ect HONDA CIVIC 2003 7.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 2003, Model line: CIVIC, Model: HONDA CIVIC 2003 7.GPages: 1139, PDF Size: 28.19 MB

Page 457 of 1139

-26 x 1,0 mmz/ / 15 N.m--' / {1 5 kgf m,€t I 11 tbf.ft)

Fl g

E

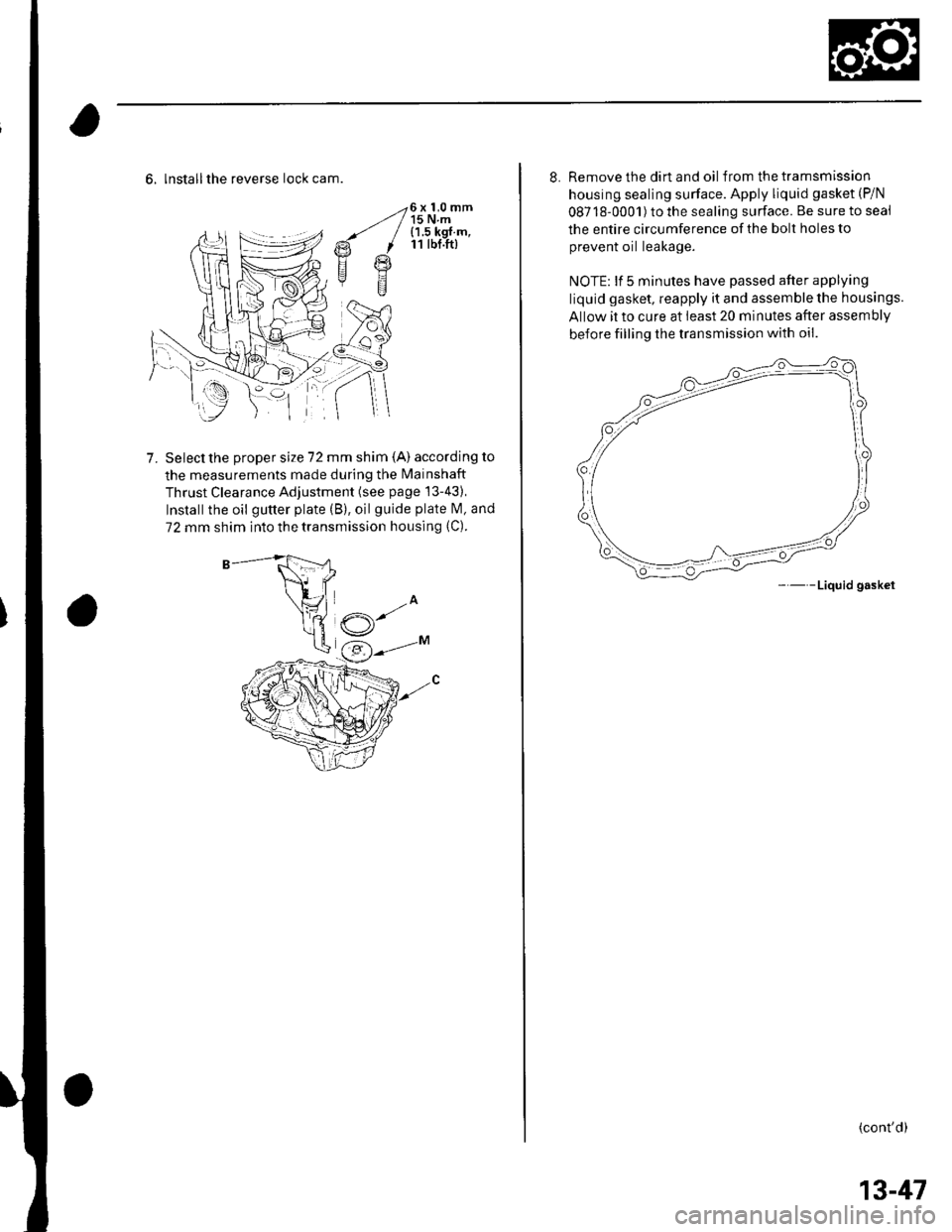

6, lnstallthe reverse lock cam.

Select the proper size 72 mm shim (A) according to

the measurements made during the Mainshaft

Thrust Clearance Adjustment (see page '13-43),

Installthe oil gutter plate (B), oilguide plate l\4, and

72 mm shim into the transmission housing (C).

7.

8. Remove the dirt and oil f rom the tramsmission

housing sealing surface. Apply liquid gasket (P/N

08718-0001) to the sealing surface. Be sure to seai

the entire circumference of the bolt holes to

prevent oil leakage.

NOTE: lf 5 minutes have passed after applying

liquid gasket, reapply it and assemble the housings.

Allow it to cure at least 20 minutes after assembly

before filling the transmission with oil.

