Panel HONDA CIVIC 2003 7.G Manual PDF

[x] Cancel search | Manufacturer: HONDA, Model Year: 2003, Model line: CIVIC, Model: HONDA CIVIC 2003 7.GPages: 1139, PDF Size: 28.19 MB

Page 879 of 1139

Ground Distribution

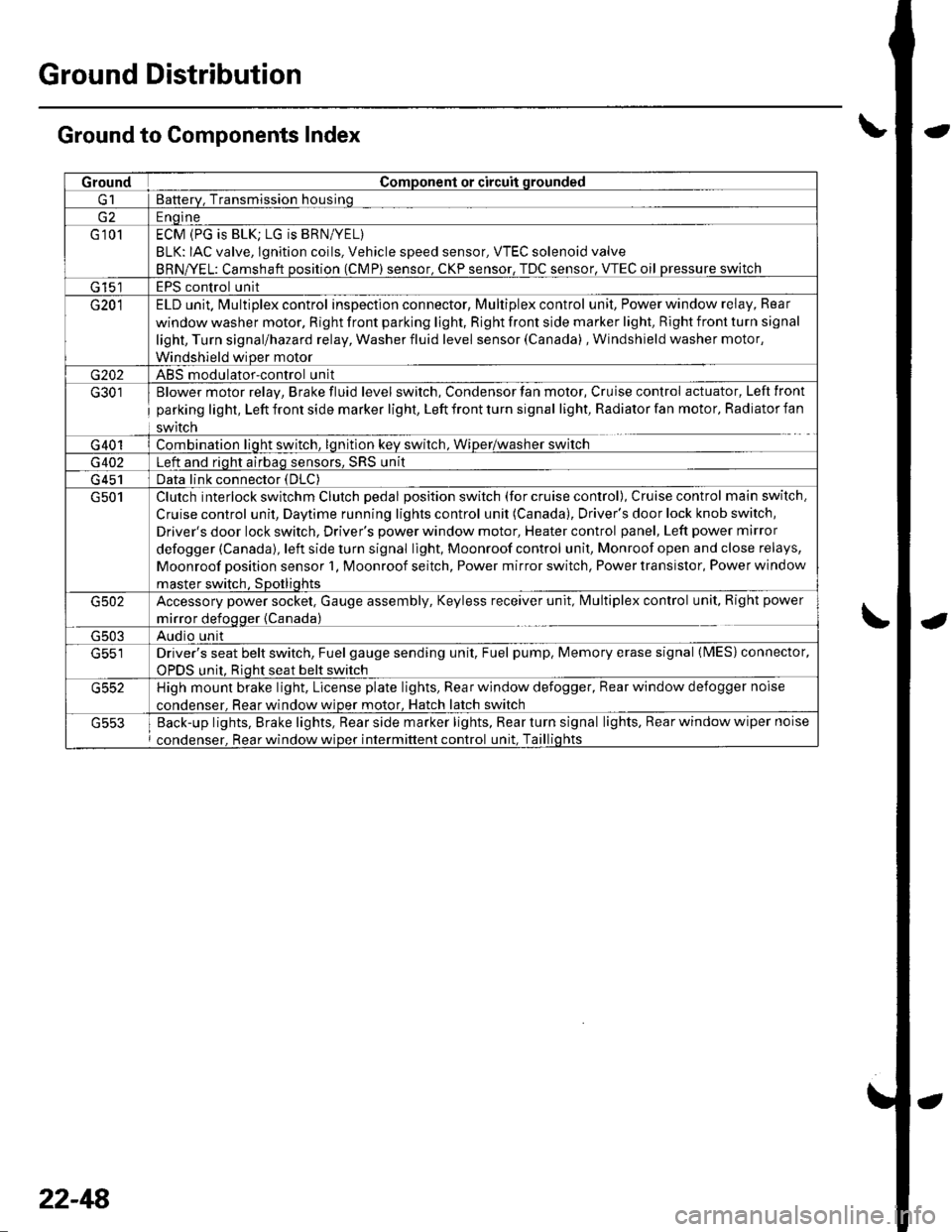

Ground to Components Index

GroundComponent or circuit qrounded

Batterv, Transmission housinq

E ngine

G 101ECM (PG is BLK; LG is BRN/YEL)

BLK: IAC valve, lgnition coils, Vehicle speed sensor, VTEC solenoid valve

BRNA/EL: Camshaft oosition (CMP) sensor. CKP sensor, TDC sensor. VTEC oil pressure switch

G 15'�]EPS control unit

G201ELD unit. Multiplex control inspection connector, Multiplex control unit, Power window relay, Rear

window washer motor, Right front parking light, Right front side marker light, Right front turn signal

light, Turn signal/hazard relay, Washer fluid level sensor (Canada) , Windshield washer motor,

Windshield wiDer motor

G202ABS modulator-control unit

G301

G401

Blower motor relay, Brake fluid level switch, Condensor fan motor, Cruise control actuator, Left front

parking light, Left front side marker light, Left front turn signal light, Radiator fan motor, Radiator fan

swrtcn

Combination liqht switch, lqnitlon kev srvitch, Wiper/wasfrer sr,virch

G402Left and riqht airbaq sensors, SRS unit

G 451Data link connector (DLC)

G501Clutch interlock switchm Clutch pedal position switch (for cruise control), Cruise control main switch,

Cruise control unit, Daytime running lights control unit (Canada), Driver's door lock knob switch,

Driver's door lock switch, Driver's power window motor, Heater control panel, Left power mirror

defogger (Canada), left side turn signal light, Moonroof control unit, Monroof open and close relays,

Moonroof position sensor '1, Moonroof seitch, Power mirror switch, Power transistor, Power window

master switch. SDotliqhts

G502Accessory power socket, Gauge assembly, Keyless receiver unit, lvlultiplex control unit, Right power

mirror defogger {Canada)

G503Audio unit

G551Driver's seat belt switch, Fuel gauge sending unit, Fuel pump, Memory erase signal (IMES) connector,

OPDS unit. Rioht seat belt switch

G552High mount brake light, License plate lights, Rear window defogger, Rear window defogger noise

condenser. Rear window wioer motor, Hatch latch switch

Back-up lights, Brake lights, Rear side marker lights, Rear turn signal lights, Rear window wiper noise

condenser, Rear window wiper intermittent control unit, Taillights

22-48

Page 895 of 1139

Gauges

2.

