Pump HONDA CR-V 1998 RD1-RD3 / 1.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1998, Model line: CR-V, Model: HONDA CR-V 1998 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 877 of 1395

Power Steering Gearbox

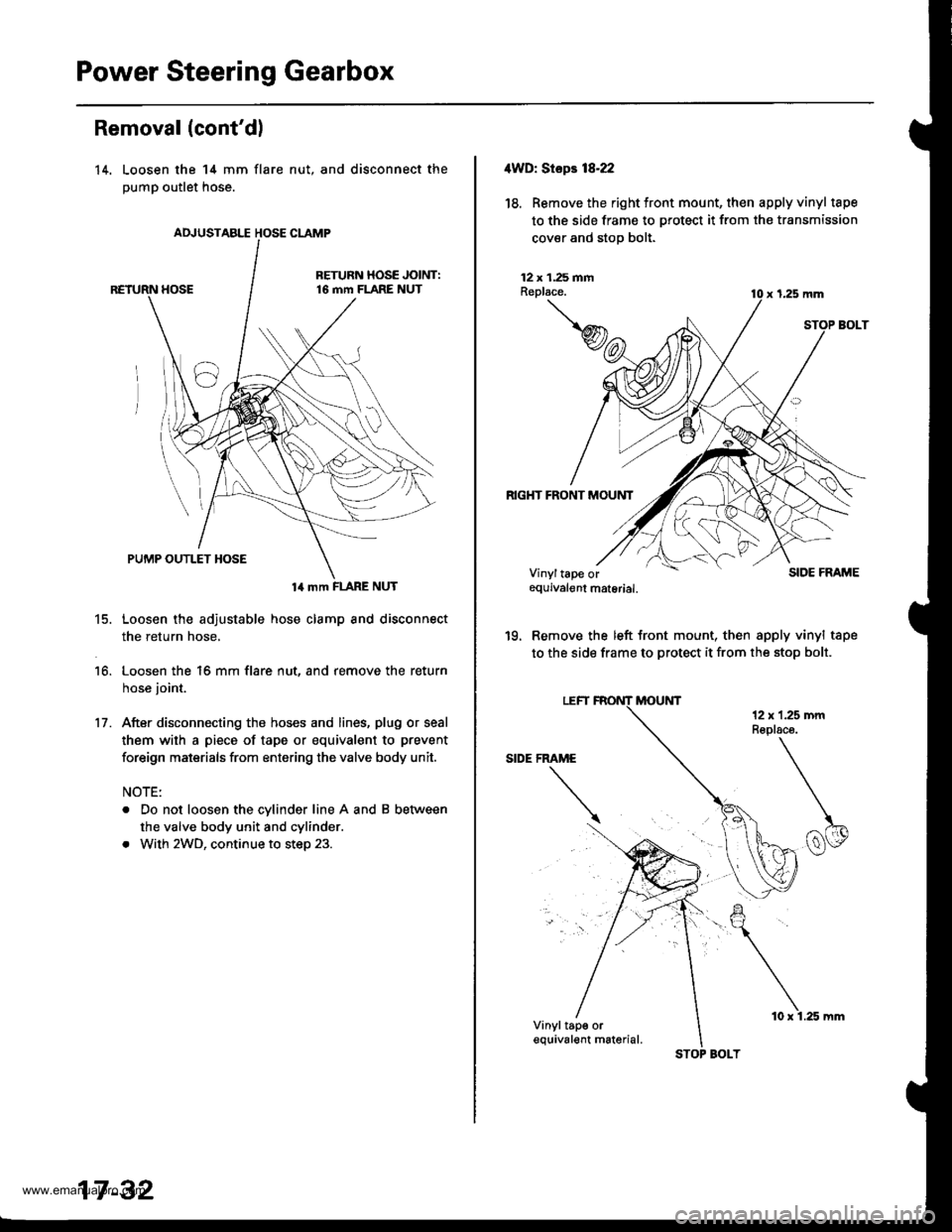

AN'USTABLE HOSE CLAMP

Removal (cont'dl

14. Loosen the 14 mm flare

pump outlet hose.

nut, and disconnect the

14 mm FLARE NUT

15. Loosen the adjustable hose clamp and disconnect

the return hose,

16. Loosen the 16 mm flare nut, and remove the return

hose joint.

17. After disconnecting the hoses and lines, plug or seal

them with a piece of tape or equivalent to prevent

foreign maisrials from entering the valve body unit.

NOTE:

. Do not loosen the cylinder line A and B between

the valve body unit and cylinder.

. With 2WD, continue to step 23.

17 -32

STOP BOLT

10 x 1.25 mm

4WD: Stepr 18-22

18. Removethe right tront mount, then apply vinyl tape

to the side frame to protect it from the transmission

cover and stop bolt.

12 x 1.25 fiiAReplace.

RIGHT FRONT MOUNT

x 1,25 mm

SIDE FRAME

'19. Remove the left front mount, then apply vinyl tape

to the side frame to protect it from the stop bolt.

Vinyltape orequivalgnt material.

