Pump HONDA CR-V 1998 RD1-RD3 / 1.G Owners Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1998, Model line: CR-V, Model: HONDA CR-V 1998 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 678 of 1395

Pressure Testing

(cont'd)

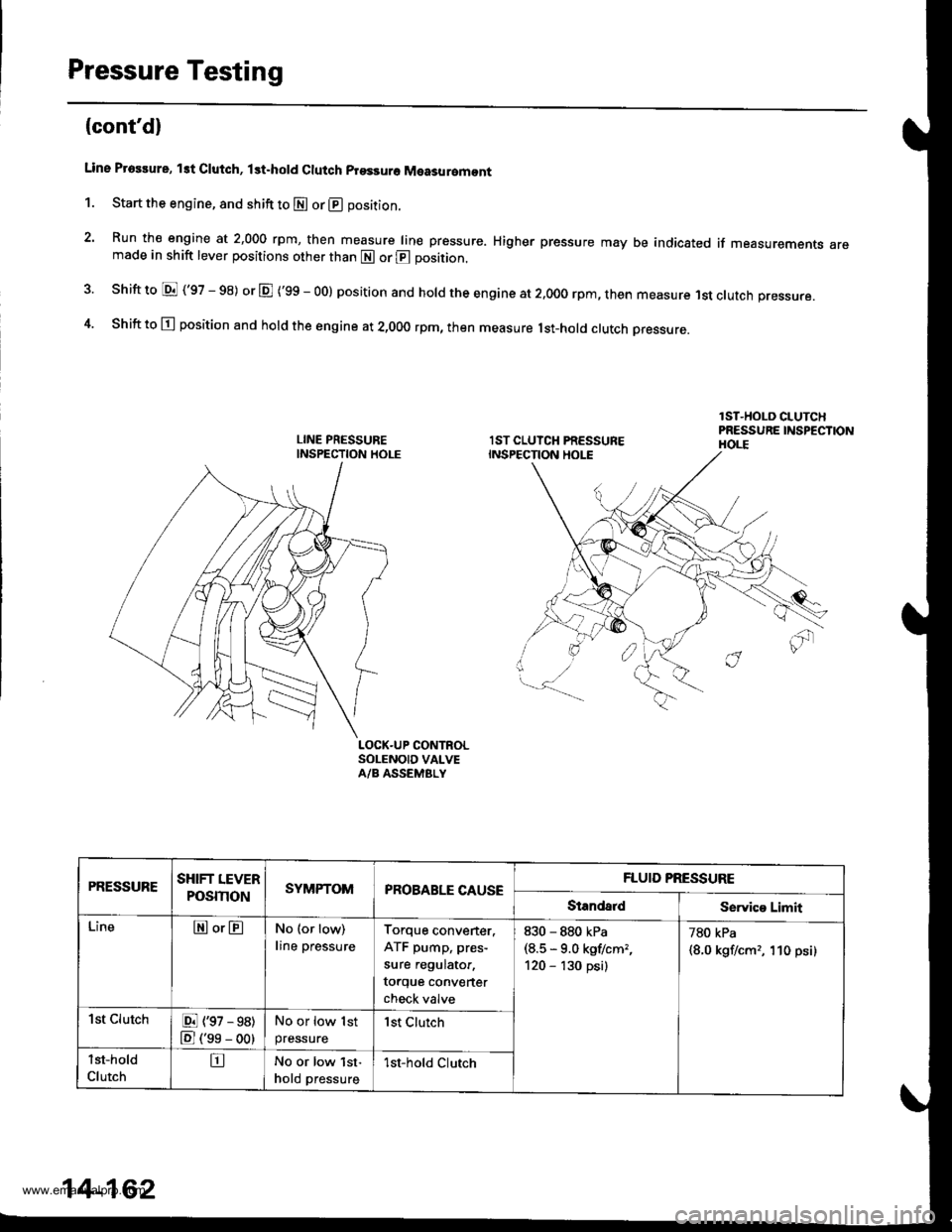

Line Proslure, lst Clutch, lst.hold Clutch prsssuro Measuromont

1. Start the engine, and shift to E or @ position.

2. Run the engine at 2,000 rpm, then measure line pressure. Higher pressure may be indicated if measurements aremade in shift lever positions other than E or @ position.

shift to E ('97 - 98) or E ('99 - oo) position and hold the engine at 2.ooo rpm, then measure 1st clutch pressure.

Shift to E position and hold the engine at 2,000 rpm, then measure lst-hotd ctutch Dressure.

LOCK.UP CONTROLSOLENOID VALVEA/B ASSEMBLY

4.

PRESSURESHIFT LEVER

POSmONSYMPTOMPROBABLE CAUSEFLUID PRESSURE

StandaldService Limit

LineEor@No (or low)

line pressure

Torque converter.

ATF pump, pres-

sure regulator,

torque converter

check valve

830 - 880 kPa(8.5 * 9.0 kgflcm,,

120 - '130 psi)

780 kPa

{8.0 kgf/cm,, 'l10 psi)

1st ClutchE (97 - 98)

E ('se - oo)

