Automatic HONDA CR-V 1997 RD1-RD3 / 1.G Owner's Guide

[x] Cancel search | Manufacturer: HONDA, Model Year: 1997, Model line: CR-V, Model: HONDA CR-V 1997 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 527 of 1395

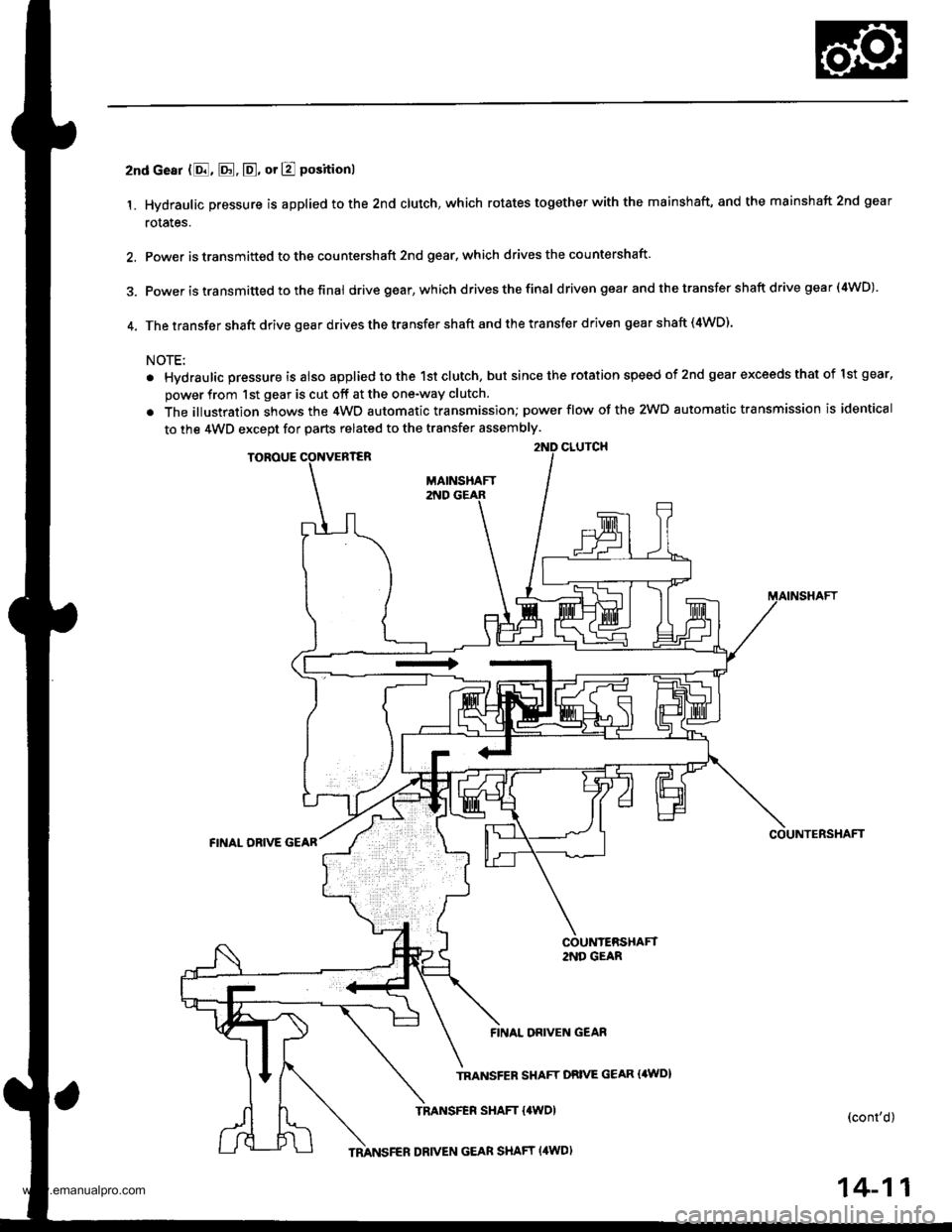

2nd cesr (8, E. E, or E positionl

1. Hydraulic pressure is applied to the 2nd clutch, which rotates together with the mainshaft, and the mainshaft 2nd gear

rotales.

2. Power is transmitted to the countershaft 2nd gear, which drives the countershaft

3. power is transmitted to the final drive gear, which drivesthefinal d riven gear and the transfer shaft drive gea r (4WD)

4. The transfer shaft drive gear drives the transfer shaft and the transfer driven gear shaft (4WD).

NOTE:

. Hvdraulic pressure is also applied to the 1st clutch, but since the rotation speed of 2nd gear exceeds that of lst gear.

power from 1st gear is cut off at the one-way clutch.

. The illustration shows the 4WD automatic transmission; power flow of the 2WD automatic transmission is identical

to the 4WD except for parts related to the transfer assembly.

