Gear HONDA CR-V 1998 RD1-RD3 / 1.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1998, Model line: CR-V, Model: HONDA CR-V 1998 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 897 of 1395

Power Steering Gearbox

Installation (cont'd)

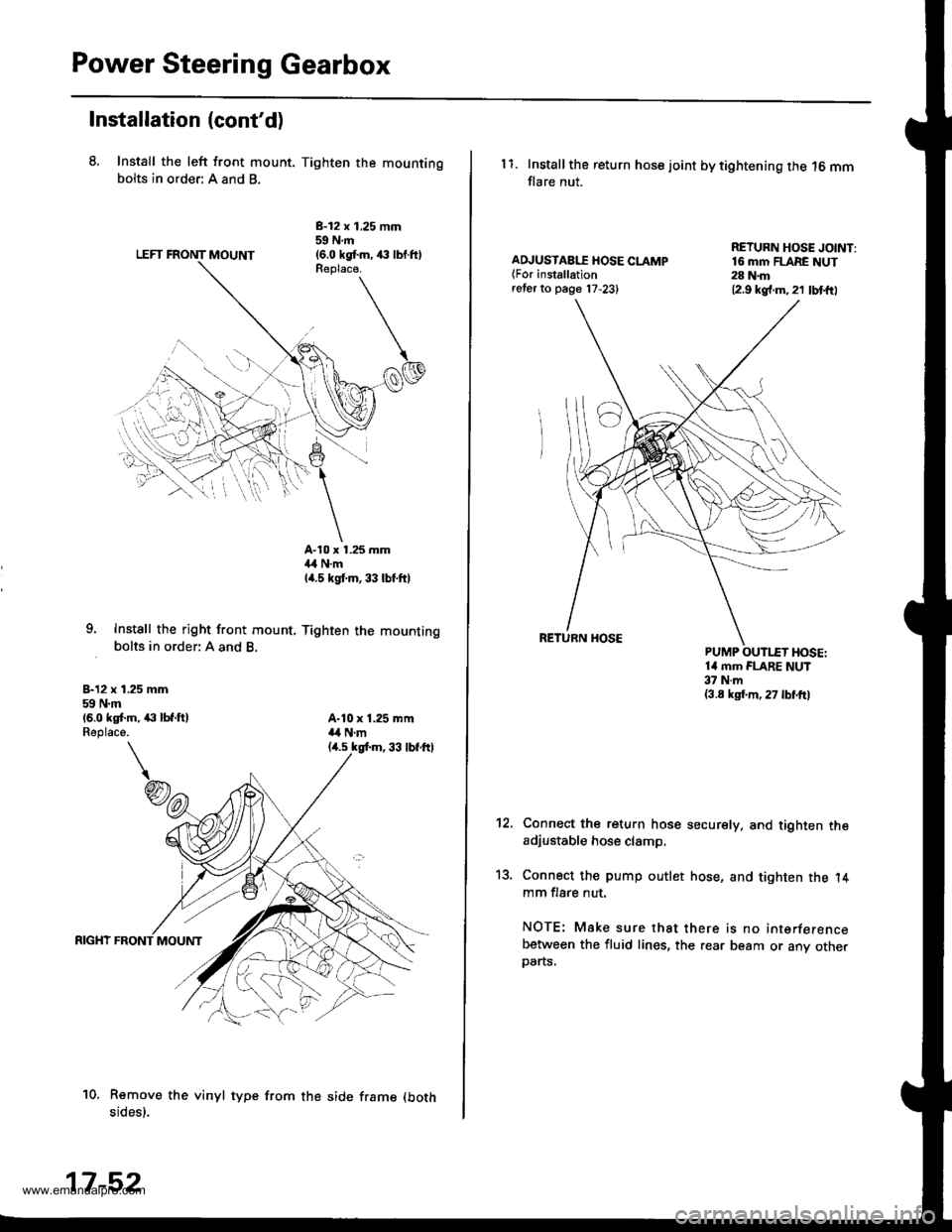

8, Install the left front mount. Tighten the mountingbolts in order: A and B.

LEFT FRONT MOUNT

B-12 x 1,25 mm59Nm(6.0 kgtm,,€ lbl.ftlReplaca.

9. Instsll the right front mount, Tighten the mountingbolts in order: A and B.

B-12 x 1.25 mm59 N.m16.0 ks[.m, ,|:| lbf.ftlReplace.

A-10 x 1.25 mm4,1 N.mla.s kgt m, 33 lbf.ft)

A-10 x 1.25 mma,a N.m

10. Remove the vinyl type from the side frame (both

sides).

17-52

11. Installthe return hose joint by tightening the 16 mmflare nut.

AD.'USTAB[T HOSE CLAMP(For installationreter to page 17,23)

RETURN HOSE JOINT:16 mm FLARE NUT28 N.m12.9 kg{.m.21 lbt{t)

14 mm FLARE NUT37 N.m(3.8 ksf.m, 27 lbl'frl

't2.

13.

Connect the return hose securely. and tighten theadjustable hose clamp.

Connect the pump outlet hose, and tighten the l4mm flare nut.

NOTE: Make sure that there is no interferencebetween the fluid lines, the rear beam or any otherparts.

www.emanualpro.com

Page 898 of 1395

't 4.

15.

