ect HONDA CIVIC 2003 7.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 2003, Model line: CIVIC, Model: HONDA CIVIC 2003 7.GPages: 1139, PDF Size: 28.19 MB

Page 506 of 1139

Electrical Power Steering (EPSI

SpecialTools ............. 17 -16

Component Location Index ......................................... 17-17

General Troubleshooting Information ....................... 17-18

DTC Troubleshooting Index .............. 17-22

Symptom Troubleshooting Index ............................... 17 -23

System Description ................. ........... 17-24

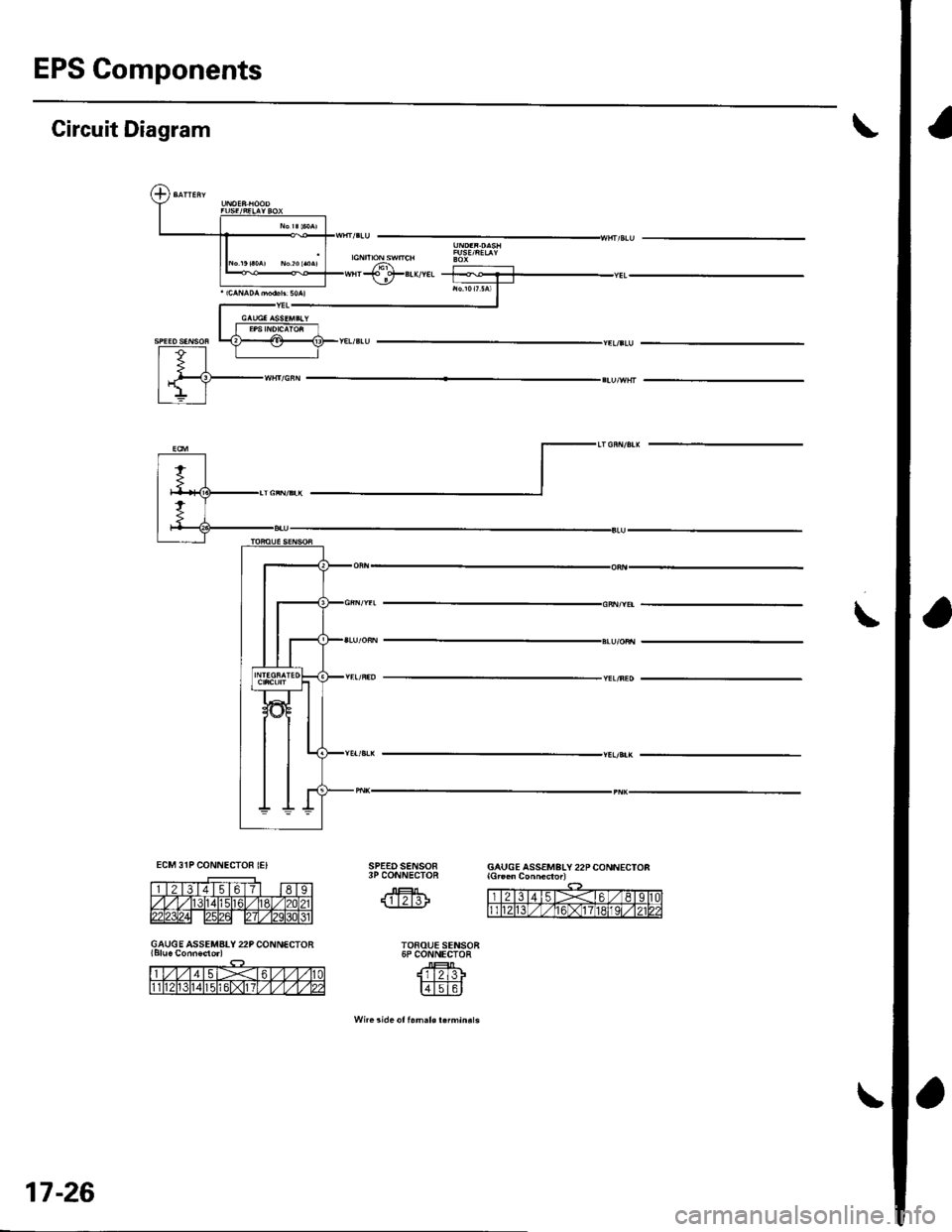

Circuit Diagram ......... 17-26

DTC Troubleshooting ............... .......... 17-28

EPS lndicator Circuit Troubleshooting ....................... 17-47

Motor Removal/lnstallation ............... 17-49

Steering Gearbox Removal ............... 17-51

Steering Gearbox Overhaul ............... 17-55

Steering Gearbox Installation ........... 17-63

EPS Control Unit Remova l/lnsta llation ....................... 17-67

Tie-rod Ball Joint Boot Replacement .......................... 17-67

Page 508 of 1139

![HONDA CIVIC 2003 7.G Workshop Manual Component Location Index

UNDER.HOODFUSE/RELAY BOX

EPS CONTROL UNITEPS Control Unit Removal/lnstallation,page 17 -67

UNDER.DASH FUSE/RELAY BOX

-,/.,....

