Troubleshooting HONDA CR-V 1998 RD1-RD3 / 1.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1998, Model line: CR-V, Model: HONDA CR-V 1998 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 1106 of 1395

Troubleshooting

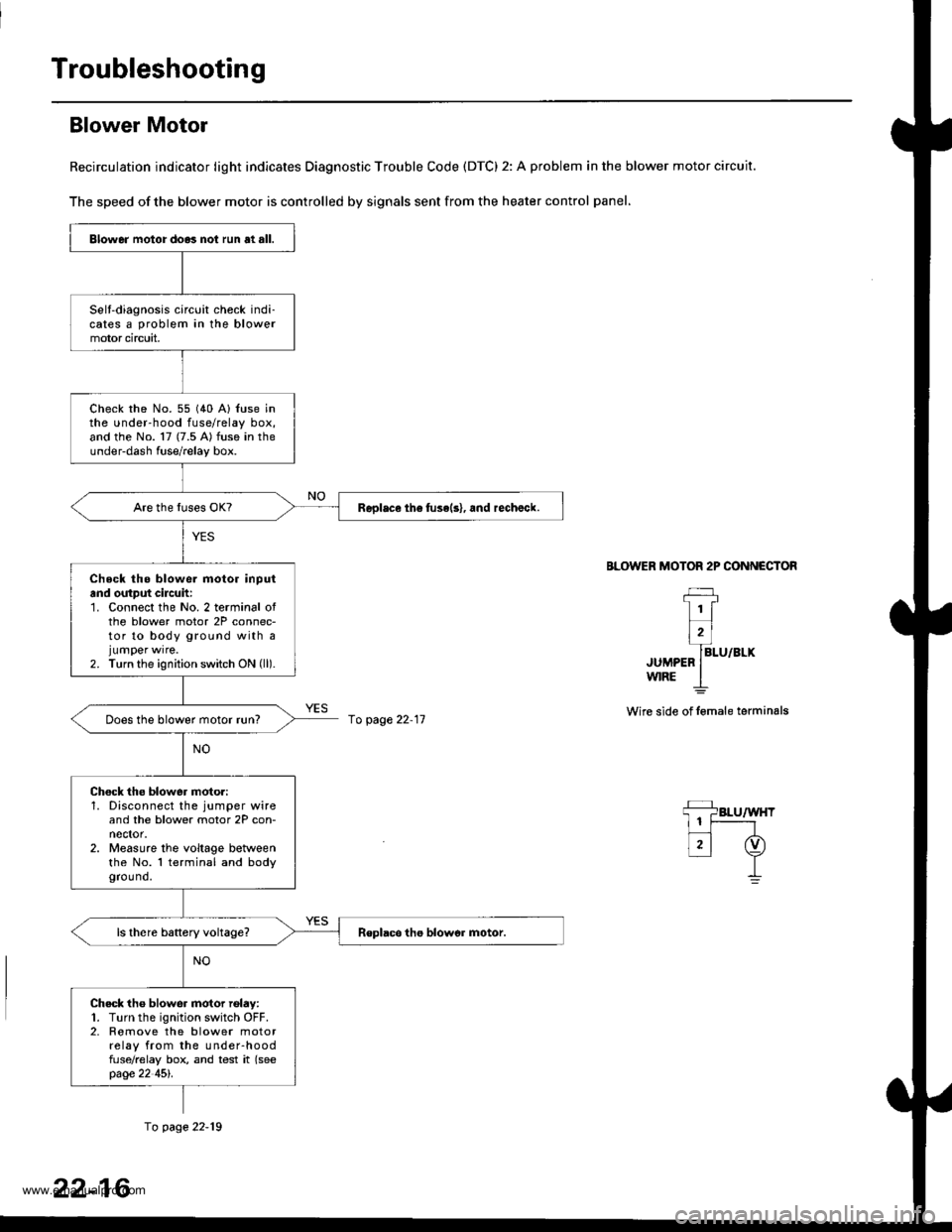

Blower Motor

Recirculation indicator light indicates Diagnostic Trouble Code (DTC) 2: A problem in the blower motor circuit.

The speed of the blower motor is controlled by signals sent from the heater control panel,

BLOWER MOTOR 2P CONNECTOR

JUMPEFw|RE

Wire side of lemale terminals

Blower motor do.3 not run at all.

Selt-diagnosis circuit check indi-cates a problem in the blowermotor circuit,

check rhe No. 55 (40 A) {use inthe under-hood fuse/relay box,and the No. 17 (7.5 A) fuse in theunder-dash fuse/relay box.

Replace th6 fuse(s), and rechalck.

Check tho blowe. motor inputand output cilcuh:1. Connect the No. 2 terminal ofthe blower motor 2P connec-tor to body ground with ajumper wrre.2. Turn the ignition switch ON (ll).

Does the blower motor run?

Chock the blower moto.:1. Disconnect the jumper wireand the blower motor 2P con-nector.2. Measure the voltage betweenthe No. l terminal and bodygrou nd.

