HONDA CR-V 1998 RD1-RD3 / 1.G Workshop Manual

CR-V 1998 RD1-RD3 / 1.G

HONDA

HONDA

https://www.carmanualsonline.info/img/13/5778/w960_5778-0.png

HONDA CR-V 1998 RD1-RD3 / 1.G Workshop Manual

Page 722 of 1395

Gountershaft

Disassembly/Reassembly

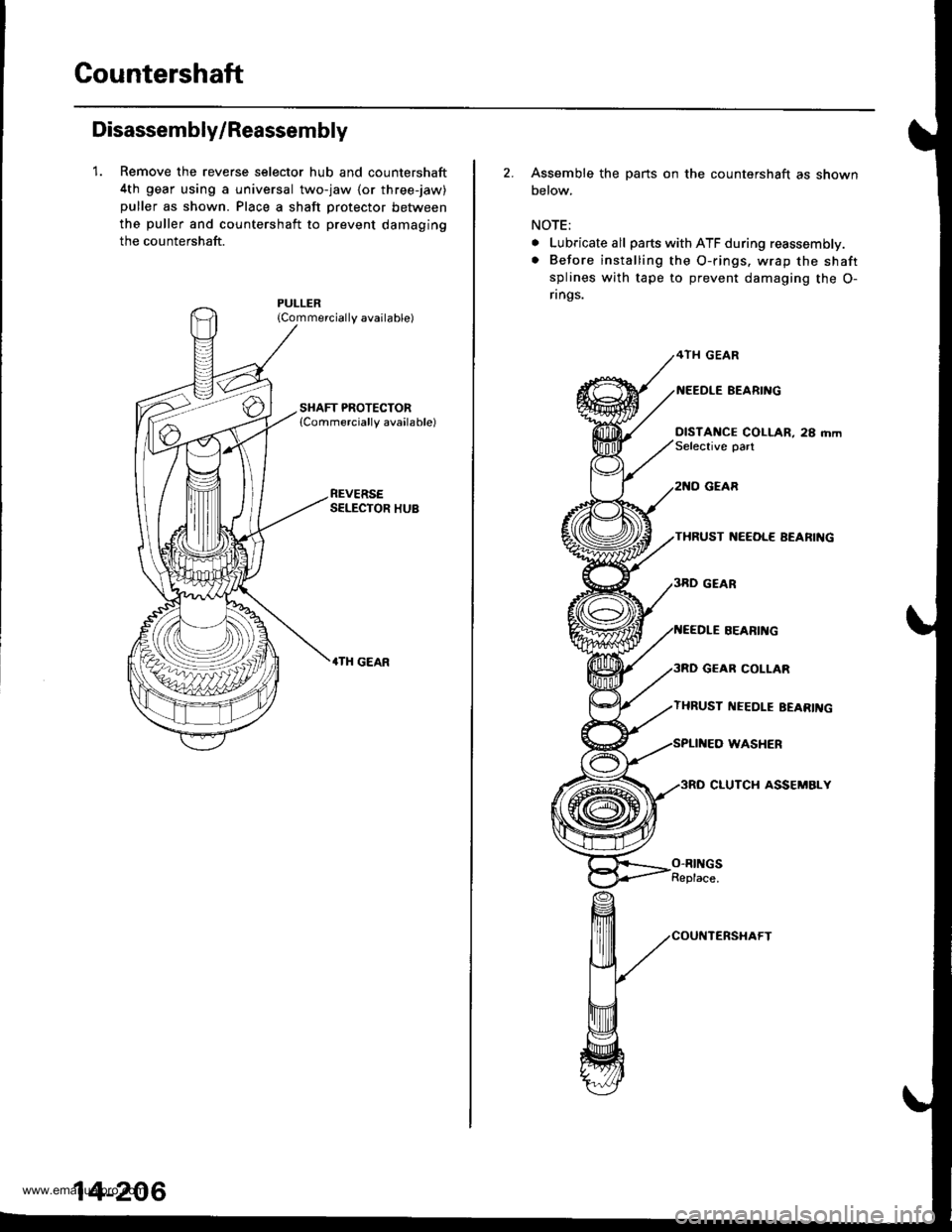

1. Remove the reverse selector hub and countershaft

4th gear using a universal two-jaw lor three-jaw)

puller as shown. Place a shaft protector between

the puller and countershaft to prevent damaging

the countershaft.

{Commercially available)

REVERSESELECTOR HUB

.TH GEAR

14-206

2. Assemble the parts on the countershaft as shown

below.

NOTE;

. Lubricate all parts with ATF during reassembly.

. Before installing the O-rings. wrap the shaft

splines with tape to prevent damaging the O-

rings.

4TH GEAR

BEARI'{G

DISTANCE COLLAR, 28 mmSelective oart

GEAR

THRUST ]{EEOL€ AEARIIIG

GEAR COLLAR

THRUST I{EEDLE EEARII{G

WASHER

3RO CLUTCH ASSEMBLY

SEARII{G

O-RINGSReplace.

