Mil HONDA CR-V 1998 RD1-RD3 / 1.G Manual PDF

[x] Cancel search | Manufacturer: HONDA, Model Year: 1998, Model line: CR-V, Model: HONDA CR-V 1998 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 396 of 1395

Intake Air System

Air Cleaner

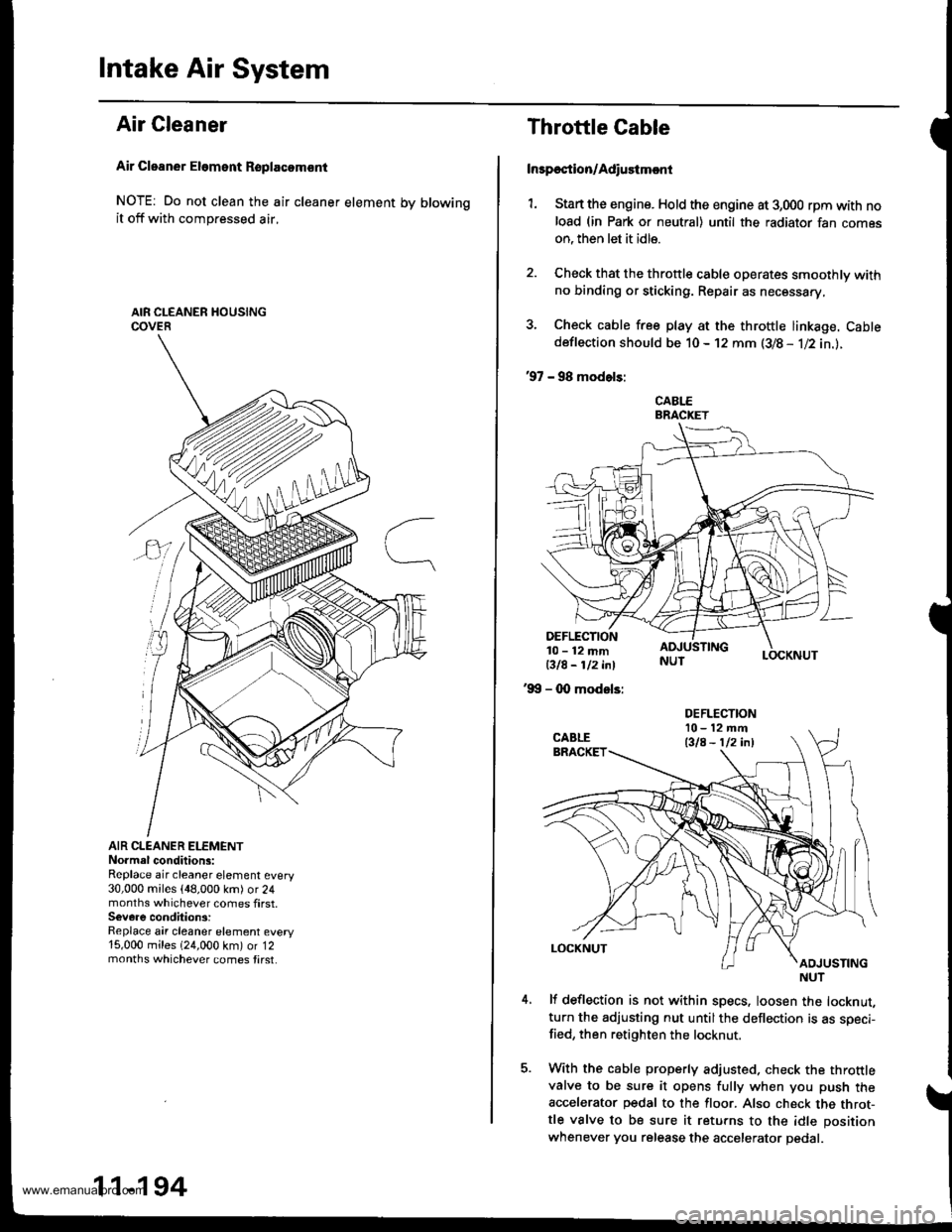

Air Cleaner Eloment Rsplacomsnt

NOTE: Do not clean the air cleaner element by blowingit off with compressed air,

AIR CLEANER ELEMENTNo.mal conditions:Replace air cleaner element every30,000 miles {48,000 km) or 24months whichever comes first.Severe condition3:Replace air cleaner element every15,000 miles 124,000 km) or 12months whichever comes tirst.

