Rpm sensor HONDA CR-V 1998 RD1-RD3 / 1.G User Guide

[x] Cancel search | Manufacturer: HONDA, Model Year: 1998, Model line: CR-V, Model: HONDA CR-V 1998 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 314 of 1395

PGM-FI System

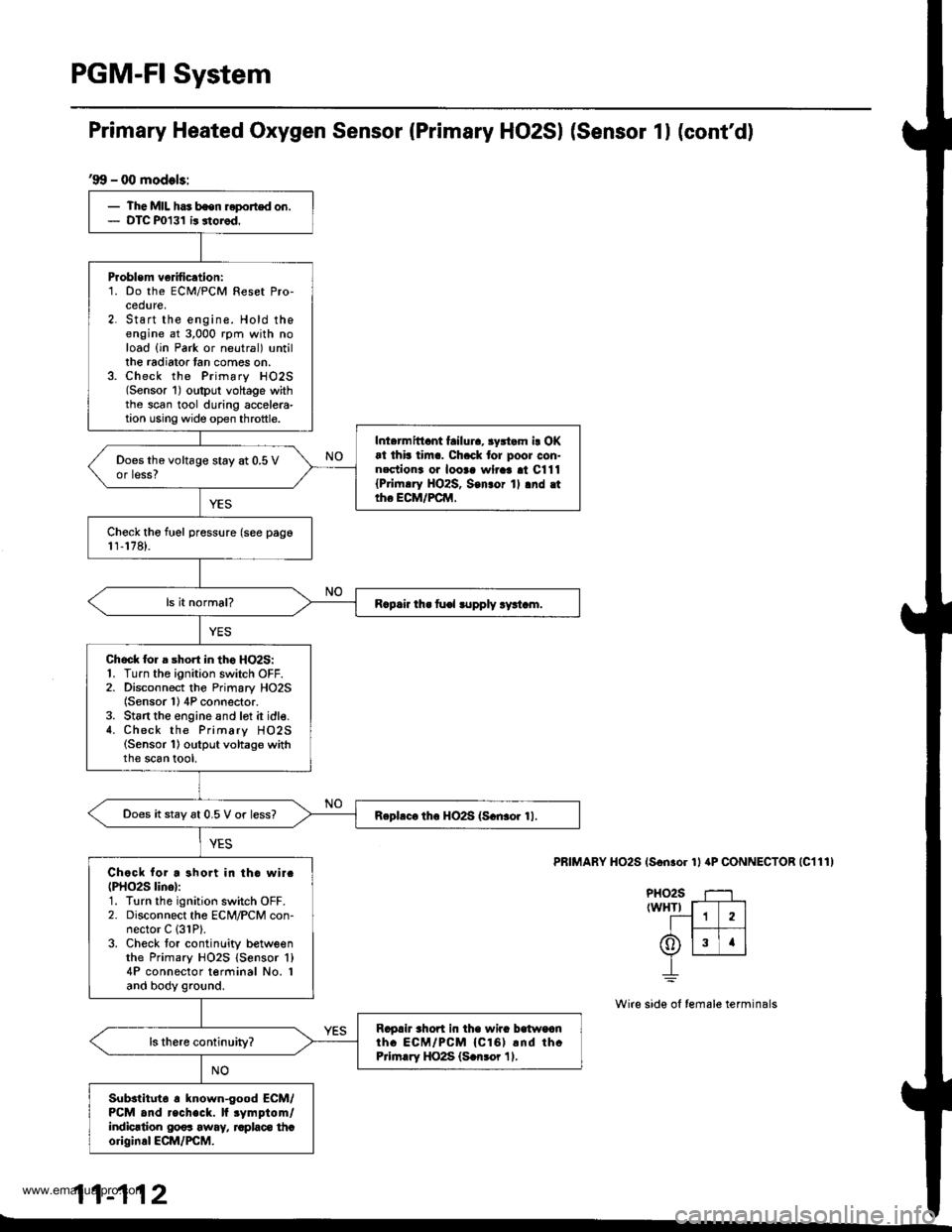

'99 - 00 models:

- The MIL has bsen reported on.- DTC P0131 ir storod.

Problem ve fication:1. Do the ECM/PCM Reset Pro-cedure,2. Start the engine. Hold theengine at 3,000 rpm with noload {in Park or neutral) untillhe radiator tan comes on.3. Check the Primary HO2S(Sensor 1) oltput voltage withthe scan tool during accelera-tion using wide op€n throttle.

Inl.rmittant failura, 3yrtam i! OKat thb tim.. Ch.ck tor poor con-nectiona oa looaa wlraa al C111{Pri|n.ry HO2S, Son3or 1l .nd .ttho ECM/FCM,

Does the voltage stay at 0.5 Vor less?

Check tho fuel pressure (see pago1r,178).

R.p.ir th. fu€l lupply ry!t.m.

Chock lor a short in tho HO2S:1. Turn the ignition switch OFF.2. Disconnect the Primary HO2S(Sensor 1) 4P connector.3. St6rt the engine and lot it idle.4. Check the Primary HO2S(Sensor 1) output voltage withthe scan tool,

Does it stay 6t 0.5 V or less?Rephc. th6 HO2S (S.n3or 11.

Chock for a short in tho wirc(PHO2S lino):1. Turn the ignition switch OFF.2. Disconnect the ECM/PCM con-nector C (31P).

3. Check tor continlity betweenthe Primary HO2S {Sensor 'l}

4P connector terminal No. Iand body ground.

Ragah rhort in tha wira balwoanth. ECM/PCM {Cl61 rnd thcPrirn.ry HO2S (S.n3or 11.

Substltut6 a known-good ECM/PCM and recheck. lf rymptom/indicrtion 00os away, raplaco thcoriginal ECM/PCM.

Primary Heated Oxygen Sensor (Primary HO2SI (Sensor 1l (cont'd)

PRIMARY HO2S (Son.or 1l aP CONNECTOR |C111)

PHO2S T--1rwHTr f-T---]

