seat HONDA CR-V 1997 RD1-RD3 / 1.G Service Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1997, Model line: CR-V, Model: HONDA CR-V 1997 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 780 of 1395

Transmission

Cooler Flushing

@@ To prevent in;ury to face and eyos, atwayswear safety glasses ot a face shield when using thetlansmission flusher.

This procedure should be performed before reinstallingthe transmission.

2.

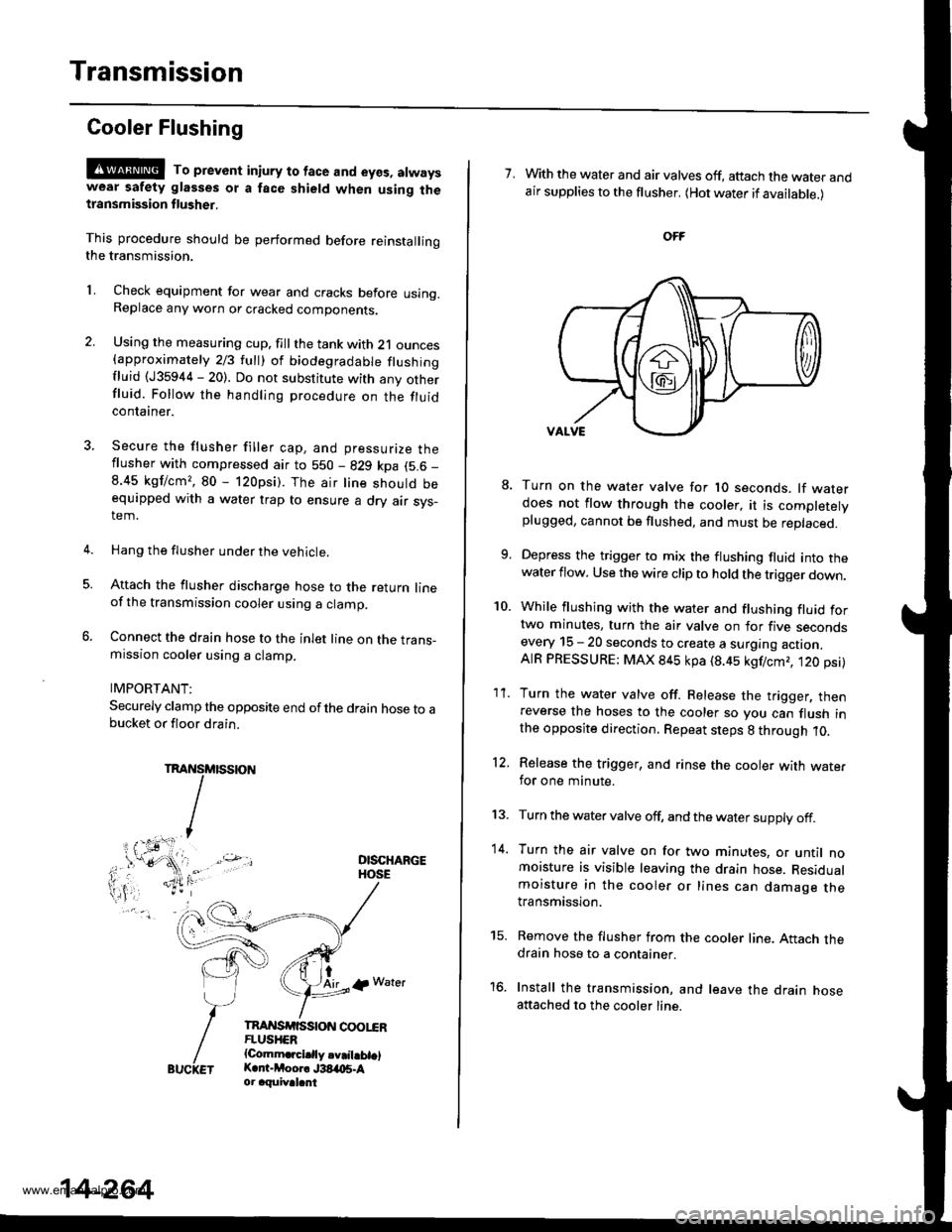

LCheck equipment for wear and cracks before using.Replace any worn or cracked components.

Using the measuring cup. fill the tank with 21 ounces{approximately 213 lull) ol biodegradable flushingfluid (J35944 - 20). Do not substitute with any otherfluid. Follow the handling procedure on the fluidcontaaner.

Secure the flusher filler cap, and pressurize theflusher with compressed air to 550 - 829 kpa (5.6 _

8.45 kgf/cm,, 80 - 120psi). The air line should beequipped with a water trap to ensure a dry air sys-tem.

Hang the flusher under the vehicle.

Attach the flusher discharge hose to the return lineof the transmission cooler using a clamp.

Connect the drain hose to the inlet line on the trans-mission cooler using a clamp.

IMPORTANT:

Securely clamp the opposite end ofthe drain hose to abucket or floor drain.

DISCHARGEHOSE

tAirlp Water

TnAI{SrfiSStoN coot"€RFLUSHER{Comm.rcidly.v.il.bt.lK.r -Moor. J38,t{15.Aor aquival.nt

5.

14-264

7. With the water and air valves off, attach the water andair supplies to the flusher. (Hot water if available.)

10.

8.

1'�I.

Turn on the water valve for 1O seconds. lf waterdoes not flow through the cooler, it is completelyplugged, cannot be flushed, and must be replaced.

Depress the trigger to mix the flushing fluid into thewater flow. Use the wire clip to hold the trigger down.

While flushing with the water and flushing fluid fortwo minutes, turn the air valve on for five secondsevery 15 - 20 seconds to create a surging action.AIR PRESSURE: MAX 845 kpa (8.45 kgf/cmr, t20 psi)

Turn the water valve off. Release the trigger, thenreverse the hoses to the cooler so you can flush inthe opposite direction. Repeat steps 8 through 10.

Release the trigger, and rinse the cooler with wate.for one minute.

Turn the water valve off, and the water supply off.

Turn the air valve on for two minutes, or until nomoisture is visible leaving the drain hose. Residualmoisture in the cooler or lines can damage thetransmission.

Remove the flusher from the cooler line. Attach thedrain hose to a container.

Install the transmission, and leave the drain hoseattached to the cooler line.

12.

13.