www.emanualpro.com

Page 723 of 1395

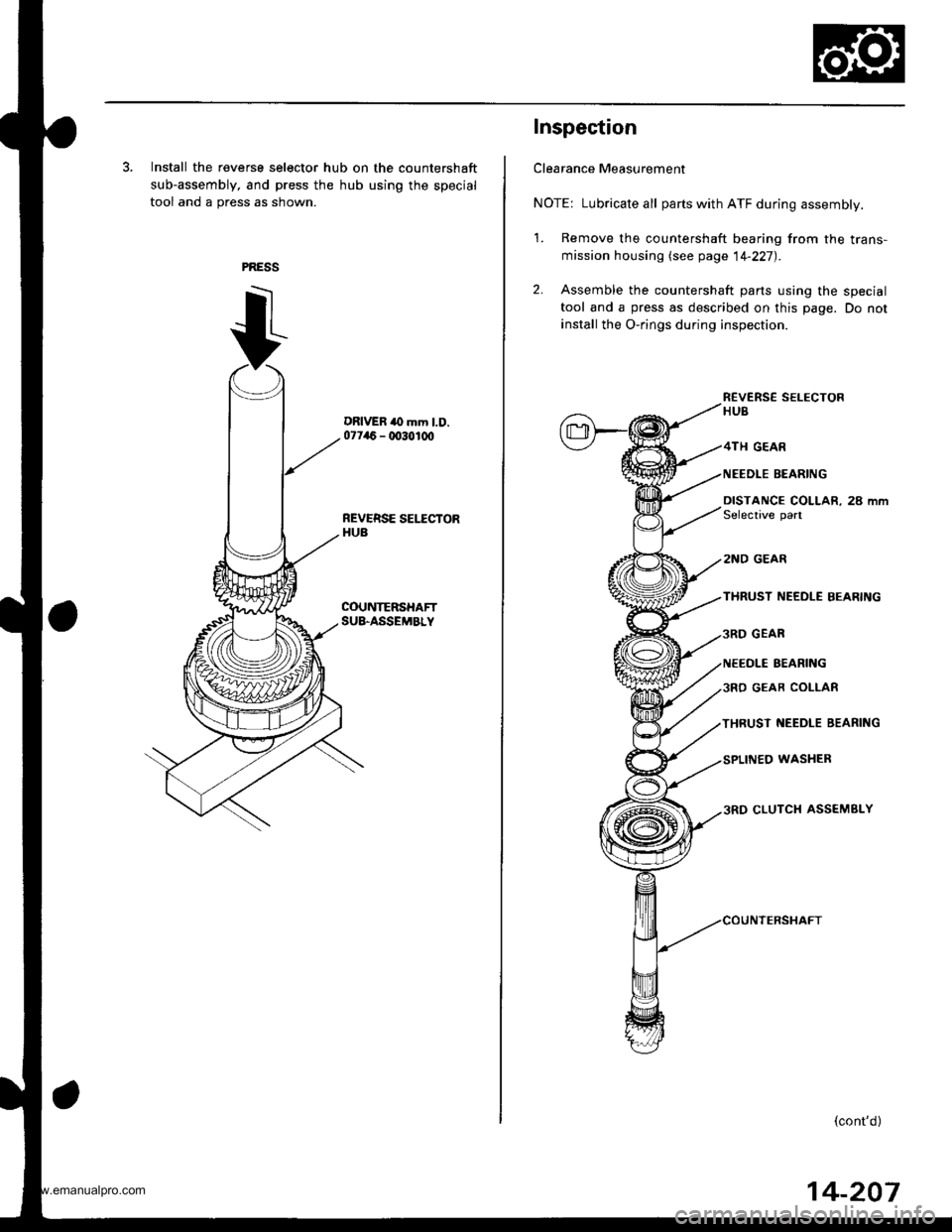

3. Install the reverse selector hub on the countershaft

sub-assembly, and press the hub using the special

tool and a press as shown.

DRIVER to mm l.D.07746 - 0030100

REVERSE SEI.ICTORHUB

COUNTERSHAFTSU&ASSEMBLY

Inspection

Clearance Measurement

NOTE: Lubricate all parts with ATF during assembly.

1. Remove the countershaft bearing from the trans-

mission housing lsee page 14-227).

2. Assemble the countershaft parts using the special

tool and a press as described on this page. Do not

install the O-rings during inspection.

R€VERS€ SELECTORHUB

GEAR

NEEDLE BEARING

DISTANCE COLLAR, 28 mmSelective part

2NO GEAR

THRUST NEEDLE BEARING

GEAR

NEEOLE BEARING

GEAR COLIAR

THRUST NEEDLE BEARING

WASHER

CLUTCH ASSEMBLY

(cont'd)

