Mil HONDA CR-V 1998 RD1-RD3 / 1.G Owners Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1998, Model line: CR-V, Model: HONDA CR-V 1998 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 572 of 1395

Troubleshooting Procedures

Checking ths Diagnostic Trouble Code (DTC)

with an O8D ll Scan tool or Honda PGM Tsster

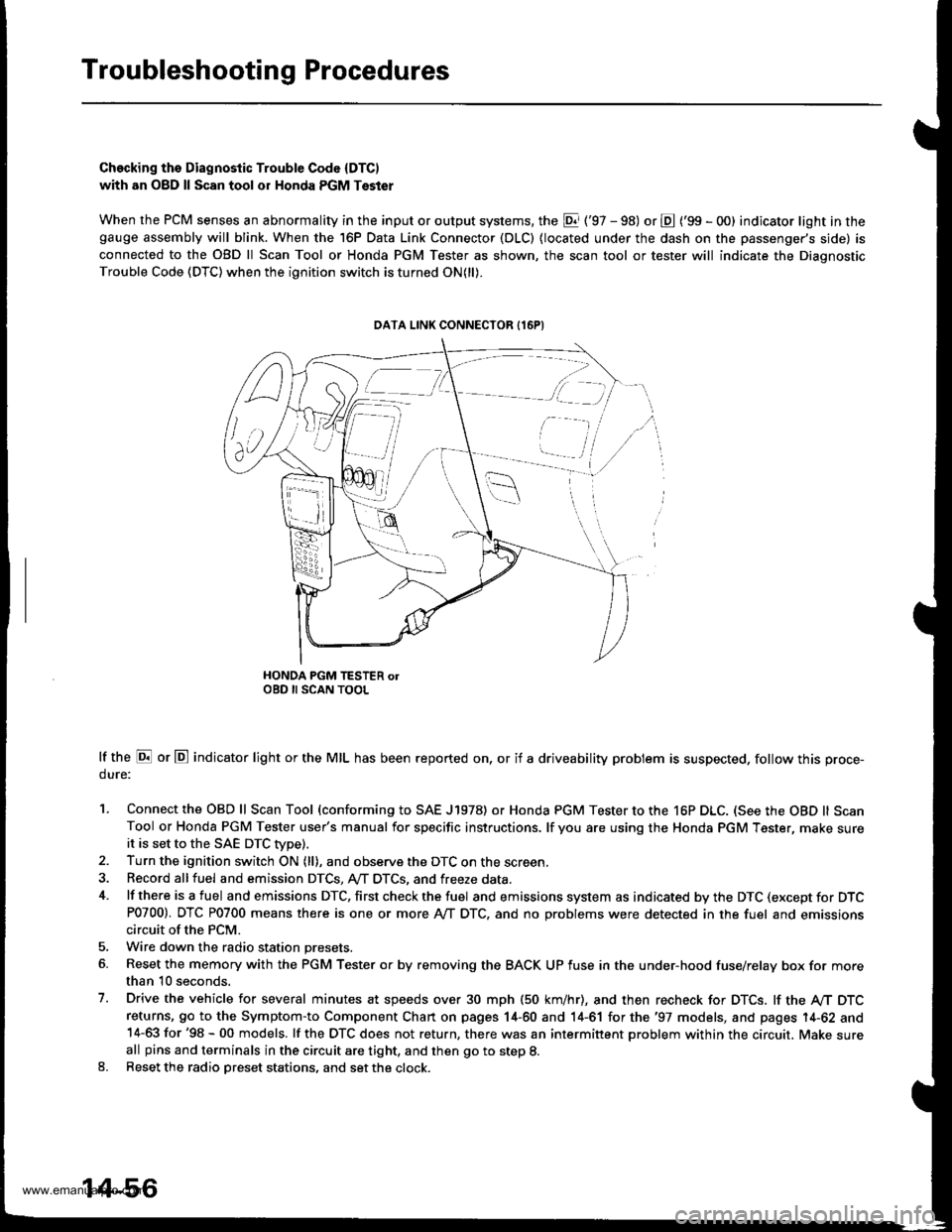

When the PCM senses an abnormality in the input or output systems, the El ('97 - 98) or E ('99 - O0) indicator light in thegauge ass€mbly will blink. When the 16P Data Link Connector (DLC) {located under the dash on the passenger's side) is

connected to the OBD ll Scan Tool or Honda PGM Tester as shown, the scan tool or tester will indicate the Diagnostic

Trouble Code (DTC) when the ignition switch is turned ON(ll).

HONDA PGM TESTER olOBD II SCAN TOOL

lf the E or E indicator light or the MIL has been reported on, or if a driveability problem is suspected, follow this proce-

dure:

1. Connect the OBD ll Scan Tool (conforming to SAE J1978) or Honda PGM Tester to the 16P DLC. (See the OBD ll ScanTool or Honda PGM Tester user's manual for specific instructions. lf you are using the Honda PGM Tester, make sureit is set to the SAE DTC Wpe).2. Turn the ignition switch ON (ll), and observe the DTC on the screen

3. Record allfuel and emission DTCS, A,,/T DTCS, and freeze data.

4. lf there is a fuel and emissions DTC, first check the fuel and emissions system as indicated by the DTC (except for DTCP0700). DTC P0700 means there is one or more Ay'T DTC, and no Droblems were detected in the fuel and emissionscircuit of the PCM.

5. Wire down the radio station presets.

6. Reset the memory with the PGM Tester o. by removing the BACK UP fuse in the under-hood fuse/relay box for morethan 10 seconds.

7. Drive the vehicle for several minutes at speeds over 30 mph (50 km/hr), and then recheck for DTCS. lf the A/T DTCreturns, 9o to the Symptom-to Component Chart on pages 14-60 and 14-61 for the '97 models, and pages 14-62 and14-63 for '98 - 00 models. lf the OTC does not return, there was an intermittent problem within the circuit. Make sureall pins and terminals in the circuit are tight, and then go to step 8.8. Reset the radio Dreset stations, and set the clock.

