ect HONDA CIVIC 2003 7.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 2003, Model line: CIVIC, Model: HONDA CIVIC 2003 7.GPages: 1139, PDF Size: 28.19 MB

Page 406 of 1139

Clutch Replacement

Spscial Tools Required. Clutch alignment disc 07JAF-PM701 1A. Ring gear holder 07LAB-PV00100 or

07924-PD20003. Clutch alignment shaft 07ZAF-PR8A100. Remover handle 07936-3710100

Pressure Plate and Glutch Disc Removal

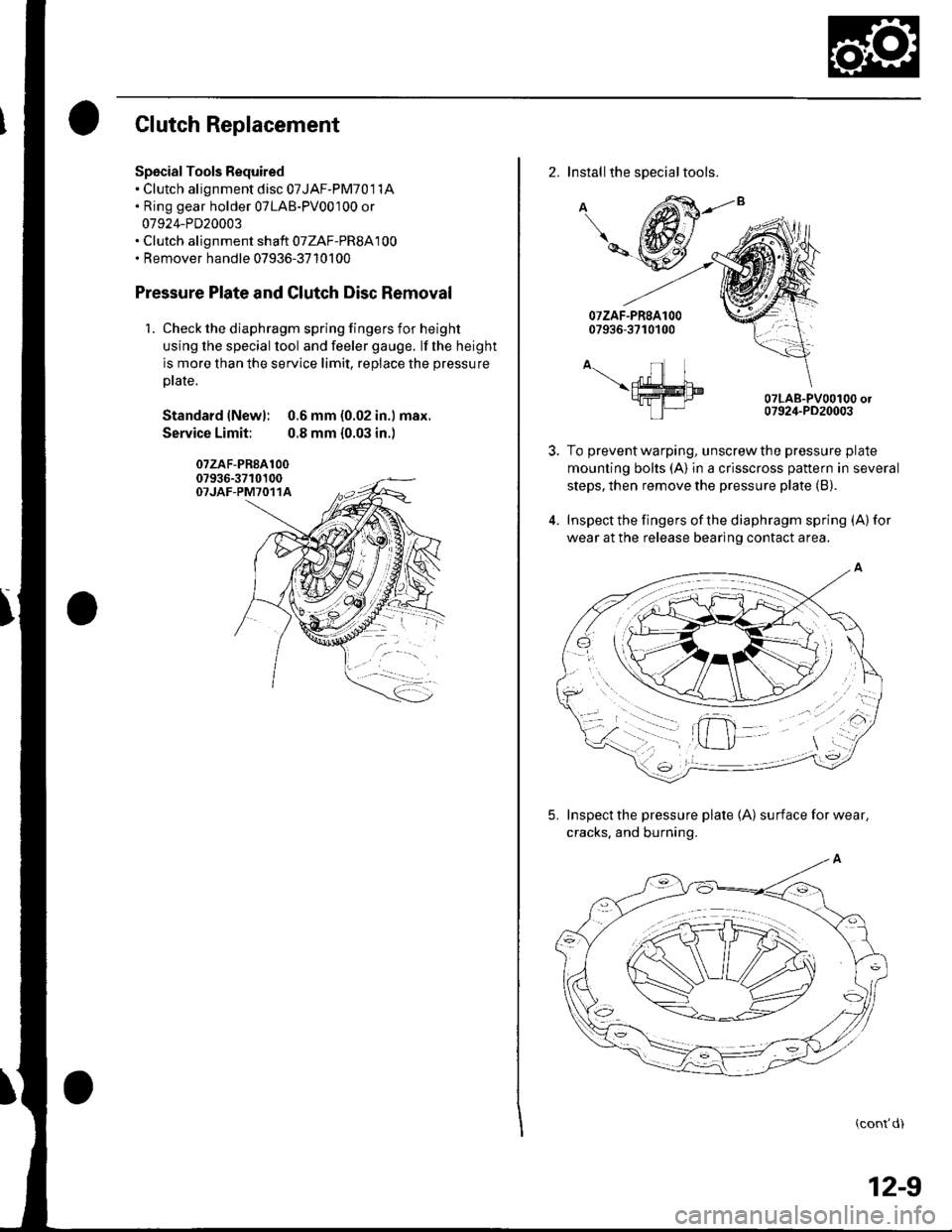

1. Check the diaphragm spring fingers for height

using lhe special lool and feeler gauge. lf the height

is more than the service limit, replace the pressure

ptate.

Standard lNewl: 0.6 mm (0.02 in.) max.

Service Limit: 0.8 mm {0.03 in.)

07zAF-PR8A10007936-3710100OTJAF-PM7O11A

2. Installthe special tools.

A

\-

A-.- nl I\ffim9fra-I tP|-

07LAB-PV00100 or07924-PD20003

To prevent warping, unscrew the pressure plate

mounting bolts (A) in a crisscross pattern in several

steps, then remove the pressure plate (B).

Inspect the fingers of the diaphragm spring (A) for

wear at the release bearing contact area.

5. Inspect the pressure plate 1A) surfaceforwear,

cracks. and burning.

(cont'd)

12-9

Page 407 of 1139

Clutch

Clutch Replacement (cont'd)