m

11-194

Throttle Cable

Inrpection/Adiustmcnt

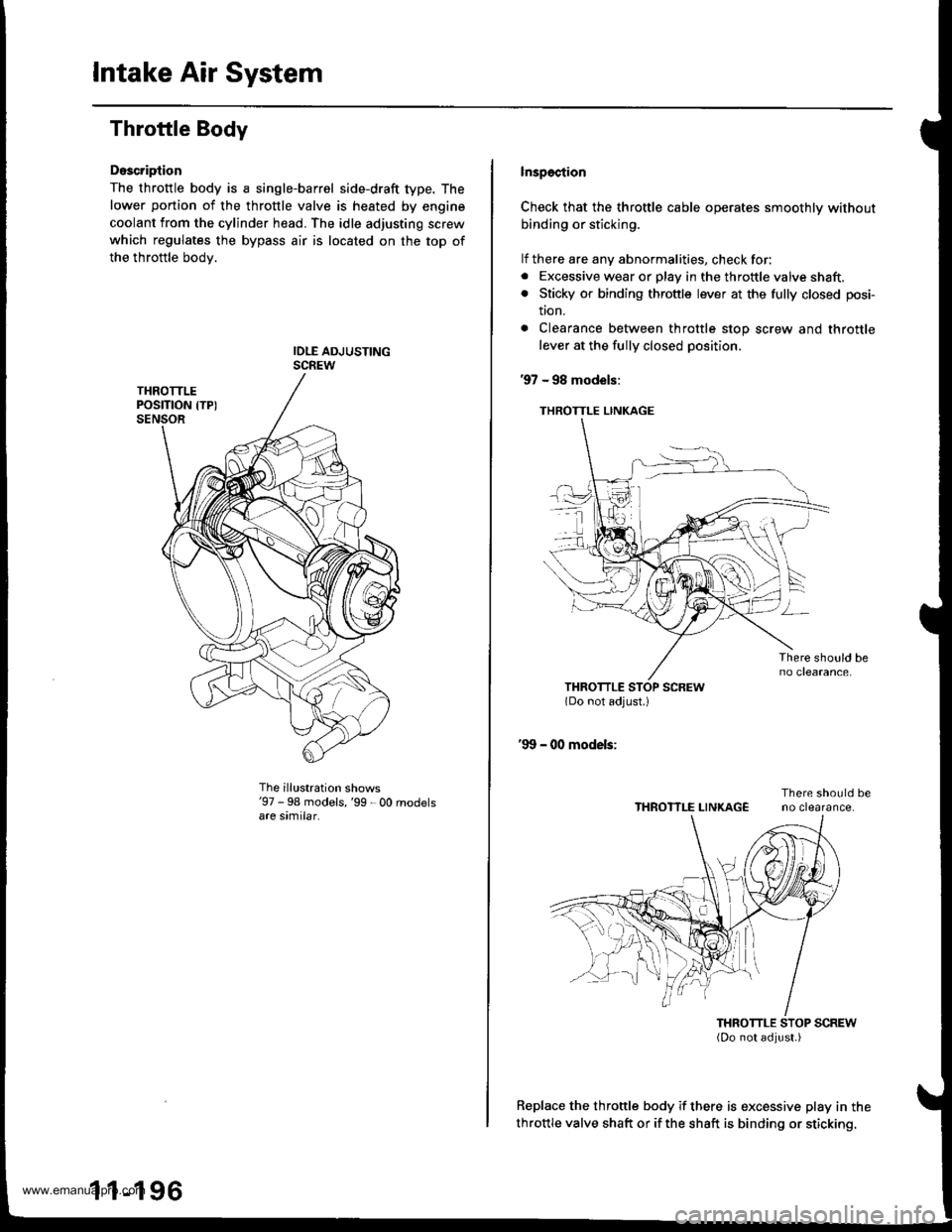

1. Stan the engine. Hold the engine at 3,000 rpm with noload (in Park or neutral) until the radiator fan comeson, then let it idle.

2. Check that the throttle cable operates smoothly withno binding or sticking. Repair as necessary,

3. Check cable free play at the throttle linkage. Cabtedeflection should be 10- 12 mm (3/8 - 1l2in.l.

'97 - 98 modols:

CABLEBRACKET

LOCKNUT

DEFLECTION10-12mmBIA- 112 i^l

'99 - 0O modsls:

lf deflection is not within specs, loosen the locknut,turn the adjusting nut untilthe deflection is as speci-fied, then retighten the locknut.

With the cable properly adjusted. check the throttlevalve to be sure it opens fully when you push theaccelerator pedal to the floor. Also check the throt-tle valve to be sure it returns to the idle position

whenever you release the accelerator pedal.

DEFLECTIONl0-12mft

Bla - 112 inl

NUT

www.emanualpro.com

Page 398 of 1395

Intake Air System

Throttle Body

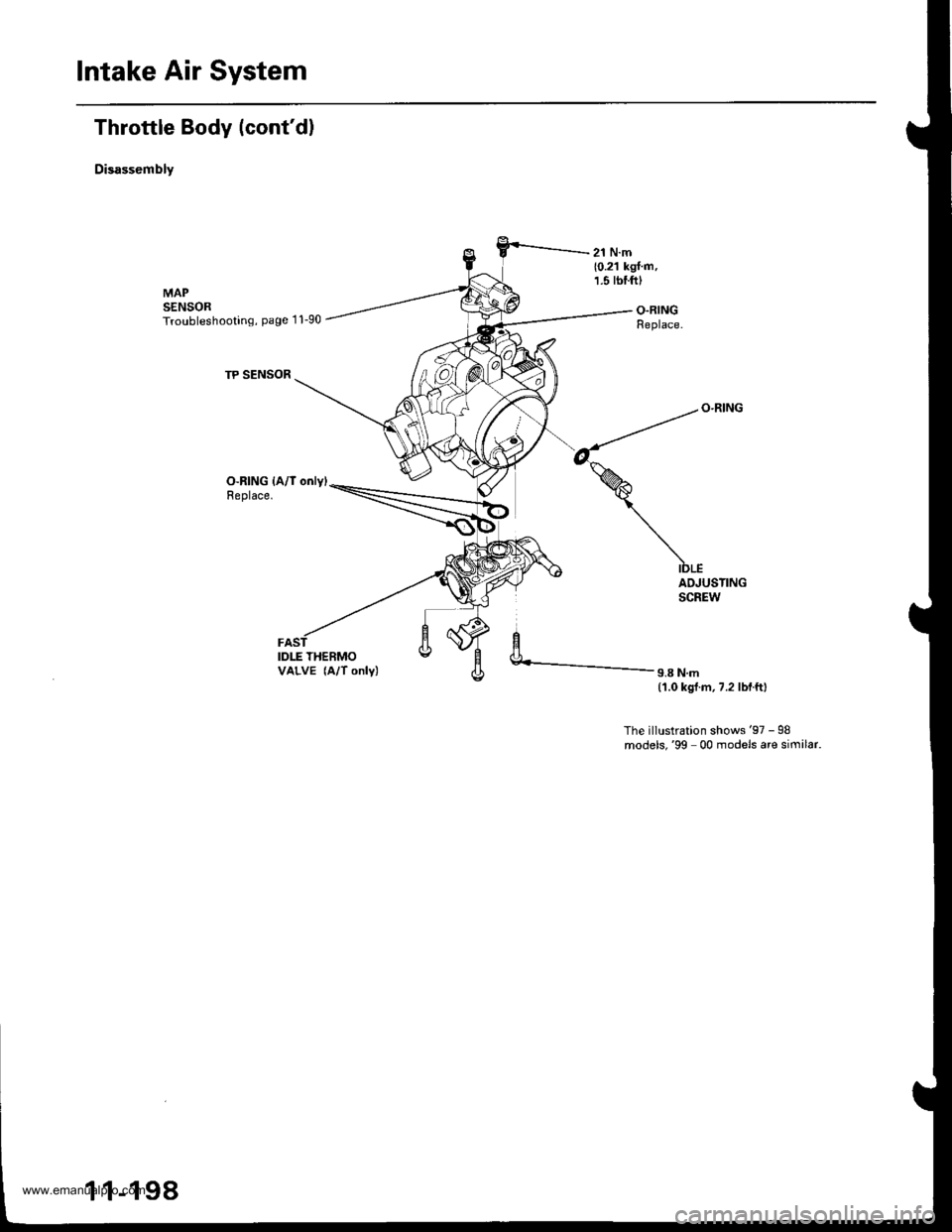

Doscription

The throttle body is a single-barrel side-draft type. The

lower portion of the throttle valve is heated by engine

coolant from the cylinder head. The idle adjusting screw

which regulates the bypass air is located on the top of

the throttle bodv.