14.

to.

www.emanualpro.com

Page 783 of 1395

Shift Lever

Removal/lnstallation

SRS components are located in this area. Review the

SRS component locations, precautions, and procedures

in the SRS section (24) before performing repairs or ser-

vrce.

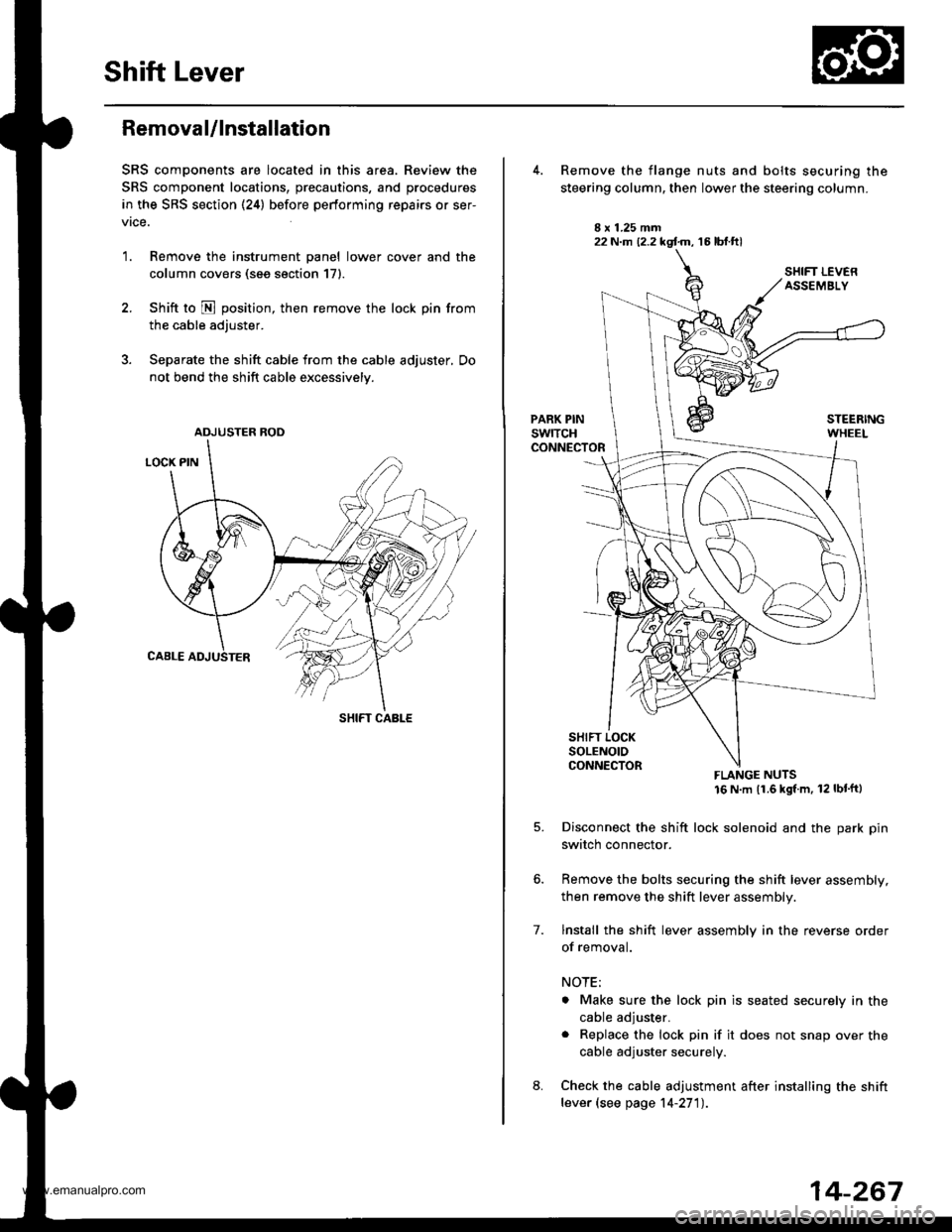

1. Remove the instrument panel lower cover and the

column covers (see section 171.

2. Shift to N position, then remove the lock pin from

the cable adjuster.

3. Separate the shift cable from the cable adjuster, Do

not bend the shift cable excessively.

ADJUSTER ROD

SHIFT CABLE

22 N.m (2.2 kgf.m, 16 lbt.ftl

7.

Remove the flange nuts and bolts securing the

steering column, then lower the steering column.

FLANGE NUTS16 N m (1.6 kgl m, 12 lbt'ftl

Disconnect the shift lock solenoid and the park pin

switch connector.

Remove the bolts securing the shift lever assembly,

then remove the shift lever assembly.

lnstall the shift lever assembly in the reverse order

of removal.

NOTE;

. Make sure the lock pin is seated securely in the

cable adjuster.

. Replace the lock pin if it does not snap over the

cable adjuster securely.

Check the cable adjustment after installing the shift

lever (see page 14-27'l).

14-267

www.emanualpro.com

Page 788 of 1395

Shift Gable

Adjustment

SRS components are located in this area. Review the SRS

component locations, precautions, and procedures in the

SRS section (241 before performing repairs or service.