- - -Liquid gasket

{cont'd)

13-47

Page 462 of 1139

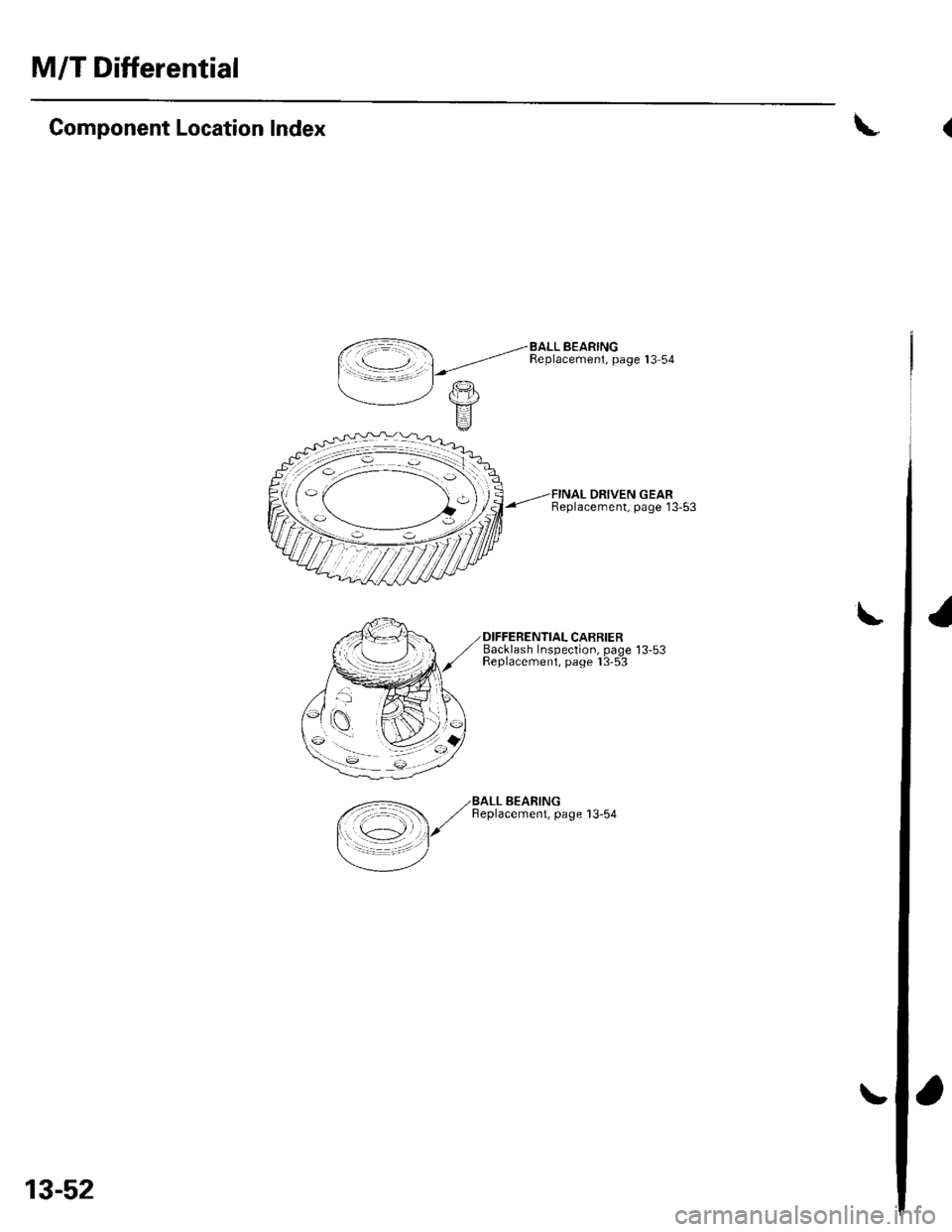

M/T Differential

Component Location Index

DRIVEN GEARBeplacement, page 13-53

Backlash Insoection. oaoe 13-53Feplacemeni, paoe I 3-5-3

\

\

,<-=- ,/BALL BEARING

/ ,/ Beplacemenl, page 13-54

I \c1 l/

=/

13-52

(

I

Page 463 of 1139

\

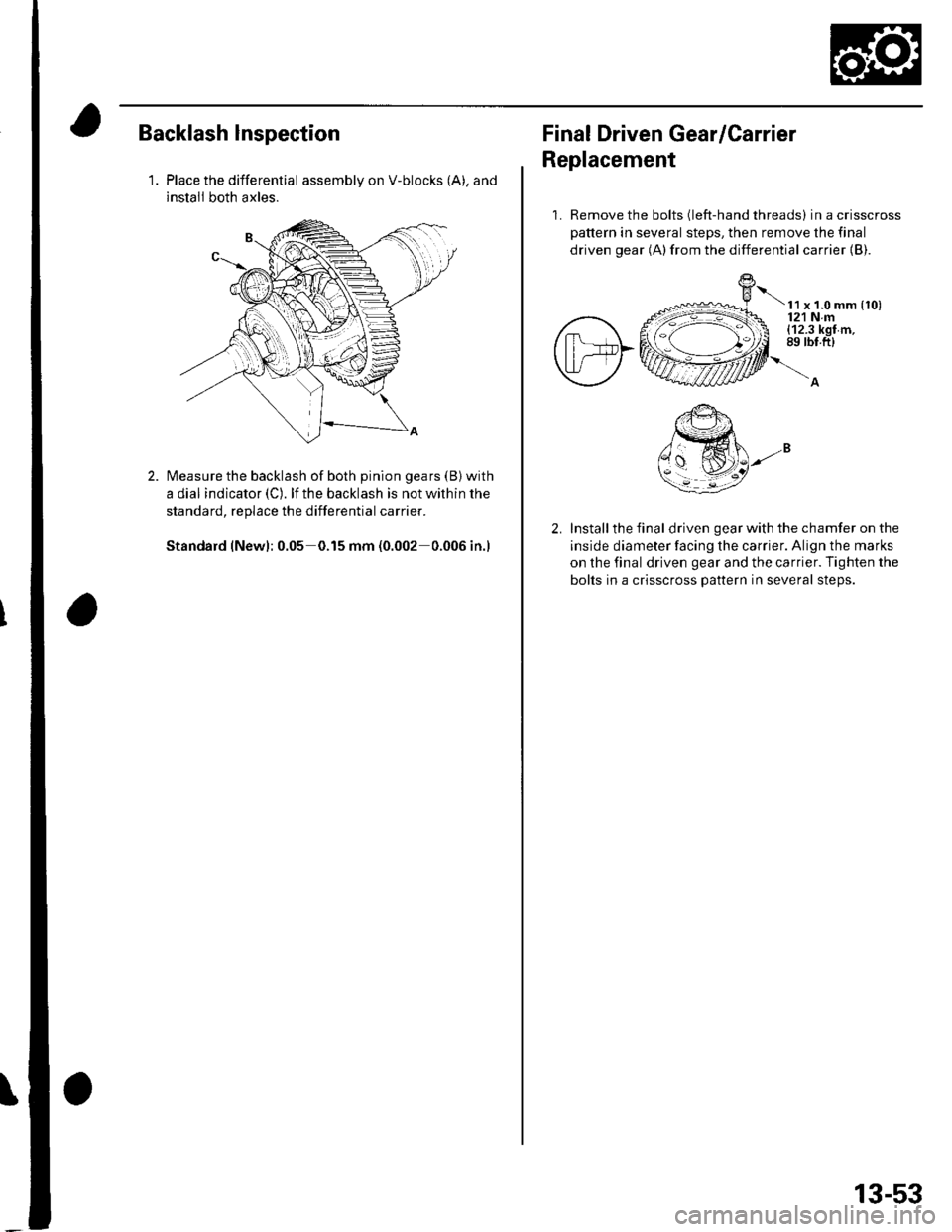

Backlash lnspection

1.Place the differential assembly on V-blocks (A), and

install both axles.

Measure the backlash of both pinion gears (B) with

a dial indicator (C). lf the backlash is not within the

standard, replace the differential carrier.

Standard (New): 0.05 0.15 mm (0.002 0.006 in.)

Final Driven Gear/Carrier

Replacement

1. Remove the bolts (left-hand threads) in a crisscross

pattern in several steps, then remove the final

driven gear (A)from the differential carrier {B).

t x t.o mm {to)121 Nm(12.3 kgf m,89 rbt.ft)

Install the final driven gear with the chamfer on the

inside diameter facing the carrier. Align the marks

on the final driven gear and the carrier. Tighten the

bolts in a crisscross pattern in several steps.