Check tho blower motor rolay:1. Turn the ignition switch OFF.2. Romove the blower motorrelay from the under-hoodfuse/relay box, and test it (seepage 22 45l'.

fo page 22-11

fo page 22-19

22-16

www.emanualpro.com

Page 1108 of 1395

Troubleshooting

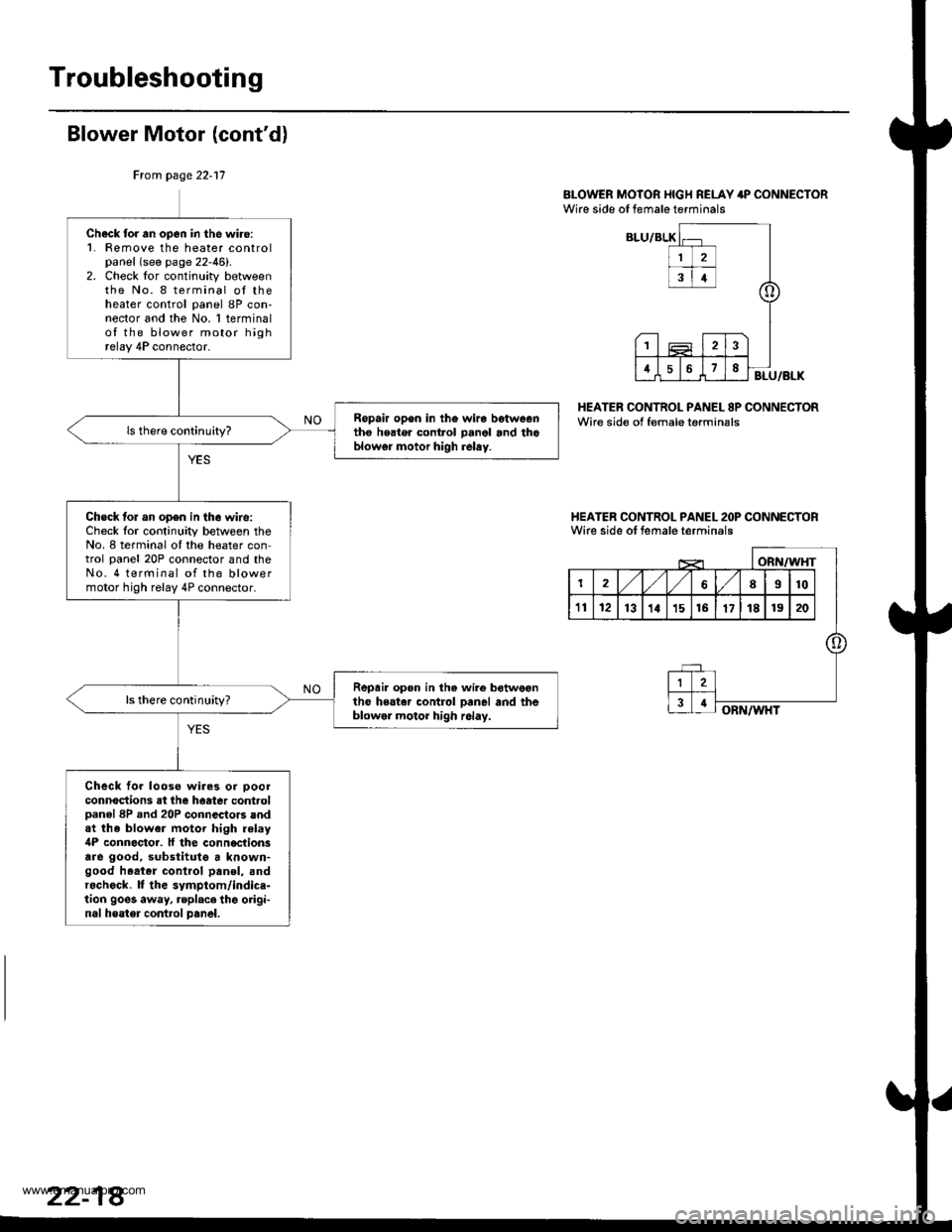

Blower Motor (cont'd)

BI-OWER MOTOR I{IGH RELAY 4P CONNECTORWire side of female terminals

HEATER CONTROL PANEL 8P CONNECTORWire side of female terminsls

I{EATER CONTROL PANEL 2OP CONNECTORWirc side ot female terminals

Ftom page 22-17

Check for an open in the wiro:1. Femove the heater controlpanel (see page 22-46).2. Check lor continuity betweenthe No. 8 terminal oI theheater control panel 8P con-nector and the No. 1 terminalof the blower motor highrelay 4P connector.

Ropair op6n in th€ wira betweentho heater control panol and thoblowgr motor high relay.

Check lor an op6n in the wire:Check lor continuity between theNo. 8 terminal oI the heater control panel 20P connector and theNo. 4 terminal of the blowermotor high relay 4P connector.

Repair open in the wire botweonthe heater control Danel and theblowel motor high r6lay.

ls there continuhy?

Check fo. looso wiles or ooolconnoctions at the haatea controlDanel 8P .nd 20P connectors andat the blower motor high relay4P connoctor. ll the conn€ctionsare good, substitutg a known-good h.at.r control panol, andr.check. lf the symptom/indice-tion goes away, replace thg origi-nal heater contrcl panel.