3.

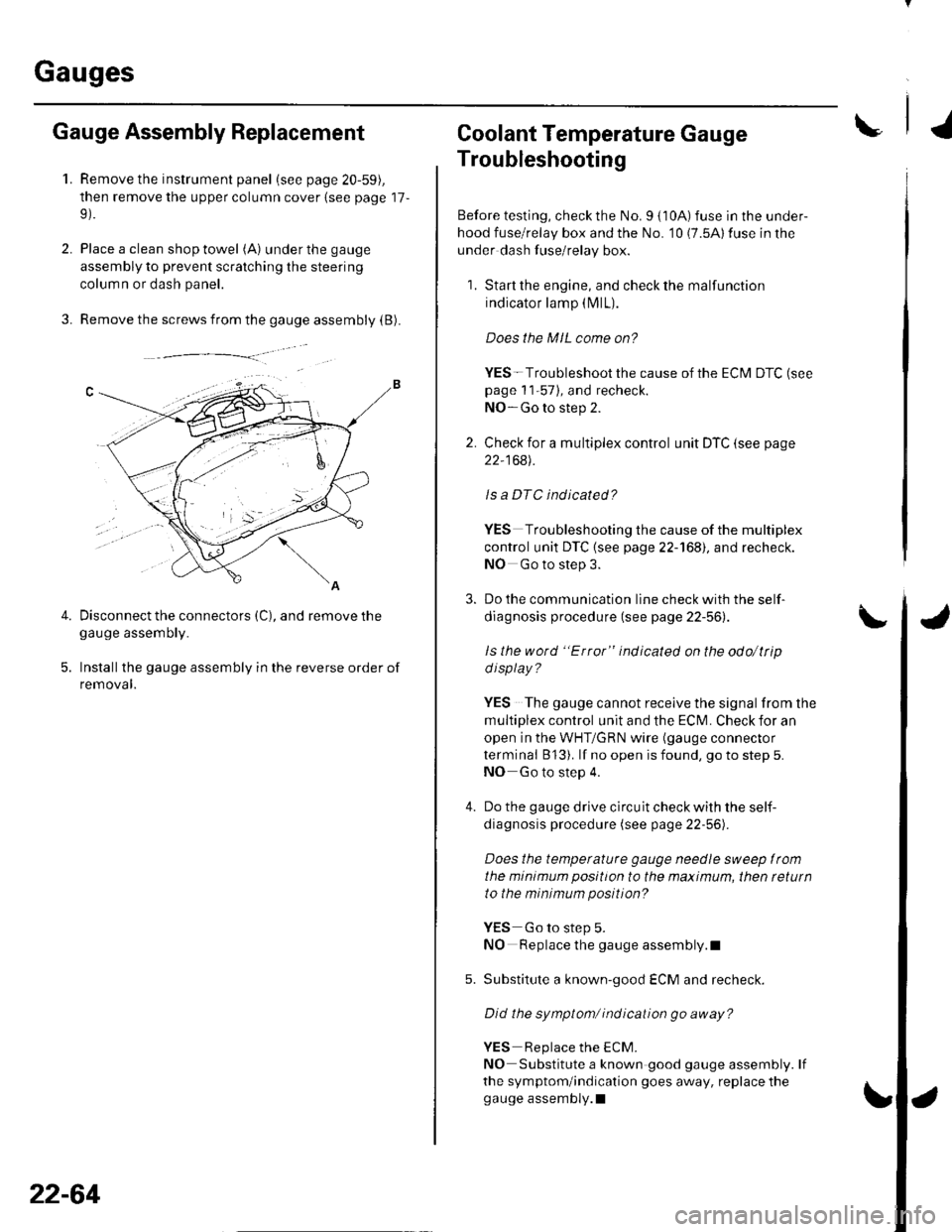

Gauge Assembly Replacement

1.Remove the instrument panel (see page 20-59),

then remove the upper column cover {see page 17-

Place a clean shop towel (A) under the gauge

assembly to prevent scratching the steering

colum n or dash panel.

Remove the screws from the gauge assembly (B).

Disconnect the connectors (C), and remove thegauge assemDry.

Installthe gauge assembly in the reverse order of

removal.

Coolant Temperature Gauge

Troubleshooting

Before testing, check the No. I { 10A) fuse in the under-

hood fuse/relay box and the No. '10 (7.5A) fuse in the

under dash fuse/relay box.

1. Start the engine, and check the malfunction

indicator lamp (MlL).

Does the MIL come on?

YES- Troubleshoot the cause of the ECM DTC (see

page 1 1-57), and recheck.

NO-Go to step 2.

2. Check for a multiplex control unit DTC (see page

22,168).

ls a DTC ind icated?

YES Troubleshooting the cause of the multiplex

control unit DTC {see page 22-168), and recheck.

NO Go to step 3.

3. Do the communication line check with the self-

diagnosis procedure (see page 22-56).

ls the word "Error" indicated on the odo/ttip

d isplay ?

YES The gauge cannot receive the signal from the

multiplex control unit and the ECI\,4. Check for an

open in the WHT/GRN wire (gauge connector

terminal B 13). lf no open is found, go to step 5.

NO Go to step 4.

4. Do the gauge drive circuit check with the self-

diagnosis procedure (see page 22-56).

Does the temperature gauge needle sweep lrom

the minimum position to the maximum, then tetutn

to the minimum position?

YES Go to step 5.

NO Replace the gauge assembly.l

5. Substitute a known-good ECM and recheck.

Did the symptom/ ind ication go away?

YES Replace the ECM.

NO Substitute a known good gauge assembly. lf

the symptom/indication goes away, replace thegauge assembly.l

4.