DATA LINK CONNECTOR {16PI

[ -=.r,

ili,i /i,

v,., i

14-56

www.emanualpro.com

Page 576 of 1395

Symptom-to-Component Chart

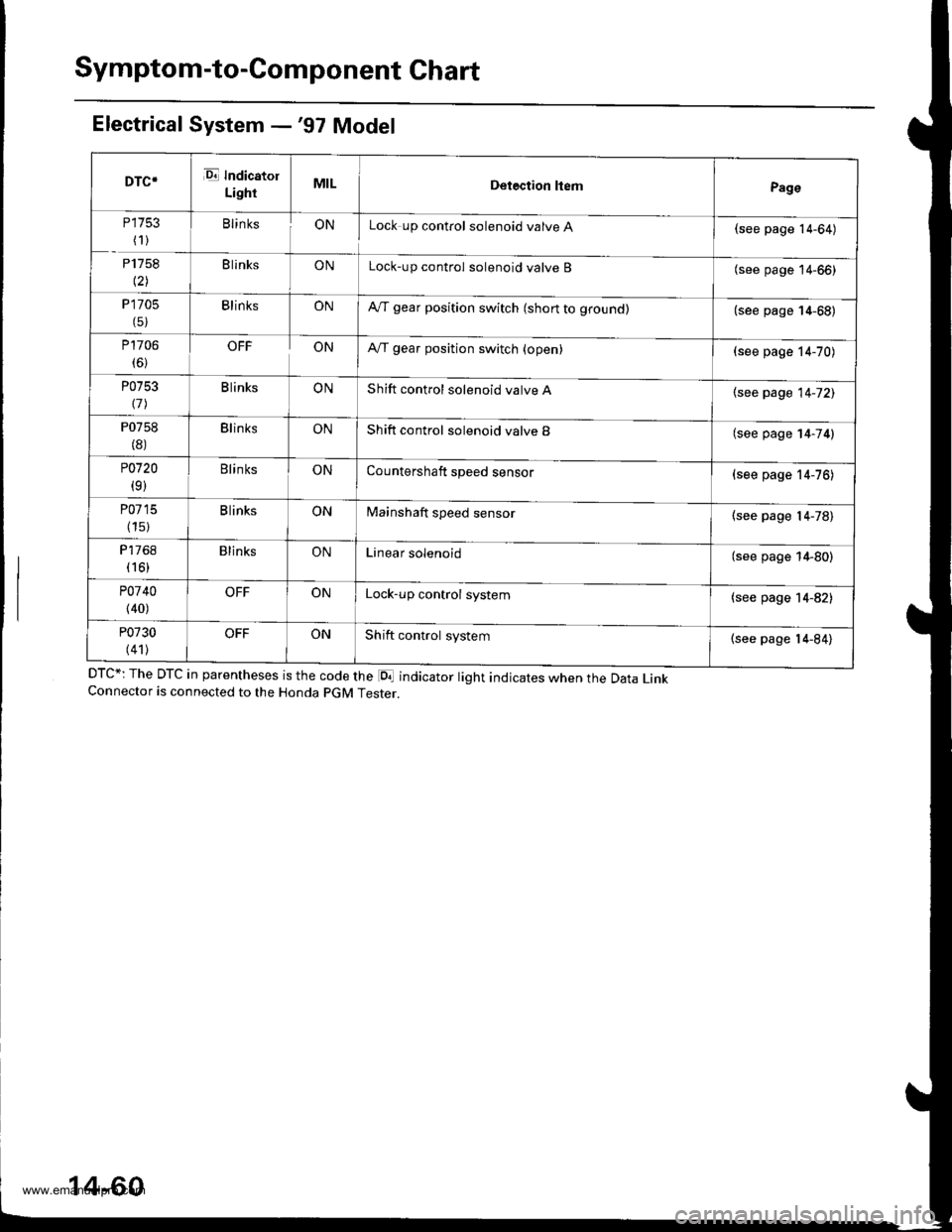

Electrical System -'97 Model

DTC*: The DTc in parentheses is the code the loa indicator right indicates when the Data LinkConnector is connected to the Honda pGM Tester.

DTC*E Indicatol

LightMILDetection ltemPage

P 1753

(1)BlinksONLock up control solenoid valve A(see page 14-64)

P1758

\21

B linksONLock-up control solenoid valve B(see page 14-66)

P 1705

(5)BlinksONA,/T gear position switch (short to ground)(see page 14-68)

P1706

(6)OFFONA,/T gear position switch {open)(see page 14-70)

P0753

\11

B linksONShift control solenoid valve A(see page 14-72)

P0758

(8)BlinksONShift control solenoid valve B(see page 14-74)

P0720

(9)BlinksONCountershaft speed sensor{see page 14-76)

P0715

(15)B linksONMainshaft speed sensor(see page l4-78)

P17 68( 16)

BlinksONLinear solenoid(see page 14-80)

P0740

{40)

OFFONLock-up control system(see page 14-82)

P0730

(41)OFFONShift control system(see page 14-84)