www.emanualpro.com

Page 1110 of 1395

Troubleshooting

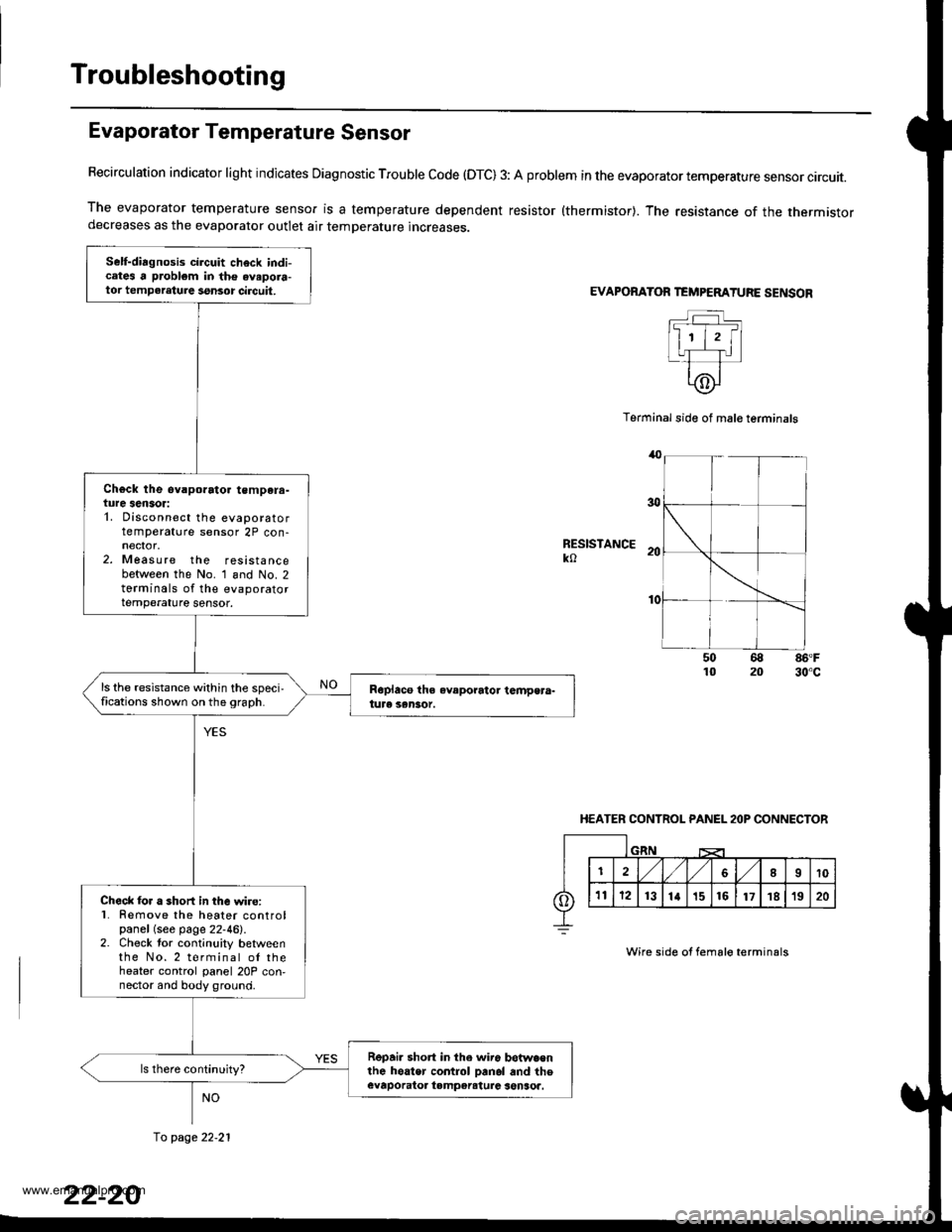

Evaporator Temperature Sensor

Recirculation indicator light indicates Diagnostic Trouble code (OTC) 3: A problem in the evaporator temperature sensor circuit.

The evaporator temperature sensor is a temperature dependent resistor {thermistor}. The resistance of the thermistordecreases as the evaporator outlet air temperature increases.

EVAPORATOR TEMPEMTURE SENSOR

Terminal side of mal€ terminals

RESISTANCEko

86'F30"c

HEATER CONTROL PANEL 2OP CONNECTOR

Wire side of fema16 terminals

Self-diagnosis circuit check indicates a problem in the avapora-tor tempeleture ssnsor circuit,

Ch€ck the ev.porato. tempera-ture sensor:1. Disconnect the evaporatortemperature sensor 2P con-

2. Measure the resistancebetween the No. 1 and No. 2torminals of the evaporatortemperature sensor.

ls the resistance within the speci,fications shown on the 9raph.

Check lor a short in the wire:l� Remove the heater controlpanel (see page 22-46).2. Check tor continuity betweenthe No.2 terminal ol theheater control panel 20P con,nector and body ground.

Repai. short in the wir6 betwa€nlhe hoater control Danol and theevaporatoa tampereturc senSoa.

