Gear HONDA CR-V 1998 RD1-RD3 / 1.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1998, Model line: CR-V, Model: HONDA CR-V 1998 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 773 of 1395

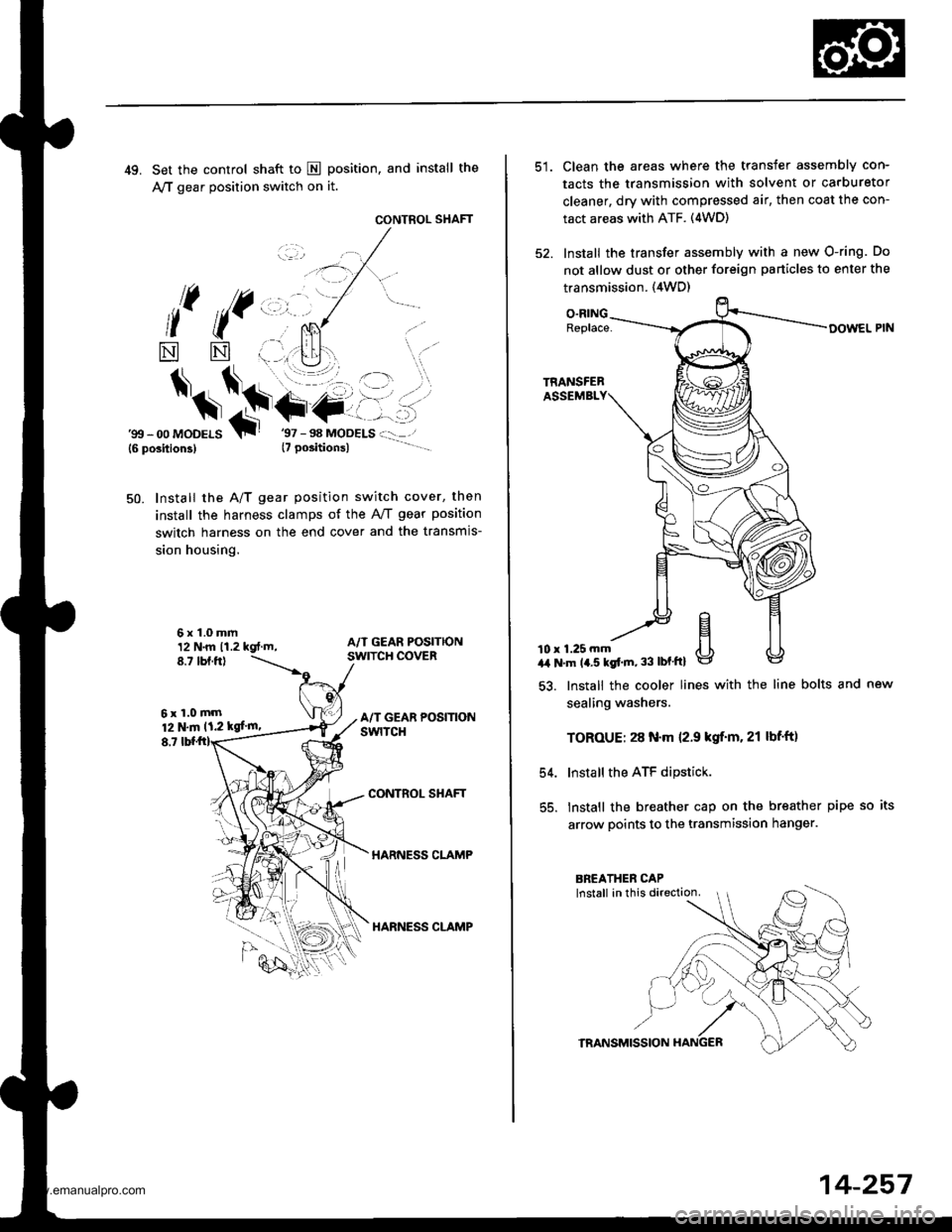

49. Set the control shaft to E position, and install the

A,/T gear position switch on it.

CONTROL SHAFT

l( ((,,, ,.

*

$*\.t+-

NN

6x1.0mm12 N.m 11.2 kgt.m,8.7 tbf.ftl

6xl.0mm12 N.m 11.2 kgf'm,

8,7

'gtt - 00 MoDELS{6 position3}T

Install the A/T gear position switch cover, then

install the harness clamps of the AviT gear position

switch harness on the end cover and the transmis-

sion housing.

50.

CONTROL SHAFT

HARNESS CLAMP

HARNESS CLAMP

Clean the areas where the transfer assembly con-

tacts the transmission with solvent or carburetor

cleaner, dry with compressed air, then coat the con-

tact areas with ATF. (4WD)

Install the transfer assembly with a new O-ring. Do

not allow dust or other foreign particles to enter the

transmission. {4WD)

O.RINGReplace-

10 r 1.25 mma,a N'm 14.5 kgt'm, 33 lbf'ftl

54.

55.

lnstall the cooler lines with the line bolts and new

sealing washers.

TOROUE: 28 N.m 12.9 kgif'm. 21 lbf'ft)

Install the ATF dipstick.

lnstall the breather cap on the breather pipe so its

arrow points to the transmission hanger.

