Vacuum HONDA CR-V 1997 RD1-RD3 / 1.G Owner's Guide

[x] Cancel search | Manufacturer: HONDA, Model Year: 1997, Model line: CR-V, Model: HONDA CR-V 1997 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 403 of 1395

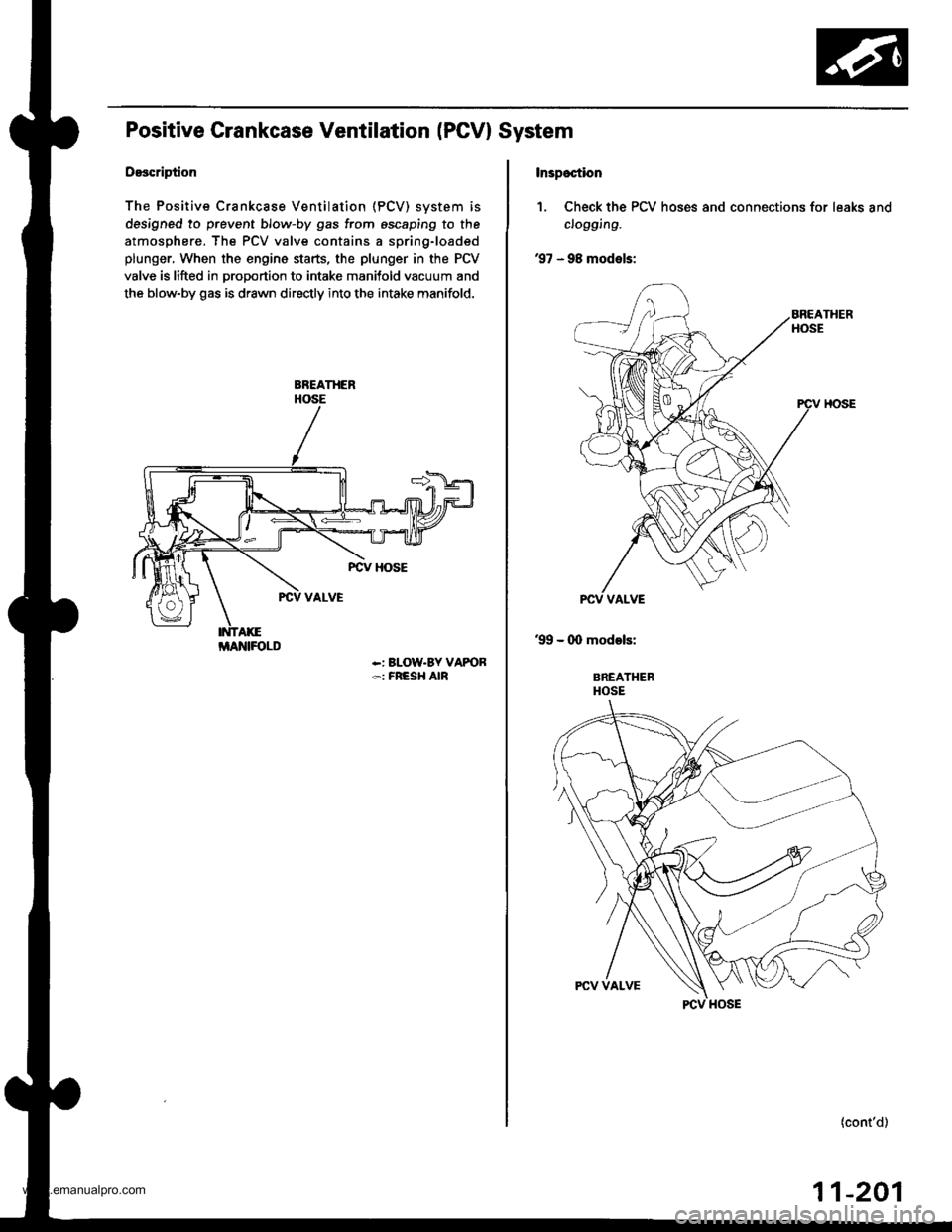

Positive Grankcase Ventilation (PGVI System

Description

The Positive Crankcase Ventilation (PCV) svstem is

designed to prevent blow-by gas from escaping to the

atmosphere. The PCV valve contains a spring-loaded

plunger, When the engine starts, the plunger in the PCV

valve is lifted in proportion to intake manitold vacuum and

the blow-by gas is drawn directly into the intake manifold.

-: BLOW.BY VAPOR-: FRESH AIR

i/lAlrllFOLD

Inspoction

1. Check the PCV hoses and connections for leaks and

clogging.

'97 - 98 models:

'99 - (X) models:

BREATHERHOSE

(cont'd)

11-201

www.emanualpro.com

Page 405 of 1395

EVAP PURGE CONTROL SOLENOID VALVE DUTY CONTROLLED AFTER

STARTING ENGINE

ENGINE COOLANT TEMPERATURE ABOVE 154"F (68'C)