fo page 22.21

www.emanualpro.com

Page 1112 of 1395

Troubleshooting

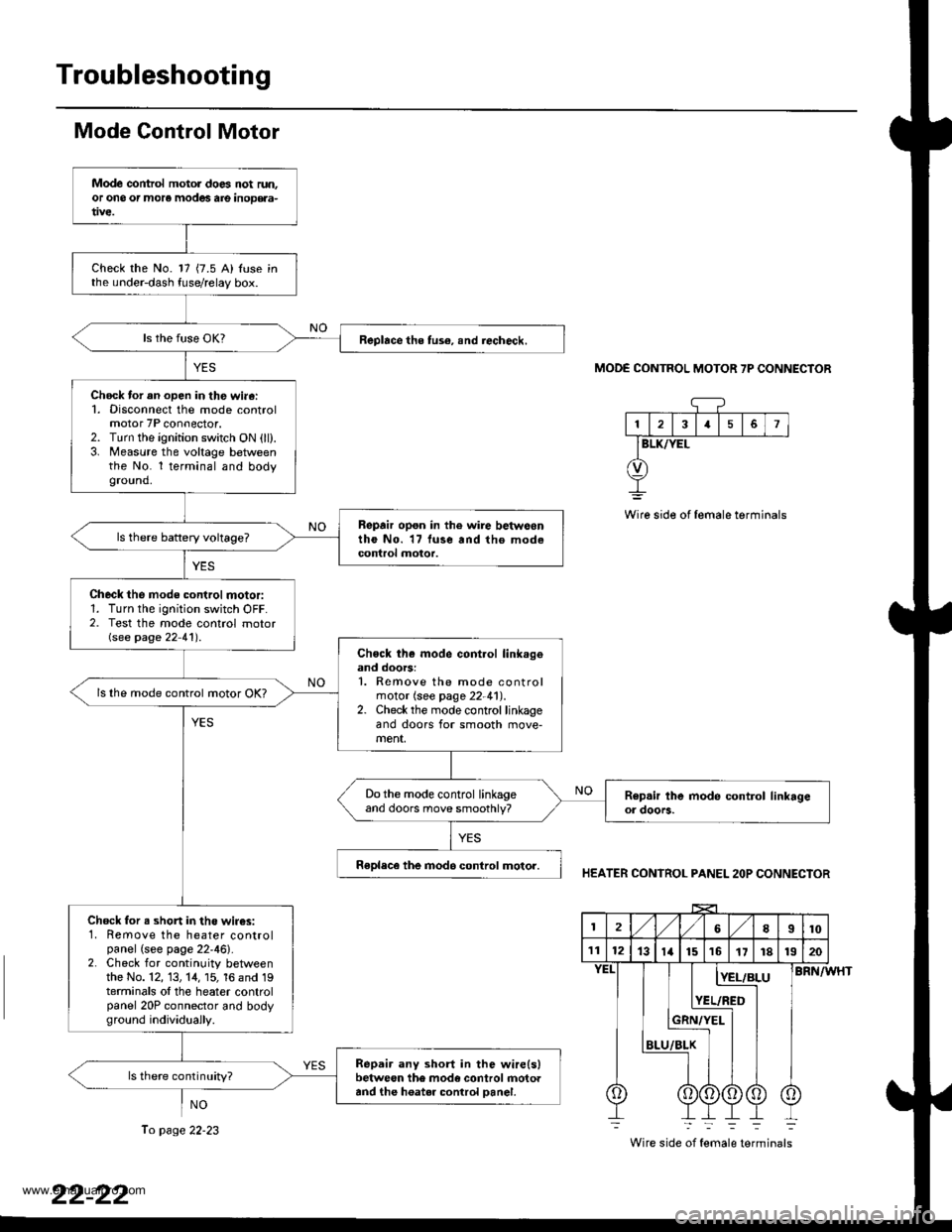

Mode Control Motor

NO

MODE CONTROL MOTOR 7P CONNECTOR

13I5

BLK/YEL

Wire side of female terminals

HEATER CONTROL PANEL 2OP CONNECTOR

BRN/WHT

Wire side of female terminals

Mode control motol does not run.or ono or more modes are inoD€aa-

Check the No. 17 {7.5 A) Iuse inthe under-dash fuse/relay box.

Replace the tus€, snd iecheck.

Chock tor an open in th€ wi.6:1. Disconnect the mode controlmotor 7P connector.2. Turn the ignition switch ON (ll).3. Measure the voltage betweenthe No. l terminal and bodyground.

Repair opon in the wire betwoontho No. 17 luse and tho modecontrol motor.

Check the mode control motor:1. Turn the ignition switch OFF.2. Test the mode control motorGee page 22 41') .

Chock th€ mode cont.ol link.geand doors:1. Remove the mode controlmotor (see page 22-41).2. Check the mode control linkageand doors for smooth move-ment,

ls lhe mode control motor OK?

Do the mode control linkageand doors move smoothly?

Replece the inod6 control motor.

Chock for s shon in the wir€s:1. Remove the heater controlpanel (see page 22'46).2. Check for continuity betweenthe No. 12, 13, 14, 15, 16 and 19terminals ol the heater controlpanel 20P connector and bodyground individuaily.

Repair any short in the wire(slbetween the mode control rnotoaand the h6ater control Danel.

ls there continuity?

2l,/1,/8I10

111213ta151617r81320

BLU

[E!r!