The illustration shows'97 - 98 models,'99 - 00 rnodelsare similar.

1 1-196

lnspection

Check that the throttle cable operates smoothly without

binding or sticking.

lf there are any abnormalities, check for:. Excessive wear or play in the throftle valve shaft.. Sticky or binding throttle lever at the fully closed posi-

tton.

. Clearance between throttle stop screw and throttle

lever at the fully closed position.

97 - 98 models:

THROTTLE LINKAGE

Replace the throttle body if there is excessive play in the

throttle valve shaft or if the shaft is binding or sticking.

THROTTLE LINKAGE

www.emanualpro.com

Page 400 of 1395

Intake Air System

Throttle Body (cont'd)

Disassembly

O-RING {A/l only)Replace.

IDLE THERMOVALVE (A/T only)

ADJUSTINGSCREW

9.8 N.m(1.0 kgl.m,7.2 lbf.ftl

The illustration shows'97 - 98models,'99 00 models are similar.

1 1-198

www.emanualpro.com

Page 402 of 1395

Emission Control System

Three Way Catalytic Converter {TWCI (cont'd}

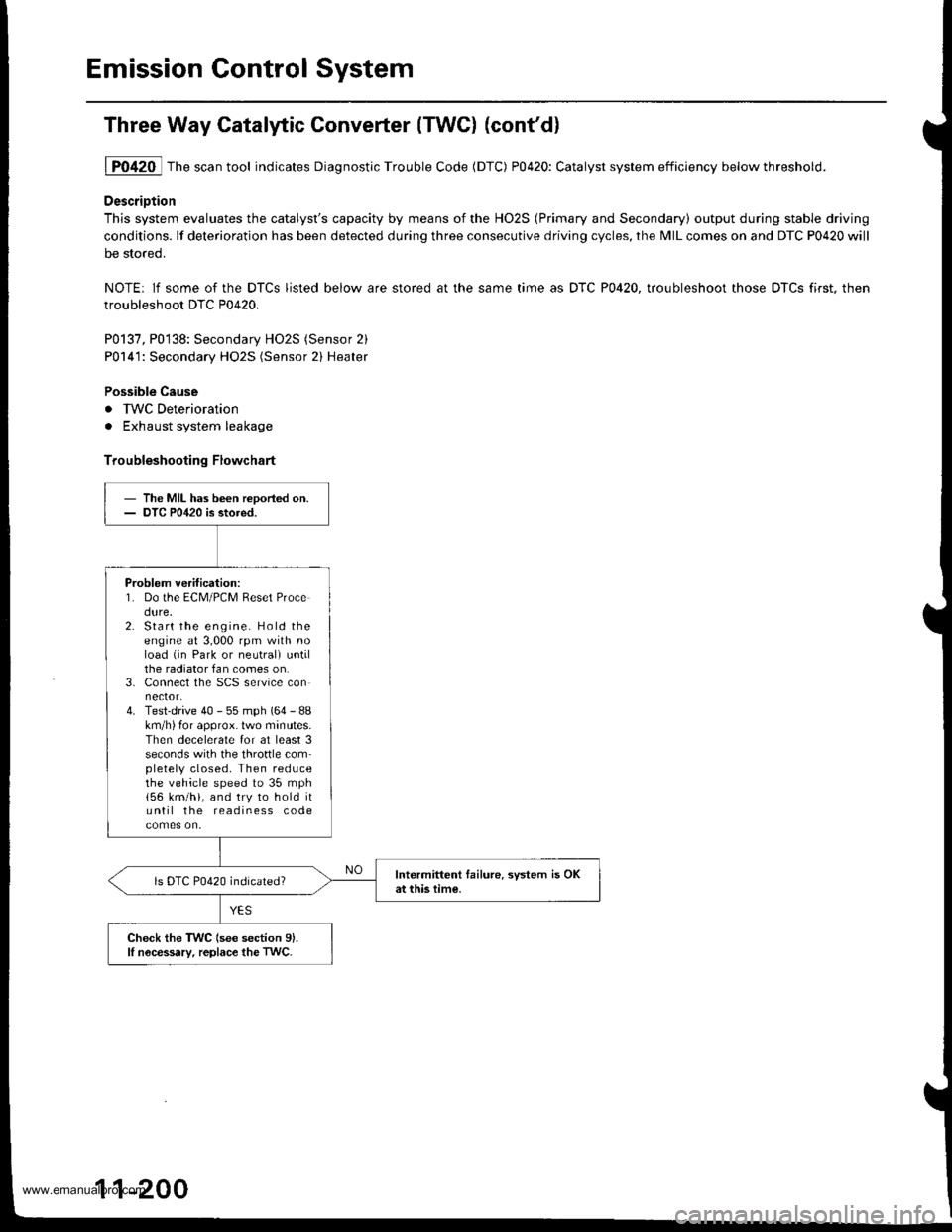

1P0420 Thescantool indicates Diagnostic Trouble Code (DTC) P0420: Catalyst system efficiency belowthreshold.

DescriDtion

This system evaluates the catalyst's capacity by means of the HO2S (Primary and Secondary) output during stable driving

conditions. lf deterioration has been detected during three consecutive driving cycles, the MIL comes on and DTC P0420 will

be stored.

NOTE: lf some of the DTCS listed below are stored at the same time as DTC P0420, troubleshoot those DTCS first. then

troubleshoot DTC P0420.

P0137, P0138: Secondary HO2S (Sensor 2)

P0141: Secondary HO2S (Sensor 2) Heater

Possible Cause

. IWC Deterioration

. Exhaust system leakage

Troubleshooting Flowchart

- The MIL has been reDoried on.- DTC P0420 is stored.

Problem verification:1. Do the ECM/PCM Reset Procedure,2. Start the engine. Hold theengine at 3,000 rpm with noload (in Park or neutrali untilthe radiator fan comes on.3. Connect the SCS service connector.4. Test-drive 40 - 55 mph (64 - 88km/h) for approx. lwo minutes.Then decelerate for at least 3seconds with the throftle completely closed. Then reducethe vehicle speed to 35 mph

156 km/h), and try to hold ituntil the readiness code

Intermittent tailure. system is OKat this time.ls DTC P0420 indicated?

Check the TWC (see section 9).lI nocessary, replace the TwC.