13-53

Page 467 of 1139

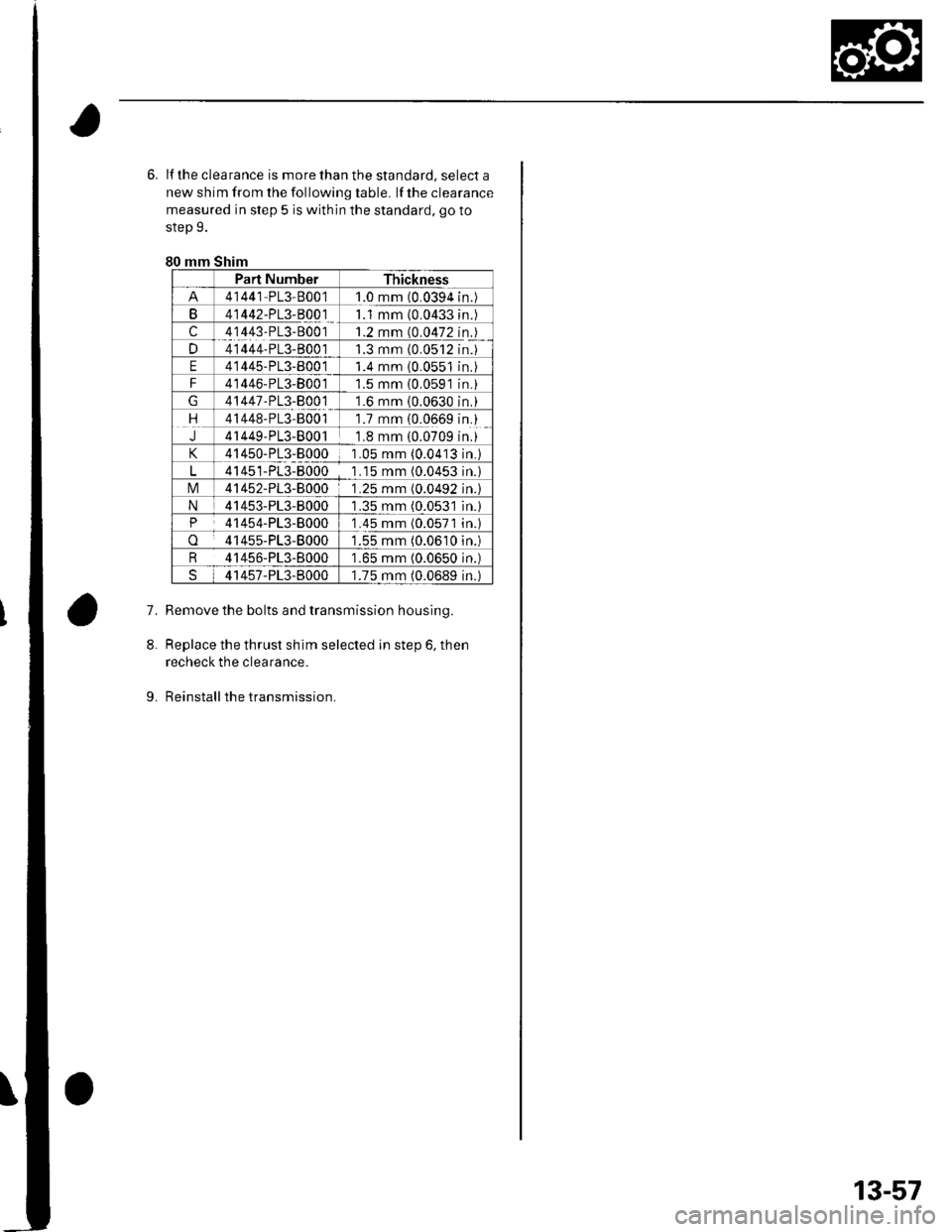

6. lf the clea rance is more than the standard, select a

new shim from the following table. lf the clearance

measured in step 5 is within the standard, go to

step 9.

80 mm Shim

Part NumberThickness

41441 PL3-80011.0 mm (0.0394n.

B41442-PL3-B00111 mm (0.0433n.

c41443-PL3-80011.2 mm (0.0472n.

D41444-PL3-B0011.3 mm {0.0512n.

E41445-PL3-800 11.4 mm 10.0551n.

F41446-PL3-80011.5 mm {0.0591n.

41447-PL3-800 11.6 mm (0.0630n.

rt41448-PL3-B0011.7 mm {0.0669n.

J41449-PL3-80011.8 mm (0.0709n.

41450-PL3-80001 .05 mm (0.0413n.)

41451-PL3-80001 .15 mm (0.0453n.l

tvl41452-PL3-80001.25 mm (0.0492n.l

N41453-PL3-80001.35 mm (0.053'ln.)

P41454-PL3-80001 .45 mm (0.0571n.l

o41455-PL3-80001.55 mm (0.0610n.)

R 41456-PL3-8000'1.65 mm (0.0650 in.)

41457-PL3-80001.75 mm (0.0689 in.)

7.Remove the bolts and transmission housing.

Replace the thrust shim selected in step 6, then

recheck the clearance.

Reinstall the transmission.

8.

9.