CLUICHTOROUE

COUNTERSHAFTFINAL ORIVE GEAR

2NO GEAR

FINAL DRIVEN GEAF

TRANSFER SHAFT DBIVE GEAR {4WD}

TRANSFER SHAFT {4WDI(cont'd)

TMNSFER DRIVEN GEAR SHAFT (4WD)

14-11

www.emanualpro.com

Page 528 of 1395

Description

Power Flow (cont'd)

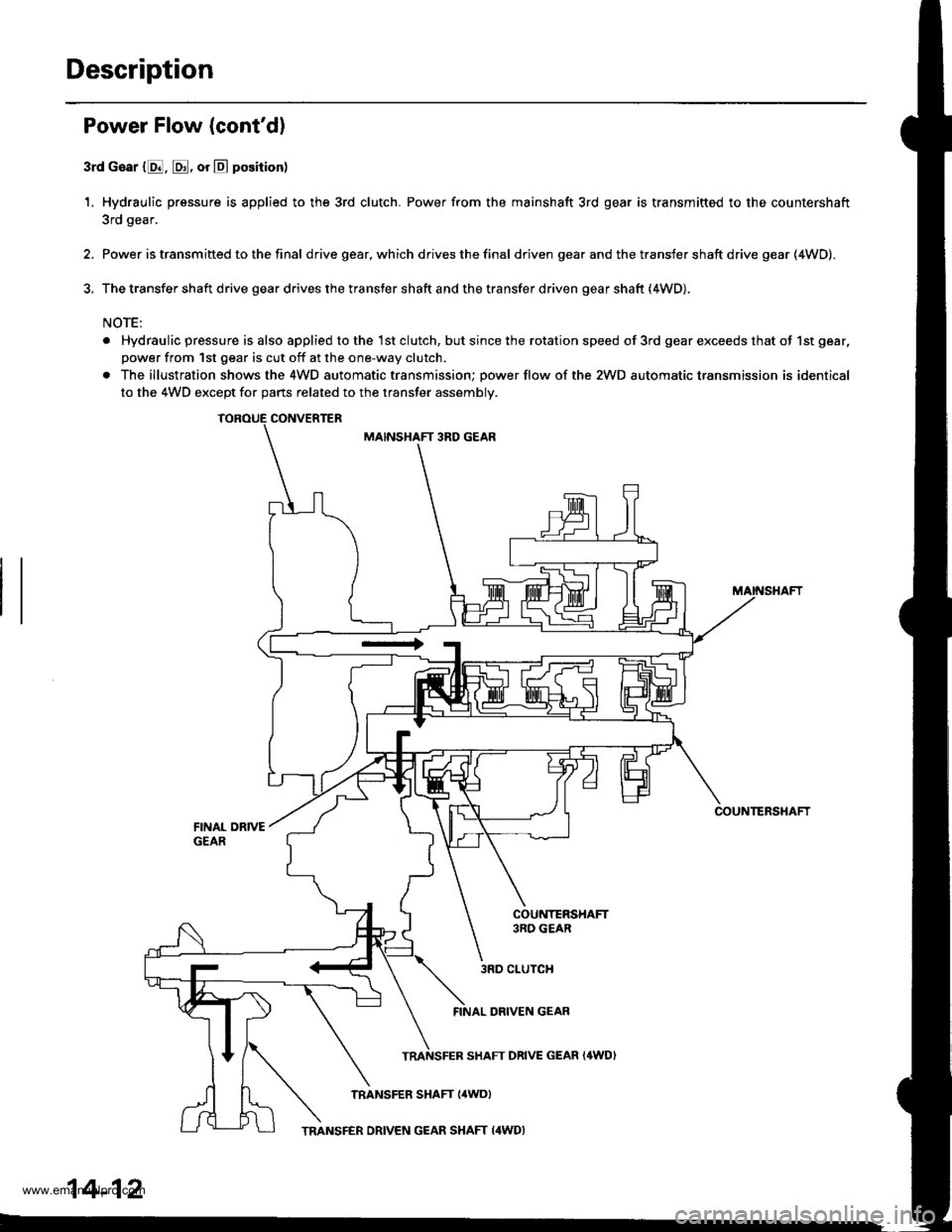

3rd Gear {8. @, or @ position)

1. Hydraulic pressure is applied to the 3rd clutch. Power from the mainshaft 3rd gear is transmitted to the countershaft

3rd gear.

2. Power is transm ifted to the final d rive gear, wh ich d rives the f inal driven gear and the transfer shaft drive gear (4WD).

3, The transfer shaft drive gear drives the transter shaft and the transfer driven gear shaft (4WD).

NOTE:

. Hydraulic pressure is also applied to the 1st clutch, but since the rotation speed of 3rd gear exceeds that of 1st gear,

power from lst gear is cut off at the one-way clutch.

. The illustration shows the 4WD automatic transmission; Dower flow of the 2WD automatic transmission is identical

to the 4WD except for parts related to the transfer assembly.