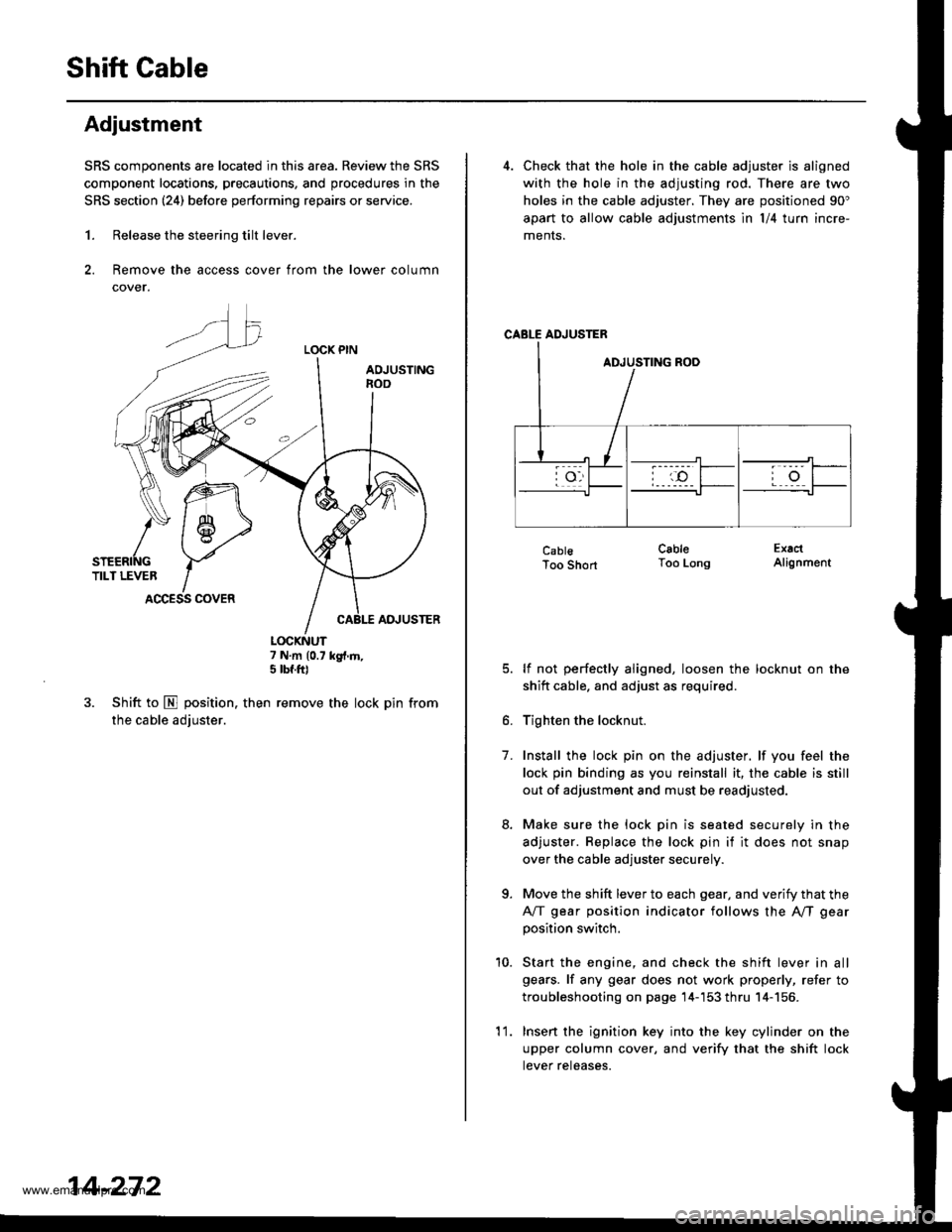

1. Release the steering tilt lever.

2. Remove the access cover from the lower column

cover.

LOCK PIN

AOJUSTINGnoo

ADJUSTER

7 N.m (0.7 kg{.m,5 tbf.ft)

3. Shift to E position. then remove the lock pin from

the cable adjuster.

K\ffi

/* 1 6-,>

snenrftc YTILT LEVER IACCESS COVER

14-272

'l 1.

4. Check that the hole in the cable adjuster is aligned

with the hole in the adjusting rod. There are two

holes in the cable adjuster. They are positioned 90"

apart to allow cable adjustments ln l/4 turn incre-

ments.

CABLE ADJUSTER

CablsToo Short

lf not perfectly aligned, loosen the locknut on the

shitt cable. and adjust as required.

Tighten the locknut.

Install the lock pin on the adjuster. lf you feel the

lock pin binding as you reinstall it, the cable is still

out of adjustment and must be readjusted.

Make sure the lock pin is seated securely in the

adjuster. Replace the lock pin if it does not snap

over the cable adjuster securely.

Move the shift lever to each gear, and verify that the

A/T gear position indicator follows the A"/T gear

position switch.

Start the engine, and check the shift lever in all

gears. lf any gear does not work properly, refer to

troubleshooting on page 14-'153 thru 14-156.

Insert the ignition key into the key cylinder on the

upper column cover, and verify that the shift lock

tever reteases.

CableToo LongExactAlignment

7.

a

10.

www.emanualpro.com

Page 790 of 1395

Shift Gable

Replacement (cont'd)