22-64

Page 914 of 1139

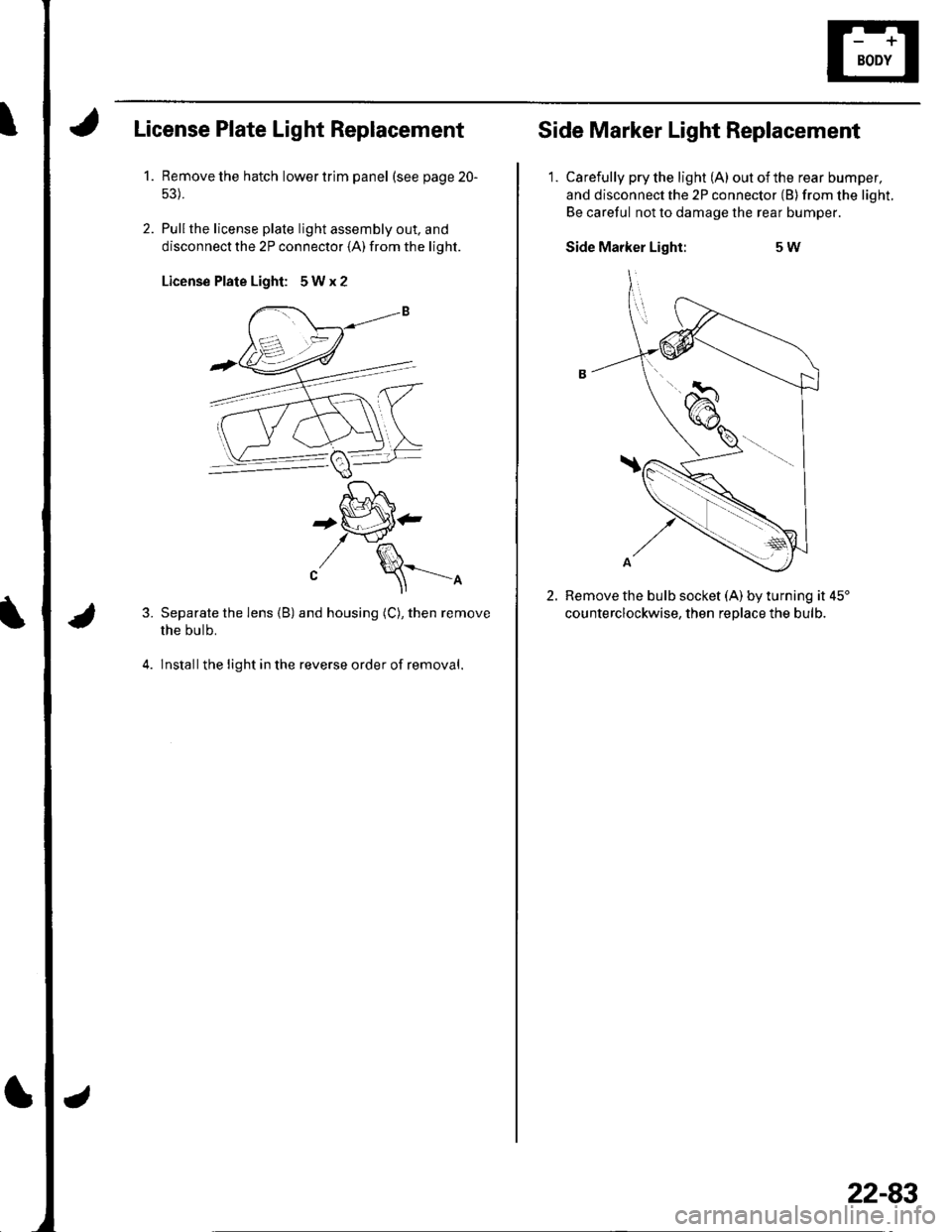

License Plate Light Replacement

1.Remove the hatch lower trim panel (see page 20-

Pullthe license plale light assembly out. and

disconnect the 2P connector (A) from the light.

License Plate Light: 5Wx2

3.

4.

'[-J^,^f , t lo \

+tiP'-t \-J'fl^

"/ \==-^

Separate the lens (B) and housing (C), then remove

the bulb.

lnstallthe light in the reverse order of removal.

Side Marker Light Replacement

1. Carefully pry the light (A) outofthe rear bumper,

and disconnect the 2P connector (B) from the light.

Be careful not to damage the rear bumper.

Side Marker Light:5W

2.Remove the bulb socket (A) by turning it 45'

counterclockwise. then reolace the bulb.