.,i,

X ]

DATA LINK CONNECTOR I16P)

TOROUE SENS HONDA CIVIC 2003 7.G Workshop Manual Component Location Index

UNDER.HOODFUSE/RELAY BOX

EPS CONTROL UNITEPS Control Unit Removal/lnstallation,page 17 -67

UNDER.DASH FUSE/RELAY BOX

-,/.,....

.,i,

X ]

DATA LINK CONNECTOR I16P)

TOROUE SENS](/img/13/5744/w960_5744-507.png)

Component Location Index

UNDER.HOODFUSE/RELAY BOX

EPS CONTROL UNITEPS Control Unit Removal/lnstallation,page 17 -67

UNDER.DASH FUSE/RELAY BOX

-,'/.,....

'.,i,

X ]

DATA LINK CONNECTOR I16P)

TOROUE SENSOR

STEERING GEARBOXSteering Gearbox Removal, page 17-51Steering Gearbox Overhaul, page 17-55Steering Gearbox Installation, page 17-63

Removal/lnstallation,page l7-49

GAUGE ASSEMBLY

MOTOR

17-17

Page 509 of 1139

EPS Components

aGeneral Troubleshooting Information

EPS Indicator

Under normal conditions, the EPS indicator comes on when

the ignitlon switch is turned to the ON (ll) position, then goes

off after the engine is started. This indicates that the bulb and

its circuit are operating correctly.

lf there is any trouble in the system after the engine is started,

the EPS indicator will stay on, and the power assist is turned

off.

When EPS indicator light comes on, the control unit

memorizes the DTC. In this case, the control unit will not

activate the EPS system after the engine starts again, but it

keeps the EPS indicator on.

When DTC 12, 16, 17, 18 or 67 is stored in the control unit, the

EPS indicator will stay on until the DTC is erased. When a

problem is detected and the EPS indicator comes on, there are

cases when the indicator stays on untilthe ignition switch is

turned 0FF, and cases when the indicator goes off

automatically when the system returns to normal. Even though

the system is operating normally, the EPS indicator will come

on under the following conditions:

Condition '1:

. The vehicle was traveling at least 12.4 mph (20 km/h), then. A rapid change in vehicle speed was detected, then. The vehicle (or the vehicle speed sensor signal) stopped for

at least 5 seconds. The engine speed was still 'l,640rpmorhigherforatleastS

seconds

Condition 2:

After the vehicle (or the vehicle speed sensor signal) has

stopped for at least 10 seconds, yet the engine speed was still

1,640 rpm or higherfor at least 20 seconds.

Condition 3:

When the engine speed is 280 rpm or less, and the vehicle is traveling at

a speed of 6,2 mph (10 km/h) or more for 3 seconds.

To determine the actual cause ofthe problem, question the

customer about the conditions during which the problem

occured, taking the above conditions into consideration.

Diagnostic Trouble Code (DTCI

. lf the CPU cannot be activated, or itfails,the EPS indicator

comes on, but the DTC is not memorized.. The memory can hold any number of DTCS. However, when

the same DTC is detected more than once, the most recent

DTC is written over the prior DTC, therefore only one

occurrence is memorized.. The DTCS are indicated repeatedly untilthe ignition switch is

turned OFF.. lf the DTC is not memorized,the EPS indicator blinks.

. The DTCS are memorized in the EEPRO| (non-volatile

memory) therefore the memorized DTCS cannot be erased

by disconnecting the battery. Perform the specified

procedures to clear DTCS.

Self-diagnosis

Self-diagnosis can be classified into two categories:.Initial diagnosis: performed right after the engine

starts and until the EPS indicator goes off.. Regular diagnosis: performed right after the initial

diagnosis until the ignition switch is turned OFF.

The EPS control unit performs the following functions

when a problem is detected by self-diagnosis;

'1. Turns on the EPS indicator.

2. Memorizes the DTC.

3. Stops power assist and manual steering operation

begrns.

NOTE:. When DTC 23 (a problem with the circuit for

engine speed signal) is detected, the power

assist will return to normal when the vehicle

speed is 0.62 mph (1 km/h) or above.. Fot DfCs 22,23, 64, or 66 the EPS indicator goes

off automatically when the system relurns to

normal. For all other codes, the EPS indicator

goes off when the system is OK after the ignition

switch is turned from OFF to ON (ll).

Restriction on Power Assist Operation

Repeated extreme steering force. such as turning the

steering wheel continuously back-and-forth with the

vehicle stopped, causes an increase of power

consumption in the EPS motor. The increase of electric

current causes the motor to heat up. Because this heat

adversely affects the system, the control unit monitors

the electric current of the motor.