Vinyltap€ orequival€nt m6terial.

www.emanualpro.com

Page 897 of 1395

Power Steering Gearbox

Installation (cont'd)

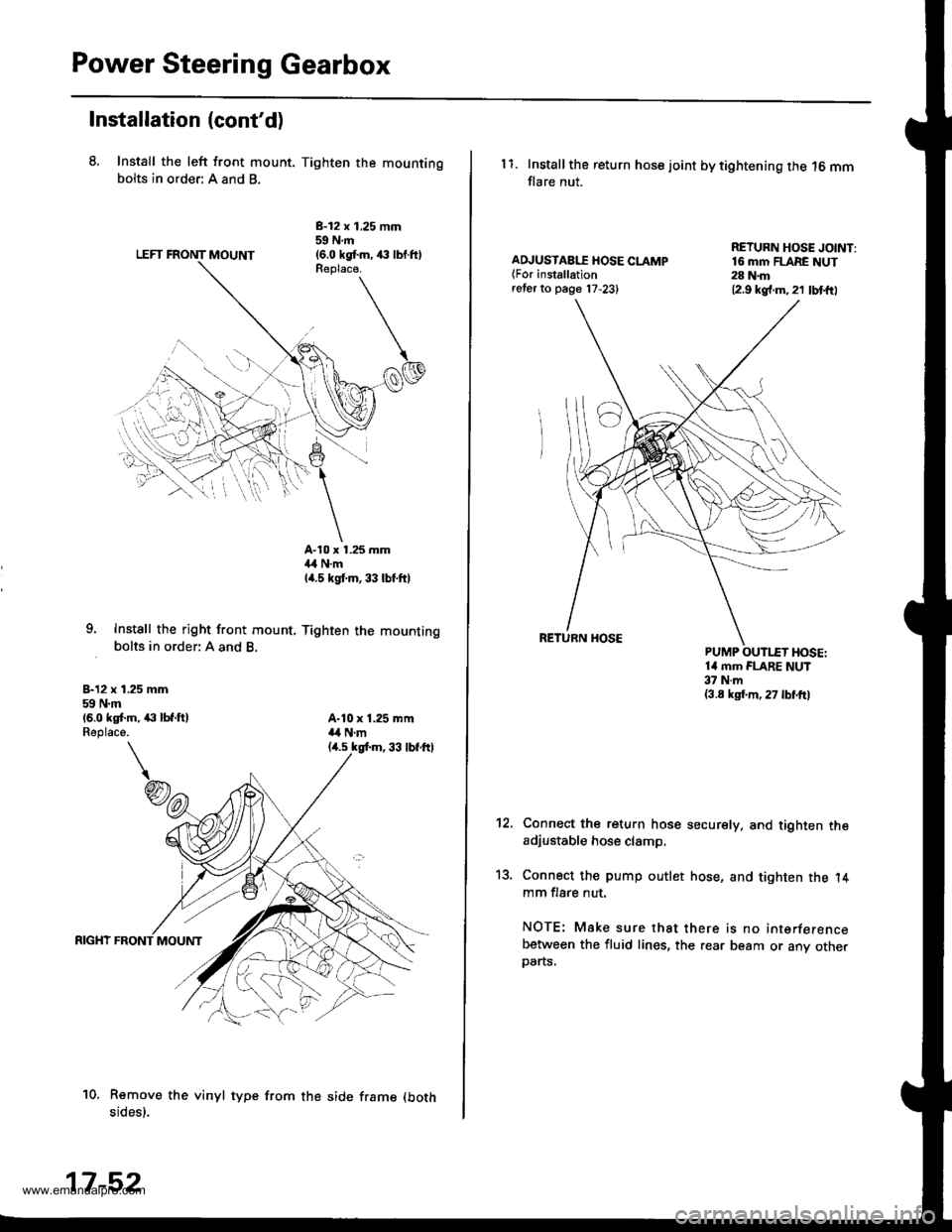

8, Install the left front mount. Tighten the mountingbolts in order: A and B.

LEFT FRONT MOUNT

B-12 x 1,25 mm59Nm(6.0 kgtm,,€ lbl.ftlReplaca.

9. Instsll the right front mount, Tighten the mountingbolts in order: A and B.

B-12 x 1.25 mm59 N.m16.0 ks[.m, ,|:| lbf.ftlReplace.

A-10 x 1.25 mm4,1 N.mla.s kgt m, 33 lbf.ft)

A-10 x 1.25 mma,a N.m

10. Remove the vinyl type from the side frame (both

sides).

17-52

11. Installthe return hose joint by tightening the 16 mmflare nut.

AD.'USTAB[T HOSE CLAMP(For installationreter to page 17,23)

RETURN HOSE JOINT:16 mm FLARE NUT28 N.m12.9 kg{.m.21 lbt{t)

14 mm FLARE NUT37 N.m(3.8 ksf.m, 27 lbl'frl

't2.

13.

Connect the return hose securely. and tighten theadjustable hose clamp.

Connect the pump outlet hose, and tighten the l4mm flare nut.

NOTE: Make sure that there is no interferencebetween the fluid lines, the rear beam or any otherparts.