22-83

Page 919 of 1139

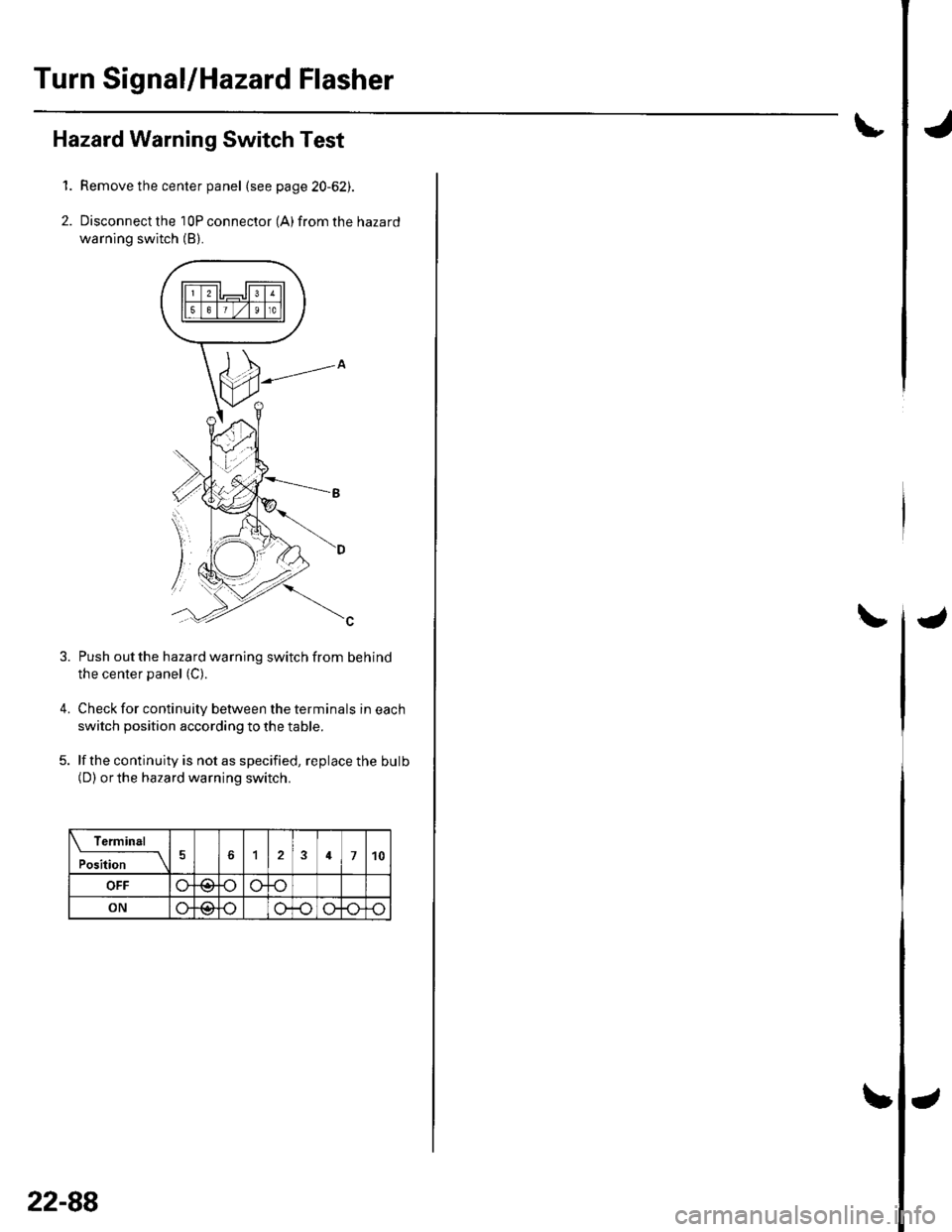

Turn Signal/Hazard Flasher

1.

2.

Hazard Warning Switch Test

Remove the center panel (see page 20-62).

Disconnect the 10P connector (A) from the hazard

warning switch (B).

4.

Push out the hazard warning switch from behind

the center panel (C).

Check for continuity between the terminals in each

switch position according to the table.

lf the continuity is not as specified, replace the bulb(D) orthe hazard warning switch.

Termin6l

;;;-_-\124710

OFF

ON@

3.

22-88

Page 928 of 1139

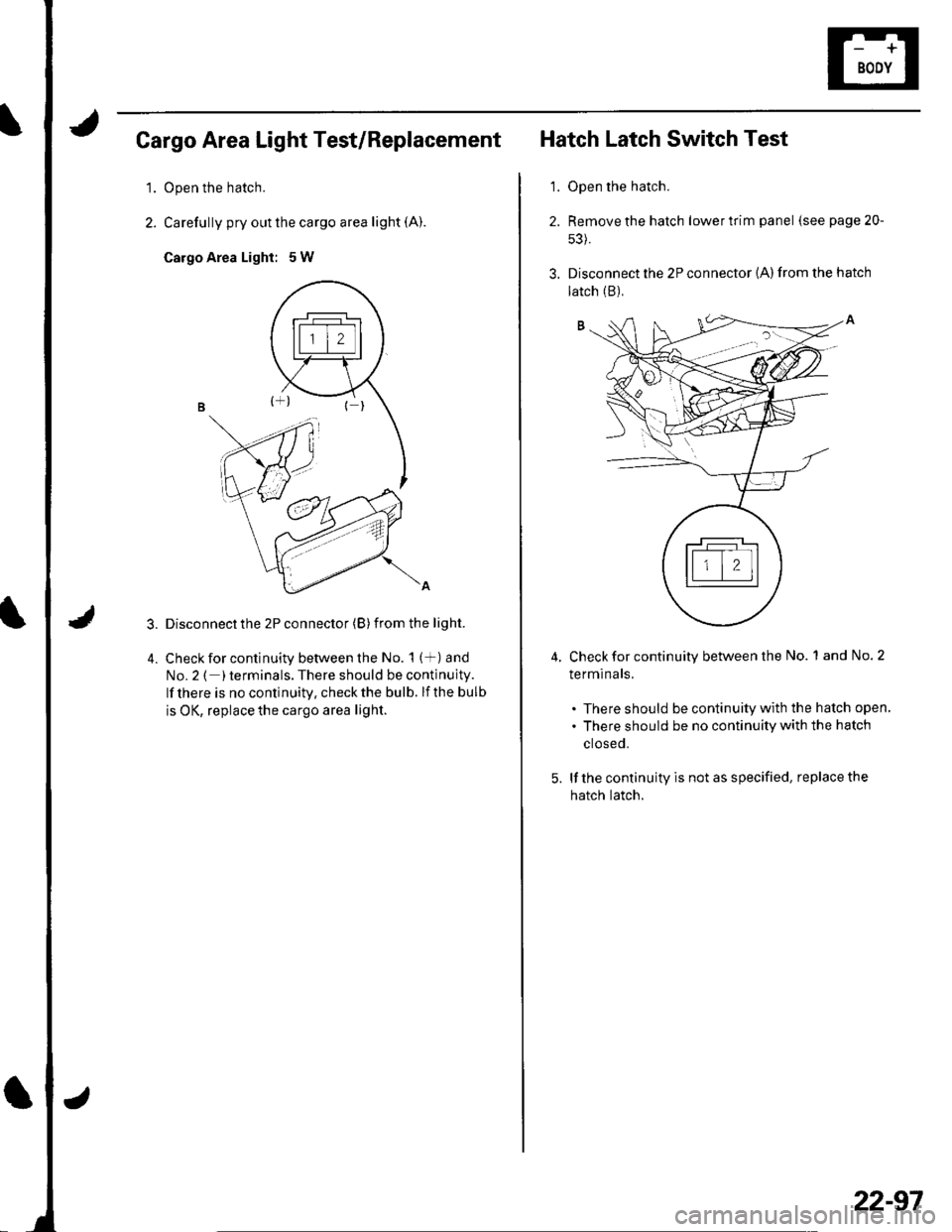

Cargo Area Light Test/Replacement

1.Open the hatch.