--1 1 2lI t--- 1t6)lslrlv L__r__J

_L

Wire side ol female terminals

11-112

www.emanualpro.com

Page 315 of 1395

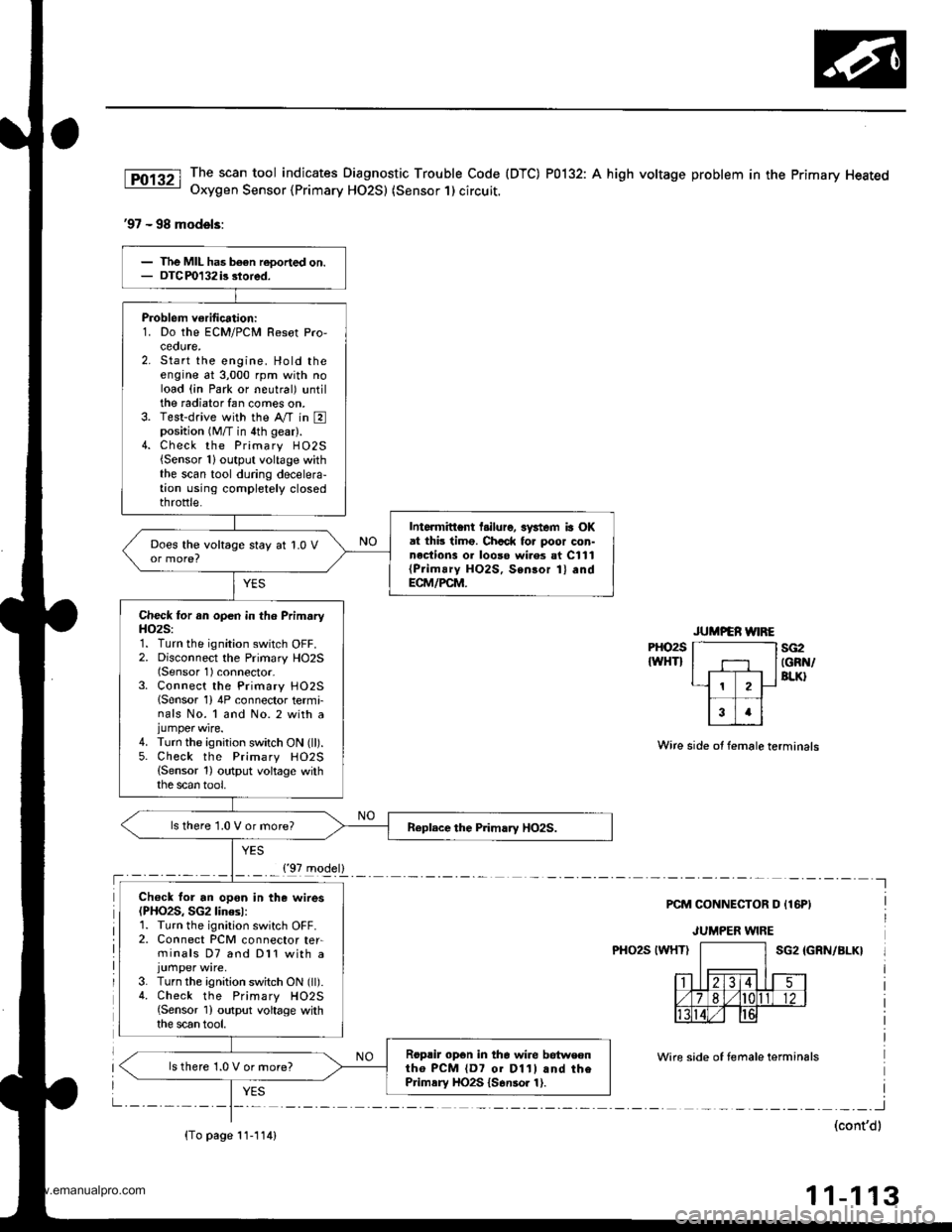

The scan tool indicates Diagnostic Trouble Code (DTC) P0132: A high voltage problem in the Primary HeatedOxygen Sensor {Primary HO2S) (Sensor 1) circuit.

'97 - 98 models:

PHO2S

IWHTIsG2IGRN/BLK}

Wire side ot female terminals

PCM CONNECTOR D {16PI

JUMPER WIRE

PHO2S IWHTISG2 IGRN/BLK}

Wire side of temale terminals

I

(cont'dl

11-113

Problem verification:1. Do the ECM/PCM Resot Pro,ceoute,2. Start the engine. Hold theengine at 3,000 rpm with noload (in Park or neutral) untilthe radiator fan comes on.3. Test-drive with the Ay'T in Eposition (M/T in 4th gear).4. Check the Primary H02S{Sensor 1}output voltage withthe scan tool during decelera-tion using completely closedthrottle.

Intormittent l.ilure, 3ystem ia OKat thb timo. Chcck fo. poor con-nections 01 looso wi.es at C111{Prim!ry HO2S, Sensor 1} andECM/PCM.

Does the voltage stay at 1.0 V

Check for an open in th6 PrimaryH()2S:1. Turn the ignition switch OFF.2. Disconnect the Primary HO2S(Sensor 1) connector-3. Connect the Primary HO25lSensor 1) 4P connector termi-nals No. 1 and No. 2 with ajumper wire.4. Turn the ignition switch ON (ll).5. Check the Primary HO2S(Sensor 1) output voltage withthe scan tool,

ls there 1.0 V or more?

Ch€ck for an opon in the wires(PHO2S, SG2linesl:1. Turn the ignition switch OFF.2. Connect PCM connector ter-minals D7 and Dl1 with a

3. Turn the ignition switch ON (ll).4. Check the Primary HO2S{Sensor 1) output voltage withthe scan tool.

Roprir opon in the wire betweontho PCM {D7 01 D11l and thePrimsry HO2S {S6nsor 1).

ls there 1.0 V or more?

{'97 model}

{To page 11-114)