14-207

www.emanualpro.com

Page 724 of 1395

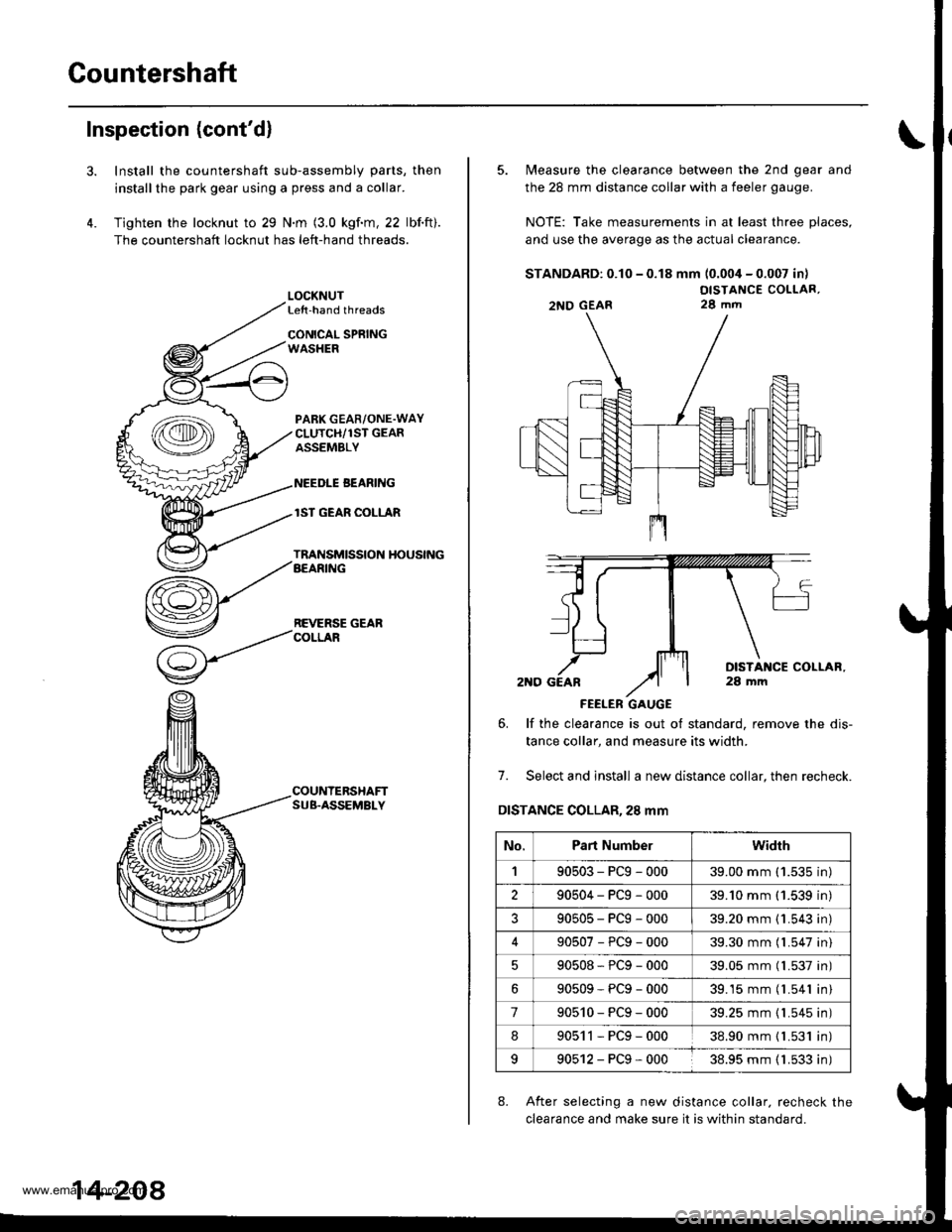

Countershaft

Inspection (cont'd)

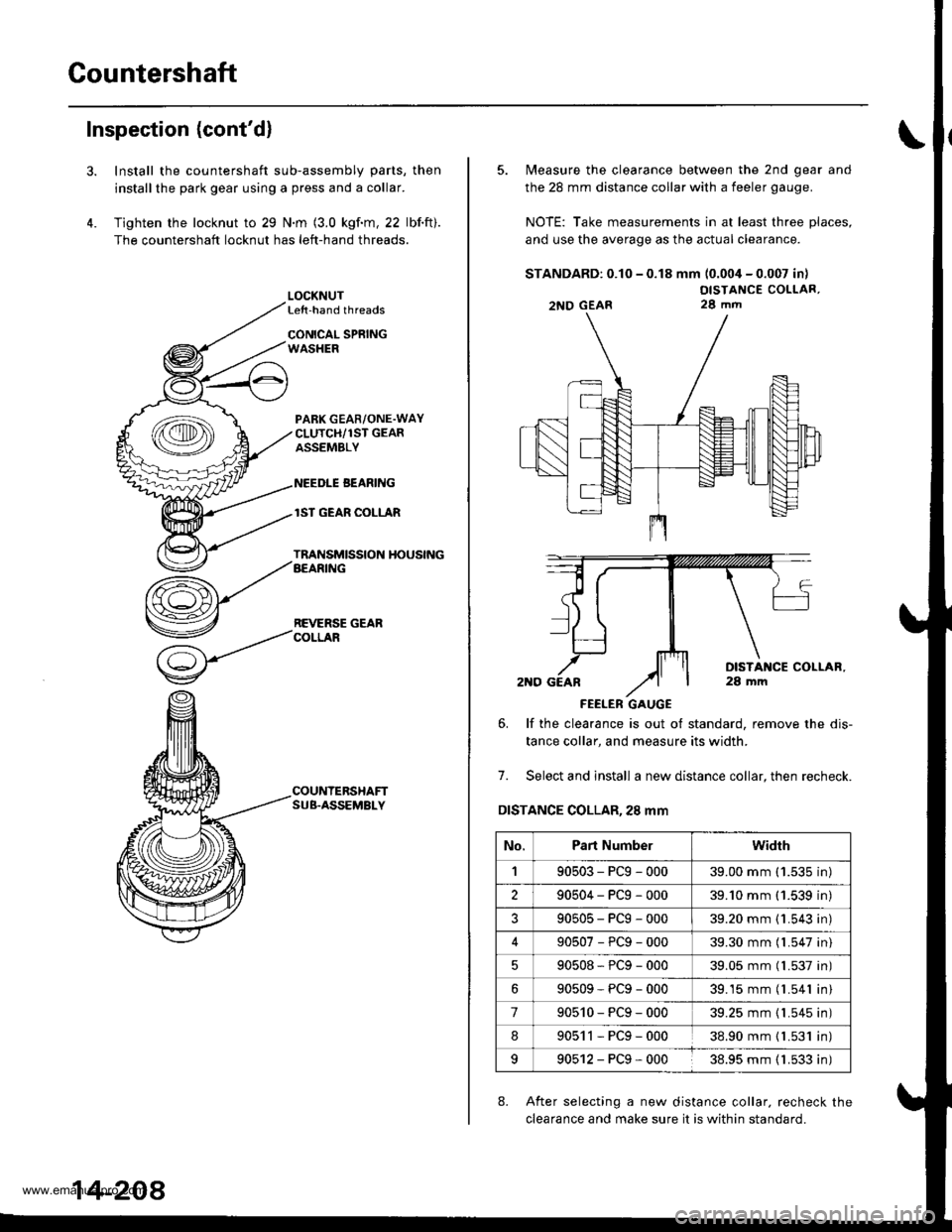

3.

4.

Install the countershaft sub-assembly parts, then

installthe park gear using a press and a collar.

Tighten the locknut to 29 N.m (3.0 kgf.m, 22 lbf.ft).

The countershaft locknut has left-hand threads.

LOCKNUTLe{t-hand threads

CONICAL SPRINGWASHER

PABK GEAR/ONE.WAYCLUTCH/1ST GEARASSEMBLY

NEEDLE BEANING

lST GEAR COLLAR

TRANSMISSION HOUSINGAEARING

REVERSE GEARCOLLAR

COUNTERSHAFTSUB.ASSEMBLY

14-208

5. Measure the clearance between the 2nd gear and

the 28 mm distance collar with a feeler gauge.

NOTE: Take measurements in at least three places,

and use the average as the actual clearance.

STANDARD: 0.10 - 0.18 mm (0.004 - 0.007 in)

OISTANCE COLLAR,28 mm

FEELER GAUGE

6. lf the clearance is out ot standard, remove the dis-

tance collar, and measure its width.

7. Select and install a new distance collar, then recheck.

DISTANCE COLLAR,28 mm

8. After selecting a new distance collar. recheck the

clearance and make sure it is within standard.