www.emanualpro.com

Page 931 of 1395

Bleeding

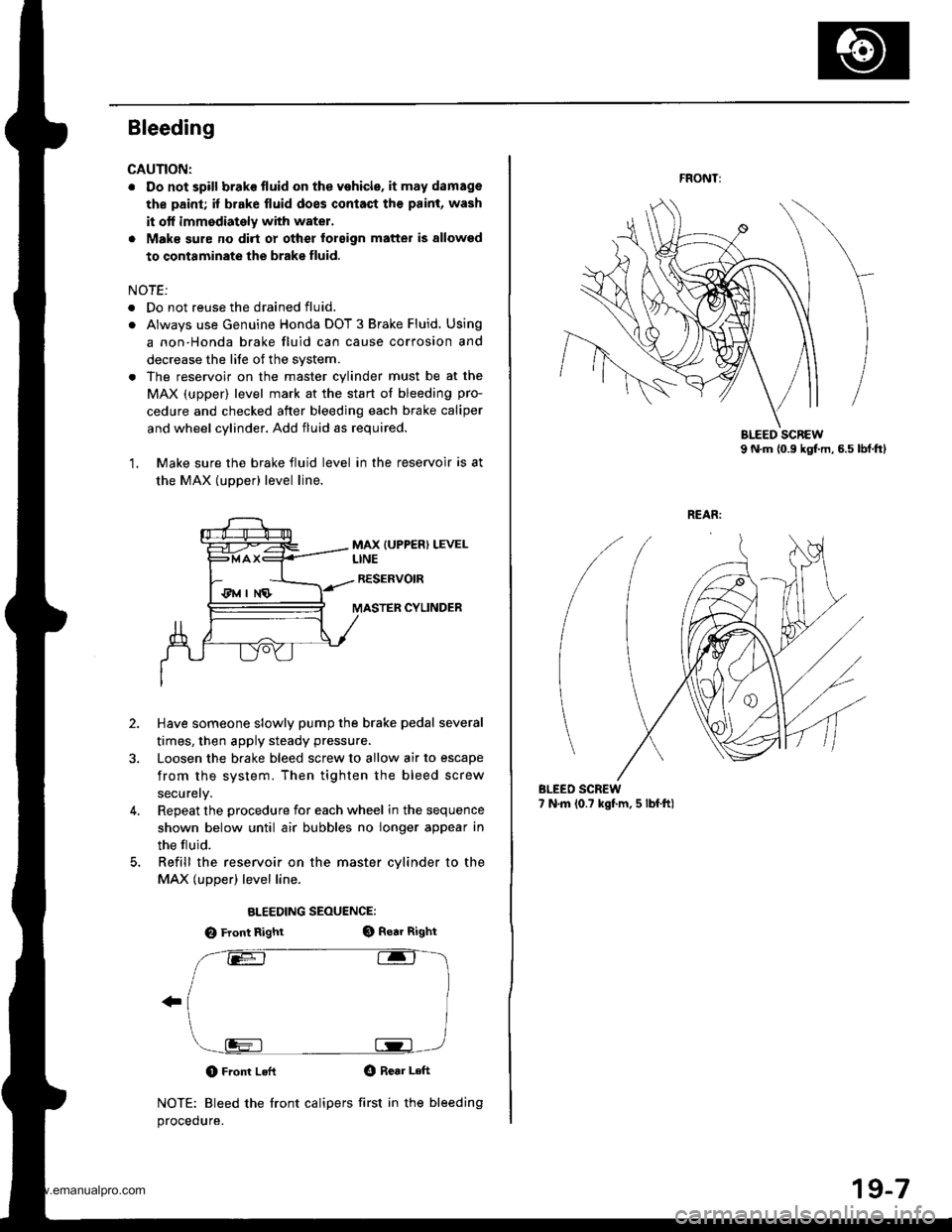

CAUNON:

. Do not spill brake tluid on the vehicle. it may damage

the paint; if brake fluid does contaqt th€ paint, wash

it otf immodiately with water.

. Maks sure no dirt oy other forsign matter is allowsd

to contaminate the brake fluid.

NOTE:

. Do not reuse the drained fluid.

. Always use Genuine Honda DOT 3 Brake Fluid. Using

a non-Honda brake fluid can cause corrosion and

decrease the life of the svstem.

. The reservoir on the master cylinder must be at the

MAX (upper) level mark at the start of bleeding pro-

cedure and checked after bleeding each brake caliper

and wheel cylinder. Add fluid as required.

1, Make sure the brake fluid level in the reservoir is at

the MAX (uDDer) level line.

MAX {UPPER) LEVELLINE

RESERVOIR

MASTER CYLINDER

2.

3.

Have someone slowly pump the brake pedal several

times, then apply steady pressu.e.

Loosen the brake bleed screw to allow air to escape

from the system. Then tighten the bleed screw

securely.

Repeat the procedure for each wheel in the sequence

shown below until air bubbles no longer appear in

the tluid.

Refill the reservoir on the master cvlinder to the

MAX (upper) level line.

ALEEDING SEOUENCE:

O Front RightGt Rear Right

O Front LeflO Rear Left

NOTE: Bleed the front calipers first in the bleeding

procedure.

4.

FRONT:

BLEEO SCREW7 N.m (0.? kgf.m, 5 lbf.ftl

19-7

www.emanualpro.com

Page 948 of 1395

Anti-lock Brake System (ABSI,'97 - 00 Models

Special Tools ............. 19-26

Component Locations ......................... 19-27

Anti-lock Brake System (ABS)

Features/Construction ............. ......, 19-2A

Circuit Diagram ......... 19-32

ABS Control Unit Terminal

Arrangement ......... 19-34

Troubleshooting Precautions ............. 19-36

Diagnostic Trouble Gode (DTC)

Diagnostic Trouble Code (DTC)

Indication (SCS Model ................ 19-38

DTG Erasure (MES Mode) ............... 19-39

Troubleshooting lndex .................... 19-40

Troubleshooting

ABS Indicator Light Does Not

Come On ............ 19-41

ABS Indicator Light Does Not

Go Off (No DTC) ........................... 19-43

DTC 1r - 18:

Wheel Sensor .... 19-45

DTC 31 - 38:

Solenoid ............. 19-47

DTC 51 - 53:

ABS Pump Motor ......................... 19-49

DTC 54:

Main Relay ......... 19-52

DTC 61:

lgnition Voltage ........................... 19-54

DTC 81:

Central Processing Unit (CPU) .... 19-55

Modulator Unit

Removal/lnstallation ....................... 19-56

ABS Control Unit

Replacement ..,...... 19-57

Pulsers/Wheel Sensors

Inspection .............. 19-57

Wheel Sensor Replacement ............ 19-58

www.emanualpro.com

Page 950 of 1395

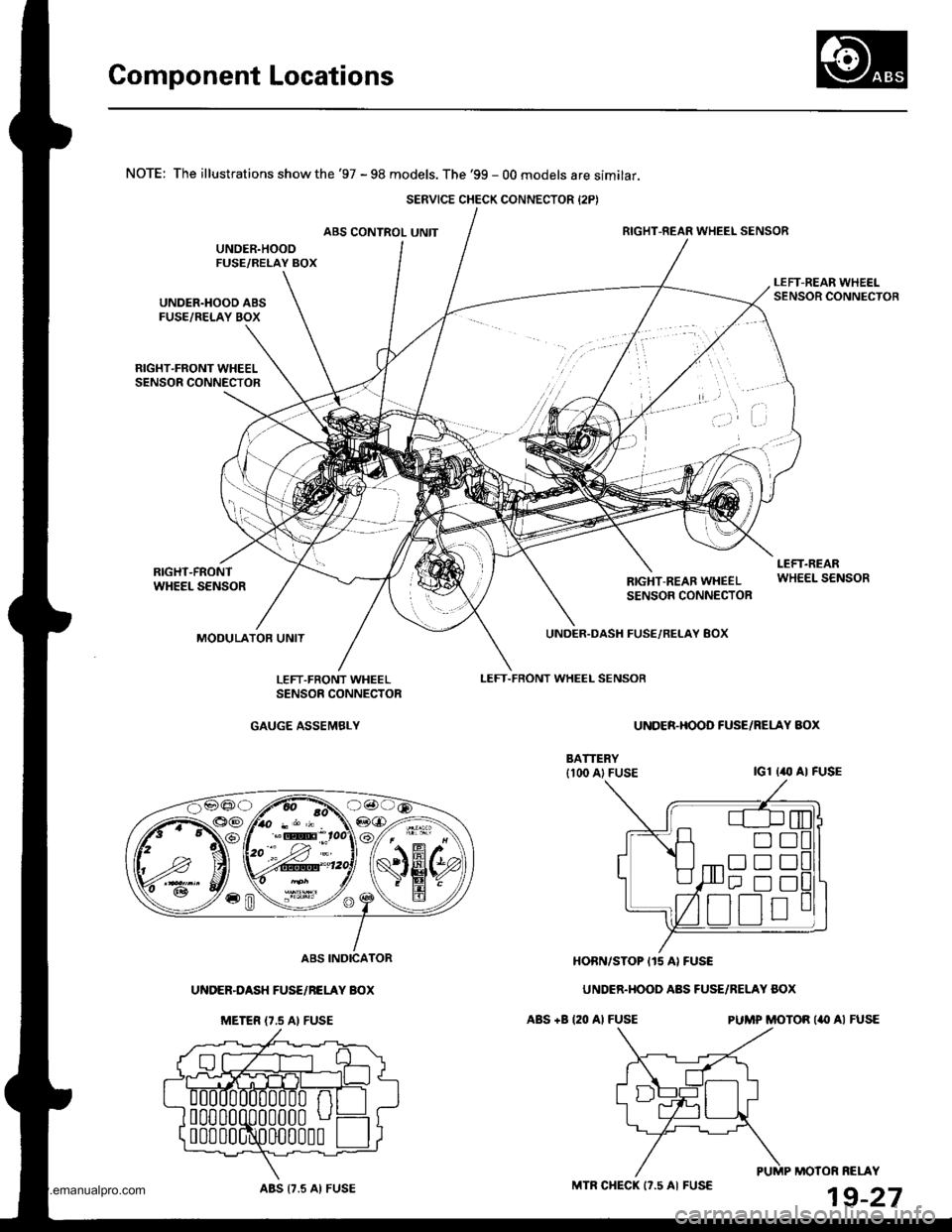

Component Locations

NOTE: The illustrations show the '97 - 98 models. The '99 - 00 models are similar.

ABS CONTROL UNITRIGHT-REAR WHEEL SENSOR

UNDER.HOOD ABSFUSE/RELAY BOX

RIGHT.FRONT WHEELSENSOR CONNECTOR

RIGHT-FRONTWHEEL SENSORRIGHT-REAB WHEELSENSOR CONNECTOR

MODULATOR UNIT

LEFT.FRONT WHEEL SENSOB

UNDER.DASH FUSE,/RELAY 8OX

UNDER.HOOO FUSE/RELAY AOX

IGl I(, AI FUSE

ABS +B 120 Al FUSEPUMP MOTOR ('II AI FUSE

HOBN/STOP I15 AI FUSE

UNDER.HOOD ABS FUSE/RELAY BOX

LEFT.FRONT WHEELSENSOE CONNECTOR

GAUGE ASSEMBLY

ABS INDICATOR

UNDER-DASH FUSE/NELAY BOX

METER {7.5 AI FUSE

MOTOR RELAY

19-27

SERVICE CHECK CONNECTOR {2PI

D!

trtrtr

[r D!

ABS {7.5 AI FUSEMTR CHECK 17.5 AI FUSE

www.emanualpro.com

Page 953 of 1395

Anti-lock Brake System (ABS)

Features/Gonstruction (cont'd)

