Troubleshooting HONDA CR-V 1998 RD1-RD3 / 1.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1998, Model line: CR-V, Model: HONDA CR-V 1998 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 851 of 1395

Troubleshooting

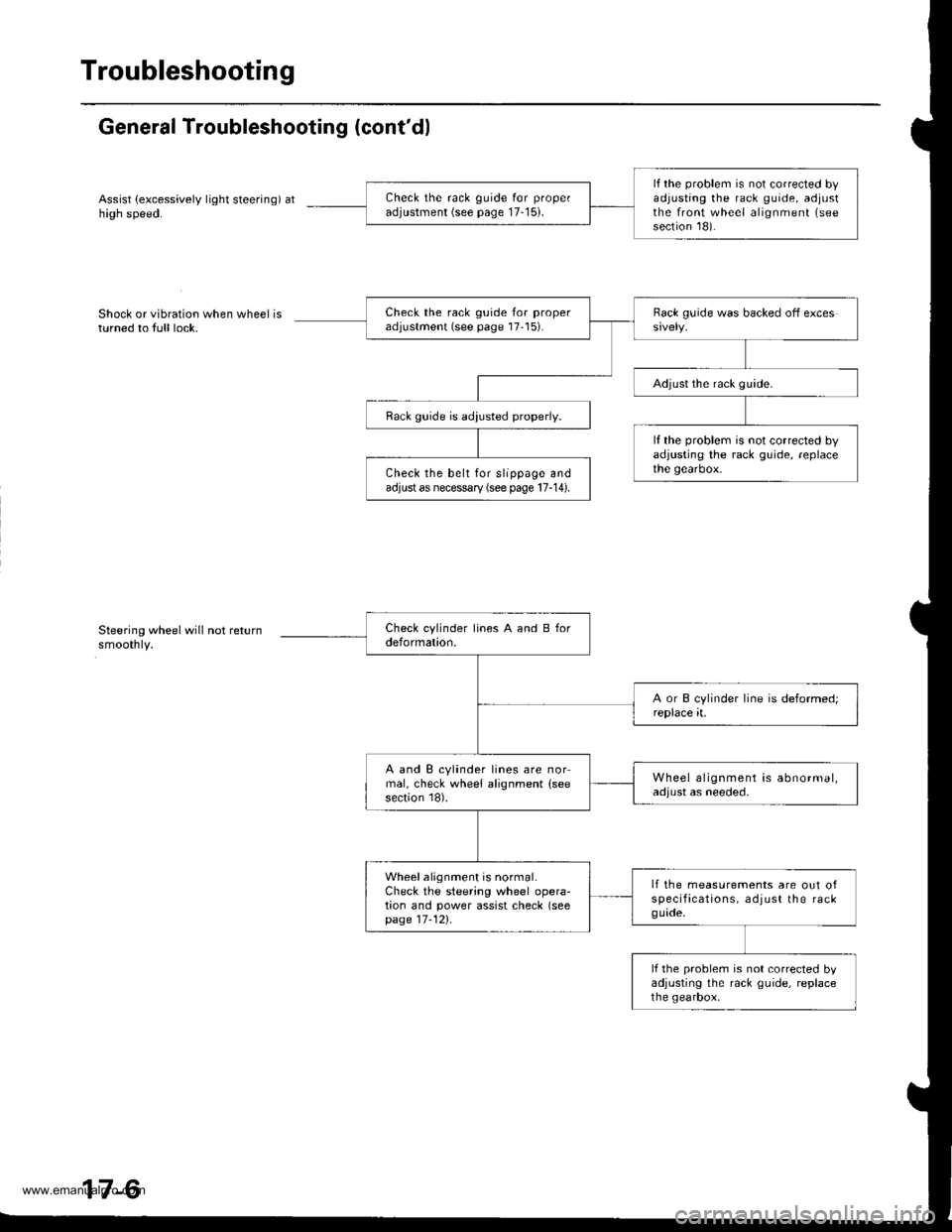

General Troubleshooting (cont'dl

Assist (excessively light steering) athigh speed.

Shock or vibration when wheel isturned to full lock.

Steering wheel will not returnsmoothly.

lf the problem is not corrected byadjusting the rack guide, adjustthe front wheel alignment (see

section 18).

Check the rack guide for proper

adjustment (see page 17-15).

Check the rack guide for properadjustment (see page 17'15).

Adjust the rack guide.

Rack guide is adiusted properly.

lf the problem is not corrected byadjusting the rack guide, replacethe gearbox.Check the belt for slippage andadjust as necessary (see page 17-14).

A and B cylinder lines are normal, check wheel alignment (see

section 18).

Wheel alignment is abnormal,adjust as needed.

Wheel alignment is normal.Check the steering wheel opera-tion and power assist check (seepage 17-121.

lf the measurements are out ofspecifacations, adjust the rackguade.