When the control unit detects heat build-up in the motor,

it reduces the electric current to the motor gradually to

protect the system, and it restricts the power assist

operation. The EPS indicator does not come on during

this function.

When steering torque is not applied to the steering

wheel, or when the ignition is turned off, and the motor

cools, the control unit will restore the power assist

gradually until it's fully restored (after approximately 15

minutes maximum).

17-18

Page 510 of 1139

How to Troubleshoot EPS DTCs

The troubleshooting flowchart procedures assume that

the cause of the problem is still present and the EPS

indicator is still on, Following the flowchart when the

EPS indicator does not come on can result in incorrect

diagnosis.

The connector iliustrations show the female terminal

connectors with a single outline and the male terminal

connectors with a double outline.

1. Ouestion the customer about the conditions when

the problem occured, and try to reproduce the

same conditions for troubleshooting. Find out

when the EPS indicator came on, such as while

turning. afterturning, when the vehicle was at a

ce rta in speed, etc.

2. When the EPS indicator does not come on during

the test drive, but troubleshooting is done based on

the DTC, check for loose connectors, poor terminal

contact. etc in the affected circuit, before you start

troubleshooting.

3. After trou bleshooting, clear the DTC and test-drive

the vehicle. Be sure the EPS indicator does not

come on.

How to Retrieve EPS DTCs

Honda PGM Tester Method:

1, With the ignition switch OFF, connect the Honda

PGM Tester (A) to the 16P data link connector (DLC)

(B) located under the dash on the driver's side of

the vehicle.

2. Turn the ignition ON (ll), and follow the prompts on

the PGM Tester to display the DTC(s) on the screen.

After determining the DTC, refer to the DTC

Troubleshooting Index.

NOTE: See the Honda PGM Tester user's manual

for specific instructions.

Service Check Signal Circuit Method:

1. With the ignition switch OFF, connect the Honda

PGM Tester (A)to the 16P data link connector (DLC)

(B) located under the dash on the driver's side of

the vehicle.

Short the SCS circuit to body ground using the

Honda PGN4 Tester.

Turn the ignition switch ON {ll).

Record the DTC.

(cont'd)