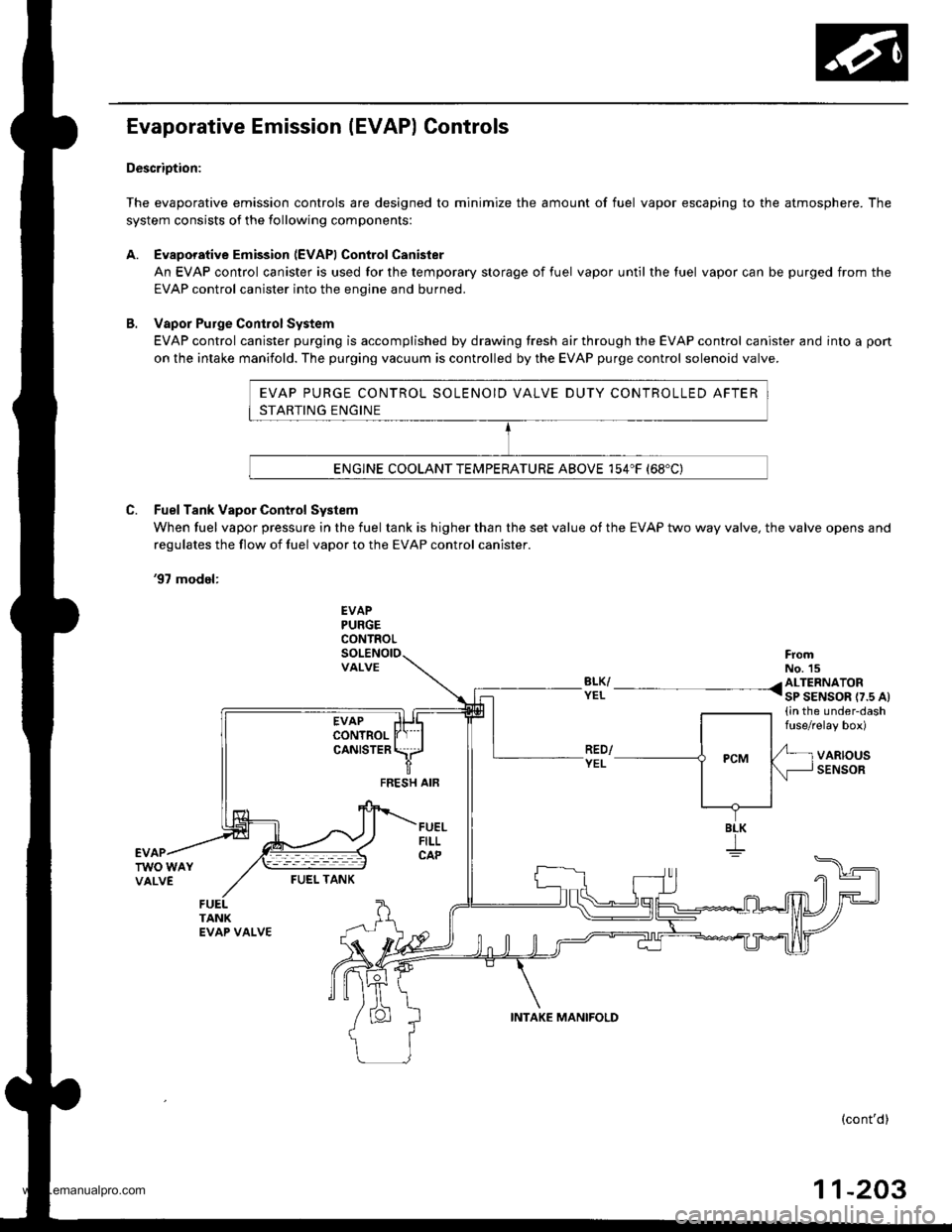

Evaporative Emission (EVAP) Controls

Description:

The evaporative emission controls are designed to minimize the amount of fuel vapor escaping to the atmosphere. The

system consists of the following components:

A. Evaporative Emission (EVAPI Control Canister

An EVAP control canister is used for the temporary storage of fuel vapor until the luel vapor can be purged from the

EVAP control canister into the enqine and burned.

B. Vapor Purge ConirolSystem

EVAP control canister purging is accomplished by drawing fresh air through the EVAP control canister and into a pon

on the intake manifold. The purging vacuum is controlled by the EVAP purge control solenoid valve.

C. Fuel Tank Vapor Control System

When fuel vapor pressure in the fuel tank is higher than the set value of the EVAP two way valve, the valve opens and

regulates the flow ot fuel vapor to the EVAP control canister.

'97 model:

EVAPPURGECONTROL

VALVEFromNo. 15BLK/ /ALTERNATORYEL I sP SENSOR r7.s At(in the under-dashfuse/relay box)

VARIOUSSENSORFEESH AIF

BLK

I

FUEI- TANK

(cont'd)

11-203

INTAKE MANIFOLD

www.emanualpro.com

Page 407 of 1395

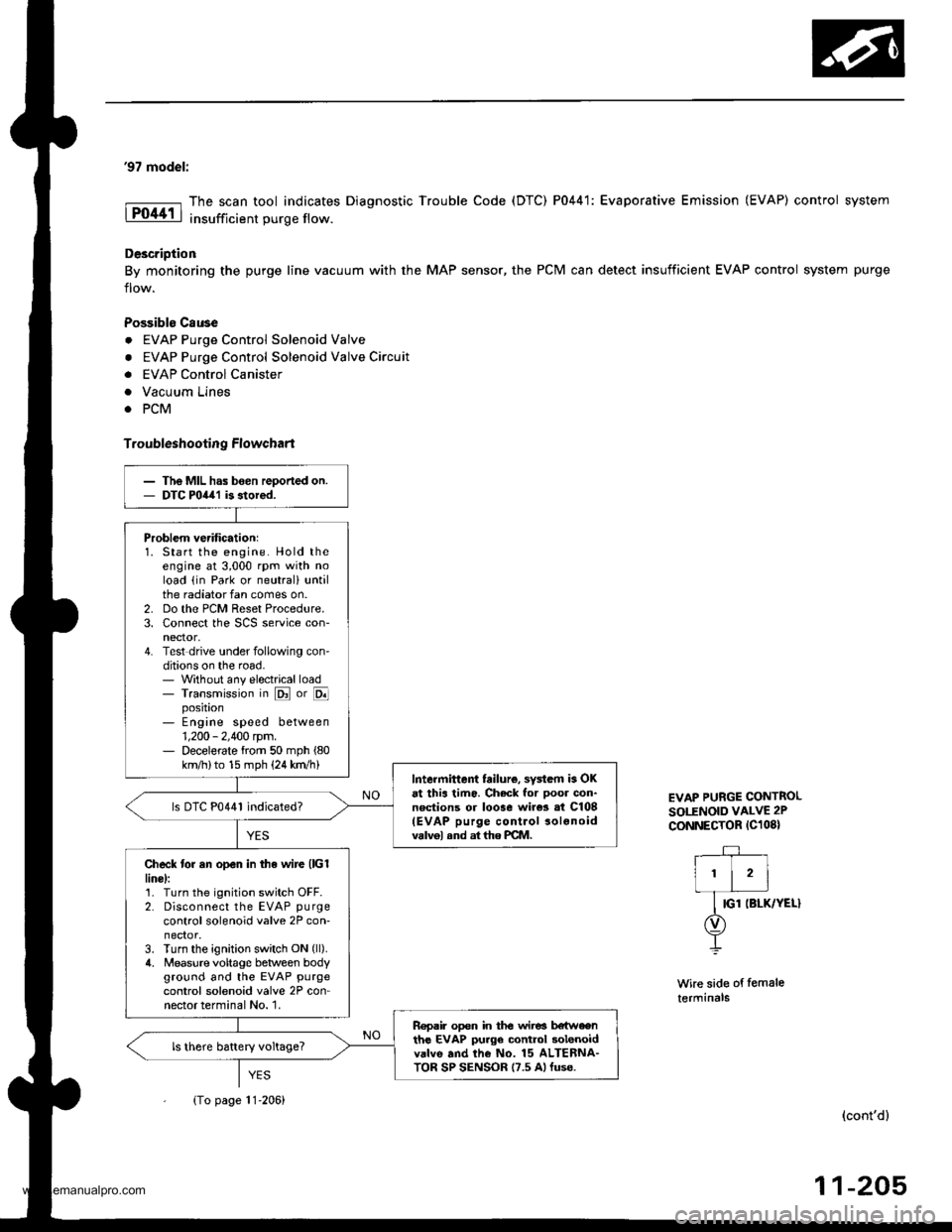

'97 model:

The scan tool indicates Diagnostic Trouble Code (DTC) P0441: Evaporative Emission (EVAP) control system

insufficient purge flow.

