ECT sensor HONDA CIVIC 2003 7.G Manual PDF

[x] Cancel search | Manufacturer: HONDA, Model Year: 2003, Model line: CIVIC, Model: HONDA CIVIC 2003 7.GPages: 1139, PDF Size: 28.19 MB

Page 304 of 1139

MIL Circuit Troubleshooting

1. Connect an OBD ll scan tool/Honda PGM Tester

(see page 11-3).

2. Turn the ignition switch ON (ll) and read the OBD ll

scan tool/Honda PGM Tester.

Does the OBD ll scan tool/Honda PGM Tester

communicate with the ECM?

YES Go to step 3.

NO Go to troubleshooting " DLC Circuit

Troubleshooting" (see page 11-109).

3. Check the OBD ll scan tool/Honda PGM Testerfor

DTCs.

Are any DTCs ind icated?

YES Go to the DTC Troubleshooting Index.

NO-Go to step 4.

4. Turn the ignition switch OFF.

5. Turn the ignition switch ON (ll)and watch the

lMalfunction Indicator Lamp (MlL).

Does the MIL come on and stay on for more than

20 seconds aftet turning the ignition switch

oN (tr)?

YES lf the MIL always comes on and stays on, go

to step 76. But if the lMlL sometimes works

normally, first check for these problems.

. An intermittent short in the wire between the

ECIM (E29) and the data link connector (DLC).

. An intermittent short in the wire between the

ECM (E31) and the gauge assembly.

NO lf the MIL is always off, go to step 6. But if the

lvllL sometimes works normally, first check for

these problems.

. A loose No. 10 METER (7.5A) fuse in the under

dash fuse/relay box.. A loose No. 20 lG (40A) (Canada: 50A)Iuse in the

under-hood fuse/relay box.. A ioose No. 6 ECU (ECM) (15A) fuse in the under-

hood fuse/relay box.

. A loose No. 17 FUEL PUMP (15A)fuse in the

under-dash fuse/relay box.. A poor connection at ECM terminal E31.. An intermittent open in the GRN/ORN wire

between the ECM (E31) and the gauge assembly.. An intermittent short in the wire between the

ECM (A21) and the manifold absolute pressure

(MAP) sensor.. An intermittent short in the wire between the

ECI\4 (A20) and the throttle posilion (TPi sensor.. An intermittent short in the wire between the

ECM (E5) and the fuel tank pressure (FTP) sensor.

6. Turn the ignition switch OFF.

7. Turn the ignition switch ON (ll).

ls the low oil pressure light on?

YES Go to step 10.

NO-Go to step 8.

8. Inspectthe No. 10 l\4ETER (7.5A)fuse inthe under-

dash fuse/relay box.

ls the luse OK?

YES Go to step L

NO Repair shon in the wire between No. 10

METER (7.5A)fuse and the gauge assembly. Also

replacethe No. 10 METER {7.5A) fuse.l

9. Inspect the No. 20 lG1 (40A) (Canada: 50A) fuse in

the under-hood fuse/relay box.

ls the f use OK?

YES Repair open in the wire between the No. 20

lG (40A) {Canadar 50A)fuse and the gauge

assembly. lf the wire is OK, test the ignition switch

{see page 22 53).

NO Repair short in the wire between No. 20 lG

(40A) lCanada: 50A)fuse and the under'dash fusel

relay box. Also replace the No.20 lG (40Ai

(Canada: 50A) fuse.I

(conr'd)