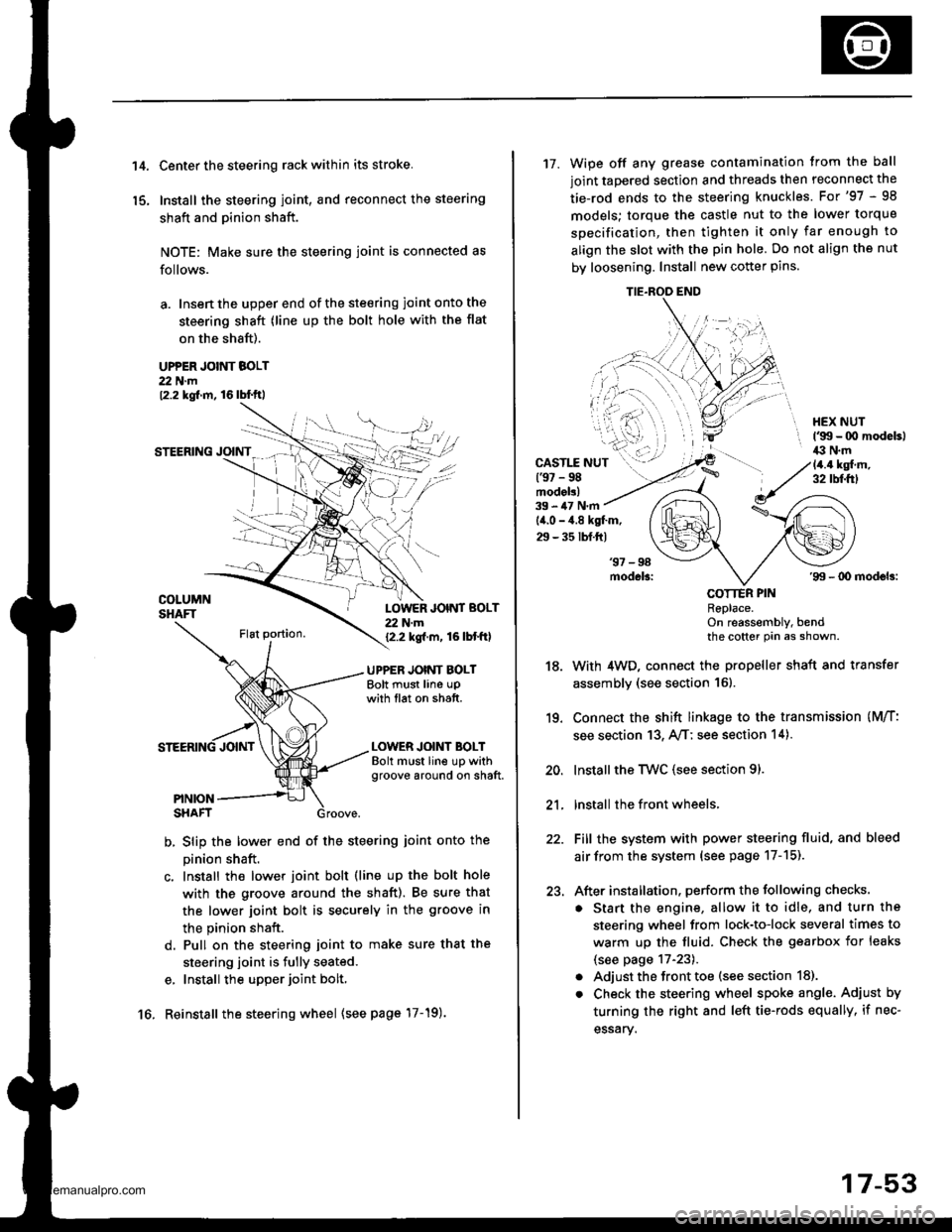

Center the steering rack within its stroke.

Install the steering joint, and reconnect the steering

shaft and pinion shaft.

NOTE: Make sure the steering joint is connected as

follows.

a. Insen the upper end of the steering joint onto the

steering shaft (line up the bolt hole with the flat

on the shaft).

UPPER JOINT BOLT22 N.m12.2 kgf.m, 16lbl.ft,

STEERING JOINT

COLUMNSHAFTLOWER JOINT BOLT22 N.m12.2 kgf.m, 16lbtftl

UPPER JOINT BOLTBolt must line upwith tlat on shatt.

LOWER JOINT BOLTBolt must line up withgroove around on shaft.

PINIONSHAFT

b, Slip the lower end of the steering ioint onto the

pinion shaft.

c. Install the lower joint bolt (line up the bolt hole

with ths groove around the shaft). Be sure that

the lower joint bolt is securely in the groove in

the pinion shaft.

d. Pull on the steering joint to make sure that the

steering joint is fully seated.

e, Install the upper joint bolt,

Reinstall the steering wheel {see page'17-19).16.

17-53

17. Wipe off any grease contamination trom the ball

joint tapered section and threads then reconnect the

tie-rod ends to the steering knuckles. For'97 - 98

models; torque the castle nut to the lower torque

specification, then tighten it only far enough to

align the slot with the pin hole. Do not align the nut

by loosening. Install new cotter pins.

CAST1T NUT(9t - 98modol!)

HEX NUTl'g!t - 00 modeb)il:l N.m14.4 ksl.m,32 tbf.f0

39 - iU N'm

lil.o - 4.8 kgl.m,

29 - 35 tbf.ftl

18.

19.

20.

21.

22.

23.

'99 - lD modeb:

COTTER PINRePlace.on reassembly, bendthe cotter Pin as shown.

With 4WD, connect the propeller shaft and transfer

assembly (see section 16).

Connect the shift linkage to the transmission (M/T:

see section 13, A,/T; see section 14).

Installthe Twc (see section 91.

lnstall the front wheels,

Fill the system with power steering fluid, and bleed

air from the system (see page 17-15).

After installation. perform the following checks.

. Start the engine, allow it to idle, and turn the

steering wheel from lock-to-lock several times to

warm up the fluid. Check the gearbox for leaks

(see page 17-23).

. Adjust the front toe (s€e section 18).

. Check the steering wheel spoke angl€. Adjust by

turning the right and left tie-rods equally, if nec-

essary.