CONVERTEF

MAINSHAFT 3RD GEAR

COUNTERSHAFT

COUNTERSHAFT3RO GEAR

3RD CLUTCH

DRIVEN GEAR

SHAFT DRIVE GEAR (4WO)

TRANSFER SHAFT (,lwDl

TRANSFER ORIVEN GEAN SHAFT (4WD)

14-12

www.emanualpro.com

Page 529 of 1395

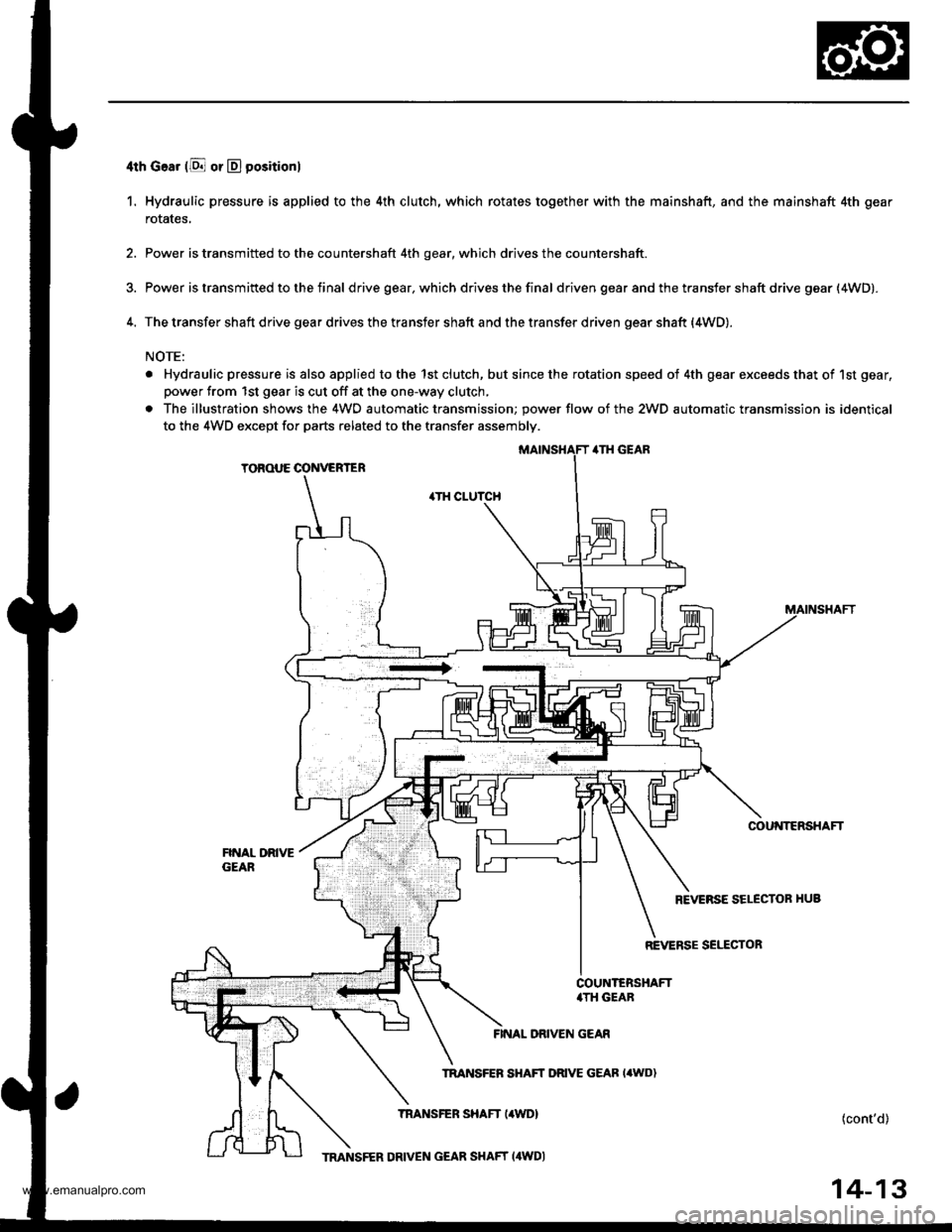

4th Goar (E or D positionl

1. Hydraulic pressure is applied to the 4th clutch, which rotates together with the mainshaft, and the mainshaft 4th gear

rotates,

2. Power is transmitted to the countershaft 4th gear, which drives the countershaft.

3. Power is transm ifted to the f inal d rive gear, which drives the fina I driven gear and the transfer shaft drive gear (4WD).

4. The transfer shaft drive gear drives the transfer shaft and the transfer driven gear shaft {4WD).

NOTE:

. Hydraulic pressure is also applied to the 1st clutch, but since the rotation speed of 4th gear exceeds that of 1st gear,

power from 1st gear is cut off at the one-way clutch,

. The illustration shows the 4WO automatic transmission; power flow of the 2WD automatic transmission is identical

to the 4WD except for parts related to the transfer assembly.

ilTH GEAR

TOROUE CONVERTER

.TH CLUTCH

COU'{TERSHAFT

REVERSE SELECTOR HUB

REVERSE SELECTOR

FINAL DRIVEN GEAR

TRANSFEB SHAFT DRIVE GEAB I'WD)

TNANSFER SHAFT I4WDI{cont'd)