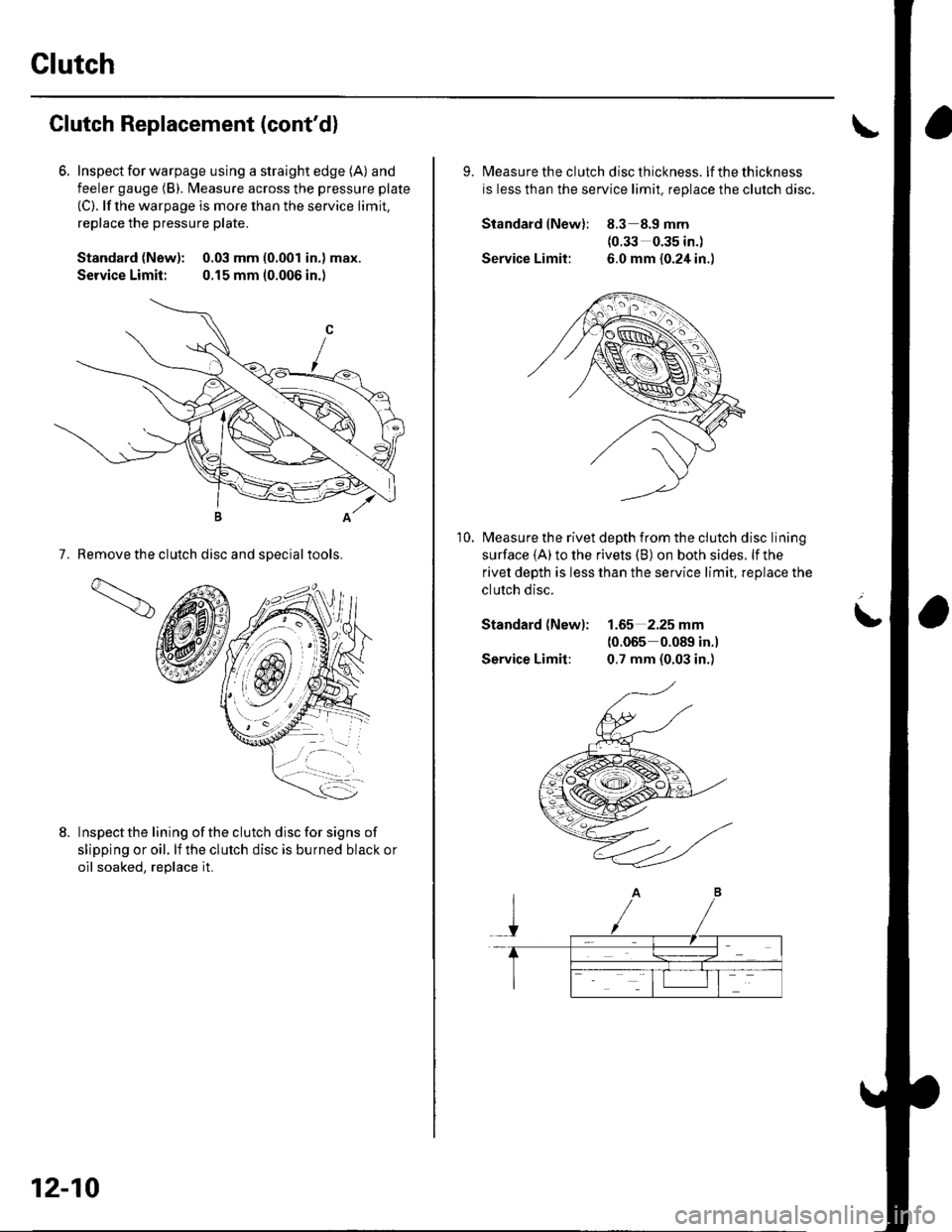

6. Inspecl for warpage using a straight edge (A) and

feeler gauge (B). l\4easure across the pressure plate

(C). lf the warpage is more than the service limit,

replace the pressure plate.

Standard {New): 0.03 mm (0.001 in.) max.

Service Limit: 0.15 mm (0.006 in.)

7. Remove the clutch disc and sDecialtools.

Inspectthe lining ofthe clutch disc for signs of

slipping or oil. lf the clutch disc is burned black or

oil soaked. reolace it.

1d

12-10

9. lvleasu re th e clutch d isc th ickness. lfthethickness

is less than the service limit, replace the clutch disc.

Standard lNew): 8.3 8.9 mm(0.33 0.35 in.)

Service Limit: 6.0 mm {0.24 in.)

Measure the rivet depth from the clutch disc lining

surface (A) to the rivets (B) on both sides. lf the

rivet depth is less than the service limit, replace the

clutch disc.

Standard (New): 1.65 2.25 mm(0.065 0.089 in.)

Service Limit: 0.7 mm (0.03 in.)

10.