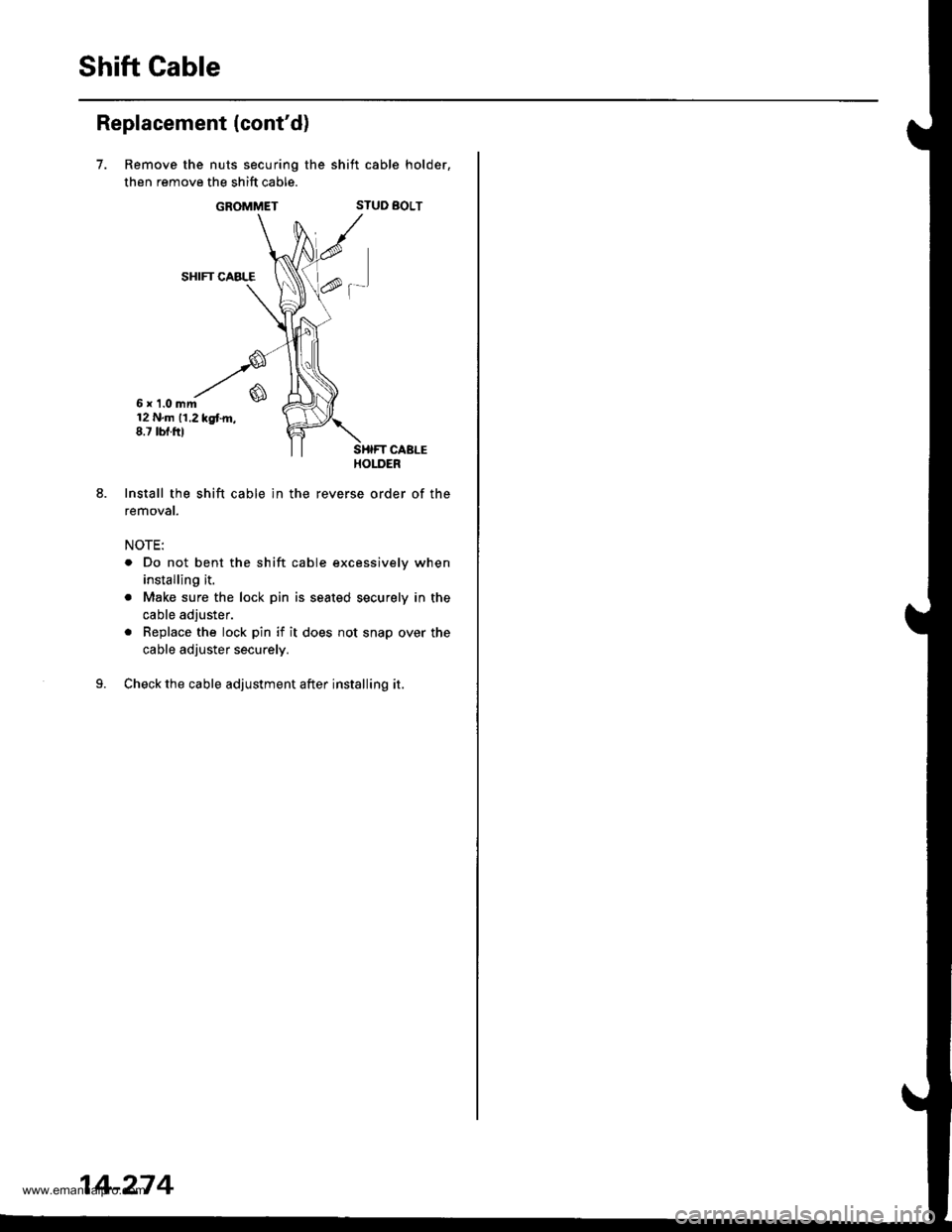

7.

6x 1.0mm12 N.m 11.2 kgtm,8.7 tbf.ftl

Install the shift cable ln the

removat.

NOTE:

Remove the nuts securing the shift cable holder,

then remove the shift cable.

GROMMETSTUD BOLT

SHIFT CABLE

f-'

. Do not bent the shift cable excessively when

installing it.

. Make sure the lock pin is seated securely in the

cable adjuster.

. Replace the lock pin if it does not snap over the

cable adjuster securely.

Check the cable adjustment after installing it.

14-274

www.emanualpro.com

Page 824 of 1395

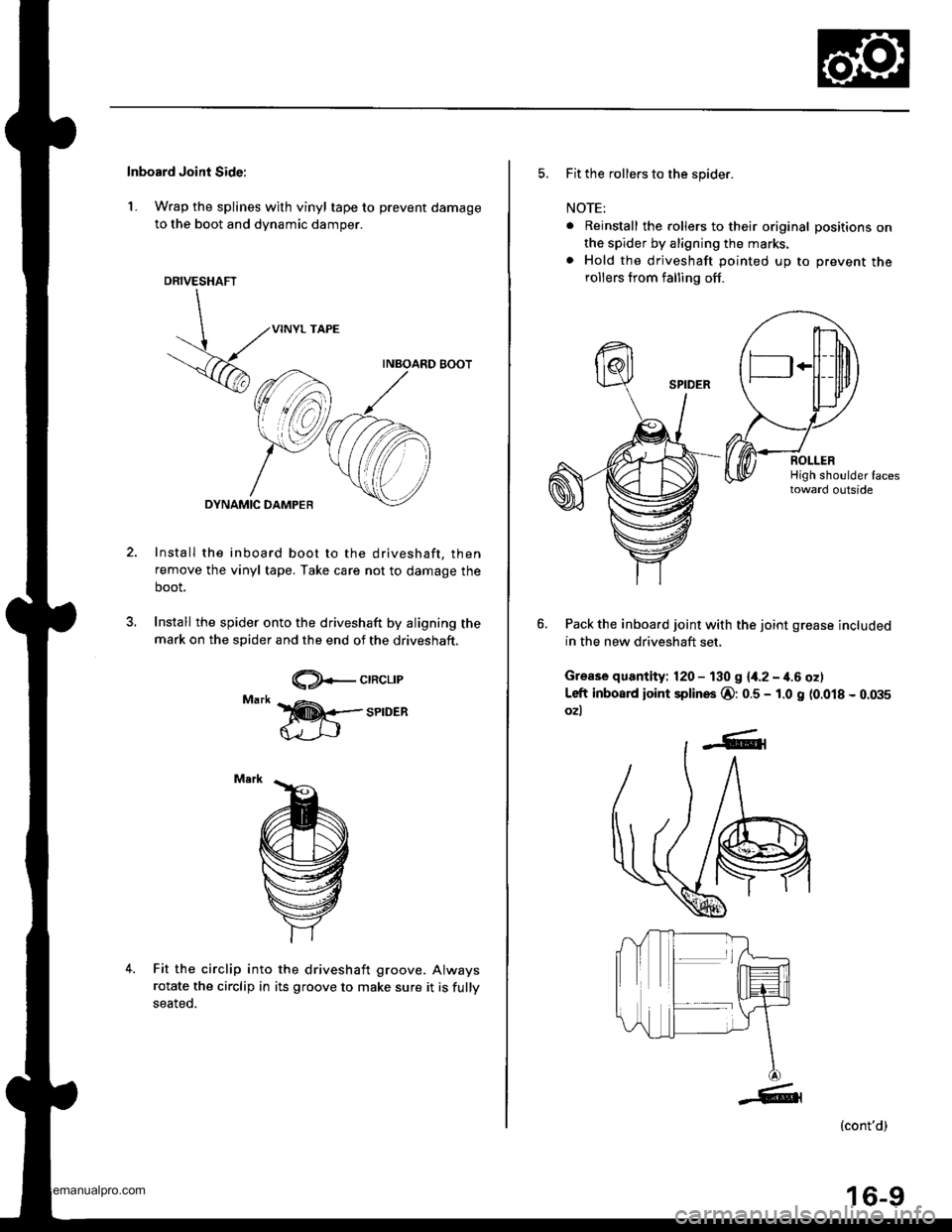

Inboard Joint Side:

1. Wrap the splines with vinyl tape to prevent damage

to the boot and dynamic damper.

DRIVESHAFT

,..',NYL rAPE

V6

uu.oa.Dsoo.�

,",^_Y,C@

Install the inboard boot to the driveshaft, then

remove the vinyl tape. Take care not to damage the

boot.

Install the spider onto the driveshaft by aligning the

mark on the spider and the end of the driveshaft.

