Srs troubleshooting HONDA CR-V 1997 RD1-RD3 / 1.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1997, Model line: CR-V, Model: HONDA CR-V 1997 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 628 of 1395

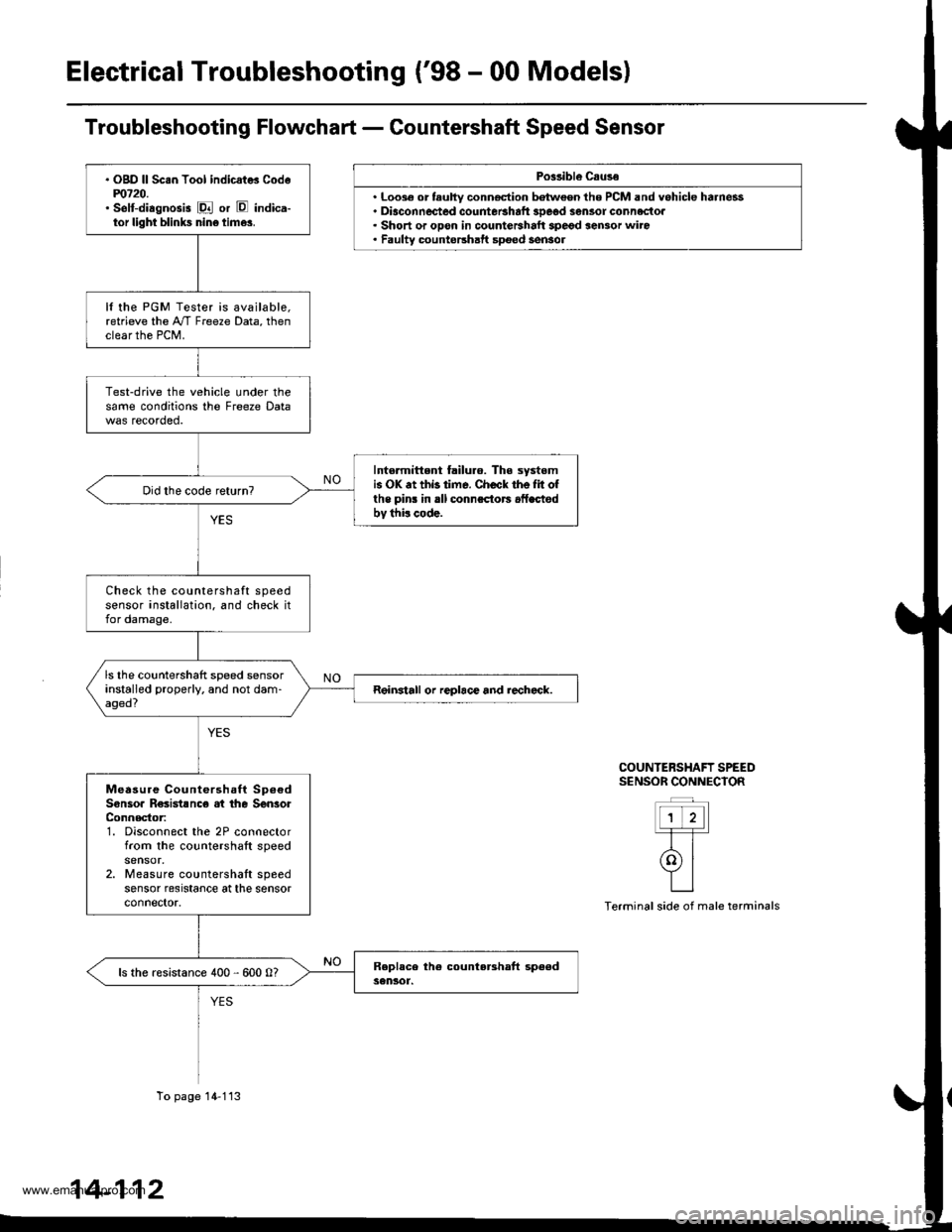

Electrical Troubleshooting ('98 - 00 Models)

Po$ibl€ Csuse

. Loo3€ or tauhy conn€ction batween the PCM and vehicle harness. Diaconnected countetshaft 3Deod sensor connectoa. Short or opon in countershalt spegd sensor wiro. Faulty countershatt spoed sensol

COUNTERSHAFT SPEEDS€NSOR CONNECIOR

ttt'l-T-T-

rolYILI

Terminal side of male terminals

. OgD ll Sc.n Tool indicat* Codem720.' selt-diagnosis E or E indica-tor light blinks nin6 time3.

It the PGM Tester is available,retrieve the A"/T Freeze Data, thenclear the PCM.

Test-drive the vehicle under thesame conditions the Freeze Data

Intormittent failuro. The systomis OK .t thb time. Check the Iit ofthe pins in rll connsctors .fLctodbv thi! code.

Check the countershaft speedsensor installation. and check itfor damage.

ls the countershaft speed sensorinstalled properly. and not dam-aged?Reinstall or replace and rechcck.

Measure Countershaft Sp6€dSonsoa R€sistsnc€ at the SenlorConnector:1. Disconnect the 2P connectorfrom the countershaft speed

2. Measure countershaft speedsensor resrstance at the sensorconnector.

ls the resistance 400 - 600 0?