TIE.ROO END

www.emanualpro.com

Page 954 of 1395

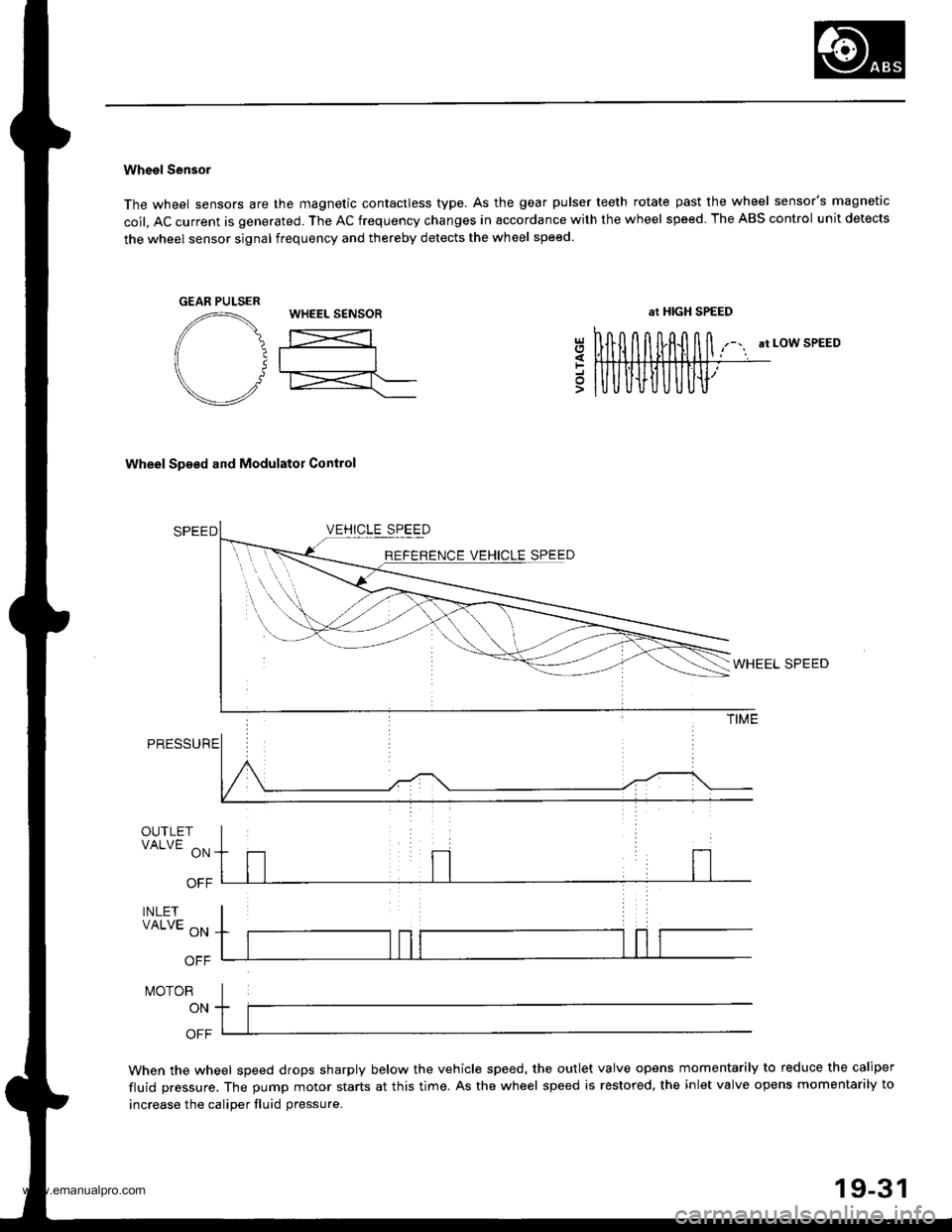

Wheel Sensor

The wheel sensors are the magnetic contactless type. As the gear pulser teeth rotate past the wheel sensor's magnetic

coil, AC current is generated. The AC frequency changes in accordance with the wheel speed. The ABS control unit detects

the wheel sensor signal frequency and thereby detects the wheel speed

at LOW SPEED

wheel Sp€od and Modulatot Control

VEHICLE SPEED

VEHICLE SPEED

WHEEL SPEED

PRESSU

OUTLETVALVE ON

OFF

INLETVALVE ON

OFF

MOTOR

ON

OFF

When the wheel speed drops sharply below the vehicle speed, the outlet valve opens momentarily to reduce the caliper

fluid pressure. The pump motor starts at this time. As the wheel speed is restored. the inlet valve opens momentarily to

increase the caliDer fluid oressure.

F

GEAR PULSER

19-31

www.emanualpro.com

Page 963 of 1395

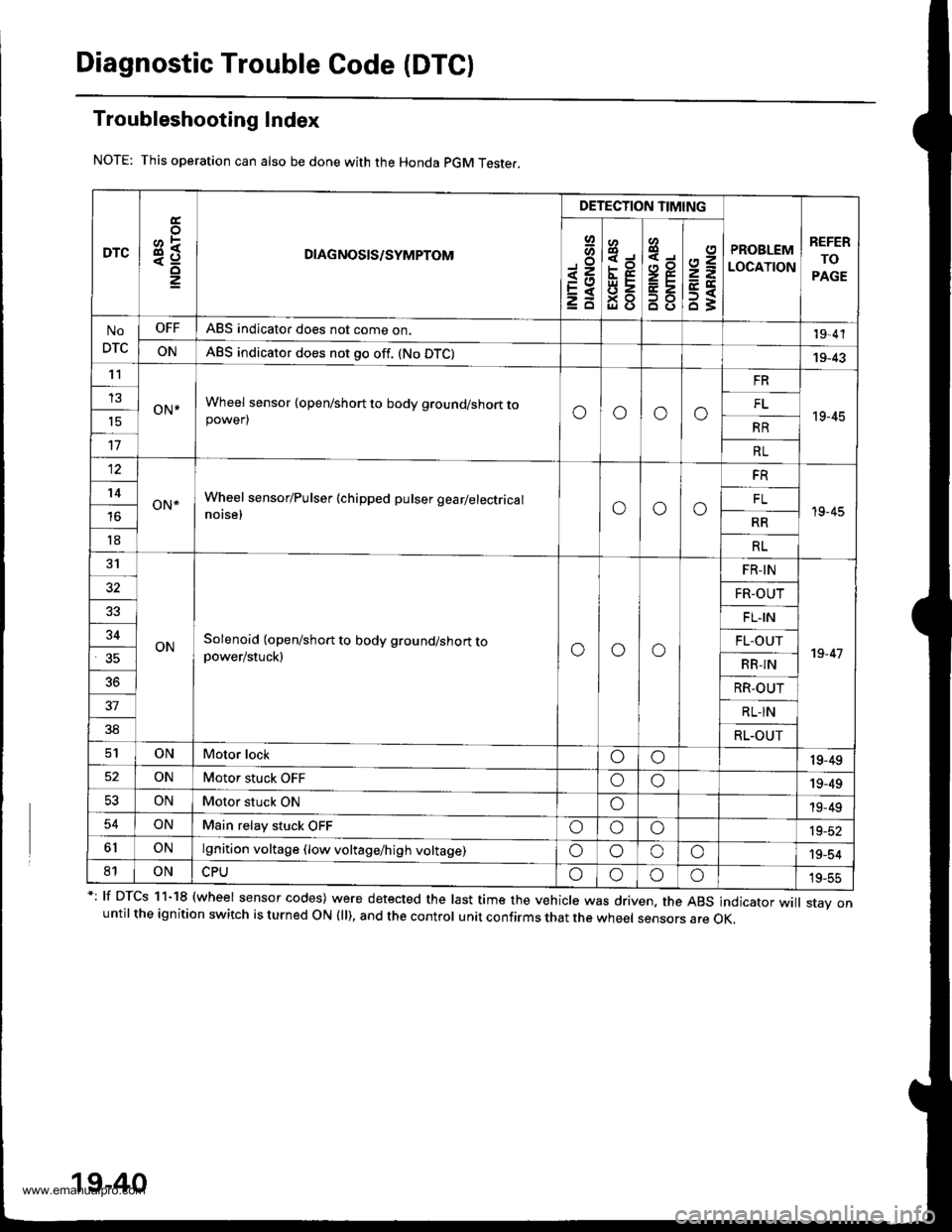

Diagnostic Trouble Code (DTC)

Troubleshooting Index

This operation can also be done with the Honda pGM Teste..