lf the problem is not corrected byadjusting the rack guide, replacethe gearbox,

www.emanualpro.com

Page 853 of 1395

Troubleshooting

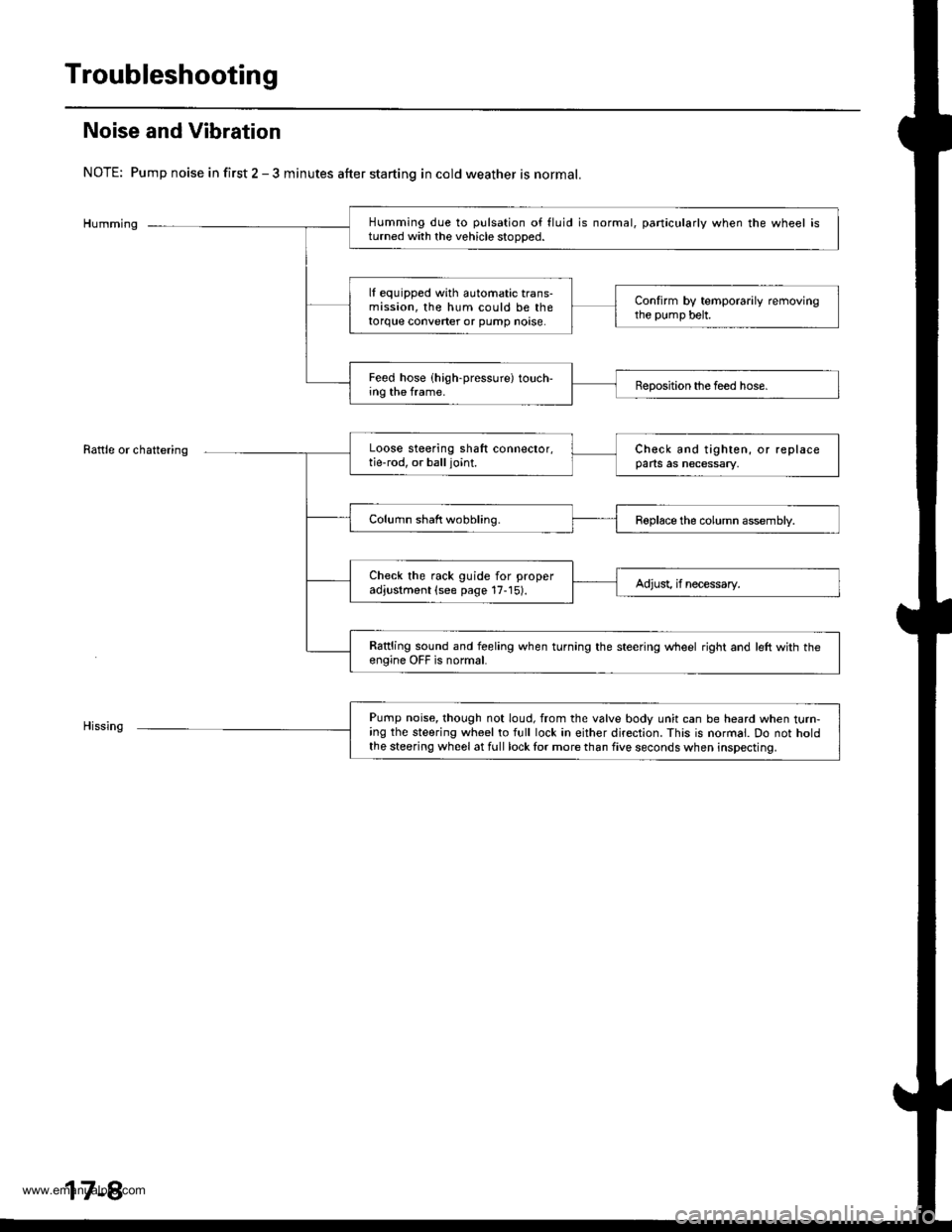

Noise and Vibration

NOTE: Pump noise in first 2 - 3 minutes after starting in cold weather is normal.

Humming

Rattle or chattering

Humming due to pulsation of fluid is normal, particularly when the wheel isturned with the vehicle stooDed.

lf equipped with automatic trans-mission, the hum could be thetorque converter or pump noase.

Confirm by temporarily removingthe pump belt.

Feed hose (high-pressure) touch-ing the frame.Beposition the feed hose.

Loose steering shaft connector,tie-rod, or balljoint.Check and tighten, or replaceparts as necessary,

Column shaft wobbling.Roplace the column assembly.

Check the rack guide for properadjustment (see page 17-15).Adjust, if necessary.

Rattling sound and feeling when turning the steering wheel right and left with th€engine OFF is normal.

Pump noise, though not loud, from the valve body unit can be heard when turn-ing the steering wheel to full lock in either direction. This is normal. Do not holdthe steering wheel at full lock lor more than five seconds when inspecting.