14-13

TMNSFER DRIVEN GEAR SHAFT (4WDI

www.emanualpro.com

Page 530 of 1395

Description

Power Flow (cont'dl

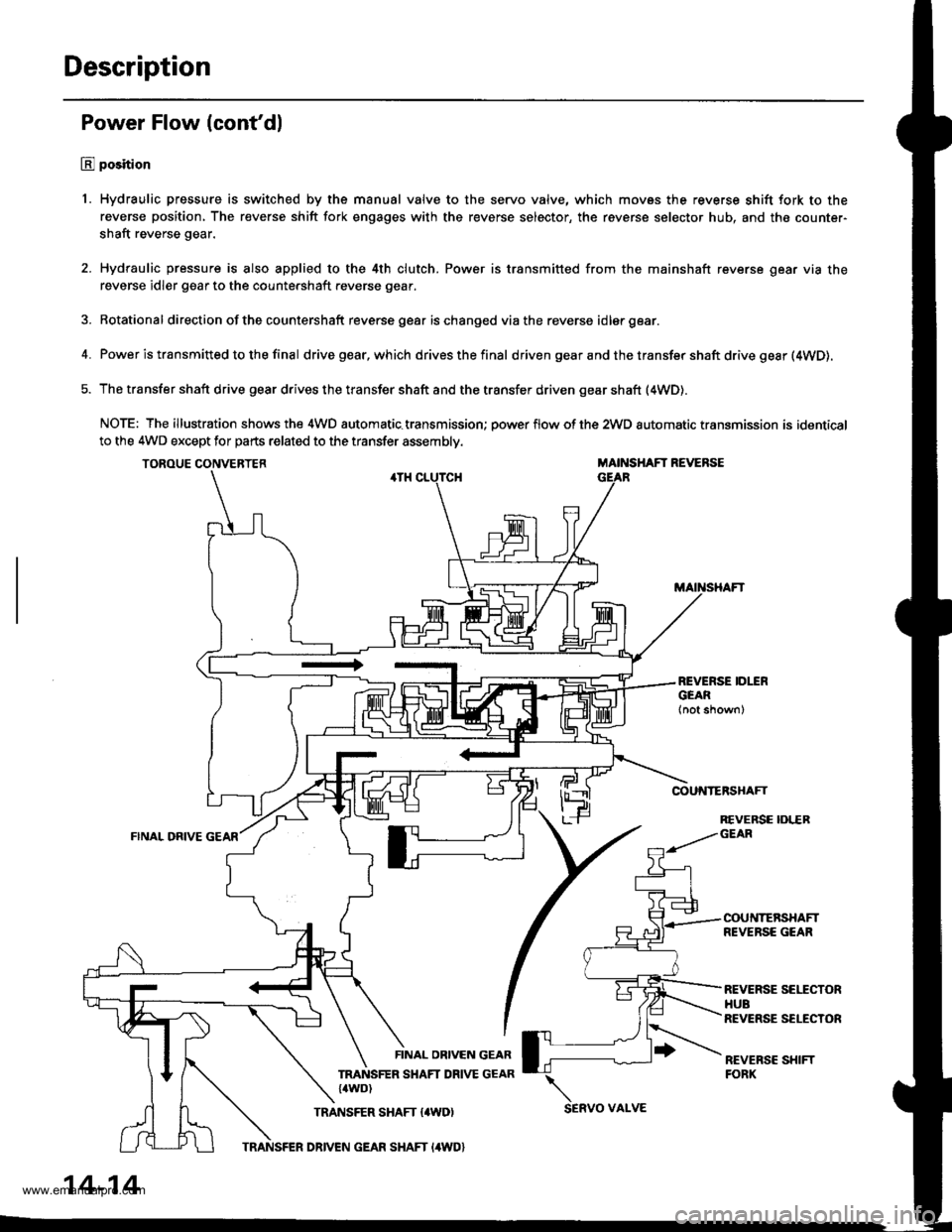

E position

1. Hydraulic pressure is switched by the manual valve to the servo valve, which movss the reverse shift fork to the

reverse position, The reverse shift fork engages with the reverse selector, the reverse selector hub, and the counter-

shaft reverse gear.

2. Hydraulic pressure is also applied to the 4th clutch. Power is transmitted from the mainshaft reverse gear via the

reverse idler gear to the countershaft reverse gear.

3. Rotational direction ofthe countershaft reverse gear ischanged viathe reverse idlergear.

4. Power is transmitted to the final drivegear,which drivesthefinal d riven gear a nd the transfer shaft drive gesr (4WD).

5. The transfer shaft drive gear drives the transfer shaft and the transfer driven gear shaft (4WD).

NOTE: The illustration shows the 4WD automatic.transmission; power flow of the 2wD automatic transmission is identical

to the 4WD except for parts related to the transfer assembly.

TOROUE CONVERTERMAINSHAFT REVERSE

COUNTERSHAFT

FINAL ORIVE

REVERSE IDLERGEAR

COUNTERSHAFTREVERSE GEAR

REVERSE SEITCTORHUBREVERSE SELECTOR

REVEBSC SHIFTFORK

FINAL OBIVEN GEAR

TRANSFER SHAFT DRIVE GEAR{4WD)

TRANSFER SHAFT {4WD)SERVO VAI-VE

14-14

TRANSFER DRIVEN GEAR SHAFT I4WD}

www.emanualpro.com

Page 535 of 1395

![HONDA CR-V 1997 RD1-RD3 / 1.G Owners Guide

Ascending Control {37 Modol}

When the PCM determines that the vehicle is climbing a hill in E] and E positions, the system extends the engagement

area of 2nd g€ar and 3rd gear to prevent the transm HONDA CR-V 1997 RD1-RD3 / 1.G Owners Guide

Ascending Control {37 Modol}

When the PCM determines that the vehicle is climbing a hill in E] and E positions, the system extends the engagement

area of 2nd g€ar and 3rd gear to prevent the transm](/img/13/5778/w960_5778-534.png)

Ascending Control {37 Modol}

When the PCM determines that the vehicle is climbing a hill in E] and E positions, the system extends the engagement

area of 2nd g€ar and 3rd gear to prevent the transmission from frequently shifting between 2nd and 3rd gears, and

between 3rd and 4th gears, so the vehicle can run smooth and have more power when needed.