YEL/RED

Ii

To page 22-23

www.emanualpro.com

Page 1114 of 1395

Troubleshooting

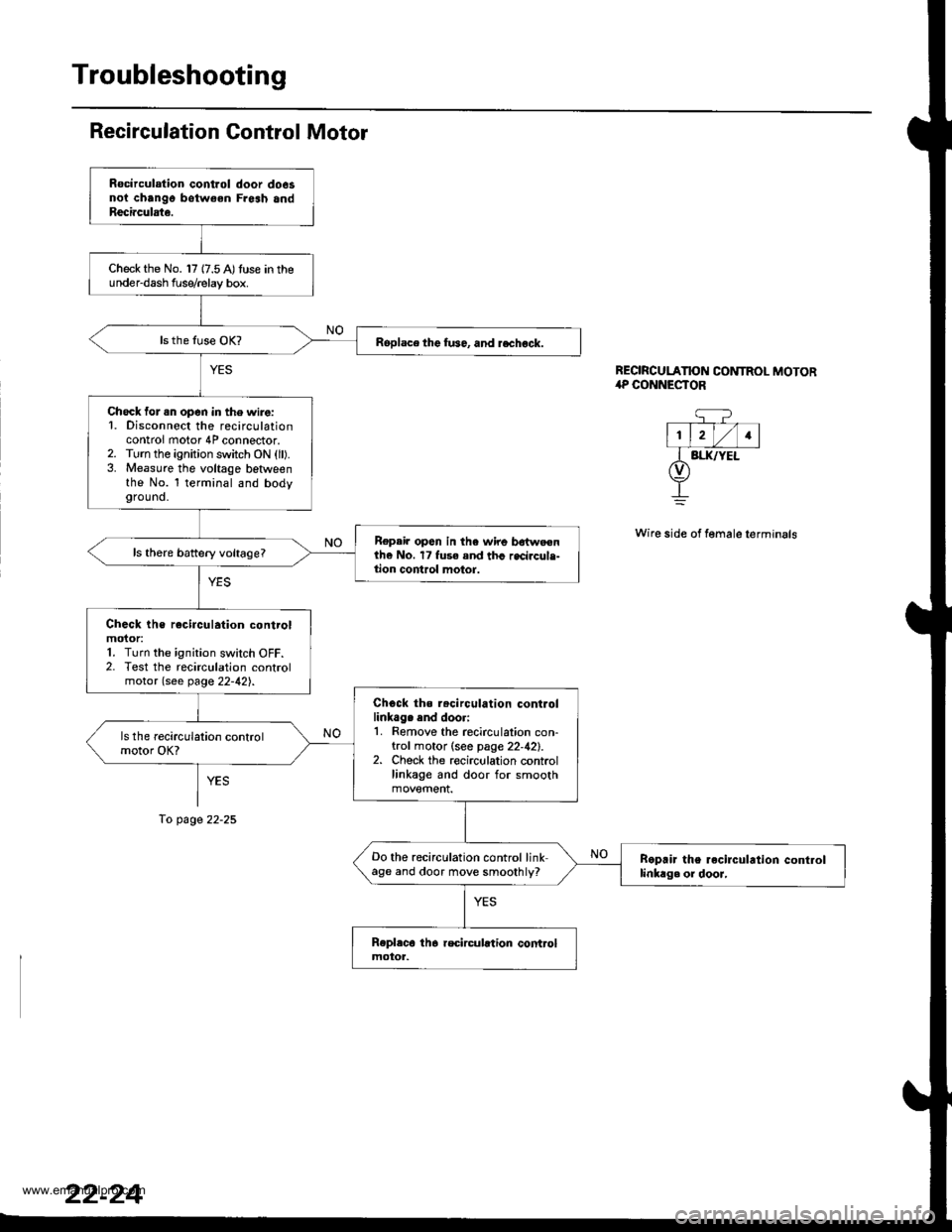

Recirculation Gontrol Motor

YES

To page 22-25

REORCULATION CONTROL MOTOR,rP CONNESTOR

q?- T--- V-l

l1, lrl/l1lI BI.IUYEL(v)

+

Wire side of female terminals

Rocirculation control door do6snoi chango botw€en Fresh andReci.culate.

Check the No. 17 {7.5 A)tuse in theunder-dash f use/relay box.

Roplace the fu36, and rechock.

Check for .n open in the wire:1. Disconnect the recirculationcontrol motor 4P connector.2. Turn the ignition switch ON (ll).3. Measure the voltage betlveenthe No. l terminal and bodyground.

Repair op6n in the wire bdtweenthe No. 17 fuse and thc recircule-tion control motor.

Check the rocirculation controlmoior:1. Turn the ignition switch OFF.2. Test the recirculation controlmotor (see page 22-42).

Chock ths r.circulation controllinkag. end doori1. Remove the recirculation con-trol motor (see page 22,42).2. Check the recirculation controllinkage and door for smooth

Do the recirculation control linkage and door move smoothly?Boprir the recirculrtion controllinkag. or dooJ,

www.emanualpro.com

Page 1116 of 1395

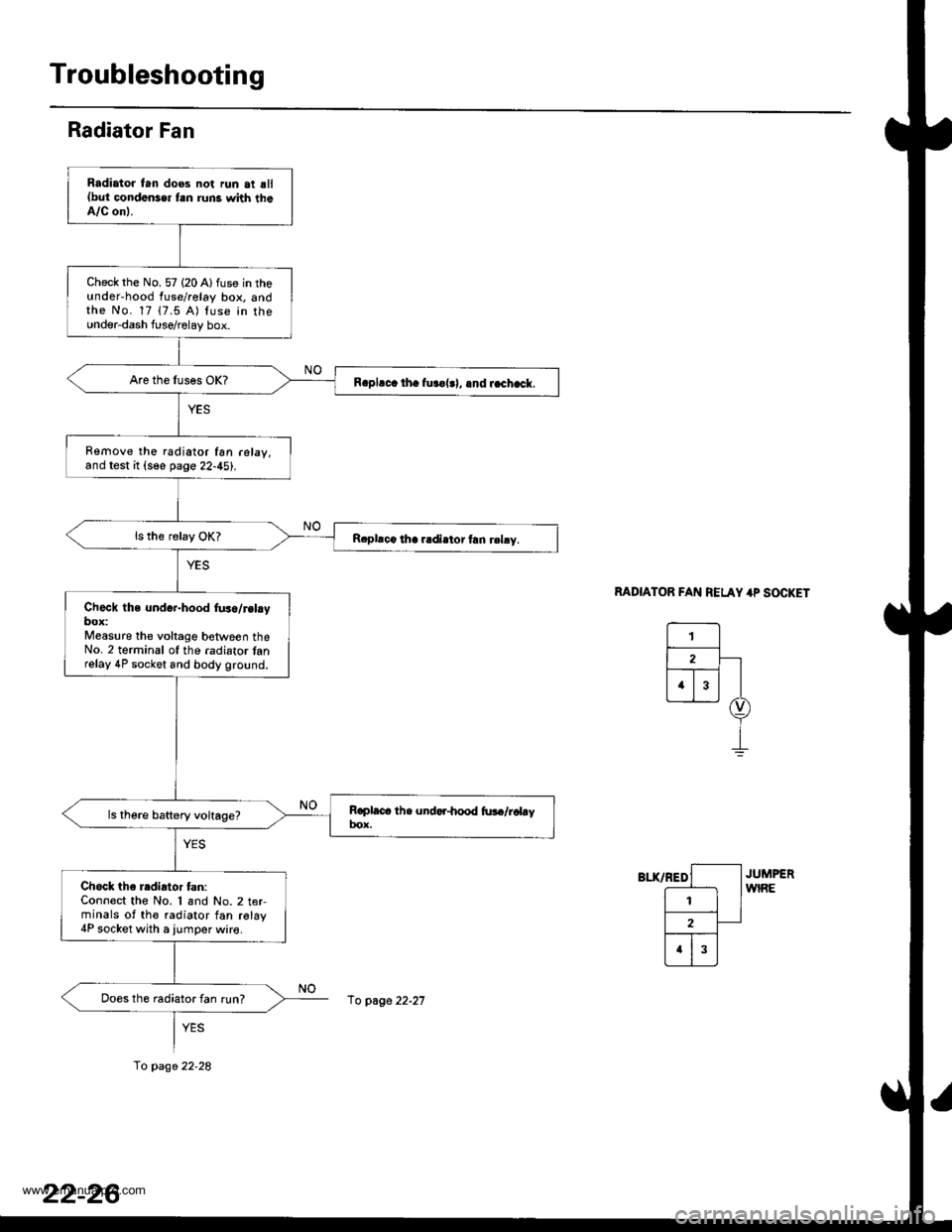

Troubleshooting

Radiator Fan

MDIATOR FAN RELAY 4P SOCKET

Radiator tan doos not run at sll(but condonser fsn runs with theA/C onl.