To page 14-113

14-112

www.emanualpro.com

Page 630 of 1395

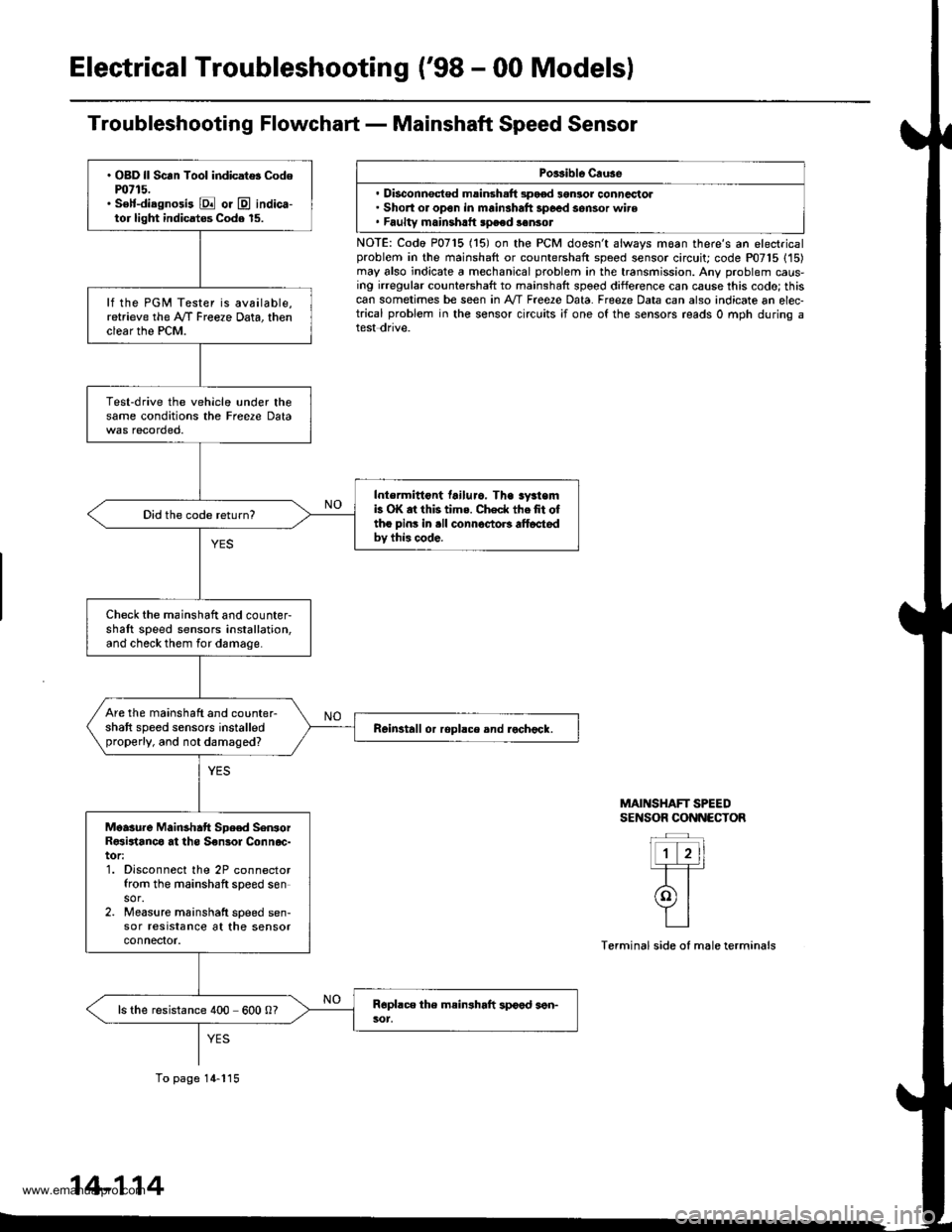

Electrical Troubleshooting ('98 - 00 Modelsl

Troubleshooting Flowchart - Mainshaft Speed Sensor

Porsible Cruse

. Disconnsct€d msinsh.ft 3pood 3gnlor conncctol. Short or open in mainshaft 3poed sensor wire. Faultv mainshrtt speed sonsot

NOTE: Codo P0715 (15) on the PCM doesn't always moan there's an electricalproblem in the mainshaft or countershaft speed sensor circuit; code P07'15 (15)may also indicate a mechanical problem in the transmission. Any problem caus-ing irregular countershaft to mainshaft spoed difference can cause this codo; thiscan sometimes be seen in A'/T Free2e Data. Freeze Data can also indicate an elec-trical problem in the sensor circuits ;f one of the sensors reads 0 mph during atest dnve.

MAINSHAFT SPEEDSENSOR CONNECTOR

Terminal side of male terminals

. OBD ll Scan Tool indicat$ Codem715.. S€lf-diagnosi3 E or @ indica-tor light indicatos Code 15.

lf the PGM Tester is available,retrieve the A/f Freeze Data, thenclear the PCM.

Test-drive the vehicle under thesame conditions the Freere Data

Intermittont tailuro. Tha sy3temb OK at this tims. Check thefit oftho pins in .ll connoctoB alt6ctedbv this code.

Did the code return?

Check the mainshaft and counter-shaft speed sensors installation,and check them for damage.

Are the mainshaft and counter-shaft speed sensors installedproperly, and not damaged?Reinstall or ropllce and rochock.

Moasure Mainshatt Spe€d SenrorR€sirtanco at ths S€nsol Connoc-tor:1. Disconnect the 2P connectorfrom the mainshaft speed sensor.2. Measure mainshatt speed sen-sor resrstance at the sensorconnefior.

ls the resistance 400 600 0?