17-8

www.emanualpro.com

Page 855 of 1395

Troubleshooting

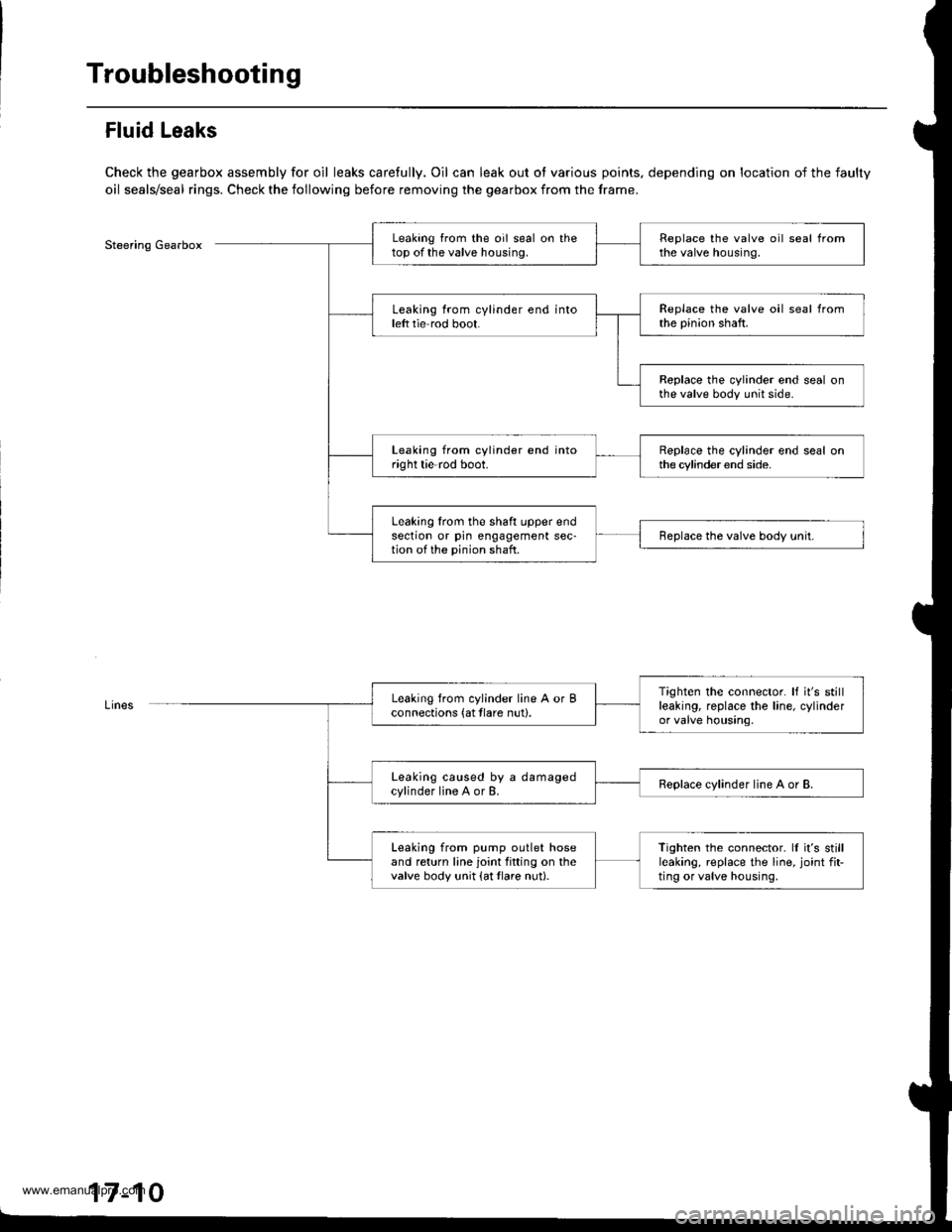

Fluid Leaks

Check the gearbox assembly for oil leaks carefully. Oil can leak out ot various points, depending on location of the faulty

oil seals/seal rings. Check the following before removing the gearbox from the frame.

Steering GearboxLeaking from the oil seal on thetop of the valve housing.Replace the valve oil seal fromthe valve housing.

Leaking from cylinder end intoleft tie rod boot.Replace the valve oil seal fromthe pinion shaft.

Replace the cylinder end seal onthe valve body unit side.

Leaking from cylinder end intoright tie-rod boot.Replace the cylinder end seal onthe cylinder end side.

Leaking lrom the shaft upper endsection or pin engagement sec-tion of the pinion shaft.Replace the valve body unit.

Tighten the connector. It it's stillleaking, replace the line, cylinderor valve housing.

Leaking from cylinder line A or Bconnections (at tlare nut).

Leaking caused by a damagedcylinder line A or B.Replace cylinder line A or B.

Leaking from pump outlet hoseand return line joint fitting on thevalve body unit {at tlare nut}.

Tighten the connector. ll it's stillleaking, replace the line, joint fit-ting or valve housing,

