle position with the scan tool.

ls there about 10% or 0.5 V when the throttle is

fully closed and about 90% or 4.5 V when the

throttle is f ully opened?

YES lntermittent failure. system is OK at this time.

Check for poor connections or loose terminals at

the TP sensor and at the ECM, I

NO Go to step 3.

3. Turn the ignition switch OFF.

4. Disconnect the TP sensor 3P connector.

5. Turn the ignition switch ON (ll).

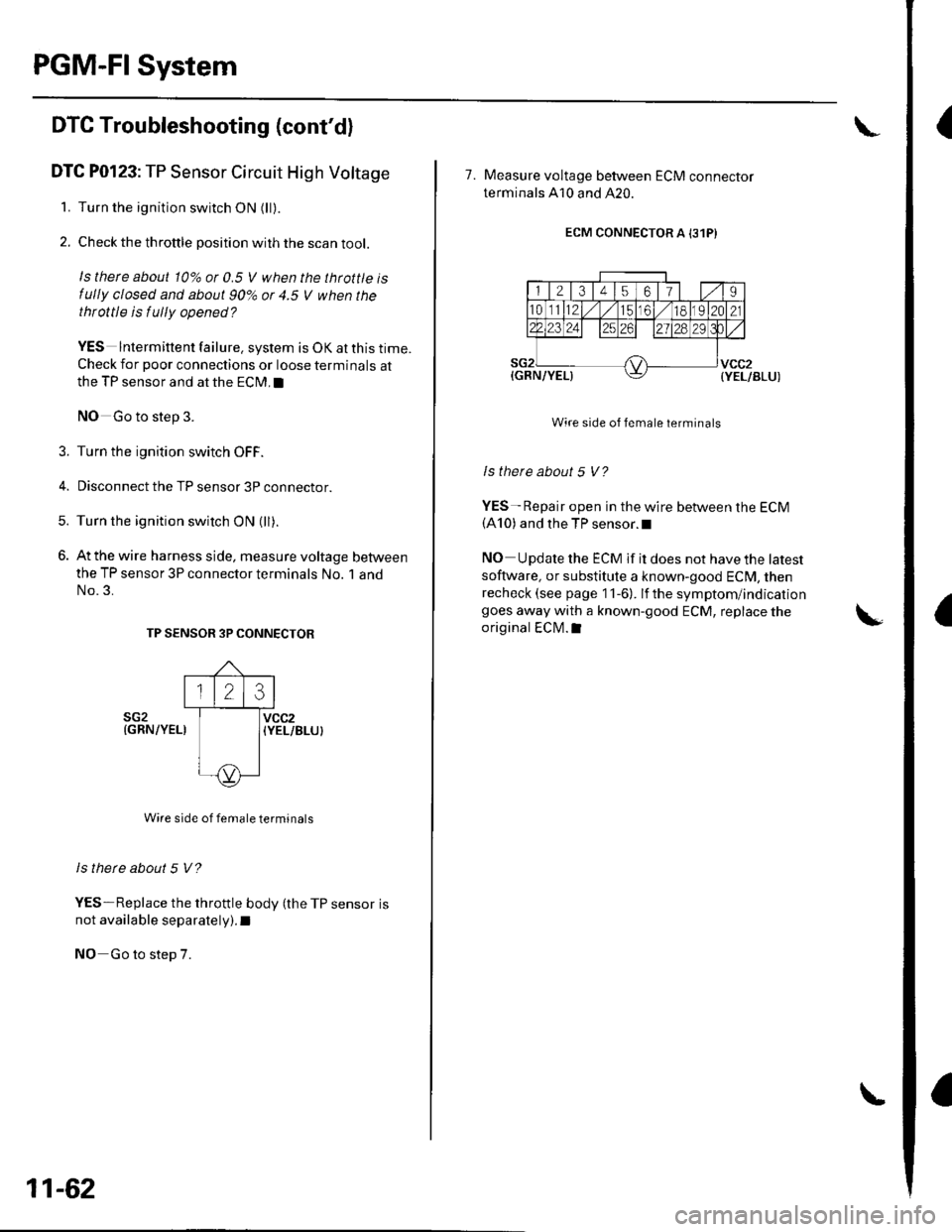

6. At the wire harness side, measure voltage between

the TP sensor 3P connector terminals No. 1 and

No.3.