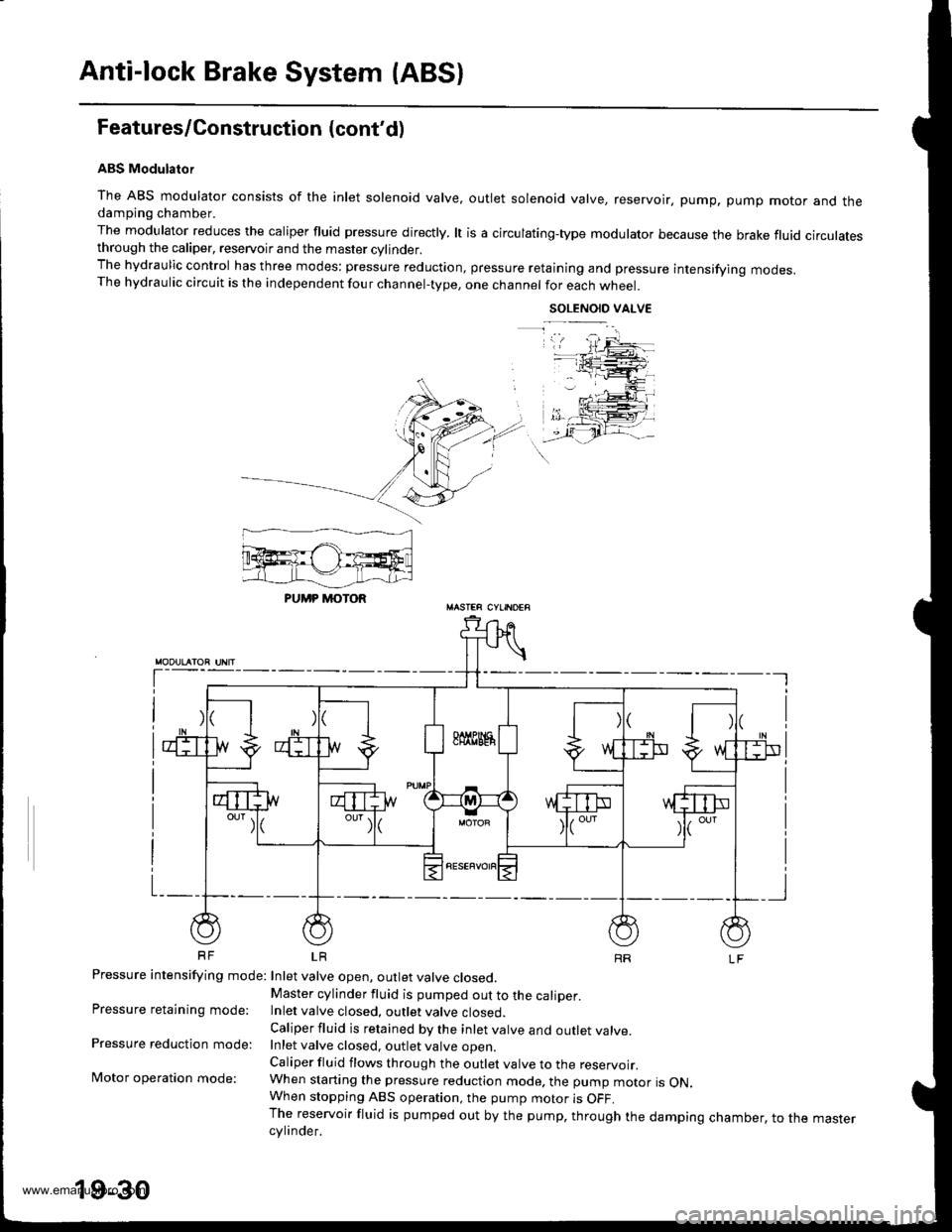

ABS Modulator

The ABS modulator consists of the inlet solenoid valve, outlet solenoid valve, reservoir, pump, pump motor and thedampjng chamber.

The modulator reduces the caliper fluid pressure directly. lt is a circulating-type modulator because the brake fluid circulatesthrough the caliper, reservoir and the master cylinder.The hydraulic control has three modes: pressure reduction, pressure retaining and pressure intensifying modes.The hydraulic circuit is the independent four channel-type, one channel for each wheel.

SOLENOID VALVE

t-

Pressure intensifying mode: Inlet valve open, outlet valve closed,

Pressure retaining mode:

Pressure reduction mode:

Motor operation mode:

Master cylinder fluid is pumped out to the caliper.Inlet valve closed, outlet valve closed.

Caliper fluid is retained by the inlet valve and outlet valve.Inlet valve closed, outlet valve ooen

Caliper fluid flows through the outlet valve to the reservoir.When starting the pressure reduction mode. the pump motor is ON.When stopping ABS operation, the pump motor is OFF.The reservoir fluid is pumped out by the pump, through the damping chamber, to the mastercylinder.