@+-crncr-rr

4.Fit the circlip into

rotate the circlip in

seated.

the driveshaft groove. Always

its groove to make sure it is fully

5. Fit the rollers to the spider.

NOTE:

. Reinstall the rollers to their original positions onthe spider by aligning the marks.

. Hold the driveshaft pointed up to prevent therollers from falling off.

Pack the inboard joint with the joint grease included

in the new driveshaft set,

Grease quantity: 120 - 130 g {4.2 - 4.6 oz)

Left inboad ioint splines @:0.5 - 1.0 g (0.018 - 0.m5

ozl

(cont'd)

F

16-9

www.emanualpro.com

Page 825 of 1395

Front Driveshafts

Reassembly {cont'd)

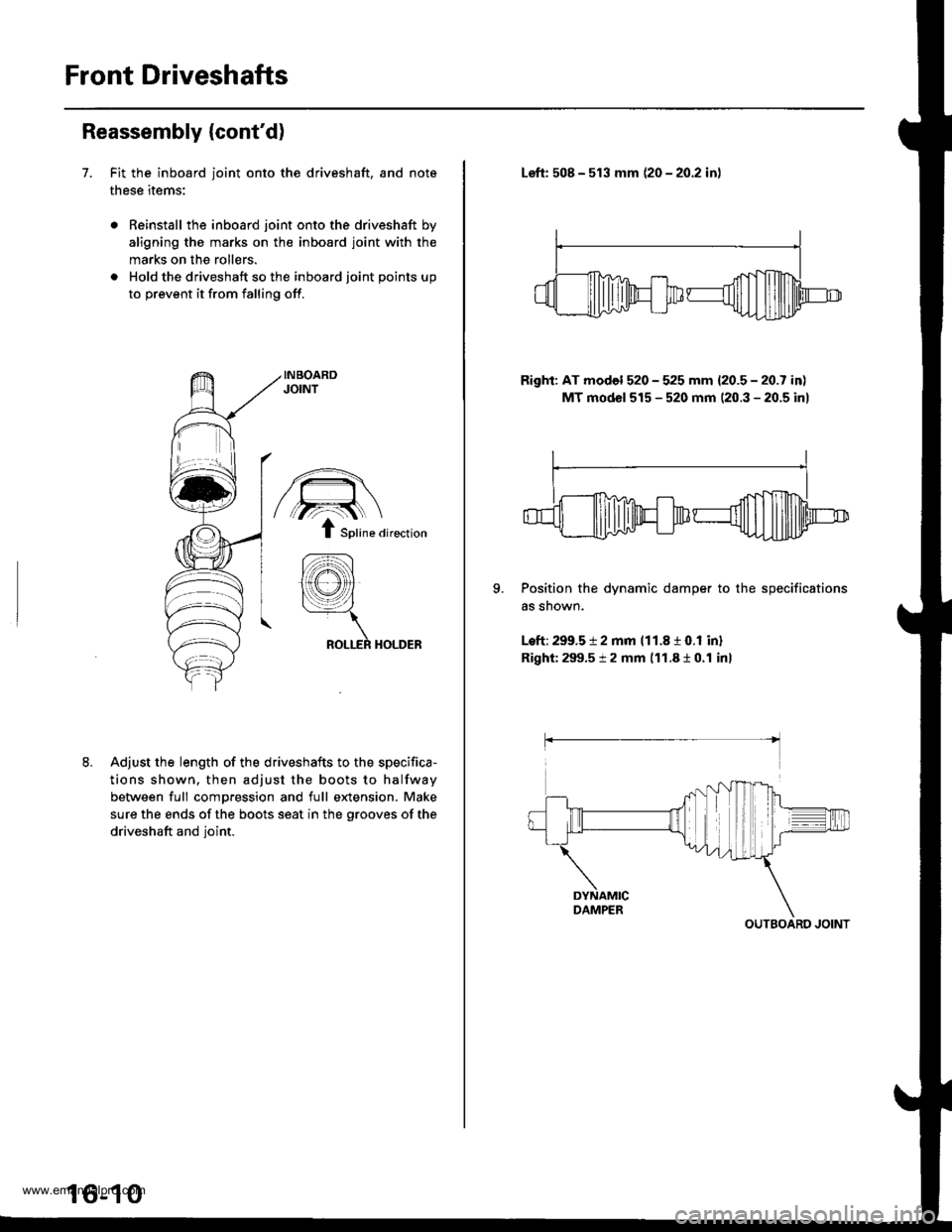

7. Fit the inboard joint onto the driveshaft, and note

these items:

Reinstall the inboard joint onto the driveshaft by

aligning ths marks on the inboard joint with the

marks on the rollers.

Hold the driveshaft so the inboard joint points up

to prevent it from falling off.

Adjust the length of the driveshafts to the specifica-

tions shown. then adjust the boots to halfway

between full compression and full e)dension. Make

sure the ends of the boots seat in the grooves of the

driveshaft and Ioint.

/€\

/,?:..�{ \

t Sptine airection

lffi

tYl:\

ROLLER HOLDER

16-10

Left: 508 - 513 mm 120 - 2O.2 inl

Right: AT model 520 - 525 mm {20.5 - 20.7 in)

MT mod6l 515 - 520 mm (20.3 - 20.5 inl

II

-flm+dm@

9. Position the dynamic damper to the specifications

as snown.