TP SENSOR 3P CONNECTOR

W;re side of female terminals

ls thete about 5 V?

YES-Replace the throttle body (the TP sensor is

not available separately). I

NO Go to step 7.

11-62

7. Measure voltage between ECM connector

terminals A10 and A20.

ECM CONNECTOR A 131PI

Wire side of female terminals

Is there about 5 V?

YES- Repair open in the wire between the ECM(A10) and the TP sensor. t

NO Update the ECM if it does not have the latest

soflware, or substitute a known-good ECM, then

recheck (see page 11-6). lf the symptom/indicationgoes away with a known-good ECM, replace the

original ECM.I

Page 270 of 1139

DTC Pl121: TP Sensor Signal Lower Than

Expected

1. Turn the ignition switch ON (ll).

2. Check the throttle position with the scan tool.

ls 12.9'/.,0.6 V, or higher indicated when the

throttle is tully opened?

YES- Intermittent failure, system is OK at this

time.I

NO-Replace the TP sensor (the TP sensor is not

available separately). I

DTCP1122:.fP Sensor Signal Higher Than

Expected

1. Turn the ignition switch ON (ll).

2. Check the throttle position with the scan tool.

ls 12.9 %,0.6 V, or less indicated when the throttle

is f ully closed?

YES Intermittent failure, system is OK at this

time.l

NO Replace the TP sensor (the TP sensor is not

available separately). I

11-63

Page 290 of 1139

DTG Pl106: BARO Sensor Range/Perfomance

Problem

1. Reset the ECM (see page 11-4).

2. Start the engine. Hold the engine at 3,000 rpm with

no load (in neutral) until the radiator fan comes on,

then let it idle.

Test-drive with the transmission in 4th gear.

Accelerate for 5 seconds using wide open throttle.

Check for a Temporary DTC with the scan tool.

Is Temporary DTC Pl106 indicated?

YES-Update the ECM if it does not have the latest

software, or substitute a known-good ECM. then

recheck (see page 11-6). lf the symptom/indication

goes away with a known-good ECM, replace the

original ECM. !

NO Intermittent failure, system is OK at this

time.I

DTC Pl107: BARO Sensor Circuit Low Voltage

DTC Pl108: BARO Sensor Circuit High

Voltage

1. Reset the ECM {see page 1 1-4).

2. Turn the ignition switch ON (ll).

ls DTC P1107 or P1108 indicated?

YES-Update the ECM if it does not have the iatest

software, or substitute a known-good ECI\4, then

recheck (see page 11-6). lf the symptom/indication

goes away with a known-good ECM, replace the

original ECI\4.I

NO- Intermittent failure, system is OK at this

trme.l

11-83

Page 295 of 1139

PGM-FI System

DTC Troubleshooting (cont'dl

DTC Pl163: Ay'F Sensor (Sensor 1 ) SlowResponse

NOTE: lf DTC P1162 is stored at the same time as DTC

P1163. troubleshoot DTC P1162 first, then recheckfor

DTC P1163.

1. Reset the ECM (see page 1 1-4).

2. Start the engine. Hold the engine at 3,000 rpm with

no load (in neutral) until the radiator fan comes on.

3. Test-drive under the following conditions:

. 55 mph (89 km/h) steady speed' Transmission in sth gear' Until the Ay'F sensor readiness code or

Temporary DTC Pl163 comes on

4. Check for a Temporary DTC with the scan tool.

ls Temporary DTC P 1163 indicated?

YES Replace the Ay'F sensor (Sensor 1).I

NO Intermittent failu re, system is OK at this time.