14-60

www.emanualpro.com

Page 578 of 1395

Symptom-to-Component Chart

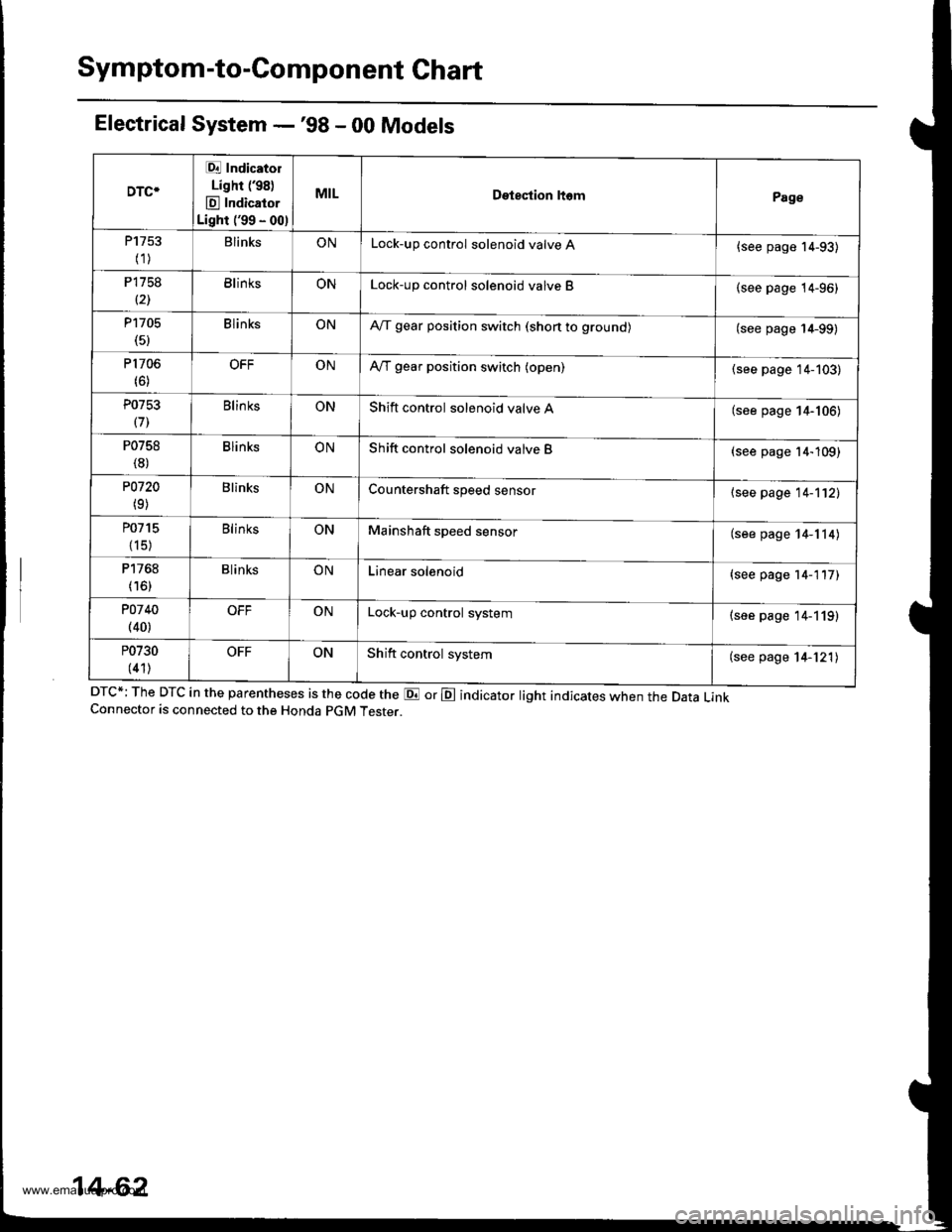

Electrical System -'98 - 00 Models

DTC*; The DTC in the parentheses is the code the E or E indicator light indicates when the Data LinkConnector is connected to the Honda pGM Tester.

DTC*

Et Indicatol

Lighr (98)

E Indicator

Light ('99 - 00)

MILDetestion ltomPage

P1753

(1)BlinksONLock-up control solenoid valve A{see page 14-93)

P1758

(21BlinksONLock-up control solenoid valve B(see page 14-96)

P1705(5)BlinksONA,/T gear position switch (shon to grounol(see page 14-99)

P1706(6)OFFONA,/T gear position switch (open)(see page 14-103)

P0753

(71Blin ksONShift control solenoid valve A(see page 14-106)

P0758

(8)BlinksONShift control solenoid valve B(see page 14-109)

P0720

(9)BlinksONCountershaft speed sensor{see page 14-112)

P0715

{15)

BlinksONMainshaft speed sensor(see page 14-114)

P1768

(16)BlinksONLinear solenoid(see page 14-117)

POl 40(40)OFFONLock-up control system(see page 14-119)

P0730

(41)OFFONShift control system(see page 14-121)

14-62

www.emanualpro.com

Page 642 of 1395

Electrical Troubleshooting ('98 - 00 Modelsl

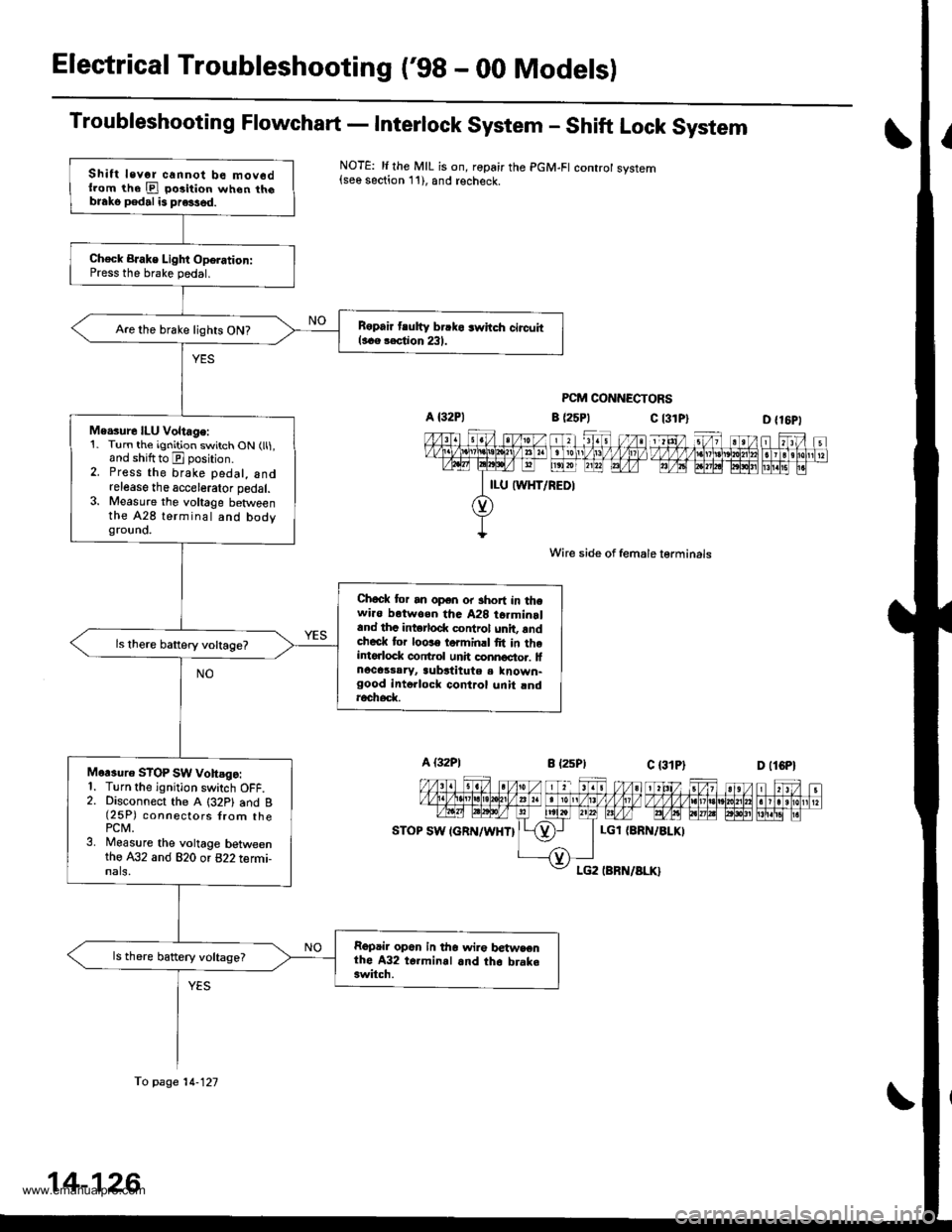

Troubleshooting Flowchart - Interlock System - Shift Lock System

NOTE: li the MIL is on, ropair the PGM-FI controt system{see section 11), and recheck.