To page 14-115

14-114

www.emanualpro.com

Page 788 of 1395

Shift Gable

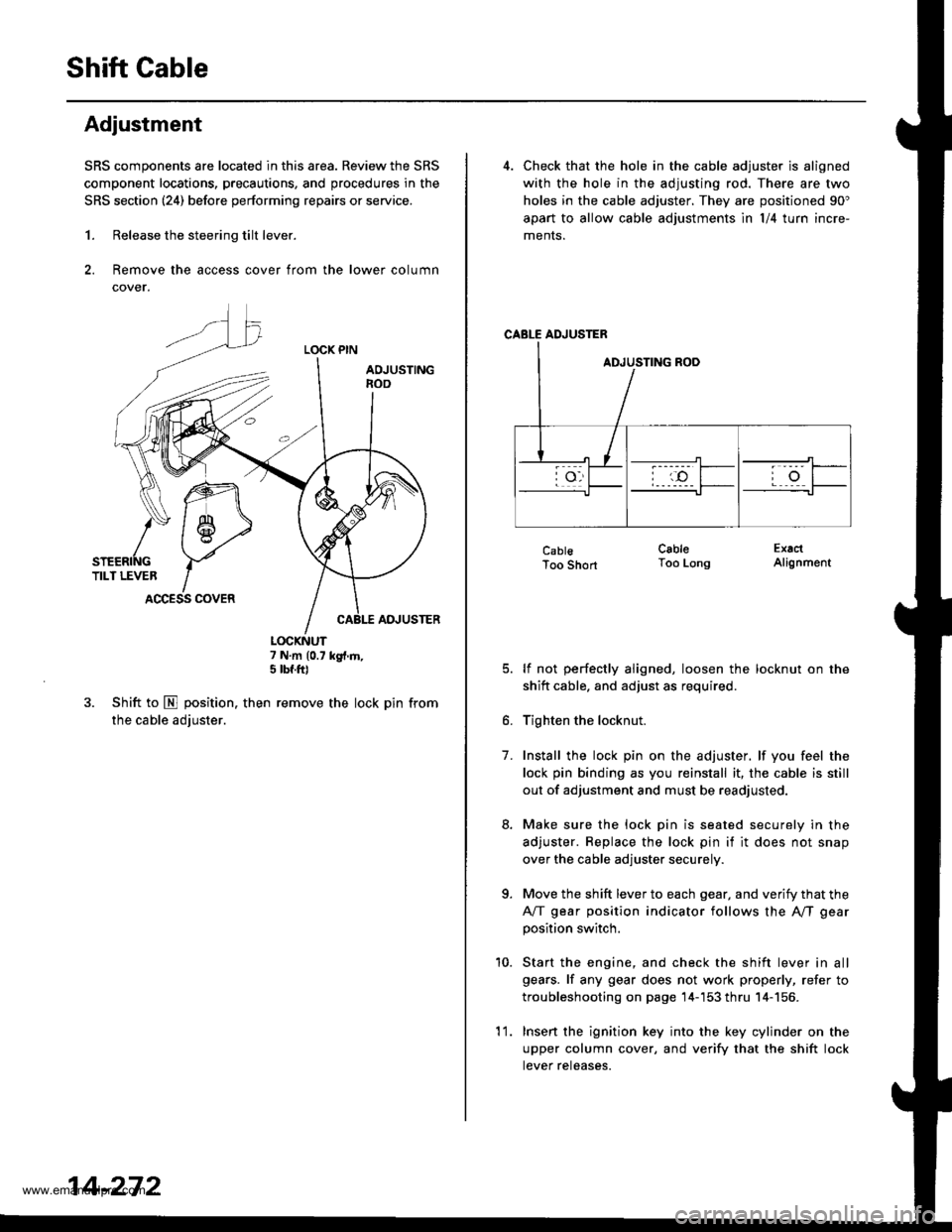

Adjustment

SRS components are located in this area. Review the SRS

component locations, precautions, and procedures in the

SRS section (241 before performing repairs or service.

1. Release the steering tilt lever.

2. Remove the access cover from the lower column

cover.

LOCK PIN

AOJUSTINGnoo

ADJUSTER

7 N.m (0.7 kg{.m,5 tbf.ft)

3. Shift to E position. then remove the lock pin from

the cable adjuster.

K\ffi

/* 1 6-,>

snenrftc YTILT LEVER IACCESS COVER

14-272

'l 1.

4. Check that the hole in the cable adjuster is aligned

with the hole in the adjusting rod. There are two

holes in the cable adjuster. They are positioned 90"

apart to allow cable adjustments ln l/4 turn incre-

ments.

CABLE ADJUSTER

CablsToo Short

lf not perfectly aligned, loosen the locknut on the

shitt cable. and adjust as required.

Tighten the locknut.

Install the lock pin on the adjuster. lf you feel the

lock pin binding as you reinstall it, the cable is still

out of adjustment and must be readjusted.

Make sure the lock pin is seated securely in the

adjuster. Replace the lock pin if it does not snap

over the cable adjuster securely.

Move the shift lever to each gear, and verify that the

A/T gear position indicator follows the A"/T gear

position switch.

Start the engine, and check the shift lever in all

gears. lf any gear does not work properly, refer to

troubleshooting on page 14-'153 thru 14-156.

Insert the ignition key into the key cylinder on the

upper column cover, and verify that the shift lock

tever reteases.

CableToo LongExactAlignment

7.

a

10.

www.emanualpro.com

Page 800 of 1395

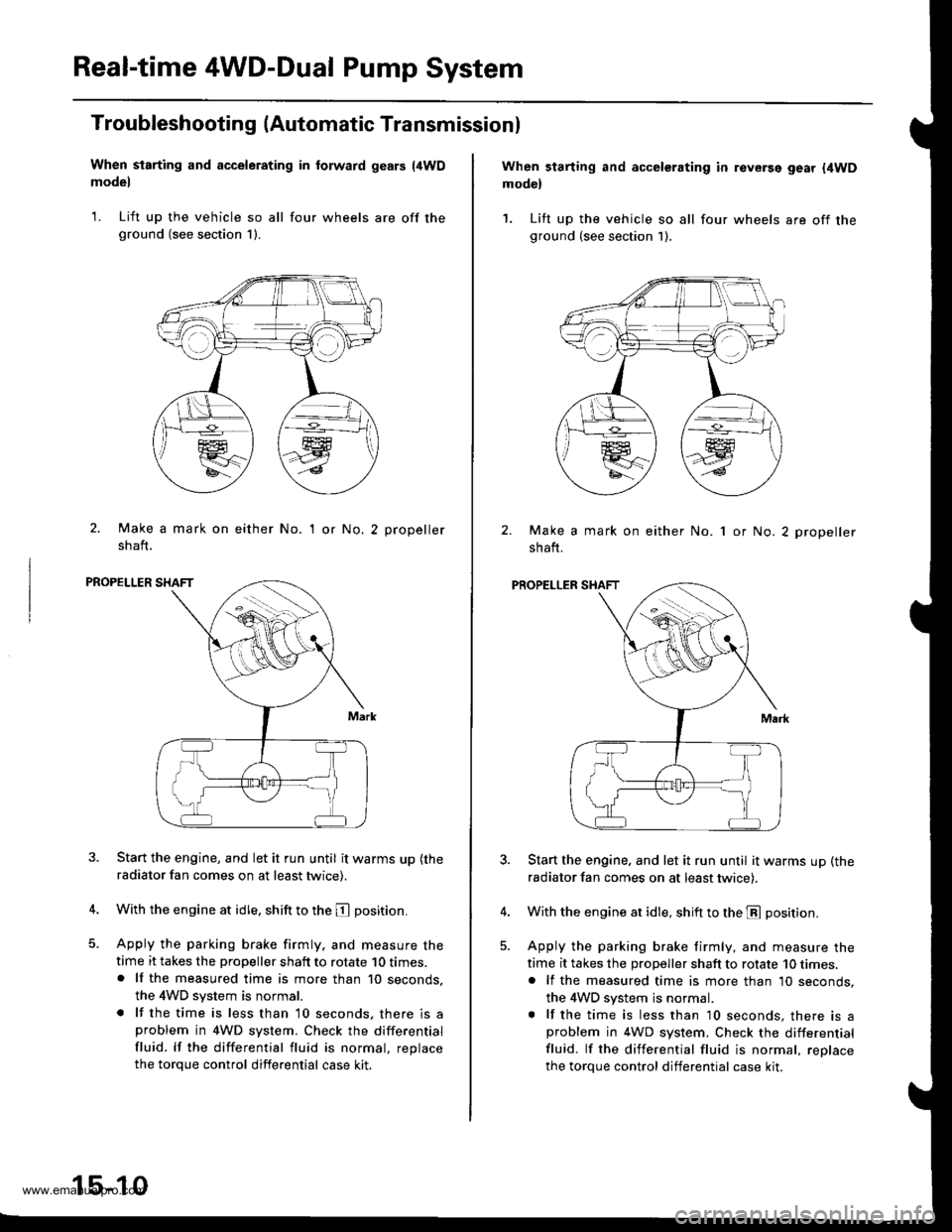

Real-time 4WD-Dual Pump System

Troubleshooting (Automatic Transmissionl

When starting and accelerating in forward gesrs {4WDmodel

1. Lift up the vehicle so all four wheels are off theground (see section 1).

2. Make a mark on either No.

shaft.