Check for poor connections or loose terminals at

the A'lF sensor (Sensor 1 ) and at the ECM. t

11-88

DTC Pl164: A,/F Sensor (Sensor 1) Circuit

Range/Performance Problem

1. Resetthe ECI\4 (see page 1t-4).

2. Start the engine. Holdtheengineat3,000 rpmwith

no load (in neutral) until the radiator fan comes on,

3. Test-drive in 3rd gear. Starting at 1,600 rpm,

accelerate using wide open throttle for at least

5 seconds. Then decelerate for at least 5 seconds

with the throttle completely closed until the A,/F

sensor readiness code is set to complete or

Temporary DTC P1 164 comes on.

4. Check for a Temporary DTC with the scan tool.

ls Temporary DTC P1164 indicated?

YES- Replace the A,,/F sensor (Sensor 1). I

NO Intermittent failure, system is OK at this time.

Check for poor connections or loose terminals at

the Ay'F sensor relay, at the Ay'F sensor (Sensor 1),

and at the EcM.l

Page 304 of 1139

MIL Circuit Troubleshooting

1. Connect an OBD ll scan tool/Honda PGM Tester

(see page 11-3).

2. Turn the ignition switch ON (ll) and read the OBD ll

scan tool/Honda PGM Tester.

Does the OBD ll scan tool/Honda PGM Tester

communicate with the ECM?

YES Go to step 3.

NO Go to troubleshooting " DLC Circuit

Troubleshooting" (see page 11-109).

3. Check the OBD ll scan tool/Honda PGM Testerfor

DTCs.

Are any DTCs ind icated?

YES Go to the DTC Troubleshooting Index.

NO-Go to step 4.

4. Turn the ignition switch OFF.

5. Turn the ignition switch ON (ll)and watch the

lMalfunction Indicator Lamp (MlL).

Does the MIL come on and stay on for more than

20 seconds aftet turning the ignition switch

oN (tr)?

YES lf the MIL always comes on and stays on, go

to step 76. But if the lMlL sometimes works

normally, first check for these problems.

. An intermittent short in the wire between the

ECIM (E29) and the data link connector (DLC).

. An intermittent short in the wire between the

ECM (E31) and the gauge assembly.

NO lf the MIL is always off, go to step 6. But if the

lvllL sometimes works normally, first check for

these problems.

. A loose No. 10 METER (7.5A) fuse in the under

dash fuse/relay box.. A loose No. 20 lG (40A) (Canada: 50A)Iuse in the

under-hood fuse/relay box.. A ioose No. 6 ECU (ECM) (15A) fuse in the under-

hood fuse/relay box.

. A loose No. 17 FUEL PUMP (15A)fuse in the

under-dash fuse/relay box.. A poor connection at ECM terminal E31.. An intermittent open in the GRN/ORN wire

between the ECM (E31) and the gauge assembly.. An intermittent short in the wire between the

ECM (A21) and the manifold absolute pressure

(MAP) sensor.. An intermittent short in the wire between the

ECI\4 (A20) and the throttle posilion (TPi sensor.. An intermittent short in the wire between the

ECM (E5) and the fuel tank pressure (FTP) sensor.

6. Turn the ignition switch OFF.

7. Turn the ignition switch ON (ll).

ls the low oil pressure light on?

YES Go to step 10.

NO-Go to step 8.

8. Inspectthe No. 10 l\4ETER (7.5A)fuse inthe under-

dash fuse/relay box.

ls the luse OK?

YES Go to step L

NO Repair shon in the wire between No. 10

METER (7.5A)fuse and the gauge assembly. Also

replacethe No. 10 METER {7.5A) fuse.l

9. Inspect the No. 20 lG1 (40A) (Canada: 50A) fuse in

the under-hood fuse/relay box.

ls the f use OK?

YES Repair open in the wire between the No. 20

lG (40A) {Canadar 50A)fuse and the gauge

assembly. lf the wire is OK, test the ignition switch

{see page 22 53).