*: lf DTcs 11-18 {wheel sensor codes) were detected the last time the vehicle was driven, the ABs indicator wi

stav onuntil the ignition switch is turned ON (ll), and the control unit confirms that the wheel sensors are OK,

19-40

DTC3R

DETECTION TIMING

PROBLEM

LOCATION

REFER

TO

PAGE

Io

<=EXzd

8

93gl (J

4,,to

B8

2=

ET63

No

DTC

OFFABS indicator does not come on.19,4'l

ONABS indicator does not go off. (No DTC)19-43't1

oN*Wheel sensor {open/short to body ground/short topower)oooo

FR

19-45

13FL't5RR

17RL

12

oN*Wheel sensor/Pulser (chipped pulser gearlelectrical

notse,ooo

FR

19-45

't4FL

RR

18RL

31

ONSolenoid (open/short to body ground/short topower/stuck)ooo

FR-IN

19-47

32FR-OUT

FL.IN

34FL-OUT

RB-IN

36RR-OUT

37RL-IN

38RL.OUT

ONMotor lockoo19-49

ONMotor stuck OFFoo19-49

53ONMotor stuck ONo19-49

54ONMain relay stuck OFFoooia_at

6lONlgnition voltage (low voltage/high voltage)oooo'19-54

81ONoooo19-55

www.emanualpro.com

Page 969 of 1395

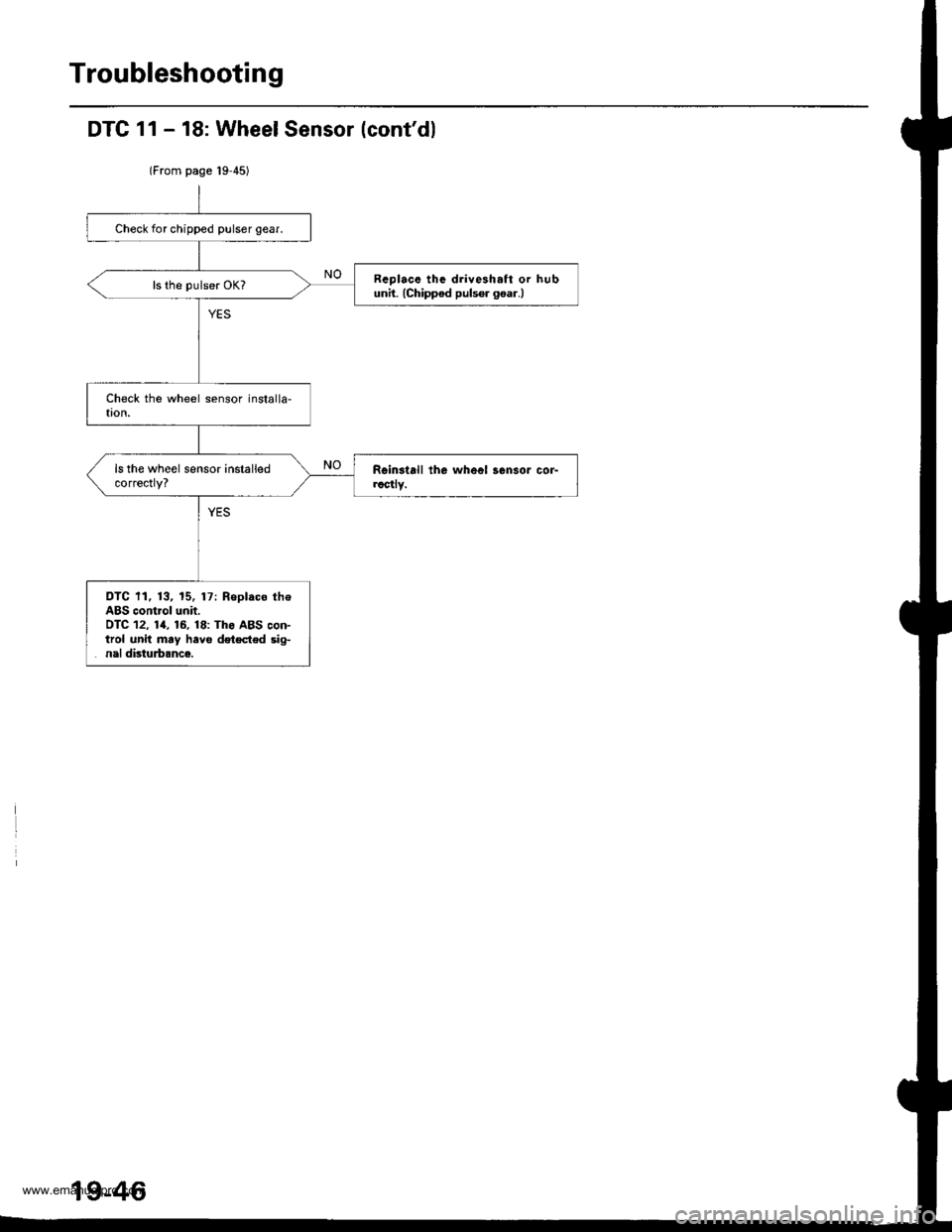

Troubleshooting

DTC 11 - 18: Wheel Sensor (cont'd)

Check for chipped pulser gear.

Rcplacs thc drive3haft or hubunh. (Chipped pulsor goar.l

DTC 11, 13, 15. 17: Replaco theABS control unit.OfC 12, 11, 16, 18: Th6 ABS con-trol unit may have dstected dg-n.l disturbsnc€.