17-19

Page 511 of 1139

EPS Components

General Troubleshooting Information (cont'dl

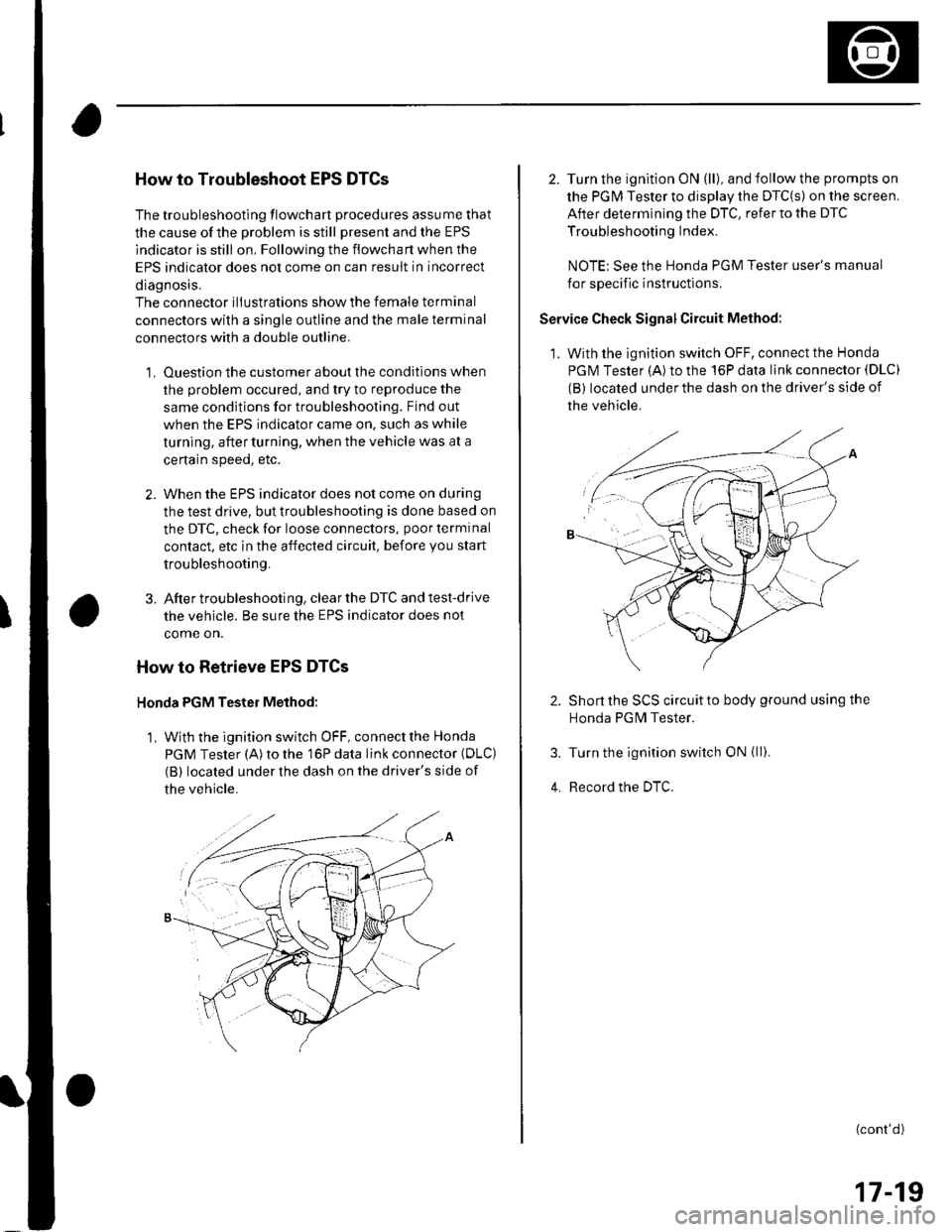

5. The blinking frequency indicates the DTC. DTCS are

indicated by a series of long and short blinks. One

long blink equals 10 short blinks. Add the long and

short blinks together to determine the DTC. After

determining the DTC, refer to the DTC

Troubleshooting Index.

The system will not indicate the DTC unless these

conditions are met:. Set the front wheels in the straight ahead drivingposition.. The ignition switch is turned ON (ll).. The engine is stopped.. The SCS circuit is shorted to body ground before

the ignition switch is turned ON (ll).

Example of DTC 23

Long blinks Short blinks(two times) (three timesl

6.

7.

Turn the ignition switch OFF.

Disconnect the Honda PGM Tester from the DLC.

17-20

How to Clear EPS DTCs

Honda PGM Tesler Method:

1. With the ignition switch OFF, connect the Honda

PGM Tester (A) to the 16P data link connector (DLC)

(B) located under the dash on the driver's side of

the vehicle.

Turn the ignition switch ON (ll), and clear the

DTC{s) by following the screen prompts on the

PGM Tester.

NOTE: See the Honda PGM Tester user's manual

for specific instructions.