NOTE:

. Shift schedules stored in ths PCM between 2nd and 3rd gears, and between 3rd and 4th gears. enable the PCM's fuzzy

logic to automatically select the most suitable gear according to the magnitude of 8 gradient.

t Fuzzy logic is a form of artificial intslligence that lets computers respond to changing conditions much like a human

mind would.

3RD - tlTHASCENoING MODE: UFhift Sch.dulc

- . FLAT ROAD MODE

-----------. : GRADUAL ASCENDING MODE

- - - - - : STEEPASCENDING MODEo5l)

FFN1NS

7,.,.7a

: 2ND-3RD SHIFTING CHARACTERISTICSCONTROL AREA| 3RD-aTH SHIFTING CHARACTER|SnCSCONTROL AREA

62 mph

1100 km/h)Vehicle .o..d

Asconding Conirol ('98 - 00 Mod.ls)

When the PCM determines that the vohicle is climbing a hill in E] and E positions ('98 model), and in E] position ('99 -

00 models), the system extends the engagement srea of 2nd gear and 3rd gear to prevent the transmission from frequent-

ly shifting between 2nd and 3rd gears, and between 3rd and 4th gears, so the vehicle can run smooth and have more

power when needed.

NOTE: Shift schedulss stored in the PCM between 2nd and 3rd gears, and between 3rd and 4th gears, enable to selsct the

most suitable gear according to th6 magnitude of a gradi€nt.

ASCENDING MODE: Up.hift Sch.dul.

NN : 2ND-3RD SXImNG CHARACTERISTICS- GoNTRoLAREA

VVVVVZ:IRD-ITHSHIFnNGCHARACTERISTICS- cot{TRoL AREA

850

o

6:l mph11fl) km/hl

(cont'd)