2NO GEAR

No.Part Numberwidrh

190503-PCg-00039.00 mm ('1.535 in)

290504-PCg-00039.'10 mm (1.539 in)

?90505-PCg-00039.20 mm {1.543 in)

90507-PCg-00039.30 mm (l.547 in)

90508*PCg-00039.05 mm (l.537 in)

90509-PCg-00039.15 mm (l.541 in)

790510-PCg-00039.25 mm {1.545 in)

890511-PCg-00038.90 mm { L531 in)

990512-PCg-00038.95 mm ( 1.533 in)

www.emanualpro.com

Page 725 of 1395

One-way Glutch

Disassembly/lnspection/Reassem bly

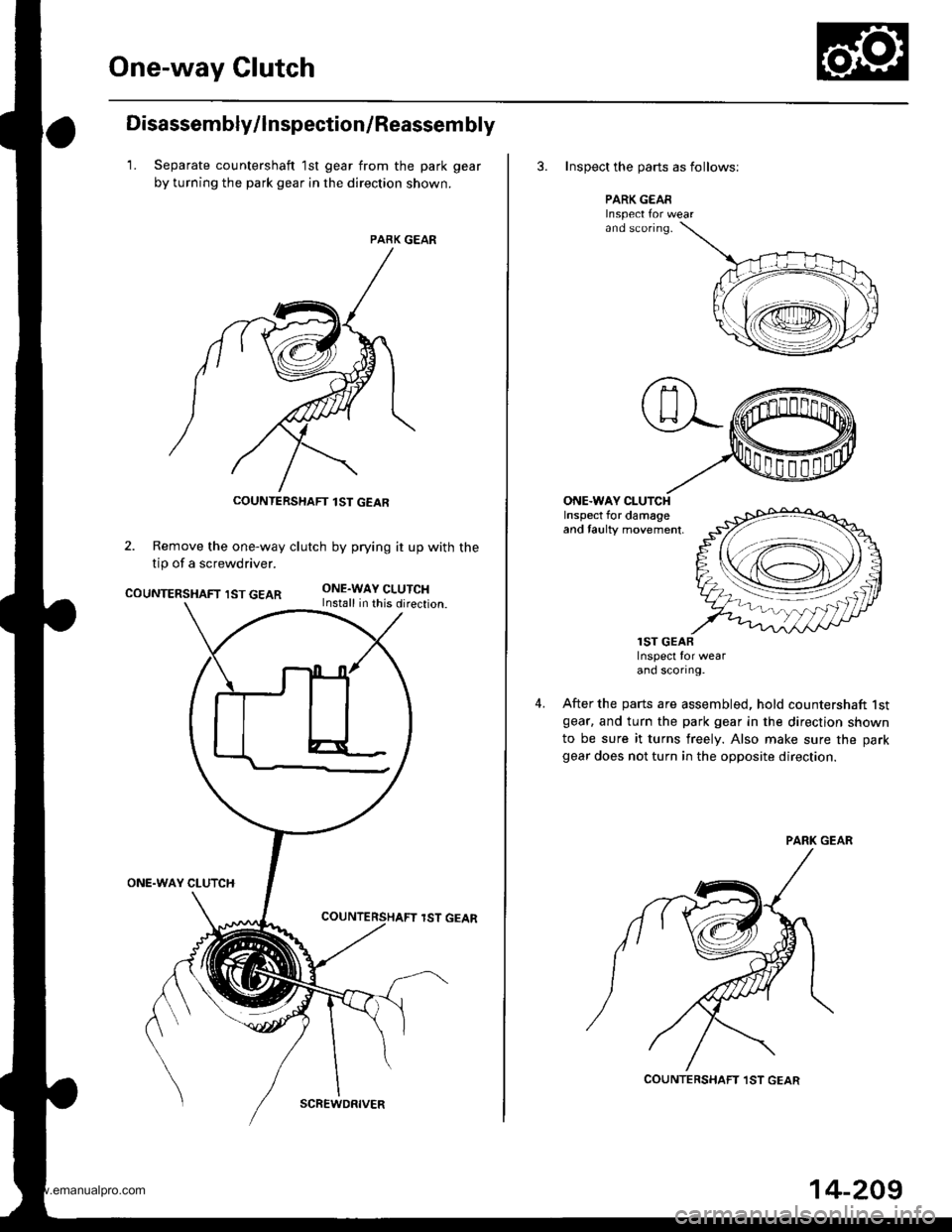

1. Separate countershaft 1st gear from the park gear

by turning the park gear in the direction shown.

PARK GEAR

2. Remove the one-way clutch by prying it up with the

tip of a screwdriver.

COUNTERSHAFT IST GEARONE.WAY CLUTCHInstall in this direction.

ONE.WAY CLUTCH

lST GEAR

COUNTERSHAFT lST GEAR

SCREWDRIVER

14-209

3. Inspect the oarts as follows;

PARK GEARInspect Ior wearand sconng.

ONE.WAY CLUTCHInspect for damageand taulty movement,

4.

lST GEARInspect for wearand scortng.

After the parts are assembled, hold countershaft lstgear. and turn the park gear in the direction shown

to be sure it turns freely. Also make sure the park

gear does not turn in the opposite direction.