Description

By monitoring the purge line vacuum with the MAP sensor, the PCM can detect insufficient EVAP control system purge

flow.

Possiblo Cause

. EVAP Purge Control Solenoid Valve

. EVAP Purge Control Solenoid Valve Circuit

. EVAP Control Canister

. Vacuum Lines

. PCM

Troubleshooting Flowchart

EVAP PURGE CONTROL

SO1TNOID VALVE 2P

CoNNECTOR (C108)

(v)

YL

Wire side of female

termrnals

(cont'd)

11-205

Th€ MIL has b€en reooited on.DTC P0441 is .tored.

Problem verificationl1. Start the engine. Hold theengine at 3,000 rpm with noload (in Park or neut.al) untilthe radiator fan comes on.2. Do the PCM Reset Procedure.3. Connect the SCS service con-nector,4. Test drive under following con'ditions on the road.- without any electrical load- Transmission in @ or @position- Engine speed between1 ,2OO - 2,4OO rpfi.- Decelerate from 50 mph (80

km/h)to 15 mph (24 km/h)Intermittent trilure, sydern is OKat this time. Check for Door con-nections or loose wir€3 at C108

IEVAP purge control solonoidvalvol .nd at the PCM.

ls DTC P0441 indicated?

Check tor an open in the wire (lcl

linel:1. Turn the ignition switch OFF.2. Disconnect the EVAP purge

control solenoid valve 2P con-nector.3. Turn the ignition switch ON (ll).

4. Measure voltage between bodyground and the EVAP purge

control solenoid valve 2P con-nector terminal No. '1,

R€pafu open in thc wir6 b€tw€enthG EVAP purge control solenoidvalve and the No. 15 ALTEBNA-TOR SP SENSOR (7.5 A)fuse.

ls there batlery voltage?

(To page 11'206)

www.emanualpro.com

Page 408 of 1395

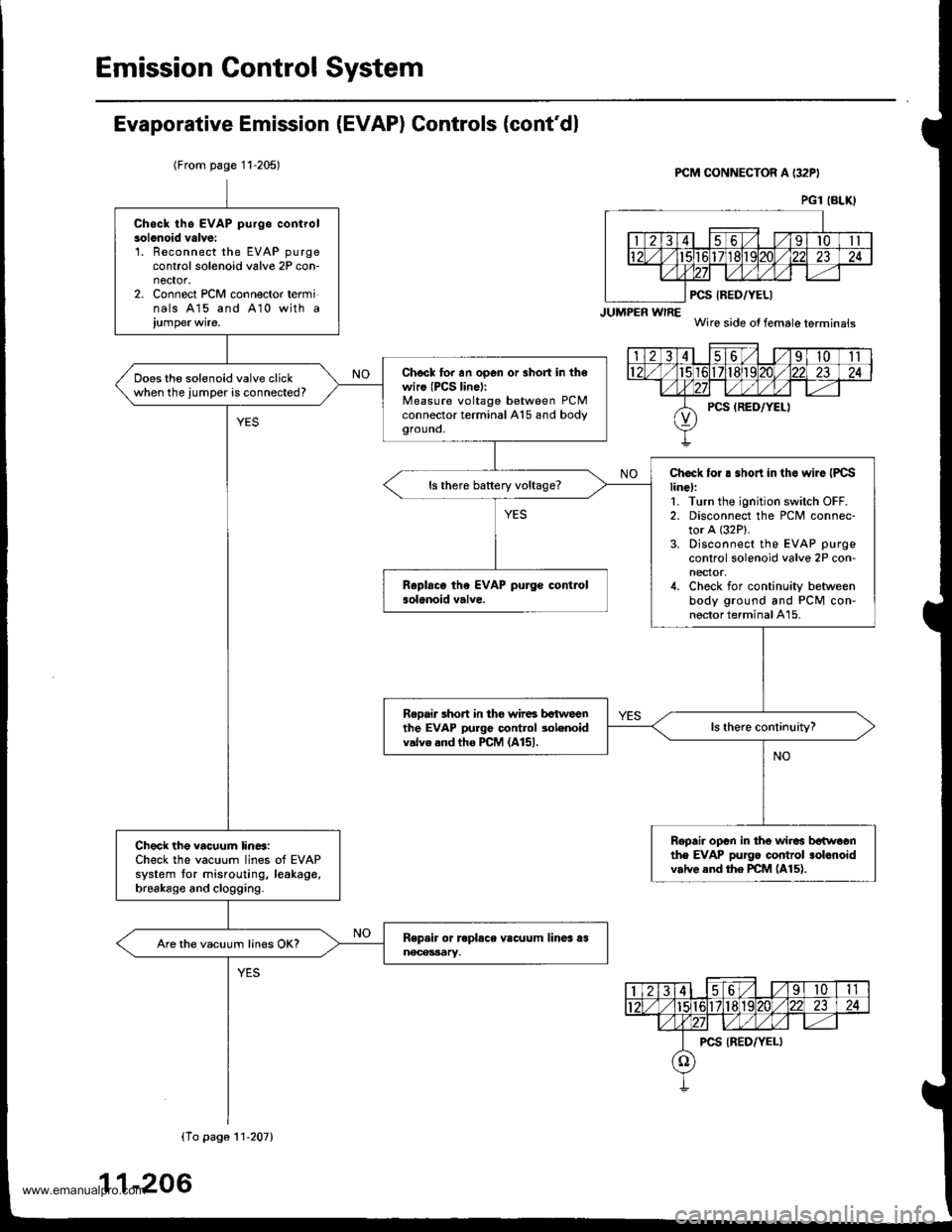

Emission Control System

Evaporative Emission (EVAP) Controls (cont'dl

(From page 11-205)PCM CONNECTOR A (32PI

JUMPER wlRE

PCS IRED/YELI

Wire side of female terminais

PG1 (BLKI

Chsck th6 EVAP purgo controlsolonoid valve:'L Reconnect the EVAP purgecontrol solenoid valve 2P con-nector.2. Connect PCM connector terminals 415 and A10 with a

Chscl to. an op6n or 3hort in th€wiro (PCS lin6):Measure voltage between PCMconnector terminal A15 and bodygrouno,

Does the solenoid valve clickwhen the jumper is connected?

Chock for . .hort in tho wiJe IPCSline):1. Turn the ignition switch OFF.2. Disconnect the PCM connec-tor A (32P).

3. Disconnect the EVAP purge

control solenoid valve 2P con-nector,4. Check for continuity betweenbody ground and PCM con-nector terminal A15.

ls there battery voltage?

Rooair short in tho wir6 bctweenthe EVAP purge control 3olenoidvalvo and tho PCM (A151.