Carefully pry out the cargo area light (A).

Cargo Area Light: 5W

Disconnect the 2P connector (B) from the light.

Check for continuity between the No. 1 (+) and

No.2 ( )terminals. There should be continuity.

lf there is no continuitv, check the bulb. lf the bulb

is OK, replace the cargo area light.

'1.

Hatch Latch Switch Test

Open the hatch.

Remove the hatch lower trim panel (see page 20-

s3).

Disconnect the 2P connector {A) from the hatch

4.Check for continuity between the No. 1 and No. 2

terminals.

. There should be continuity with the hatch open

. There should be no continuity with the hatch

ctoseo.

lf the continuity is not as specified, replace the

hatch latch.

latch (B),

22-97

Page 931 of 1139

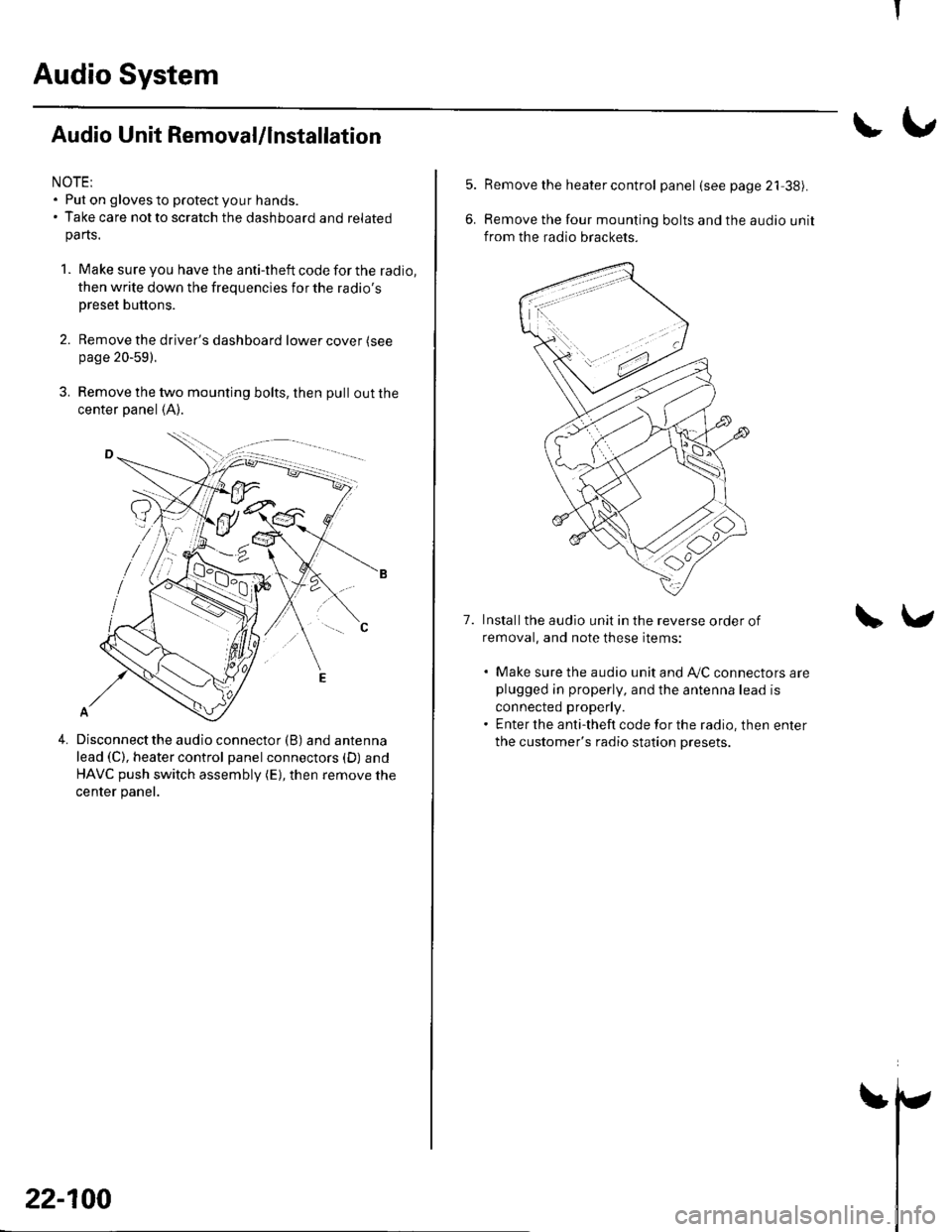

Audio System

Audio Unit Removal/lnstallation

NOTE:. Put on gloves to protect your hands.. Take care not to scratch the dashboard and relatedpa rts.

1. Make sure you have the anti-theft code for the radio,

then write down the frequencies for the radio's

preset buttons.

2. Remove the driver's dashboard lower cover (see

page 20-59).

3. Remove the two mounting bolts, then pull out the

center panel (A).

4.Disconnect the audio connector (B) and antenna

lead (C), heater control panel connectors (D) and

HAVC push switch assembly (E), then remove the

center panel.

22-100

!\,

7.

Remove the heater control panel (see page 21 38).

Remove the four mounting bolts and the audio unit

from the radio brackets.

Installthe audio unit in the reverse order of

removal, and note these items:

. Make sure the audio unit and A/C connectors areplugged in properly, and the antenna lead is

connected properly.. Enter the anti-theft code for the radio, then enter

the customer's radio station presets.