L

Page 408 of 1139

Flywheel Inspection

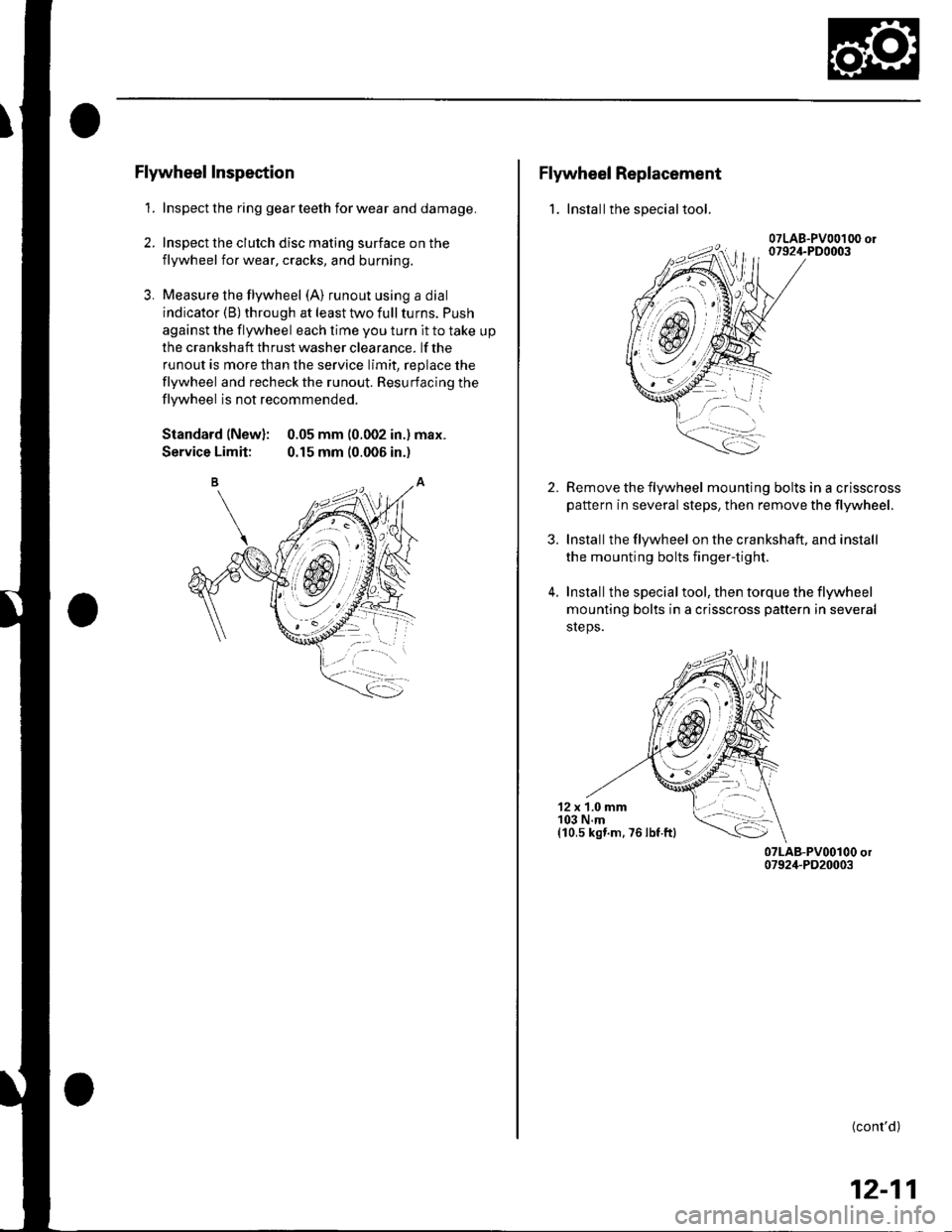

1. Inspect the ring gear teeth for wear and damage.

2. Inspect the clutch disc mating surface on the

flywheel for wear, cracks, and burning.

3. Measure the flywheel (A) runout using a dial

indicator (B) through at least two full turns. Push

against the flywheel each time you turn it to take up

the cra nksh aft th rust washer clea rance. lf the

runout is more than the service limit, replace the

flywheel and recheck the runout. Resurfacing the

flywheel is not recommended.

Standard (New): 0.05 mm (0.002 in.) max.

Service Limit: 0.15 mm (0.006 in.)

Flywheel Replacement

1. Installthe special tool.

2.

3.

4.

Remove the flywheel mounting bolts in a crisscross

pattern in several steps, then remove the tlywheel.

Installthe flywheel on the crankshaft, and install

the mounting bolts fingertight.

Installthe specialtool, then torque the flywheel

mounting bolts in a crisscross pattern in several

sreps.

12 x 1.0 mm103 N.m(10,s kst.m. 76 lbf ftl

(cont'd)

12-11

Page 411 of 1139

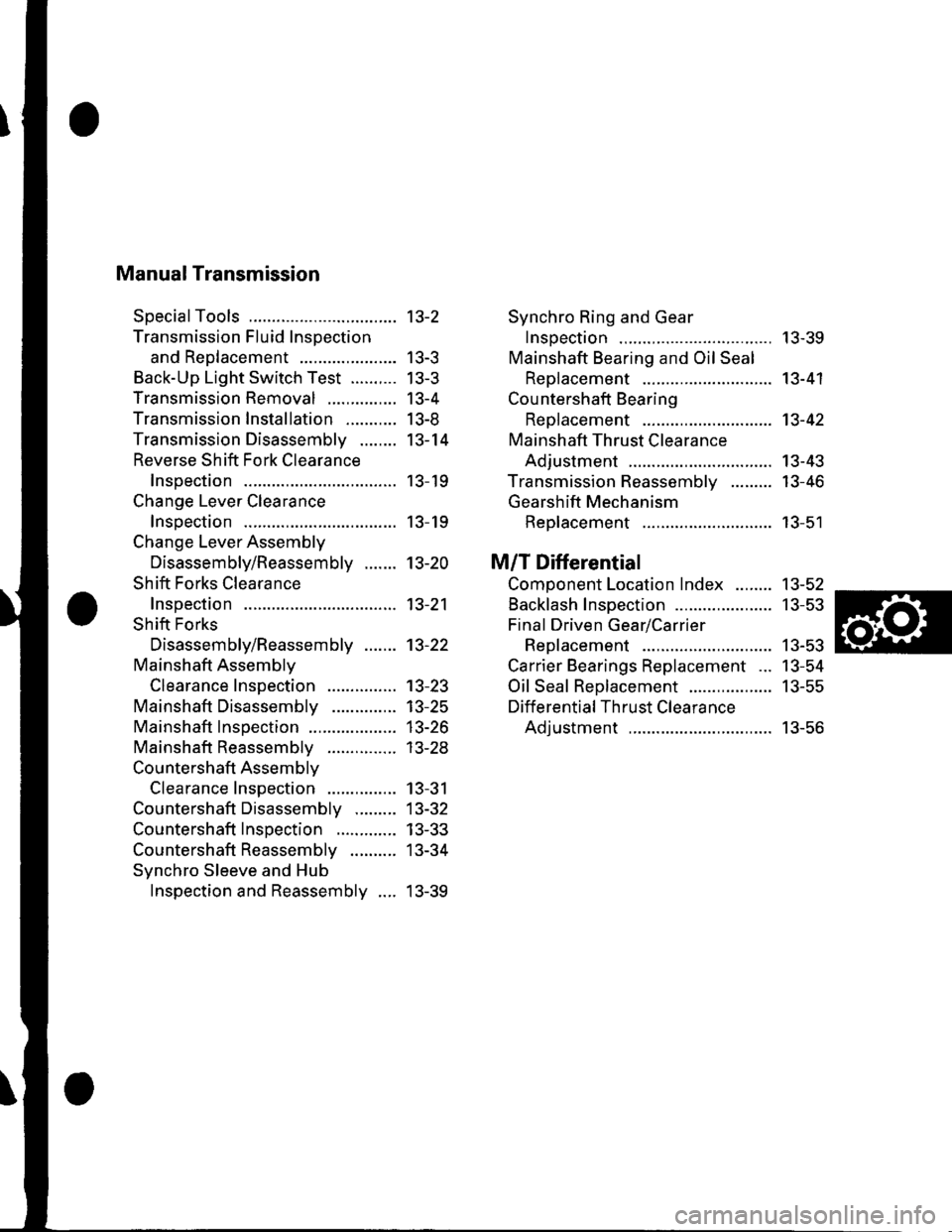

Manual Transmission

SpecialTools

Transmission Fluid Inspection

and Reo1acement ...................-.