www.emanualpro.com

Page 317 of 1395

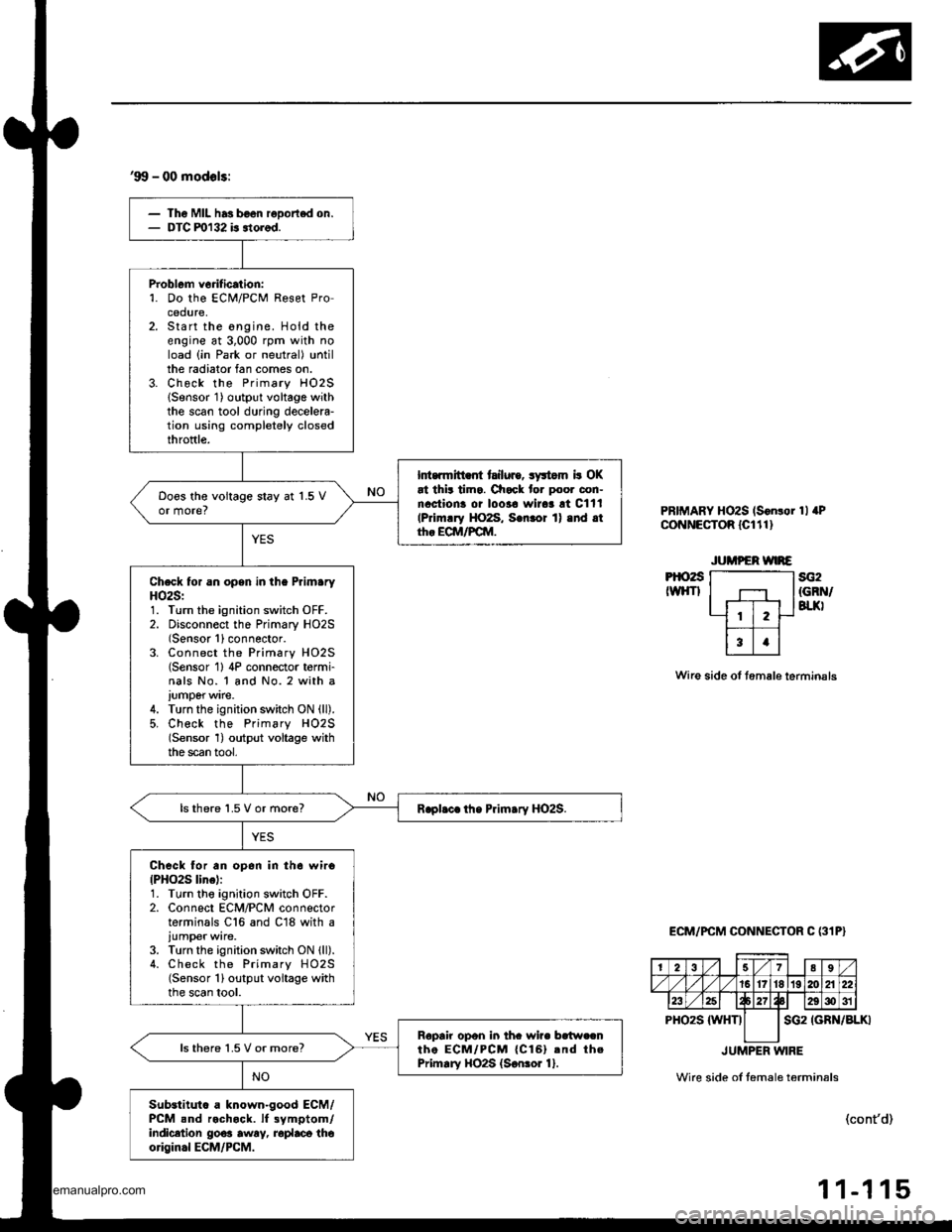

'99 - 00 modols:

Th6 Mll has b€on reDortod on.DTC ml32 is itorod.

Problem vorification:'1. Do the ECi!4/PCM Reset Procedure,Start the ongine. Hold theengine at 3,000 rpm with noload (in Park or neutral) untilthe radiator fan comes on.Check the Primary HO2SlSensor 1) output voltage withthe scan tool during decelela-tion using completely closedthroftle.

Int.rmitt .fi tailuro, syltom b OKat thit tima. Check for poor con-nactiona oi loo3a wirar !t Cltl(Primrry HO2S, S.nror 1) .nd .tth. ECM/FCM.

Doos the voitage stay at 1.5 Vor more?

Check for an opsn in the PrlmaryHO2S:1. Turn the ignition switch OFF.2. Disconnect the Primary HO2S(Sensor 1)connector.3. Connect the Primary HO2S(Sensor 1) 4P connector t6rmi-nals No. 1 and No. 2 with a

iumperwire.4. Turn the ignition switch ON (ll).

5, Check the Primsry H02S(Sensor 1) output voltage withthe scan tool,

lsthere 1.5 V or more?

Check for an op6n in th6 wiro{PHO2S line):1. Turn tho ignition switch OFF.2. Connect ECM/PCM connectorterminals C16 and C18 with a

iumper wire.3. Turn the ignition switch ON lll).4. Check the Primary HO2S(Sensor 1) output voltage withthe scan tool.

Ropair opon in thc wire bc{w.cnthe ECM/PCM {Cl6}.nd thePrimary HO2S {S€nror 1}.ls there 1.5 V or more?

Substituto a known-good ECM/PCM snd rochock. lf 3ymptom/indicetion go€a awry, roplaca thoorigin.l ECM/PCM.

PRIMARY HOzS (S6n!or 1l aPCoNNECTOR lcltl)

Pt()2sIWHTIsG2{GRN/BTJ(I

Wire side of tem6le terminsls

ECM/PCM CONNECTOR C (31P}

IGRN/BLKI

JUMPER WIRE

Wire side ol temale t6rmin6ls

(cont'd)

-1 15

2789

/1617't819120A22

23E29g)31

PHO2S {WHTIsG2

11

www.emanualpro.com

Page 318 of 1395

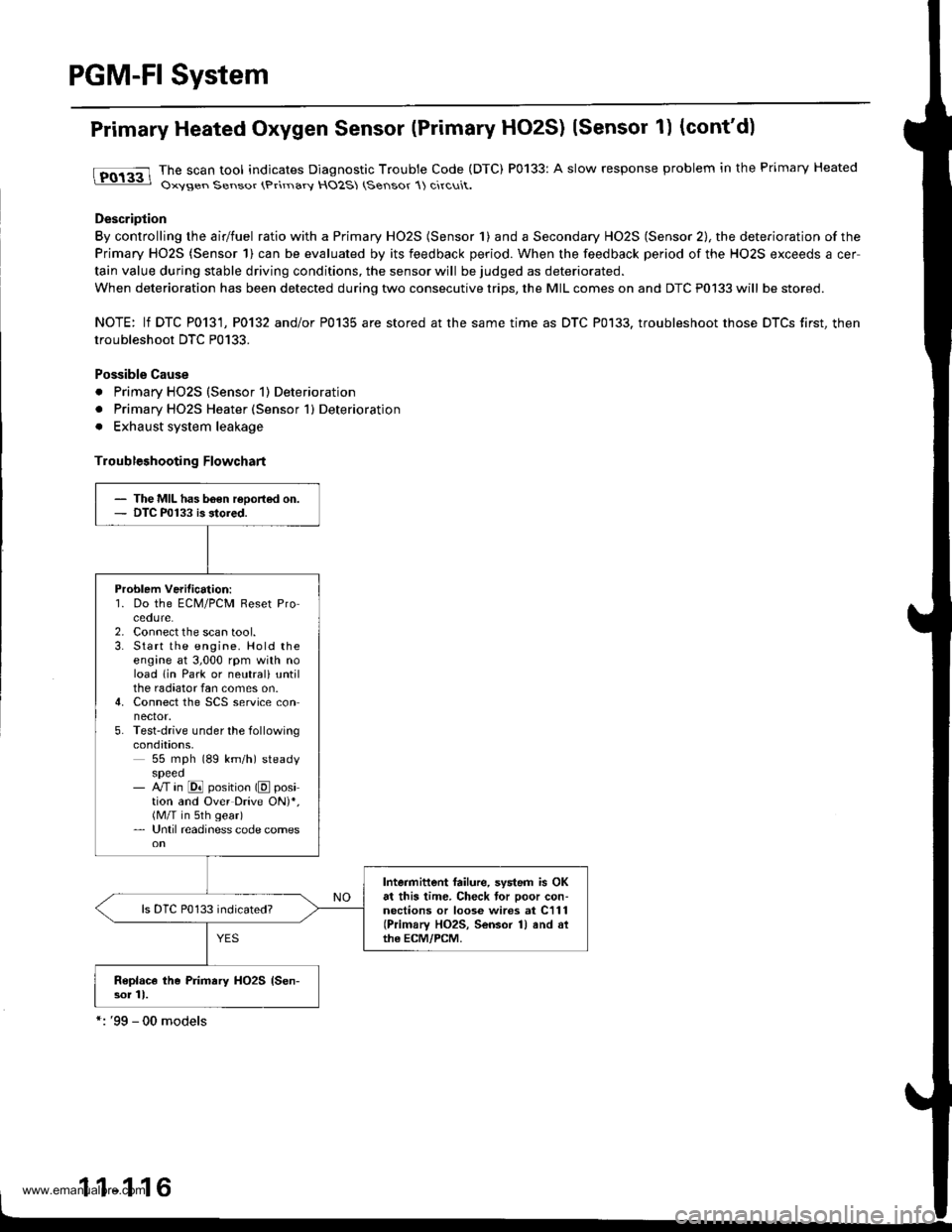

PGM-FI System

Primary Heated Oxygen Sensor (Primary HO2S) lSensor 1) (cont'd)

tFO133 lhe scan tool indicates Diagnostic Trouble Code (DTC) P0133: A slow response problem in the Primary Heated: Oxysen Sensor (Primarv HO2S (Sensor 1) circuit.