TRANSMISSION

14-257

www.emanualpro.com

Page 777 of 1395

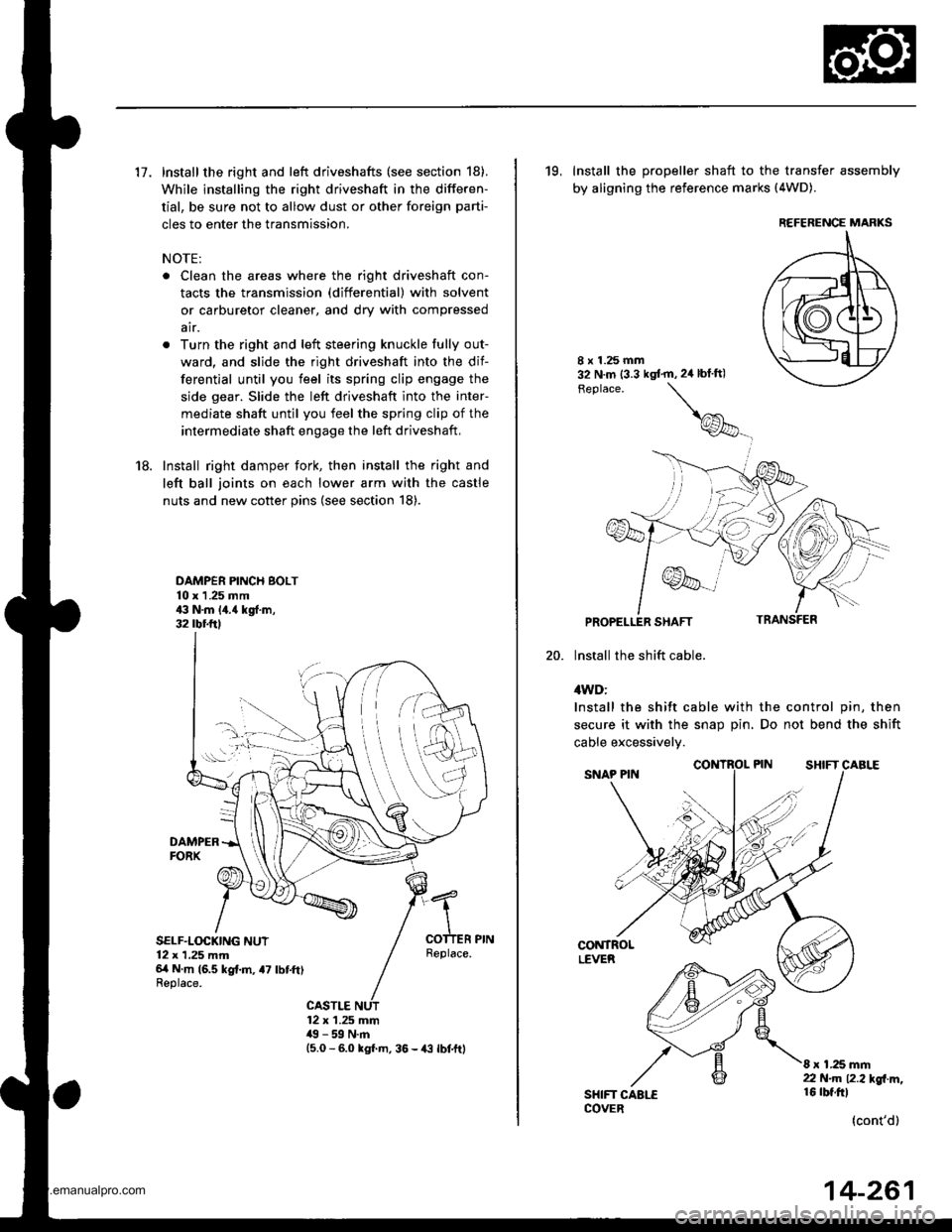

17. Install the right and left driveshafts (see section 18).

While installing the right driveshaft in the differen-

tial, be sure not to allow dust or other foreign parti-

cles to enter the transmission.

NOTE:

. Clean the areas where the right driveshaft con-

tacts the transmission (differential) with solvent

or carburetor cleaner, and dry with compressed

air.

. Turn the right and left steering knuckle fully out-

ward, and slide the right driveshaft into the dif-

ferential until you feel its spring clip engage the

side gear. Slide the left driveshaft into the inter-

mediate shaft until you feel the spring clip of the

intermediate shaft engage the left driveshaft,

18. Install right damper fork, then install the right and

left ball joints on each lower arm with the castle

nuts and new cotter pins (see section 18).

DAMPER PINCH BOLT10 x 1 .25 mm43 N.m 14.{ kgf.m,32 rbr.ftl

DAMPERFORX

SELF.LOCKING NUT12 x 1,25 mm6/t N m (6.5 kg{.m, a7 lbtft)Replace.

Replace.

CASTLE12 x 1.25 mm49 - 59 N.m15.0 - 6.0 kgl m, 36 - {3 lbtftl

19, Install the propeller shaft to the transfer assembly

by aligning the reference marks (4WD).

20.

8 x 1.25 mm32 N.m (3.3 kgt'm,2ir blft)

Feplace.

\

@_

PROPELLER SHAFT

lnstall the shift cable.

4WD:

Install the shift cable with the control pin, then

secure it with the snap Din. Do not bend the shift

cable excessivelv.