NO Repair short in the wire between No. 20 lG

(40A) lCanada: 50A)fuse and the under'dash fusel

relay box. Also replace the No.20 lG (40Ai

(Canada: 50A) fuse.I

(conr'd)

11-97

Page 312 of 1139

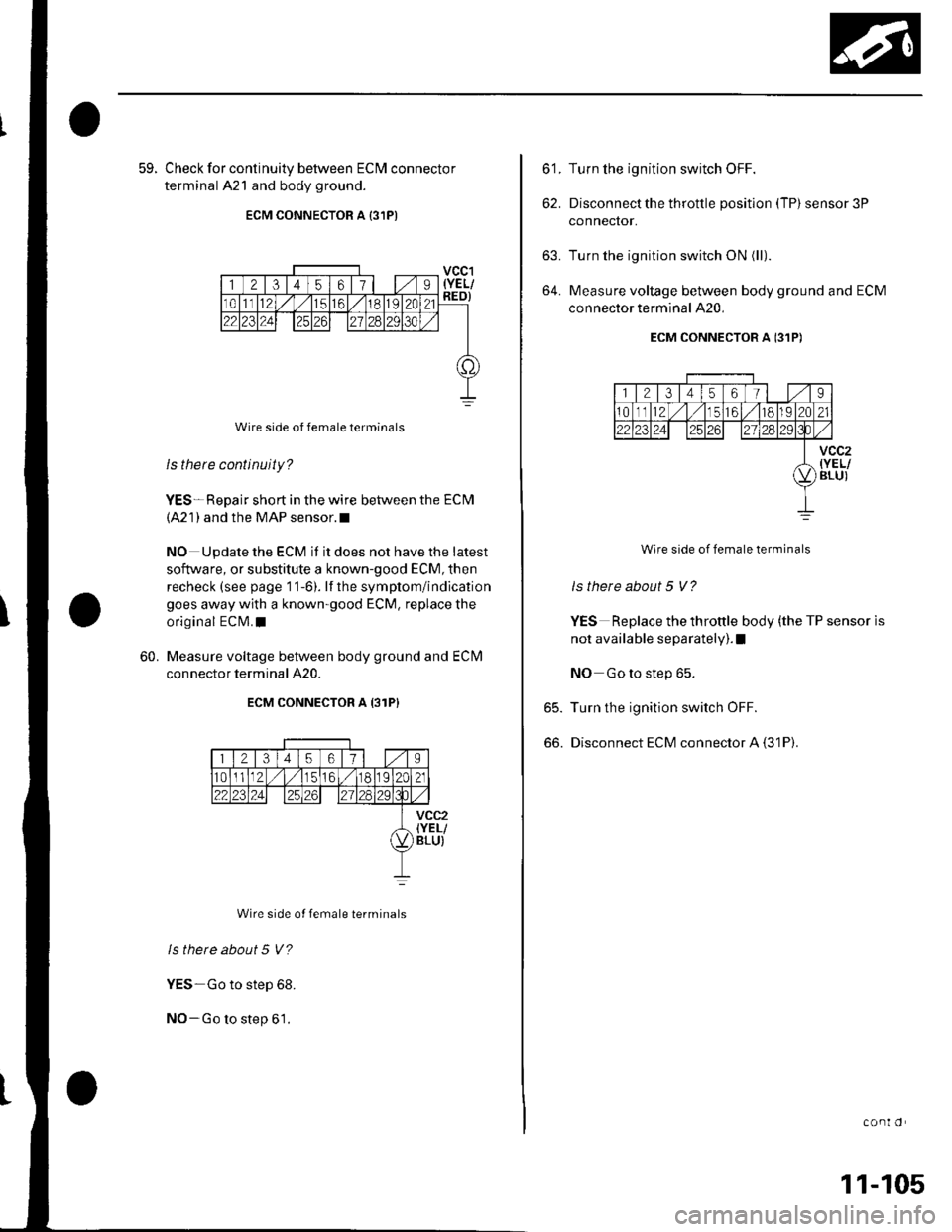

59. Check for continuitv between ECIM connector

terminal 421 and body ground.