PCM CONNECTORS

c l3lPl

Wire side of female lerminals

c t3lPt

D {16P1

1 tttt/ 5t/ 1 a t /tlt 1 t\/t ,/ VVV tl t ttj,r\1e\10l211n . I 3 rholr1 t?m@-@Effilil"

D (lCPl

| 2ttt/ ;t /n) ).tt)/ 1 21:/ tvvvvv nnvl.lnl2

I r r ero

12wE gp]P] polr EI!l!!i r.

a (25P1

LGl {8RN/ALKI

Shift levor cannot be mov6dllom the E po3ition when th6blako pedal is pre3sed.

Ch€ck BJake Light Oporation:Press the brake pedal.

B6pair tlutty brrko 3whch circuitl..e rection 231.Are the brake lights ON?

Me.sure ILU Voltage:1. Turn the ignition switch ON (ll1,and shiftto E position.2. Press the brake pedal, andrelease the accelerator pedal.3. Measure the voltage betweenthe A28 terminal and bodygrouno.

Chock tor an open or short in thewi.o botwoen tha A28 t6rminrland thc intorlod( control unit, rndcheck tor loose torminrl fit in theintorlock conftol unh connoctor. lfnocassaryr aubstitute a known-good intollock control unit rndroch6d(

Mor3uro STOP SW vohsgo:1. Turn the ignition switch OFF.2. Disconnect the A (32P1 and B(25P) connectors {rom thePCM.3. Measure the voltage betweenthe A32 and 820 or 822 termi-nals,

Repair op6n in tho wir€ betwsenthe A32 t6.minal and th6 brake3witch.

ls there battery voltage?

fo page 14-121

14-126

www.emanualpro.com

Page 702 of 1395

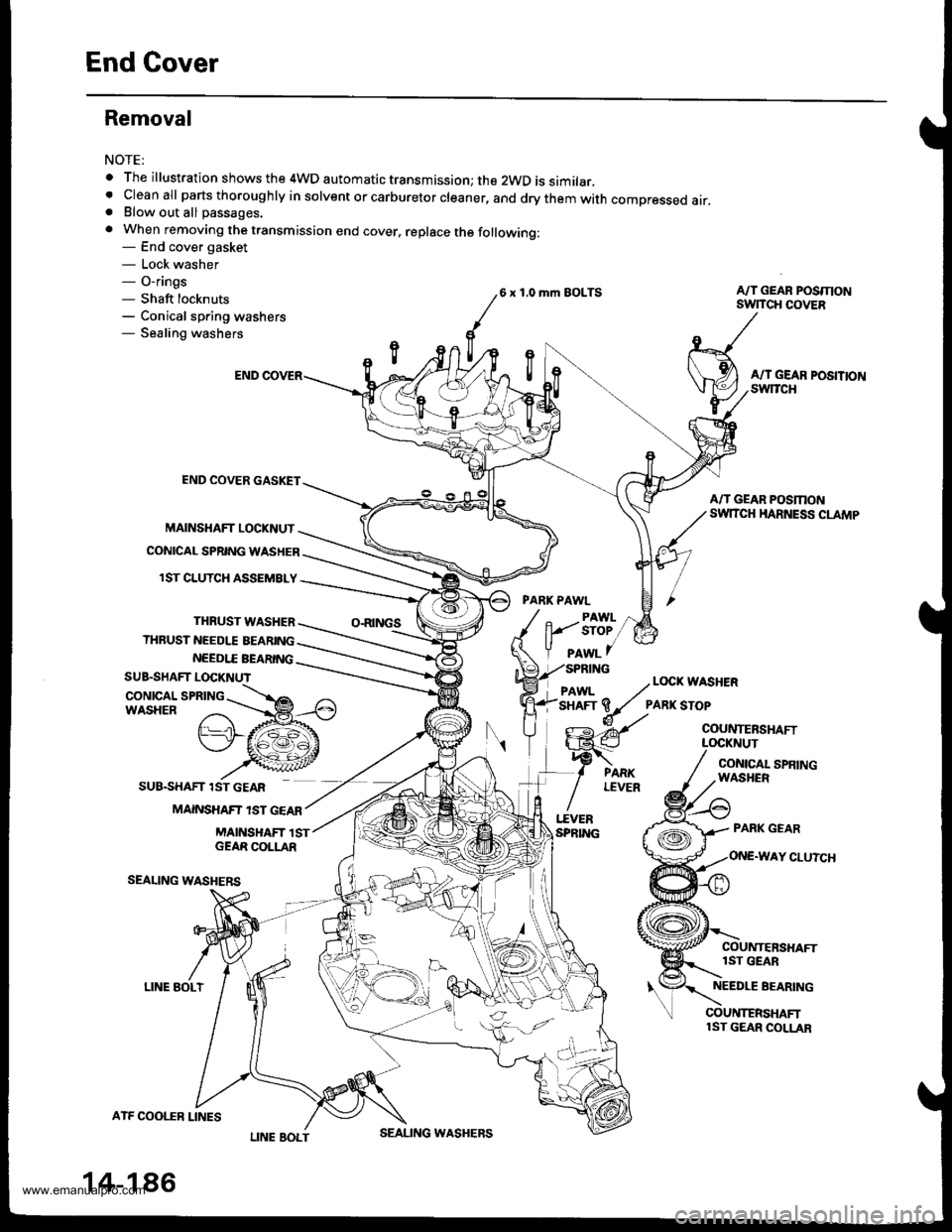

End Cover

Removal

NOTE:

o The illustration shows the 4WD automatic transmission; the 2WD is similar.. cleanall parts thoroughly in solvent or carburetor cleaner, and drythem with compressed air.. Blow out all passages.

. When removing the transmission end cover, replace the following:- End cover gasket- Lock washer- O-rings- Shaft locknuts- Conical spring washers- Sealing washers