CONTROLLEVER

SHIFT CAALECOVER

8 x 1.25 mm22 N.m 12.2l'gl m,16 rbt.ftl

(cont'd)

REFERENCE MARKS

14-261

www.emanualpro.com

Page 779 of 1395

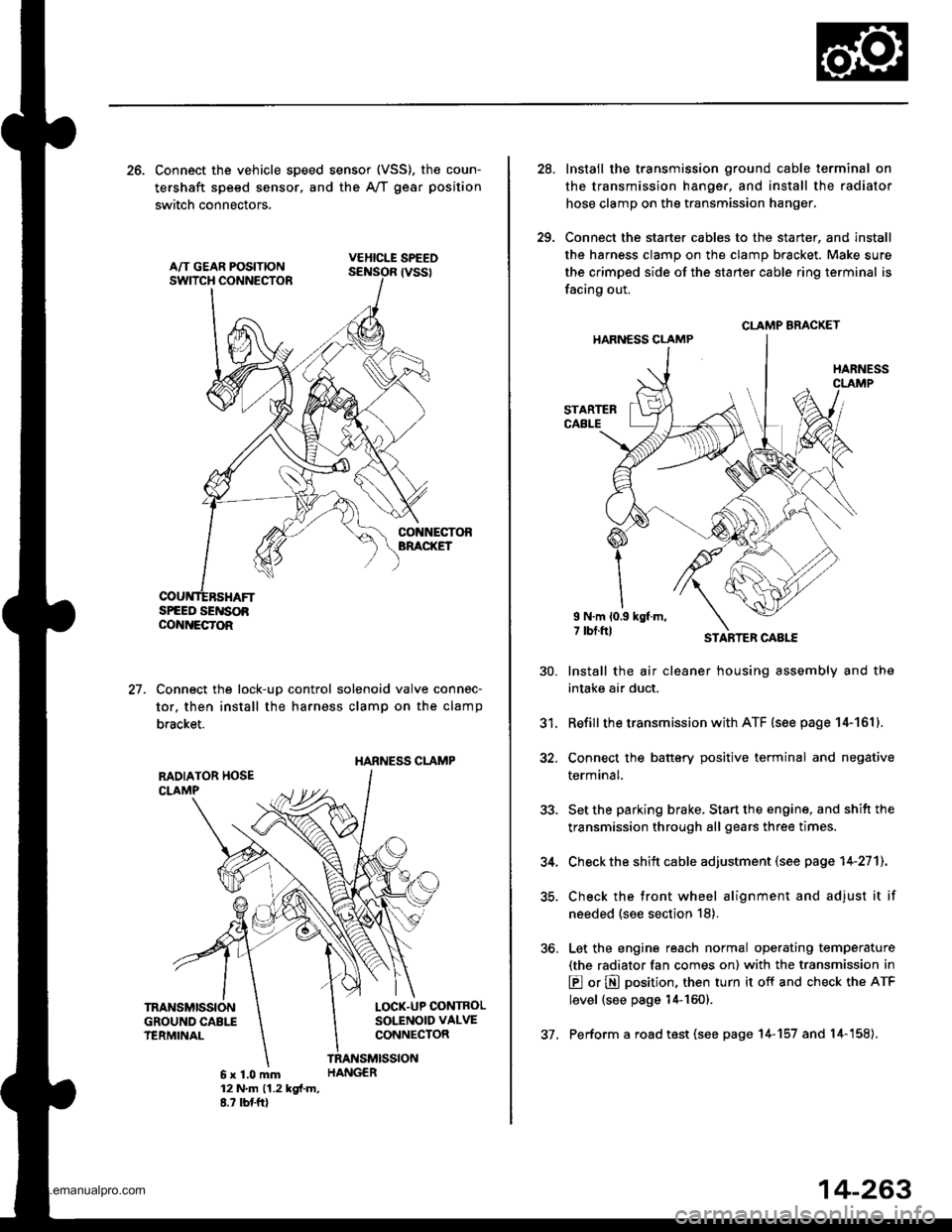

26. Connect the vehicle speed sensor (VSS). the coun-

tershaft speed sensor. and the A,/T gear position

switch connectors,

VEHICLE SPEEO

SPEED SENSOACO'{NECTOR

Connect the lock-up control solenoid valve connec-

tor, then install the harness clamp on the clamp

bracket.

HARNESS CI-AMP

27.

RADIATOR HOSECLAMP

TRANSMISSIONGROUND CAB1ITERMINAL

LOCK-UP OONTROLSOLENOID VALVECONNECTOR

6x1.0mm12 N'm (1.2 kgi.m,8.? tbtftl

28.

29.

Instail the transmission ground cable terminal on

the transmission hanger, and install the radiator

hose clamp on the transmission hanger,

Connect the starter cables to the starter, and install

the harness clamD on the clamD bracket. Make sure

the crimped side of the starter cable ring terminal is

facing out.

STARTEBCABLE

STARTER CAAtf,

Install the air cleaner housing assembly and the

intake air duct.

Refill the transmission with ATF (see page 14-161).

Connect the battery positive terminal and negative

terminal.

Set the parking brake, Start the engine, and shift the

transmission through all gears three times.

Check the shift cable adjustment (see page 14-271]-.

Check the tront wheel alignment and adjust it if

needed (see section 18).

Let the engine reach normal operating temperature

(the radiator fan comes on) with the transmission in

E or N position, then turn it off and check the ATF

level {see page 14-160).

Perform a road test (see page 14-157 and 14-158).

30.

31.

34.

CLAMP BRACKET

37.