Ropair open in the wir6 betwoonthe EVAP pu]go control .olonoidv.lve end the PCM (A15).

Check the vacuum lin6:Check the vacuum lines of EVAPsystem tor misrouting, leakage,brsakago and clogging.

Are the vacuum lines OK?

(To pago 11'207)

11-206

www.emanualpro.com

Page 409 of 1395

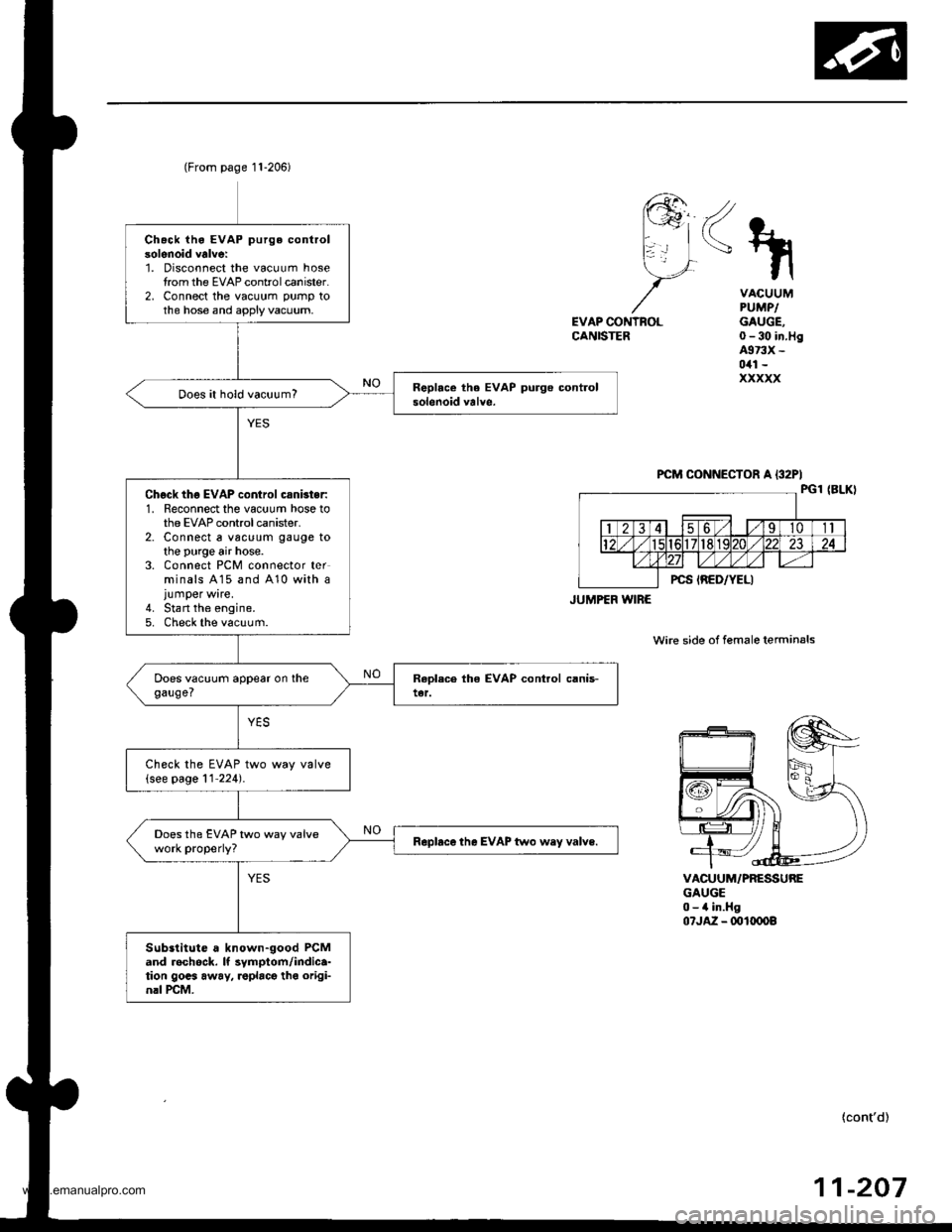

Chack iho EVAP purge controlsolenoid valve:1. Disconnect the vacuum hosetrom the EVAP controlcanister.2, Connect the vacuum pump tothe hose and apply vacuum,

Does it hold vacuum?

Chgck thg EVAP control csnbter:1. Reconnect the vacuum hose tothe EVAP control canister.2. Connect a vac!um gauge tothe purge air hose.3. Connect PCM connector terminals A15 and 410 with ajumper wire.4. Stan the engine.5. Check the vacuum.

Check the EVAP two way valve(see page 11'224).

Does the EVAP two way valvework properly?Rapbce the EVAP two wey valve.

Substitute a known-good PCMand rechock. It symptom/indica-tion gocs away, roplacg tho origi-nrl rcM.

(From page 11-206)

JUMPEF WIRE

<\

EVAP CONTNOLCANISTER

VACUUMPUMPIGAUGE,0-30 in.Hg4973X -

0il1 -

xxxxx

VACUUM/PRESSUREGAUGE0-4 in.Hg07JA2 - ml(x)o8

wire side of female terminals

{cont'd)

-20711

www.emanualpro.com

Page 410 of 1395

Emission Control System

Evaporative Emission (EVAP) Controls (cont'd)