11-97

Page 306 of 1139

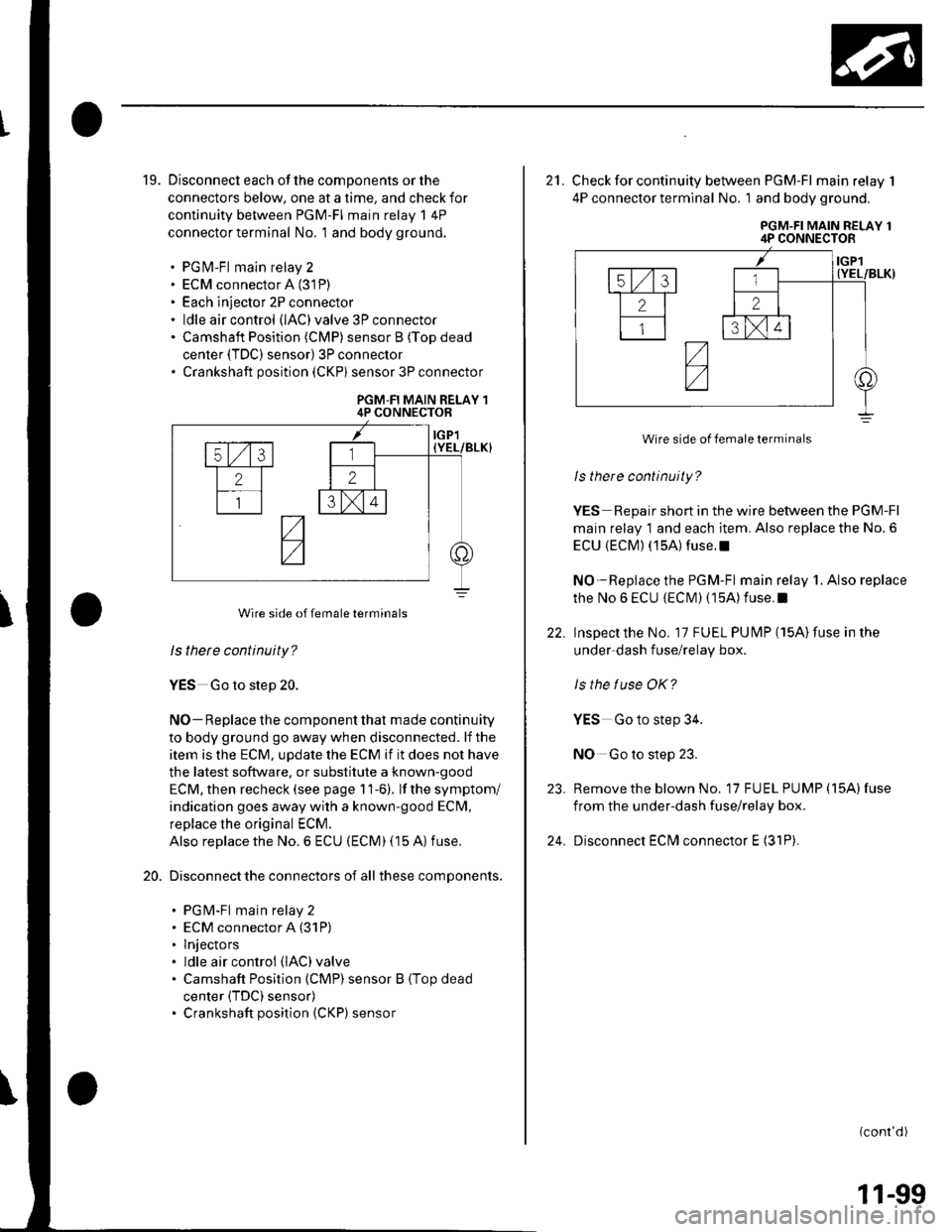

19. Disconnect each of the components or the

connectors below, one at a time, and check for

continuity between PGM-FI main relay 1 4P

connector terminal No. 1 and body ground.

. PGfvl-Fl main relay 2. ECM connector A (31P)

. Each injector 2P connector. ldle air control (lAC)valve 3P connector. Camshaft Position (CMP) sensor B (Top dead

center (TDC) sensor) 3P connector. Crankshaft position (CKP) sensor 3P connector

PGM-FI MAIN RELAY 14P CONNECTOR

ls thete continuity?

YES Go to step 20.

NO- Replace the component that made continuity

to body ground go away when disconnected. lf the

item is the ECM, update the ECM if it does not have

the latest software. or substitute a known-good

ECM, then recheck (see page 11-6). lf the symptom/

indication goes away with a known'good ECM,

replace the original ECM.

Also replace the No. 6 ECU (ECM) (15 A) fuse,

Disconnect the connectors of all these components.

. PGM-Fl main relay 2. ECM connector A (31P)

. lnjectors. ldle air control (lAC)valve

. Camshaft Position {CMP) sensor B (Top dead

center (TDC) sensor). Crankshaft position (CKP) sensor

20.

Wire side of female terminals

22.

21. Check for continuity between PGM-FI main relay 1

4P connector termlnal No. 1 and body ground.

PGM-FI MAIN RELAY 14P CONNECTOR

ls there continuity?

YES Repair short in the wire between the PGM-Fl

main relay 1 and each item. Also replace the No. 6

ECU {ECM) (15A) fuse.l

NO-Replace the PGM-Fl main relay 1. Also replace

the No 6 ECU {ECIM) (15A) f use. I

Inspectthe No. 17 FUEL PUI\4P (15A)fuse in the

under-dash f use/relay box.

ls the tuse OK?

YES Go to step 34.

NO Go to step 23.

Remove the blown No, 17 FU EL PUMP (15A) fuse

from the under-dash fuse/relay box.

Disconnect ECfvl connector E (31P).

(conr'd)

23.

24.