13-57

Page 468 of 1139

Driveline/Axle

SpecialTools ............. 16-2

Driveshaft Inspection ......................... 16-3

Driveshafts Removal .......................... 16-3

Driveshafts Disassembly ................... 16-5

Dynamic Damper Replacement ........ 16-8

Driveshafts Reassembly .................... 16-9

Driveshafts lnstallation ...................... 16-17

lntermediate Shaft Removal .............. 16-19

Intermediate Shaft Disassembly ................................. 16-20

lntermediate Shaft Reassembly .................................. 16-22

lntermediate Shaft lnstallation .................................... 16-24

Page 470 of 1139

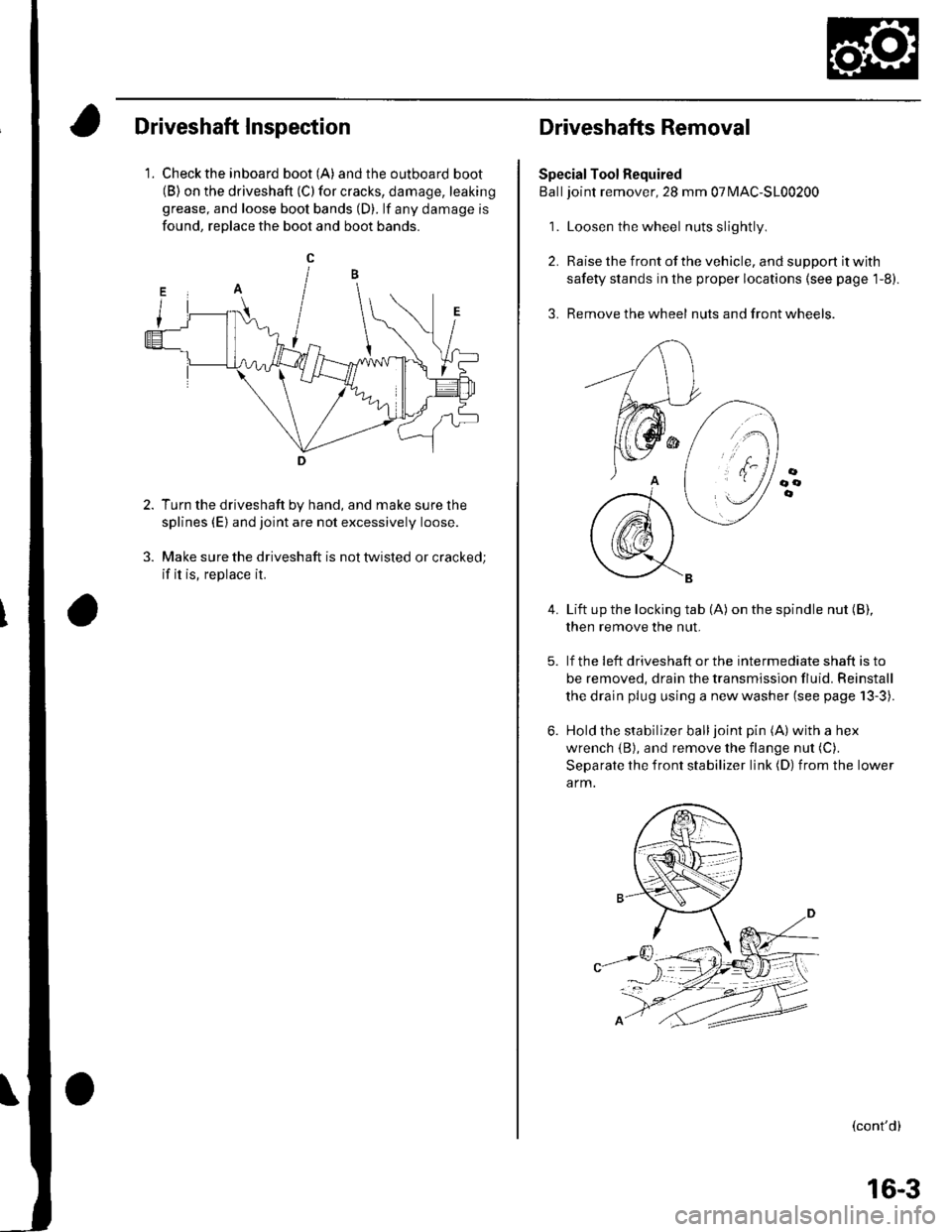

Driveshaft Inspection

1. Check the inboard boot (A) andthe outboard boot(B) on the driveshaft (C) for cracks, damage, leaking

grease, and loose boot bands (D). lf any damage is

found, reDlace the boot and boot bands.

Turn the driveshaft by hand, and make sure the

splines (E) and joint are not excessively loose.

Make sure the driveshaft is not twisted or cracked;

if it is, replace it.

Driveshafts Removal

Special Tool Required

Balljoint remover, 28 mm 07MAC-S100200

1. Loosen the wheel nuts slightly

2. Raise the front of the vehicle, and support it with

safety stands in the proper locations (see page 1-8).

3. Remove the wheel nuts and front wheels.

4.Lift up the locking tab (A) on the spindle nut (B),

then remove the nut.

lf the !eft driveshaft or the intermediate shaft is to

be removed, drain the transmission fluid. Reinstall

the drain plug using a new washer (see page 13-3).

Hold the stabilizer balljoint pin (A) with a hex

wrench {B), and remove the flange nut (C).

Separate the front stabilizer link (D) from the lower

a rm.

(cont'd)

16-3

Page 475 of 1139

Driveline/Axle

9.