ECM CONNECTOR A {3,IPI

Wire side of female terminals

ls there continuity?

YES*Repair short in the wire between the ECM(421) and the MAP sensor.l

NO Update the ECM it it does not have the latest

soflware, or substitute a known-good ECM, then

recheck (see page 1'l-6). lf the symptom/indication

goes away with a known-good ECM, replace the

original ECM.I

Measure voltage between body ground and ECM

connector terminal 420.

ECM CONNECTOR A {3TP}

60.

1121345ot/I

101111256/ 11892t212'231?4?qTln29

vcc2IYEL/BLU)

Wire side ot female terminals

ls there about 5 V?

YES-Go to step 68.

NO-Go to step 61.

t t,

oz,

63.

64.

Turn the ignition switch OFF.

Disconnect the throttle position (TP) sensor 3P

connector.

Turn the ignition switch ON (ll).

Measure voltage between body ground and ECM

connector terminal 420,

ECM CONNECTOR A 131P)

Wire side of female terminals

ls there about 5 V?

YES Replace the thronle body (the TP sensor is

not available separately). I

NO Go to step 65.

Turn the ignition switch oFF.

Disconnect ECM connector A (31P).

65.

66.

conl o

11-105

Page 337 of 1139

ldle Control System

DTC Troubleshooting

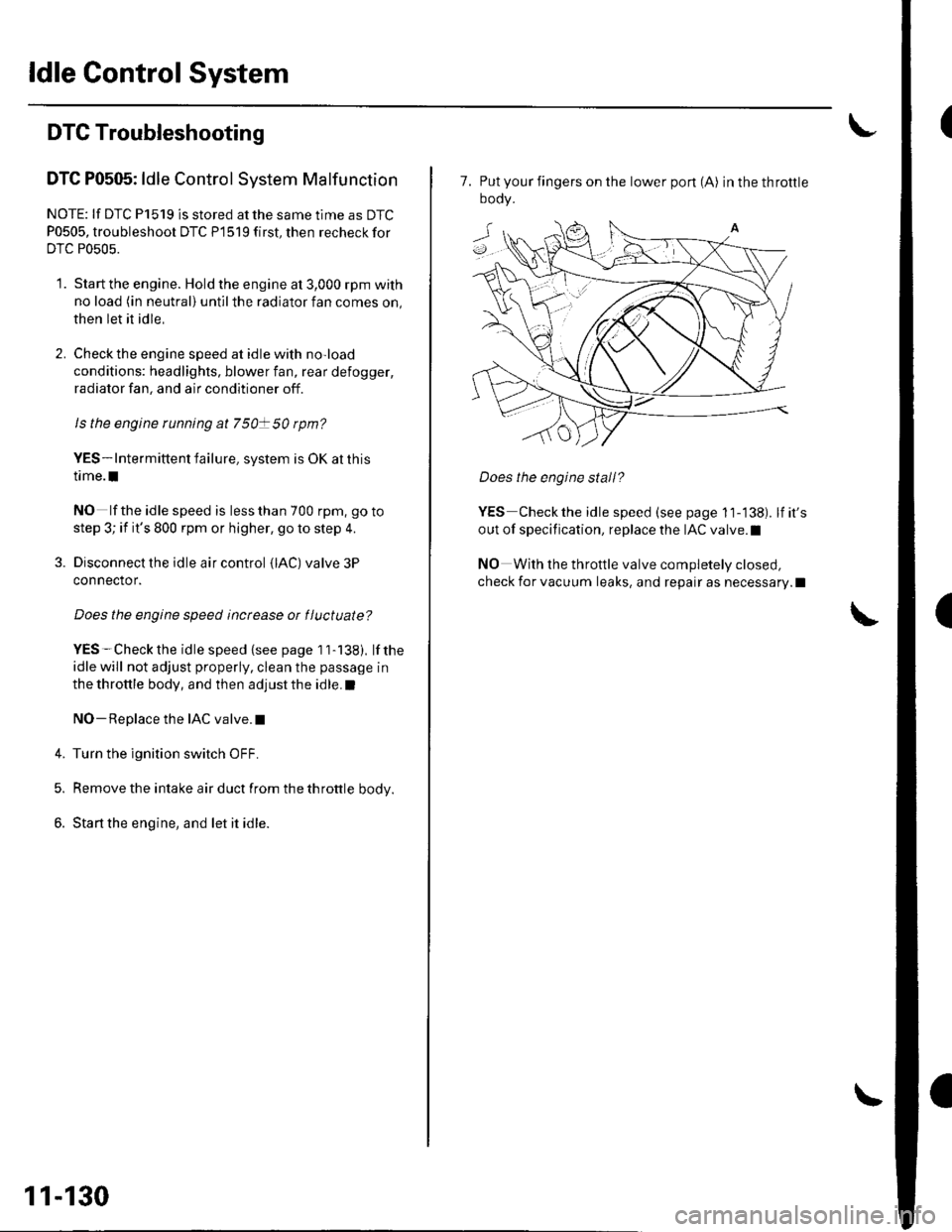

DTC P0505: ldle Control System Malfunction

NOTE: lf DTC P1519 is stored atthe same time as DTC

P0505, troubleshoot DTC P1519 first, then recheck for

DTC P0505.

1. Start the engine. Hold the engine at 3,000 rpm with

no load (in neutral) until the radiator fan comes on,

then let it idle,

2. Checkthe engine speed at idle with no,load

conditions: headlights, blower fan, rear defogger,

radiator fan, and air conditioner off.

Is the engine running at 750t50 rpm?

YES - Intermittent failure, system is OK at this

trme.I

NO lf the idle speed is less than 700 rpm, go to

step 3; if it's 800 rpm or higher, go to step 4.

3. Disconnect the idle air control {lAC) valve3P

connector.

Does the engine speed increase or fluctuate?

YES- Check the idle speed {see page 1 1-138). lf the