19-46

www.emanualpro.com

Page 992 of 1395

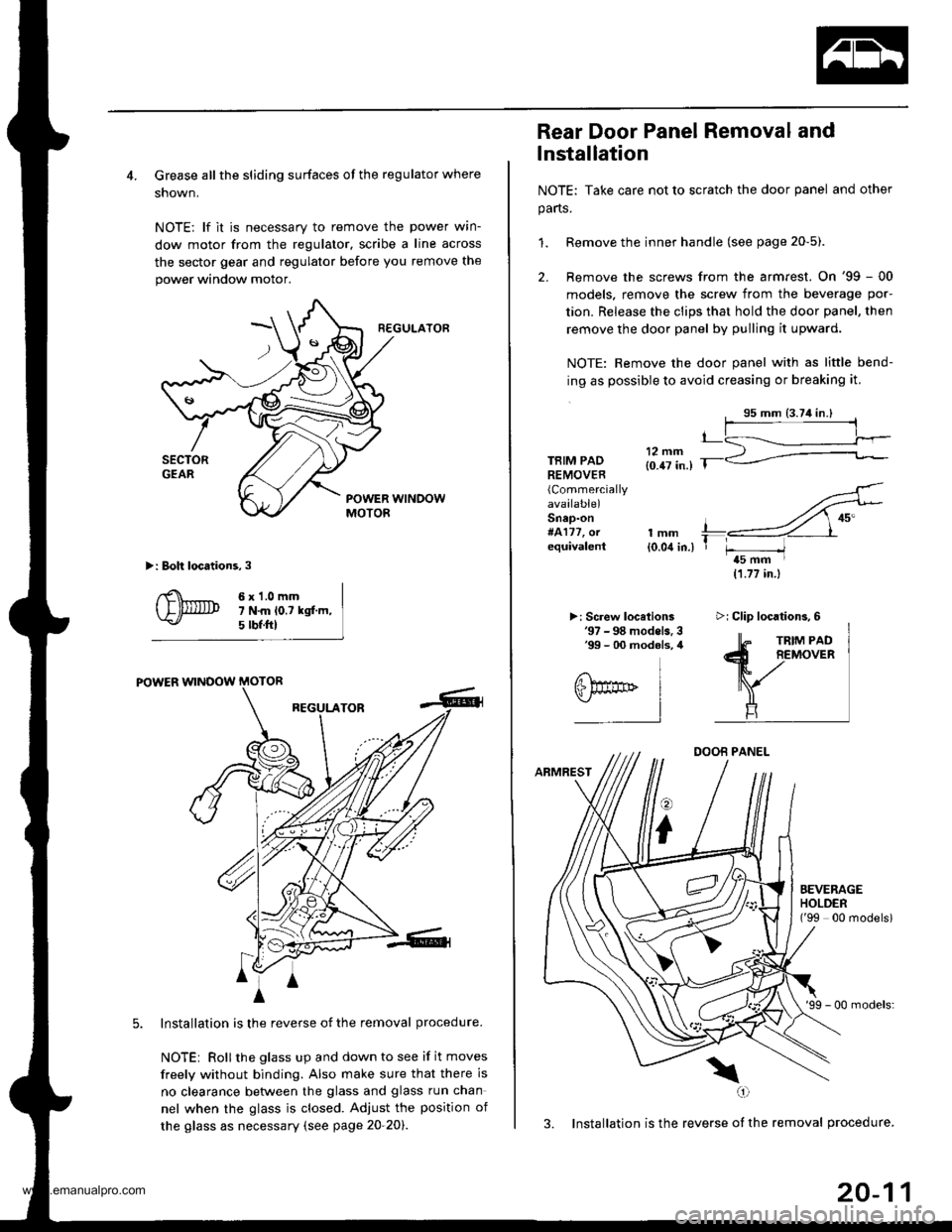

4. Grease all the sliding surfaces of the regulator where

shown.

NOTE: lf it is necessary to remove the power wrn-

dow motor from the regulator, scribe a line across

the sector gear and regulator before you remove the

power window motor.

R€GULATOF

>: Boh locations,3

6x1.0mm7 N.m lo.t kgf.m,5 tbf.ftl

POWER WINOOW MOTOR

REGULATOR

Installation is the reverse of the removal procedure.

NOTEi Rollthe glass up and down to see if it moves

freely without binding. Also make sure that there is

no clearance betlveen the glass and glass run chan

nel when the glass is closed. Adjust the position of

the glass as necessary (see page 20-20).

4

A

m^i

A

Rear Door Panel Removal and

lnstallation

NOTE: Take care not to scratch the door panel and other

parts.

1. Remove the inner handle (see page 20-5).

2. Remove the screws from the armrest. On '99 - 00

models, remove the screw from the beverage por-

tion. Release the clips that hold the door panel, then

remove the door panel by pulling it upward.

NOTE: Remove the door panel with as little bend-

ing as possible to avoid creasing or breaking it.

TBIM PADREMOVER(Commercially

available)Snap-on#4177, orequivalentlmm{0.04 in.)

>: Screw locelions'97 - 98 models. 3'99 - 00 modols, 4

11.77 in.)

DOOB PANEL

ARMREST

o

i

'99 - 00 models:

3. Installation is the reverse of the removal procedure.

\(,1

t_

T r-----/t5 mm I

EEVERAGEHOLDEN('99 00 modelsi

>i Clip locations,6

20-11

www.emanualpro.com

Page 996 of 1395

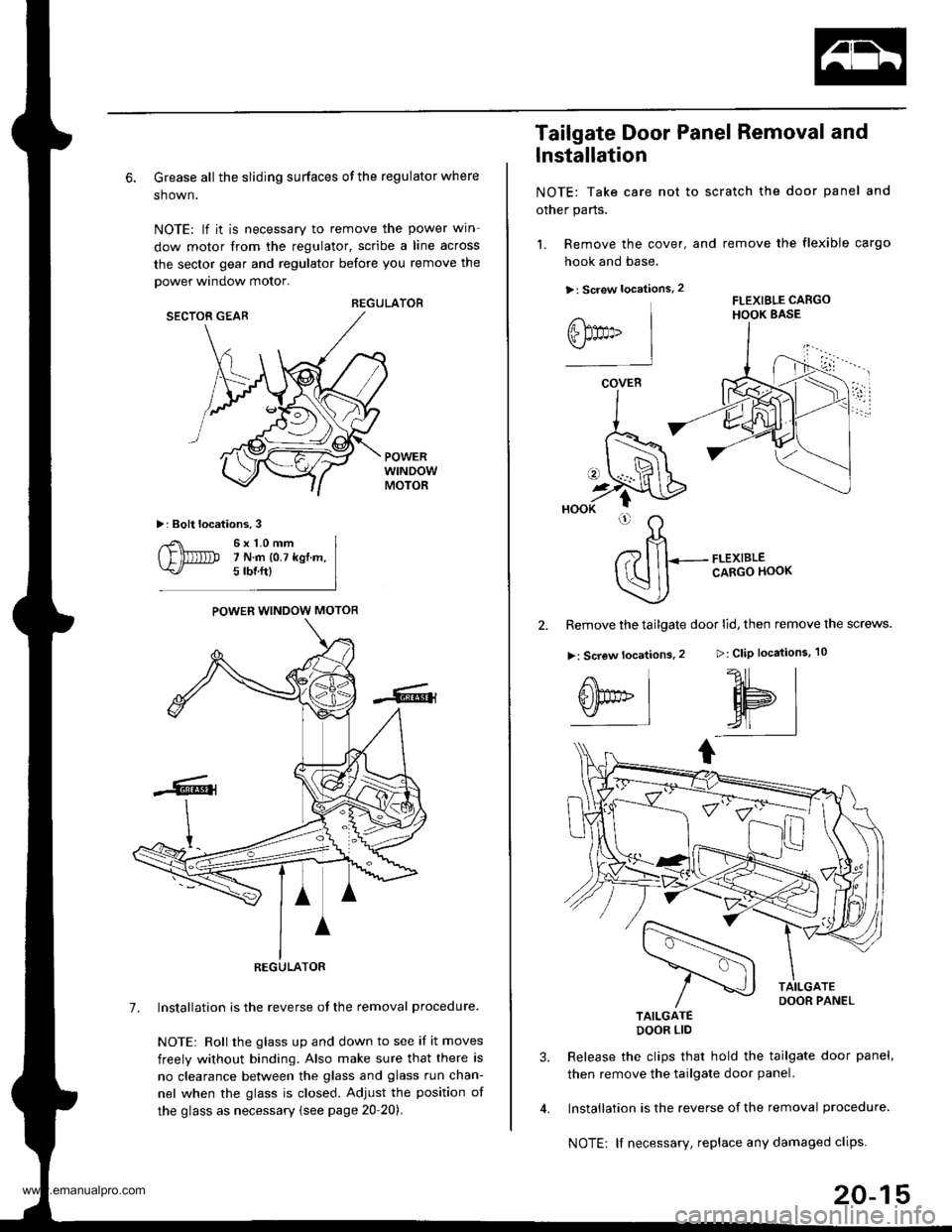

6. Grease all the sliding surfaces of the regulator where

shown.

NOTE: lf it is necessary to remove the power win-

dow motor from the regulator, scribe a line across

the sector gear and regulator before you remove the

power window motor.

REGULATORSECTOR GEAB

POWERwtNDowMOTOR

>: Bolt locations.3

6x1.0mm7 N.m 10.7 kgf.m,5 rbnftl

POWER WINDOW MOTOR

REGULATOR

7. lnstallation is the reverse of the removal procedure.

NOTEr Roll the glass up and down to see if it moves

freely without binding. Also make sure that there is

no clearance between the glass and glass run chan-

nel when the glass is closed. Adjust the position of

the glass as necessary {see page 20 20).

1. Remove the cover,

hook and base.

>: Screw locations.2

Tailgate Door Panel Removal and

lnstallation

NOTE: Take care not to scratch the door panel and

other parts.

and remove the flexible cargo

FLEXIBLE CARGOHOOK BASE

>: CliP locations.

?11 |

HPI,4| |

I

FLEXIBLECARGO HOOK

2. Remove the tailgate door lid, then remove the screws.

>: Screw locations.2

TAILGATEDOOR LIO

Release the clips that hold the tailgate door panel,

then remove the tailgate door panel.

Installation is the reverse of the removal procedure.

NOTE: lf necessary, replace any damaged clips.

3.

@t"