COUNTERSHAFT ,IST GEAR

www.emanualpro.com

Page 726 of 1395

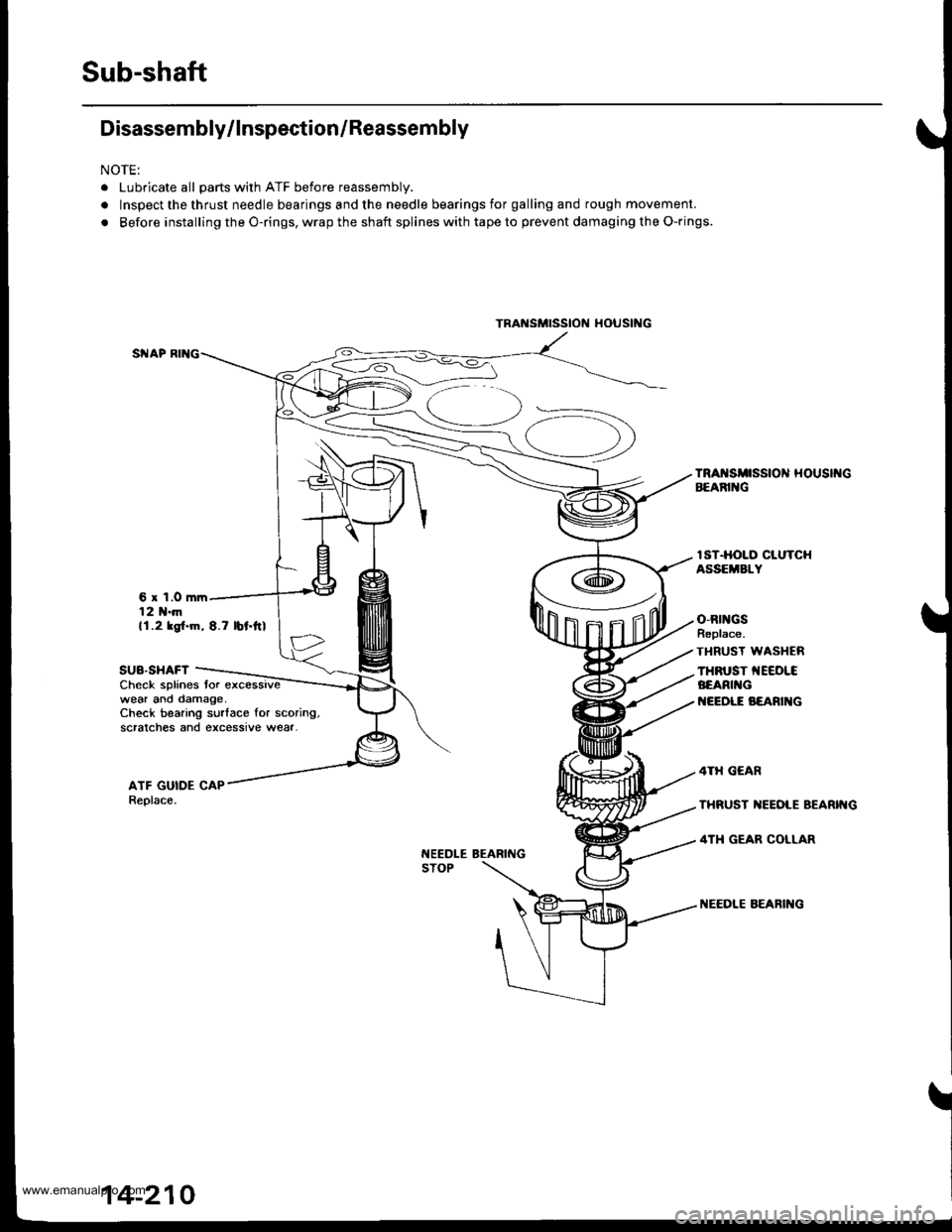

Sub-shaft

Disassembly/lnspection/Reassembly

NOTE:

. Lubricate all parts with ATF before reassembly.

. Inspect the thrust needle bearings and the needle bearings for galling and rough movement.

. Before installing the O-rings, wrap the shaft splines with tape to prevent damaging the O-rings.

6 x 1.0 mrr12 1{.mll.2 ksl.m, 8.7 lbt.ftl

SUB.SHAFTCheck splines tor excessivewear ano damage,Check bearing surlace for scoring,scralches and excessive wear-

t{EEDLE BEARINGSTOP

IST.HOLO CLUTCHASSEMBLY

o,Rtl{GSReplace.

TI{RUST WASI{ER

THFUST TEEOLCBEARI G

I{EEDLE B€ARI G

TRAi{SMTSStON tl()UStNG

14-210

www.emanualpro.com

Page 727 of 1395

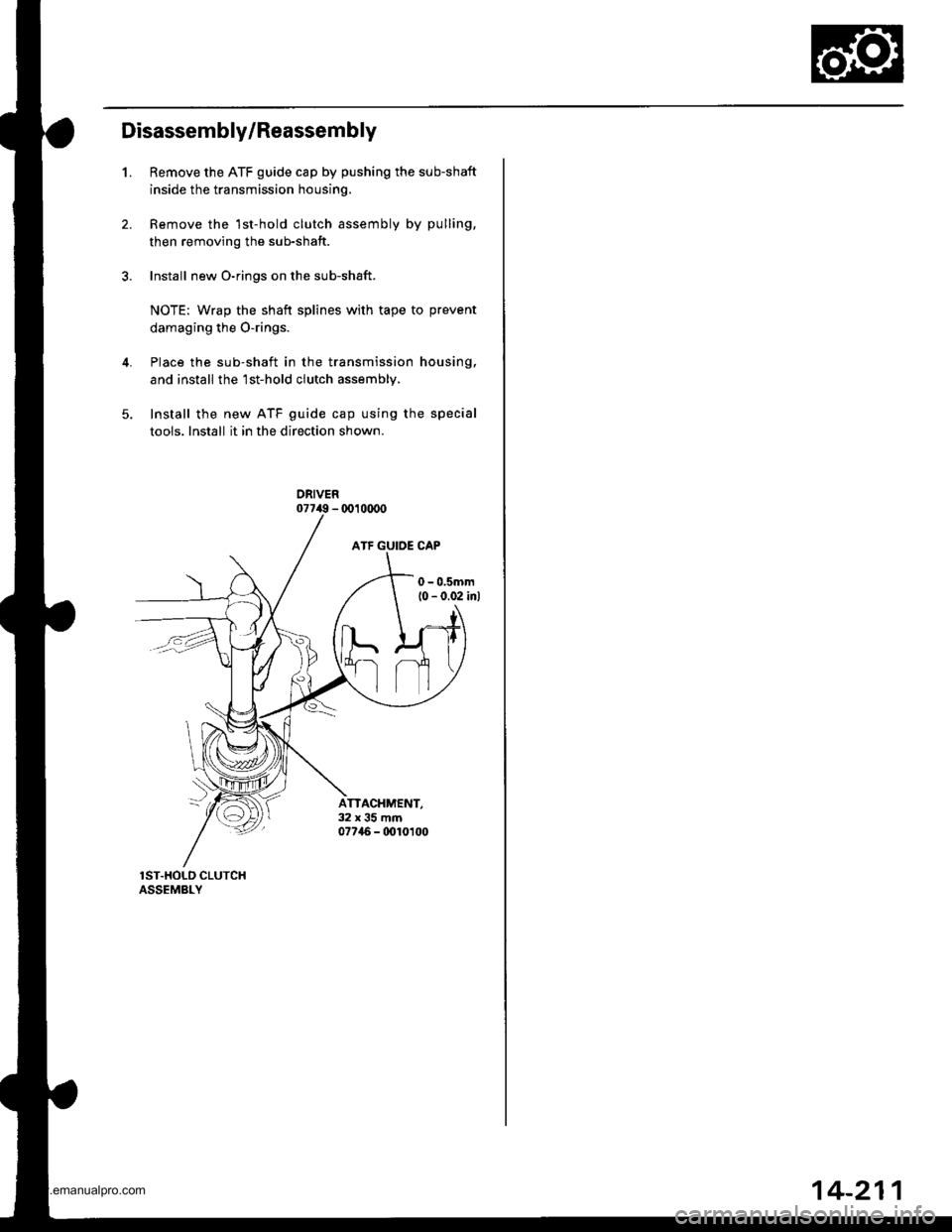

Disassembly/Reassembly

1.Remove the ATF guide cap by pushing the sub-shaft

inside the transmission housing.