No or low 1st

pressurelst Clurch

lst-hold

ClutchtrNo or low lst-

hold pressure1st-hold Clutch

14-162

www.emanualpro.com

Page 695 of 1395

oa;\,6

G)!o,

a@,6

@o(a

@(}

@a@@@@@@@6@@)@@@@@@@@@@@@@

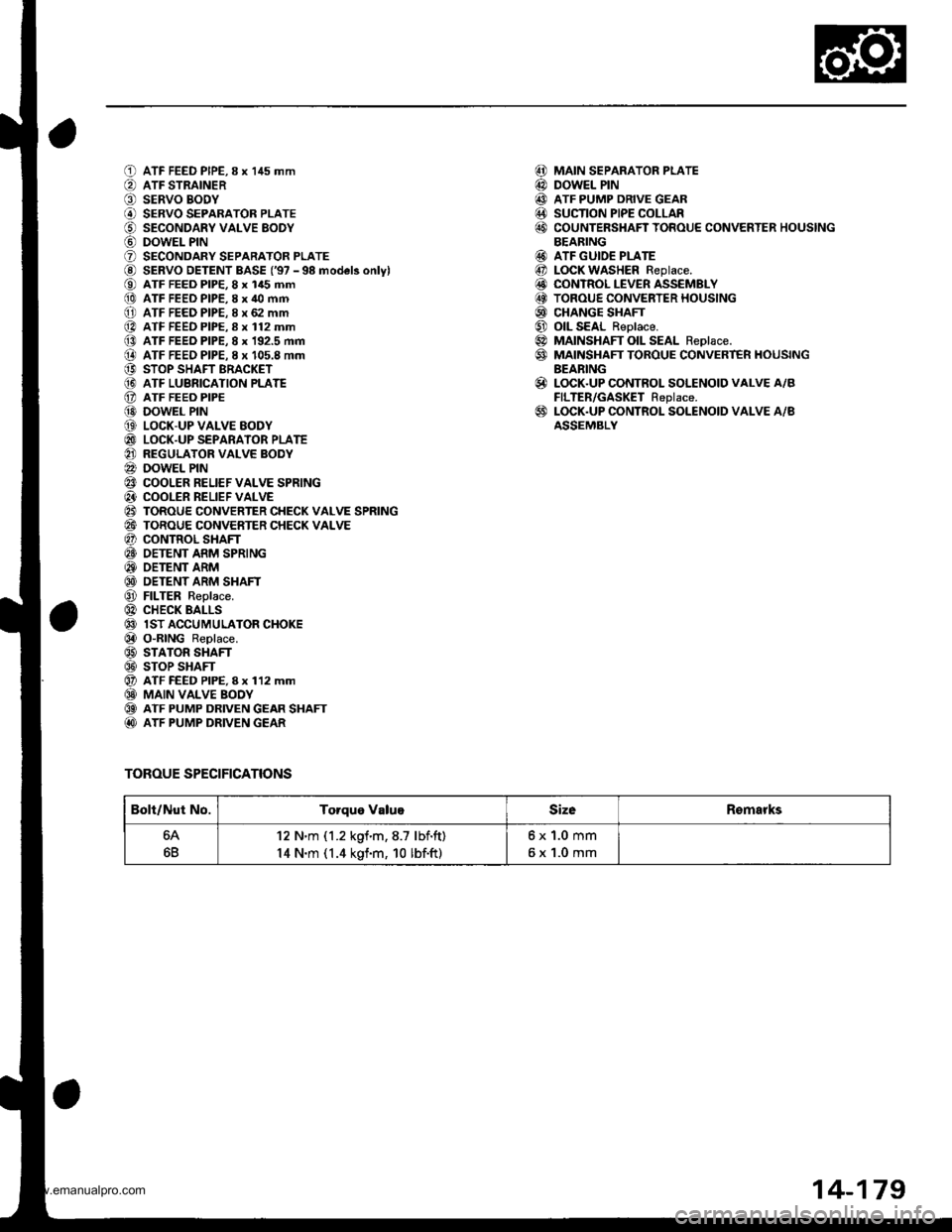

ATF FEED PIPE,8 x 145 mmATF STRAINERSERVO BODYSERVO SEPARATOR PLATESECONDARY VALVE EODYDOWEL PINSECONDARY SEPARATOR PLATESERVO DETENT BASE ('97 - 98 model3 onlylATF FEED PIP€, 8 x 145 mmATF FEED PIPE,8 x 40 mmATF FEED PIPE. 8 x 62 mmATF FEED PIPE.8 x 112 mmATF FEED PIPE, 8 x 192.5 mmATF FEEO PIPE. I x 105.8 mmSTOP SHAFT BRACKETATF LUBRICATION PLATEATF FEEO PIPEDOWEL PINLOCK-UP VALVE EODYLOCK-UP SEPARATOR PLATEREGULATOR VALVE BODYDOWEL PINCOOLER RELIEF VALVE SPRINGCOOLER RELIEF VALVETOROUE CONVERTER CHECK VALVE SPRINGTOROUE CONVERTER CHECK VALVECONTROL SHAFTOETENT ARM SPRINGOETENT ARMDETENT ARM SHAFTFILTER Replace.CHECK BALLSlST ACCUMULATOR CHOKEO"RING Replace.STATOR SHAFTSTOP SHAFTATF FEED PIPE, I x 112 mmMAIN VALVE BOOYATF PUMP DRIVEN GEAR SHAFTATF PUMP DRIVEN GEAR

TOROUE SPECIFICATIONS

MAIN SEPARATOR PLATEDOWEL PINATF PUMP DRIVE GEARSUCTION PIPE COLLARCOUNTERSHAFT TOROUE CONVERTER HOUSINGBEARINGATF GUIDE PLATELOCK WASHER Replace.CONTROL LEVER ASSEMBLYTOROUE CONVERTER HOUSINGCHANGE SHAFTOIL SEAL Reolace.MAINSHAFT OIL SEAL Reolace.MAINSHAFT TOROUE CONVERT€R HOUSINGBEARINGLOCK.UP CONTROL SOLENOID VALVE A/BFILTER/GASKET Replace.LOCK.UP CONTROL SOLENOID VALVE A/BASSEMBLY

@@@@@

@@@@@@@@

@

@

Bolt/Nut No.Torque ValugSizeRomarks

64

6B

12 N'm (1.2 kgf.m,8.7 lbf.ft)

14 N.m (1.4 kgf.m, 10 lbf.ft)

6x1.0mm

6x1.0mm

14-179

www.emanualpro.com

Page 701 of 1395

![HONDA CR-V 1998 RD1-RD3 / 1.G Owners Manual

ai_la2,

(41/4.:4.