Wire side of female terminals

11-99

Page 311 of 1139

PGM-FI System

MIL Circuit Troubleshooting (cont'dl

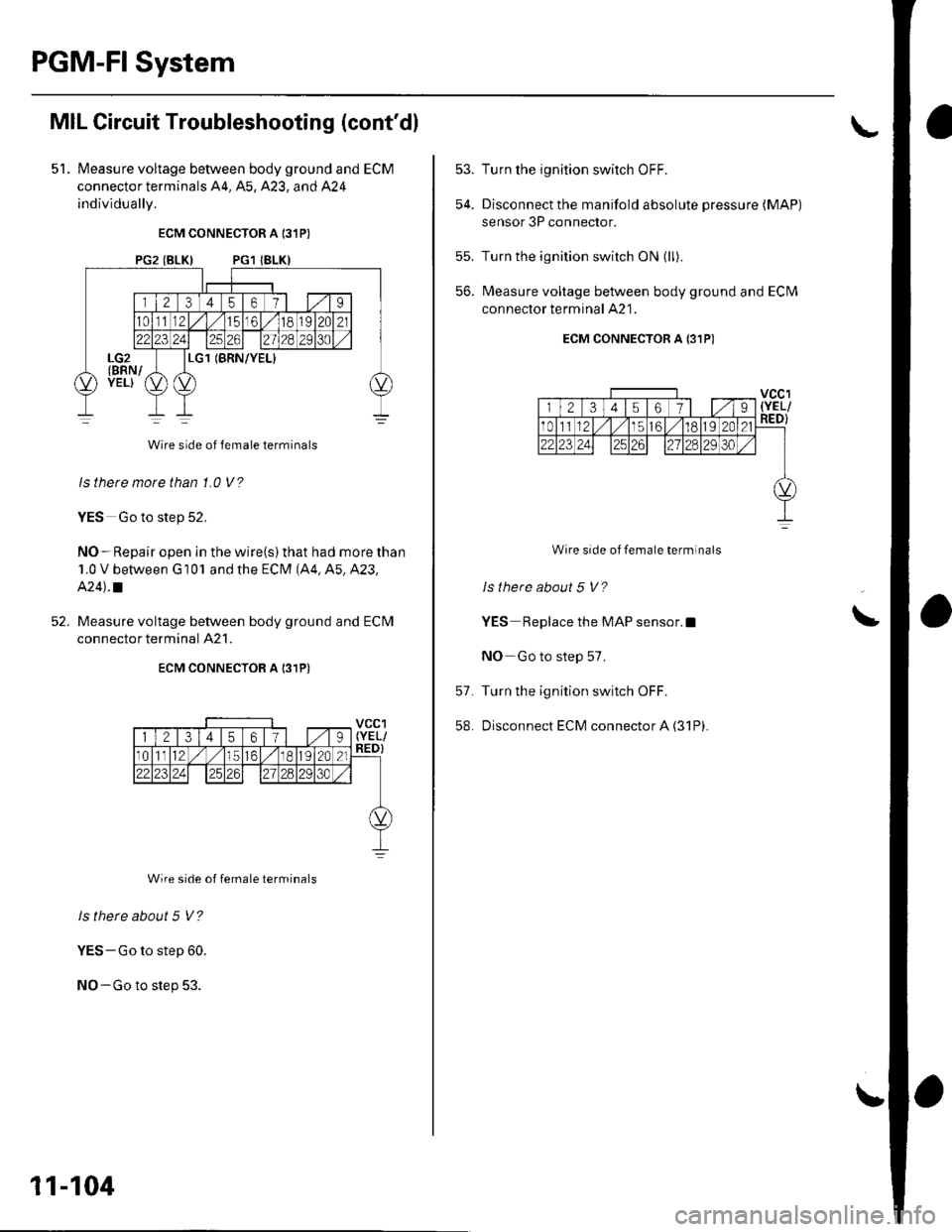

51. Measure voltage between body ground and ECM

connector terminals 44, A5, 423, and 424

individuallv.

ECM CONNECTOR A 131P)

PG2 (BLK) PG1 IBLKI

Wire side of female terminals

ls there morc than 1.0 V ?

YES Go to step 52.

NO-Repair open in the wire(s) that had more than

1.0 V between G 10'l and the ECM (A4, A5, A23,

A24l.a

Measure voltage between body ground and ECM

connector terminal 421.

ECM CONNECTOR A 131P)

Wire side of female terminals

ls there about 5 V?

YES-Go to step 60.

NO-Go to step 53.

11-104

53.

54.

Turn the ignition switch OFF.

Disconnect the manifold absolute pressure (MAP)

sensor 3P connector.

Turn the ignition switch ON (ll).

Measure voltage between body ground and ECM

connector terminal A21.

ECM CONNECTOR A {31P)

Wire side of female terminals

ls there about 5 V?

YES Replace the MAP sensor.l

NO Go to step 57.

Turn the ignition switch OFF.

Disconnect ECM connector A (31P).

55.

56.

\

57.

58.

Page 312 of 1139

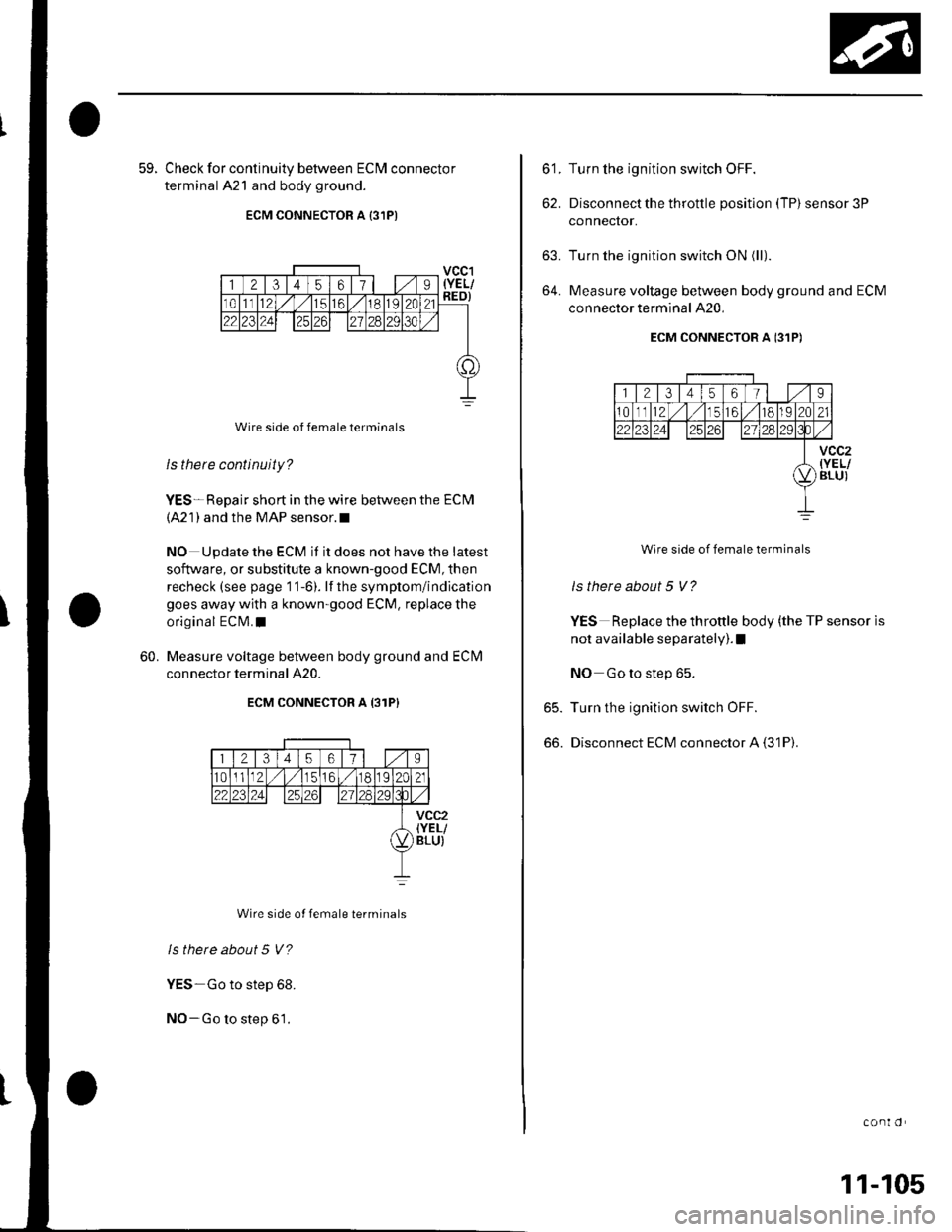

59. Check for continuitv between ECIM connector

terminal 421 and body ground.