Remove the 1st-hold clutch assembly by pulling,

then removing the sub-shaft.

Install new O-rings on the sub-shaft.

NOTE: Wrap the shaft splines with tape to prevent

damaging the O-rings.

Place the sub-shaft in the transmission housing,

and install the'lst-hold clutch assembly,

Install the new ATF guide cap using the special

tools. Install it in the direction shown.

ATTACHMENT,32x35mm07746 - 0010t00

14-211

www.emanualpro.com

Page 729 of 1395

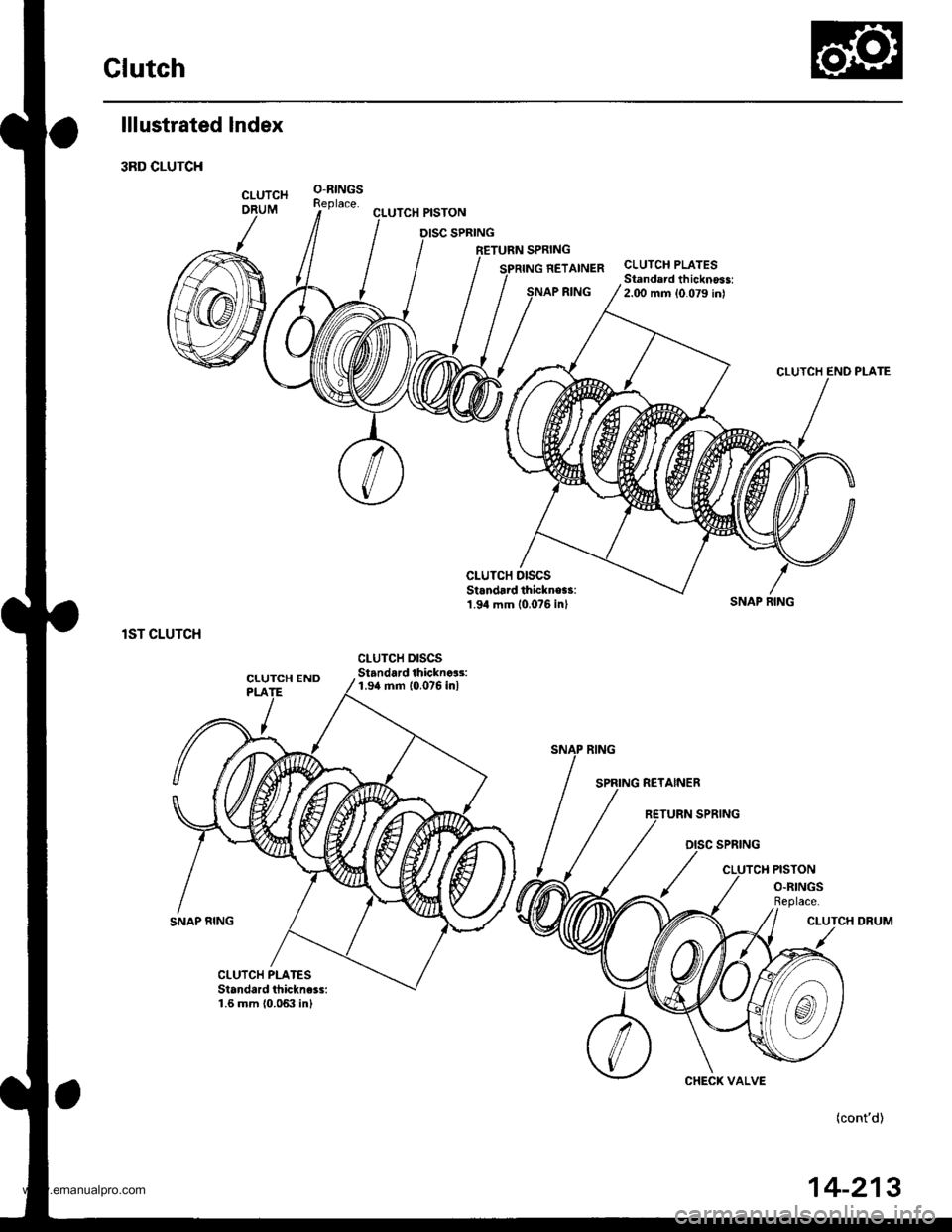

Glutch

lllustrated lndex

3RD CLUTCH

lST CLUTCH

SNAP RING

CLUTCH PISTON

RETURN SPRING

NETAINER

RING

CLUTCH PLATESStandard thicknoss:2.00 mm 10.079 inl

CLUTCH DISCSStandard thickne$:1.94 mm (0 0?6 inl

CLUTCH DISCSStandard thicknca3:1.9a mm 10.076 inl

SNAP FING

CLUTCH DRUM

(cont'd)