\7)

1.0)tl

(3]

t9.1q

oo,ID@,8!Itt\,29

€4

69

aa.21

600toa

04

6!)ent00t.@

ATF FEED PIPE, I x 145 mm

ATF STRAINERSERVO BODYSERVO SEPARATOB PLATESECONDABY VALVE BOOYDOWEL PINSECONDAR HONDA CR-V 1998 RD1-RD3 / 1.G Owners Manual

ai_la2,

(41/4.:4.

\7)

1.0)tl

(3]

t9.1q

oo,ID@,8!Itt\,29

€4

69

aa.21

600toa

04

6!)ent00t.@

ATF FEED PIPE, I x 145 mm

ATF STRAINERSERVO BODYSERVO SEPARATOB PLATESECONDABY VALVE BOOYDOWEL PINSECONDAR](/img/13/5778/w960_5778-700.png)

ai_la2',

(41/4.:4.

\7)

1.0)tl

(3]

t9.1q

oo,ID@,8!Itt\,29

€4

69

aa.21

600toa

04

6!)ent00t.@

ATF FEED PIPE, I x 145 mm

ATF STRAINERSERVO BODYSERVO SEPARATOB PLATESECONDABY VALVE BOOYDOWEL PINSECONDARY SEPARATOR PLATE

SERVO DETENT BASE ('98 model onlvl

ATF FEED PIPE, 8 x 145 mmATF FEED PIPE.8 x 40 mmATF FEED PIPE,8 x 62 mmATF FEED PIPE, I x 112 mm

ATF FEED PIPE, 8 x 192.5 mm

ATF FEED PIPE, 8 x 105.8 mm

STOP SHAFT BRACKETATF LUERICATION PLATEATF FEED PIPEDOWEL PINLOCK-UP VALVE BODYLOCK-UP SEPARATOR PLATE

REGULATOR VALVE BOOYDOWEL PINCOOLER RELIEF VALVE SPRINGCOOLER BELIEF VALVETOROUE CONVERTER CHECK VALVE SPRING

TOROUE CONVERTER CHECK VALVECONTNOL SHAFTDETENT ARM SPRINGDETENT ARMDETENT ARM SHAFTFILTER Replace.CHECK BALLS1ST ACCUMULATOR CHOKEO-RING Replace.STATOR SHAFTSTOP SHAFTATF FEED PIPE. 8 x 112 mmMAIN VALVE BODYATF PUMP DRIVEN GEAR SHAFTATF PUMP DRIVEN GEAR

MAIN SEPARATOR PLATE

DOWEL PINATF PUMP DRIVE GEARSUCTION PIPE COLLARCOUNTEBSHAFT TOROUE CONVERTER HOUSING

BEARINGATF GUIDE PLATEATF MAGNETTOBOUE CONVERTER HOUSINGOIL SEAL Beplace.MAINSHAFT OIL SEAL Replace.MAINSHAFT TOROUE CONVERTER HOUSING