'I or No.2 propeller

PROPELLER SHAFT

Start the engine, and let it run until it warms up (the

radiator fan comes on at least twice).

With the engine at idle. shift to the E position.

Apply the parking brake firmly. and measure thetime it takes the propeller shaft to rotate 10 times.. lf the measured time is more than 10 seconds,

the 4WD system is normal.

. lf the time is less than 10 seconds, there is aproblem in 4WD system. Check the differential

fluid. lf the differential fluid is normal, replace

the torque control differential case kit.

15-10

When starting and accelerating in revGrsg gear {4WDmodel

1. Lift up the vehicle so all four wheels are off theground (see section 1).

Make a mark on either No.

shaft.

1 or No. 2 propeller

PROPELLER SHAFT

Start the engine. and let it run until it warms up (the

radiator fan comes on at least twicei.

With the engine at idle, shift to the E position.

Apply the parking brake firmly, and measure the

time it takes the proDeller shaft to rotate 10 times,. lf the measured time is more than 10 seconds,

the 4WD system js normal.. lf the time is less than 10 seconds, there is aproblem in 4WD system. Check the differential

fluid. lf the differential fluid is normal, reolace

the torque control differential case kit.

www.emanualpro.com

Page 846 of 1395

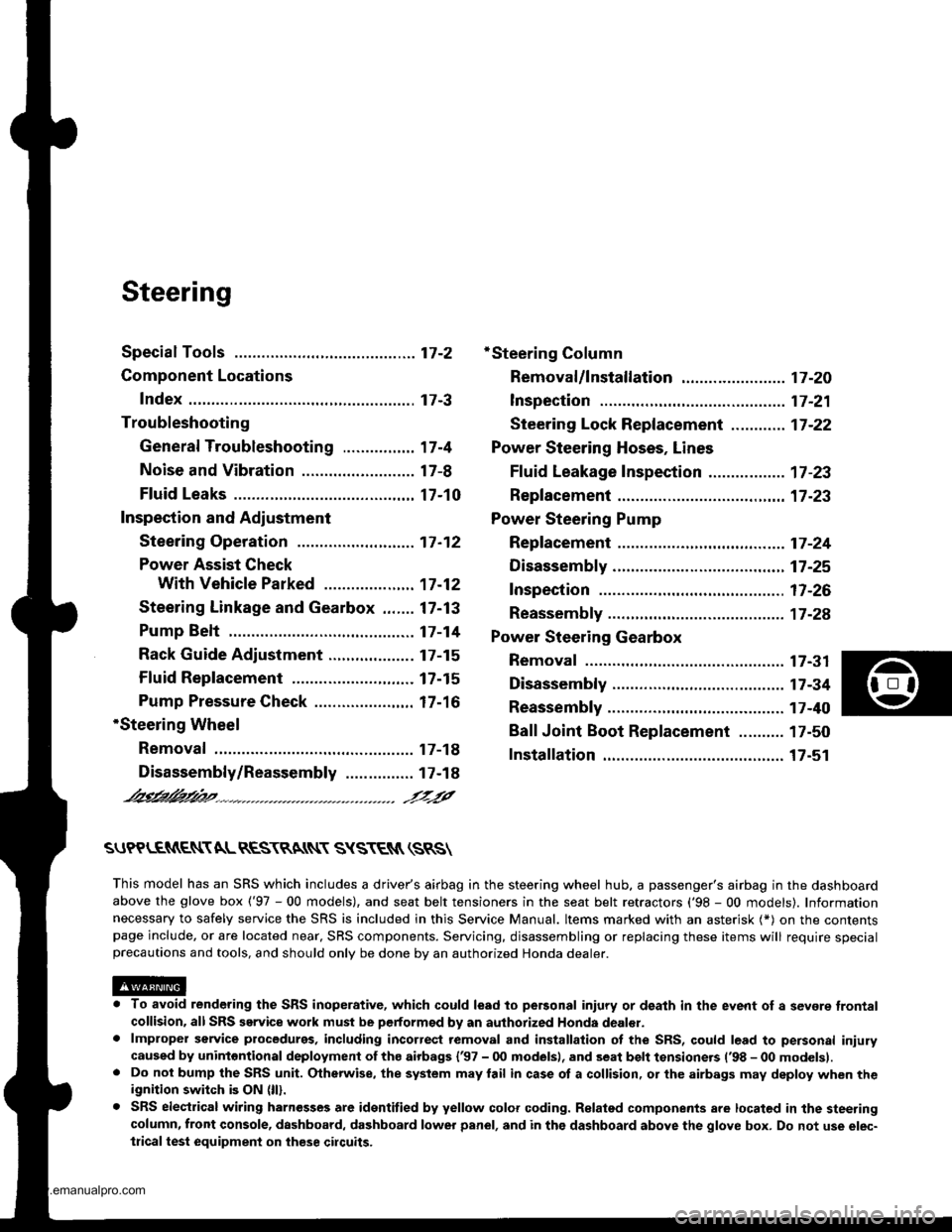

Steering

Special Toofs ............. 17-2

Component Locations

Index ................ ....... 17-3

Troubleshooting

General Troubleshooting ................ 1 7-4

Noise and Vibration ......................... 17-8

Fluid Leaks ............. 17-10

Inspection and Adiustment

Steering Operation .......................... 17-12

Power Assist Check

With Vehicle Parked ....................

Steering Linkage and Gearbox .......

Pump Belt

Rack Guide Adjustment ...................

Fluid Rep|acement ...................,,.,....

Pump Pressure Check .................,,...

*Steering Wheel

Removal ................. 17-18

*Steering Column

Removal/lnstallation ................ ....... 17 -2O

lnspection .............. 17-21

Steering Lock Replacement ............ 17 -22

Power Steering Hoses, Lines

Ffuid Leakage Inspection ................. 17 -23

Repfacement .......... 17-23

Power Steering Pump

Repfacement .......... 17-24

Disassembly ...........17-25

fnspection .............. 17-26

Reassembly ............ 17-28

Power Steering Gearbox

Removal ................. 17-31

Disassembly ........... 17-34

Reassembly ............ 17-40

Ball Joint Boot Replacement .......... 17-50

Installation ............. 17-51

17-12

17-13

17-14

l7-15

17-15

17-16

Disassembly/Reassembly............... 17-18

4'%/b.......... -r'-7--a/

SUPPLEN\EN AL RES\RA(N SYSTES{ (SRS\

This model has an SRS which includes a driver's airbag in the steering wheel hub. a passenger's airbag in the dashboardabove the glove box ('97 - 00 models), and seat belt tensioners in the seat belt retractors ('98 - 00 models). Informationnecessary to safely service the SRS is included in this Service Manual. ltems marked with an asterisk (*) on the contentspage include, or are located near, SBS components. Servicing. disassembling or replacing these items will require specialprecautions and tools, and should only be done by an authorized Honda oearer.