PUMP MOTOR

19-30

www.emanualpro.com

Page 954 of 1395

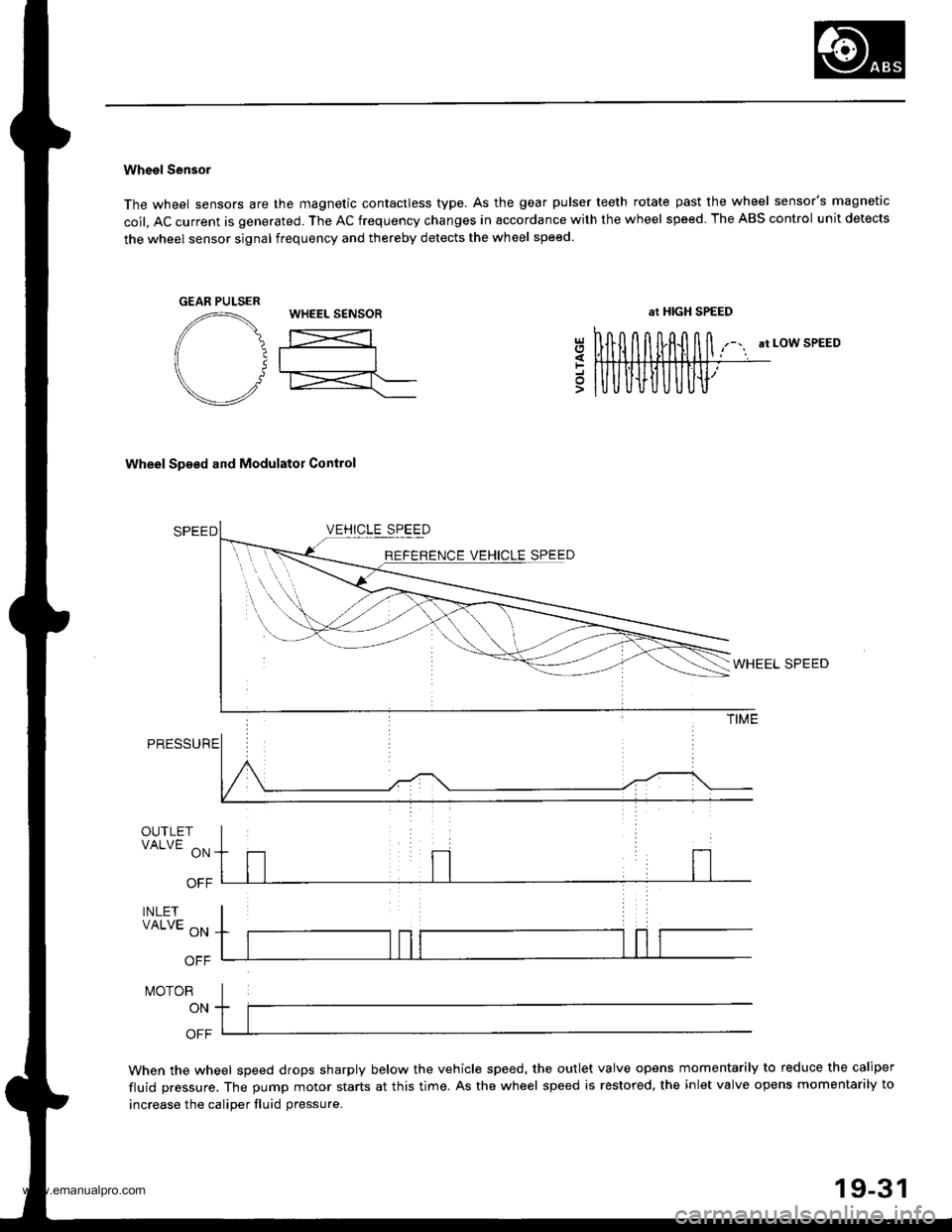

Wheel Sensor

The wheel sensors are the magnetic contactless type. As the gear pulser teeth rotate past the wheel sensor's magnetic

coil, AC current is generated. The AC frequency changes in accordance with the wheel speed. The ABS control unit detects

the wheel sensor signal frequency and thereby detects the wheel speed

at LOW SPEED

wheel Sp€od and Modulatot Control

VEHICLE SPEED

VEHICLE SPEED

WHEEL SPEED

PRESSU

OUTLETVALVE ON

OFF

INLETVALVE ON

OFF

MOTOR

ON

OFF

When the wheel speed drops sharply below the vehicle speed, the outlet valve opens momentarily to reduce the caliper

fluid pressure. The pump motor starts at this time. As the wheel speed is restored. the inlet valve opens momentarily to

increase the caliDer fluid oressure.