COVER

i

20-15

www.emanualpro.com

Page 1161 of 1395

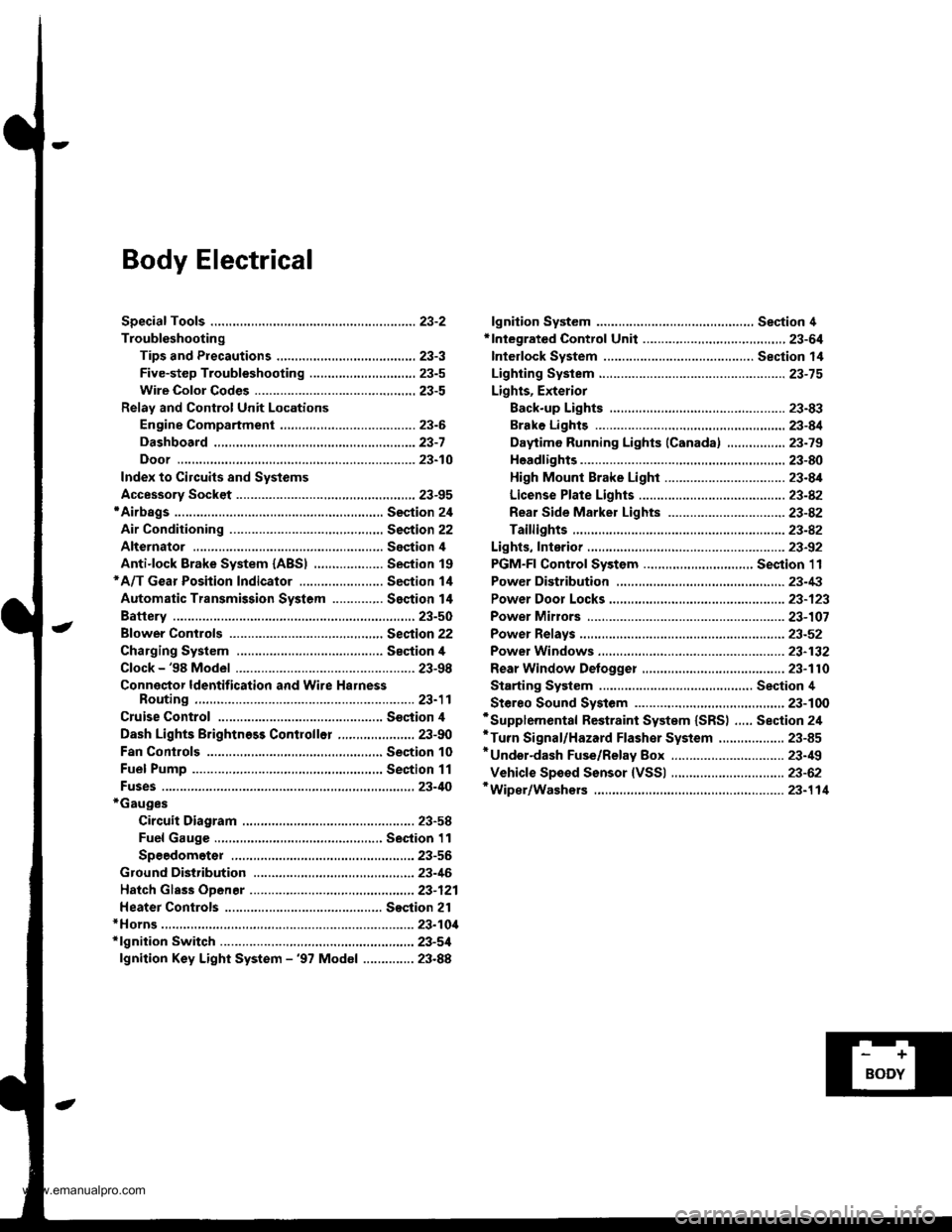

Body Electrical

Speciaf Toofs ,...,..,.............-.23-2

Troubleshooting

Tips and Precautions ......,.,..........,.................. 23-3

Five-step Troubleshooting ........,.,.,...,,.,......... 23-5

Wire Color Codes ...,....,.. 23-5

Relay and Control Unit Locations

Engine Compartment ..,.,......,......................... 23-6

Dashboard ,.,.,..............-.- 23-7

Door ....................... .........23-10

Index to Cilcuits and Sysiems

Accessory Socket .. ,....,.,..,.,. 23-95*Airbags ................ .,....,. Sestion 24

Air Conditioning ,.,.,.... Section 22

Alternator ................... Section 4

Anti-lock Brake System {ABSI ................... Section 19'A/T Gear Position Indicator ....................... Section 1,1

Automatic Transmission System ...........,.. Section 14

Battery ................... ..............23-50

Blower Controls .,...,.,, Section 22

Charging System ....... Seqtion il

Clock -'98 Model ................ 23-98

Connector ldentification and Wire HarnessRouting .................. ......... 23.11

Cruise Control ............ Ssction 4

Dash Lights Brightness Contlo||er ..................... 23-90

Fan Conlrols ...,......,.... Section 10

Fuel Pump ,..,.,...,....,.... Section 11

Fuses...................... .,,.,.,.,.,,.,23-40*Gauges

Circuit Diagram ......-....-..23-58

Fuel Gauge .....,.,..... Section 11

Speedometer ..,..........,... 23-56

Ground Distribution ,....,.,...23-46

Hatch Glsss ODenor .........................,.,.,.,.,..,.,.,.,,. 23-121

Heater Controls .-........ Soction 21*Horns.,...,..,.,.,....... ................23"104*fgnition Switch ,,.,.,..,.,.,,.,.,.,23-51

lgnition Key Light System -'97 Mod6l .............. 23.88

-+

BODY

www.emanualpro.com

Page 1174 of 1395

![HONDA CR-V 1998 RD1-RD3 / 1.G Workshop Manual

Connector ldentification and Wire Harness Routing

Engino Wire Harness

Connecto; or

Terminal

Number of

CavitiesLocationConneqts toNotos

c101

c102

c103

c 104

c105

c105

c106

c 107

c 108

c 109

c]10

c1ll HONDA CR-V 1998 RD1-RD3 / 1.G Workshop Manual

Connector ldentification and Wire Harness Routing

Engino Wire Harness

Connecto; or

Terminal

Number of

CavitiesLocationConneqts toNotos

c101

c102

c103

c 104

c105

c105

c106

c 107

c 108

c 109

c]10

c1ll](/img/13/5778/w960_5778-1173.png)

Connector ldentification and Wire Harness Routing

Engino Wire Harness

Connecto; or

Terminal

Number of

CavitiesLocationConneqts toNotos

c101

c102

c103

c 104

c105

c105

c106

c 107

c 108

c 109

c]10

c1l'l

c112

c113

c't 14

cl16

cl16

c117

c118

c119

c120

c121

c't22

c't23

c't25

cl26

cl27

cr 28

cl29

c130

c131

c132

c 133

c134

c134

c135

c 136

10

6

1

2

1

2

1

10

20

31

16

22

l0

l0'14

14

1

Left side of engine compartment

Left side of engine compartment

Middle of engine

Middle of engine

Left side of engine compartment

Left side of engine compartment

Middle of engine

Middle of engine

Middle of engine

Middle of engine

Middle of engine

Middle of engine

Middle of engine

Middle of engine

Middle of engine

Middle of engine

Middle of engine

Middle of engine

Middle of engine

Middle of engine

Middle of engine

Right side of engine

Middle of engine

Behind right kick panel

Under right side of dash

Under right side of dash

Under right side of dash

Under right side of dash

Under right side of dash

Right side of engine

Right side of engine

Middle of engine

Middle of engine

Middle of engine

Middle of engine

Middle of engine

Middle of engine

Left side of engine compartment

Middle of engine

Middle of engine

Main wire harness (C304)

Main wire harness (C305):'97 - 98 models

No. 1 fuel injector

Crankshaft speed fluctuation (CKF) sensor

Alternator

Alternator

Engine oil pressure switch

No.2 fuel injector

Evaporative emission (EVAP) purge

control solenoid valve

No. 3 fuel injector

No. 4 fuel injector

Primary heated oxygen sensor(Primary HO2S) (sensor 1)

Radiator fan switch

Coolant temperature sending unit

Engine coolant temperature (ECT) sensor

Mainshaft speed sensor

Lock-up control solenoid valve

Back-up light switch

Shift control solenoid valve

Linear solenoid valve

Countershaft speed sesnsor

Starter solenoid

Distributor

Junction connector

PCM

ECIWPCM

ECM/PCM

ECM/PCM

Main wire harness (C,|:}1)