Page 512 of 1139

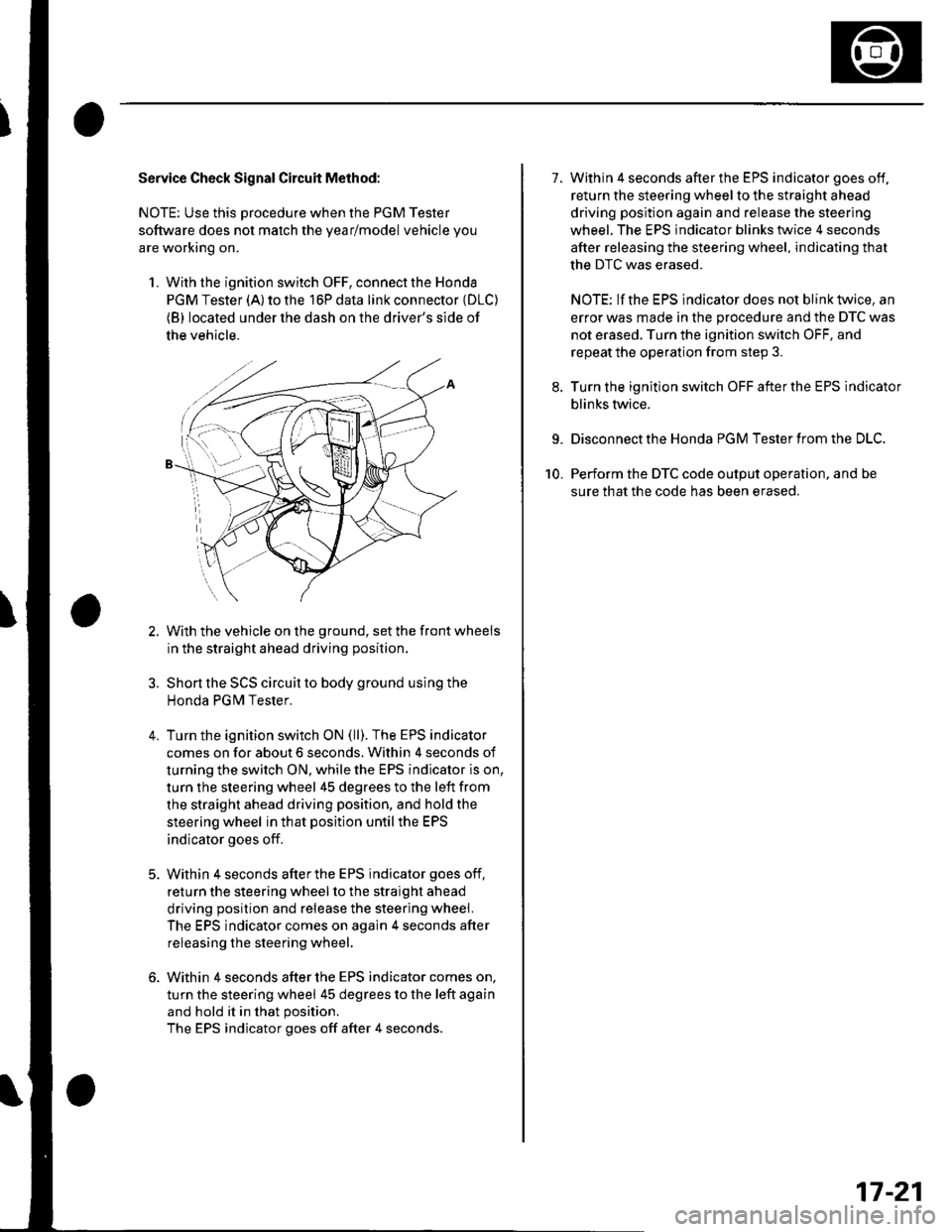

Service Check Signal Circuit Method:

NOTE: Use this procedure when the PGM Tester

software does not match the yearlmodel vehicle you

are working on.

1. With the ignition switch OFF, connect the Honda

PGM Tester (A) to the 16P data link connector {DLC)(B) located under the dash on the driver's side of

the vehicle.

With the vehicle on the ground, set the front wheels

in the straight ahead driving position.

Short the SCS circuit to body ground using the

Honda PGM Tester.

Turn the ignition switch ON (ll). The EPS indicator

comes on for about 6 seconds. Within 4 seconds of

turning the switch ON, while the EPS indicator is on,

turn the steering wheel 45 degrees to the left from

the straight ahead driving position, and hold the

steering wheel in that position until the EPS

indicator goes off.

Within 4 seconds afterthe EPS indicator goes off,

return the steering wheel to the straight ahead

driving position and release the steering wheel.

The EPS indicator comes on again 4 seconds after

releasing the steering wheel,

Within 4 seconds after the EPS indicator comes on,

turn the steering wheel 45 degrees to the left again

and hold it in that position.

The EPS indicator goes off after 4 seconds.

4.

1.Within 4 seconds after the EPS indicator goes off,

return the steering wheel to the straight ahead

driving position again and release the steering

wheel. The EPS indicator blinks twice 4 seconds

after releasing the steering wheel, indicating that

the DTC was erased.

NOTE: If the EPS indicator does not blink twice, an

error was made in the procedure and the DTC was

not erased. Turn the ignition switch OFF, and

repeat the operation from step 3.

Turn the ignition switch OFF afterthe EPS indicator

blinks twice.

9. Disconnect the Honda PGM Tester from the DLC.

10. Perform the DTC code output operation, and be

sure that the code has been erased.