END COVER GASKET

MAINSHAFT LOCKNUT

CONICAL SPRING WASHER

6 x 1 .0 rhm EOLTS

PARK PAWL

A/T GEAR POSMONSwlTCH COVER

NEEDI.T BEARING

SUB.SHAFT LOCKNUT

CONICAL SPRINGWASHER

LINE AOLT

ATF COOI.f B LINES

14-186

PAwL 7// Locx wASHER

'sHAFr 9/ ?ARK srop

o-- Ay' couNTERsHAFr

G-€ LocKNUr!€ / ..t,"o, "oo

A/T GEAR POSMONSW|TCH HARNESS CLAMP

CONICAL SPRINGWASHCR

A/T GEAR POSITION

PARK GEAR

Y CLUTCH

lST GEAR

NEEDLE BEARING

1ST CLUTCH ASSEMBLY

THRUST WASHER

THRUST NEEDLE AEARING

O.RINGS

\\

SUB.SHAFT 1ST GEAR

MAINSHAF? 'ST GEAR

MAINSHAFT 1STGEAR COLLAR

SEALING WASHERS

!€'-l

I"EVERSPRING

COUNTERSHAFTlST GEAR COLLAR

PAWL

lt1/ sroe

Y plwl f

L/'SPRING

LOCKNUT

LINE BOLTSEALING WASHERS

www.emanualpro.com

Page 704 of 1395

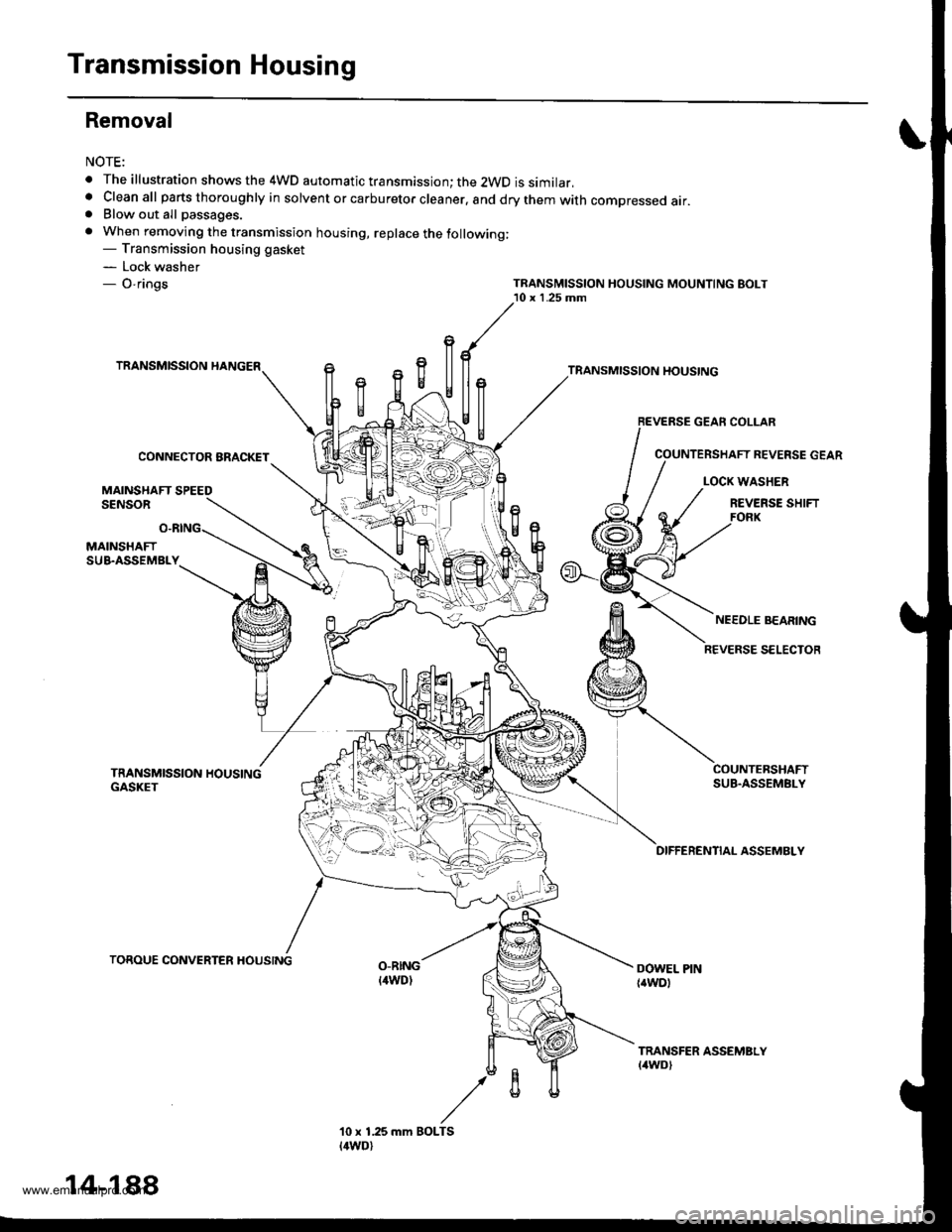

Transmission Housing

Removal

NOTE:

. The illustration shows the 4WD automatic transmission; the 2WD is similar,. Cleanall parts thoroughly in solvent or carburetor cleaner. and drythemwith compressed air.. Blow out all passages.

. When removing the transmission housing, replace the lollowing:- Transmission housing gasket- Lock washer- O-rings

TRANSMISSION HANGERTRANSMISSION HOUSING

REVERSE GEAN COLLAR

TRANSMISSION HOUSING MOUNTING EOLT

CONNECTOR BRACKET

MAINSHAFT SPEEDSENSOR

REVERSE GEAR

LOCK WASHER

REVERSE SHIFT

MAINSHAFTSUB.ASSEMBLY

TRANSMISSION HOUSINGGASKET

DIFFERENTIAL ASSEMBLY

TOROUE CONVERTER HOUSINGO-RINGt4wDl

TRANSFER ASSEMBLYt4wDt

10 x 1.25 mm

l4wo)