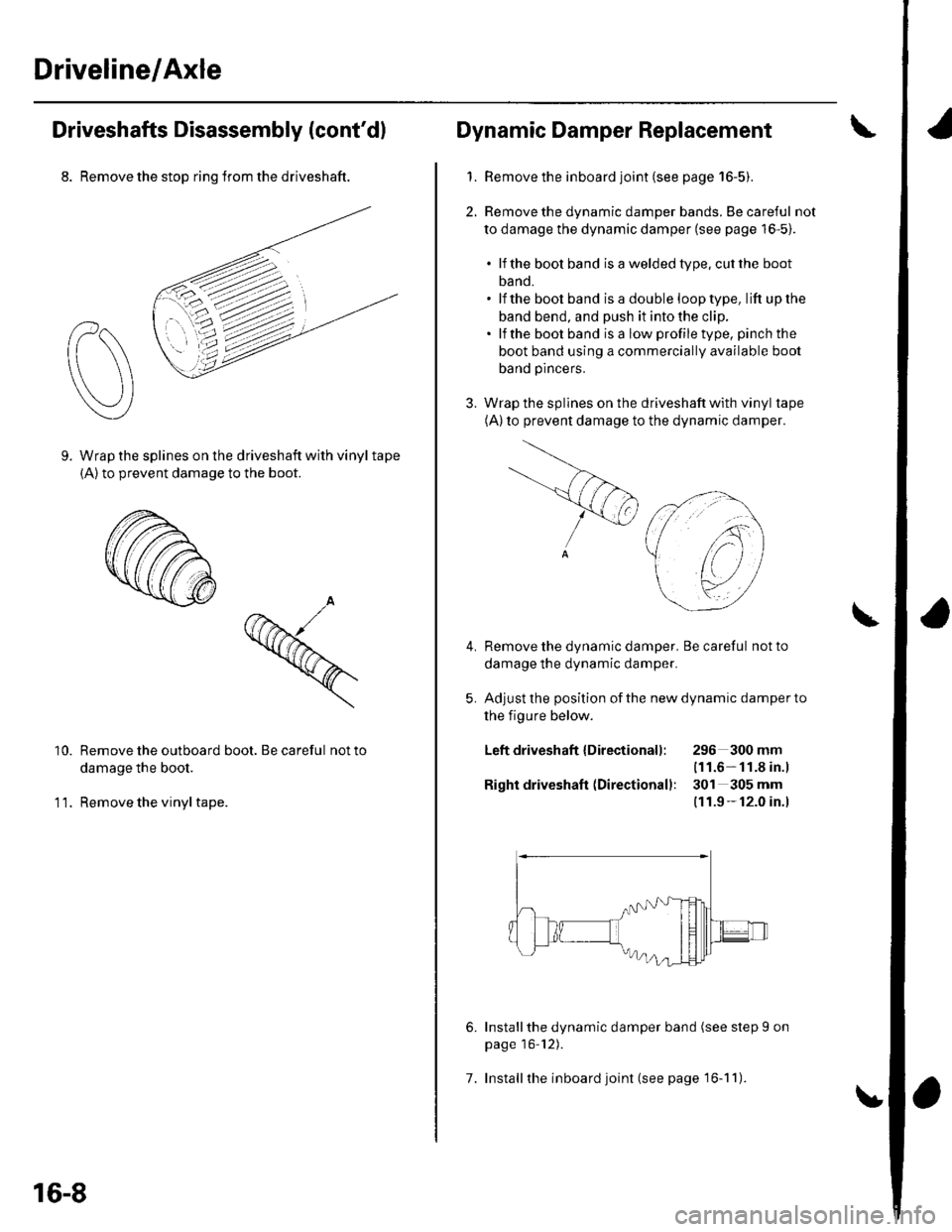

Driveshafts Disassembly (cont'dl

8. Remove the stop ring trom the driveshaft.

Wrap the splines on the driveshaft with vinyl tape(A) to prevent damage to the boot.

Remove the outboard boot. Be careful not to

damage the boot.

Remove the vinyl tape.

10.

11.

16-8

7.

Dynamic Damper Replacement

1. Remove the inboard joint (see page 16-5).

2, Remove the dynamic damper bands. Be careful not

to damage the dynamic damper (see page 16-5).

. lf the bool band isaweldedtype.cutthe boot

band.. lf the boot band isa double looptype, lift upthe

band bend, and push it into the clip.. lfthe boot band is a low profile type, pinch the