17-21

Page 513 of 1139

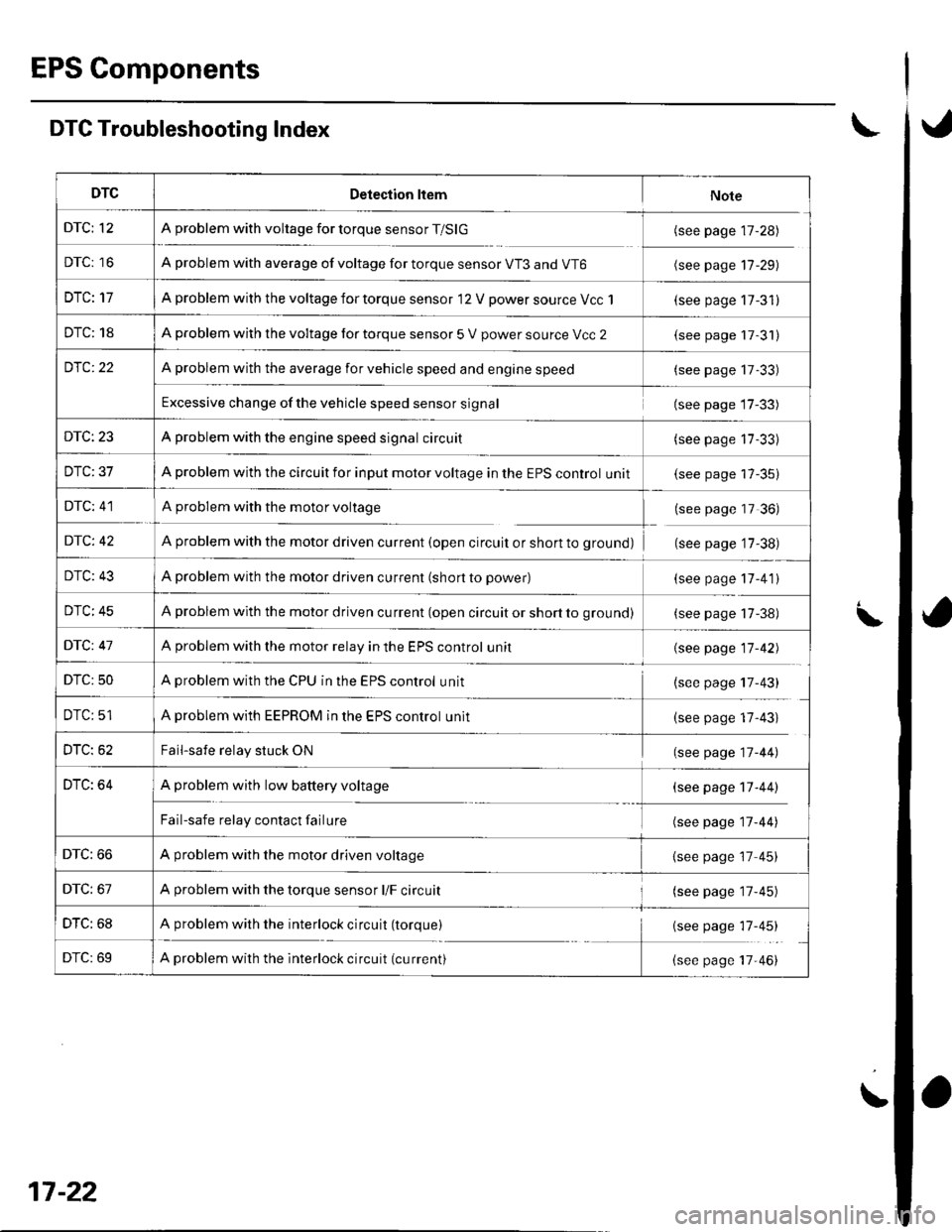

EPS Components

DTC Troubleshooting Index

DTCDetection ltemNote

DTC; 12A problem with voltage for torque sensor T/SlG(see page 17-28)

DTC: 16A problem with average of voltage for torque sensor VT3 and VT6(see page 17-29)

DTC: 17A problem with the voltage for torque sensor 12 V power source Vcc 1(see page 17-31)

DTC: 18A problem with the voltage for torque sensor 5 V power source Vcc 2(see page 17-31)

DfC:22A problem with the average for vehicle speed and engine speed(see page 17-33)

Excessive change of the vehicle speed sensor signal{see page 17-33)

DTC: 23A problem with the engine speed signal circuit(see page 17-33)

DTC: 37A problem with the circuit for input motor voltage in the EPS control unit(see page 17-35)

DTC: 41A problem with the motor voltage(see page 17 36)

DfC: 42A problem with the motor driven current (open circuit or short to grounol(see page '17-38)

DTC: 43A problem with the motor driven current (short to power)(see page 17-41)

DTC: 45A problem with the motor driven current (open circuit or short to grou nol(see page 17-38)

DfC: 47A problem with the motor relav in the EPS control unit{see page 17-42)

DTC: 50A problem with the CPU in the EPS control unit(see page 17-43)

DTC: 51A problem with EEPROM in the EPS control unlt(see page 17-43)

DTC: 62Fail-safe relay stuck ON(see page 17-44)

DTC: 64A problem with low battery voltage

Fail-safe relay contact failure

(see page 17-44)

(see page 17-44)

DTC: 66A problem with the motor driven voltage{see page 17 45)

DTC: 67A problem with the torque sensor l/F circuit(see page 17'45)

DTC: 68A problem with the interlock circuit (torque){see page 17-45)

DTC: 69A problem with the interlock circuit (current)(see page 17-46)