\v

I

Page 933 of 1139

Audio System

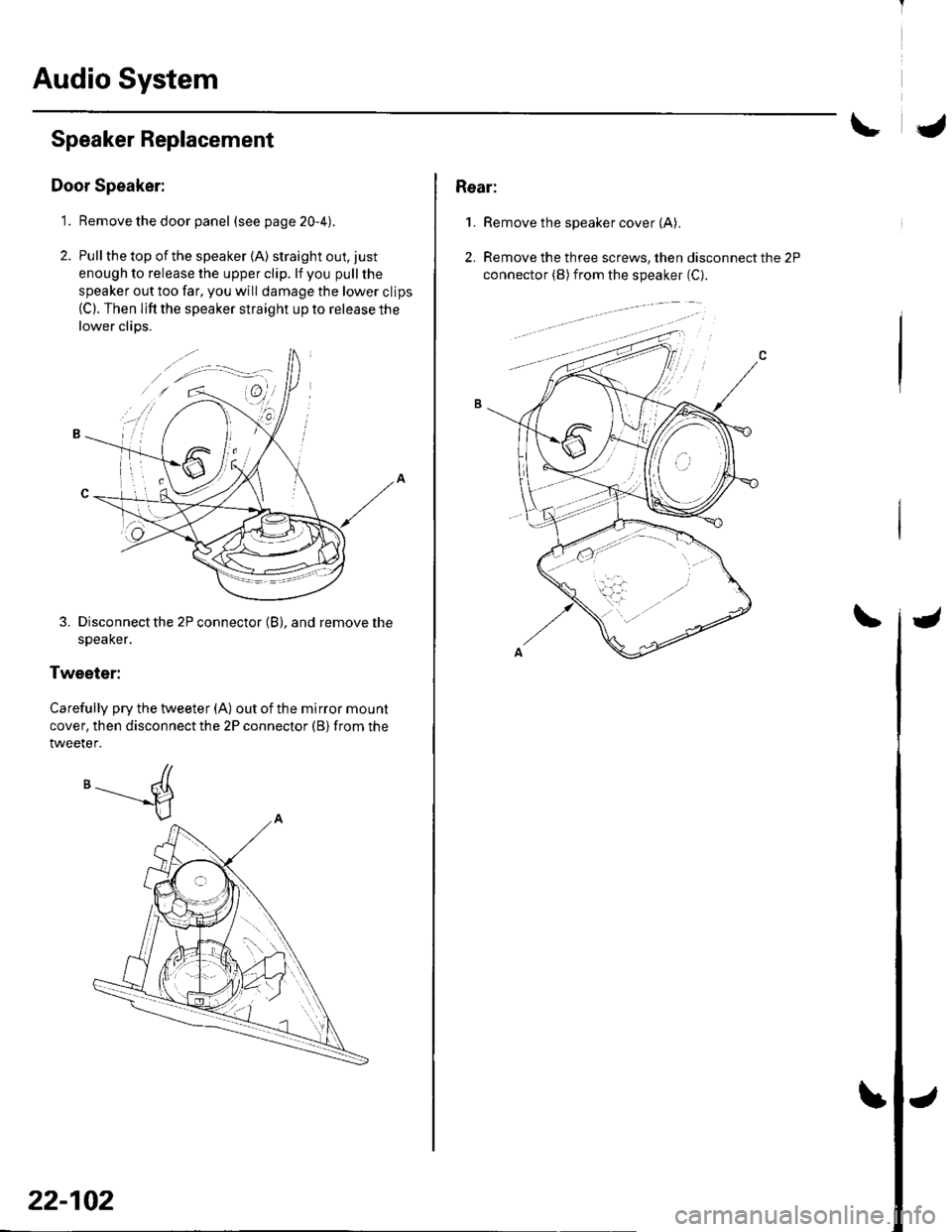

Speaker Replacement

Door Speaker:

1. Remove the door panel (seepage20-4).

2. Pull the top of the speaker {A) straight out, just

enough to release the upper clip. lf you pull the

speaker out too far, you will damage the lower clips(C). Then lifi the speaker straight up to release the

lower clips.

3. Disconnect the 2P connector (B), and remove the

speaKer.

Tweeter:

Carefully pry the tweeter (A) out of the mirror mount

cover, then disconnect the 2P connector (B) from the

tweeter.

'-----d

22-102

Rear:

1.Remove the speaker cover (A).

Remove the three screws, then disconnect the 2P

connector (B) from the speaker (C).

2.