14-263

www.emanualpro.com

Page 788 of 1395

Shift Gable

Adjustment

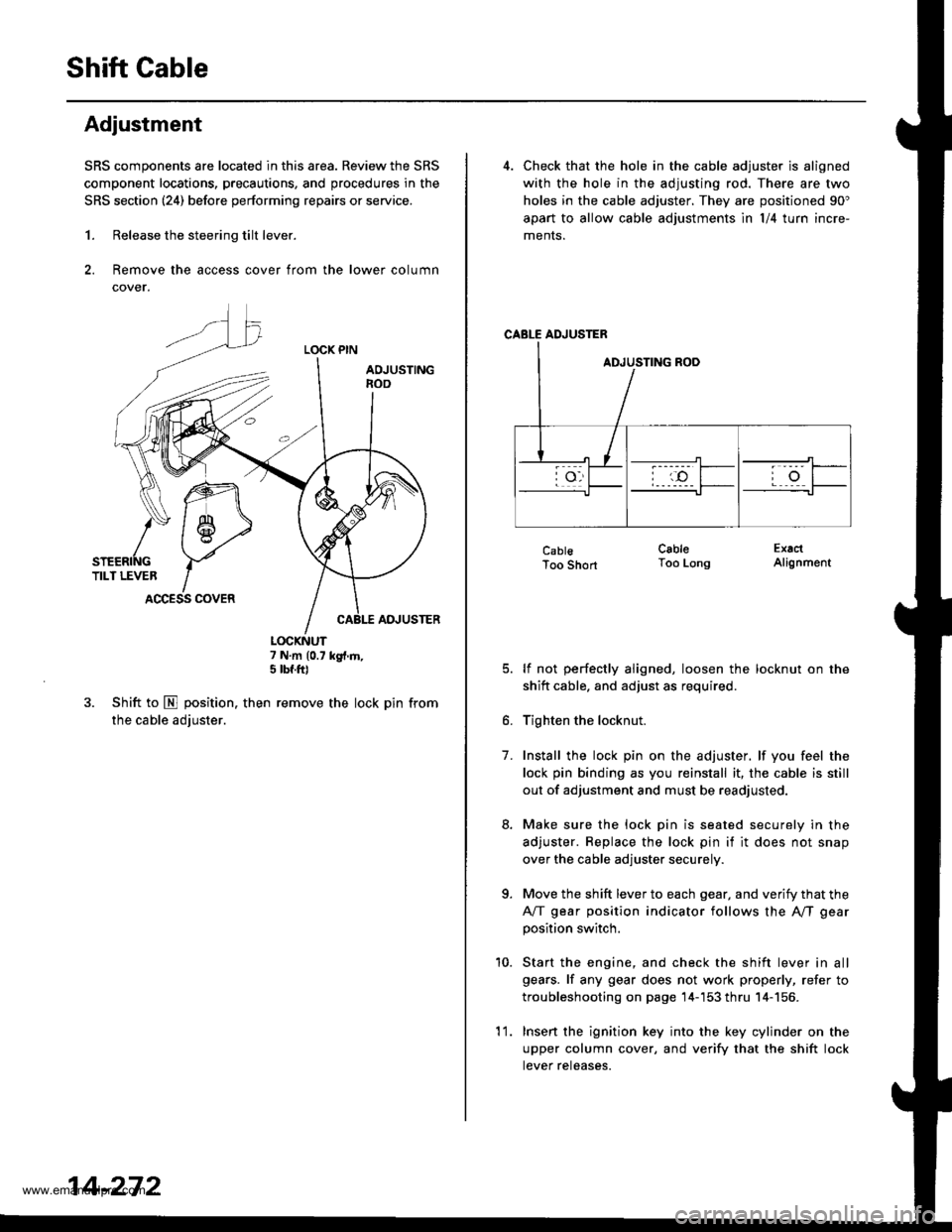

SRS components are located in this area. Review the SRS

component locations, precautions, and procedures in the

SRS section (241 before performing repairs or service.

1. Release the steering tilt lever.

2. Remove the access cover from the lower column

cover.

LOCK PIN

AOJUSTINGnoo

ADJUSTER

7 N.m (0.7 kg{.m,5 tbf.ft)

3. Shift to E position. then remove the lock pin from

the cable adjuster.

K\ffi

/* 1 6-,>

snenrftc YTILT LEVER IACCESS COVER

14-272

'l 1.

4. Check that the hole in the cable adjuster is aligned

with the hole in the adjusting rod. There are two

holes in the cable adjuster. They are positioned 90"

apart to allow cable adjustments ln l/4 turn incre-

ments.

CABLE ADJUSTER

CablsToo Short

lf not perfectly aligned, loosen the locknut on the

shitt cable. and adjust as required.

Tighten the locknut.

Install the lock pin on the adjuster. lf you feel the

lock pin binding as you reinstall it, the cable is still

out of adjustment and must be readjusted.

Make sure the lock pin is seated securely in the

adjuster. Replace the lock pin if it does not snap

over the cable adjuster securely.

Move the shift lever to each gear, and verify that the

A/T gear position indicator follows the A"/T gear

position switch.

Start the engine, and check the shift lever in all

gears. lf any gear does not work properly, refer to

troubleshooting on page 14-'153 thru 14-156.

Insert the ignition key into the key cylinder on the

upper column cover, and verify that the shift lock

tever reteases.