2ND - 3RD

2ND + 3RD 3RD + 4TH

Vahicl. sDctd

14-19

www.emanualpro.com

Page 546 of 1395

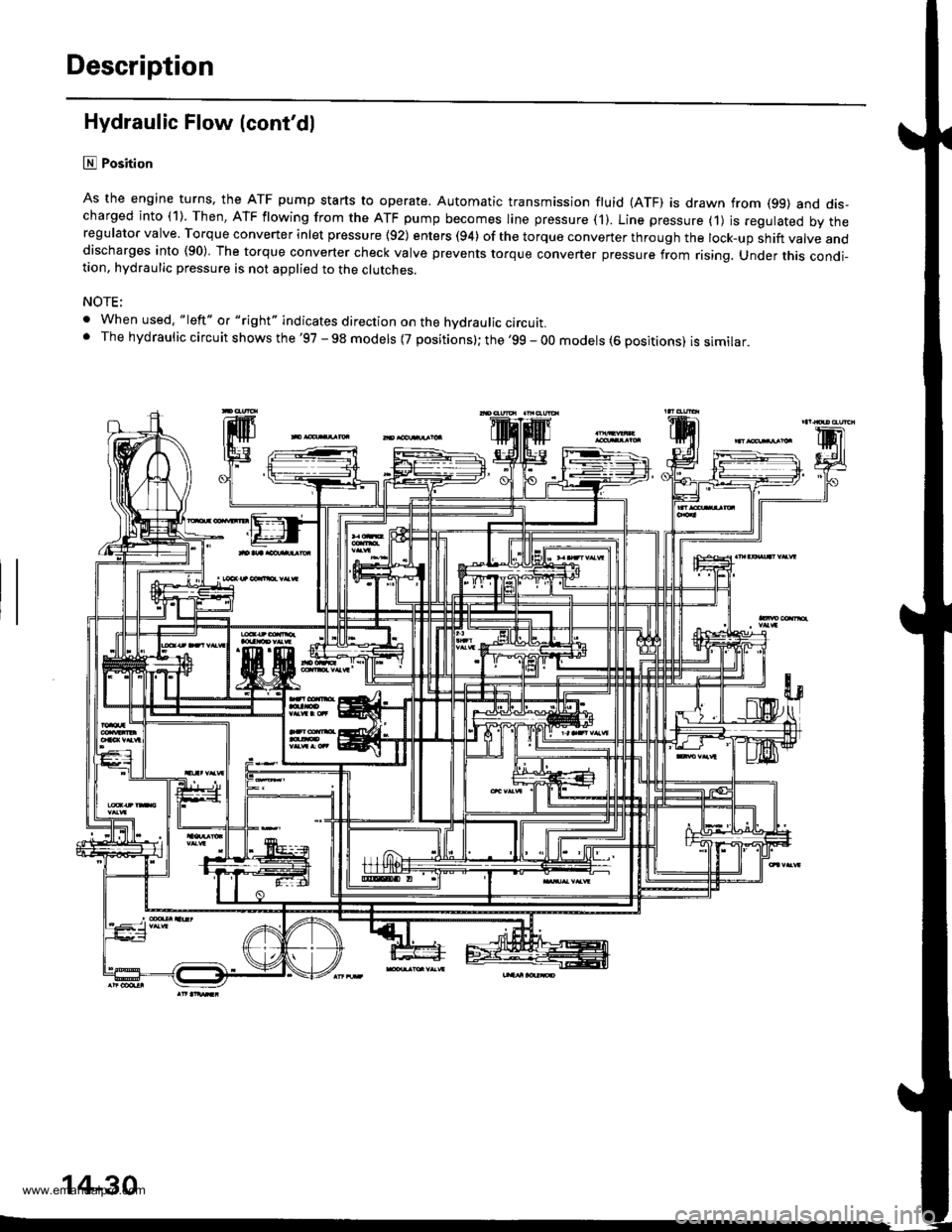

Description

Hydraulic Flow (cont'dl

lll Position

As the engine turns, the ATF pump starts to operate. Automatic transmission fluid (ATF) is drawn from (99) and dis-charged into (1). Then, ATF flowing from the ATF pump becomes line pressure ('l). Line pressure (1) js regulated by theregulator valve. Torque converter inlet pressure {92) enters (94) of the torque conveTter through the lock-up shift valve anddischarges into (90) The torque converter check valve prevents torque converter pressure from rising. Under this condi-tion, hydraulic pressure is not applied to the clutches.

NOTE;

. When used. "|eft" o. "right" indicates direction on the hvdraulic circutt.. The hydraulic circuit shows the '97 - 98 models {7 positions}; the '99 - 00 models (6 positions) is similar.

'lF'.j.l

14-30

www.emanualpro.com

Page 577 of 1395

NOTE: When the OBD ll Scan Tool or Honda PGM Tester indicate DTC(s) for the automatic transmission control system'

the scan tool or tester indicates code P0700 simultaneously. code P07oo means a detection of some automatic transmis-

sion problem in the PGM-Fl control system

lf the self-diagnostic E indicator light does not blink, perform an inspection according to the table below.

NOTE: lf a customer describes the symptom for code P1706 (6), it will be necessary to recreate the symptom by test-driv-

ing, then recheck the OTC.

SymptomInspectionRef. page

E indicator light is on constantly (not blinking) whenever the ignition

switch is ON (ll).14-86

E indicator light does not come on for two seconds after ignition

switch is first turned ON (ll).

't 4-41

Shift lever cannot be moved from @ position with the brake pedal

Dressed,Check shift lock system14-89

lgnition key cannot be moved from ACC (l) position to LOCK {0) posi

tion with the shift lever in E position.Check keY interlock system14-91

14-61

www.emanualpro.com

Page 579 of 1395

NOTE: When the OBD ll Scan Tool or Honda PGM Tester indicate DTC(S) for the automatic transmission control system,

the scan tool or tester indicates code P0700 simultaneously. Code P0700 means a detection of some automatic transmis-

sion problem in the PGM-Fl control system.

lf the self-diagnostic E or E indicator light does not blink, perform an inspection according to the table below.

NOTE: lf a customer describes the symptom for code P17OO (6), it will be necessary to recreate the symptom by test-driv-

ing. then recheck the DTC.

SymptomInspectionRef. page

E or E indicator light does not come on for two seconds after ignition

switch is first turned ON (ll).14-123

E or E] indicator light is on constantly (not blinking) whenever the

ignition switch is oN {ll).

14-125

Shift lever cannot be moved from E position with the brake pedal

presseo.Check shift lock system14-'t26

lgnition key cannot be moved from ACC (l) position to LOCK (0) posi-

tion with the shift lever in E position.Check key interlock system14-129

O/D OFF indicator light does not come on for two seconds after ignition

switch is first turned ON (ll). ('99 - 00 models)14-131

The O/D OFF indicator light is on constantly whenever the ignition

switch is ON (ll). ('99 - 00 models)14-132

The O/D OFF indicator light does not come on even though the Over-

Drive (O/Dl switch is pressed in E position. ('99 - 00 models)