boot band using a commercially available boot

band pincers.

3. Wrap the splines on the driveshaft with vinyl tape

(A)to prevent damage to the dynamic damper.

Remove the dynamic damper. Be careful not to

damage the dynamic damper.

Adjust the position of the new dynamic damper to

the figure below.

Left driveshaft {Directionall: 296 300mm(11.6- 11.8 in.)

Right driveshaft (Directionall: 301 305 mm

(11.9 - 12.0 in.l

5.

6.Installthe dynamic damper band (see step I on

page 16'12).

Install the inboard joint (see page 16-1 1).

Page 480 of 1139

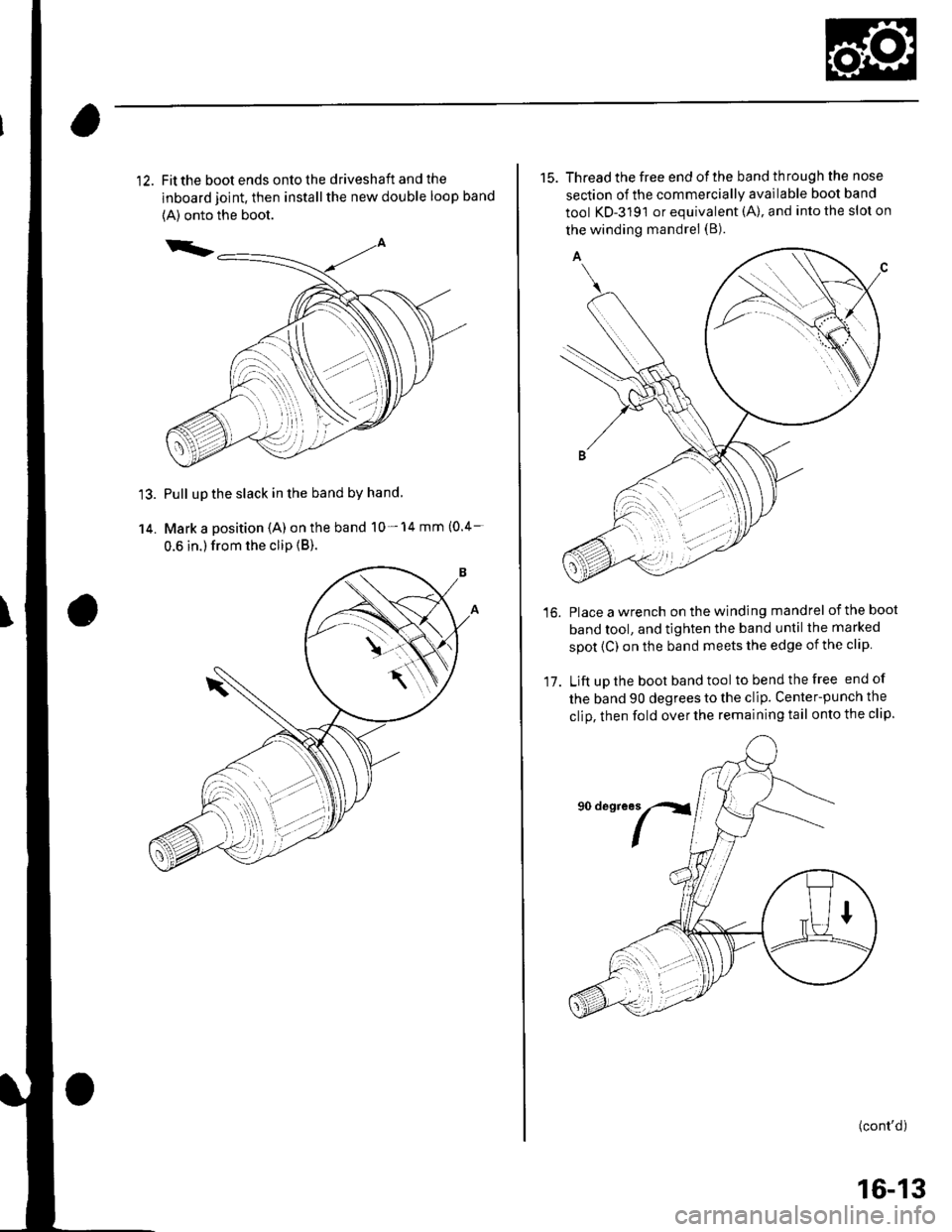

Fit the boot ends onto the driveshaft and the

inboard joint, then install the new double loop band

{A) onto the boot.