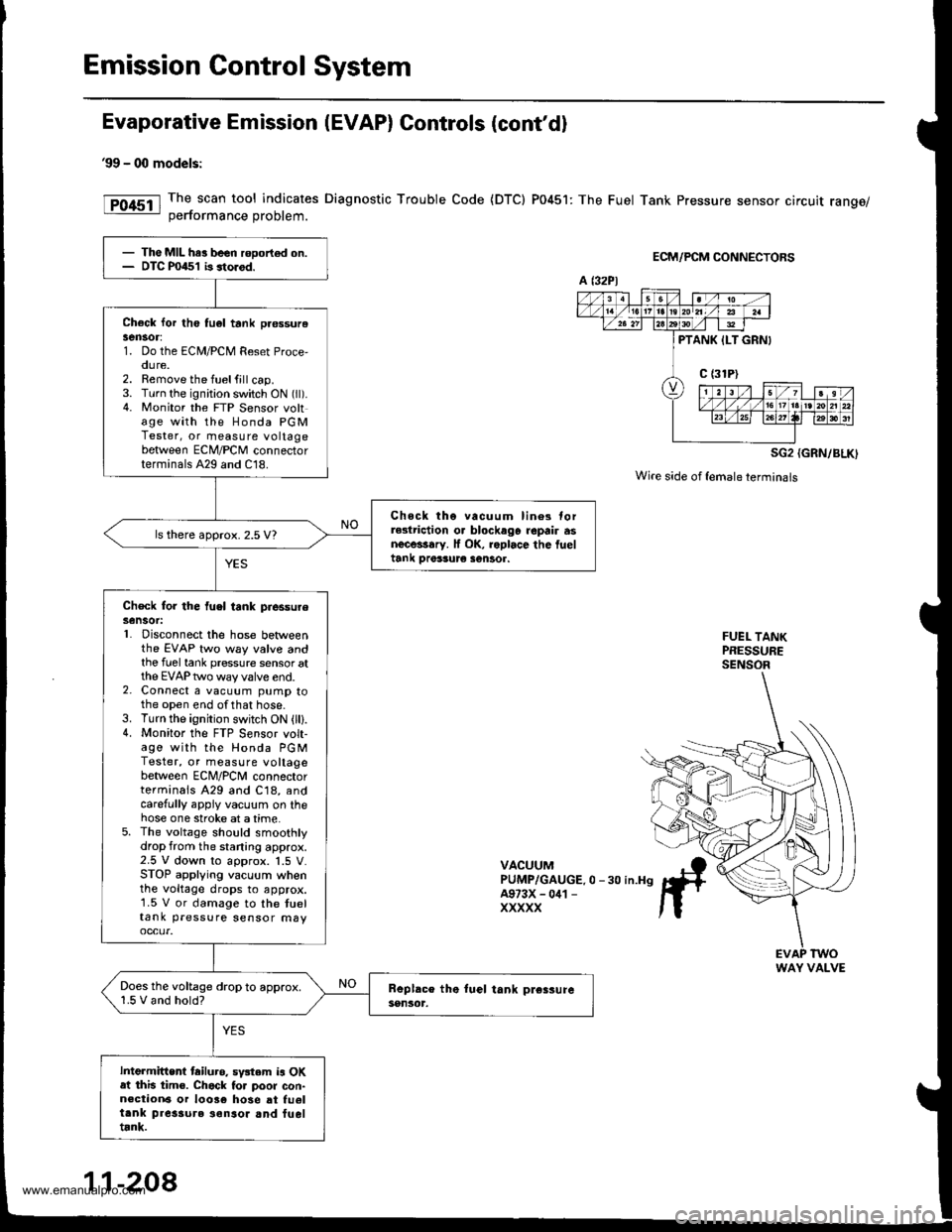

99 - 00 models:

The scan tool indicates Diagnostic Trouble Code {DTC) P0451: The Fuel Tank Pressure sensor circuit range/oerformance Droblem.

ECM/PCM CONNECTORS

SG2 {GRN/BLK)

Wire side of {emaleterminals

FUEL TANKPRESSURESENSOR

VACUUMPUMP/GAUGE.0 -30 in.H9A973X - 041 -

XXXXX

- The MIL har been rooort€d on.- DTC P0451 b storod.

Check lor th6 tu6l tank pr€ssurelen30r:1. Do the ECM/PCM Reset Proce,oure.2. Remove the fuelfill cap.3. Turn the ignition switch ON (ll).4. Monitor the FTP Sensor voltage with the Honda PGMTester, or measure voltagebetween ECM/PCM connectorterminals A29 and C18.

Chock tho vacuum lin6s torrGlriction o. blockago repair asnecessary. lf OK, roplace the fueltank Drer3ur€ sentor.

ls there approx. 2.5 V?

Check for the fuel tank piessureSensot:L Disconnect the hose betweenthe EVAP two way valve andthe fuel tank pressure sensor atthe EVAP two way valve end.2. Connect a vacuum pump tothe open end ofthat hose.3. Turn the ignition switch ON (lll.4. Monitor the FTP S€nsor volt-age with the Honda PGMTester, or measure voltagebetween ECNI/PCNI connectorterminals A29 and C18, andcarefully appiy vacuum on thehose one stroke at a time.5. The voltage should smoothlydrop from the staning approx.2.5 V down to approx. 1.5 V.STOP applying vacuum whenthe voltage drops to approx.1.5 V or damage to the tueltank pressure sensor may

Does the voltage drop to approx.1.5 V and hold?

Intermittent tailuro. sv3tem is OKat this tim€. Chack to. poor con-n€ction6 or 10036 hose at fu6ltank pres3ure ionsor and fueltrnk.