Left: 299.5 t 2 mm 111.8 r O.l inl

Right: 299.5 t 2 mm 111.810.1 inl

OUTBOARO JOINT

www.emanualpro.com

Page 828 of 1395

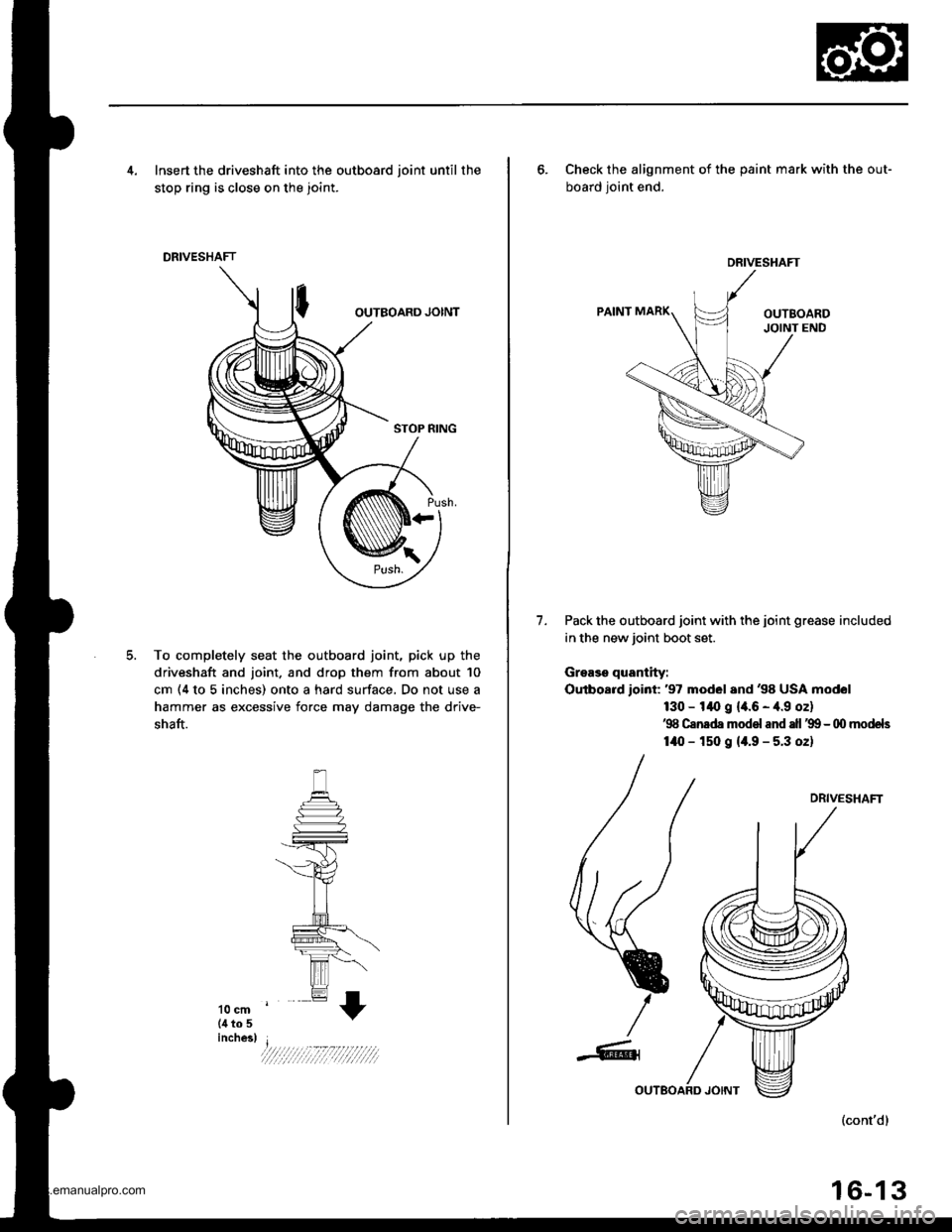

4. lnsert the driveshaft into the outboard ioint until the

stop ring is close on the joint.

DRIVESHAFT

To completely seat the outboard joint, pick up the

driveshaft and joint. and drop them from about 10

cm (4 to 5 inches) onto a hard surface, Do not use a

hammer as excessive force may damage the drive-

shaft.

i/,,,t| :l,r;;:,:.'i,,1;'/l

6. Check the alignment of the paint mark with the out-

board joint end.

DRIVESHAFT

1.Pack the outboard joint with the joint grease included

in the new joint boot set.

Grease quantity:

Outboard ioini: '97 model and '98 USA model

130 - 140 g {,1.6 - ,0.9 oz}'98 C8n8d8 modsl 8nd all '99 - 00 models

ll0 - tso g {i1.9 - 5.3 ozl

DRIVESHAFT

(cont'd)