Description

By controlling the airlfuel ratio with a Primary HO2S (Sensor 1) and a Secondary HO2S (Sensor 2), the deterioration of the

Primary HO2S (Sensor 1) can be evaluated by its feedback period. When the feedback period of the HO2S exceeds a cer

tain value during stable driving conditions, the sensor will be judged as deteriorated.

When deterioration has been detected during two consecutive trips, the MIL comes on and DTC P0133 will be stored.

NOTE: lf DTC P0131, P0132 and/or P0135 are stored at the same time as DTC P0133. troubleshoot those DTCS first, then

troubleshoot DTC P0133.

Possible Cause

. Primary HO2S (Sensor 1) Deterioration

. Primary HO2S Heater (Sensor 1) Deterioration

. Exhaust system leakage

Troubleshooting Flowchart

- The MIL has b6€n reoorted on.- DTC P0133 is stored.

Problem Verilication:'1. Do the ECM/PCM Reset Procedure.2. Connect the scan tool.3. Start the engine. Hold theengine at 3,000 rpm with noload lin Park or neutrali untilthe radiator fan comes on.4. Connect the SCS service connector.5. Test-drive under the followingcondations,55 mph (89 km/h) steadyspeed- M in @ position (E position and Over Drive ON)*,(M/T in sth gear)- Until readiness code comes

Intermittent failure, system is OKat this time. Check tor poor con-nections or loose wires at C111(Primary HO2S, Sensor 1) and althe ECM/PCM.

Replace the Primary HO2S {Sen-sor 11.

1 1-1 16

www.emanualpro.com

Page 319 of 1395

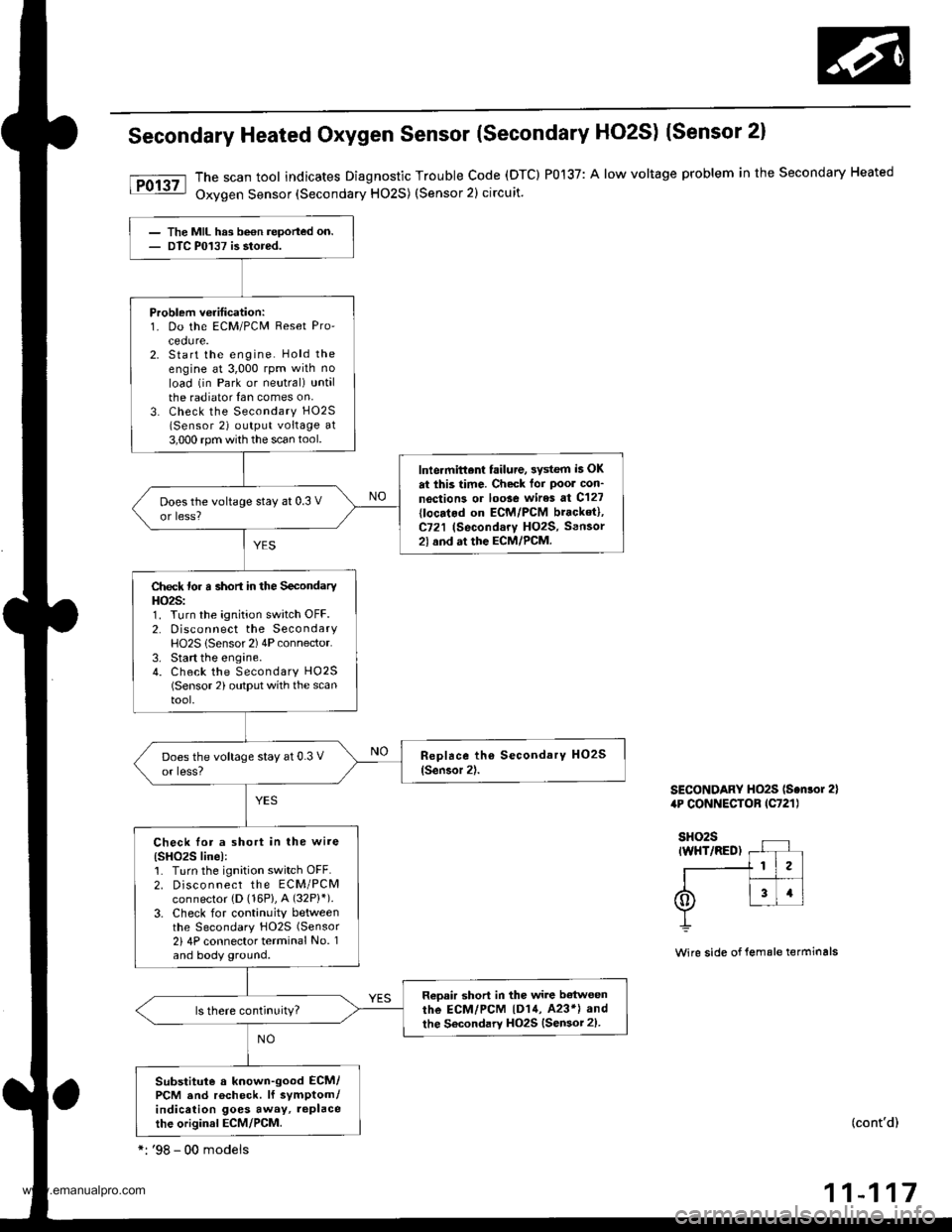

Secondary Heated Oxygen Sensor (Secondary HO2S) (Sensor 2)

The scan tool indicates Diagnostic Trouble code (DTC) P0137: A low voltage problem in the secondary Heated

Oxygen Sensor (Secondary HO2S) (Sensor 2) circuit.

SECONDARY HO2S ls.nlor 2)4P CONNECTOB lC721l

Wire side of lemale terminals

(cont'd)

11-117

The MIL hrs been reported on.DTC P0137 is stored.

Problem veritication:1. Do the ECM/PCM Reset Pro'cedure.2. Start the engine. Hold theengine at 3,000 rpm wilh no

load (in Park or neutral) untalthe radiator {an comes on,3. Check the Secondary H02S

lSensor 2) output voltage at3,000 rpm with the scan tool.

lnlermittent failure, 3ystem i5 OK

at this time. Check tor Poor con'

noction3 or loose wires at C127

{locatod on ECM/PCM bracket},C721 (Secondary HO2S, Sensor2l and at the ECM/PCM.

Does the voltage stay at 0.3 V

or less?