a t32Pl

PTANK ILT GRNI

WAY VALVE

11-208

www.emanualpro.com

Page 411 of 1395

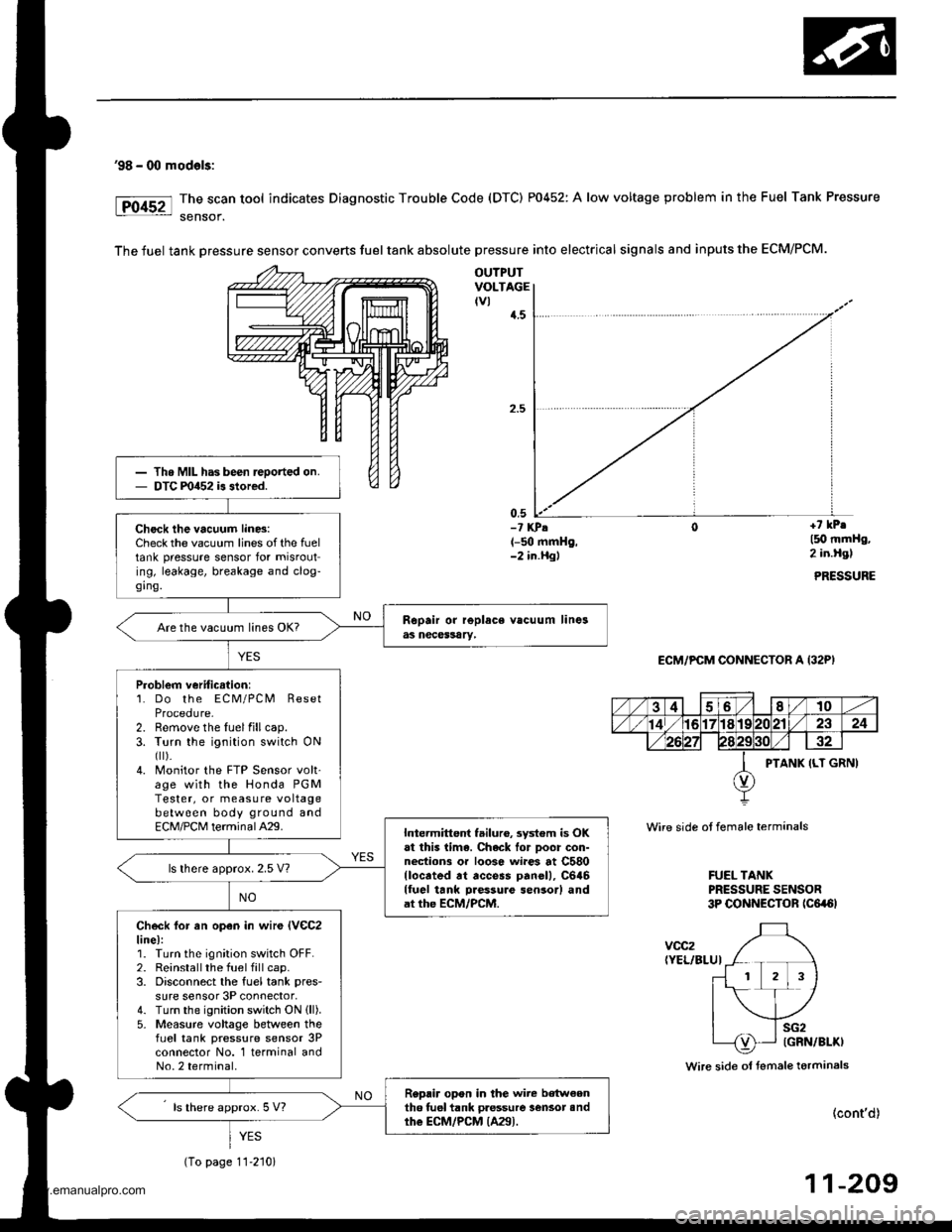

'98 - 00 mod€ls:

The scan tool indicates Diagnostic Trouble Code (DTC) P0452: A low voltage problem in the Fuel Tank Pressure

sensof.

The fuel tank Dressure sensor converts fuel tank absolute pressure into electrical signals and inputs the ECM/PCM.

OUTPUTVOLTAGEtvl{.5

0,5-? KPA(-50 mmHg,-2 in.Hgl

+7 kPr

l5O mmHg,2 in.Hgl

PRESSURE

ECM/PCM CONNECTOR A (32P)

Wire side ot female terminals

FUEL TANKPRESSURE SENSOR3P CONNECTOR tc6a6l

voc2(YEL/BLUI

Wire side ol fsmale terminals

(cont'd)

11-209

Th. MIL has been reoorted on.DTC m452 is stored.

Check the vacuum lin6:Check the vacuum lines of the fueltank pressure sensor for misrouting, leakage, breakage and clog-ging.

Are the vacuum lines OK?

Problem veriticstion:1. Do the ECM/PCM ResetProcedure-2. Remove the luelfillcap.3. Turn the ignition switch ONfl r).4. Monitor the FTP Sensor volt'age with the Honda PGMTester, or measure voltagebetween body ground andECM/PCM terminalA29.Intermittent failuro, system is OKat this lima. Chack lor Door con-nections or loose wi.es at C580llocrted rt access panell, C646lluel tank Daessure sensor) andat the ECM/PCM.

ls lhere approx. 2.5 V?

Check lor an open in wir€ lVeC2line):1. Turn the ignition switch OFF.2. Reinstallthe fuel fill cap.3. Disconnect the fuel tank pres-

sure sensor 3P connector,4. Turn the ignition switch ON (ll).

5- Measure voltage between thefLrel tank pressure sensor 3Pconnector No. 1 terminal andNo.2 terminal.

Replir opon in the wire b€tw€enth6 tuel tank pressure lensot andthe ECM/PCM {A29).ls there approx. 5 V?

YES

(To page 11-210)

www.emanualpro.com

Page 413 of 1395

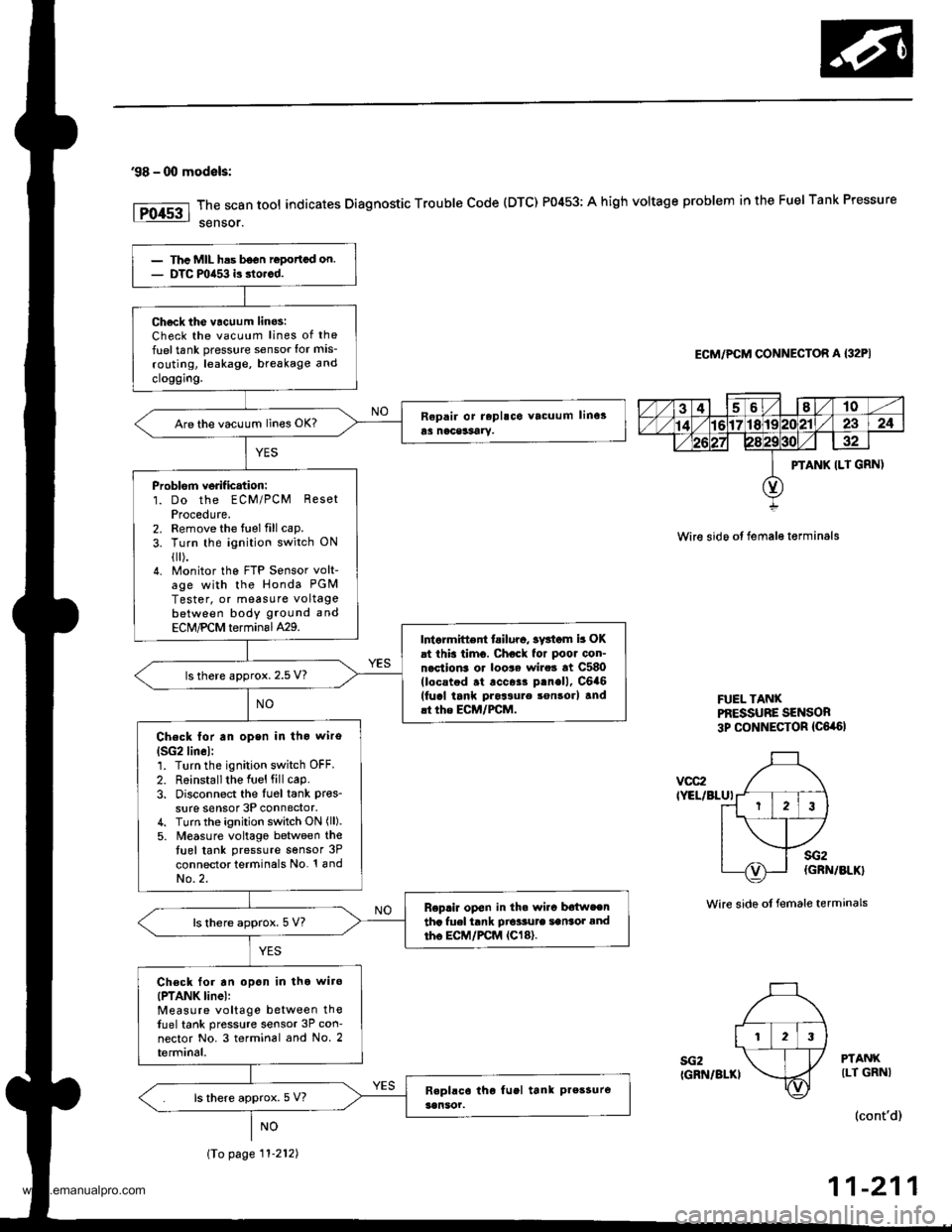

'98 - 00 modals:

The scan tool indicates Diagnostic Trouble Code (DTC) P0453: A high voltage problem in the Fuel Tank Pressure

sensor.