BEARINGLOCK.UP CONTROL SOLENOID VALVE A/B

FILTER/GASKET Replace.LOCK-UP CONTROL SOLENOID VALVE A/B

ASSEMELY

i4ll(4d

@@.!!l

art)@@@@li]t

TOROUE SPECIFICATIONS

Bolt/Nut No.Torque ValueSizeRemarks

12 N.m (1.2 kgim,8.7 lbf'tt)6x1.0mm

14-185

www.emanualpro.com

Page 706 of 1395

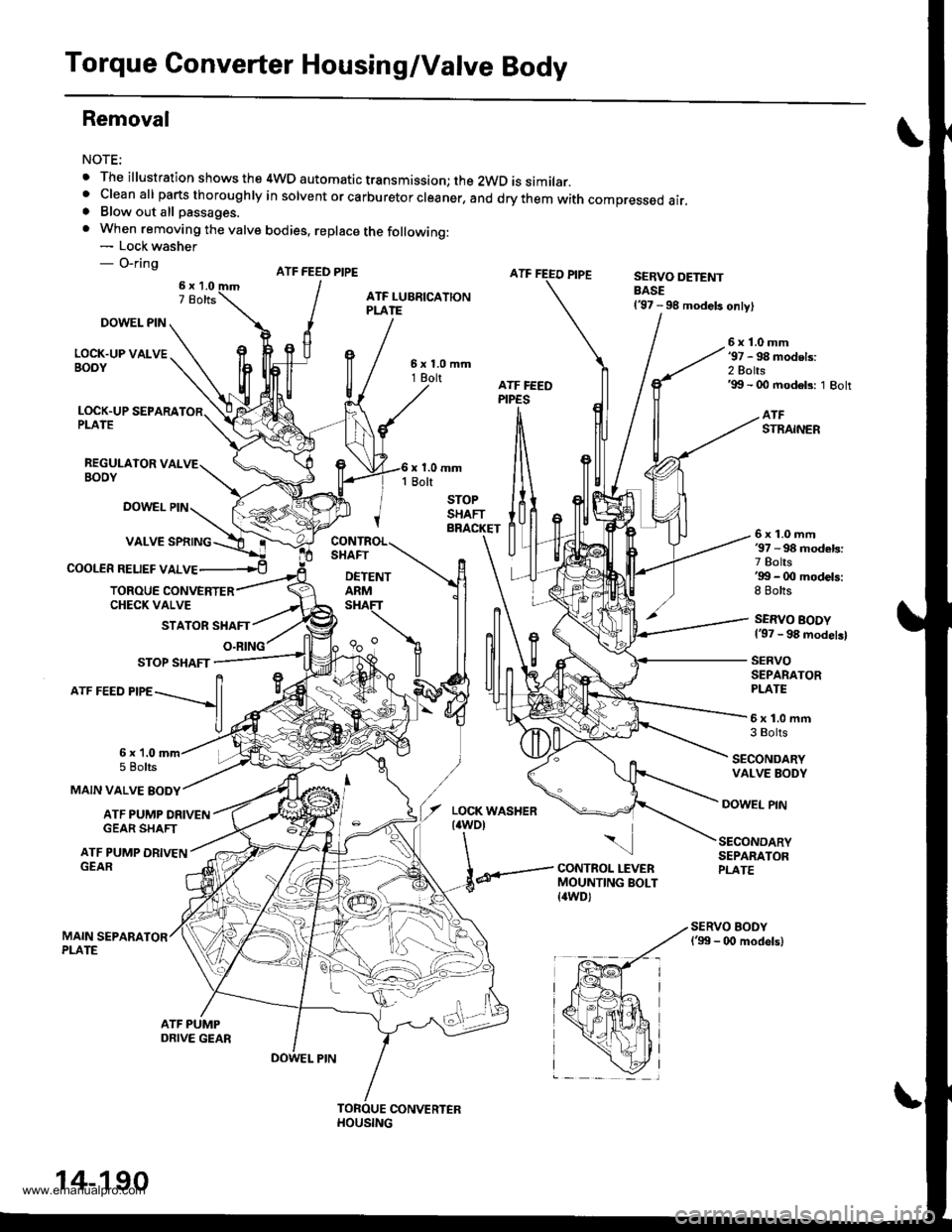

Torque Converter Housing/Valve Body

Removal

NOTE:

. The illustration shows the 4WD automatic transmission; the 2WD is similar.' cleanall parts thoroughry in sorvent or carburetor creaner, and drythem with compressed air.. Blow out all passages.

. When removing the valve bodies, replace the following:- Lock washer- O-ringATF FEED PIPESERVO DETENTBASE137 - 98 models only)

DOWEL PIN

LOCK.UP VALVEBOOY

6x1.0mm'97 - 98 models:2 Bolts'99 - 00 modeb: 1 Bolt

LOCK.UP SEPARAPLATE

REGULAIOR VALVEBOOY

ATFSTRAINER

DOWEL PIN

COOLER RELIEF VALVE

6x1.0mm37 - 98 models:7 Bolts'gg - 0O models:8 Bolts

SERVO BODY137 - 98 modelsl

SERVOSEPARATORPLATE

TOROUE CONVERTERCHECK VALVE

STATOR SHAFT

O.RING

5x1.0mfi3 Bolts

SECONDARYVALVE BODY

MAIN VALVE BODY

6x 1.05 Bolts

ATF PUMP ORIVENGEAR SHAFT

DOWEL PIN

ATF PUMP DRIVENGEAR

\

CONTROL LEVERMOUNTING BOLT{awD)

SECONDARYSEPARATORPLATE

14-190

www.emanualpro.com

Page 707 of 1395

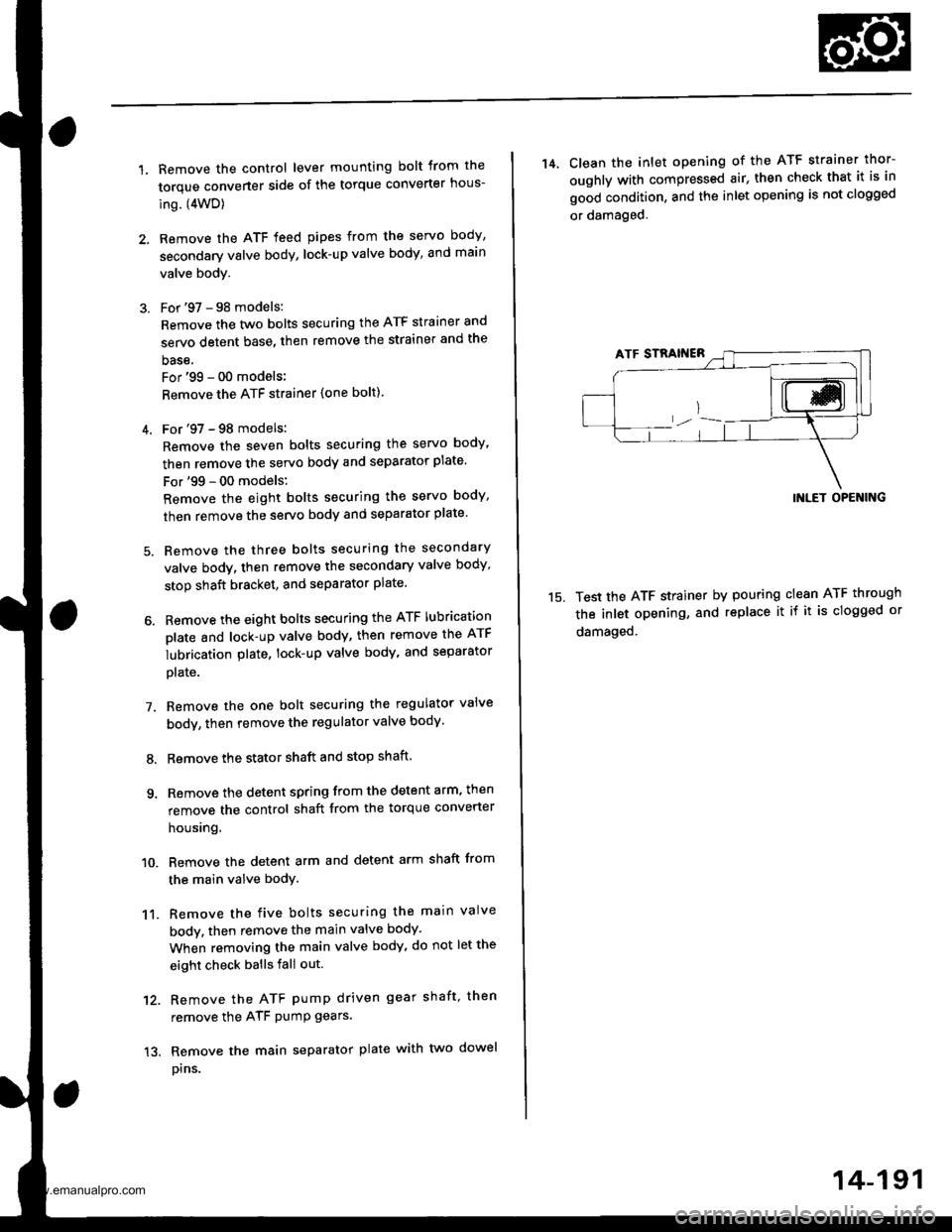

1.Remove the control lever mounting bolt trom the

torque converter side of the torque converter hous-

ing. (4WD)

Remove the ATF feed pipes from the servo body,

secondary valve body, lock-up valve body, and main

valve body.