17-10

www.emanualpro.com

Page 861 of 1395

lnspection and Adjustment

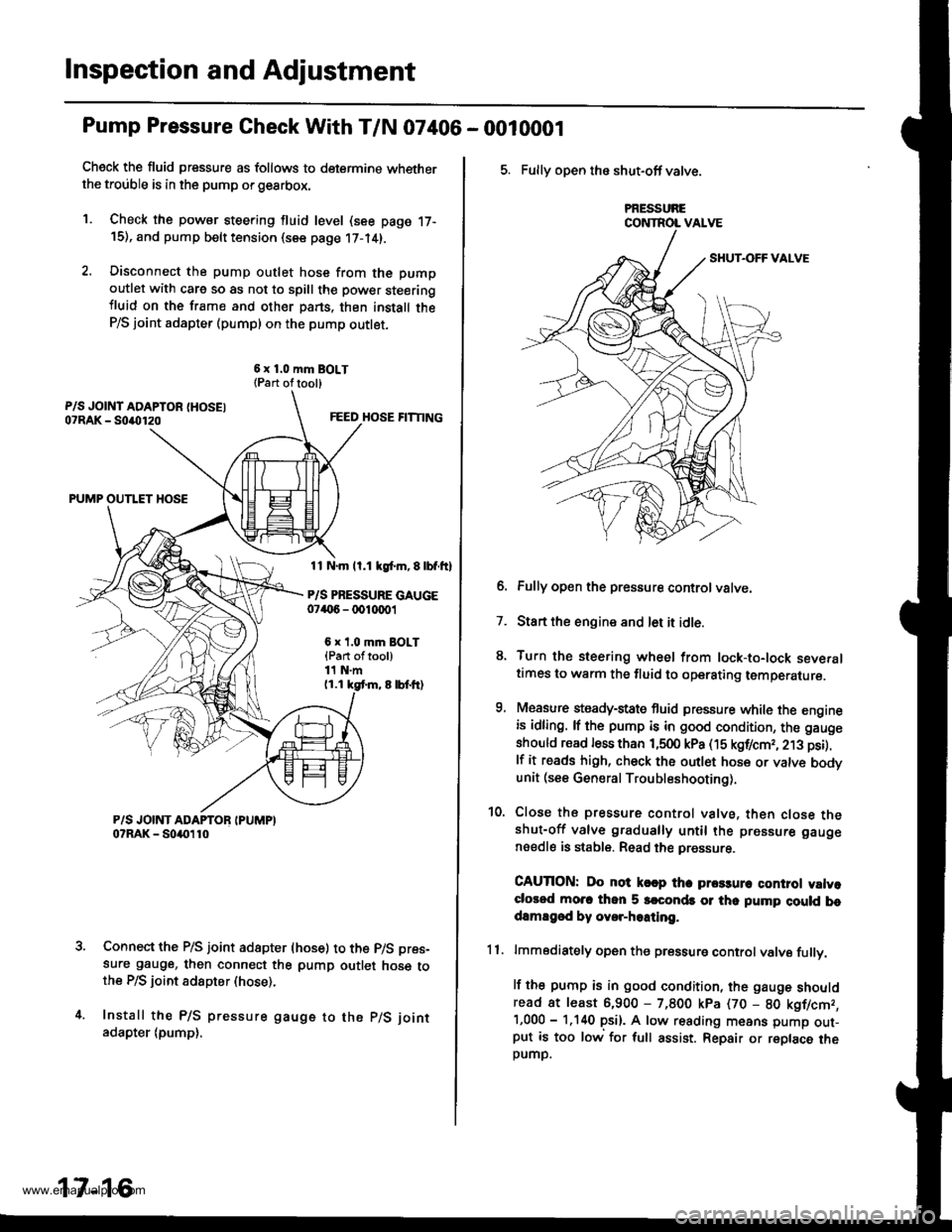

Pump Pressure Gheck With T/N 07406 - 0010001

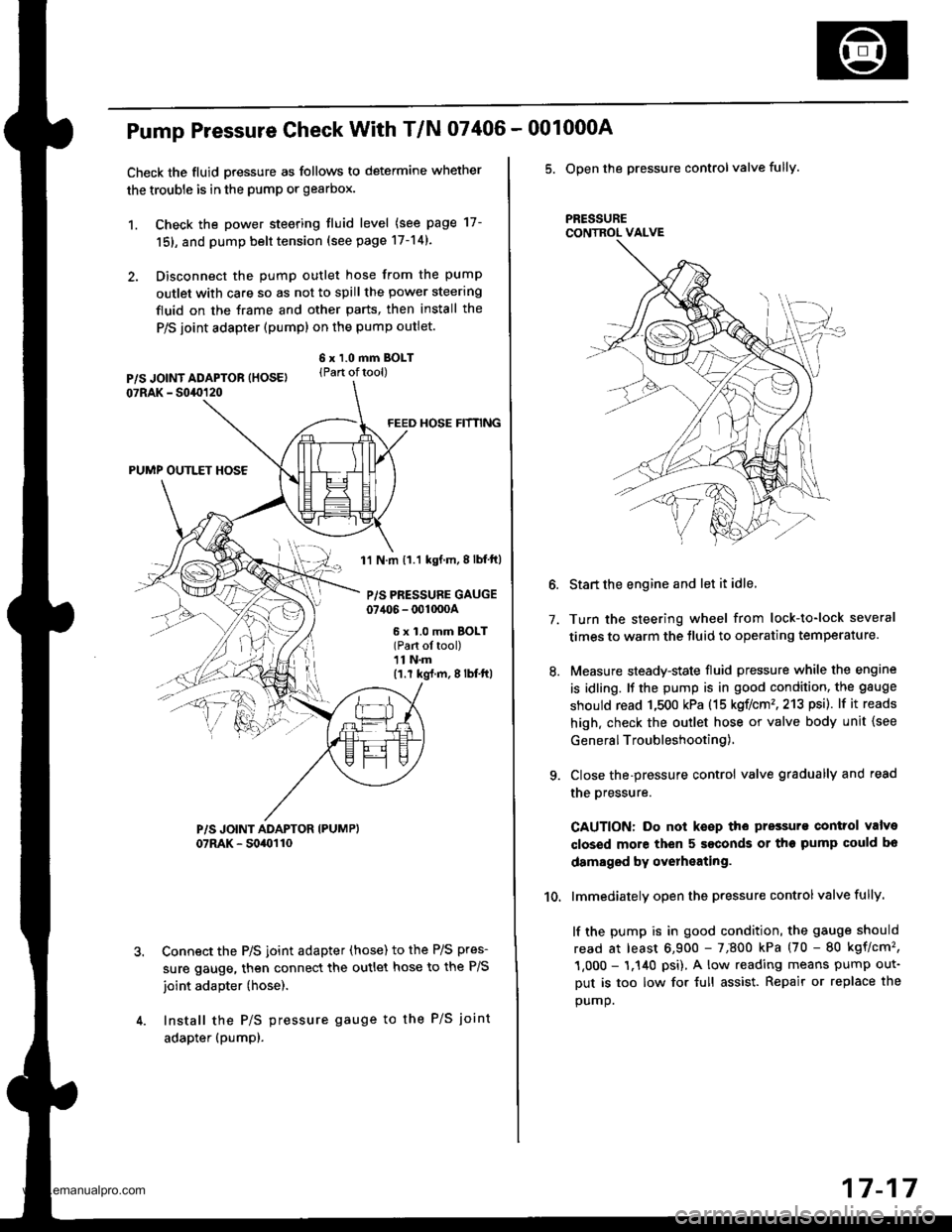

Check the fluid pressure as follows to determine whetherthe trouble is in the pump orgearbox.

1. Check the powsr steering fluid level (see page 17-15), and pump belt tension (see page 17-14).

2. Disconnect the pump outlet hose from the pump

outlet with care so as not to spill the pow€r steeringiluid on the frame and other pans. thon install theP/S joint adapter (pumpl on the pump outlet.

6 x 1.0 mm BOLT{Part oftool)

FEED HOSE FITTING

PUMP OUTLET HOSE

11 N.m ll.1 kgl.m, E lbf.ftl

P/S PRESSURE GAUGE07('6 - 0010001

6 x t.0 mm BOLT{Part oftool)11 N.m(1.1 kgt m, 8 lbf.tr)

Connect the P/S joint adapter (hose) to the p/S pres-

sure gauge, then connect the pump outlet hose tothe P/S ioint adspter (hose).