11-200

www.emanualpro.com

Page 407 of 1395

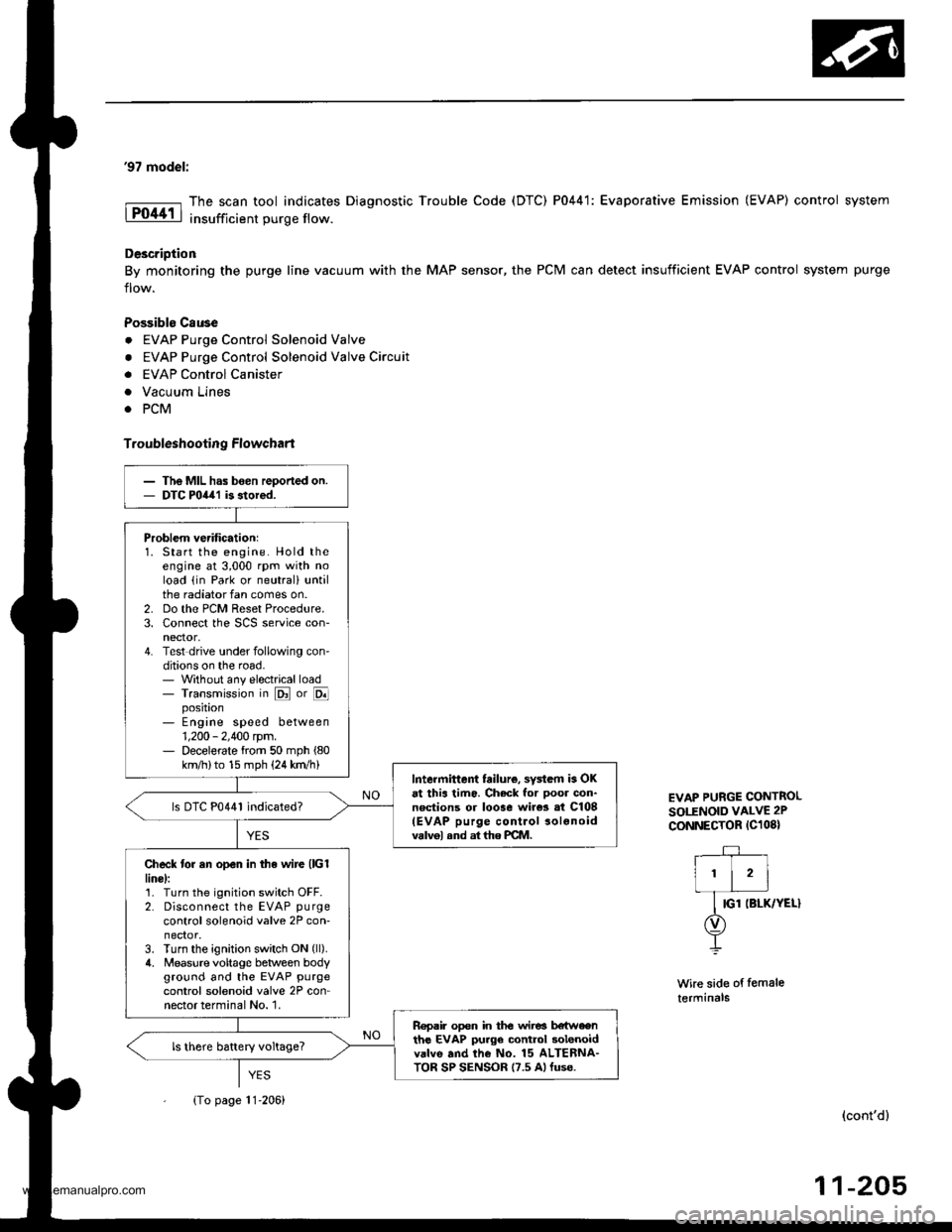

'97 model:

The scan tool indicates Diagnostic Trouble Code (DTC) P0441: Evaporative Emission (EVAP) control system

insufficient purge flow.

Description

By monitoring the purge line vacuum with the MAP sensor, the PCM can detect insufficient EVAP control system purge

flow.

Possiblo Cause

. EVAP Purge Control Solenoid Valve

. EVAP Purge Control Solenoid Valve Circuit

. EVAP Control Canister

. Vacuum Lines

. PCM

Troubleshooting Flowchart

EVAP PURGE CONTROL

SO1TNOID VALVE 2P

CoNNECTOR (C108)

(v)

YL

Wire side of female

termrnals

(cont'd)

11-205

Th€ MIL has b€en reooited on.DTC P0441 is .tored.

Problem verificationl1. Start the engine. Hold theengine at 3,000 rpm with noload (in Park or neut.al) untilthe radiator fan comes on.2. Do the PCM Reset Procedure.3. Connect the SCS service con-nector,4. Test drive under following con'ditions on the road.- without any electrical load- Transmission in @ or @position- Engine speed between1 ,2OO - 2,4OO rpfi.- Decelerate from 50 mph (80

km/h)to 15 mph (24 km/h)Intermittent trilure, sydern is OKat this time. Check for Door con-nections or loose wir€3 at C108

IEVAP purge control solonoidvalvol .nd at the PCM.

ls DTC P0441 indicated?

Check tor an open in the wire (lcl

linel:1. Turn the ignition switch OFF.2. Disconnect the EVAP purge

control solenoid valve 2P con-nector.3. Turn the ignition switch ON (ll).

4. Measure voltage between bodyground and the EVAP purge

control solenoid valve 2P con-nector terminal No. '1,

R€pafu open in thc wir6 b€tw€enthG EVAP purge control solenoidvalve and the No. 15 ALTEBNA-TOR SP SENSOR (7.5 A)fuse.

ls there batlery voltage?