To avoid rendering the SRS inoperative, which could lead to peFonal iniury or death in the event of a sevore trontalcollision. allSRS service work must be performod by an authorized Honda dealer.lmproper service procedurgs, including incorrect removal and installalion of the SRS, could lead to personal iniurycaused by unintontional deployment of th€ airbags {'97 - 00 models), and seat belt tensioners ('98 - 00 modelsl.Do not bump the SRS unit. Otherwise, the system may lail in case ot a collision, or the airbags may deploy when theignition switch is ON (lll.

SRS electrical wiring harnesses are identitied by yellow colof coding. Ralated components are located in the steeringcolumn, front console, dashboard, dashboard lower panel, and in the dashboard above the glove box. Do not use elec-trical test equipment on these cilcuits,

www.emanualpro.com

Page 1215 of 1395

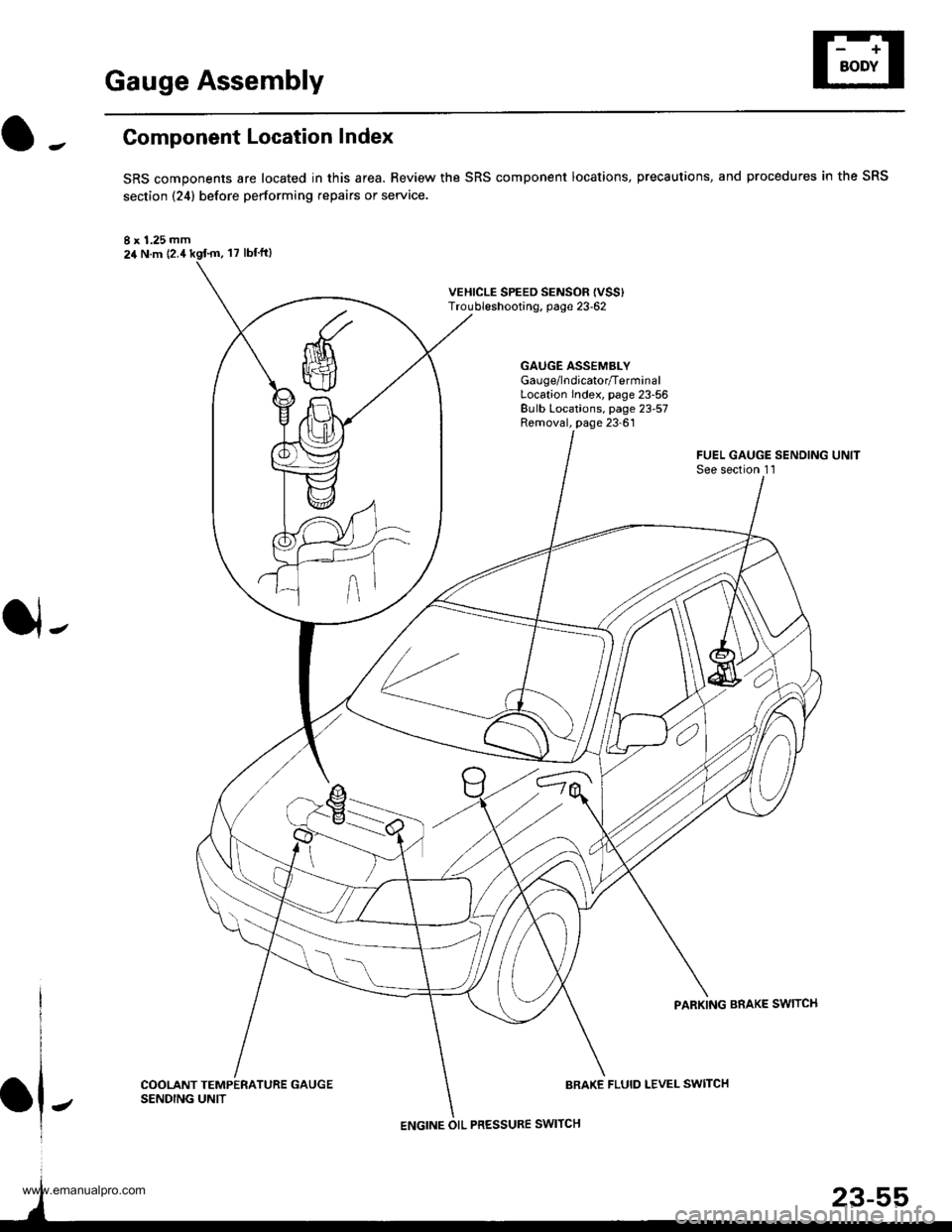

Gauge Assembly

Component Location Index

SRS components are located in this area. Review the SRS component locations, precautions, and procedures in the SRS

section {24} before performing repairs or service.

I x 1.25 mm24 N.m {2.4

VEHICLE SPEED SENSOF {VSS'Troubleshooting, page 23-62

GAUGE ASSEMBLYGau ge/lndicator/TerminalLocation Index, page 23-56Bulb Locations, page 23-57Removal, page 23-61

J-

FUEL GAUGE SENDING UNITSee section 1 l

PARKING BRAKE SWITCH

COOLANT TEMPERATURE GAUGESENDING UNITBRAKE FLUID LEVEL SWITCH

ENGINE OIL PRESSURE SWITCH

www.emanualpro.com

Page 1310 of 1395

)