Page 935 of 1139

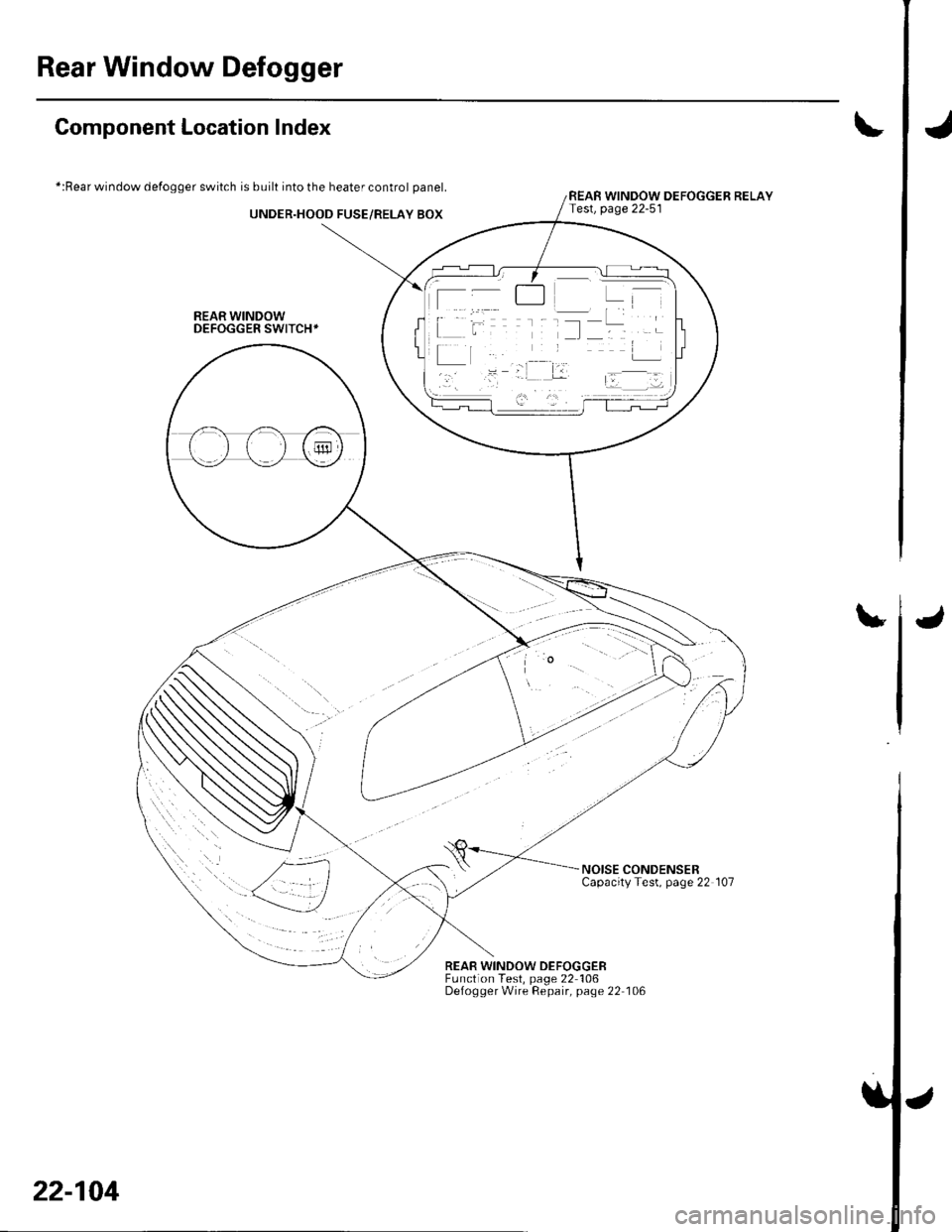

Rear Window Defogger

J

I

Component Location Index

*:Rear window defogger switch is built into the heater control panel.

UNDER.HOOD FUSE/RELAY BOX

REAR WINDOWDEFOGGER SWITCH+

t

REAR WINDOW DEFOGGER RELAYTest, page 22-51

u

NOISE CONDENSERCapacityTest, page 22 107

REAR WINDOW DEFOGGEBFunction Test, page 22 106Defogger Wire Repair, page 22 106

22-104

J

Page 937 of 1139

Rear Window Defogger

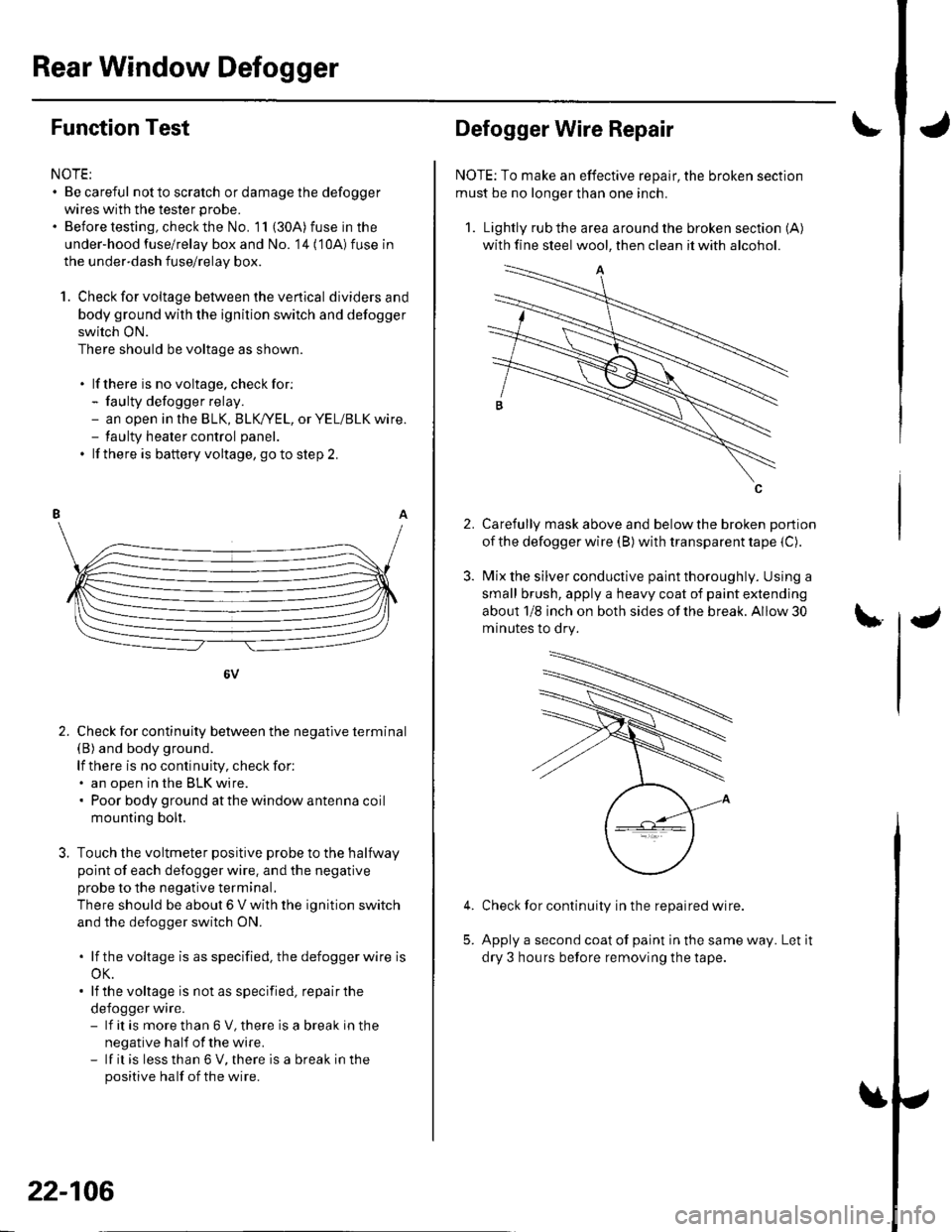

Function Test

NOTE:. Be careful not to scratch or damage the defogger

wires with the tester probe.