ECM CONNECTOR A {3,IPI

Wire side of female terminals

ls there continuity?

YES*Repair short in the wire between the ECM(421) and the MAP sensor.l

NO Update the ECM it it does not have the latest

soflware, or substitute a known-good ECM, then

recheck (see page 1'l-6). lf the symptom/indication

goes away with a known-good ECM, replace the

original ECM.I

Measure voltage between body ground and ECM

connector terminal 420.

ECM CONNECTOR A {3TP}

60.

1121345ot/I

101111256/ 11892t212'231?4?qTln29

vcc2IYEL/BLU)

Wire side ot female terminals

ls there about 5 V?

YES-Go to step 68.

NO-Go to step 61.

t t,

oz,

63.

64.

Turn the ignition switch OFF.

Disconnect the throttle position (TP) sensor 3P

connector.

Turn the ignition switch ON (ll).

Measure voltage between body ground and ECM

connector terminal 420,

ECM CONNECTOR A 131P)

Wire side of female terminals

ls there about 5 V?

YES Replace the thronle body (the TP sensor is

not available separately). I

NO Go to step 65.

Turn the ignition switch oFF.

Disconnect ECM connector A (31P).

65.

66.

conl o

11-105

Page 313 of 1139

PGM-FI System

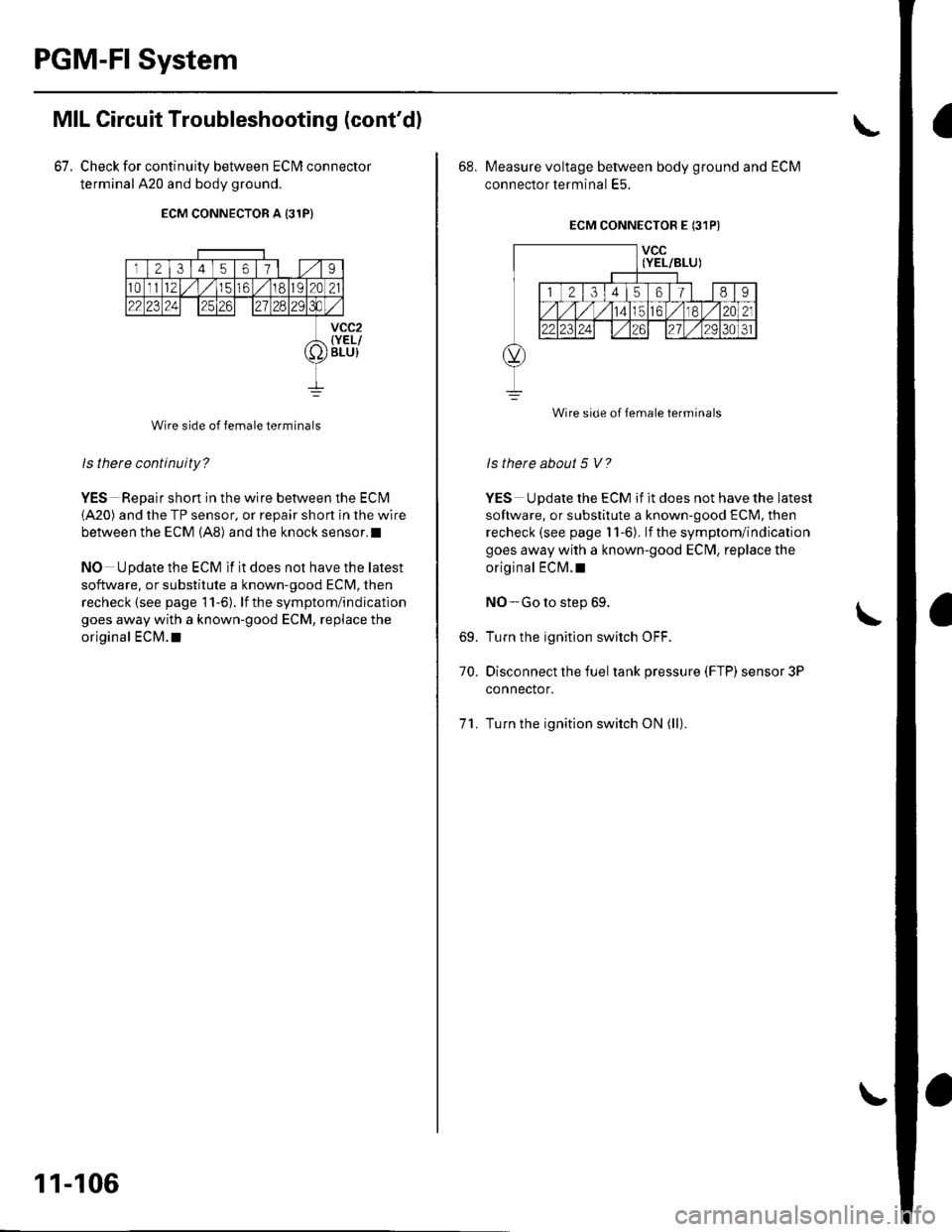

67.

MIL Circuit Troubleshooting (cont'd)

Check for continuity between ECIM connector

terminal A20 and body ground.

ECM CONNECTOR A (31P)

rl2l3145ot/9

10t1121,/ 1,/1516ta,92A21

22 '3241 12526n

o

Wire side of female terminals

ls there continuity?