Check rhe No. 57 (20 Alfuse in theunderhood fuse/relay box, andthe No. 17 17.5 A) luse in the0nder-dash fuserelay box.

R.pl.c. th. fur€|.l, .nd r.chack.

Remove the radiator fan r6lay,and test it {see page 22-45).

R.pllco tha r.diator frn rehy.

Check the und.r-hood fus./r.l.ybox:Measure the voltage between theNo. 2 terminal ol the .adiator tanrelay 4P socket and body ground.

Chock the radiator tan:Connect the No. 1 and No.2 t€rminals of the radiator fan relay4P socket with a iumper wire.

Does th6 radiator fan run?

fo page 22-28

fo page 22-21

www.emanualpro.com

Page 1118 of 1395

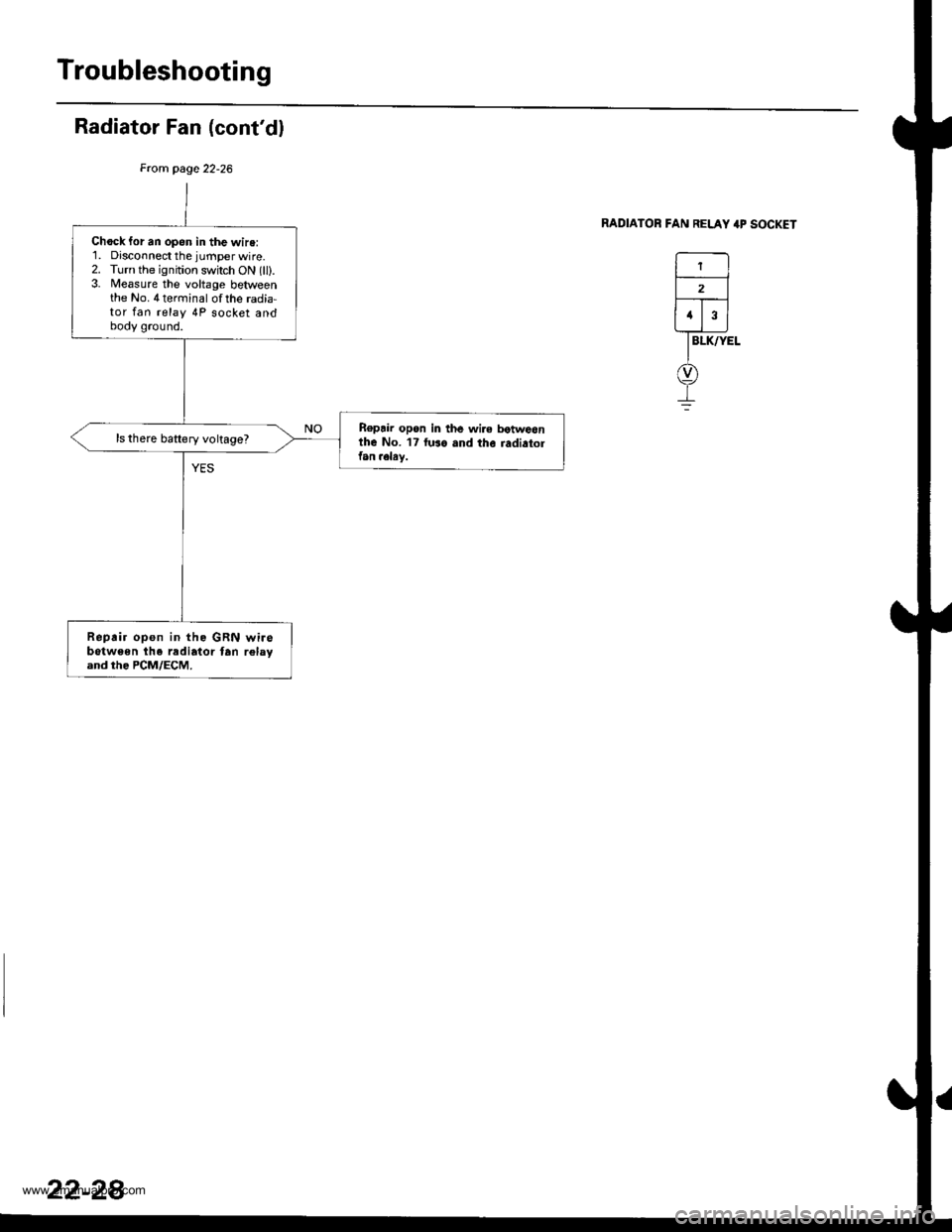

Troubleshooting

Radiator Fan (cont'dl

From page 22-26

RADIATOR FAN RELAY 4P SOCKET

BLK/YEL

1

2

a

Chock for an open in the wire:'1. Disconnect the jurnper wire.2. Turn the ignition switch ON (ll).3. lleasure the voltage betweenthe No.4terrninal of the radia-tor fan relay 4P socket andbody ground.

R€pair open in th6 wire botwoonthe No. 17 fuso and the radiatolfan .elsy.

ls there battery voltage?

Rep.ir open in the GRN wirebotw€en lhe radiator tan relayand the PCM/ECM.

22-28

www.emanualpro.com

Page 1120 of 1395

![HONDA CR-V 1998 RD1-RD3 / 1.G Workshop Manual

Troubleshooting

Condenser Fan {contd)

CONDENSER FAN RELAY 4P SOCKET

r---------t wHT

lr_f__l12 | |

fT;.] |I/Or\j/

I

G

CONDENSER FAN 2P CONNECTORWire side ol temale torminals

-r+-,.12

TBtK

@

!