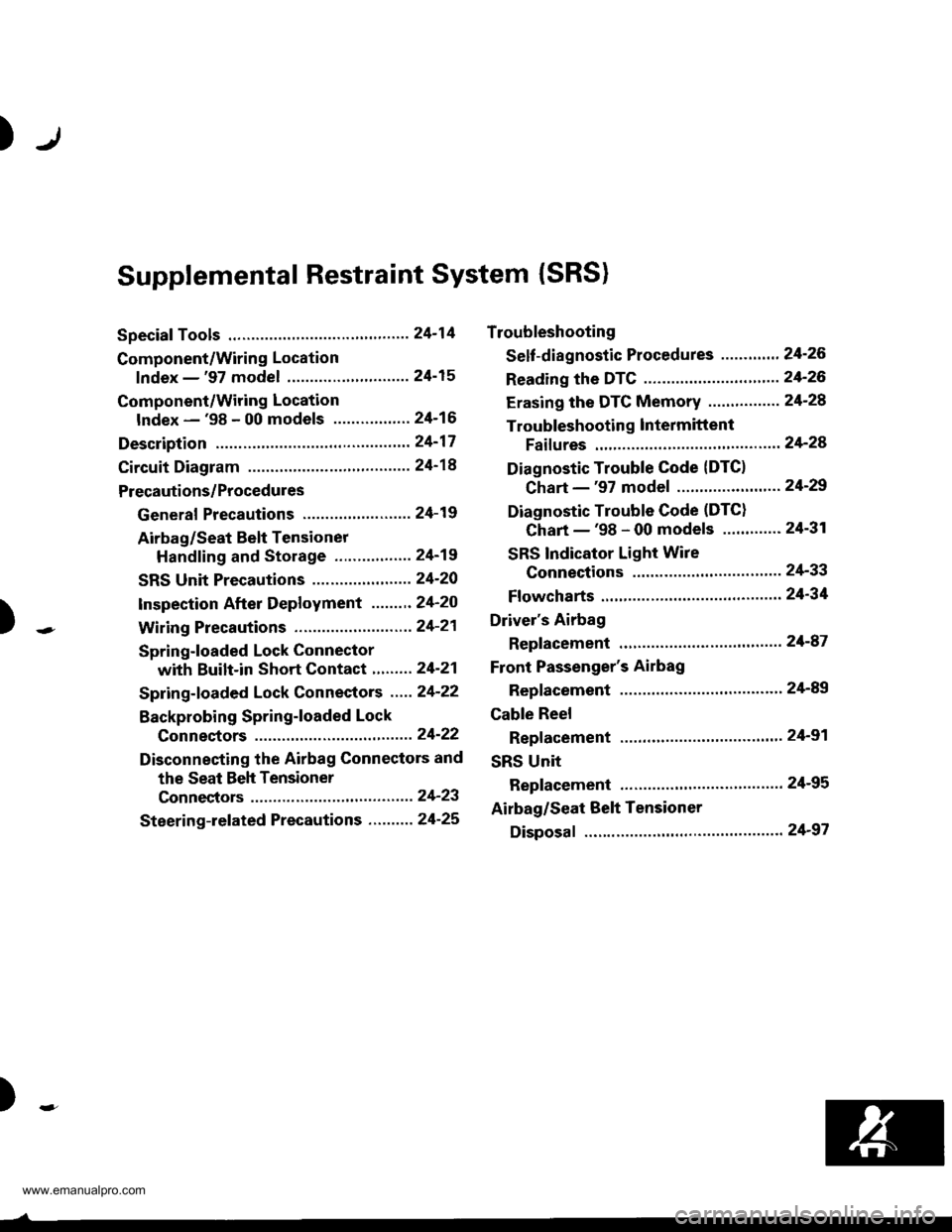

Supplemental Restraint System (SRS)

Special Tools .."....."" 24-14

Component/Wring Location

lndex - '97 model ..........'.." '.....""" 24-15

Component/Wiring Location

lndex - '98 - 00 models ..............." 24-16

Description .'.........."'.24'17

Circuit Diagram .........24'14

Precautions/Procedures

General Precautions ......".."'........... 24-19

Airbag/Seat Belt Tensioner

Handling and Stolage ....''........... 24-19

SRS Unit Precautions ...............'...... 24-20

lnspeciion After Deployment .......'.24'20

)