Back-Up Light Switch Test ..........

Transmission Removal

Transmission Installation ...........

Transmission Disassemblv ........

Reverse Shift Fork Clearance

lnsoection

Change Lever Clearance

lnsoection

Change Lever Assembly

Disassembly/Reassembly .......

Shift Forks Clearance

Inspection

Shift Forks

Disassembly/Reassembly .......

Mainshaft Assemblv

Clearance Inspection

Mainshaft Disassembly

Mainshaft lnsoection

Mainshaft Reassembly

Countershaft Assemblv

Clearance Inspection

Countershaft Disassembly .........

Countershaft Inspection .............

Countershaft Reassembly ..........

Synchro Sleeve and Hub

Inspection and Reassembly ....

Synchro Ring and Gear

Insoection ....... 13-39

Mainshaft Bearing and Oil Seal

Replacement ........................,... 13-41

Cou ntershaft Bearing

ReDlacement .. 13-42

Mainshaft Thrust Clearance

Adiustment ..... 13-43

Transmission Reassemblv ......... 13-46

Gearshift Mechanism

Replacement ............................ 13-51

M/T Differential

Comoonent Location Index ........ 13-52

Backlash Inspection ..................... 13-53

Final Driven Gear/Carrier

Replacement .. 13-53

Carrier Bearings Replacement ... 13-54

Oil Seal Replacement .................. 13-55

Differential Thrust Clearance

Adiustment ..... 13-56

13-2

| 5-J

tJ-5

13-4

I J-at

13-14

13- 19

13- 19

13-20

13-21

13-22

13-23't3-25

13-26

| 5-2.5

13-31

13-32

13-33

13-34

13-39

Page 412 of 1139

Manual Transmission

SpecialTools

Inspection Tool Set,

Must be used with commercially available 3/8" '16 Slide Hammer.

-4

Z-'

U

@o

I

rS'D

AD;nrf

\".,i'i

IN

@

I

@

@

-4

-a ,/

Q)-''

o

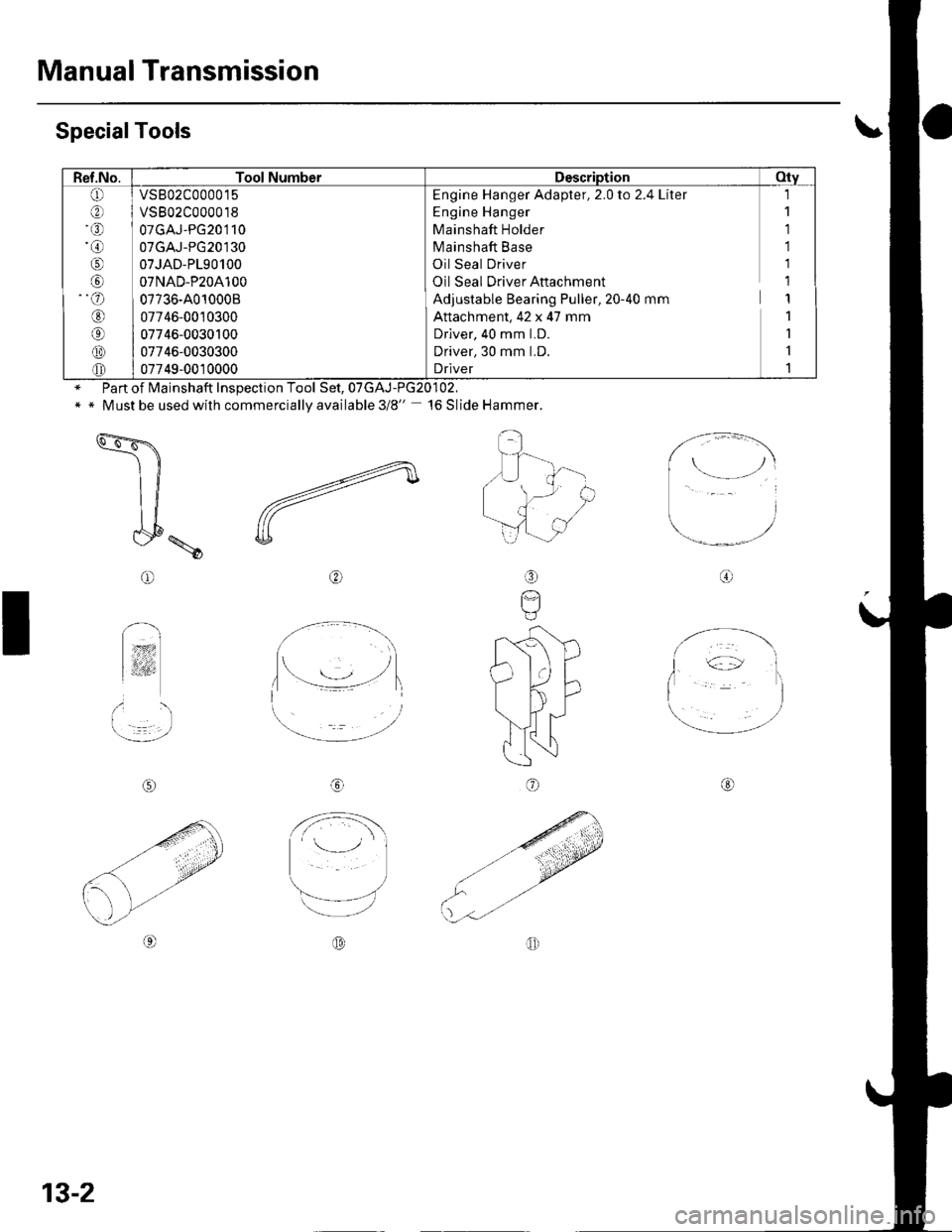

Ref.No.Tool NumberDescription Oty

(!lar\

ral

@

o

ori)

@

@

@

vs802c000015

vs802c000018

07GAJ-PG20'�]10

07GAJ-PG20130

07JAD-P190100

07NAD-P20A100

07736-A01000B

07746-0010300

07746-0030100

07746-0030300

07749-0010000

l,l

l

Engine Hanger Adapter, 2.0 to 2.4 Liter

Engine Hanger

Mainshaft Holder

Mainshaft Base

Oil Seal Driver

Oil Seal Driver Aftachment

Adjustable Bearing Puller, 20-40 mm

Attachment, 42 x 47 mm

Driver, 40 mm LD.