Check for a short in the SecondaryHO2S:1. Turn the ignition switch OFF.2. Disconnect the SecondaryHO2S lSensor 2) 4P connector.3. Start the engine.4. Check the Secondary HO25(Sensor 2) output with the scantool.

Check lor a short in the wire(SHO2S linel:1. Turn the ignition switch OFF.2. Disco n nect the ECM/PCMconnector {D (16P}, A (32P}').

3. Check for continuity betweenthe Secondary HO2S (Sensor

2i 4P connector terminal No. 1and body ground.

Reoair short in the wire b€twoen

rhe ECM/PCM |D14, 423*l and

the Secondary HO2S {Sensor 2).

Substitute a known-good ECM/PCM and rocheck. lf symptom/indication goes away, replacethe original ECM/PCM.

*: '98 - 00 modeis

www.emanualpro.com

Page 320 of 1395

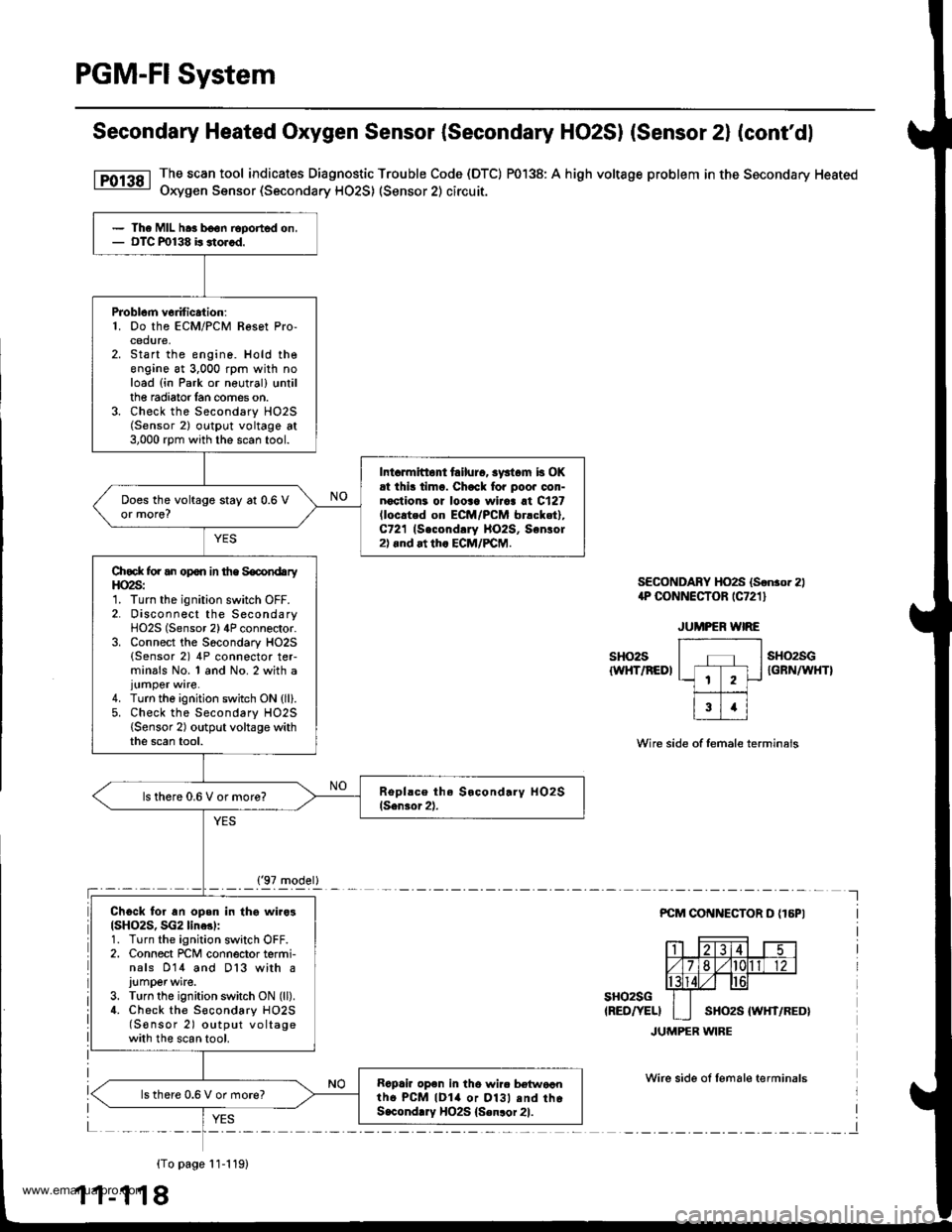

PGM-FI System

Secondary Heated Oxygen Sensor (Secondary HO2SI (Sensor 2l (cont'dl

The scan tool indicates Diagnostic Trouble Code (DTC) P0138: A high voltage problem in the Secondary Heated

Oxygen Sensor (Secondary HO2S) (Sensor 2) circuit.

SECONDABY HO2S (Sonror 2)1P CONNECTOR rC721 l

sHo2s{WHT/REDI

sH()2sGIGFN/WHTI

Wire side of female terminals

PCM COI{NECTOR D {16PI

sHo2sG(RED/YELI

JUMPER WIRE

Wirc side ol lemale terminals

{To page 11-119)

1 1-1 18

The MIL hra b€on Eported on,OTC m138 b stor.d.

PJoblcm v6dtic.tion:1. Do the ECM/PCM Resot Pro-cedure,Start the engine. Hold theengine at 3,000 rpm with noload (in Park or neutral) trntilthe radiator lan comes on.Check the Secondary HO2S(Sensor 2) outpl.rt voltage at3,000 rpm with the scan tool.

Int.rmitto tailurc, syst.m b OKrt ihi! timo. Chack fo. poo. oon-noctioni or looaa wiiaa at C127lloc.ted on EcM/PcM br.cket),C721 (Second!ry llO2S, Sonlol2).nd at th. ECM/PCM.

Does the voltage stay at 0.6 Vor more?

Chock for an opon in the SocondaryHO2S:1. Turn the ignition switch OFF.2. Disconnect the SecondaryHO2S (Sensor 2) 4P connector.3. Connect the Socondary HO2S(Sensor 2) 4P connector ter-minals No. 1 and No. 2 with a

4. Turn the ignition switch ON {ll}.5. Check the Secondary HO2S{Sensor 2) output voltage withthe scan tool.

ls there 0.6 V or more?

Ch6ck for an open in thg wiro3(SH()2S, SG2 line3l:1. Turn the ignition switch OFF.2. Connect rcM connector termi-nals 014 and D13 with a

J!mper wite.3. Turn the ignition switch ON (ll).

4. Check the S€condary HO2S(S€nsor 2) output voltagewith the scan tool.

Rapair op6n in tho wir. b€{woantho PcM lDla or Dl3l .nd thoS.condlry HO2S {Senlor 21.

lsthere 0.6 V or more?