Pull up the slack in the band by hand

Mark a position (A) on the band 10- 14 mm (0.4-

0.6 in.) from the clip {B).

15. Thread the free end ofthe band through the nose

section of the commercially available boot band

tool KD-3191 or equivalent (A), and into the slot on

the winding mandrel (B).

Place a wrench on the winding mandrel of the boot

band tool, and tighten the band until the marked

spot (C) on the band meets the edge of the clip

Lift uD the boot band tool tobendthefree end of

the band 90 degrees to the clip. Center-punch the

clio, then fold over the remaining tail onto the clip.

16.

17.

(cont'd)

16-13

Page 482 of 1139

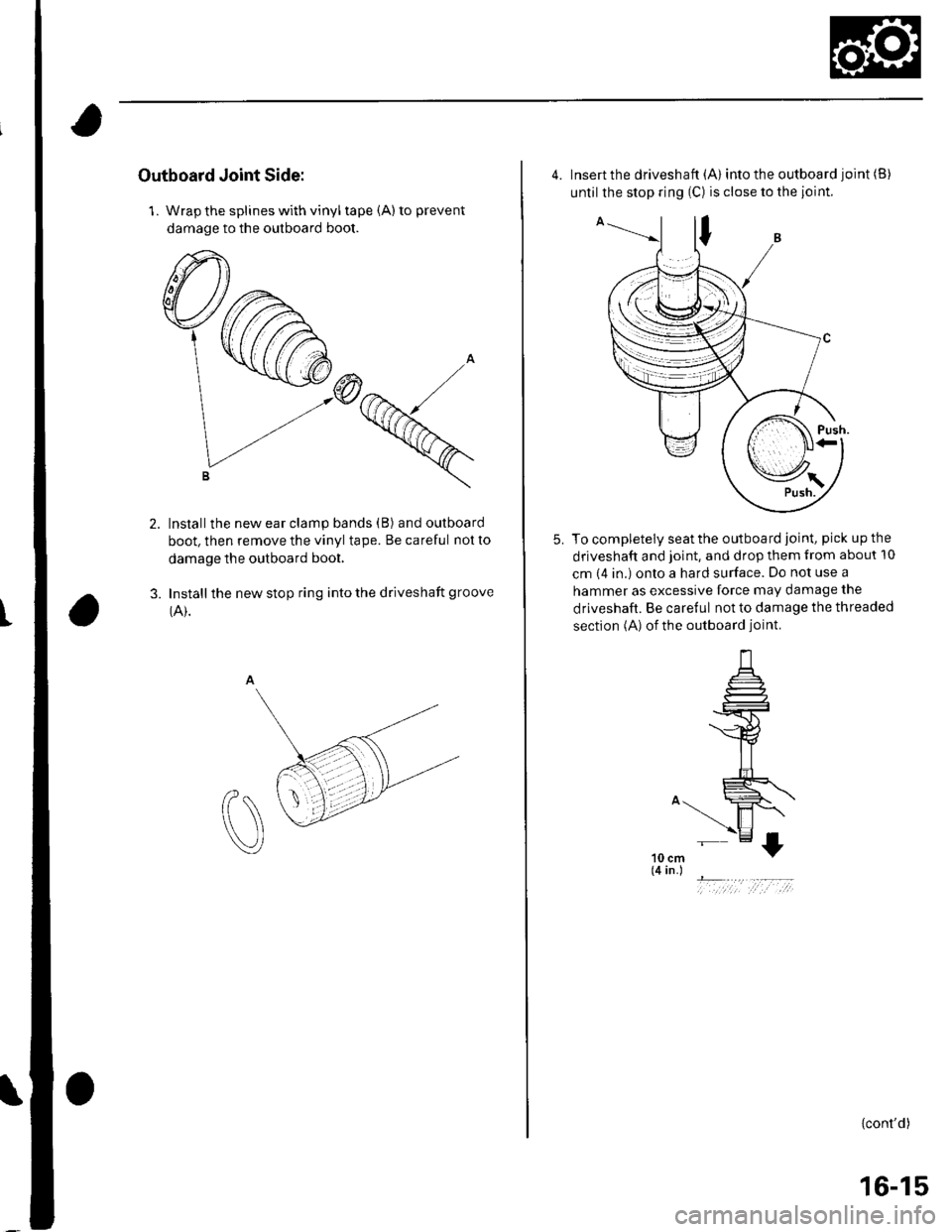

Outboard Joint Side:

1. Wrap the splines with vinyl tape (A) to prevent

damage to the outboard boot.

Installthe new ear clamp bands (B) and outboard

boot, then remove the vinyl tape. Be careful not to

damage the outboard boot.

Install the new stop ring into the driveshaft groove

(A).3.

t

4. Insert the driveshaft (A) into the outboard joint (B)

until the stop ring (C) is close to the joint.