Driver, 30 mm LD.

Driver

on Tool Set. 07GAJ-PG20102.of Mainshaft

\'---''

13-2

Page 413 of 1139

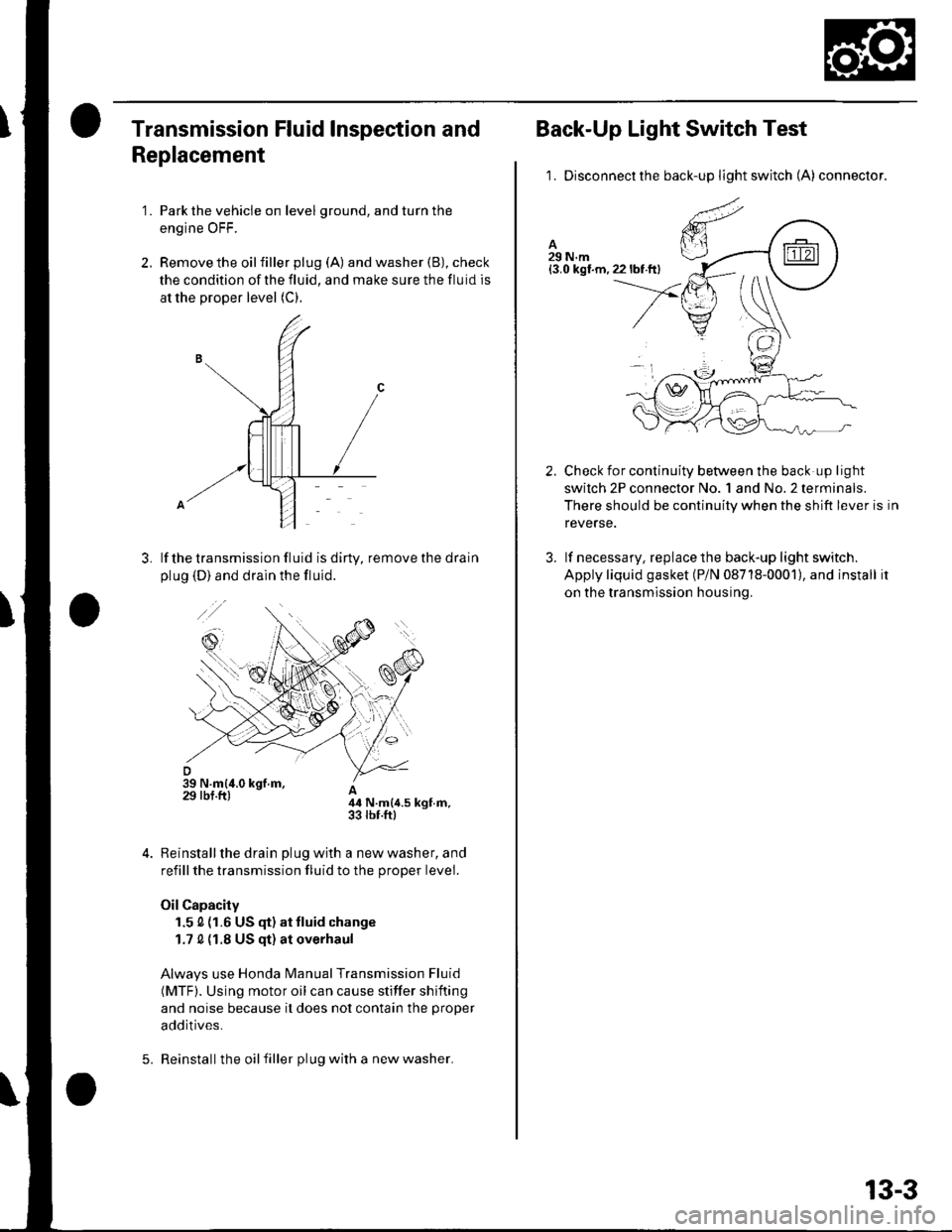

Transmission Fluid Inspection and

Replacement

'1. Park the vehicle on level ground, and turn the

engine OFF.

2. Remove the oilfiller plug (A) and washer (B), check

the condition of the fluid, and make sure the fluid is

at the proper level (C).

lf the transmission fluid is diny, remove the drain

plug (D) and drain the fluid.

A44 N.m{4.5 kgt.m,33 rbr.ftl

Reinstall the drain plug with a new washer, and

refill the transmission fluid to the proper level.

Oil Capacity

1.5 0 (1.6 US (F) at tluid change

1.7 0 {1.8 US qt) at overhaul

Always use Honda Manual Transmission Fluid

(MTF). Using motor oil can cause stiffer shifting

and noise because it does not contain the proper

additives.

Reinstall the oil filler plug with a new washer.5.

13-3

Back-Up Light Switch Test

1. Disconnectthe back-up light switch (A) connector.

Check for continuity between the back up light

swilch 2P connector No. 1 and No.2 terminals.

There should be continuity when the shift lever is in

reverse.

lf necessary, replace the back-up light switch.

Apply liquid gasket (P/N 08718-0001), and install it

on the transmission housing.

2.

3.