(To page 11'206)

www.emanualpro.com

Page 410 of 1395

Emission Control System

Evaporative Emission (EVAP) Controls (cont'd)

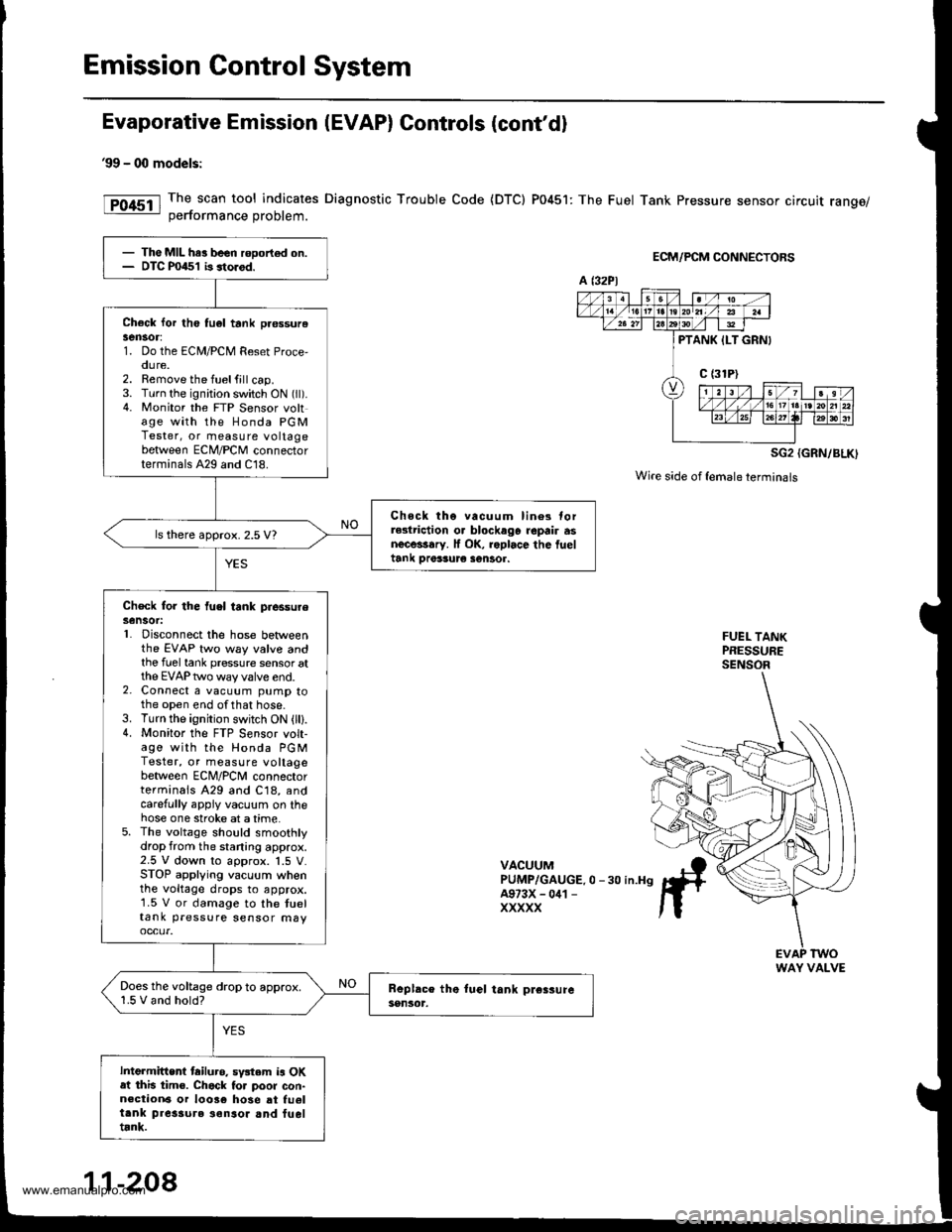

99 - 00 models:

The scan tool indicates Diagnostic Trouble Code {DTC) P0451: The Fuel Tank Pressure sensor circuit range/oerformance Droblem.

ECM/PCM CONNECTORS

SG2 {GRN/BLK)

Wire side of {emaleterminals

FUEL TANKPRESSURESENSOR

VACUUMPUMP/GAUGE.0 -30 in.H9A973X - 041 -

XXXXX

- The MIL har been rooort€d on.- DTC P0451 b storod.

Check lor th6 tu6l tank pr€ssurelen30r:1. Do the ECM/PCM Reset Proce,oure.2. Remove the fuelfill cap.3. Turn the ignition switch ON (ll).4. Monitor the FTP Sensor voltage with the Honda PGMTester, or measure voltagebetween ECM/PCM connectorterminals A29 and C18.

Chock tho vacuum lin6s torrGlriction o. blockago repair asnecessary. lf OK, roplace the fueltank Drer3ur€ sentor.

ls there approx. 2.5 V?

Check for the fuel tank piessureSensot:L Disconnect the hose betweenthe EVAP two way valve andthe fuel tank pressure sensor atthe EVAP two way valve end.2. Connect a vacuum pump tothe open end ofthat hose.3. Turn the ignition switch ON (lll.4. Monitor the FTP S€nsor volt-age with the Honda PGMTester, or measure voltagebetween ECNI/PCNI connectorterminals A29 and C18, andcarefully appiy vacuum on thehose one stroke at a time.5. The voltage should smoothlydrop from the staning approx.2.5 V down to approx. 1.5 V.STOP applying vacuum whenthe voltage drops to approx.1.5 V or damage to the tueltank pressure sensor may

Does the voltage drop to approx.1.5 V and hold?

Intermittent tailuro. sv3tem is OKat this tim€. Chack to. poor con-n€ction6 or 10036 hose at fu6ltank pres3ure ionsor and fueltrnk.