14-1 88

BOLTS

www.emanualpro.com

Page 706 of 1395

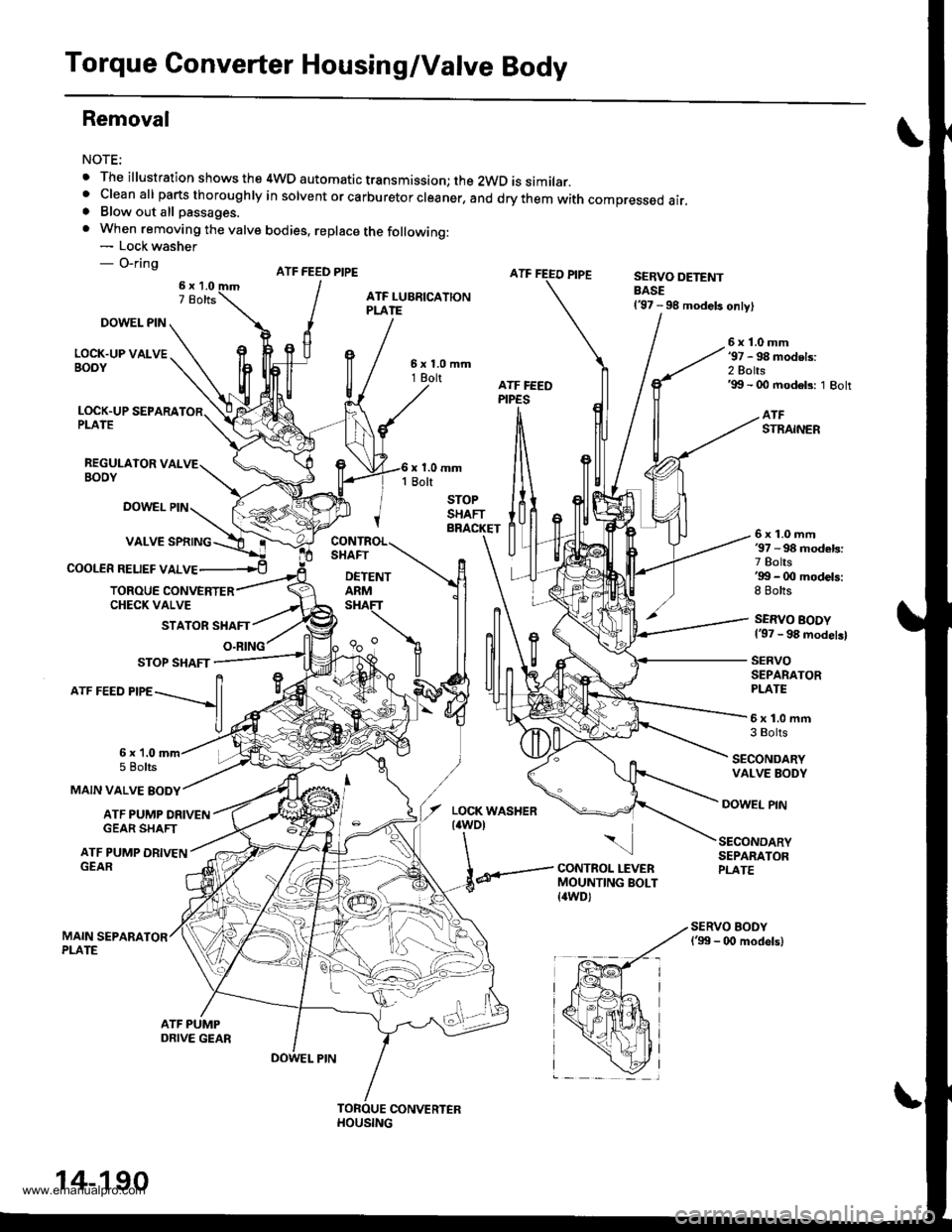

Torque Converter Housing/Valve Body

Removal

NOTE:

. The illustration shows the 4WD automatic transmission; the 2WD is similar.' cleanall parts thoroughry in sorvent or carburetor creaner, and drythem with compressed air.. Blow out all passages.

. When removing the valve bodies, replace the following:- Lock washer- O-ringATF FEED PIPESERVO DETENTBASE137 - 98 models only)

DOWEL PIN

LOCK.UP VALVEBOOY

6x1.0mm'97 - 98 models:2 Bolts'99 - 00 modeb: 1 Bolt

LOCK.UP SEPARAPLATE

REGULAIOR VALVEBOOY

ATFSTRAINER

DOWEL PIN

COOLER RELIEF VALVE

6x1.0mm37 - 98 models:7 Bolts'gg - 0O models:8 Bolts

SERVO BODY137 - 98 modelsl

SERVOSEPARATORPLATE

TOROUE CONVERTERCHECK VALVE

STATOR SHAFT

O.RING

5x1.0mfi3 Bolts

SECONDARYVALVE BODY

MAIN VALVE BODY

6x 1.05 Bolts

ATF PUMP ORIVENGEAR SHAFT

DOWEL PIN

ATF PUMP DRIVENGEAR

\

CONTROL LEVERMOUNTING BOLT{awD)

SECONDARYSEPARATORPLATE

14-190

www.emanualpro.com

Page 740 of 1395

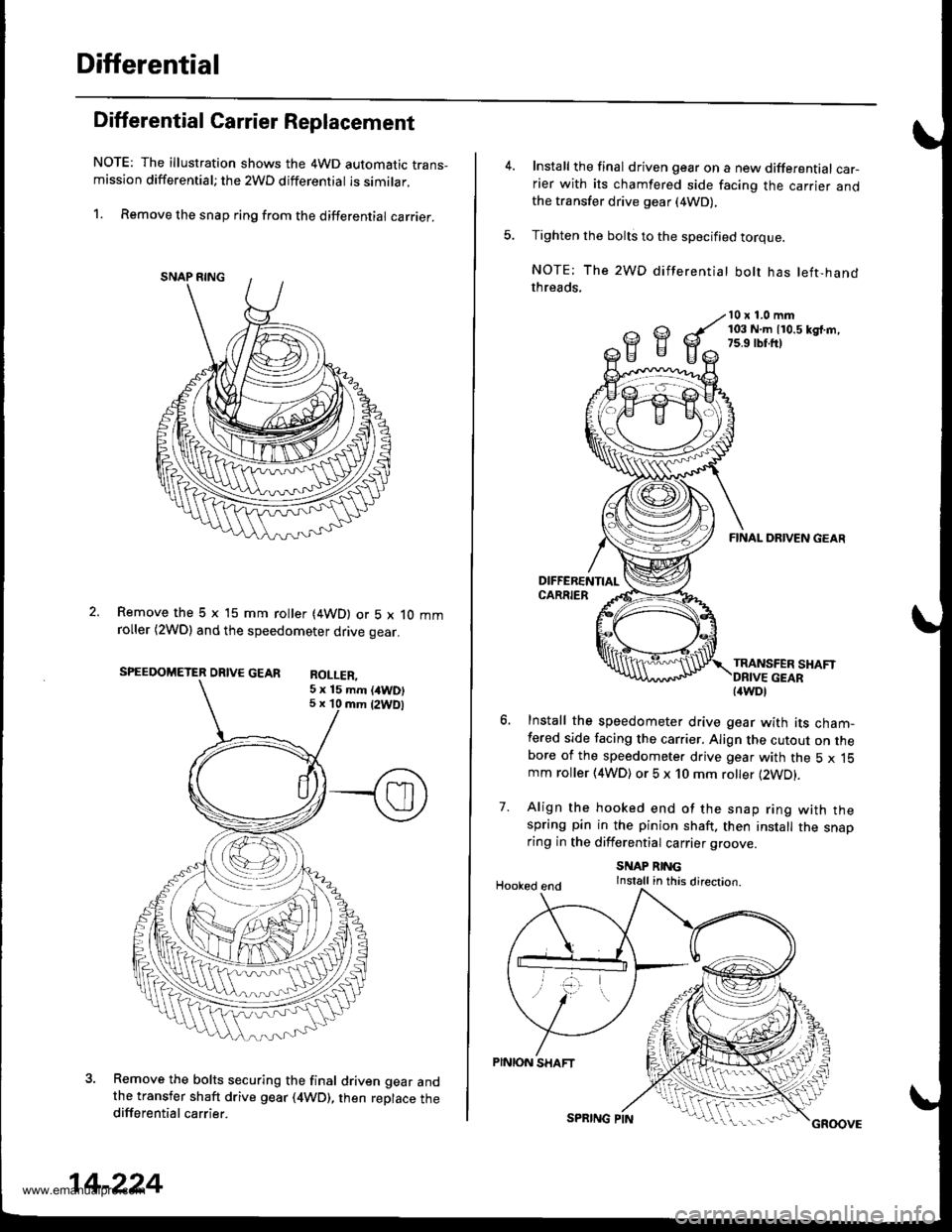

Differential

Differential Carrier Replacement

NOTE: The illustration shows the 4WD automatic trans-mission differential; the 2WD differential is similar.