To completely seat the outboard joint, pick up the

driveshaft and joint, and drop them from about 10

cm (4 in.) onto a hard surface. Do not use a

hammer as excessive force may damage the

driveshaft. Be careful not to damage the threaded

section (A) of the outboard joint.

5.

10 cm(4 in.)

- ..,..,1 ;,t ,:-,;

{cont'd)

16-15

Page 485 of 1139

Driveline/Axle

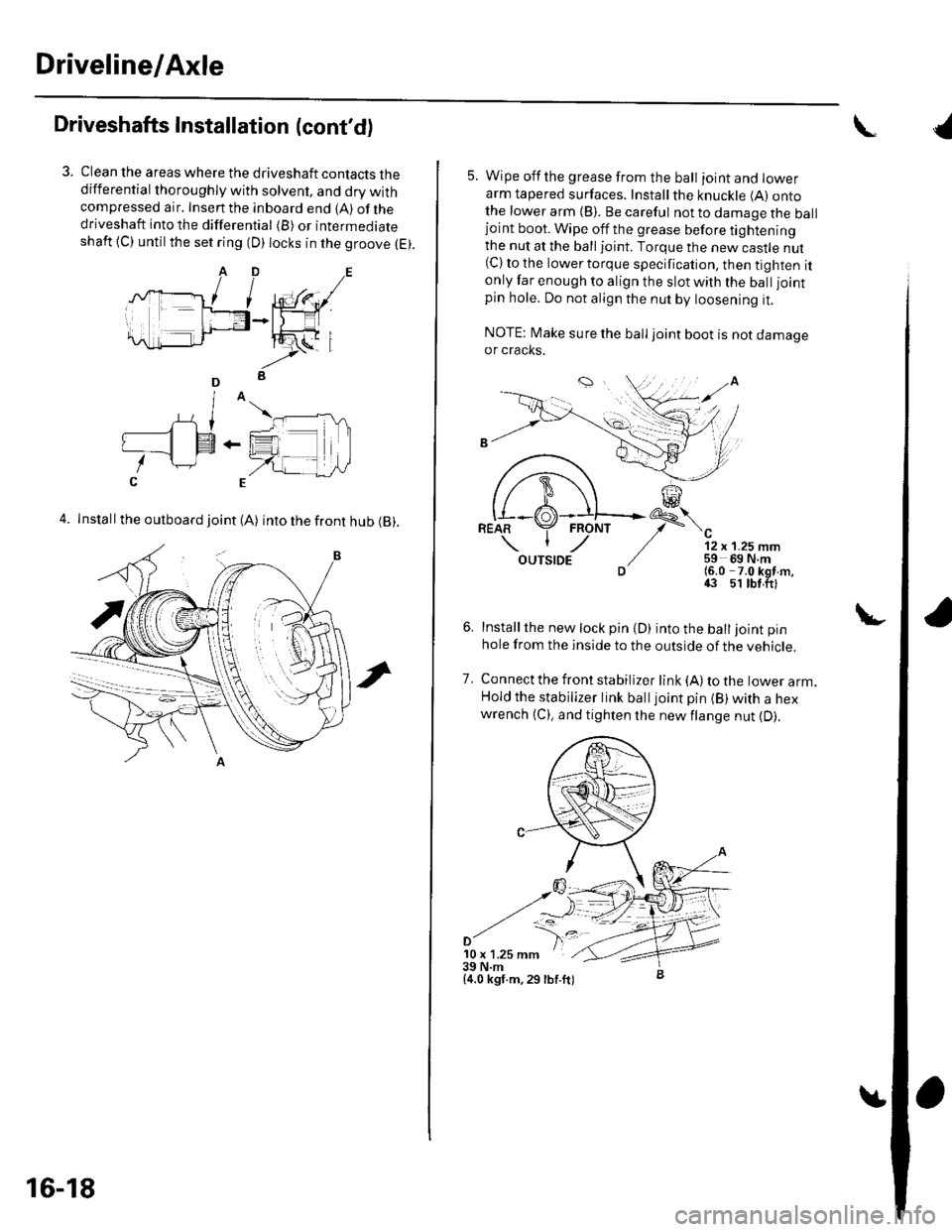

Driveshafts Installation (cont'd)

Clean the areas where the driveshaft contacts thedifferential thoroughly with solvent, and dry withcompressed air. Insenthe inboard end {A) ofthedriveshaft into the differential (B) or intermediateshaft {C) until the set ring (D) locks in the groove (E).

4. Install the outboard joint (A) into the front hub (B).

16-18

5. Wipe offthe grease from the ball ioint and lowerarm tapered surfaces. Installthe knuckle (A) ontothe lower arm {B). Be careful not to damage the balljoint boot. Wipe off the grease before tighteningthe nut at the ball joint. Torque the new castle nut(C) to the lower torque specification, then tighten itonly far enough to align the slot with the ball joint

pin hole. Do not align the nut by loosening it.

NOTE: Make sure the ball joint boot is not damageor cracks.

"-'t-

12 x 1.25 mm59 69 N.m(6.0 -7.0 kgf m,43 51 tbt.ftl

Installthe new lock pin {D) into the balljoint pin

hole from the inside to the outside of the vehicle.

Connect the front stabilizer link {A) to the lower arm.Hold the stabilizer link balljoint pin (B) with a hexwrench {C), and tighten the newflange nut {D).

7.

'10 x 1.25 mm39 N.m{4.0 kgf.m,29 lbf.ft)

{