CableToo LongExactAlignment

7.

a

10.

www.emanualpro.com

Page 794 of 1395

Description

Rear Differential

Outline

The Real-time 4WD-Dual Pump System model has a hydraulic clutch and a differential mechanism in the rear differential

assembly. Under normal conditions, the vehicle is driven by the front wheels. However, depending on to the driving force

of the front wheels and the road conditions. the system instantly transmits appropriate driving force to the rear wheels

without requiring the driver to switch between 2WD (tront wheel drive) and 4WD (four wheel drive). The switching mecha-

nism between 2WD and 4WD is integrated into the rear differential assembly to make the system light and compact.

ln addition, the dual-pump system switches off the rear-wheel-drive force when braking in a forward gear. This allows the

braking system to work properly on models equipped with an Anti-lock Braking System (ABS).

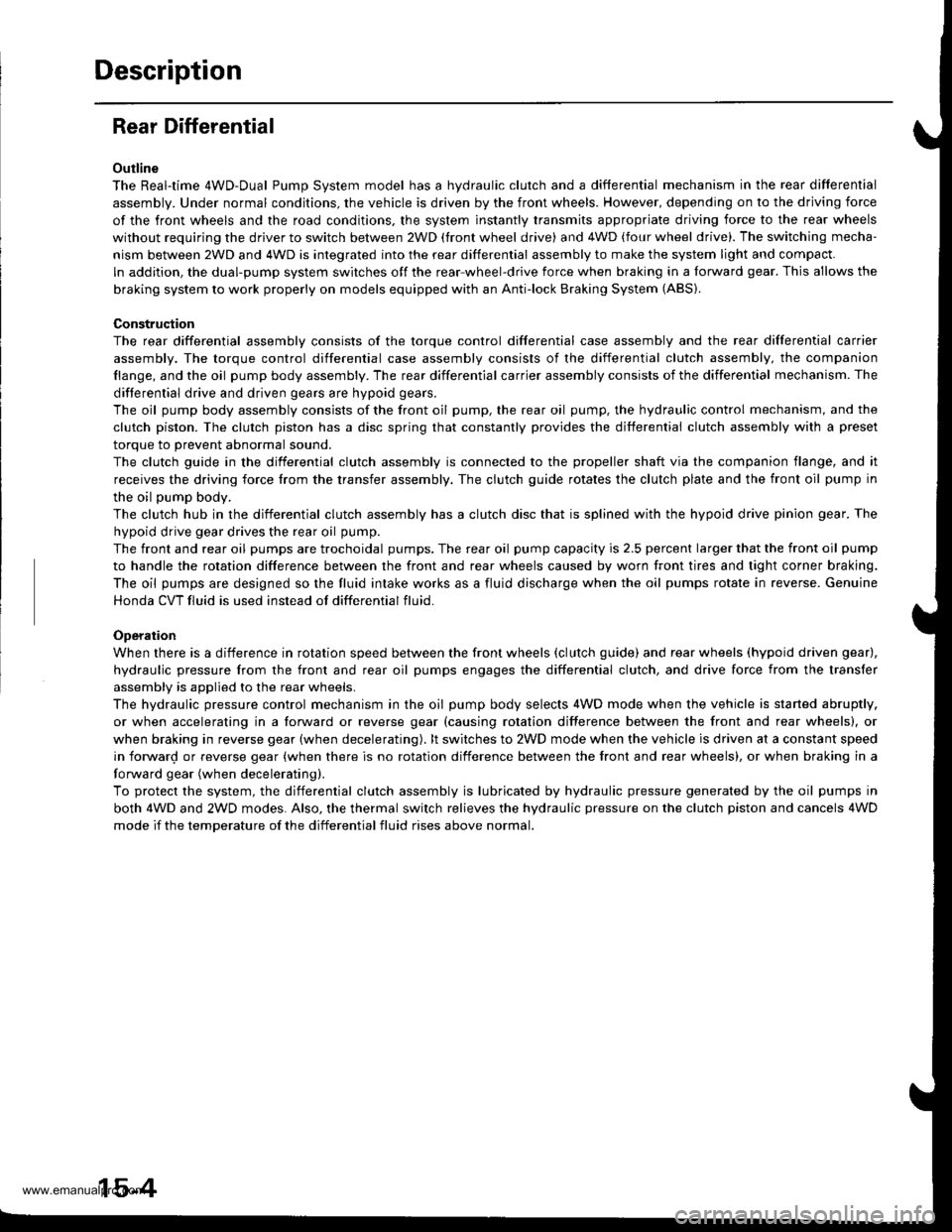

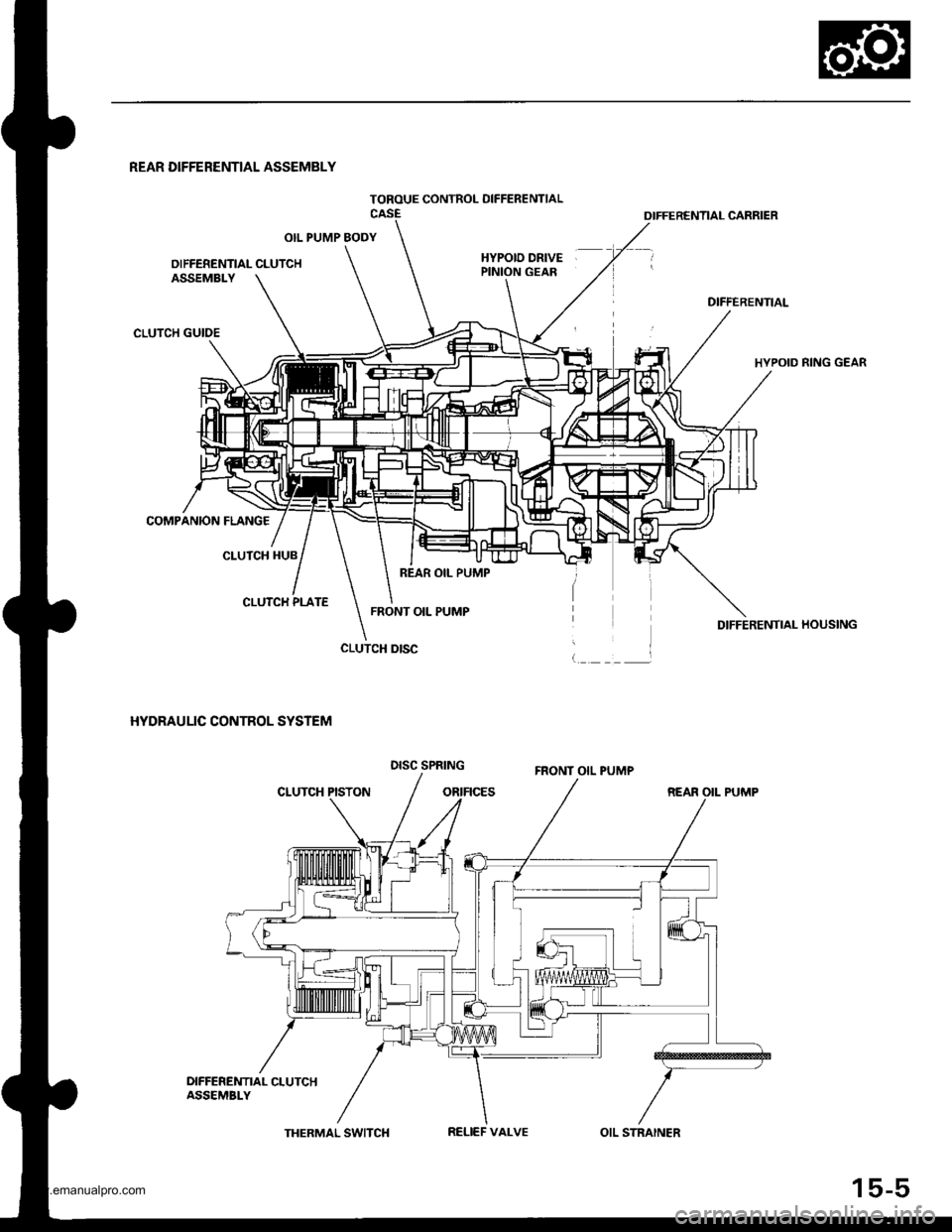

Construction

The rear differential assembly consists of the torque control differential case assembly and the rear differential carrier

assembly. The torque control differential case assembly consists of the differential clutch assembly, the companion

flange, and the oil pump body assembly. The rear differential carrier assembly consists of the differential mechanism. The

differential drive and driven gears are hypoid gears.

The oil pump body assembly consists of the front oil pump, the rear oil pump, the hydraulic control mechanism, and the

clutch piston. The clutch piston has a disc spring that constantly provides the differential clutch assembly with a preset