('97 model)

www.emanualpro.com

Page 322 of 1395

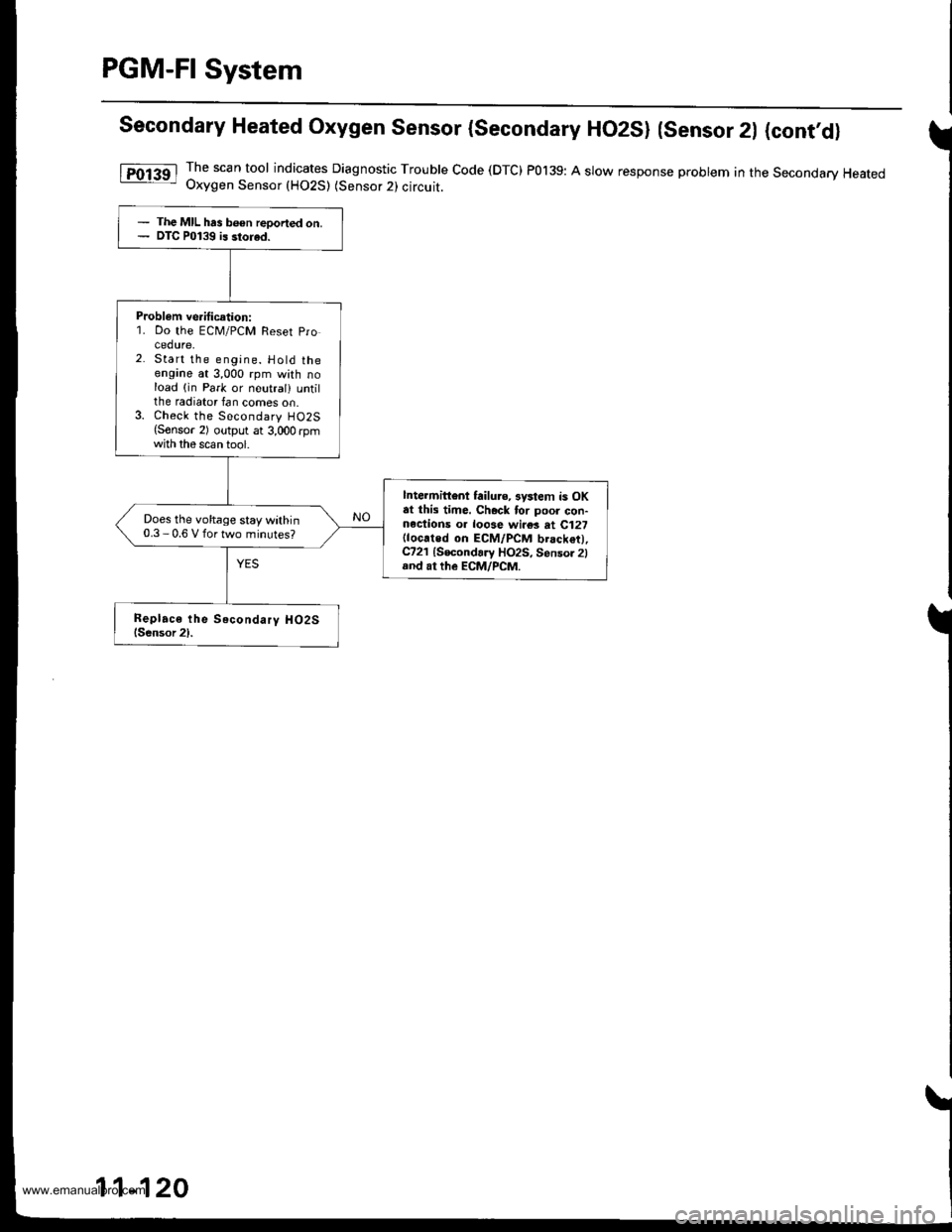

PGM-FI System

Secondary Heated Oxygen Sensor (secondary HO2SI (sensor 2l (cont,d)

lTol3al The scan tool indicates Diagnostic Trouble Code (DTC) P0139: A slow response probtem in the Secondary Heated- Uxygen Sensor (HO2S) (Sensor 2l circuit.

- The MIL has b€en reoorted on.- DTC P0139 is storad.

Probl€m ve.itication:1. Do the ECM/PCM Reset Procedure,Start the engine. Hold theengine at 3,000 rpm with noload (in Park or neutral) untilthe radiator fan comes on.Check the Secondary HO2S(Sonsor 2) output at 3,000 rpmwith the scan tool.

lntehittont failure, 3ystem is OKat this time. Chock for poor con-nections o. loose wi.es at C127(located on ECM/PCM brack€t),C721 {Secondary HO2S, Sensor 2land at the EcM/PcM.

Does the voltage stay within0.3 - 0.6 V for two minutes?