Page 414 of 1139

Manual Transmission

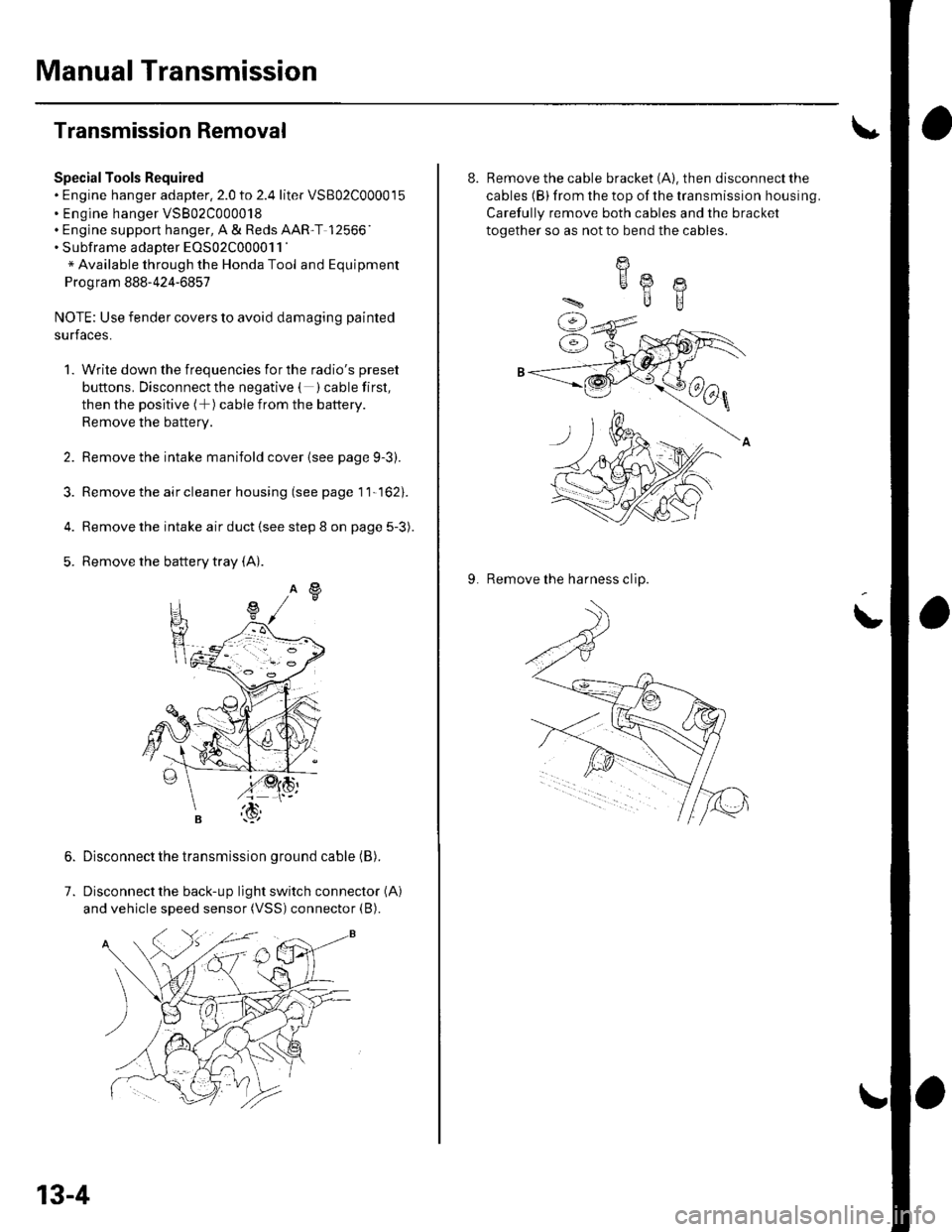

Transmission Removal

SpecialTools Required. Engine hanger adapter.2.0 to 2.4 liter VSB02C000015. Engine hanger VSB02C000018. Engine support hanger, A & Reds AAR'T 12566'. Subframe adaDter EOS02C000011 '

* Available through the Honda Tool and Equipment

Program 888-424-6857

NOTE: Use fender covers to avoid damaging painted

surfaces.

4.

1.

7.

Write down the frequencies for the radio's preset

buttons. Disconnect the negative ( ) cable first,

then the positive ( )cable from the battery.

Remove the battery.

Remove the intake manifold cover {see page g-3).

Remove the air cleaner housing (see page 1 1-162).

Remove the intake air duct {see step 8 on page 5-3).

Remove the battery tray (A).

Disconnect the transmission ground cable (B).

Disconnect the back-up light switch connector (A)

and vehicle speed sensor (VSS) connector (B).

13-4

8. Remove the cable bracket (A). then disconnect the

cables (B) from the top of the transmission housing.

Carefully remove both cables and the bracket

together so as not to bend the cables.