idle will not adjust properly, clean the passage in

the throttle body, and then adjust the idle. I

NO- Replace the IAC valve.I

4. Turn the ignition switch OFF.

5. Remove the intake air duct from the throttle body.

6. Start the engine, and let it idle.

11-130

(

7. Put your fingers on the lower pon (A) inthethrottle

oooy.

Does the engine stall?

YES Checkthe idle speed (see page 11-138). lfit's

out of specification, replace the IAC valve.l

NO With the throttle valve completely closed,

check for vacuum leaks, and repair as necessary.l

Page 346 of 1139

ECM ldle Learn Procedure

The idle learn procedure must be done so the ECM can

learn the engine idle characteristics.

Do the idle learn procedure whenever you do any of

these actions:. Disconnect the battery.

Replace the ECM or disconnect its connector.

Reset the ECM.

NOTE: Erasing DTCS with the Honda PGM Tester

does not require you to do the idle learn procedure.

Remove the No.6 ECU {ECM) ( 15A) fuse from the

under-hood fuse/relay box.

Remove the No.19 baftery (80A) fuse from the under-

hood fuse/relay box.

Remove PGM-FI main relay 1.

Remove any of the wires from the under-hood fuse/

retay Dox.

Disconnect any of the connectors from the under

hood fuse/relay box.

Disconnect the connector between the engine

compartment wire harness and ECM wire harness.

Disconnect the G2 terminal from the transmission

ho u srng.

Disconnectthe G'l terminal from the body.

Disconnectthe G101 terminal from the cylinder head

cover.

Procedure:

To complete the idle learn procedure, do this:

1. Make sure all electrical items (Ay'C, audio, rear

defogger, l:ghts, etc.,) are off.

2. Start the engine, and hold it at 3,000 rpm with no

load {in neutral) until the radiator fan comes on, or

until the engine coolanttemperature reaches 194"F(90'c).

3. Let the engine idle for about 5 minutes with the

throttle fully closed.

NOTE: lf the radiator fan comes on, do not include its

running time in the 5 minutes.

11-139