11-120

www.emanualpro.com

Page 327 of 1395

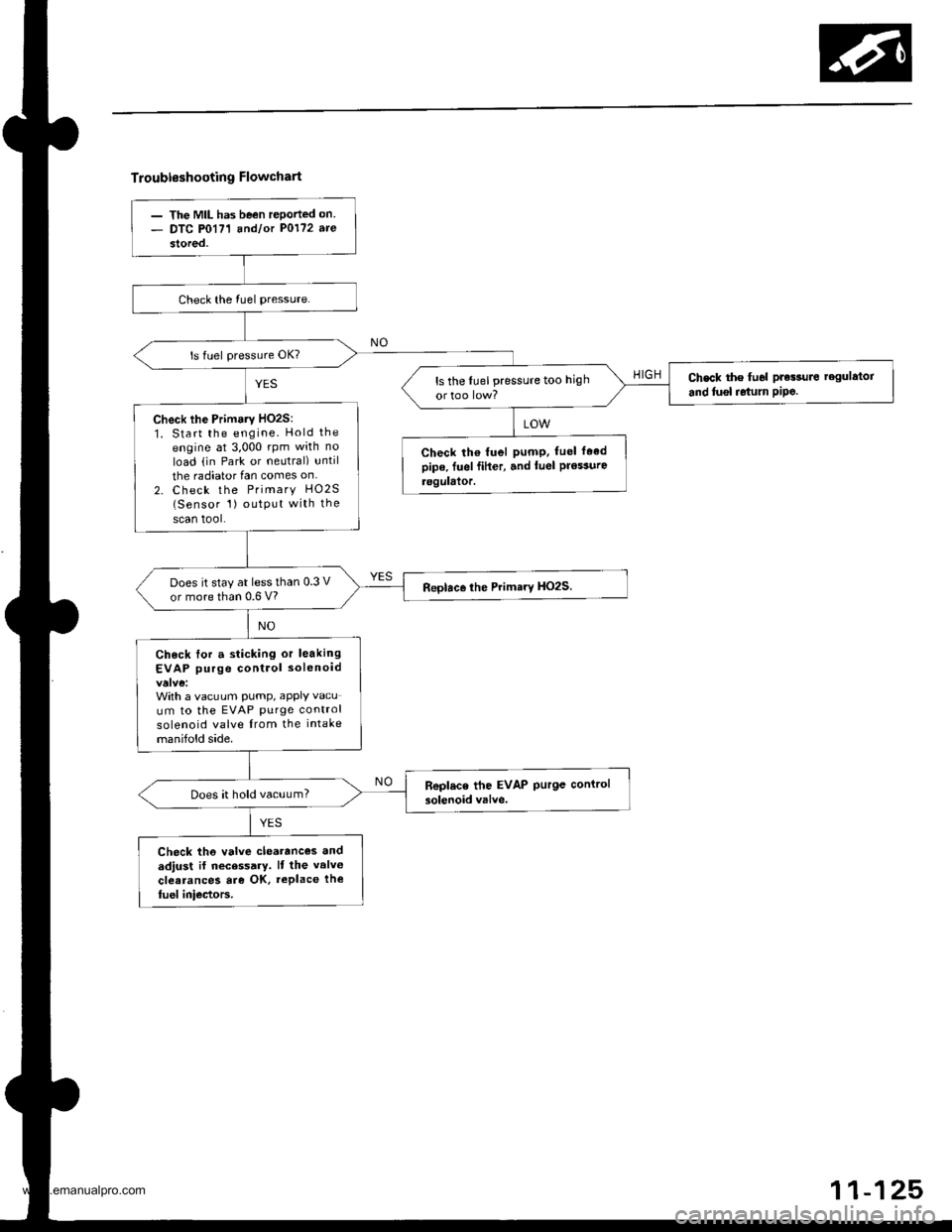

Troubleshooting Flowchart

- The MIL has been rePorted on- DTC P0171 andlot P0172 are

stored,

Check the lu6l pressuro regulator

and tusl relum PiPe.ls the lLrel pressure too high

Check lhe Primaty HO2S:1. Start the engine. Hold the

engine at 3,000 rpm with no

load (in Park ot neutral) until

the radiator fan comes on

2. Check the Primary HO2S(Sensor 1) outPut with the

scan tool.

Check lh€ fuel pumP. fuel faedpipe. fuel fiher, and luel Prossurc.eguhior.

Does it stay at lessthan 0.3 V

or more than 0.6 V?

Check for a sticking or leaking

EVAP purge control solenoid

With a vacuum pump, aPPIY vacu

um to the EVAP Purge control

solenoid valve from the intake

manifold side.

Does it hold vacuum?

Check th6 valve clearanc€s and

adjust il necessary. It the valv€

clearances are OK, replace the

fuel iniectors.

www.emanualpro.com

Page 328 of 1395

PGM-FI System

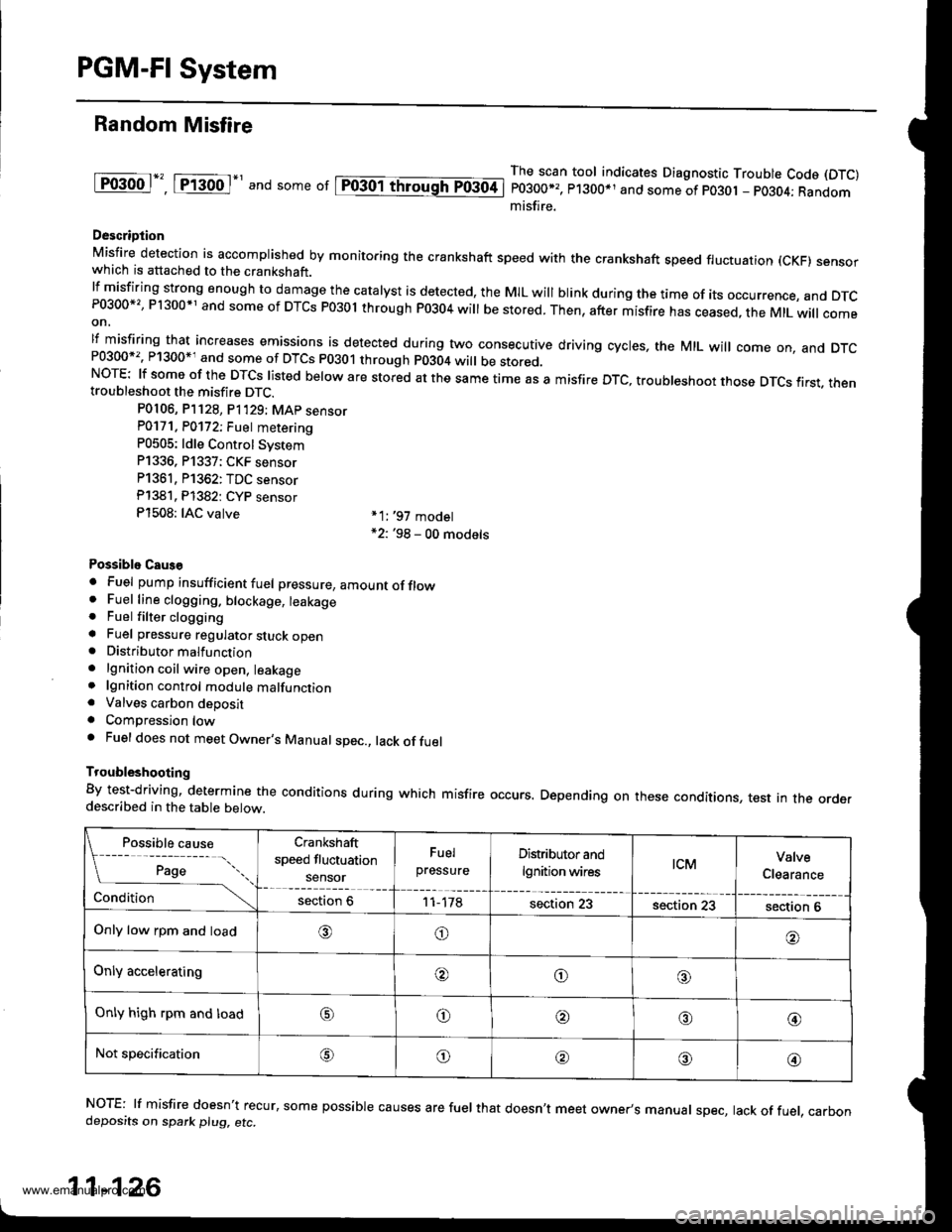

Random Misfire

lF()gool", tftod-' and some or lpiogol throughTo3oti

The scan tool indicates Diagnostic Trouble Code (DTC)

P0300*,, P1300*1 and some of po30t - pO3O4; Randommisfire.

Descriotion

Misfire detection is accomplished by monitoring the crankshaft speed with the crankshaft speed fluctuation (cKF) sensorwhich is attached to the crankshaft.lfmisfiring strong enough to damage the catalyst is detected, the MIL will blink during the time of its occurrence, and DTcP0300*'�, P1300*1 and some of DTCs P03ol through P0304 will be stored. Then, after misfire has ceased, the MtL will comeon,

lf misfiring that increases emissions is detected during two consecutive driving cycles, the MIL will come on, and DTcand some of DTCS p0301 through p0304 wi

be stored.NOTE: lf some of the DTCS listed below are stored at the same time as a misfire DTc, troubleshoot those DTcs first. thentroubleshoot the misfire DTC.