9. Remove the harness clip.

I

HA @

ilB

Page 422 of 1139

Manual Transmission

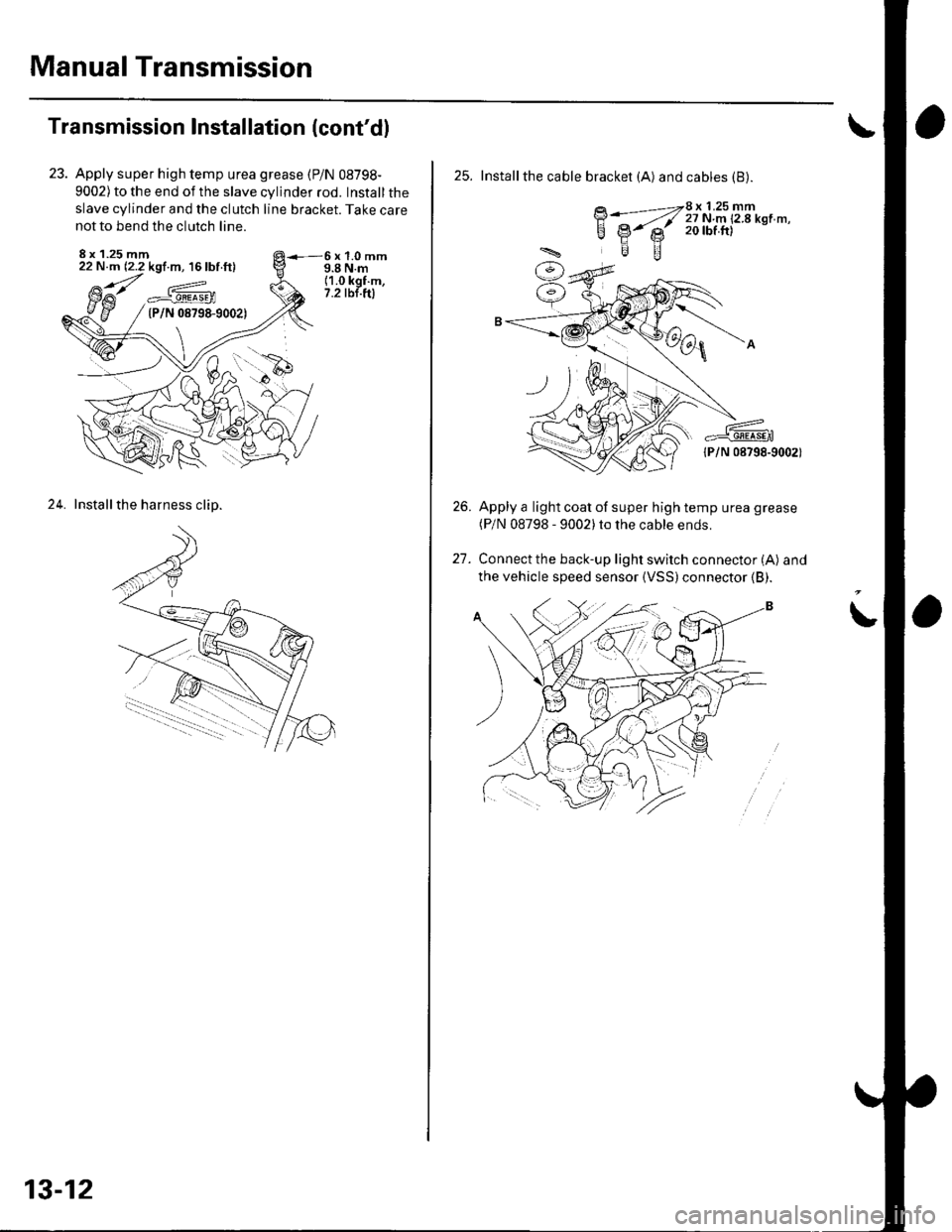

Transmission Installation (cont'dl

Apply super high temp urea grease (P/N 08798-

9002) to the end of the slave cylinder rod. Install the

slave cylinder and the clutch line bracket. Take care

not to bend the clutch line.

8 x 1.25 mm22 N.m (2.2 kgf.m, 16 lbf ft)6x1.0mm9.8 N.m(1.0 kgf.m,7.2 tbt.ftla^_#._gEEa9En(P/N 08798-9002)

24. Installthe harness clip.

13-12

25. Installthe cable bracket (A) and cables (B).

BWZ[i:i'u'T!'*n'-'

lPlN 08798-9002)

Apply a light coat of super high temp urea grease(P/N 08798 - 9002)to the cable ends.

Connect the back-up light switch connector (A) and

the vehicle speed sensor {VSS)connector (B).

26.