17-22

Page 515 of 1139

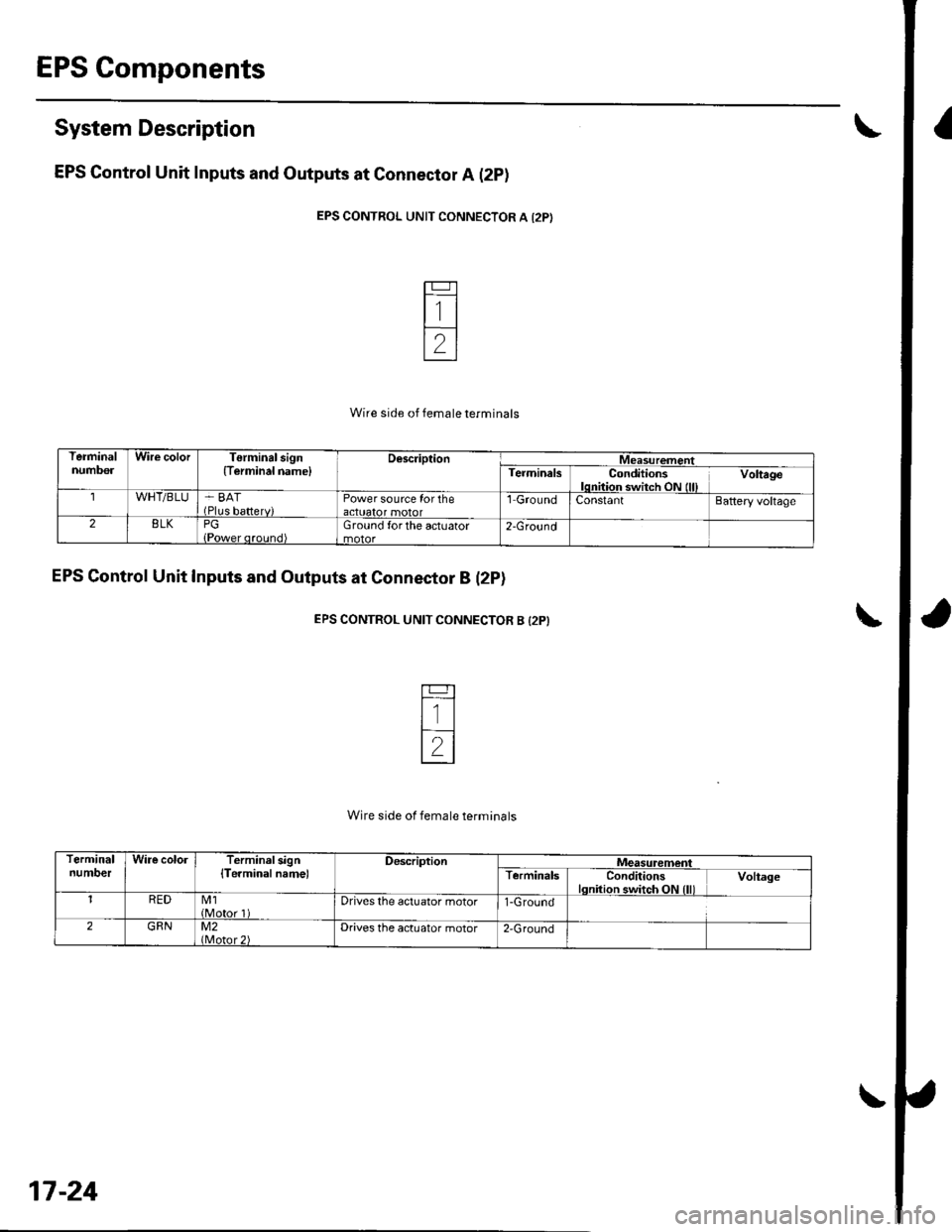

EPS Gomponents

System Description

EPS Gontrol Unit Inputs and Outputs at Connector A (2pl

EPS CONTROL UNIT CONNECTOR A {2P)

Wire side of female terminals

EPS Control Unit Inputs and Outputs at Connector B (2P)

EPS CONTROL UNIT CONNECTOB B {2P}

Wire side of female terminals

TermanalnumbolWire colorTerminal sign(Terminal namelDescriptionMeasurementTerminalsConditionslqnitiqr switch ON (lllVoltage

WHT/BLU-' BAT(Plus bafterv)Power source for theactuator motorl GroundConstantBattery voltage

28LKPGGround forthe actuator2-Ground

TerminalnumDerWire cololTerminalsign{Te.mioalname)DescriptionMeasuremenlTerminalsConditionslqnition switch ON llllVoltage