Check Over-Drive {O/D}

switch circuit14-133

14-63

www.emanualpro.com

Page 676 of 1395

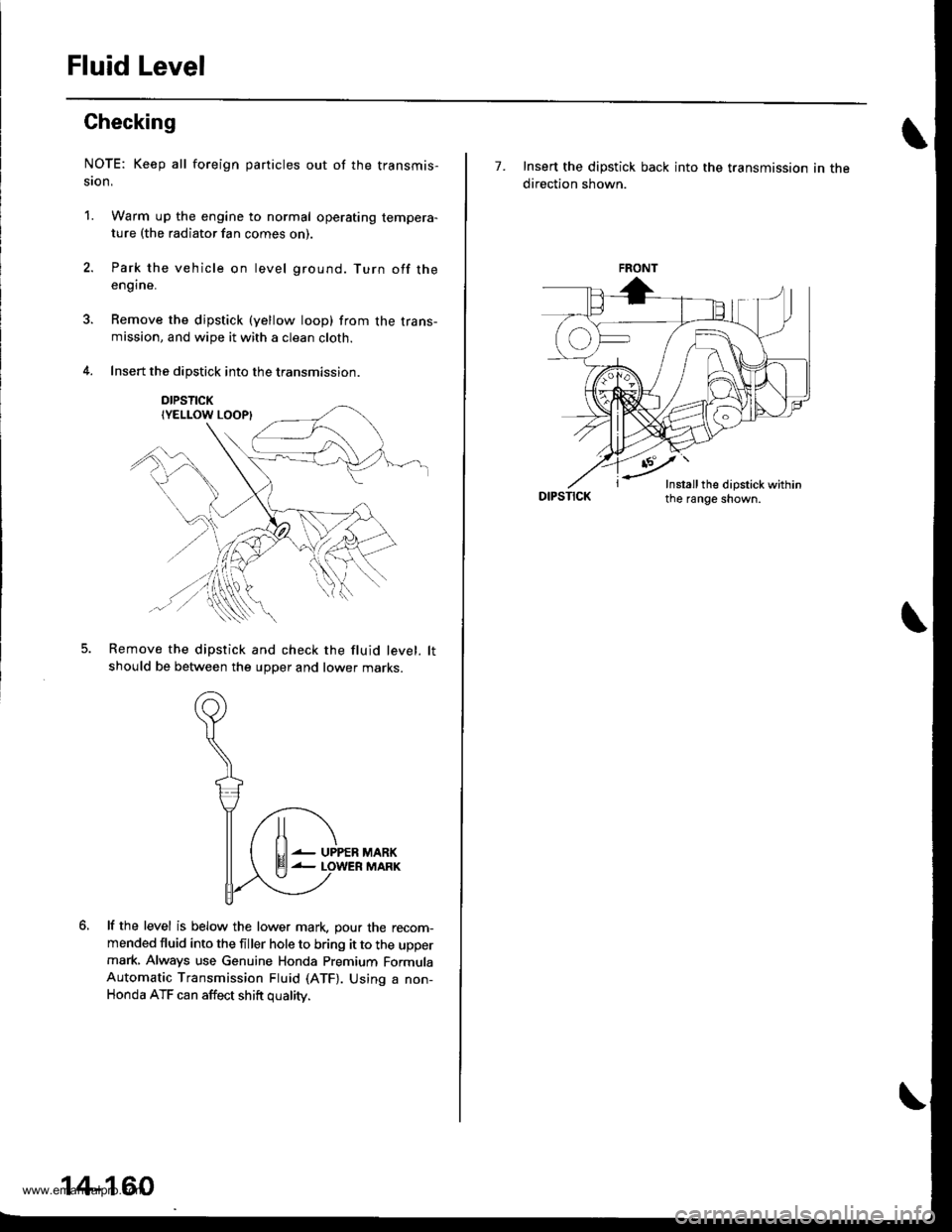

Fluid Level

Checking

NOTE: Keep all foreign particles out of the transmis-

ston,

1. Warm up the engine to normal operating tempera-ture (the radiator fan comes on)

Park the vehicle on level ground. Turn off theengine.

Remove the dipstick (yellow loop) from the trans-mission, and wipe it with a clean cloth.

Insert the dipstick into the transmission.

DIPSTICK

Remove the dipstick and check the fluid level. lt

should be between the upper and lower marKs.

lf the level is below the lower mark. pour the recom-mended fluid into the filler hole to bring it to the uppermark, Always use Genuine Honda Premium FormulaAutomatic Transmission Fluid (ATF). Using a non-Honda ATF can affect shift oualitv.

lt

El--

UPPERMARKMARK

14-160

7. Insert the dipstick back into the transmission in the

direction shown.

DIPSTICK

FRONT

-'-Y'