YES Repair shon in the wire between the ECN4

{A20) and the TP sensor, or repair short in the wire

between the ECM (A8) and the knock sensor. t

NO Update the ECM if it does not have the latest

software. or substitute a known-good ECM, then

recheck (see page l1-6). lf the symptom/indication

goes away with a known-good ECM, replace the

original ECM.t

vcc2{YEL/BLU}

11-106

68. Measure voltage between body ground and ECM

connector terminal E5.

ECM CONNECTOR E (31PI

Is there about 5 V?

YES U pdate the ECM if it does not have the latest

software, or substitute a known-good ECM, then

recheck (see page 11-6). lf the symptom/indication

goes away with a known-good EClvl, replace the

original ECM.t

NO-Go to step 69.

Turn the ignition switch OFF.

Disconnect the fuel tank pressure (FTP) sensor 3P

connector.

Turn the ignition switch ON (ll).

69.

70.

11.

Wire side of female terminals

Page 314 of 1139

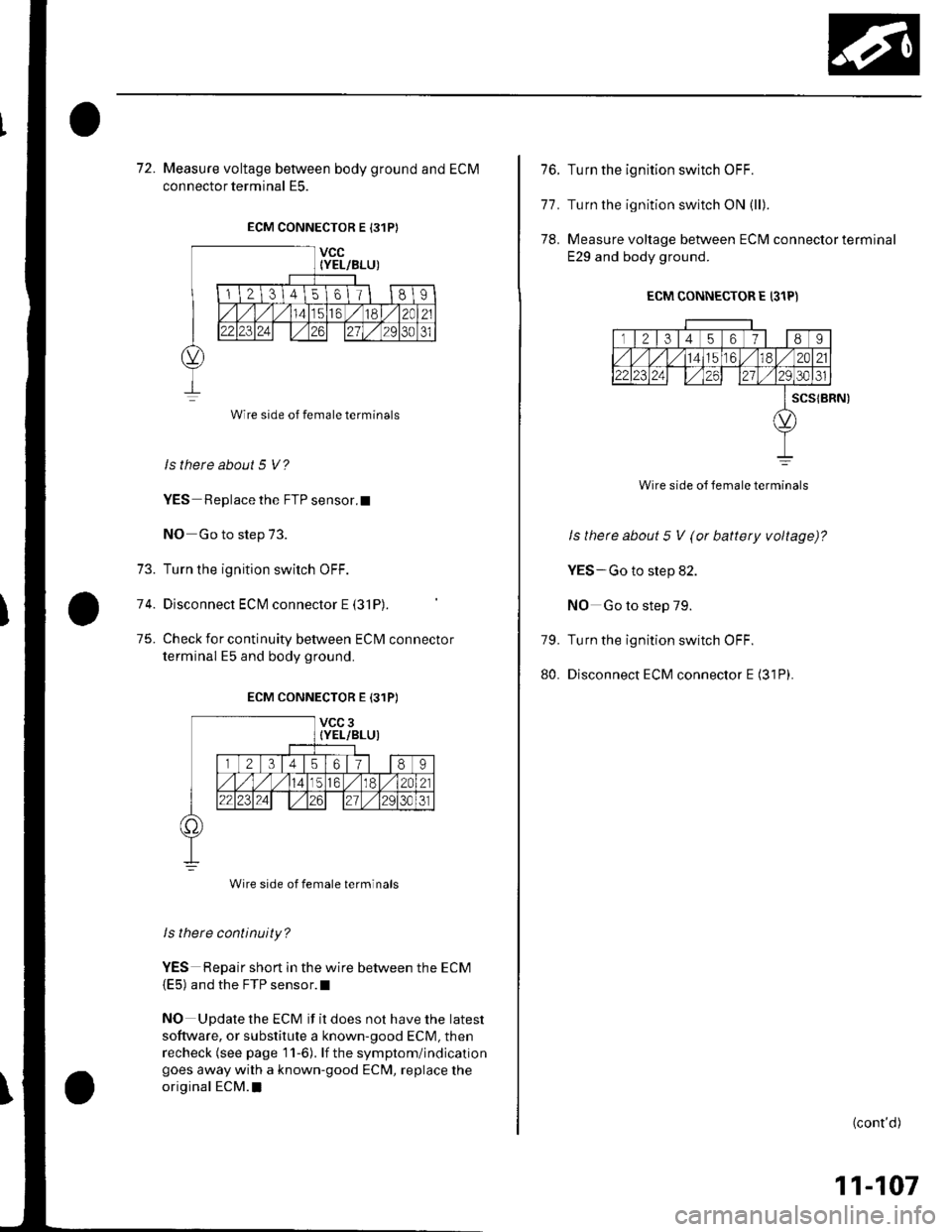

13.

74.

75.

72. Measure voltage between body ground and ECM

connector terminal E5.

ECM CONNECTOR E 131P}

ls there about 5 V?

YES Replace the FTP sensor.t

NO Go to step 73.

Turn the ignition switch OFF.

Disconnect ECM connector E (3'lP).

Check for continuity between ECM connector

terminal E5 and body ground.

ECM CONNECTOR E {31PI

Is there continuity?

YES Repair short in the wire between the ECM(E5) and the FTP sensor.l

NO Update the ECM if it does not have the latest

software, or substitute a known-good ECM, then

recheck (see page 11-6). lf the symptom/indicationgoes away with a known-good ECM, replace the

original ECM.I

Wire side of female terminals

Wire side of female terminals

76.

77.

78.

79.

80.

Turn the ignition switch OFF.

Turn the ignition switch ON (ll).

Measure voltage between ECM connector terminal

E29 and body ground.

ECM CONNECTOR E (31P)

rl2l31456189

,/1,/1141562A212223241 l,/2930

scstBRN)

Wire side of female terminals

ls there about 5 V (or battery voltage)?