with Built-in Short Contact '...'....24-21

Spring-loaded Lock Connectors .."' 24-22

BackProbing SPring-loaded Lock

Conneetors ,.......24-22

Disconnecting the Airbag Connectors and

the Seat Beh Tensioner

Connectors ....'....24-23

Steering-lelated Precautions .......... 24-25

Troubleshooting

Self -diagnostic Procedures ............. 24-26

Reading the DTC .................. .....".."' 24'26

Erasing the DTC Memory ................24-28

Troubleshooting lntermittent

Faifures "'...........24'24

Diagnostic Trouble Gode {DTC}

Chart -'97 model ....""....... "......24-29

Diagnostic Trouble Gode (DTCI

Chart -'98 - 00 models ............. 24-31

SRS Indicator Light Wire

Connections ','," 24'33

Ff owcharts ....-........24'34

Driver's Airbag

Repf acement ..'......21'87

Front Passenger's Airbag

Repfacement .....'.',24'AS

Gable Reel

Replacement .......'.24-91

SRS Unit

Replacement .........24-95

Airbag/Seat Belt Tensioner

Disposaf .................24'97

)-e

www.emanualpro.com

Page 1312 of 1395

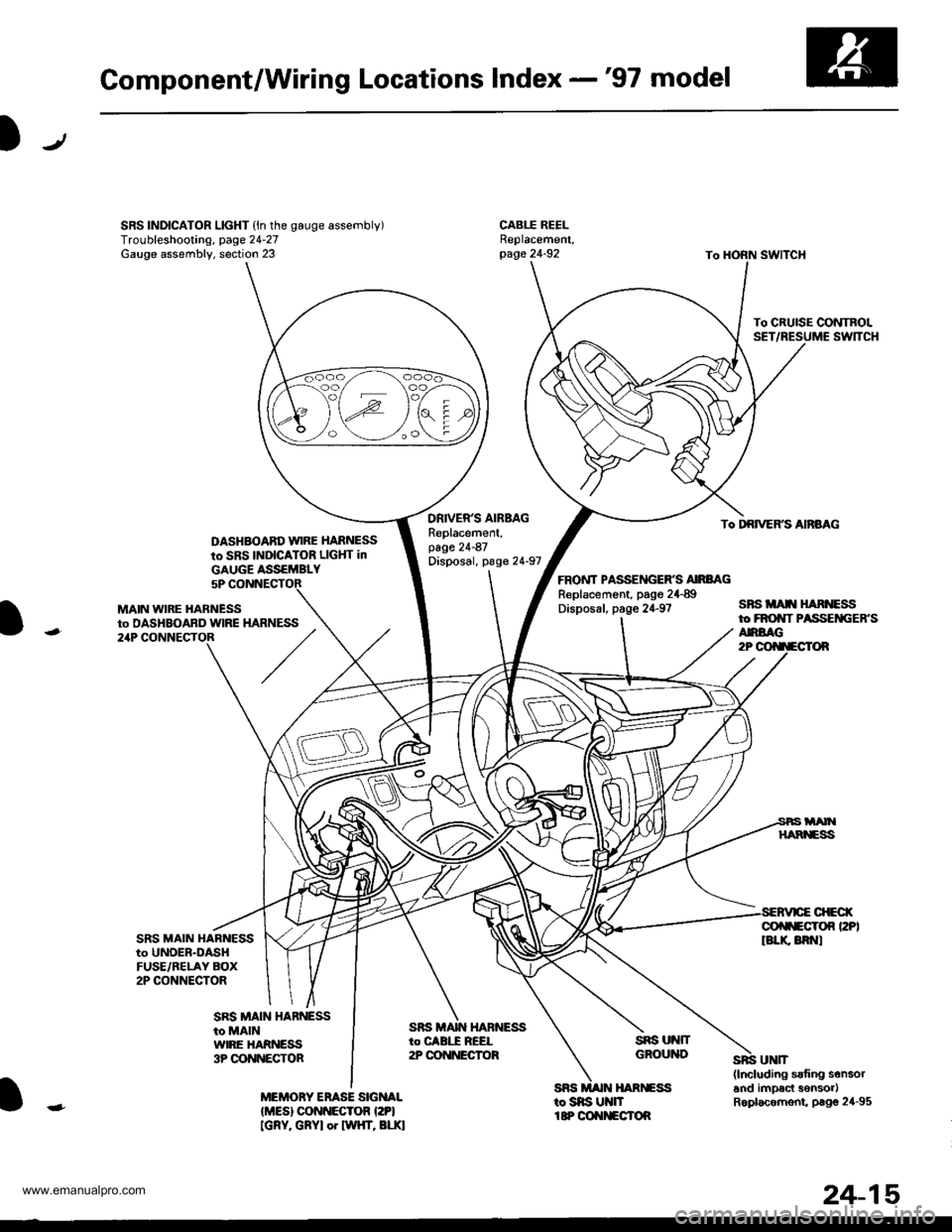

Component/Wiring Locations Index -'97 model

SRS INDICATOR LIGHT (ln the gauge assembly)Troubleshooting, page 24-27Gauge assembly, section 23

DASHBOABD w|RE HARNESS

to SBS INDICATOR LIGHT in

DRIVER'S AIBMGReplacement,page 21-87Disposal, page 24-97

To CRUISE CONTROLSET

To DRIVERS AnBAG

ANBAG2P

sBsitAr[ ] nNEssto FROI|T PASSEiIGEB.S

FRONT PASSEITGER'S AIRBAGReplacement, pago 24{9Disposal, page 24-97

sns ut{fTGROUND

SES MAIN HAR]GSStosns U nItP OOIIITECTOR

MAIN WIRE HABNESSto DASHBOABD wlRE21P

SRS MAIN HABNESSto UNOEB-DASHFUSE/BELAY BOX2P CONNECTOR

GOf$ECrOn PPIlBLr( 8R t

MEMORY ERASE SIGNALIMES) CONNECTOR I2PI[GRY. GRYI or twHT, BLr.l

GAUGE ASSEMBLY5P

HARNESS

SRS MAIN HARNESSto MAINWIRE HARNESS3P OONNECTOR

24-15

www.emanualpro.com

Page 1313 of 1395

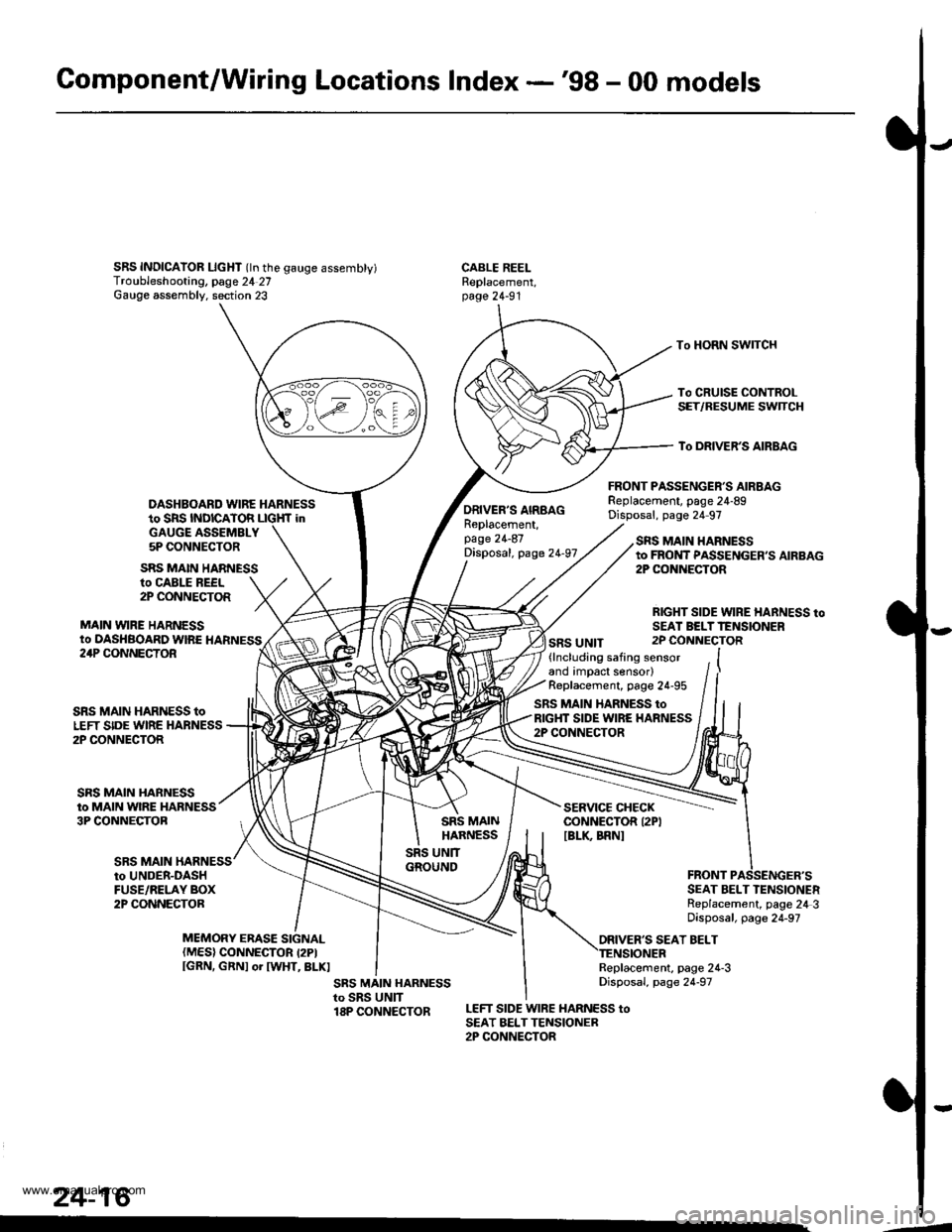

Gomponent/Wiring Locations Index -'98 - 00 models

SRS INDICAIOR LIcHT (ln the gauge assembty)Troubleshooting, page 24 27Gauge assembly. section 23