Install the P/S pressure gauge to the p/S joint

adapter (pump),

17-16

5. Fully open the shut-off valve.

PRESSURECONTROL VALVE

6. Fully open the pressure controlvatve.

7. Start the engine and let it idle.

8. Turn the steering wheel from lock-to-lock severaltimes to warm the fluid to operating temperature.

9, Measure steady-state fluid pressure while the engineis idling. lf the pump is in good condition, the gauge

should read less than 1,500 kPa (15 kgf/cmr, 213 psi).

lf it reads high, check the outlet hose or valve bodvunit (see General Troubleshooting).

10. Close the pressure control valve, then close theshut-off valve gradually until the pressure gauge

nsedle is stable. Read the pressure.

CAUTION: Do not k€ap tha prca3un control valvoclorod mo.c thon 5 srconds or thc pump cluld bodamEgod by ovor-hoating.

11. lmmodiately open the pressure controlvalve fullv.

lf the pump is in good condition, the gauge shouldread at least 6,900 - 7,800 kpa (70 - 80 kgflcmr,'1,000 - 1.140 psi). A low reading means pump out-put is too low for full assist. Repair or replace theDUMD.

www.emanualpro.com

Page 862 of 1395

Pump Pressure Check With T/N 07406 -

Check the fluid pressure as follows to determine whether

the trouble is in the pump or gearbox.

1. Check the power steering tluid level (see page 17-

151, and pump belt tension (see page 17-14).

2. Disconnect the pump outlet hose from the pump

outlet with care so as not to spill the power steering

fluid on the frame and other parts, then install the

P/S joint adapter (pump) on the pump outlet.

6 x 1.0 mm BOLT(Part oftool)

FEED HOSE HfNNG

PUMP OUTLET HOSE

1'l N.m 11.1 kgf.m,8lbf ft)

P/S PRESSURE GAUGE07406 - 001000A

6 x 1.0 mm BOLT(Part ol tool)11 N.m(1.r kg{.m,8lbf'ft|

Connect the P/S joint adapter (hose) to the P/S pres-

sure gauge, then connect the outlet hose to the P/S

joint adapter (hose).

Install the P/S pressure gauge to the P/S joint

adapter (pumpl.

001000A

5. Open the pressure controlvalve fully.

PRESSURECONTROL VALVE

7.

10.

Start the engine and let it idle.

Turn the steering wheel from lock-to-lock several

times to warm the tluid to operating temperature.

Measure steady-state fluid pressure while the engine

is idling. It the pump is in good condition, the gauge

should read 1,500 kPa (15 koflcm'�,213 psi). lf it reads

high. check the outlet hose or valve body unit {see

General Troubleshooting),

Close the-pressure control valve gradually and read

the oressure.

CAUTION: Do not keep the pressurs control valve

closed more then 5 seconds or the pump could bo

damaged by overheating.

lmmediately open the pressure controlvalve fully.

lf the pump is in good condition, the gauge should

read at least 6,900 - 7;800 kPa (70 - 80 kgflcm'�,

1,000 - 1.140 psi), A low reading means pump out-

Dut is too low for {ull assist. Repair or replace the

oumo.

17-17

www.emanualpro.com

Page 948 of 1395

Anti-lock Brake System (ABSI,'97 - 00 Models

Special Tools ............. 19-26

Component Locations ......................... 19-27

Anti-lock Brake System (ABS)

Features/Construction ............. ......, 19-2A

Circuit Diagram ......... 19-32

ABS Control Unit Terminal

Arrangement ......... 19-34

Troubleshooting Precautions ............. 19-36

Diagnostic Trouble Gode (DTC)

Diagnostic Trouble Code (DTC)

Indication (SCS Model ................ 19-38

DTG Erasure (MES Mode) ............... 19-39

Troubleshooting lndex .................... 19-40

Troubleshooting

ABS Indicator Light Does Not

Come On ............ 19-41

ABS Indicator Light Does Not

Go Off (No DTC) ........................... 19-43

DTC 1r - 18:

Wheel Sensor .... 19-45

DTC 31 - 38:

Solenoid ............. 19-47

DTC 51 - 53:

ABS Pump Motor ......................... 19-49

DTC 54:

Main Relay ......... 19-52

DTC 61:

lgnition Voltage ........................... 19-54

DTC 81:

Central Processing Unit (CPU) .... 19-55

Modulator Unit

Removal/lnstallation ....................... 19-56

ABS Control Unit

Replacement ..,...... 19-57

Pulsers/Wheel Sensors

Inspection .............. 19-57

Wheel Sensor Replacement ............ 19-58

www.emanualpro.com

Page 959 of 1395

Troubleshooting Precautions

ABS lndicalor

1 lf the system is oK, the ABS indicator goes off two seconds after turning the ignition switch oN 1l) wathout staningthe engine, and then comes on again and goes off after two seconds. This occurs because the ABS control unit isturned on by the lG2 power source.2. The ABS indicator comes on when the ABS control unit detects a problem in the system. However, even thouoh thesystem is operating properly, the ABs indicator will come on too, under the following conditions:. Signal disturbance

. Wheel spin

. Only drive wheels rotate. Battery voltage fluctuates

To determine the actual cause of the problem, question the customer about the problem, taking these conditions intoconsideration:

3 When a problem is detected and the ABS indicator comes on, the indicator can stay on until the ignition switch isturned OFF, or it can automatically go off, depending on the mode.. Indicator stays on untilthe ignition switch is turned off: When the system is in the system down mode.. Indicator automatically goes off: When the system is in the control inhibition mode.4 The ABS indicator stays on when the system is reactivated without erasing the DTC, but it goes off after starting thevehicle.

When the wheel sensor system is faulty and the ABS indicator comes on. the algorithm of the system automatically turnsoff the ABS indicator after the wheel speed signal returns to the normal speed. Also, when the DTc is erased, the cpu isreset and the ABS indicator goes off when the system checked out normal by the initial diagnosis.Therefore, test-drive the vehicle after servicing the wheel sensor system. and be sure that the ABS indicator does notcome on.