F

GEAR PULSER

19-31

www.emanualpro.com

Page 957 of 1395

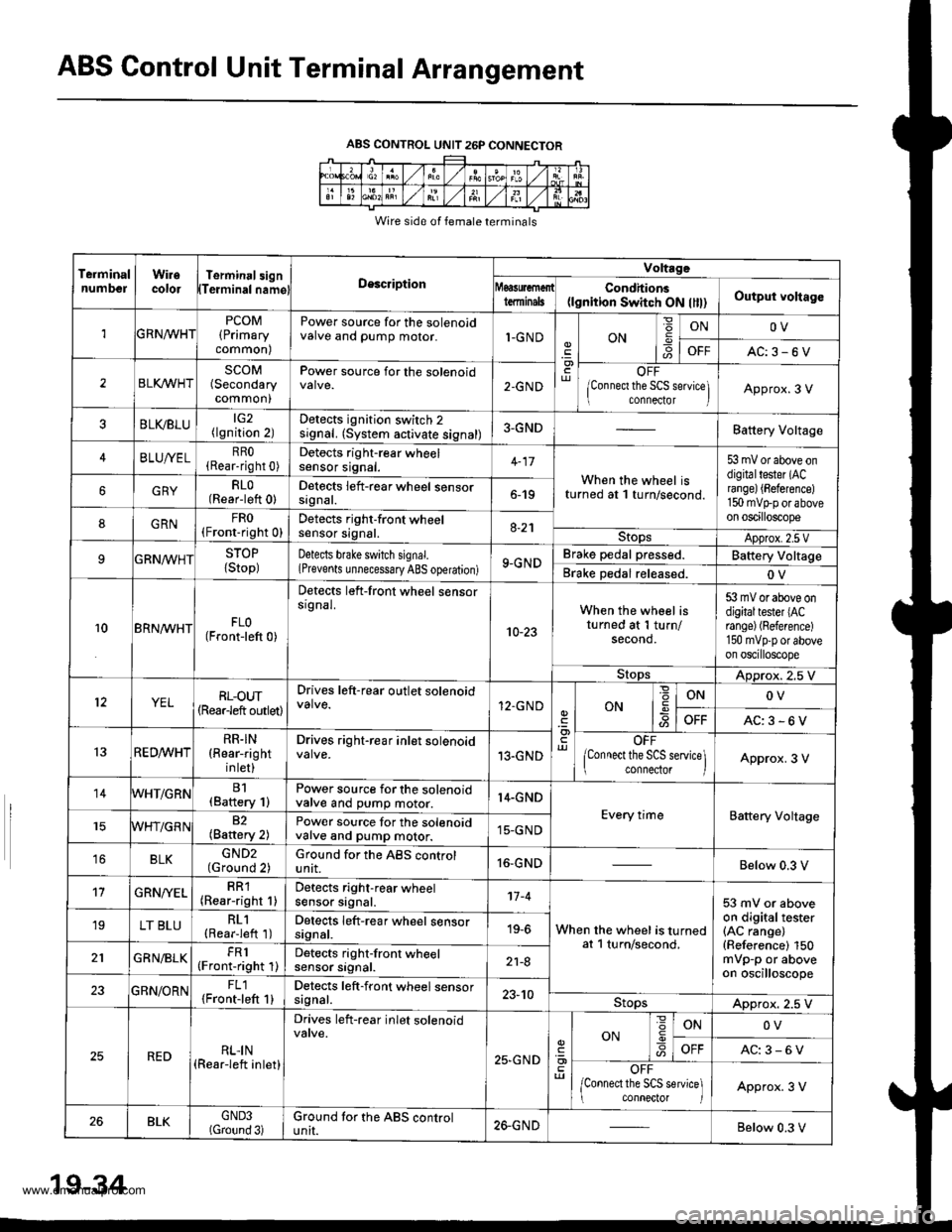

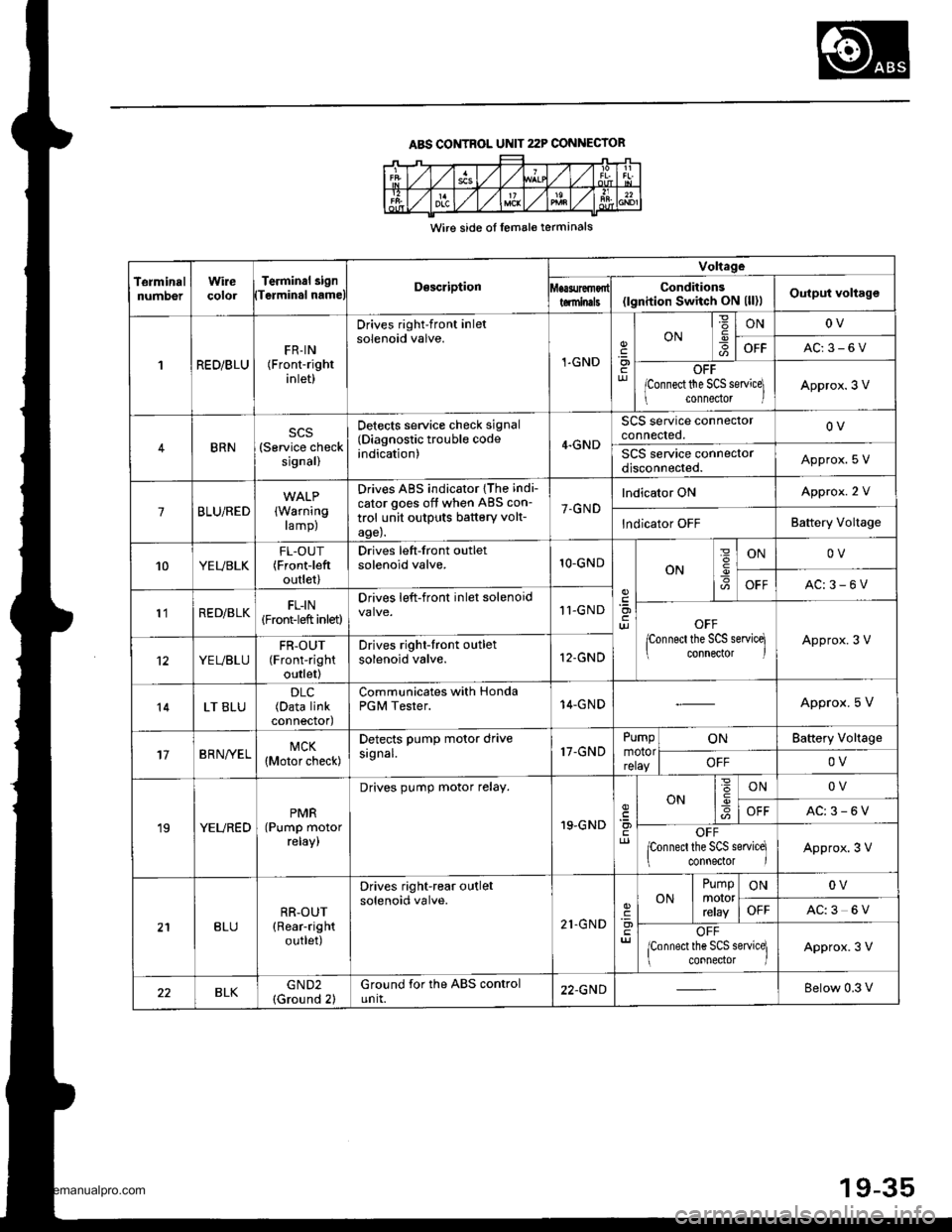

ABS Control Unit Terminal Arrangement

ABS CONTROL UNIT 26P CONNECTOR

Wire side of female terminals

TeiminalnumbelWiiecolorTerminal3ignTeiminalnamglDescription

Voltrge

tdminalsCondhions(lgnition Switch ON llll)Output voltago

1GRNn/VHTPCOM(Primary

common)

Power source for the solenoidvalve and pump motor.1-GNDON6

ONOV

OFFAC:3-6V

2BLI(WHTSCOM(Secondary

common)

Power source for the solenoid2-GNDOFF

lConnect the SCS seNice] connector IApprox.3 V

BLVBLU(lgnition 2)Detects ignition switch 2signal. (System activate signal)3-GNDBattery Voltage

4BLUA/ELRRO(Rear-right 0)Detocts right-rear wheelsensor srgnat.When the wheel isturned at 1 turn/second.

53 mV or above ondigitaltester (ACrange) {Beference)150 mvtrp or aboveon oscilloscope

GRYRLO(Rear-left 0)Detects left-rear wheel sensorsrgnat.6-19

8GRNFRO(Fronr-right 0)Detects right-front wheelsensor signal.8-21StopsApprox.2.5 VSTOP

{Stop)Detects bfake switch signal.(Prevents unnecessary ABS operation)9-GNDBrake pedal pressed.Battery Voltage

Brake Dedal released.OV

10BRN^/VHTFLO(Front-left 0)

Detects left-front wheel sensorsrgnal.

10-23

When the wheel isturned at 1 turn/second.