IVT gear position switch

Vehicle speed sensor (VSS)

Throttle position (TP) sensor

MAP sensor

ldle air control (lAC)valve

lntake air temperature (lAT) sensor

Junction connector

Junction connector

Power steering pressure (PSP) switch

Junction connector

Knock sensor (KS)

A/r

USA

Canada

Alr

AlT

M/'r

Afi

'97mooel

'97 model'98 - 00

mooets

'99 - 00

models

T101

r102

Left side of en0ine companment

Right side of engine compartment

Alternator

Under-hood fuse/relay box

G101Middle of engineEngine ground, via engine wire harness

23-14

www.emanualpro.com

Page 1205 of 1395

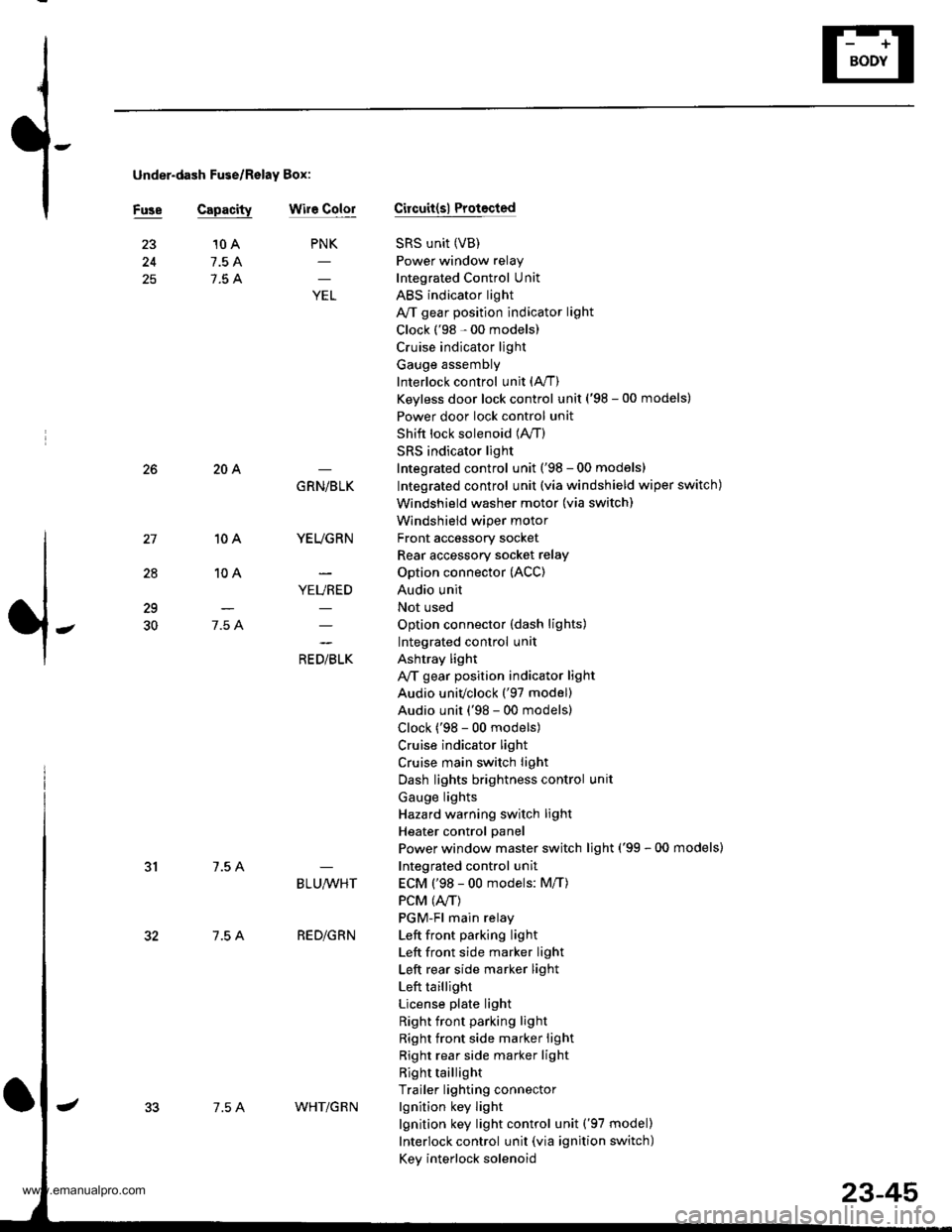

under-dash Fuse/Relay Box:

Fuse Capacitywir6 ColorCircuit(sl Protocted

SRS unit (VB)

Power window relay

Integrated Control Unit

ABS indicator light

A/T gear position indicator light

Clock ('98 - 00 models)

Cruise indicator light

Gauge assembly

Interlock control unit (A,/T)

Keyless door lock control unit ('98 - 00 models)

Power door lock control unit

Shift lock solenoid (lVT)

SRS indicator light

Integrated control unit ('98 - 00 models)

Integrated control unit (via windshield wiper switch)

Windshield washer motor (via switch)

Windshield wiper motor

Front accessory socket

Rear accessory socket relay

Option connector (ACC)

Audio unit

Not used

Option connector (dash lights)

Integrated control unit

Ashtray light

A,/T gear position indicator light

Audio univclock ('97 model)

Audio unit ('98 - 00 models)

Clock ('98 - 00 models)

Cruise indicator light

Cruise main switch light

Dash lights brightness control unit

Gauge lights

Hazard warning switch light

Heater control panel

Power window master switch light ('99 - 00 models)

Integrated control unit

ECM ('98 - 00 models: M/T)

PCM (4./T)

PGM-Fl main relay

Left front pa.king light

Left front side marker light

Left rear side marker light

Left taillight

License plate light

Right front parking light

Right front side marker light

Right rear side marker light

Right taillight

Trailer lighting connector

lgnition key light

lgnition key light control unit ('97 model)

Interlock control unit (via ignition switch)

Key interlock solenoid

25

PNK

;

10 A

7.5 A

7.5 A

28

10A

10A

7.5 A

204

7.5 A

7.5 A

GRN/BLK

YEUGRN

YEURED

a, olrL"

29

30

BLU,ryVHT

RED/GRN

7.5 AWHT/G R N

23-45

www.emanualpro.com