1REDM1(Motor 1Drives lhe actuator motor1-Ground

2GRNM2Drives the actuator motor2'Ground

17-24

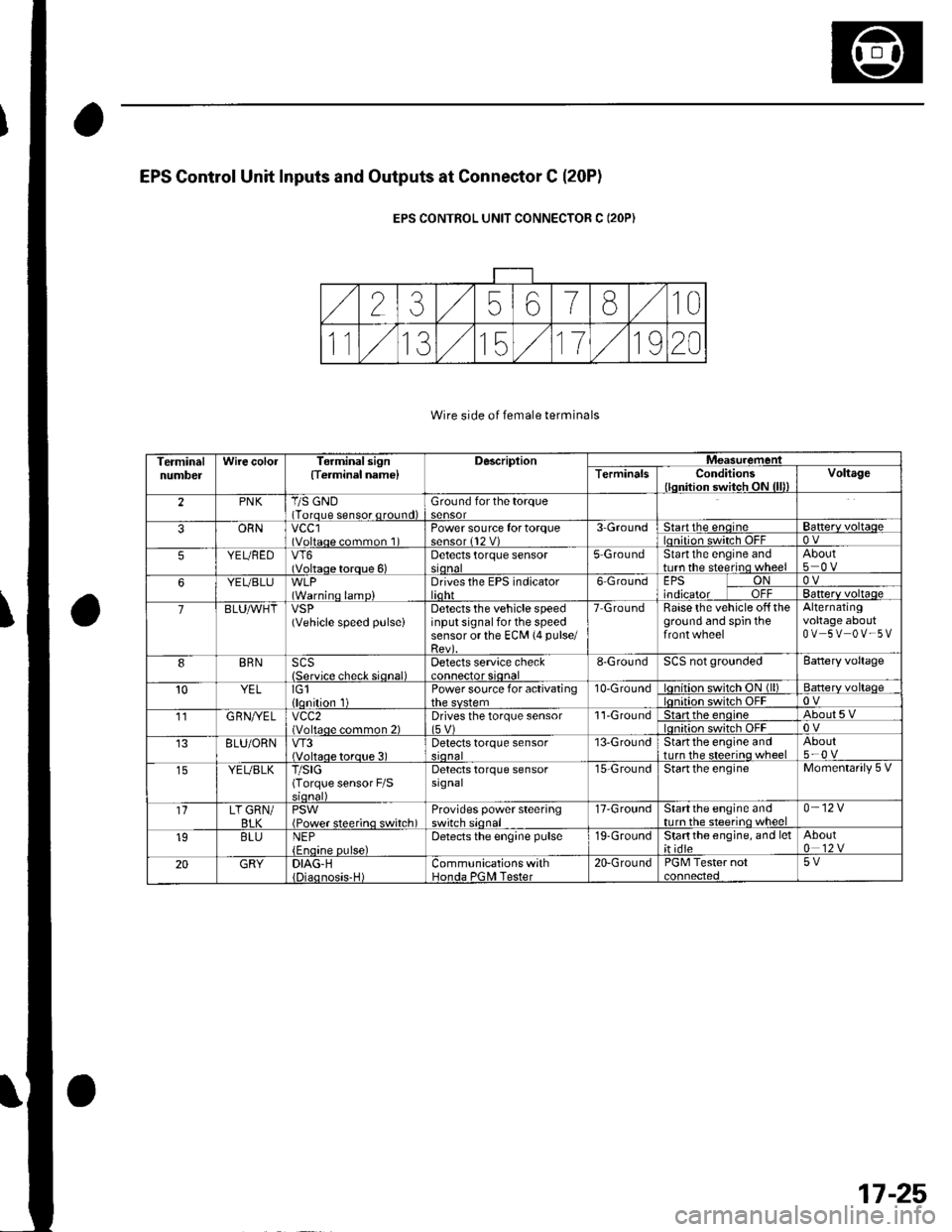

Page 516 of 1139

EPS Gontrol Unit Inputs and Outputs at Connestor C (20P1

EPS CONTROL UNIT CONNECTOR C (2OP)

Wire side of female terminals

TerminalnumbelWire colorTerminal sign{Terminel name}DescriplionMeasuremeniTerminalsConditions{lqnition switch ON {lll)Voltage

2PNKT/S GND(Torque sensor qround)Ground for the torque

ORNvccl(Voltaqe common 1Power source fortorque3-Groundtartthe enqrneBa$erv voltaqeOV

5YEUBEDVT6(Voltaqe torque 6)Detects torque sensorstonal5 GroundStartthe engine andturn the steerino wheelAbout

YEUBLU(Warninq lamp)Drives the EPS indicatorlidhr6 GroundEPS ONtnotcatol uTl-OVBanerv voltaqe

7BLUAVHTVSP(Vehicle speed pulseiDetects the vehicle speedinput signal for the speedsensor or the ECM (4 pulse/

Raise the vehicle off theground and spin theAlternatingvoltage aboutOV 5V OV-5V

BRNSCS{Servjco check siqnal)Detects service check8-GroundSCS not groundedBattery voltage

10YELIG1llqnition 1Power source for activating10-Groundon switch ON (ll)Batterv voltaqeon switch OFF11G RN//ELvcc2(Voltaqe common 2)Drives the torque sensor1'l-Groundtan the enoineAbout5Von switch OFF8LU/ORNVT3(Voltaoe toroue 3)Detects torque sensor13-GroundStartthe engine andtrrrn the steerino wheelAbout5-0 v

YEUBLKT/SIG(Torque sensor F/SDetects torque sensorsrgnal15-GroundStartthe engineMomentarily 5 V

1'lLT GRN/BI KPSWiPower steerino switch)Provides power steeringswitch sionall7-GroundStartthe engine andnrrn the steerino wheel0-12V

19BLUNEPDetects the engine pulse19-GroundStartthe engine, and let;t idte

20GRYDIAG-HCommunications withHonda PGNI Tester20-GroundPGM Tester not5V

17-25

Page 517 of 1139

a

EPS Components

\Circuit Diagram

\

SPE€DSENSOR3P CONNECTOR

@

TOFOUE SENSOR6P CONNECTOR

lli2l3Fr;T;T-I(=J_:_LvJ

Wn. !ide ot f.m.l€ r.fmin.ls

GAUGE ASSEMBLY 22P CONNECTON

GAUGE ASSEMATY 22P CONNECTOR

17-26