ECM/PCM CONNECTOR A {32PI

Wire sido ot fema16 t€rminals

FUEL TANXPf,ESSUBE SENSOR3p CONNECTOR {C6,a6l

vcc2IYEL/BLUI

sG2IGRN/BLKI

sG2(GRN/BLK}

Wire side ot female terminals

PTANKILT GRNI

(cont'd)

11-211

PTANK ILT GRN)

123

Thc MIL has b6on ropottcd on.DTC mia53 is dorcd.

Ch6ck tho vacuum linos:Check the vacuum lines of the

fuel tank pressure sensor lor mis-

routing, leakage, breakage and

cloggrng.

Are the vacuum lines OK?

Problorn verif ication:1. Do the ECM/PCM ResetProcedute.2. Remove the fuel fill cap.

3. Turn the ignition switch ON

{[).4. Monitor the FTP Sensor volt-age with the Honda PGM

Tester, or measure voltagebetween body ground and

ECM,PCM terminal429.Intarmittent tailuro, sv3iom b OKat this timo. Chock for poor con-nection3 or loo$ wire3 at C580(locstod .t .cc$r p.nell, C6a6(fucl tank pros3ure son3orl and.t the ECM/FCM.

ls there approx. 2.5 V?

Check lor an open in tho wiro

lSG2lin6l:1. Turn the ignition switch OFF.

2. R6installthe Iuel fill cap.3. Disconnect the Iu6l tank pres_

sure sensor 3P connector,4. Turn the ignition switch ON (ll).

5. M€asure voltago between thetuel tank pressure sensor 3P

connector terminals No. '! andNo.2.

Replir op€n in th. wi.c b€{weentha fuel tank Dio'sute sansot andtho EC|,/PCM {Cl8}.ls there approx. 5 V?

Ch€ck for an opon in tho wiro(PTANK linel:Measure voltage between thefuel tank pressure sensor 3P con-nector No. 3 terminal and No. 2terminal.

ls there approx. 5 V?

\To page 11-212)

www.emanualpro.com

Page 416 of 1395

Emission Control System

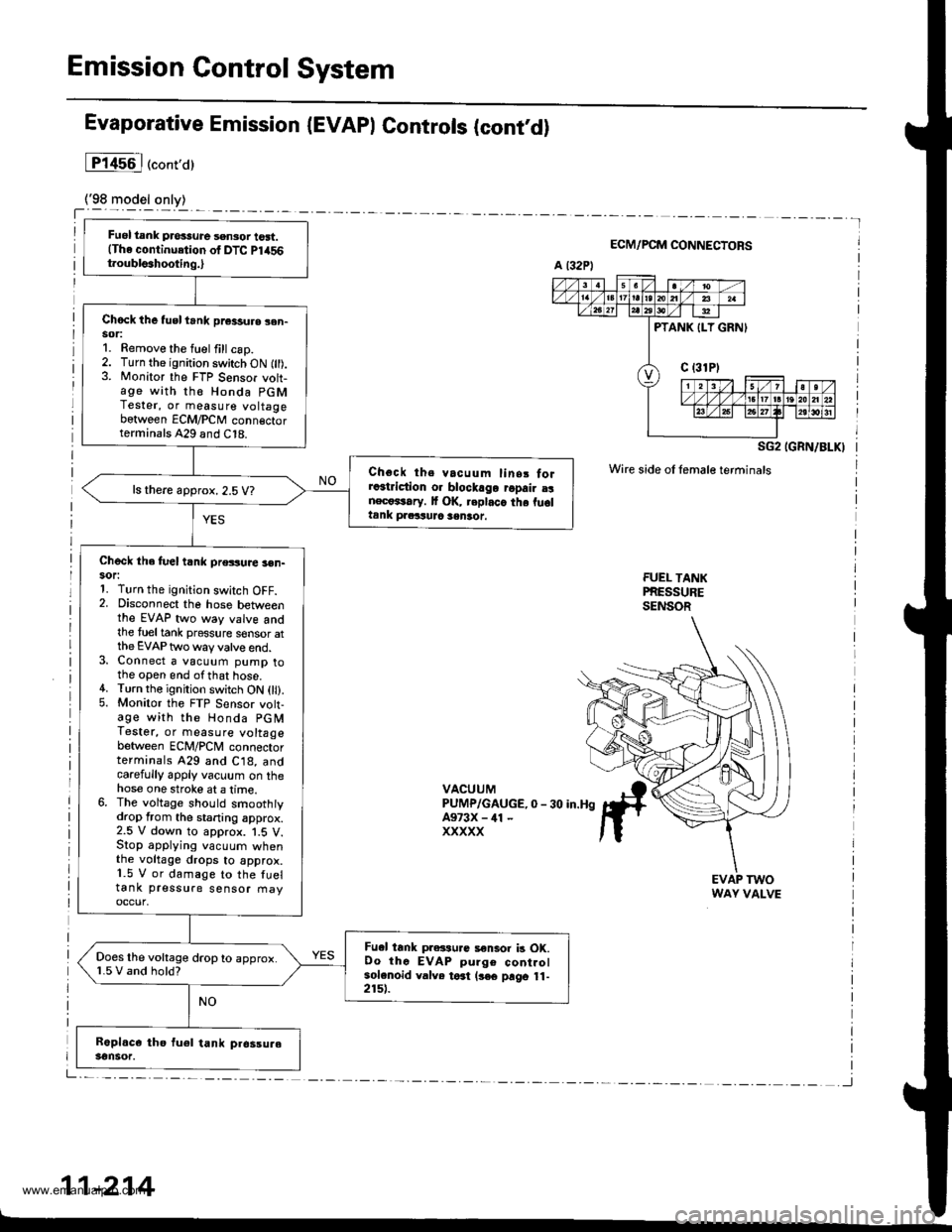

Fuel tank pros3ure sensor tost.(The continuetion of DTC Pl456t.oubls3hooting.,

Chock the tusl trnk pr€3sure sen-sor:1. Remove the fuel fill csp.2. Turn the ignition switch ON fll).3. Monitor the FTP Sensor voh-age with th€ Honda PGMTester, or measure voltagebetween ECM/PCM conn€ctorterminals A29 and C18.

Choct ths vacuum linsr forra3triction o. blockago ropair a!nect*rary. It OK, replaca the fu6ltank praituJc sentot.

ls there approx. 2.5 V?