16-13

www.emanualpro.com

Page 833 of 1395

Front DriveshaftsIntermediate Shaft

Installation {cont'd}

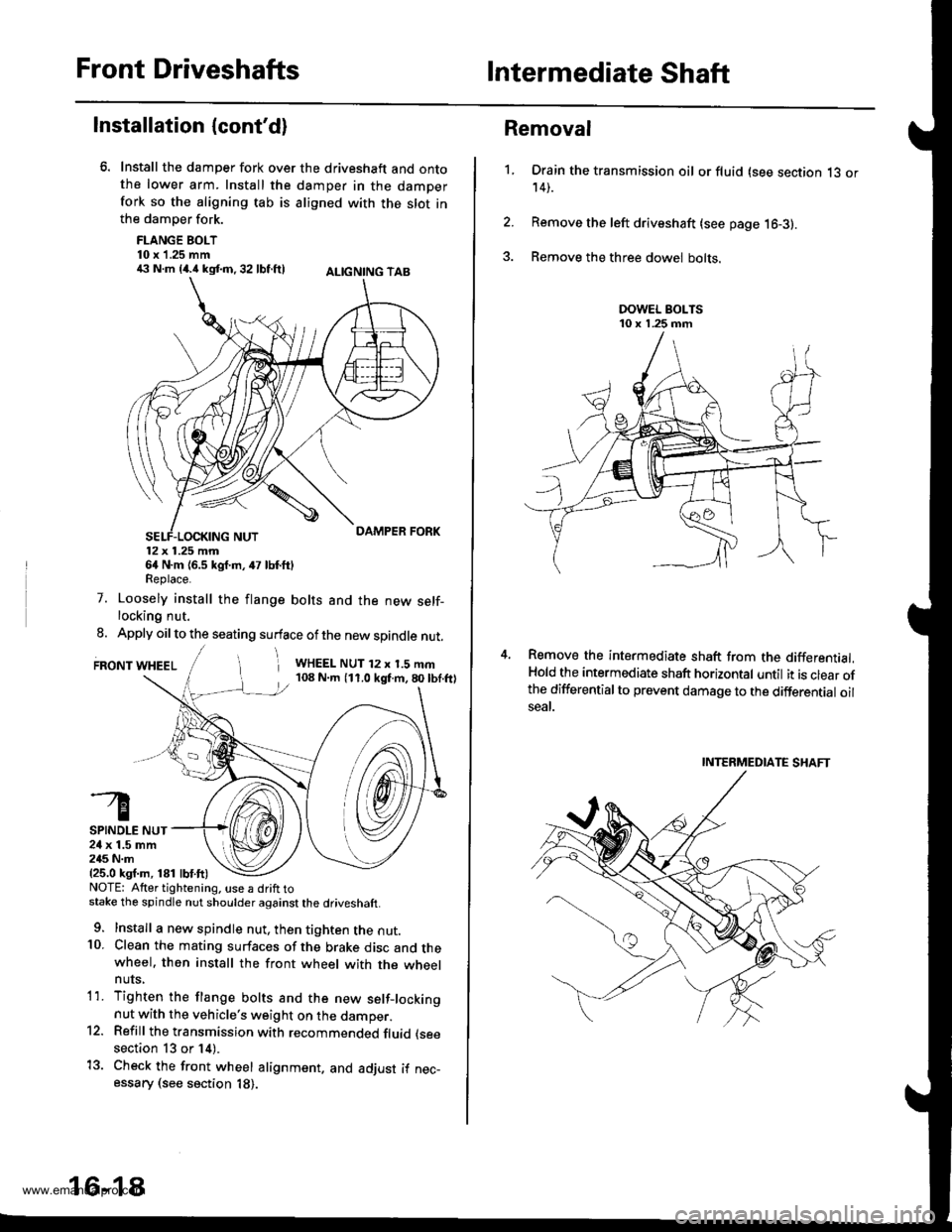

Install the damper fork over the driveshaft and ontothe lower arm. Install the damper in the damperfork so the aligning tab is aligned with the slot inthe damper fork.

FLANGE BOLT10 x 1.25 mm€ N.m {4.i1kst.n,32 lbf.ftl ALtcNtNG TAB

12x 1.25 mm64 N.m {6.5 kgf.m, 47 lbf.ftlReplace.

7. Loosely install the flange bolts and the new self-locking nut.

8. Apply oil to the seating surface of the new spindle nut.

FRONT WHEELi WHEEL NUT 12 x 1.5 mm108 N.m (11.0 kgf.m,80lbf.ftl

SPINDLE NUT24 x 1.5 mm245 N.m{25.0 ksf.m, 181 lbf.ft)NOTE: Atter tightening. use a drift tostake the spindle nut shoulder against the driveshaft.

9. Install a new spindle nut, then tighten the nut.10. Clean the mating surfaces of the brake disc and thewheel. then install the front wheel with the wheelnuts,

1'1. Tighten the flange bolts and the new setf-lockingnut with the vehicle's weight on the damper.12. Refill the transmission with recommended fluid (see

section 13 or 14).

13. Check the front wheel alignment. and adjust if nec-essary (see section 18).

16-18

1.

Removal

Drain the transmission oil or fluid (see section 13 or14).

Remove the left driveshaft (see page 16-3).

Remove the three dowel bolts.

Remove the intermediate shaft from the differential.Hold the intermediate shaft horizontal until it is clear ofthe differentialto prevent damage to the differential oilseal.

INTERMEDIATE SHAFT

www.emanualpro.com

Page 835 of 1395

Intermediate Shaft

Reassembly

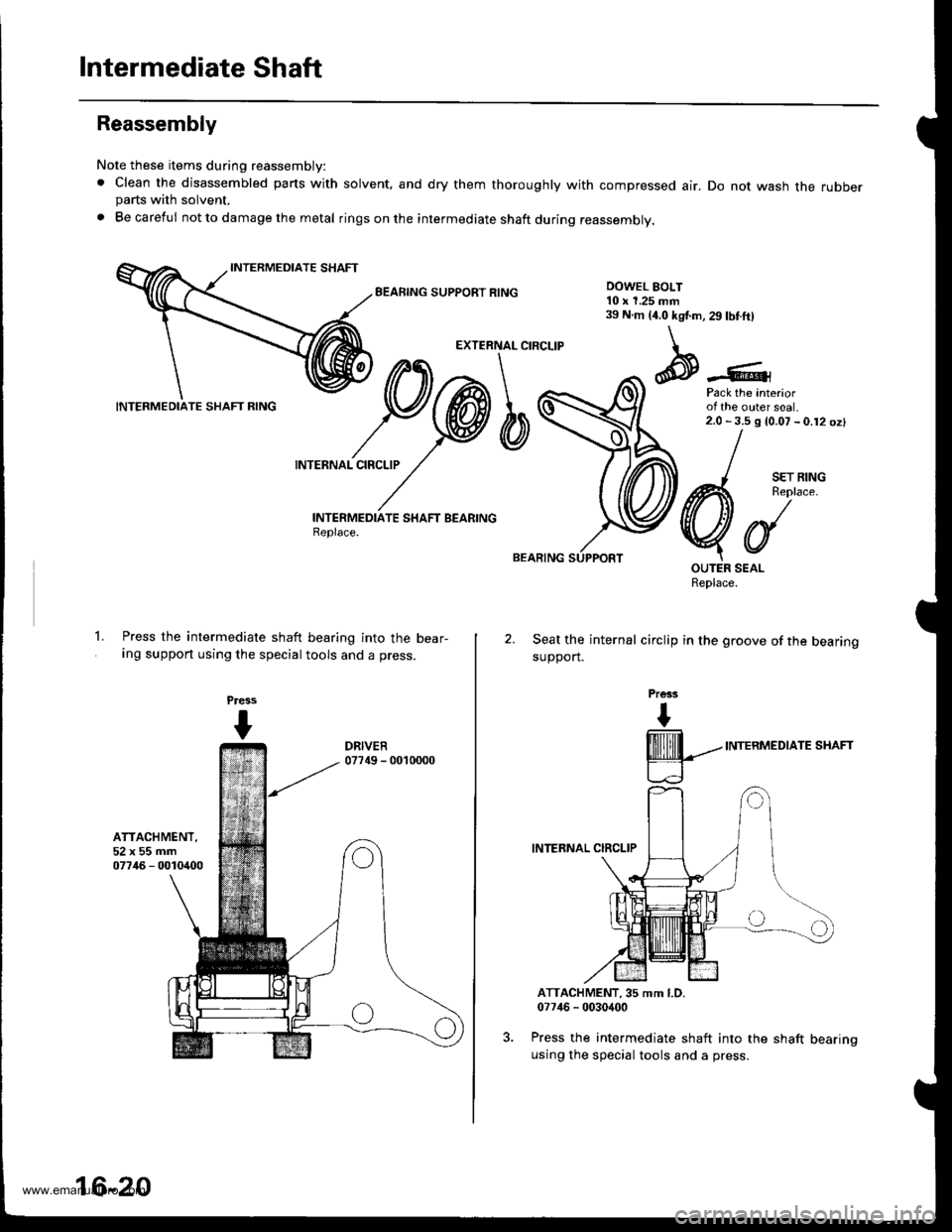

Note these items during reassembly:

. Clean the disassembled parts withparts with solvent.