YES-Go to step 82.

NO Go to step 79.

Turn the ignition switch OFF.

Disconnect ECM connector E (31P).

(cont'd)

11-107

Page 320 of 1139

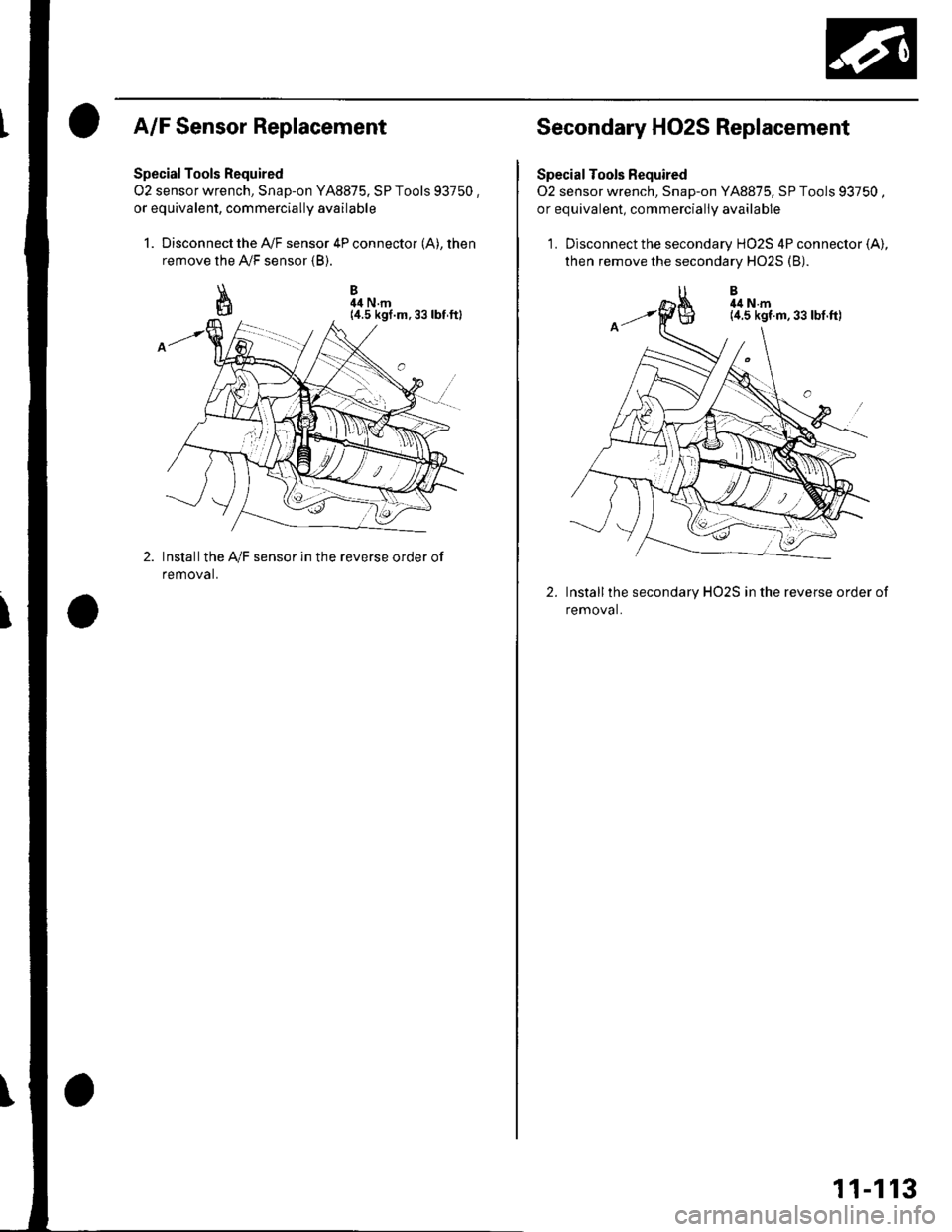

A/F Sensor Replacement

Special Tools Required

O2 sensor wrench, Snap-on YA8875. SP Tools 93750 ,or equivalent, commercially availabre

1. Disconnect the A,/F sensor 4P connector (A), then

remove the A,/F sensor {B).

\I

ffi

B44 N.m

Installthe IVF sensor in the reverse order of

removal.

Secondary HO2S Replacement

Special Tools Fequired

02 sensor wrench, Snap-on YA8875, SP Tools 93750 ,or equivalent, commerciallV available

1. Disconnect the secondary HO2S 4P connector (A),

then remove the secondary H02S (B).

Installthe secondary HO2S in the reverse order of

removal.

2.