CHECK VALVE

14-213

www.emanualpro.com

Page 730 of 1395

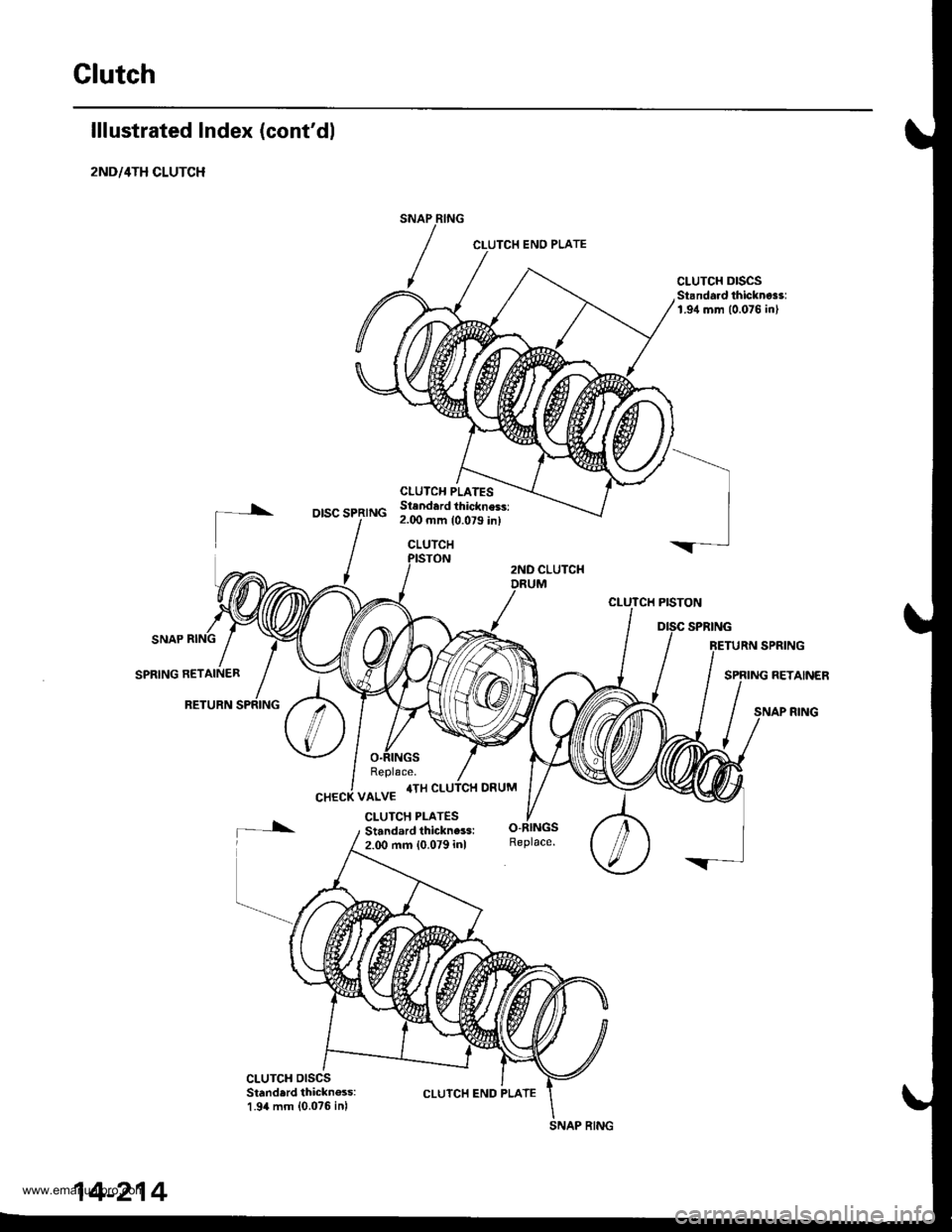

Clutch

lllustrated Index (cont'dl

2ND/4TH CLUTCH

[*

CLUTCH PLATESStendard thickness:2.00 mm {0.079 in)

CLUTCH

OISC SPRING

I

I2ND CLUTCH

CLUTCH PISTON

sPl

I

Repl6ce.

uoavE nr"