. Before testing, check the No. 11 (30A) fuse in the

under-hood fuse/relay box and No. '14 ('10A) fuse in

the under-dash fuse/relay box.

1. Check for voltage between the ve rtica I dividersand

body ground with the ignition switch and defogger

switch ON.

There should be voltage as shown.

. lf there is no voltage. checkfor:- faulty defogger relay.- an open in the BLK, BLK,/YEL, or YEL/BLK wire.- taulty heater control panel.

. lf there is battery voltage, goto step 2.

6V

Check for continuity between the negative terminal(B) and body ground.

lf there is no continuity, check for:. an open in the BLK wire.. Poor body ground at the window antenna coil

mounting bolt.

Touch the voltmeter positive probe to the halfway

point of each defogger wire. and the negative

probe to the negative terminal,

There should be about 6 V with the ignition switch

and the defogger switch ON.

. lf thevoltage is asspecified, the defoggerwlre is

oK.. lf the voltage is not as specified, repair the

defogger wire.- lf it is more than 6 V, there is a break in the

negative half of the wire.- lf it is less than 6 V, there is a break in the

positive half of the wire.

2.

22-106

2.

Defogger Wire Repair

NOTE: To make an effective repair, the broken section

must be no longer than one inch.

1. Lightly rub the area around the broken section (A)

with fine steel wool, then clean it with alcohol.

Carefully mask above and below the broken portion

of the defogger wire (B) with transparent tape {C).

Mix the silver conductive paint thoroughly. Using a

small brush, apply a heavy coat of paint extending

about 1/8 inch on both sides of the break. Allow 30

minutes to dry.

Check for continuity in the repaired wire.

Apply a second coat of paint in the same way. Let it

dry 3 hours before removing the tape.

5.

Page 938 of 1139

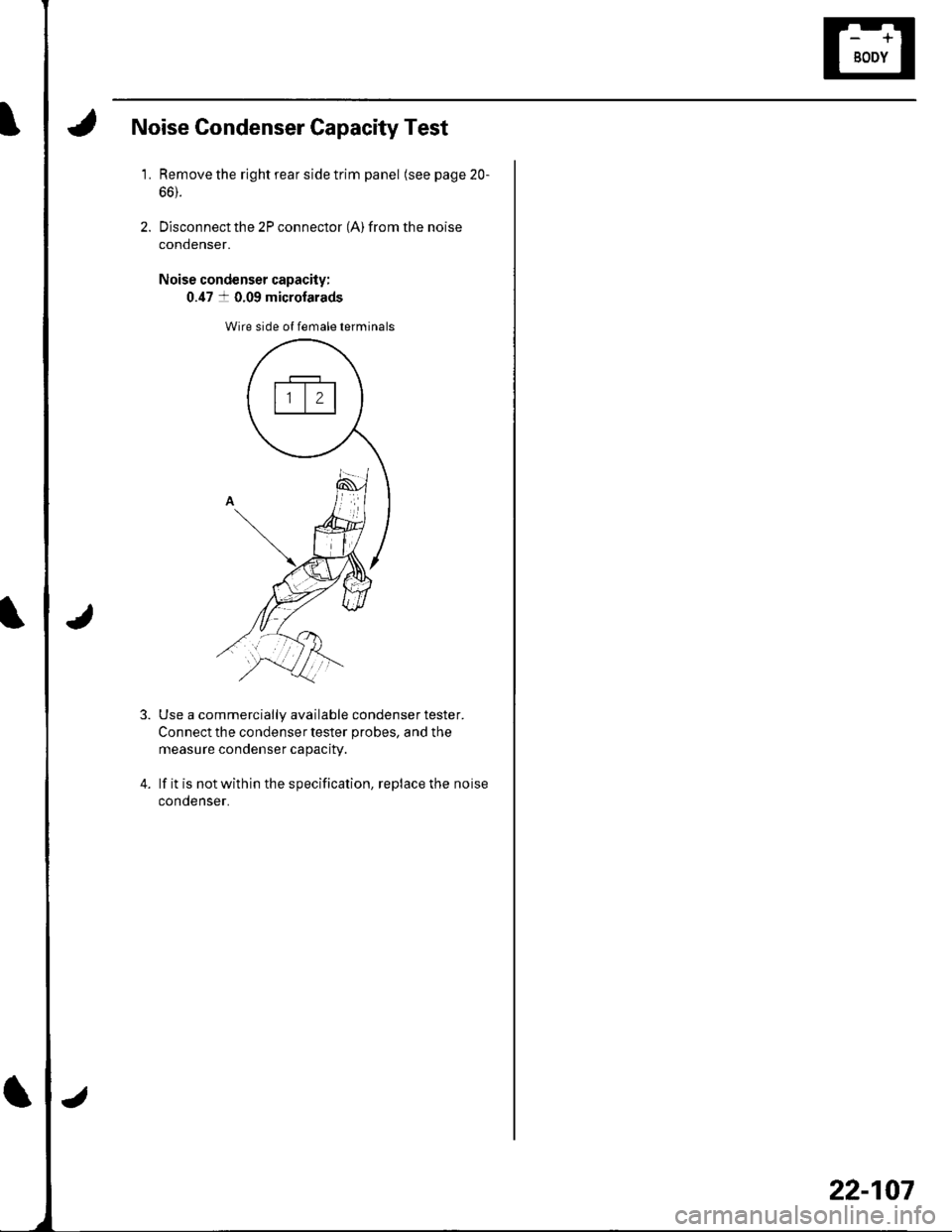

Noise Gondenser Capacity Test

1.Remove the right rear side trim panel (see page 20-

66).

Disconnect the 2P connector (A) from the noise

condenser.

Noise condenser capacity:

0.47 a 0.09 microfarads

Wire side ol female terminals

4.

Use a commercially available condenser tester.

Connect the condenser tester probes, and the

measure condenser capacity.

lf it is not within the specification, replace the noise

condenser.

22-107