. Be careful not to damage the metal

solvent, and dry them thoroughly with compressed

rings on the intermediate shaft during reassembly.

air. Do not wash the rubber

BEARING SUPPORT RING

INTERNAL CIRCLIP

Press the intermediate shaft bearing into the bear-ing support using the special tools and a press.

EXTERNAL CIRCLIP

DOWEL EOLT10 x 1.25 mm39 N.m 14.0 kg't m, 29lbf.ft)

Press

I

W--

L!

Pack the interiorof the outer seal.2.0 -3.5 g {0.07 -0.r2 oz}

'L

BEARING SUPPORTOUTER SEA-Replace.

Seat the internal circlip in the groove of the bearingsupport.

INTERMEDIATE SHAFT

ATTACHMENT.35 mm l.D.07746 - 0030400

Press the intermediate shaft into the shaft

using the special tools and a press.

ATTACHMENT,52x55mm07746 - 0010400

INTERMEDIATE SHAFT RING

Prcss

t

16-20

bearing

www.emanualpro.com

Page 836 of 1395

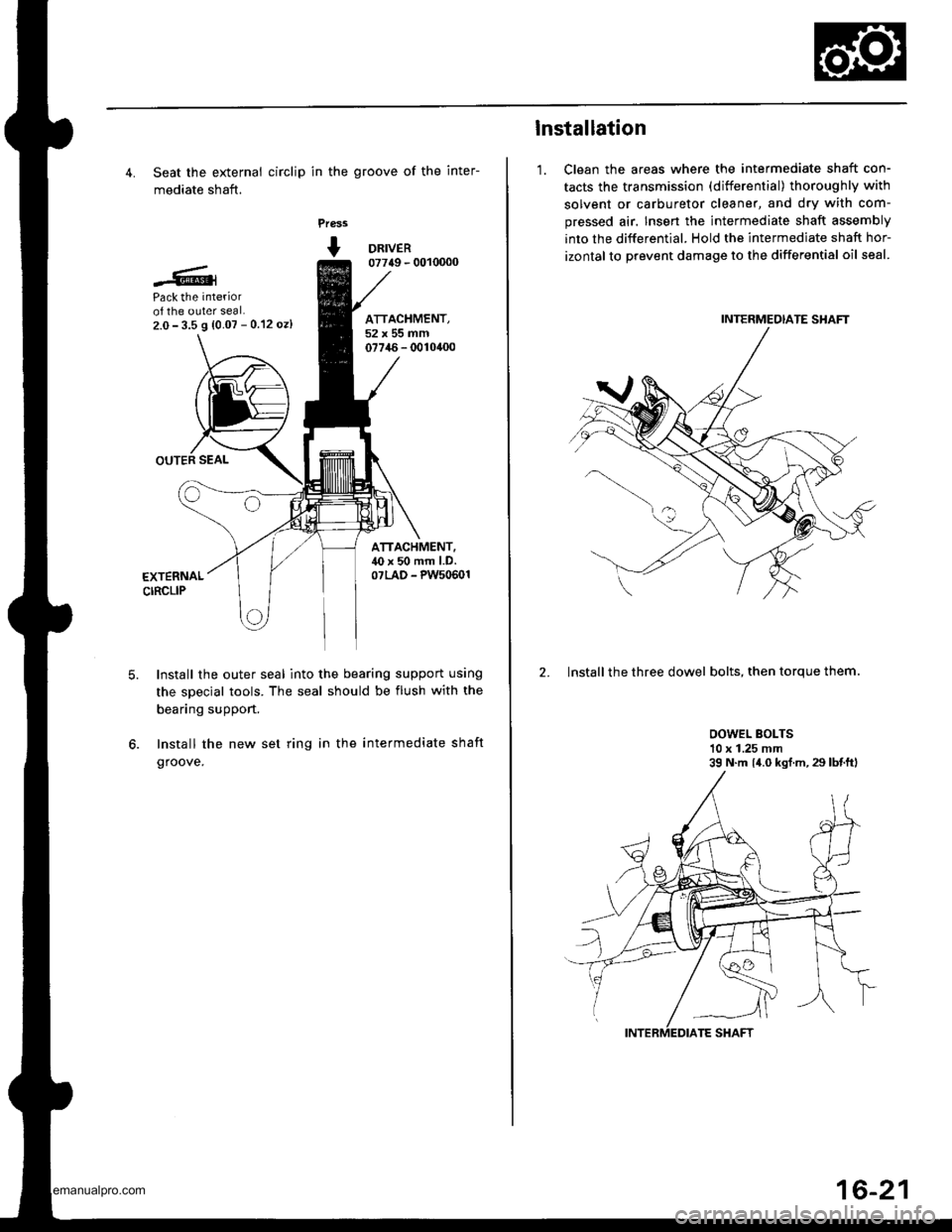

4. Seat the external circlip in the groove of the inter-

mediate shaft.

Press

+ DRNER07749 - 0010000

Pack the interiorof the outer seal.2.0- 3.5 9 {0.07 - 0.12 oz)

OUTER SEAL

ATTACHMENT,52x55mm07746- 0010400

ATTACHMENT.40 x 50 mm l.D.07LAD - PW50601EXTERNALCIRCLIP

6.

Install the outer seal into the bearing support using

the special tools. The seal should be flush with the

bearing support.

Install the new set ring in the intermediate shaft

groove.

lnstallation

1. Clean the areas where the intermediate shaft con-

tacts the transmission (differential) thoroughly with

solvent or carburetor cleaner, and dry with com-

pressed air. Insen the intermediate shaft assembly

into the differential. Hold the intermediate shaft hor-

izontal to prevent damage to the differential oil seal.

2. Install the three dowel bolts, then torque them.

OOWEL BOLTS10 x 1.25 mm39 N.m {4.0 kgf.m, 29 lbtftl

INTERMEOIATE SHAFT

16-21

www.emanualpro.com