For '97 - 98 models:

Remove the two bolts securing the ATF strainer and

servo detent base, then remove the strainer and the

base.

For'99 - 00 models;

Remove the ATF strainer {one bolt).

4. For'97 - 98 models:

Remove the seven bolts securing the servo body,

then remove the servo body and separator plate'

For'99 - 00 models:

Remove the eight bolts securing the servo body,

then remove the servo body and separator plate'

5. Bemove the three bolts securing the secondary

valve body, then remove the secondary valve body'

stop shaft bracket, and separator plate.

6. Remove the eight bolts securing the ATF lubrication

plate and lock-up valve body, then remove the ATF

lubrication plate, lock-up valve body' and separator

plate.

7. Remove the one bolt securing the regulator valve

body, then remove the regulator valve body'

8. Remove the stator shaft and stop shaft.

9. Remove the detent spring from the detent arm, then

remove the control shaft from the torque converter

houslng.

10. Remove the detent arm and detent arm shaft from

the main valve body.

11. Remove the five bolts securing the main valve

body, then remove the main valve body.

When removing the main valve body, do not let the

eight check balls fall out.

12. Remove the ATF pump driven gear shaft, then

remove the ATF PumP gears.

13. Remove the main separator plate with two dowel

prns.

14, Clean the inlet opening of the ATF strainer thor-

oughly with compressed air, then check that it is in

good condition, and the inlet opening is not clogged

or damaged.

15.

INLET OPENING

Test the ATF strainer by pouring clean ATF through

the inlet opening, and replace it if it is clogged or

damaged.

14-191

www.emanualpro.com

Page 711 of 1395

ATF Pump

Inspection

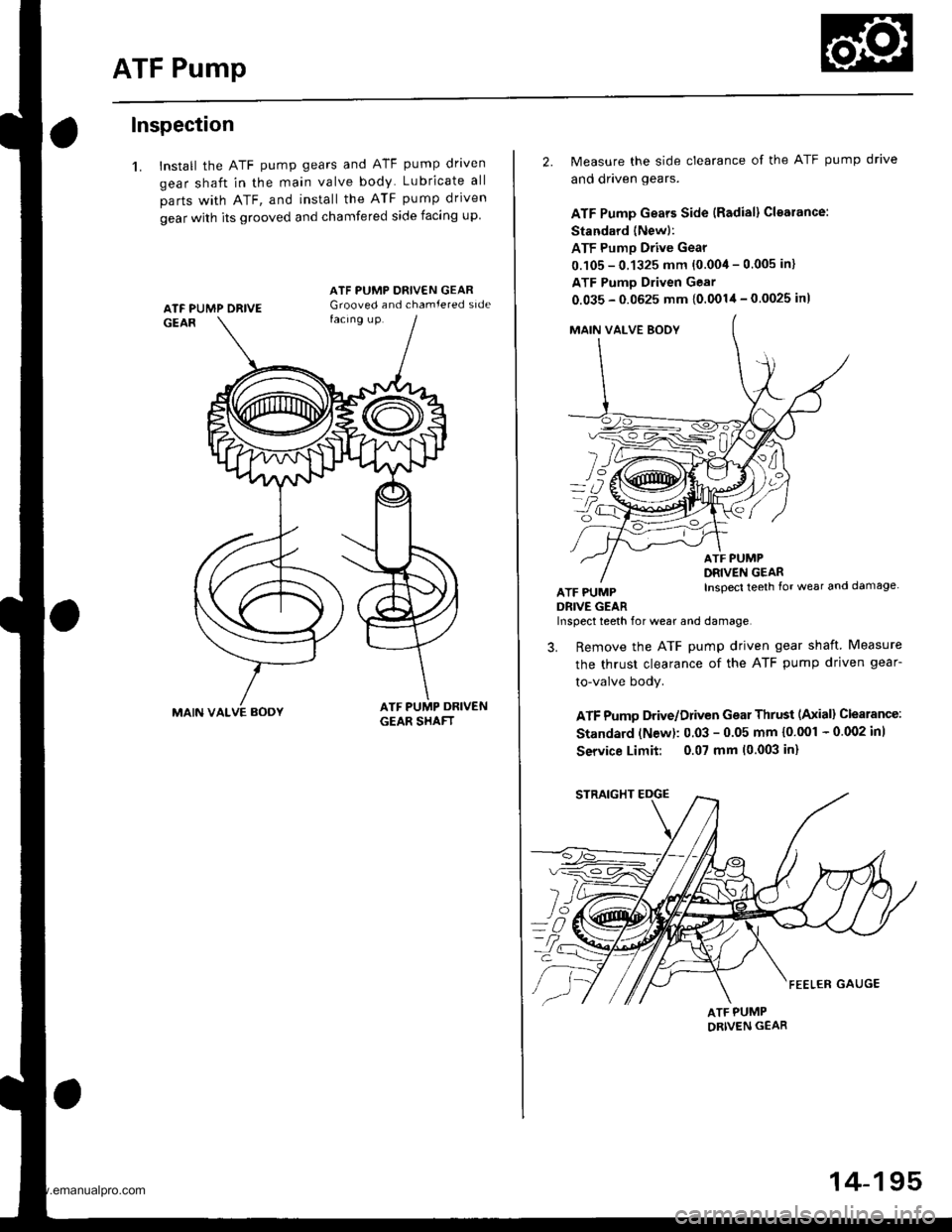

1. Install the ATF pump gears and ATF pump driven

gear shaft in the main valve body Lubricate all

parts with ATF, and install the ATF pump driven

gear with its grooved and chamfered side facing up

MAIN VALVE AOOY

ATF PUMP ORIVE

2. Measure the side clearance of the ATF pump drive

and driven gears.