1. Remove the snap ring from the differential carrier.

Remove the 5 x 15 mm roller (4WD) or 5 x 10 mmroller (2WDl and the speedometer drive gear.

SPEEDOMETER DRIVE GEAR RoI I FP

Remove the bolts securing the final driven gear andthe transfer shaft drive gear (4WD), then replace thedifferential carrier.

5 x 15 mm (/tWD)5 x 10 mm {2WDl

14-224

SPRING PINGROOVE

Install the final driven gear on a new differential car-rier with its chamfered side facing the carrier andthe transfer drive gear (4WD),

Tighten the bolts to the specified torque.

NOTE: The 2WD differentiat bolt has left-handthreads,

10 x 1.0 mm103 N.m 110.5 kd.m,7s.9 rbr.ft)

7.

FINAL DRIVEN GEAR

TRANSFER SHAFT

Install the speedometer drive gear with its cham-fered side facing the carrier. Align the cutout on thebore of the speedometer drive gear with the 5 x 15mm roller (4WD) or 5 x 10 mm roller (2WD).

Align the hooked end of the snap ring with thespring pin in the pinion shaft. then install the snaoring in the differential carrier groove

SNAP RINGInstall in this direction.Hooked end

PINION SHAFT

{4WDl

www.emanualpro.com

Page 766 of 1395

Transmission

Reassembly

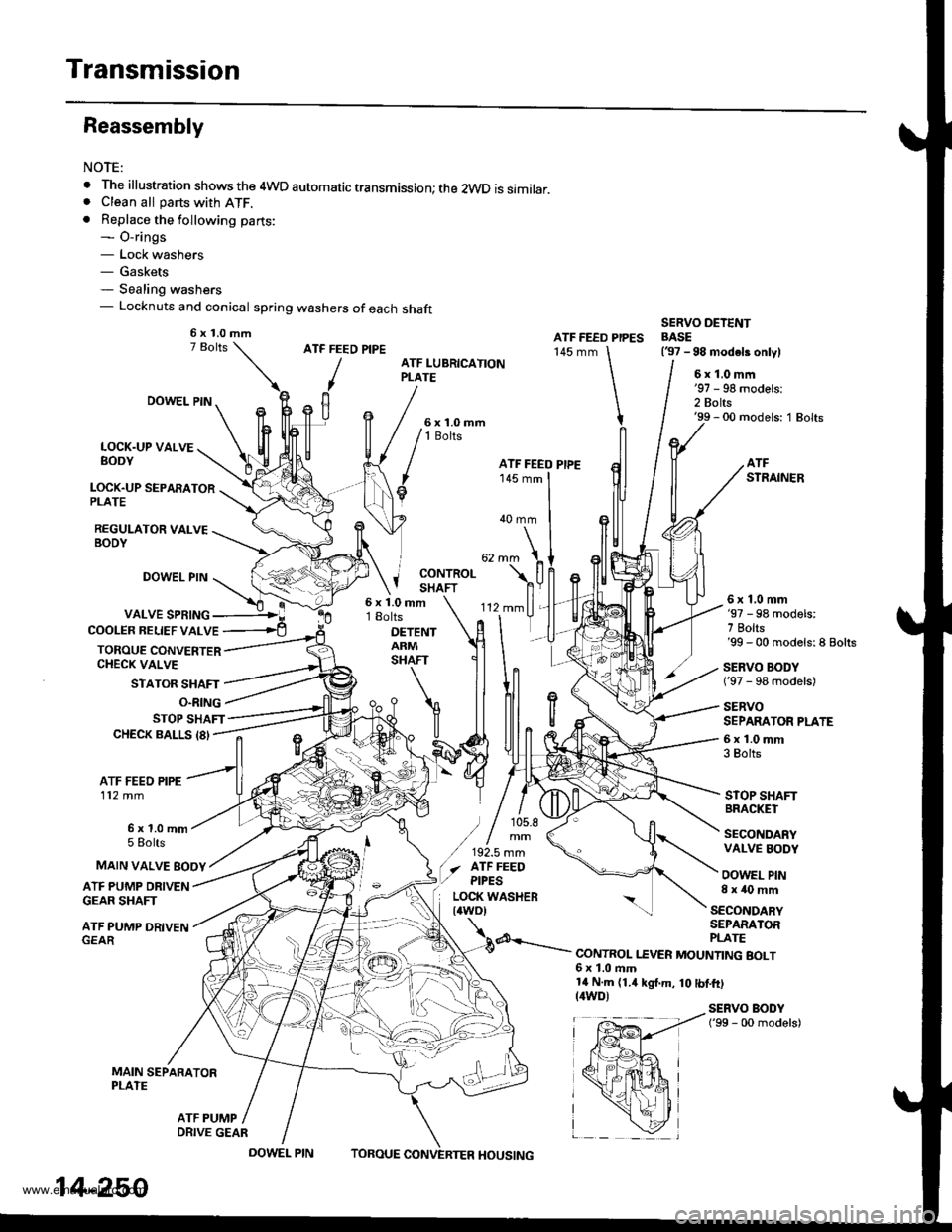

NOTE:

. The illustration shows the 4WD automatic transmission; the 2WD is similar.. Clean all parts with ATF.. Replace the following parts:- O-rings- Lock washers- Gaskets- Sealing washers- Locknuts and conical spring washers of each shaft

ATF FEED PIPE

/

ATF FEED PIPES145 mm

SERVO DETENTBASE(37 -98 modeb onlylATF LUBRICATIONPLATE6x1.0mm

2 Bolts'99 - 00 models: 1 Bolts

LOCK.UP VALVEBODY

LOCK.UP SEPARATORPLATE

REGULATOR VALVEBODY

DOWEL PIN

DOWEL PIN

VALVE SPRING

STATOR SHAFT

'-

'112mmll,

rlT

ATFSTRAINER

40 mm

j coNrRoLI SHAFT

COOLER BELIEF VALVE

TOROUE CONVERTERCHECK VALVE

6x1.0mm18olts

DETENTARMSHAFT

6x1,0mm'97 - 98 models:7 Bolts'99 - 00 models:8 Bolts

SERVO BODY('97 - 98 models)