t1

Page 423 of 1139

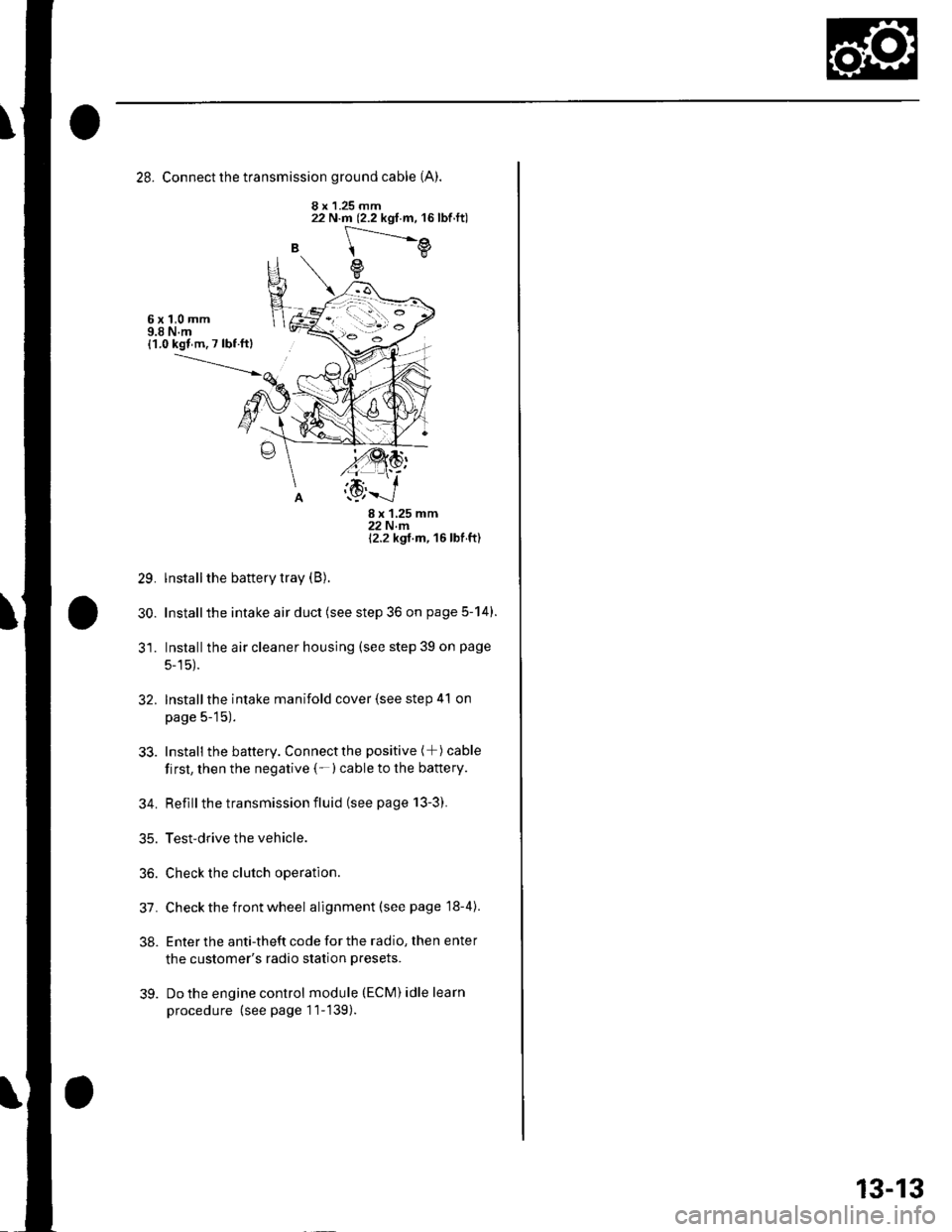

28. Connect the transmission ground cable (A).

8 x 1.25 mm

B

22 N.m (2.2 kgf.m, 16lbf.ft)

[---.-.---e

e

6x1,0mm9.8 N.m{1.0 kgl m. 7 lbf ftl

29.

30.

8x125mm22Nm12.2 kgt m, 16 lbf ft)

lnstall the battery tray (B).

Installthe intake air duct (see step 36 on page 5-14).

Installthe air cleaner housing (see step 39 on page

5-15).

Installthe intake manifold cover (see step 41 on

page 5-15).

Install the battery. Connectthe positive (+) cable

first, then the negative (-)cable to the battery.

Reflllthe transmission fluid (see page 13-3).

Test-drive the vehicle.

Check the clutch operation.

Check the front wheel alignment (see page 18-4).

Enter the anti-theft code for the radio, then enter

the customer's radio station presets.

Do the engine control module (ECM) idle learn

procedure (see page 11-139).

32.

33.

34.

35.

36.

31.

38.

39.

13-13

Page 428 of 1139

Manual Transmission

Transmission Disassembly (cont'd)

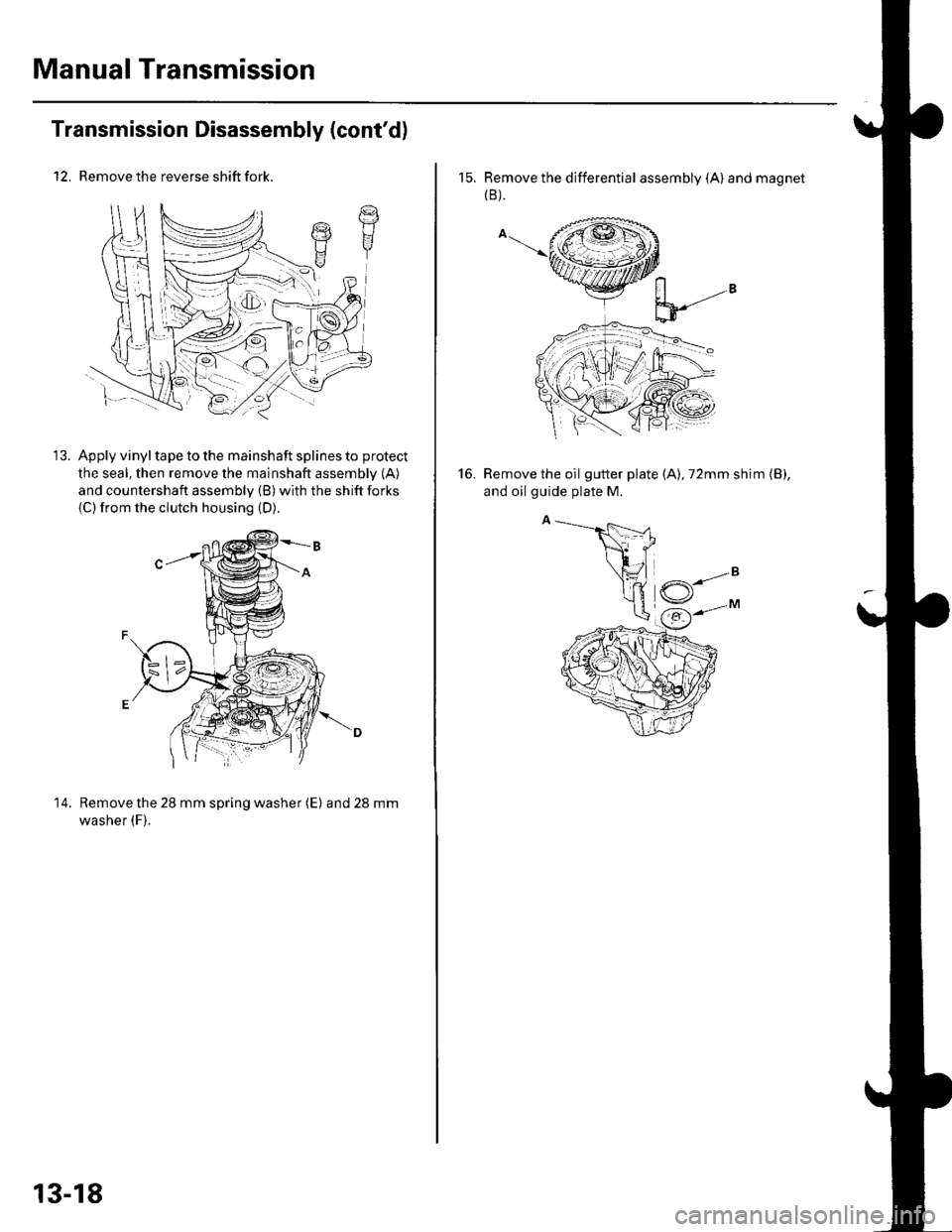

12. Remove the reverse shift fork.

Apply vinyl tape to the mainshaft splines to protect

the seal, then remove the mainshaft assembly (A)

and countershaft assembly (B) with the shift forks

{C)from the clutch housing (D).

14. Remove the 28 mm spring washer (E) and28mm

washer (F).

t7t1I

13-18

15. Remove the differential assembly (A) and magnet(B ).

Remove the oil gutter plate (A), 72mm shim (B),

and oil guide plate M.

16.