ATF Pump Gears Side {Radial} Cloarance:

Standard (Newl:

ATF Pump Drive Gear

0.105 - 0.1325 mm {0.004 - 0.005 in}

ATF Pumo Driven Gear

0.035 - 0.0625 mm {0.0014 - 0.0025 in)

MAIN VAI-VE BOOY

fl

L/

ATF PUMPDRIVE GEAR

ATF PUMPDRIVEN GEARInspecl teeth {or wear and damage

Inspect teeth for wear and damage,

3. Remove the ATF pump driven gear shaft Measure

the thrust clearance of the ATF pump driven gear-

to-valve body.

ATF Pumo Drive/Driven Gear Thrust (Axiall Clearance:

Standard (N€w): 0.03 - 0.05 mm {0'001 - 0 002 inl

Service Limit: 0.07 mm 10.003 in)

ATF PUMPORIVEN GEAR

14-195

www.emanualpro.com

Page 766 of 1395

Transmission

Reassembly

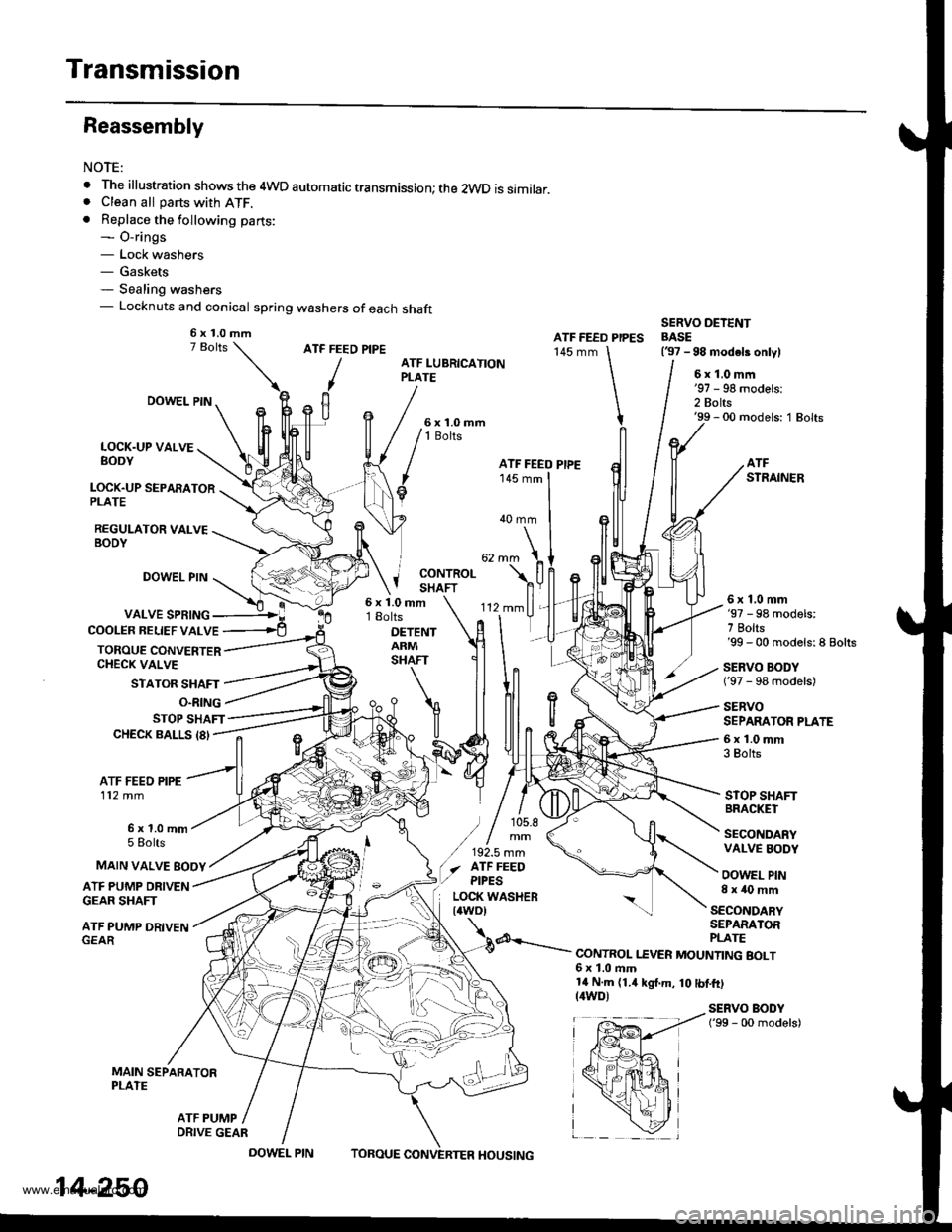

NOTE:

. The illustration shows the 4WD automatic transmission; the 2WD is similar.. Clean all parts with ATF.. Replace the following parts:- O-rings- Lock washers- Gaskets- Sealing washers- Locknuts and conical spring washers of each shaft

ATF FEED PIPE

/

ATF FEED PIPES145 mm

SERVO DETENTBASE(37 -98 modeb onlylATF LUBRICATIONPLATE6x1.0mm

2 Bolts'99 - 00 models: 1 Bolts

LOCK.UP VALVEBODY

LOCK.UP SEPARATORPLATE

REGULATOR VALVEBODY

DOWEL PIN

DOWEL PIN

VALVE SPRING

STATOR SHAFT

'-

'112mmll,

rlT

ATFSTRAINER

40 mm

j coNrRoLI SHAFT

COOLER BELIEF VALVE

TOROUE CONVERTERCHECK VALVE

6x1.0mm18olts

DETENTARMSHAFT

6x1,0mm'97 - 98 models:7 Bolts'99 - 00 models:8 Bolts

SERVO BODY('97 - 98 models)