SERVOSEPARATOR PLATE

6x1.0mm3 Bolts

STOP SHAFTBRACKET

SECONDARYVALVE BODY

OOWEL PIN8x40mm

O.RING

STOP SHAFTCHECK BALLS 18'

ATF FEED PIPE112 mm

6x1.0mm5 Eolts

ATF PUMP DRIVENGEAR SHAFT

ATF PUMP DRIVEN

MAIN SEPARATORPLATE

MAIN VALVE EOOY

SECONDARYSEPARATOR

d---.- PLATE--.- CONTROL I.EVER MOUNTING BOLT6x1.0ftm14 N.m (1.4 kgt.m, 10 tbf.ft)(4WD)SERVO BODY('99 - 00 models)

ATF PUMP

6x1.0mm

ATF FEEO PIPE

) / 105.8

/,,!.,::(./ afF FEEO,/ ptpEs

EP,---!ir{+*a r

fpffi4 i

x*hi

_ \zl

14-250

DRIVE GEAR

DOWEL PINTOBOUEHOUSING

www.emanualpro.com

Page 910 of 1395

Front Suspension

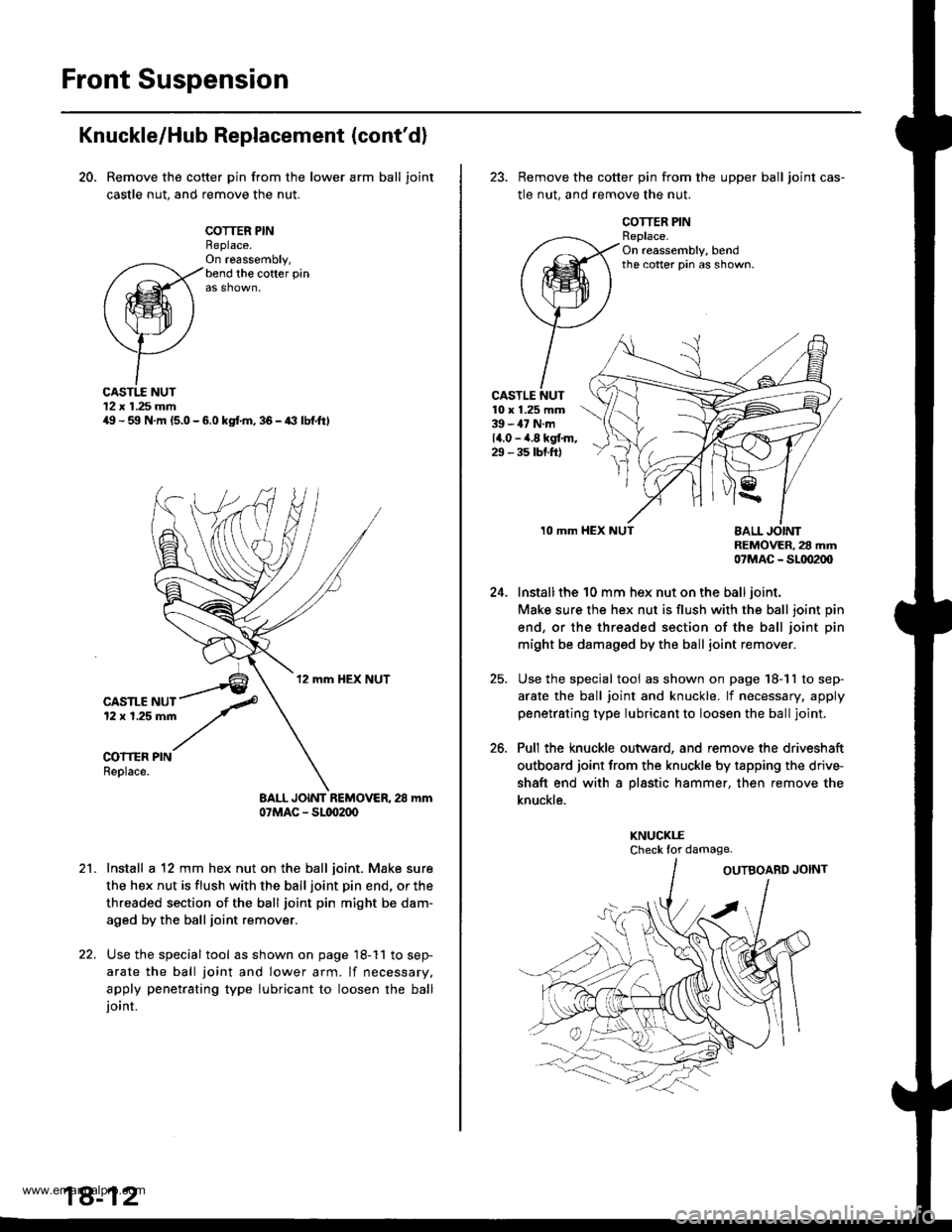

Knuckle/Hub Replacement (cont'd)

20. Remove the cotter pin from the lower arm ball joint

castle nut, and remove the nut.

COTTER PINReplace.On ra6ssembly,bend the cofter pin

CASTI.E NUT12 x 1.25 mmilg - 59 N.m (5.0 - 6.0 kgf.m, 36 - a3 lbf.ftl

CASTLE NUT12 x 1.25 mm

COITER PINReplace.

BALL JOINT REMOVER, 28 mm07MAC - Sl(xr2(x,

Install a 12 mm hex nut on the ball joint. Make sure

the hex nut is flush with the ball joint pin end, or the

threaded section of the ball joint pin might be dam-

aged by the ball joint remover.

Use the special tool as shown on page 18-11 to sep-

arate the ball joint and lower arm. lf necessary,

apply penetrating type lubricant to loosen the balljoint.

18-12

23. Remove the cotter pin from the upper ball joint cas-

tle nut, and remove the nut.

COTTER PINReplace.On reassembly, bendthe cotter pin as shown.

CASTLE NUT10 x 1.25 mm39 - 47 N.m14.0 - ,4.8 kgt m,29 - 35 tbt.ftl

24.

25.

26.

10 mmnEMOVER, 28 mm07MAC _ SLtD2(xl

Install the 10 mm hex nut on the ball joint.

Make sure the hex nut is flush with the ball joint pin

end, or the threaded section of the ball joint pin

might be damaged by the ball joint remover.

Use the special tool as shown on page 18-11 to sep-

arate the ball joint and knuckle. lf necessary, apply

penetrating type lubricant to loosen the ball joint.

Pull the knuckle outward, and remove the driveshaft

outboard joint from the knuckle by tapping the driv+

shaft end with a pl8stic hammer, then remove the

knuckle.

KNUCKI.ECheck lor damage.

www.emanualpro.com