Chock f HONDA CR-V 1998 RD1-RD3 / 1.G Workshop Manual

Troubleshooting

Condenser Fan {contd)

CONDENSER FAN RELAY 4P SOCKET

r---------t wHT

lr_f__l12 | |

fT;.] |I/Or\j/

I

G

CONDENSER FAN 2P CONNECTORWire side ol temale torminals

-r+-,.12

TBtK

@

!

Chock f](/img/13/5778/w960_5778-1119.png)

Troubleshooting

Condenser Fan {cont'd)

CONDENSER FAN RELAY 4P SOCKET

r---------t wHT

lr_f__l12 | |

fT;.] |I/Or\j/

I

G

CONDENSER FAN 2P CONNECTORWire side ol temale torminals

-r+-,.12

TBtK

@

!

Chock for an open in the wire:'1. Disconnect the iumper wire.2. Disconnect the condenser fan2P connector.3. Check for continuity betweenthe No. 1 terminal of the con,denser fan relay 4P socket andthe No. 2 terminal of the con-denser fan 2P connector.

Ropair open in the wire betwoenth€ condenser fan rslay and thecondenser tan.

ls there continuity?

Chech tor an open in the wire:Check for continuity between theNo. I terminal of the condenserfan 2P connector and bodyground.

Check for an open in thg wirebetween the condenser fan andbody ground. lf the wiro is OK.check tor poor ground .t G202.

Replace tho condenser tan motor.

22-30

www.emanualpro.com

Page 1124 of 1395

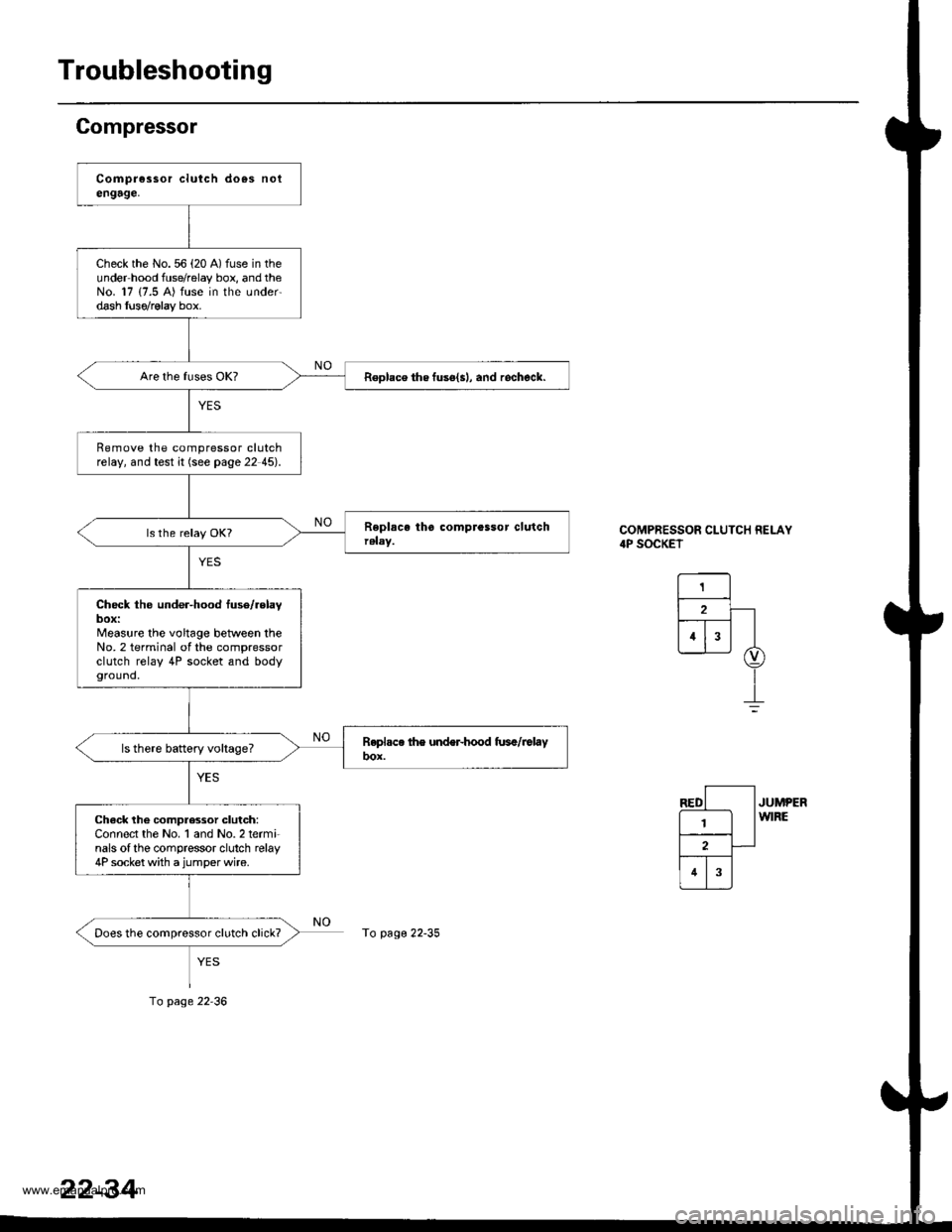

Troubleshooting

To page 22-35

Check the No. 56 (20 A) fuse in theunder hood fuse/relay box, and theNo. 17 (7.5 A) fuse in the underdash luso/rglay box.

Replace the fuso(sl, and r6check.

Remove the compressor clutchrelay, and test it (see page 22 45).