Insrall the dipstick within

www.emanualpro.com

Page 677 of 1395

Pressure Testing

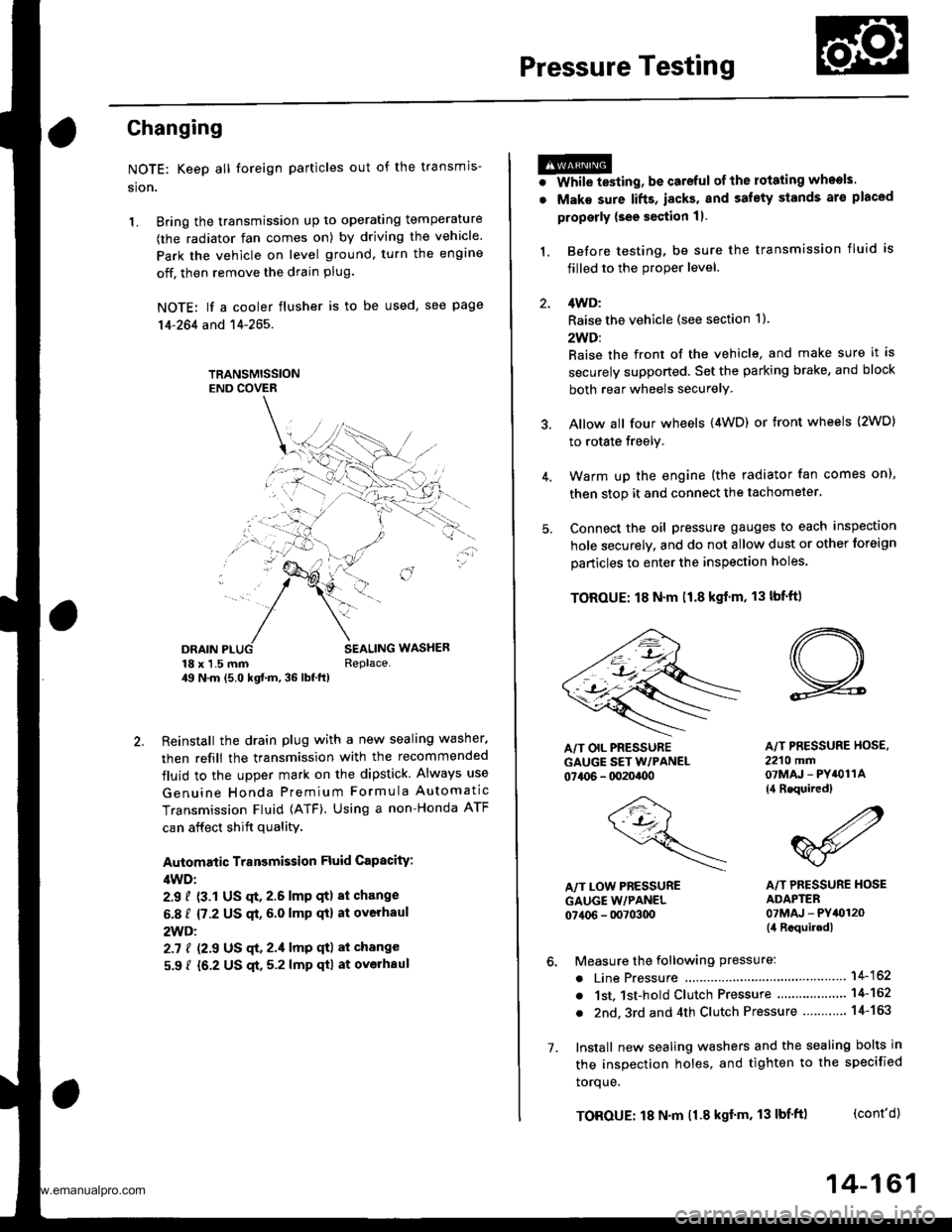

Changing

NOTE: Keep all foreign particles out of the transmis-

sion.

1. Bring the transmission up to operating temperature

(the radiator fan comes on) by driving the vehicle.

Park the vehicle on level ground. turn the engane

off. then remove the drain Plug.

NOTE: lf a cooler flusher is to be used, see page

14-264 and 14-265.

TRANSMISSIONEND COVER

DRAIN18 x 1.5 mmSEALING WASHEBReplace.49 N.m {5.0 kgt.m, 36 lbf.tl)

Reinstall the drain plug with a new sealing washer,

then refill the transmission with the recommended

fluid to the uDper mark on the dipstick. Always use

Genuine Honda Premium Formula Automatic

Transmission Fluid (ATF) Using a non-Honda ATF

can affect shift quality.

Automatic Transmission Fluid Capacity:

4WD;

2.9 { (3.1 US qt. 2.6 lmp qt) 8t change

5.8 ? {7.2 US $, 6.0 lmp qt} at ovethaul

2WD:

2.7 | l2.S US qt,2.1lmp qtl ai change

5.9 ? {6.2 US $, 5.2 lmp qtl at ovolhaul

2.

a

a

1.

Wlrile testing, be careful of the rotaling wheols.

Mako sure lifts, iacks, and safety stands ar€ placed

properly (see scction 11.

Before testing, be sure the transmission fluid is

filled to the proPer level.

4WD:

Raise the vehicle (see section 11.

2WD:

Raise the front of the vehicle, and make sure it is

securely supported. Set the parking brake, and block

both rear wheels securely.

Allow all four wheels {4WD) or front wheels (2wD}

to rotate freely.

Warm up the engine (the radiator fan comes on),

then stop it and connect the tachometer.

Connect the oil pressure gauges to each inspection

hole securely, and do not allow dust or other foreign

particles to enter the inspection holes.

TOROUE: 18 N'm ll.8 kgf'm, 13 lbf'ft)

5.

A/T PRESSURE HOS€,2210 mm07MAJ - PYiOllA

{4 Requircd}

,4'/"' ,a

W'

A/T PRESSURE HOSEADAPTER07MAJ - PYt0120(il Rcquiledl

6. Measure the following Pressure:. Line Pressure ..........,14-162

. 1st. 1st-hold Clutch Pressure .............'. 14-162

. 2nd,3rd and 4th Clutch Pressure .......... 14-163

7. Install new sealing washers and the sealing bolts in

the inspection holes, and tighten to the specified

toroue.

(cont'd)

A/T OIL PRESSUREGAUGE SET W/PANEL07{06 - 0020400

/4\\-J-- (

+..\.-.\-'-\

A/T LOW PBESSUREGAUGE w/PANEL07406 - 0070300

TOROUE: 18 N'm 11.8 kgf'm, 13 lbf'ft)

14-161

www.emanualpro.com