a t32Pl

PTANK ILT GRNI

WAY VALVE

11-208

www.emanualpro.com

Page 411 of 1395

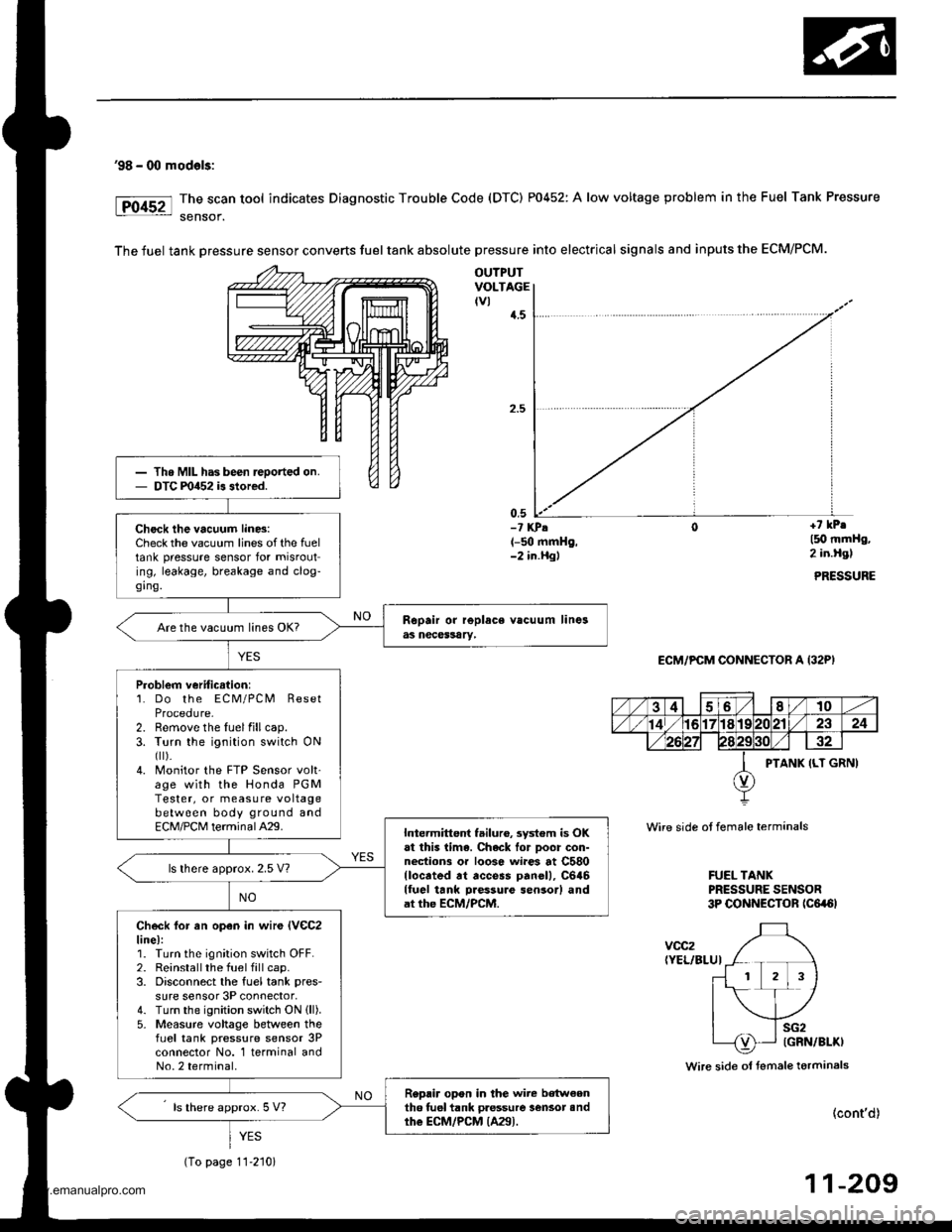

'98 - 00 mod€ls:

The scan tool indicates Diagnostic Trouble Code (DTC) P0452: A low voltage problem in the Fuel Tank Pressure

sensof.

The fuel tank Dressure sensor converts fuel tank absolute pressure into electrical signals and inputs the ECM/PCM.

OUTPUTVOLTAGEtvl{.5

0,5-? KPA(-50 mmHg,-2 in.Hgl

+7 kPr

l5O mmHg,2 in.Hgl

PRESSURE

ECM/PCM CONNECTOR A (32P)

Wire side ot female terminals

FUEL TANKPRESSURE SENSOR3P CONNECTOR tc6a6l

voc2(YEL/BLUI

Wire side ol fsmale terminals

(cont'd)

11-209

Th. MIL has been reoorted on.DTC m452 is stored.

Check the vacuum lin6:Check the vacuum lines of the fueltank pressure sensor for misrouting, leakage, breakage and clog-ging.

Are the vacuum lines OK?

Problem veriticstion:1. Do the ECM/PCM ResetProcedure-2. Remove the luelfillcap.3. Turn the ignition switch ONfl r).4. Monitor the FTP Sensor volt'age with the Honda PGMTester, or measure voltagebetween body ground andECM/PCM terminalA29.Intermittent failuro, system is OKat this lima. Chack lor Door con-nections or loose wi.es at C580llocrted rt access panell, C646lluel tank Daessure sensor) andat the ECM/PCM.

ls lhere approx. 2.5 V?

Check lor an open in wir€ lVeC2line):1. Turn the ignition switch OFF.2. Reinstallthe fuel fill cap.3. Disconnect the fuel tank pres-

sure sensor 3P connector,4. Turn the ignition switch ON (ll).

5- Measure voltage between thefLrel tank pressure sensor 3Pconnector No. 1 terminal andNo.2 terminal.

Replir opon in the wire b€tw€enth6 tuel tank pressure lensot andthe ECM/PCM {A29).ls there approx. 5 V?

YES

(To page 11-210)