DASHBOARD WIRE HARNESSto SRS INDICATOR LIGHf inGAUGE ASSEMBLY5P CONNECTOR

FRONT PASSENGER'S AIRBAGReplacement, page 24-89Disposal, page 24 97

CABLE REELReplacement,page 24-91

To HORN SWITCH

To CRUISE CONTROLSET/RESUME SWTCH

To DRIVER'S AIRBAG

ro CABLE REEL2P CONNECTOR

MAIN VYIRE HARNESSto DASHBOARD WIRE HARNESS

SRS MAIN HARNESS

ORIVER'S AIRBAGReplacement,page 24-87Disposal, page 24-97

SRS UNIT

SRS MAIN HARNESSto FROI{T PASSENGER,S AIRBAG2P CONiIECTOR

RIGHT SIDE WIRE HARNESS toSEAI BELTTENSIONER2P CONNECTOR24P CONNECTOR

SRS MAIN

SRS MAIN HARNESS toLEFT SIDE WIRE HARNESS2P CONNECTOR

SRS MAIN HARNESSto MAIN WIRE HARNESS3P CONNECTOB

(lncluding safing sensorand impact sensor)Replacement, page 24-95

SRS MAIN HARNESS toRIGHT SIDE WIRE HARNESS2P CONNECTOR

SERVICE CHECKCONNECTOR I2PIIBLK BRNI

to UNDER-DASHFUSE/RELAY BOX2P CONNECTORSEAT BELT TENSIONERReplacement, page 24 3Disposal, page 24-97

ORIVER'S SEAT BELTMEMORY ERASE SIGNAL(MES) CONNECTOR I2PIIGRN, GRNI or IWHT, BLKIReplacement, page 24-3Disposal, page 24-97

LEFT SIDE WIRE HARNESS toSEAT BELTTENSIONER2P CONNECTOR

24-16

.4

www.emanualpro.com

Page 1317 of 1395

Precautions/Procedures

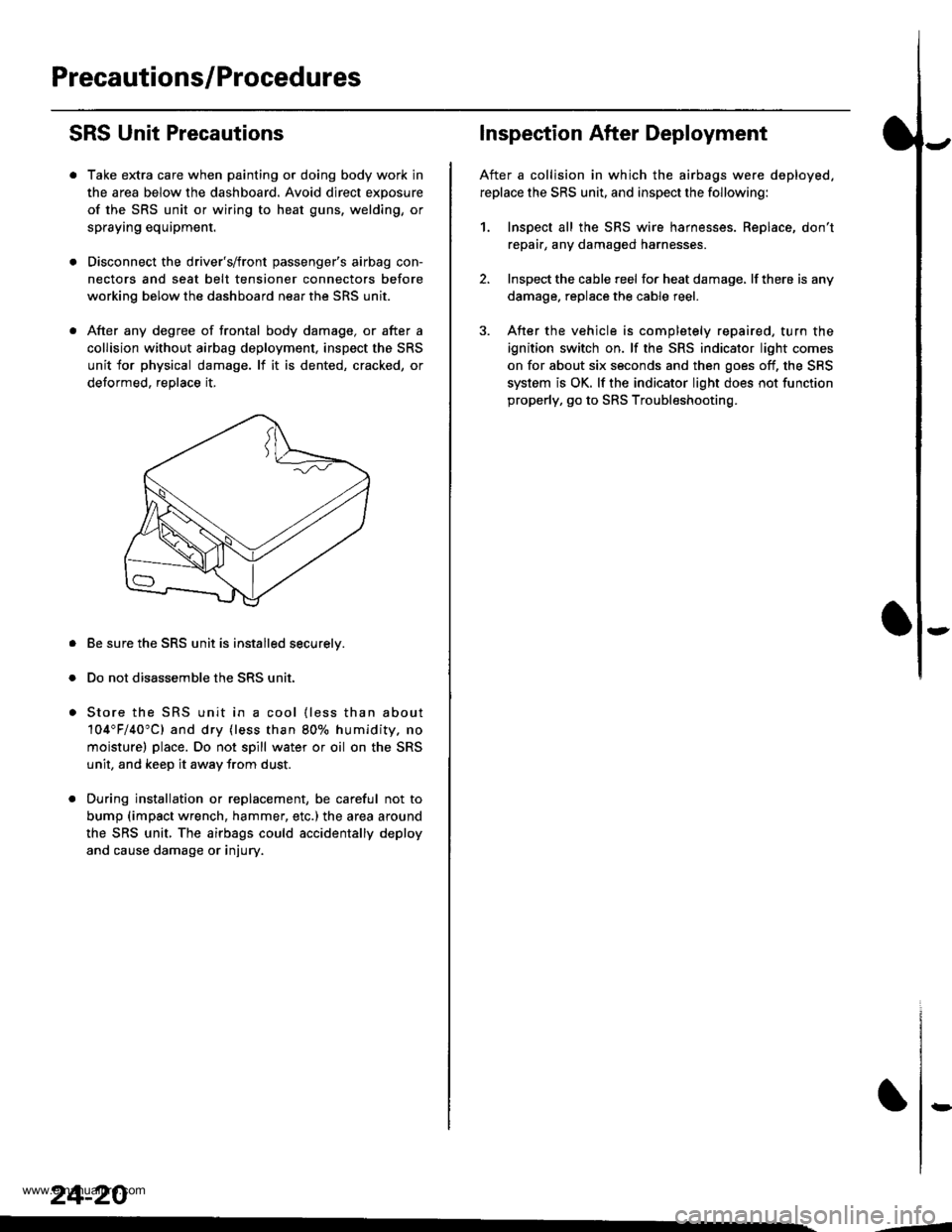

SRS Unit Precautions

Take extra care when painting or doing body work in

the area below the dashboard. Avoid direct exposure

of the SRS unit or wiring to heat guns, welding, or

spraying equipment.

Disconnect the driver's/front passenger's airbag con-

nectors and seat belt tensioner connectors before

working below the dashboard near the SRS unit.

After any degree of frontal body damage, or after a

collision without airbag deployment, inspect the SRS

unit for physical damage. lf it is dented, cracked, or

detormed, reolace it,

Be sure the SRS unit is installed securelv.

Do not disassemble the SRS unit.

Store the SRS unit in a cool {less than about

104"F/40"C) and dry {less than 80o/o humidity. no

moisture) place. Do not spill water or oil on the SRS

unit, and keep it awav from dust.

During installation or replacement, be careful not to

bump (impact wrench, hammer, etc.) the area a[ound

the SRS unit, The airbags could accidentally deploy

and cause damage or injury.

24-20

,..4

Inspection After Deployment

After a collision in which the airbags were deployed.

replace the SRS unit, and inspect the following:

1. Inspect all the SRS wire harnesses. Replace, don't

repair, any damaged harnesses

2. Inspect the cable reel for heat damage, lf there is any

damage. replace the cable reel.

3. After the vehicle is completely repaired, turn the

ignition switch on. lf the SRS indicator light comes

on for about six seconds and then goes off, the SRS

system is OK. lf the indicator light does not function

properly, go to SRS Troubleshooting.

rD

www.emanualpro.com