torque to Drevent abnormal sound.

The clutch guide in the differential clutch assembly is connected to the propeller shaft via the companion flange, and it

receives the driving force lrom the transfer assembly. The clutch guide rotates the clutch plate and the front oil pump in

the oil pump body.

The clutch hub in the differential clutch assembly has a clutch disc that is splined with the hypoid drive pinion gear. The

hypoid drive gear drives the rear oil pump.

The front and rear oil pumps are trochoidal pumps. The rear oil pump capacity is 2.5 percent larger that the front oil pump

to handle the rotation difference between the front and rear wheels caused by worn front tires and tight corner braking.

The oil pumps are designed so the fluid intake works as a fluid discharge when the oil pumps rotate in reverse. Genuine

Honda CVT fluid is used instead of differential fluid.

Operation

When there is a difference in rotation speed between the front wheels (clutch guide) and rear wheels (hypoid driven gear),

hydraulic pressure from the front and rear oil pumps engages the differential clutch, and drive force from the transler

assembly is applied to the rear wheels.

The hydraulic pressure control mechanism in the oil pump body selects 4WD mode when the vehicle is started abruptly,

or when accelerating in a forward or reverse gear (causing rotation difference between the front and rear wheels). or

when braking in reverse gear {when decelerating). lt switches to 2WD mode when the vehicle is driven at a constant speed

in forwar! or reverse gear (when there is no rotation difference between the front and rear wheels), or when braking in a

fo rwa rd gear (when decelerating).