11-113

Page 321 of 1139

PGM-Fl System

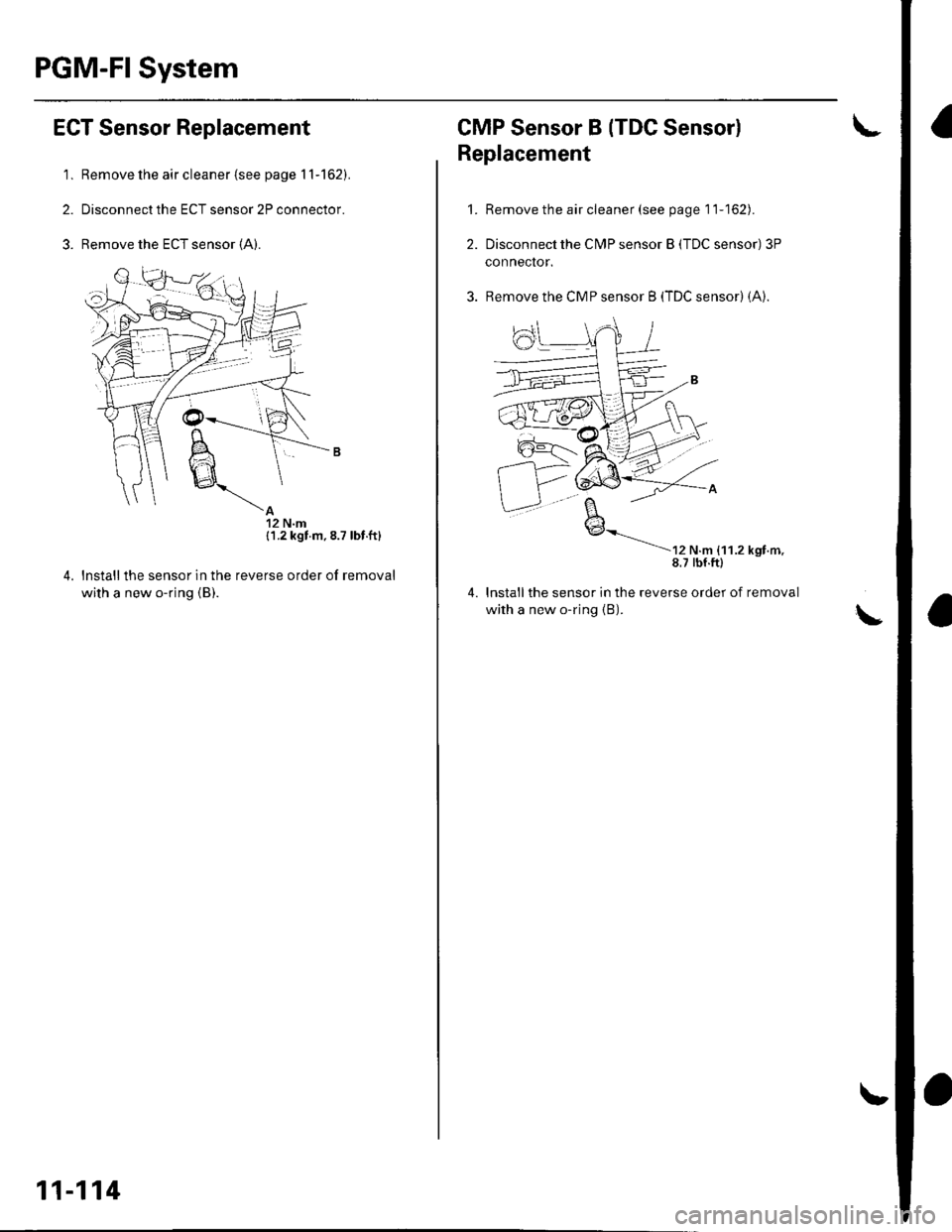

ECT Sensor Replacement

'1. Remove the air cleaner {see page 11-162).

2. Disconnect the ECT sensor 2P connector.

3. Remove the ECT sensor (A).

{1.2 kgt m.8.7 lbt.ft}

reverse order of removallnstallthe sensor in the

with a new o-ring {B).

11-114

CMP Sensor B (TDC Sensorl

't.

2.

Replacement

Remove the air cleaner (see page 11-162).

Disconnect the CN4P sensor B (TDC sensor) 3P

conneclor.

Remove the CMP sensor B (TDC sensor) (A).

----

r, ".- ,',',., *nr...8.7 tbf.ftl

lnstallthe sensor in the reverse order of removal

with a new o-ring {B).

4.