5 When the ABS control unit outputs battery voltage to the gauge assembly, the ABS indicator ooes off.

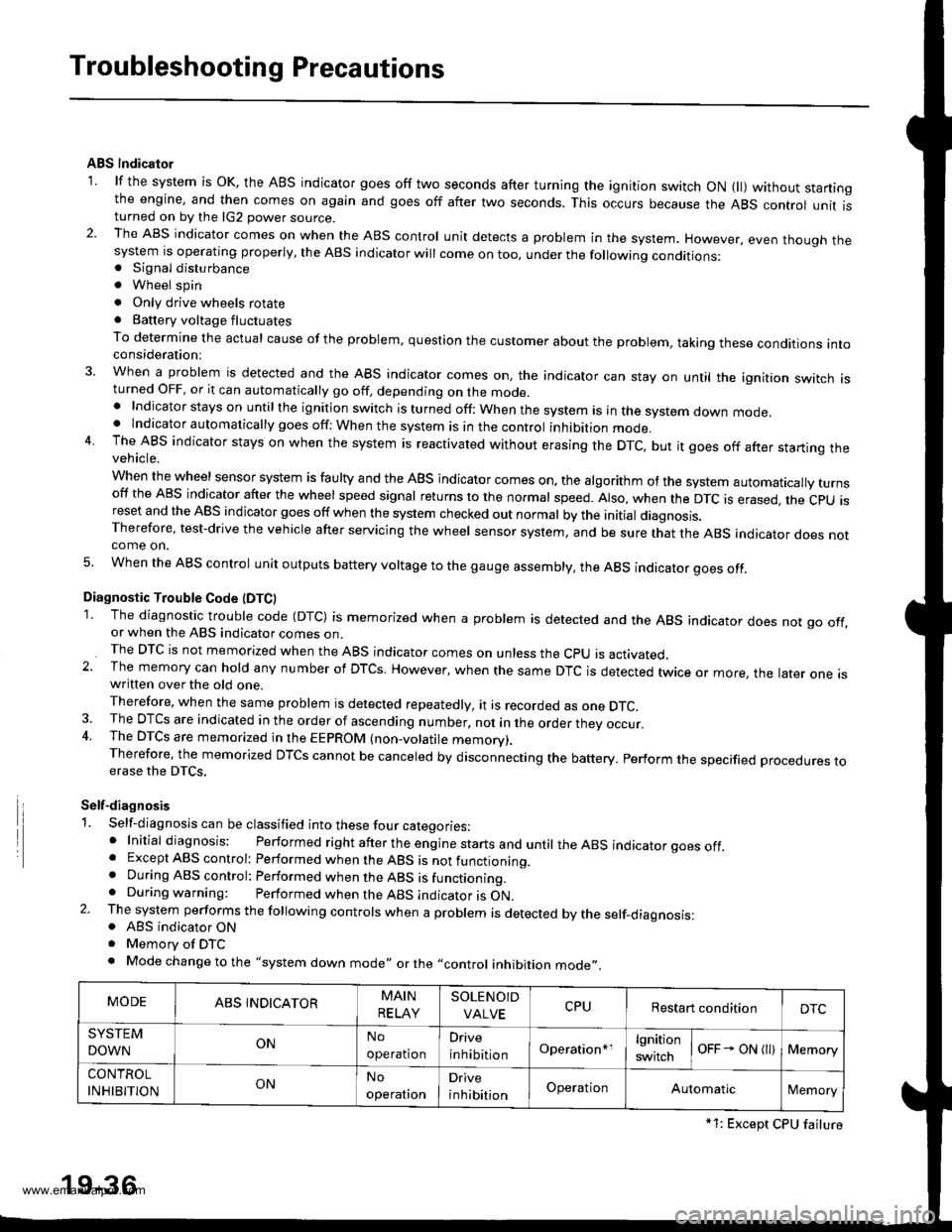

Diagnostic Trouble Code (DTCI

1. The diagnostic trouble code (DTc) is memorized when a problem is detected and the ABS indicator does not go off,or when the ABS indicator comes on.The DTc is not memorized when the ABS indicator comes on unress the cpu is activated,2 The memory can hold any number of DTCs. However, when the same DTc is detected twice or more, the tater one iswritten over the old one.

Therefore, when the same problem is detected repeatedly, it is recorded as one DTC.3. The DTCs are indicated in the order of ascending number, not in the order they occur.4. The DTCS are memorized in the EEPROM (non-volatile memorv).Therefore, the memorized DTcs cannot be canceled by disconnecting the battery. perform the specified procedures toerase the DTCS.

Self-diagnosis

1. Self-diagnosis can be classified into these four categories:' Initial diagnosis: Performed right after the eng ine starts and untir theABS indicator goes off.. Except ABS control: Performed when the ABS is not functioning.. During ABS control: Performed when the ABS is functioning.. During warning: Performed when the ABS indicator is ON.2. The system performs the fo|owing contrors when a probrem is detected by the serf-diagnosis:. ABS indicator ON. Memorv of DTC. Mode changetothe "system down mode,, or the ,,control inhibition mode,,.

MODEABS INDICATORMAIN

RELAY

SOLENOID

VALVECPURestart conditionDTC

SYSTEM

DOWNONNo

operation

Drive

inhibitionOperation*rlgnition

switchoFF - ON l)Memory

CONTROL

INHIBITIONONNo

operal|on

Drive

inhibitionOperationAutomaticlMemory

*1: Except CPU failure

19-36

www.emanualpro.com

Page 960 of 1395

Kickback'1. The motor operates when the ABS is functioning. and the fluid in the reservoir is forced out to the master cylinder,

causing kickback at the brake pedal.

2. The ABS control unit operates the solenoid valve when the brake pedal is released after the initial diagnosis You may

hear the solenoid valve operate at this time, but it is normal

Pumo Motol

1. The pump motor operates when the ABS is functioning

2. The ABS control unit checks the pump motor operation during acceleration. You may hear the motor operate at this

time, but it is normal.