To protect the system, the differential clutch assembly is lubricated by hydraulic pressure generated by the oil pumps in

both 4WD and 2WD modes. Also, the thermal switch relieves the hydraulic pressure on the clutch piston and cancels 4WD

mode if the temDerature of the differential fluid rises above normal.

www.emanualpro.com

Page 795 of 1395

TOROUE CONTROL OIFFERENTIAL

REAR DIFFERENTIAL ASSEMBLY

OIL PUMP BODY

OIFFERENTIAL CLUTCHHYPOID DRIVEPINION GEAR

OIFFERENTIAL CARRIER

DIFFERENTIAL

HYPOID RING GEAR

DIFFERENTIAI- HOUSING

REAR OII- PUMP

ASSEMBLY

CLUTCH GUIDE

COMPANION FLANG€

CLUTCH HUB

CLUTCH PLATE

HYDRAULIC CONTROL SYSTEM

CLUTCH PISTON

CLUTCH DISC

REAR OIL PUMP

FRONT OIL PUMP

DISC SPRINGFRONT OIL PUMP

DIFFEREMT|AL CLUTCHASSEMBI-Y

THERMAL SWITCHRELIEF VALVEOIL STRAINER

15-5

www.emanualpro.com

Page 800 of 1395

Real-time 4WD-Dual Pump System

Troubleshooting (Automatic Transmissionl

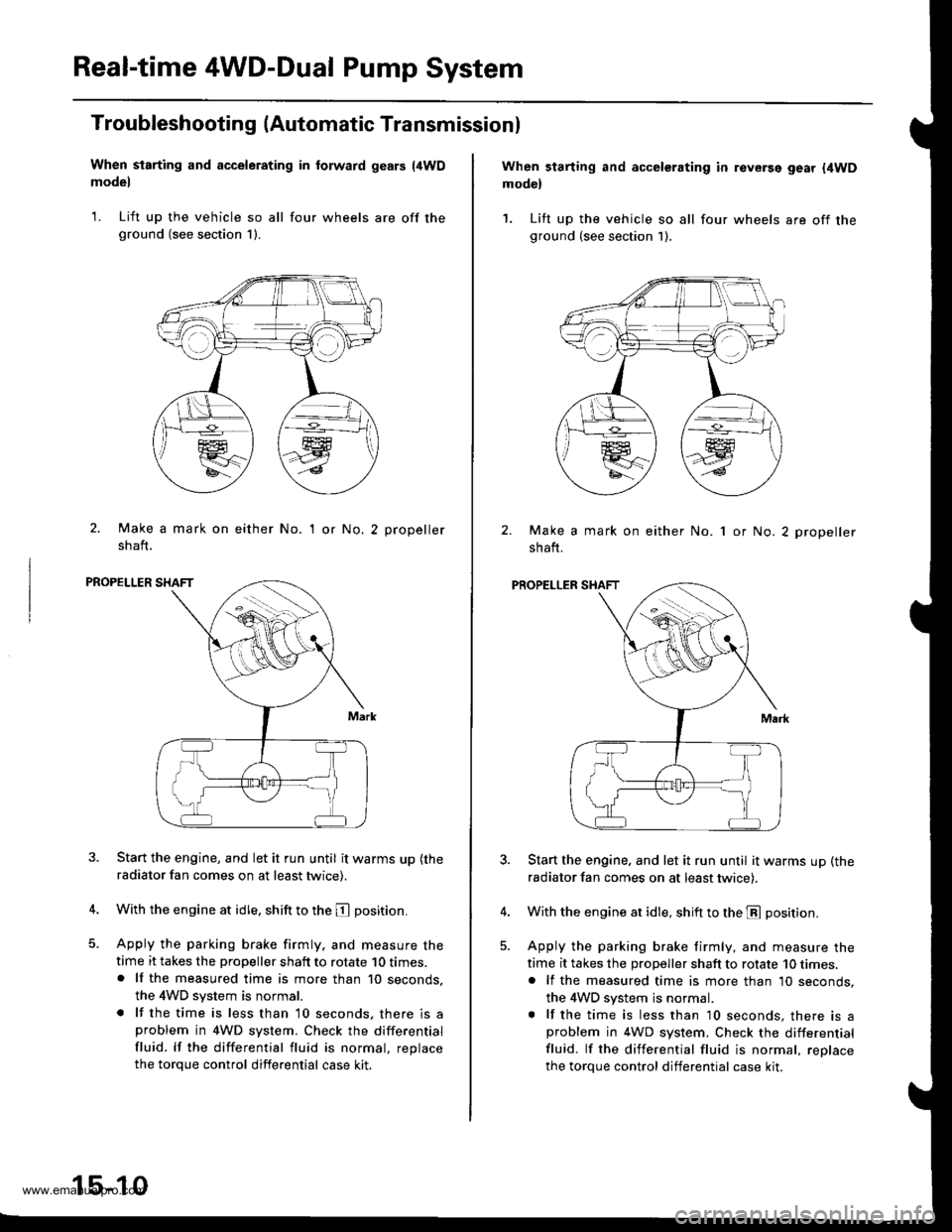

When starting and accelerating in forward gesrs {4WDmodel

1. Lift up the vehicle so all four wheels are off theground (see section 1).

2. Make a mark on either No.

shaft.

'I or No.2 propeller

PROPELLER SHAFT

Start the engine, and let it run until it warms up (the

radiator fan comes on at least twice).

With the engine at idle. shift to the E position.

Apply the parking brake firmly. and measure thetime it takes the propeller shaft to rotate 10 times.. lf the measured time is more than 10 seconds,

the 4WD system is normal.

. lf the time is less than 10 seconds, there is aproblem in 4WD system. Check the differential

fluid. lf the differential fluid is normal, replace

the torque control differential case kit.

15-10

When starting and accelerating in revGrsg gear {4WDmodel

1. Lift up the vehicle so all four wheels are off theground (see section 1).

Make a mark on either No.

shaft.

1 or No. 2 propeller

PROPELLER SHAFT

Start the engine. and let it run until it warms up (the

radiator fan comes on at least twicei.