SERVOSEPARATOR PLATE

6x1.0mm3 Bolts

STOP SHAFTBRACKET

SECONDARYVALVE BODY

OOWEL PIN8x40mm

O.RING

STOP SHAFTCHECK BALLS 18'

ATF FEED PIPE112 mm

6x1.0mm5 Eolts

ATF PUMP DRIVENGEAR SHAFT

ATF PUMP DRIVEN

MAIN SEPARATORPLATE

MAIN VALVE EOOY

SECONDARYSEPARATOR

d---.- PLATE--.- CONTROL I.EVER MOUNTING BOLT6x1.0ftm14 N.m (1.4 kgt.m, 10 tbf.ft)(4WD)SERVO BODY('99 - 00 models)

ATF PUMP

6x1.0mm

ATF FEEO PIPE

) / 105.8

/,,!.,::(./ afF FEEO,/ ptpEs

EP,---!ir{+*a r

fpffi4 i

x*hi

_ \zl

14-250

DRIVE GEAR

DOWEL PINTOBOUEHOUSING

www.emanualpro.com

Page 767 of 1395

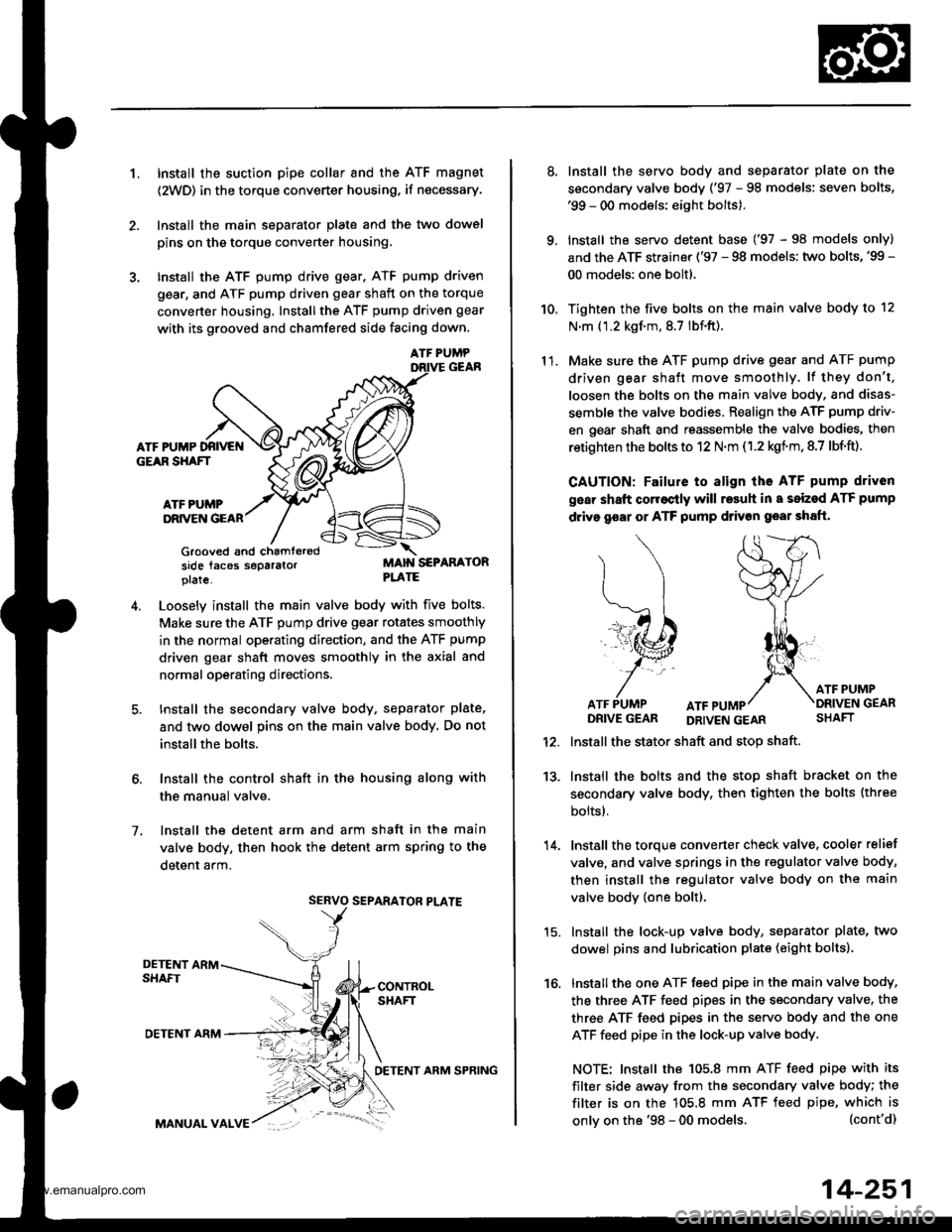

1.Install the suction pipe collar and the ATF magnet

{2WD) in the torque converter housing, if necessary.

lnstall the main seDarator Dlate and the two dowel

pins on the torque converter housing,

Install the ATF pump drive gear. ATF pump driven

gear, and ATF pump driven gear shaft on the torque

converter housing. Installthe ATF pump driven gear

with its grooved and chamfered side facing down.

ATF PUMPGEAR

ATF PUMP D{IVEf{GEAR SHAFT

ATF PUi'PORIVEN GEAR

Grooved and chamteredside faces separatorplate.

MAIN S€PAR/ATORPLATE

5.

o.

Loosely install the main valve body with five bolts.

Make sure the ATF pump drive gear rotates smoothly

in the normal operating direction, and the ATF pump

driven gear shaft moves smoothly in the axial and

normal operating directions.

Install the secondary valve body, separator plate,

and two dowel pins on the main valve body. Do not

installthe bolts.