Brake Fluid Replacement/Ail Bleeding

L Brake fluid replacement and air bleeding procedures are the same as for vehicles without ABS To ease bleeding, start

with the front wheels.

Troubleshooting

1. The troubleshooting flowchart procedures assume that the cause of the problem is still present and the ABS indicator

is still on. Following the flowchart when the ABS indicator does not come on can result in incorrect diagnosis.

2. Ouestion the customer about the conditions when the problem occurred, and try to reproduce the same conditions

for troubleshooting.

Self-diagnosis is made at various times such as the initial diagnosis, except ABS control, during ABS control, during

acceleration, during the specified vehicle speed, etc. Therefore, the symptom canngt be checked unless the check

conditions match with the problem conditjons

3. When the ABS jndicator does not come on during the test-drive. but troubleshooting is performed based on the DTC,

check lor loose connectors, poor contact of the terminals, etc., before you start troubleshooting.

4. After troubleshooting, erase the DTC and test-drive the vehicle. Be sure the ABS indicator does not come on.

5. The connector illustratjons show the female terminals with a single outline and the male terminals with a double out-

l ne.

ABS Function Test

To simulate ABS operation and activate the solenoid valves and pump, use the Honda PGM Tester.

Connect the PGM Tester to the 16P Data Link Connector (DLC). When the System Select menu is displayed, select the ABS

Test Mode menu, and follow the tester's prompts.

19-37

www.emanualpro.com

Page 963 of 1395

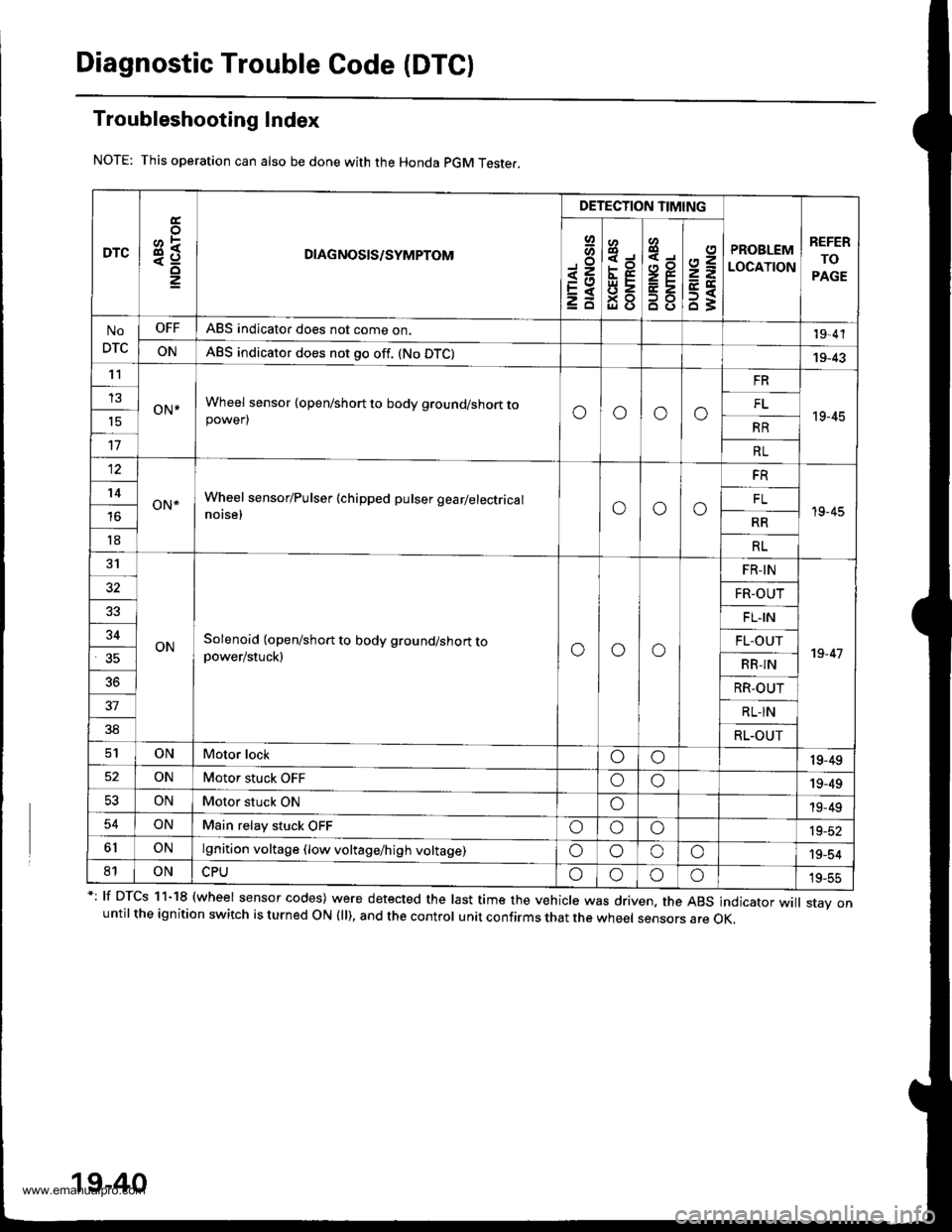

Diagnostic Trouble Code (DTC)

Troubleshooting Index

This operation can also be done with the Honda pGM Teste..