P0106, P]128, P1'129; MAp sensorP0171. P0172; Fuet metering

P0505: ldle Control Svstem

P1336, P1337; CKF sensor

P1361, P1362: TDC sensor

Pl381. Pl382: CYP sensor

P1508: IAC valve *1:,97 model*2: '98 - 00 models

Possiblo Caus€

. Fuel pump insufficient fuel pressure, amountofflow. Fuel line clogging. blockage, leakage. Fuel filter clogginga Fuel pressure regulator stuck open. Distributormalfunction

. lgnition coil wire open, leakage. lgnition control module malfunction. Valves carbon deposita Compression lowa Fuel does not meet Owner's Manual spec., lack offuel

Troubleshooting

By test-driving, determine the conditions during which misfire occurs. Depending on these conditions, test in the orderdescribed in the table below.

Possible cause

[ ;;;;- -....

Crankshaft

speed fluctuation

sensor

Fuel

pressureDistributor and

lgnition wirestcMValve

Clearance

Conditionsection 611-178section 23section 23section 6

Only low rpm and load,6)o

Only acceleratingooo

Only high rpm and loado@,a'@

Not specificationG\o@o@

NOTE: lf misfire doesn't recur, some possible causes are fuel that doesn't meet owner's manual spec, lack of fuel, carbondeposits on spark plu9, etc.

11-126

www.emanualpro.com

Page 332 of 1395

PGM-FI System

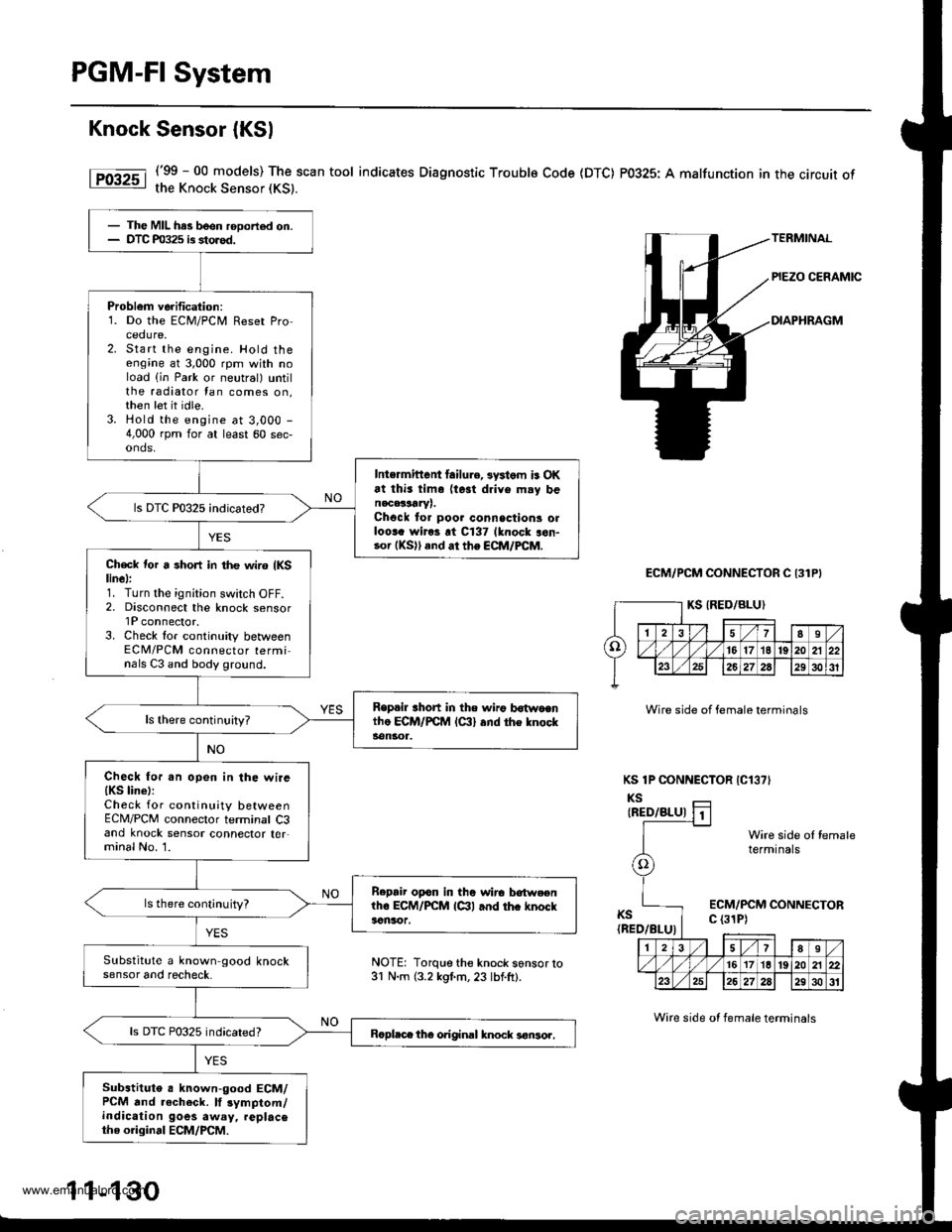

Knock Sensor {KSl

('99 - 00 models) The scan tool indicates Diagnostic Troublo Code (DTC) P0325: A malfunction in the circuit ofthe Knock Sensor (KS).

ECM/PCM CONNECTOR C 131P}

Wire side of female terminals

KS 1P CONNECTOR IC13?'

KSIRED/BLU)

KS(BED/BLU)

Wire side ol femaletermtnals

ECM/PCM CONNECTORc (31P)

- The MIL has been rooorted on.- DTC m325 is storod.

Problem verification:1. Do the ECM/PCir, Reset Procedure,2. Start the engine. Hold theengine at 3,000 rpm with noload (in Park or neutral) untilthe radiator tan comes on,then let it idle.3. Hold the engine at 3,000 -

4,000 rpm for at least 60 sec-onds,

Intermittent lailu.e, 3ystom is OKat thi3 tim. (te3t drive m.y benacalLrYr.Chock to. poor connsctions olloora wiros rt C137 lknock aon-.o. (KS)) and ar the ECM/FCM.

Ch€ck tor a short in the wir6 {KSlinel:1. Turn the ignition switch OFF.2, Disconnect the knock sensorlP connector.3. Check lor continuity betweenECM/PCM connector terminals C3 and body ground.

Replil rhort in the n irg b6{wocntho ECM/PCM lc:ll and the knocks€ngr1.

Check fo..n open in the wire{KS line):Check for continuity betweenECM/PCM connector terminal C3and knock sensor connector ter,minal No. 1.

B.pair opon in the wirc lrotweenlho ECM/PCM lctl and thc knockacnsor.

ls there cont;nuity?

Substitute a known-good knocksensor and recheck.

ls DTC P0325 indicated?Bcpl.ce the original knock 3€nsor,

Substituto a known-good ECM/PCM and .echeck. lf 3ymptom/indication goes away, replacethe original ECM/PCM.

NOTE: Torque the knock s6nsor to31 N.m (3.2 kgl.m, 23 lbf.ft).

1 1-130

Wire side ot female terminals

www.emanualpro.com