www.emanualpro.com

Page 413 of 1395

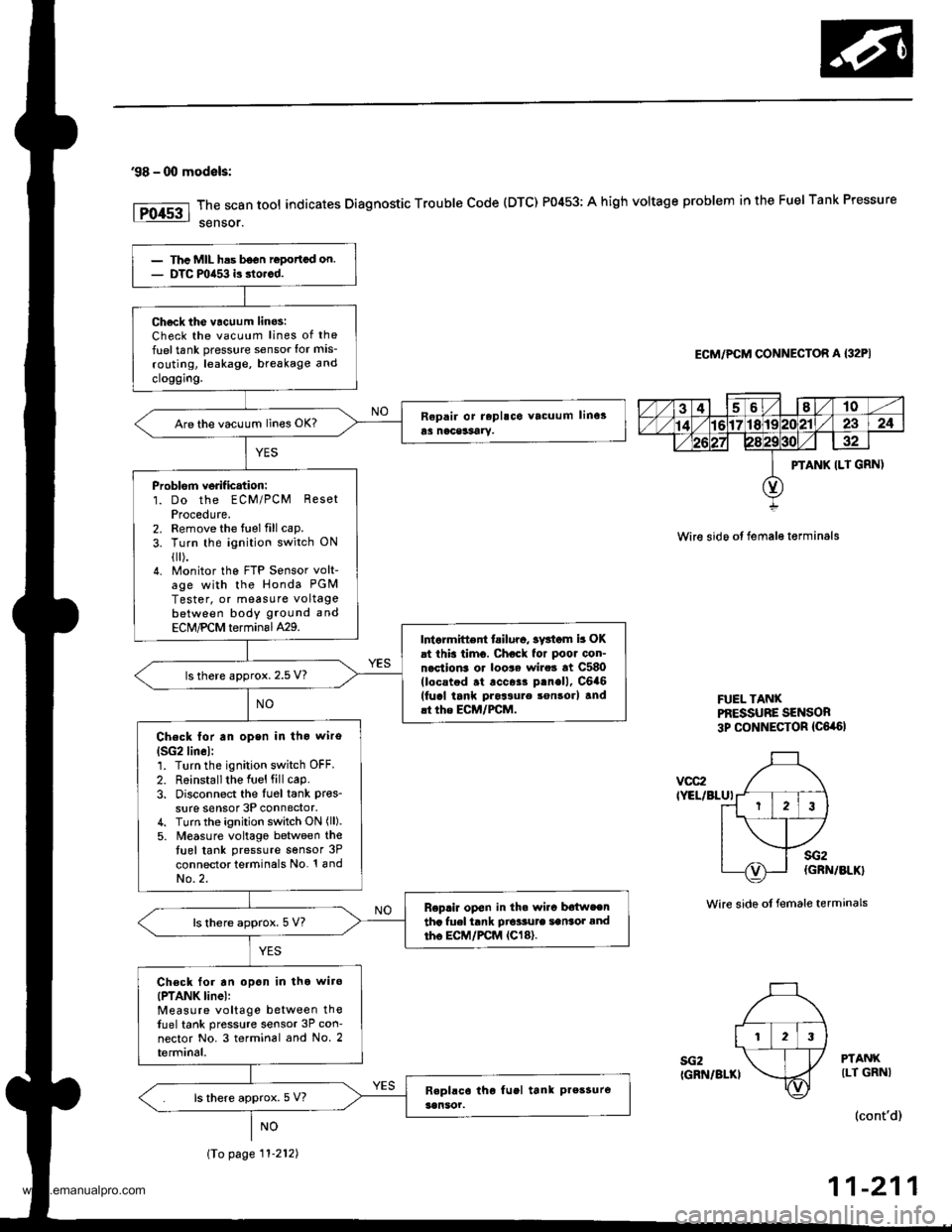

'98 - 00 modals:

The scan tool indicates Diagnostic Trouble Code (DTC) P0453: A high voltage problem in the Fuel Tank Pressure

sensor.

ECM/PCM CONNECTOR A {32PI

Wire sido ot fema16 t€rminals

FUEL TANXPf,ESSUBE SENSOR3p CONNECTOR {C6,a6l

vcc2IYEL/BLUI

sG2IGRN/BLKI

sG2(GRN/BLK}

Wire side ot female terminals

PTANKILT GRNI

(cont'd)

11-211

PTANK ILT GRN)

123

Thc MIL has b6on ropottcd on.DTC mia53 is dorcd.

Ch6ck tho vacuum linos:Check the vacuum lines of the

fuel tank pressure sensor lor mis-

routing, leakage, breakage and

cloggrng.

Are the vacuum lines OK?

Problorn verif ication:1. Do the ECM/PCM ResetProcedute.2. Remove the fuel fill cap.

3. Turn the ignition switch ON

{[).4. Monitor the FTP Sensor volt-age with the Honda PGM

Tester, or measure voltagebetween body ground and

ECM,PCM terminal429.Intarmittent tailuro, sv3iom b OKat this timo. Chock for poor con-nection3 or loo$ wire3 at C580(locstod .t .cc$r p.nell, C6a6(fucl tank pros3ure son3orl and.t the ECM/FCM.

ls there approx. 2.5 V?

Check lor an open in tho wiro

lSG2lin6l:1. Turn the ignition switch OFF.

2. R6installthe Iuel fill cap.3. Disconnect the Iu6l tank pres_

sure sensor 3P connector,4. Turn the ignition switch ON (ll).

5. M€asure voltago between thetuel tank pressure sensor 3P

connector terminals No. '! andNo.2.

Replir op€n in th. wi.c b€{weentha fuel tank Dio'sute sansot andtho EC|,/PCM {Cl8}.ls there approx. 5 V?

Ch€ck for an opon in tho wiro(PTANK linel:Measure voltage between thefuel tank pressure sensor 3P con-nector No. 3 terminal and No. 2terminal.

ls there approx. 5 V?

\To page 11-212)