Check the fuel t nk pressuae 3en-sor:1. Turn the ignition switch OFF.2. Disconnect the hose betweenthe EVAP two way valve andthe tueltank pressure sensor atthe EVAP two way valve end.3. Connect a vacuum pump tothe open end ofthat hose.4. Turn the ignition switch ON 0l).5. Monitor the FTP Sensor volt-age with the Honda PGMTestet, or measure voltagebetween ECM/PCM connectorterminals 429 and C18, andcarefully apply vacuum on thehose one stroke at a lime.6. The voltage should smoothtydrop from the staning approx.2.5 V down to approx. 1.5 V.Stop applying vacuum whenthe voltage drops to approx.1.5 V or damage to the fueltank pressure sensor fiayoccur,

Fu.l tank pressu.c a€nlor b OK.Oo thc EVAP pulge controlsolenoid valve toat (3€€ prgo 11-2151.

Does the voltage drop to approx.1.5 V and hold?

Evaporative Emission (EVAPI Controls (contd)

lP14s6l("ont,a)

ECM/PCM CONNECTORS

SG2 IGRN/BLKI

Wire side oI female terminals

FUEI- TANKPRESSURESENSOR

VACUUMPUMP/GAUGE,0 - 30 in.HgA973X - ill -

xxxxx

EVAP TWOWAY VALVE

11-214

www.emanualpro.com

Page 417 of 1395

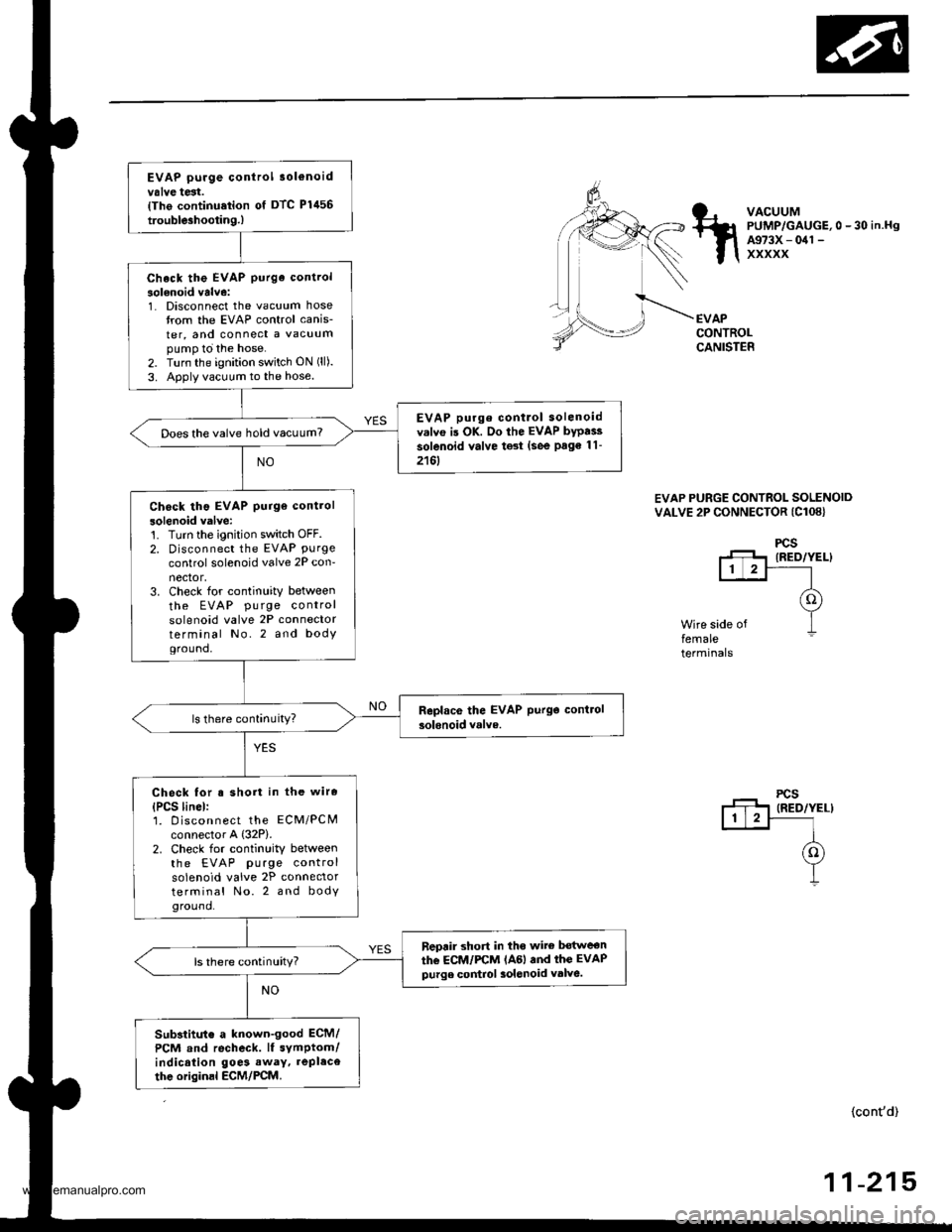

EVAP purge control 3ol€noidvalve test.{Tho continu.tion of DTC Plil56

trouble3hootin9.)

Check the EVAP purge control

solenoid valve:1. Disconnect the vacuum hosetrom the EVAP control canis-

ter, and connect a vacuumpump to the hose.2. Turn the ignition switch ON (ll).

3. Apply vacuum to the hose.

EVAP purge contlol solenoidv.lvo is OK. Do the EVAP bypai3

solenoid valve test (see Page 11-

2161

Does the valve hold vacuum?

Check tho EVAP purge control

solenoid valve:'t. Turn the ignition switch OFF.2. Disconnect the EVAP Purgecontrol solenoid valve 2P con-nector,3. Check for continuity between

the EVAP pu rge controlsolenoid valve 2P connectorterminal No.2 and bodYground,

Check for s short in the wire

{PCS linel:1. D iscon nect the ECM/PCMconnector A {32P).2. Check for continuity betweenthe EVAP purge controlsolenoid valve 2P connectorterminal No. 2 and bodyground.

neprir short in tho wite bot$reon

the ECM/FCM lAGl and thc EVAPpurge control 3olenoid valve.ls there continuity?

Substitut€ a known-good ECM/

PCM and recheck. lf symptom/indication goe3 away. repl.ce

thc originsl ECM/PCM.

VACUUMPUMP/GAUGE,0 - 30 in.HgA973X - 041 -

xxxxx

EVAPCONTROLCANISTER

EVAP PURGE CONTROL SOLENOIDVALVE 2P CONNECTOR (Cl08}

Wire side offemaleterminals

(cont'd)

-21511

www.emanualpro.com