53 mV or above ondigitaltester lACrange) (Reference)

150 mvpp or aboveon oscilloscope

StopsADprox. 2.5 V

YELRL-oUT(Rearleft outlet)

Drives left-rear outlet solenoid12.GNDONONOV

OFFAC:3-6V

13RED^/vHTRR.IN(Rear-right

inlet)

Drives right-rear inlet solenoid13.GNDOFF

lConnect the SCS service\ connector IApprox. 3 V

14WHT/GRNB1(Baftery 1)Power source for the solenoidvalve and pump motor.14.GND

Every timeBattery Voltage82(Battery 2)Power source for the solenoidvalve and pump motor.15-GND

16BLKGND2(Ground 2)Ground for the ABS controlunit.16-GNDBelow 0.3 V

't7GRN/YELRR1(Rear-right 1)Detects right-rear wheelsensor signal.'t7 -4

When the wheel is turnedat l turn/second,

53 mV or aboveon digitaltester(AC range)(Reference) 150mVp-p or aboveon oscilloscope

19LT BLURL1(Rearieft 1)Detects left-rear wheel sensorsignal.19-6

GRN/BLKFR1(Front-right 1)Detects right-front wheelsensor srgnat.21-8

23GBN/ORNFL1{Front-left 1}Detects left-front wheel sensorsagnal.23-10StopsApprox. 2.5 V

REDRLI N(Rear-left inlet)

Drives left-rear inlet solenoid

25,GND

ON

=

-9ONOV

AC:3-6V

OFF

/Connect the SCS service] conneclor IApprox. 3 V

26BLKGND3(Gtound 3)Ground tor the ABS controluntI.26-GNDBelow 0.3 V

19-34

www.emanualpro.com

Page 958 of 1395

ABS CONTROL UNIT 22P CONNECIOR

Wire side ol lemale terminals

TerminalnumDerWirecolorTerminal 3i9nTerminal nameDescription

Voltage

Conditions(lgnition Switch ON (ll)lOutput voltagetominals

1RED/BLUFR-IN(Front-right

inlet)

Drives right-front inletsolenoid valve.

1-GND.9otur

ONIONOV

OFFAC:3-6V

OFF

lconnect the SCS servicel

connedor lApprox.3 V

BRN(Service checksignal)

Detects service check signal(Diagnostic trouble codeindication)4.GND

SCS service connectorconnected.OV

SCS service connectordisconnected.Approx. S V

7BLU/RED(Warning

ramp)

Drives ABS indicator {The indi-

cator goes off when ABS con-

trol unit outputs battery volt-age).

7.GND

lndicator ONApprox. 2 V

lndicator OFFBattery Voltage

10YEUBLKFL-OUT(Frontieft

outlet)

Drives left-front outletsolenoid valve.1O-GNDON

=

I

ONOV

OFFAC:3-6V

l'lRED/BLKFL-IN(Front-left inlet)

Drives left-front inlet solenoid11-GNDOFF

lconnect the SCS servicq connector lApprox.3 V

YEUBLUFR-OUT(Front-right

outlet)

Drives right-front outletsolenoid valve.12-GND

14LT BLU(Data linkconnectod

Communicates with HondaPGM Tester.14-GNDApprox. 5 V

17BRN/YELMCK(Motor check)

Detects PumP motor drivesignal.17-GNDPumpmotorrelay

ONBattery Vollage

OFFOV

19YEUREDPMR(Pump motorreray,

Drives pump motor relay.

19.GNDcl)

ON6IONOV

OFFAC:3-6V

OFFponnecl the SCS service]

connector IApprox.3 V

BLURR-OUT(Rear-right

outlet)

Drives right-rear outletsolenoid valve.

21.GND'a)

ONPumpmororrcray

ONOV

OFFAC:3 6V

OFF

lconnect the SCS service] connector lApprox.3 V

BLKGND2(Ground 2)Ground for the ABS controlunit.22.GNDBelow 0.3 V

19-35

www.emanualpro.com

Page 960 of 1395

Kickback'1. The motor operates when the ABS is functioning. and the fluid in the reservoir is forced out to the master cylinder,

causing kickback at the brake pedal.

2. The ABS control unit operates the solenoid valve when the brake pedal is released after the initial diagnosis You may

hear the solenoid valve operate at this time, but it is normal

Pumo Motol

1. The pump motor operates when the ABS is functioning

2. The ABS control unit checks the pump motor operation during acceleration. You may hear the motor operate at this

time, but it is normal.

Brake Fluid Replacement/Ail Bleeding

L Brake fluid replacement and air bleeding procedures are the same as for vehicles without ABS To ease bleeding, start

with the front wheels.

Troubleshooting

1. The troubleshooting flowchart procedures assume that the cause of the problem is still present and the ABS indicator

is still on. Following the flowchart when the ABS indicator does not come on can result in incorrect diagnosis.

2. Ouestion the customer about the conditions when the problem occurred, and try to reproduce the same conditions

for troubleshooting.

Self-diagnosis is made at various times such as the initial diagnosis, except ABS control, during ABS control, during

acceleration, during the specified vehicle speed, etc. Therefore, the symptom canngt be checked unless the check

conditions match with the problem conditjons

3. When the ABS jndicator does not come on during the test-drive. but troubleshooting is performed based on the DTC,

check lor loose connectors, poor contact of the terminals, etc., before you start troubleshooting.

4. After troubleshooting, erase the DTC and test-drive the vehicle. Be sure the ABS indicator does not come on.

5. The connector illustratjons show the female terminals with a single outline and the male terminals with a double out-

l ne.

ABS Function Test

To simulate ABS operation and activate the solenoid valves and pump, use the Honda PGM Tester.

Connect the PGM Tester to the 16P Data Link Connector (DLC). When the System Select menu is displayed, select the ABS

Test Mode menu, and follow the tester's prompts.

19-37

www.emanualpro.com