*: lf DTcs 11-18 {wheel sensor codes) were detected the last time the vehicle was driven, the ABs indicator wi

stav onuntil the ignition switch is turned ON (ll), and the control unit confirms that the wheel sensors are OK,

19-40

DTC3R

DETECTION TIMING

PROBLEM

LOCATION

REFER

TO

PAGE

Io

<=EXzd

8

93gl (J

4,,to

B8

2=

ET63

No

DTC

OFFABS indicator does not come on.19,4'l

ONABS indicator does not go off. (No DTC)19-43't1

oN*Wheel sensor {open/short to body ground/short topower)oooo

FR

19-45

13FL't5RR

17RL

12

oN*Wheel sensor/Pulser (chipped pulser gearlelectrical

notse,ooo

FR

19-45

't4FL

RR

18RL

31

ONSolenoid (open/short to body ground/short topower/stuck)ooo

FR-IN

19-47

32FR-OUT

FL.IN

34FL-OUT

RB-IN

36RR-OUT

37RL-IN

38RL.OUT

ONMotor lockoo19-49

ONMotor stuck OFFoo19-49

53ONMotor stuck ONo19-49

54ONMain relay stuck OFFoooia_at

6lONlgnition voltage (low voltage/high voltage)oooo'19-54

81ONoooo19-55

www.emanualpro.com

Page 964 of 1395

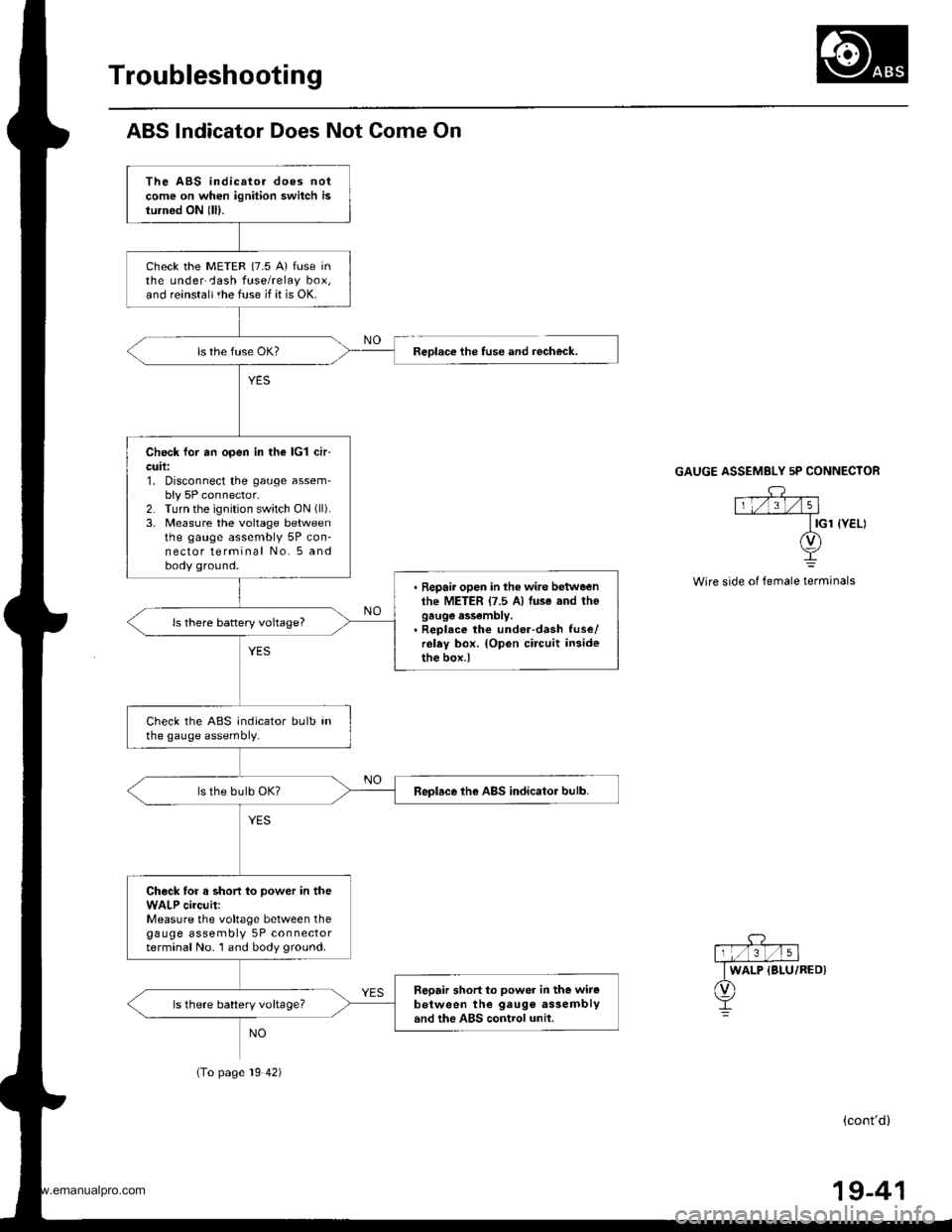

Troubleshooting

ABS lndicator Does Not Come On

The ABS indicator does notcome on when ignition switch isturnod ON lll).

check the METER {7.5 A} fuse inthe underCash fuse/relay box,and reinstaltthe fuse if it is OK.

Check for an open in the lcl ch-cuil:1. Disconnect the gauge assem-bly 5P connector.2. Turn the ignition switch ON (ll).

3. Measure the voltage betweenthe gauge assembly 5P con-nector terminal No. 5 andbody ground.

. Repair open in the wire betweenlhe METER {7.5 A) luse and thogauge assembly.. Reolece the under-dash fuse/relay box. (Opon circuit insidethe box.)

ls there battery voltage?

Check the ABS indicator bulb inthe gauge assembly.

Replace the ABS indicator bulb.

Check for a short to power in theWALP circuit:Measure the voltage between thegauge assembly 5P connectorterminal No. 1 and body ground.

Sepair short to power in the witeb€tween the gaug€ assemblyand the ABS control unil.ls there battery voltageT

Reolace the tuse and recheck.

(To page 19 42)

GAUGE ASSEMBLY 5P CONNECTOR

Wire side of female terminals

(cont'd)

19-41

www.emanualpro.com