Page 322 of 1139

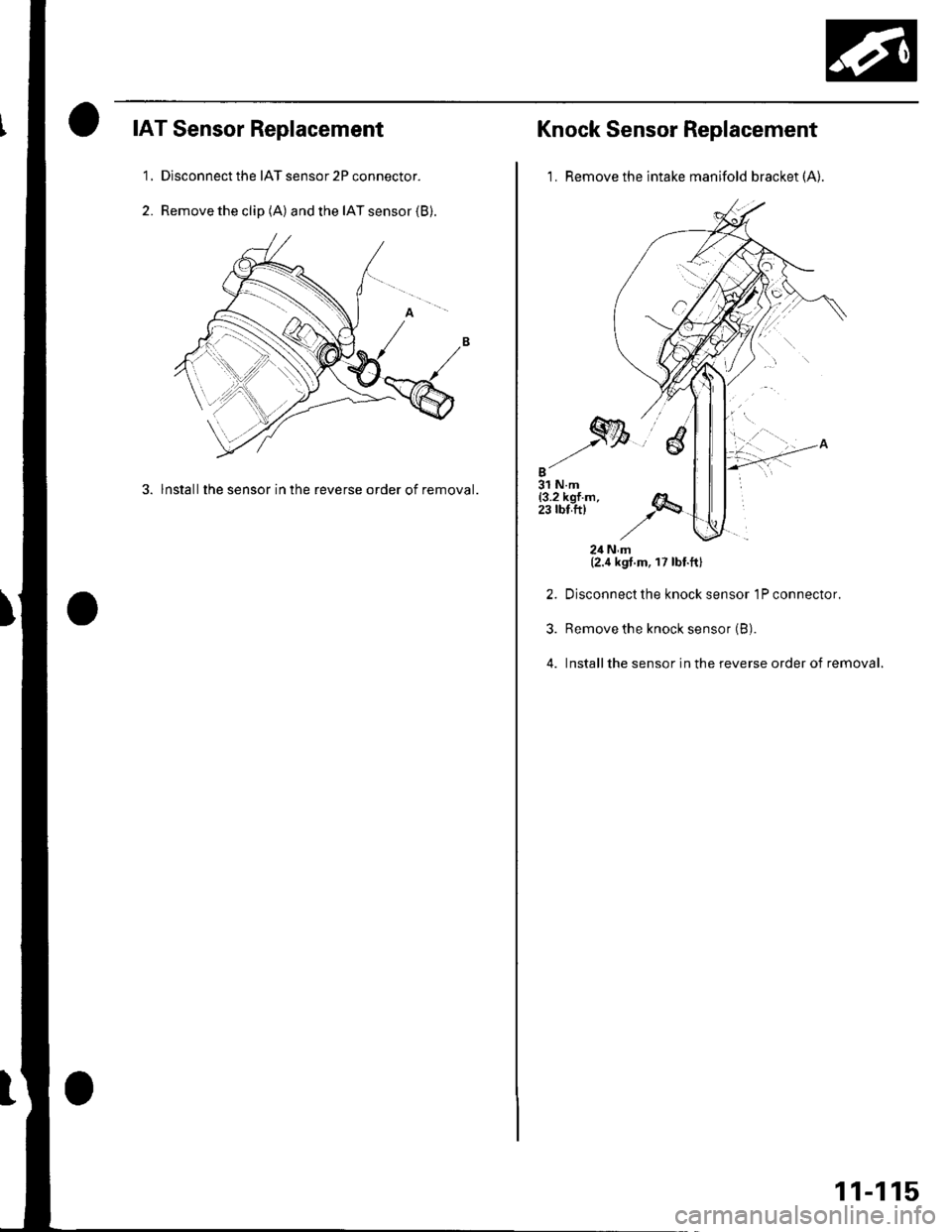

IAT Sensor Replacement

1, Dlsconnect the IAT sensor 2P connector.

2. Remove the clip (A) and the IAT sensor (B).

3. lnstallthe sensor in the reverse order of removal.

Knock Sensor Replacement

1. Remove the intake manifold bracket (A).

2.

3.

4.

24Nm(2.4 kgt.m, 17 lbt.ftl

Disconnect the knock sensor 1P connector.

Remove the knock sensor (B).

Installthe sensor in the reverse order of removal.

11-115

Page 323 of 1139

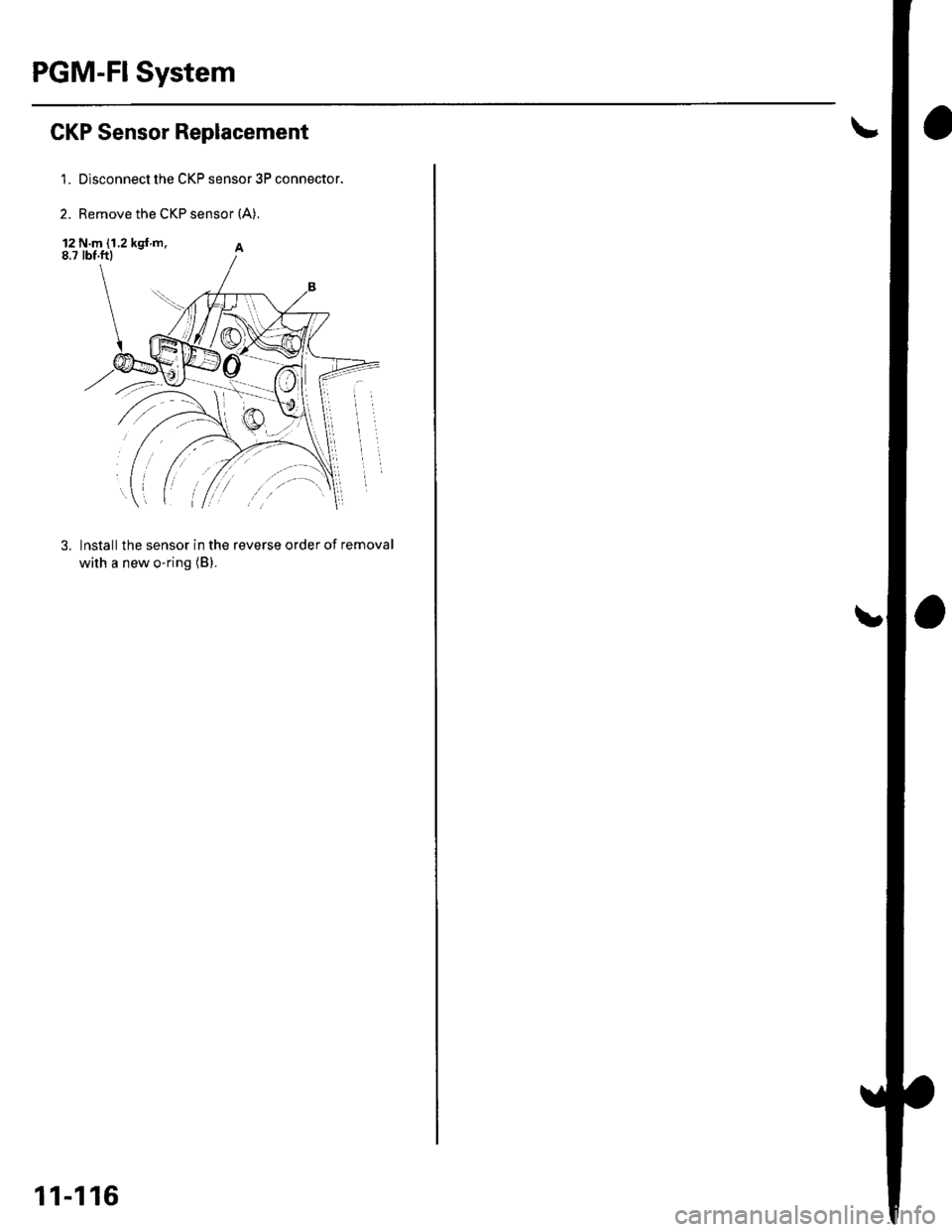

PGM-FI System

GKP Sensor Replacement

1. Disconnect the CKP sensor 3P connector.

2. Remove the CKP sensor {A).

12 N.m (1.2 kgt m.8.7 tbf.ftl

3. lnstall the sensor in the reverse order of removal

with a new o-ring (B).

11-116