Check the under-hood fuse/relayDOX:Measure the voltage between theNo. 2 terminal of the compressorclutch relay 4P socket and bodyground,

Chack lhe complessor clutch:Connect the No. 1 and No. 2 termi-nals ofthe comoressor clutch relav4P socket with a jumper wire.

Does the comprossor clutch click?

22-34

To page 22-36

www.emanualpro.com

Page 1126 of 1395

Troubleshooting

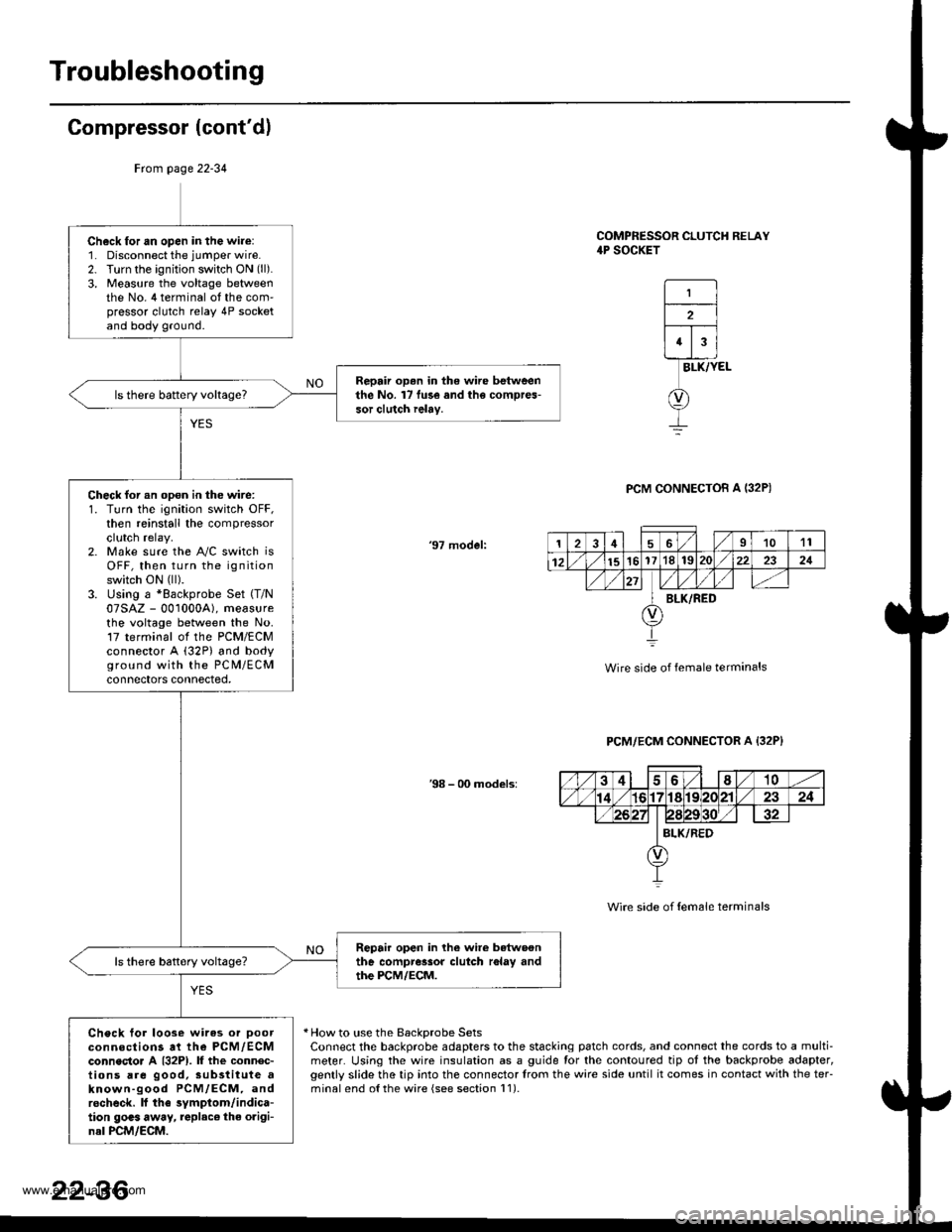

Compressor (cont'dl

COMPRESSOR CLUTCH RELAY4P SOCKET

1

2

43

BLK/YEL

PCM CONNECTOB A I32P)

'97 model:

Wire side of female terminals

PCM/ECM CONNECTOR A {32P}

38 - 00 models:

Wire side of {em6le terminals

* How to use the BackDrobe SetsConnect the backprobe adapters to the stacking patch cords, and connect the cords to a multi-meter. Using the wire insulation as a guide for the contoured tip ot the backprobe adapter,gently slide the tip into the connector trom the wire side until it comes in contact with the teFminalend o{the wire {see section l1).

Frcm page 22-34

Ch6ck for an open in the wire:1. Disconnect the jumper wire.2. Turn the ignition switch ON (ll).

3, Measure the voltage betweenthe No. 4 terminal ot the com'pressor clutch relay 4P socketand body ground.

Repair op.n in the wire betweenthe No. l7 fu3e and the compres-sor clutch ielay.

Check for an opon in the wire:1. Turn the ignition switch OFF,then reinstall the compressorclutch relay.2. Make sure the A"/C switch isOFF, then turn the ignitionswitch ON (ll).

3. Using a *Backprobe Set (T/N

07SAZ - 001000A), measurethe voltage between the No.17 terminal ol the PCM/ECMconnector A (32P) and bodyground with the PC M/ECMconnectors connected,

Repair open in lhe wire betwoonthe compressor clutch r6lay andthe PCM/ECM.

Check tor loose wires or Doorconnections at the PCM,/ECMconnecto. A {32P1. lf the connec-tions are good, sub3titute aknown-good PCM/ECM, androcheck. lf the symptom/indica-tion goas away, replac€ the origi-nal PCM/ECM.

126I1011

12151617'181S222321

BLK/RED

22-36

www.emanualpro.com