CLUTCH PLATESStandard thicknesai2.00 mm {0.079 inl

SNAP RING

14-214

www.emanualpro.com

Page 731 of 1395

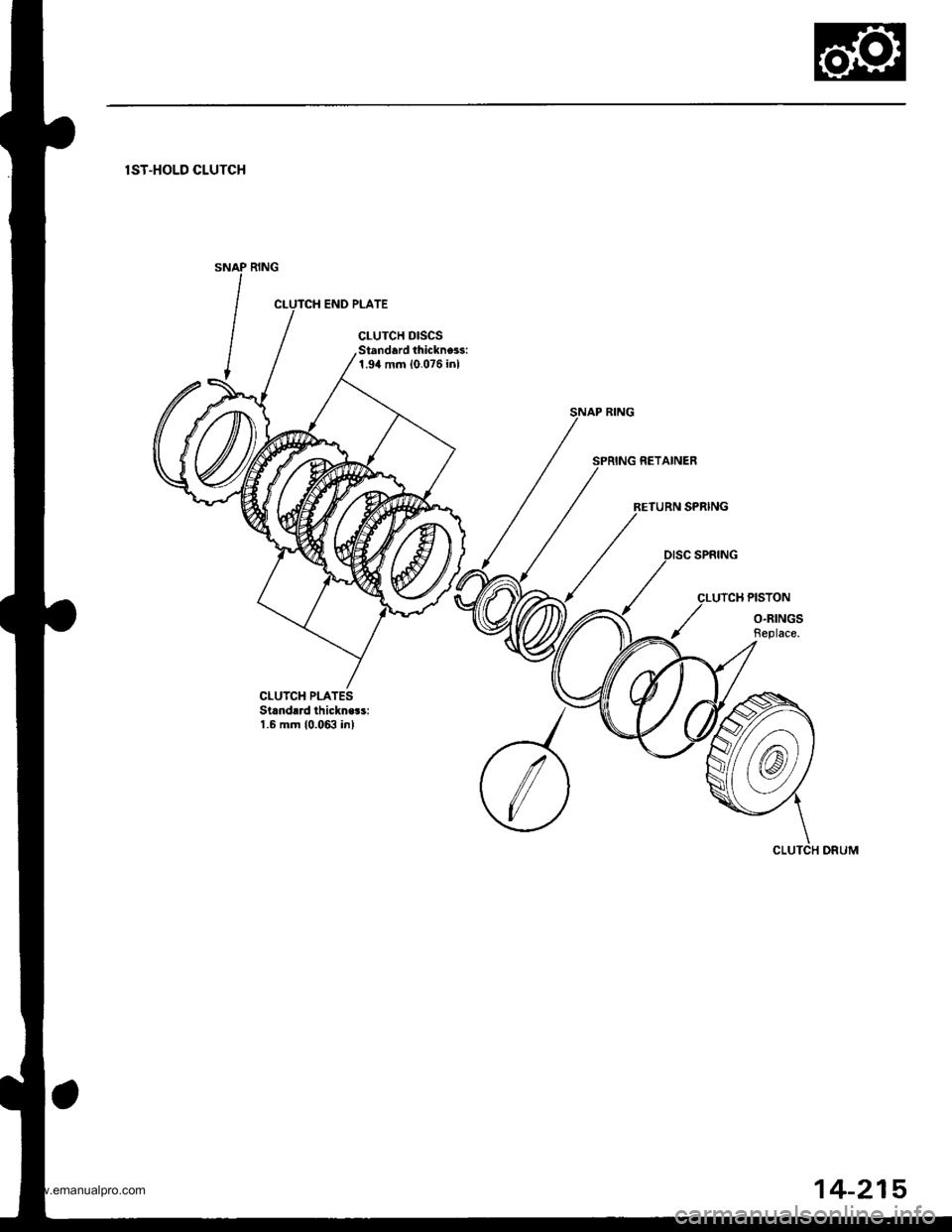

lST-HOLD CLUTCH

thickness:

RETURN SPRING

c

/

LUTCH PISTON

O.RINGS

14-215

www.emanualpro.com

Page 732 of 1395

Clutch

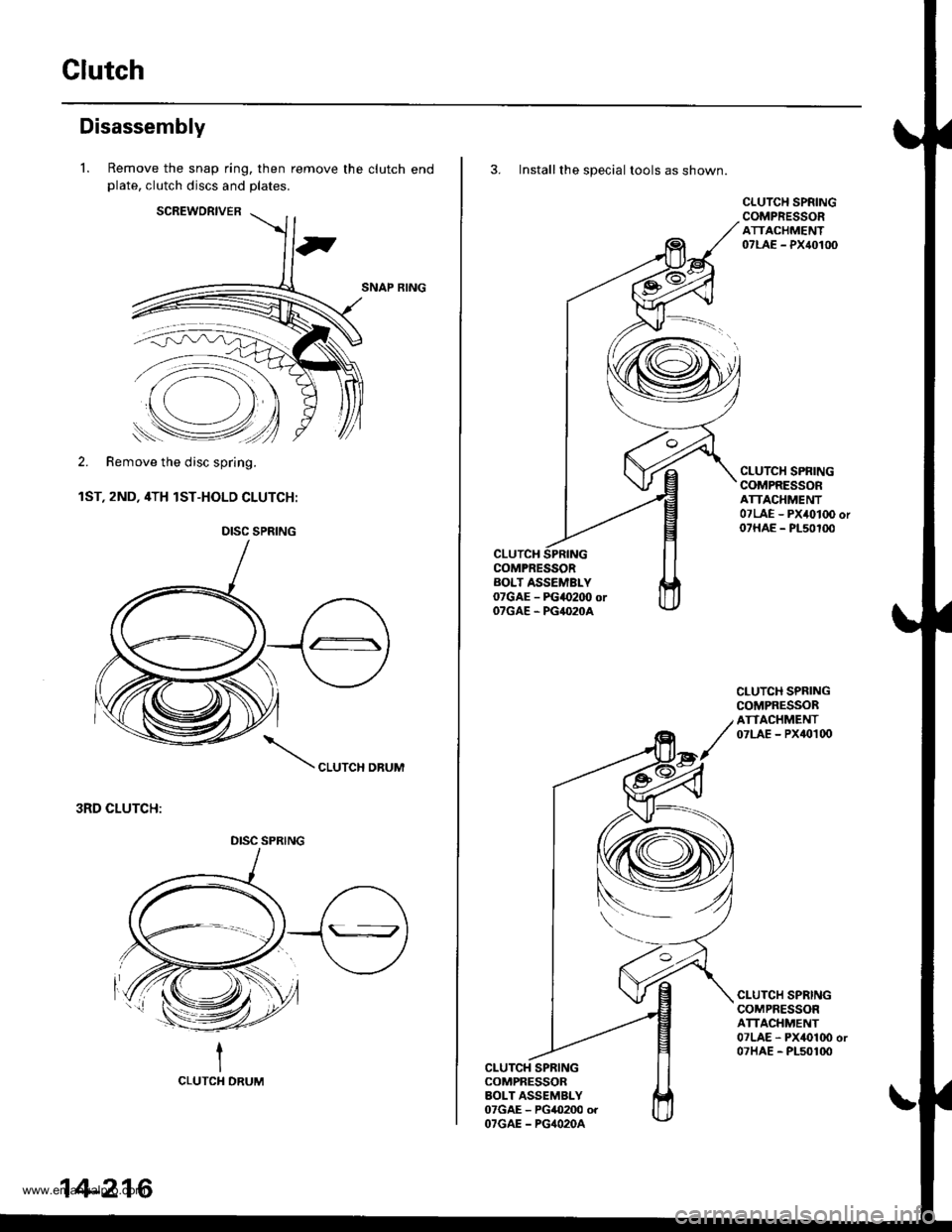

Disassembly

l. Remove the snap ring, then remove the clutch endplate, clutch discs and plates.

SCREWORIVER

SNAP RING

2. Remove the disc spring.

1ST, 2ND, 4TH lST-HOLD CLUTCH:

CLUTCH DBUM

3RD CLUTCH:

-'=*.=:--

'..p

Remove the disc spring.

DISC SPRING

DISC SPRING

14-216

3. Install the special tools as shown.

CLUTCHCOMPRESSORAOLT ASSEMBLY07GAE - FGao2OO orOTGAE . PG4O2OA

CLUTCH SPNINGCOMPRESSORATTACHMENT07LAE - PX40100

CLUTCH SPRINGCOMPRESSORATTACHMENT07LAE - PX4010O or07HAE - PL50100

CLUTCH SPRINGCOMPRESSORATTACHMENT07LAE - PX40t00

CLUTCH SPRINGCOMPRESSORATTACHMENT07LAE - PX4010O or07HAE - PL50100

CLUTCH SPRINGCOMPRESSORBOLT ASSEMBLY07GAE - PG0200 orOTGAE - PG4O2OA

www.emanualpro.com