www.emanualpro.com

Page 415 of 1395

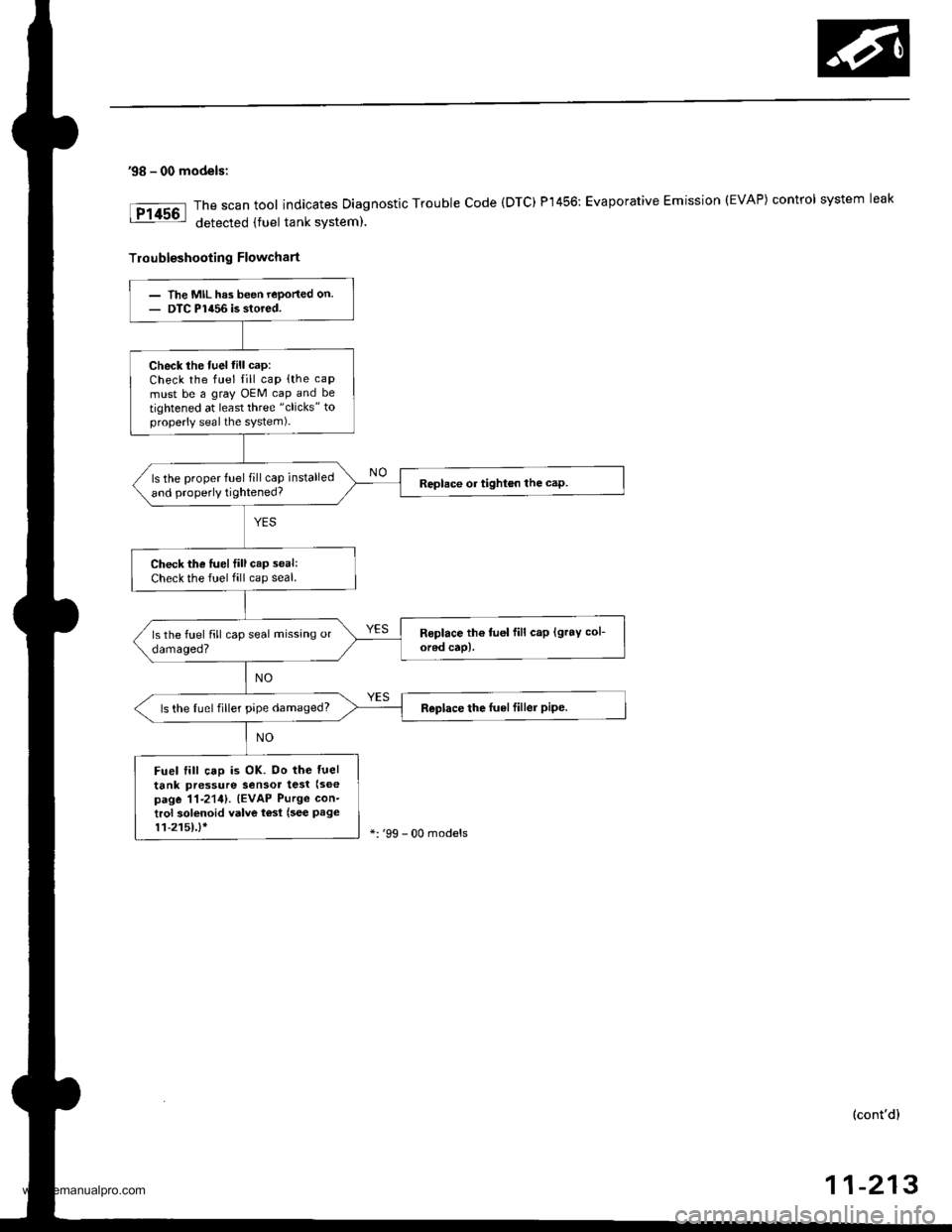

'98 - 00 models:

The scan tool indicates Diagnostic Trouble code (DTC) P1456: Evaporative Emission (EVAP) control system leak

detected {fuel tank system).

Troubleshooting Flowchart

- The MIL has been reported on.- DTC P1456 is stored.

Check the fuel fill cap:Check the fuel fill cap (the caP

must be a gray OEM cap and be

tightened at least three "clicks" toproperly seal the system)-

ls the proper fuel fill cap installed

and properly tightened?Replace or tighton the cap.

Check the lueltill cap seal:

Check the fuel fill cap seal.

Replace the luelfiller pipe.ls the tuel filler pipe damaged?

Fuel till caD is OK. Do the luel

tank pressure Sensor test (see

page 11-2111. (EVAP Purge con-

trol solenoid valve t€sl (see Page11-2151.1r':'99 - 00 models

(cont'd)

11-213

www.emanualpro.com

Page 421 of 1395

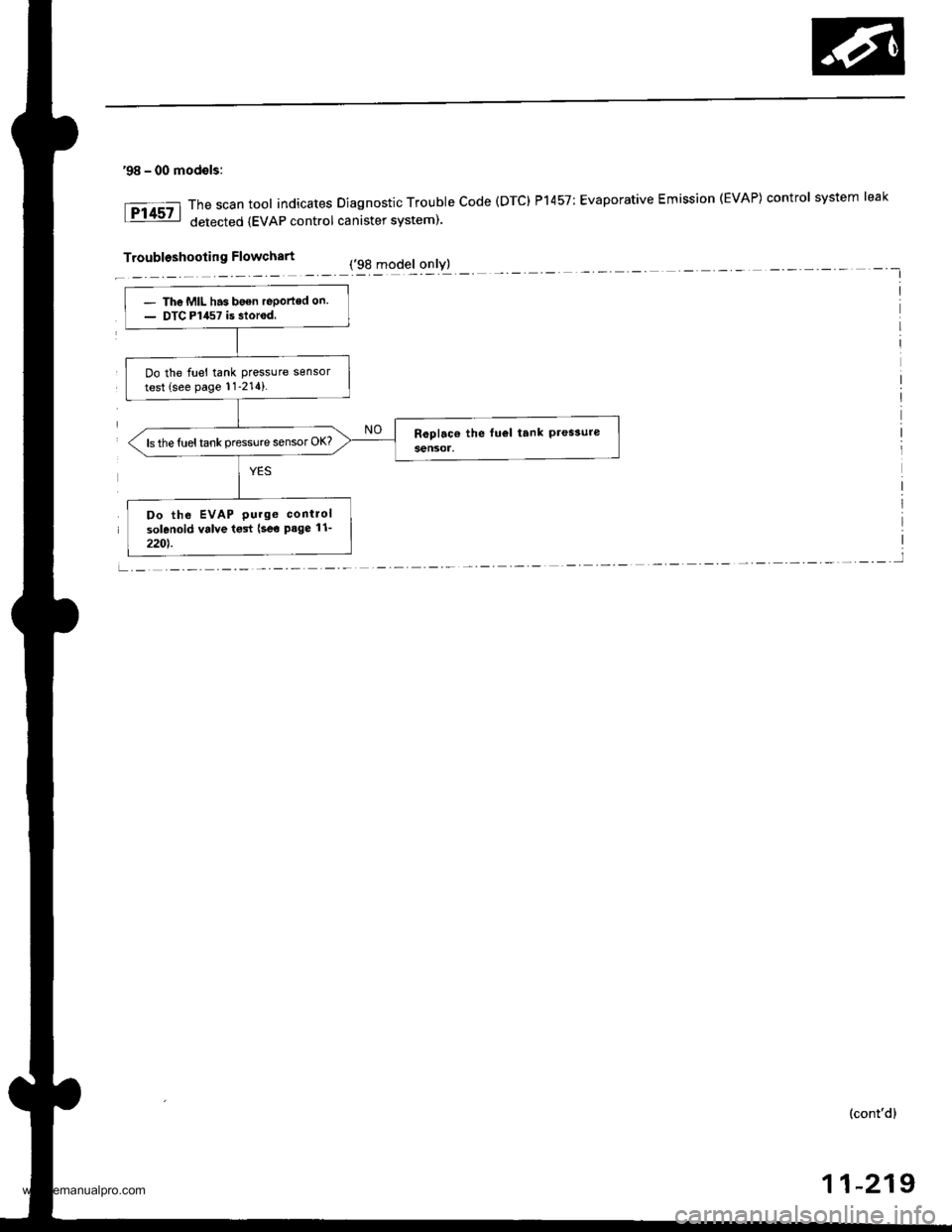

'98 - 00 mod€ls:

The scan tool indicates Diagnostic Trouble code (DTc) P1457: Evaporative Emission (EVAP) Control system leak

detected (EVAP control canister system).

Troubl6shooting Flowchart('98 model only)_]

I

- The MIL has been rePorted on.- DTC P1,157 is storod.

Do the fuel tank Pressure sensor

test {see page 11-214).

ls the {ueltank pressure sensor OK?

Do the EVAP Purge contlol

solenoid valve test lsea Page 1l_

220t.

(cont'dl

11-219

www.emanualpro.com