Install the control shaft in the housing along with

the manual valve.

lnstall the detent arm and arm shaft in the main

valve body, then hook the detent arm spring to the

detent arm.

SEBVO SEPARATOR PLATE

7.

DETENT ARMSHAFT

OETENT ARM

CONTROLSHAFT

MANUAL VAIVE

OETENT ARM SPRING

onlv on the '98 - 00 models,

14-251

1l.

9.

8.

10.

Install the servo body and separator plate on the

secondary valve body ('97 - 98 models: seven bolts,'99 - 00 models: eight bolts).

lnstall the servo detent base ('97 - 98 models only)

and the ATF strainer ('97 - 98 models: two bolts,'99 -

00 models: one boltl.

Tighten the five bolts on the main valve body to 12

N'm (1.2 kgf.m, 8.7 lbf.ft).

Make sure the ATF pump drive gear and ATF pump

driven gear shaft move smoothly. lf they don't,

loosen the bolts on the main valve body, and disas-

semble the valve bodies. Realign the ATF pump driv-

en gear shaft and reassemble the valve bodies, then

retighten the bolts to 12 N.m (1.2 kgim, 8.7 lbf.ft).

CAUTION: Failure to align the ATF pump driven

gear shaft corroctly will rosult in a seizsd ATF pump

drive gear or ATF pump drivon gear shaft.

ATF PUMP ATFGEARDRIVE GEAR DBIVEN GEARSHAFT

Install the stator shaft and stop shaft

Install the bolts and the stop shaft bracket on the

secondary valve body, then tighten the bolts (three

bolts).

Install the torque converter check valve, cooler relief

valve, and valve springs in the regulator valve body,

then install the regulator valve body on the main

valve body {one boltl.

Install the lock-up valve body, separator plate, two

dowel pins and lubrication plate (eight bolts).

Installthe one ATF feed pipe in the main valve body,

the three ATF feed pipes in the secondary valve, the

three ATF feed pipes in the servo body and the one

ATF feed pipe in the lock-up valve body.

NOTE: lnstall the 105.8 mm ATF feed pipe with its

filter side away from the secondary valve body; the

filter is on the 105.8 mm ATF feed pipe, which is(cont'd)

13.

14.

15.

16.

www.emanualpro.com

Page 791 of 1395

Differential

Rear Differential

Special Tools .......... ...........15-2

Description

Rear Differential ................................. 15-4

Hydraulic Flow ............ ,.. 15-6

Real-time 4WD-Dual Pump System

Troub|eshootin9 ................................. 15-10

Rear Differential Assembly

Troubleshooting ................................. 15-13

Maintenance

Differential Fluid ........... . 15-14

Rear Differential Assembly

lllustrated Index .......... .. 15-15

Removal/lnstallation .... 15-16

Differential Carrier Assembly

Leak Repair .................... 15-18

OilSeals

Replacement ...,................................... 15-19

Rear Differential Assembly

Disassembly ..........,......., 15-20

Reassembly .................... 15-23

www.emanualpro.com

Page 794 of 1395

Description

Rear Differential

Outline

The Real-time 4WD-Dual Pump System model has a hydraulic clutch and a differential mechanism in the rear differential

assembly. Under normal conditions, the vehicle is driven by the front wheels. However, depending on to the driving force

of the front wheels and the road conditions. the system instantly transmits appropriate driving force to the rear wheels

without requiring the driver to switch between 2WD (tront wheel drive) and 4WD (four wheel drive). The switching mecha-

nism between 2WD and 4WD is integrated into the rear differential assembly to make the system light and compact.

ln addition, the dual-pump system switches off the rear-wheel-drive force when braking in a forward gear. This allows the

braking system to work properly on models equipped with an Anti-lock Braking System (ABS).

Construction

The rear differential assembly consists of the torque control differential case assembly and the rear differential carrier

assembly. The torque control differential case assembly consists of the differential clutch assembly, the companion

flange, and the oil pump body assembly. The rear differential carrier assembly consists of the differential mechanism. The

differential drive and driven gears are hypoid gears.

The oil pump body assembly consists of the front oil pump, the rear oil pump, the hydraulic control mechanism, and the

clutch piston. The clutch piston has a disc spring that constantly provides the differential clutch assembly with a preset

torque to Drevent abnormal sound.

The clutch guide in the differential clutch assembly is connected to the propeller shaft via the companion flange, and it

receives the driving force lrom the transfer assembly. The clutch guide rotates the clutch plate and the front oil pump in

the oil pump body.

The clutch hub in the differential clutch assembly has a clutch disc that is splined with the hypoid drive pinion gear. The

hypoid drive gear drives the rear oil pump.

The front and rear oil pumps are trochoidal pumps. The rear oil pump capacity is 2.5 percent larger that the front oil pump

to handle the rotation difference between the front and rear wheels caused by worn front tires and tight corner braking.

The oil pumps are designed so the fluid intake works as a fluid discharge when the oil pumps rotate in reverse. Genuine

Honda CVT fluid is used instead of differential fluid.

Operation

When there is a difference in rotation speed between the front wheels (clutch guide) and rear wheels (hypoid driven gear),

hydraulic pressure from the front and rear oil pumps engages the differential clutch, and drive force from the transler

assembly is applied to the rear wheels.

The hydraulic pressure control mechanism in the oil pump body selects 4WD mode when the vehicle is started abruptly,

or when accelerating in a forward or reverse gear (causing rotation difference between the front and rear wheels). or

when braking in reverse gear {when decelerating). lt switches to 2WD mode when the vehicle is driven at a constant speed

in forwar! or reverse gear (when there is no rotation difference between the front and rear wheels), or when braking in a

fo rwa rd gear (when decelerating).

To protect the system, the differential clutch assembly is lubricated by hydraulic pressure generated by the oil pumps in

both 4WD and 2WD modes. Also, the thermal switch relieves the hydraulic pressure on the clutch piston and cancels 4WD

mode if the temDerature of the differential fluid rises above normal.

www.emanualpro.com