With the engine at idle, shift to the E position.

Apply the parking brake firmly, and measure the

time it takes the proDeller shaft to rotate 10 times,. lf the measured time is more than 10 seconds,

the 4WD system js normal.. lf the time is less than 10 seconds, there is aproblem in 4WD system. Check the differential

fluid. lf the differential fluid is normal, reolace

the torque control differential case kit.

www.emanualpro.com

Page 801 of 1395

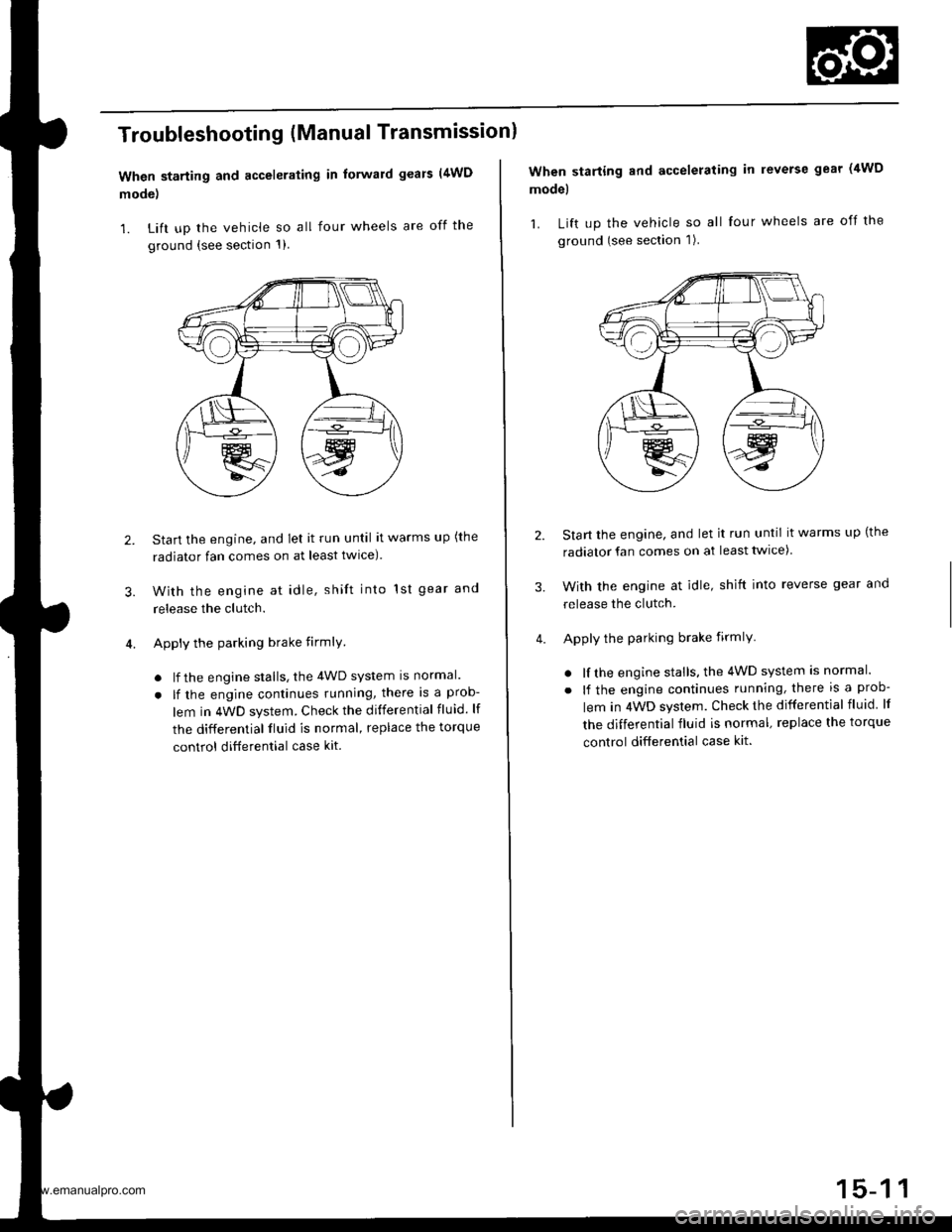

Troubleshooting (Manual Transmissionl

When starting and accelerating in forward gears (4WD

mode)

1. Lift up the vehicle so all four wheels are off the

ground {see section 1)

3.

Start the engine, and let it run until it warms up (the

radiator fan comes on at least twlce).

With the engine at idle, shift into 1st gear and

release the clutch.

Apply the parking brake firmlY

. lf the engine stalls, the 4WD system is normal.

. lf the engine continues running, there is a prob-

lem in 4WD system. Check the differential fluid. lf

the differential fluid is normal, replace the torque

control ditferential case kit.

2.

When starting and accelerating in reverse gear (4WD

model

1. Lift up the vehicle so all four wheels are off the

ground (see section 1).

Start the engine, and let it run until it warms up (the

radiator fan comes on at least twice)

With the engine at idle, shift into reverse gear and

release the clutch.

Apply the parking brake firmlY

. lf the engine stalls, the 4WD system is normal.

. lf the engine continues running, there is a prob-

lem in 4WD system. Check the differential fluid lf

the differential fluid is normal, replace the torque

control differential case kit.

3.

www.emanualpro.com

Page 802 of 1395

Real-time 4WD-Dual Pump System

Troubleshooting (Automatic Transmission/Manual Transmission)

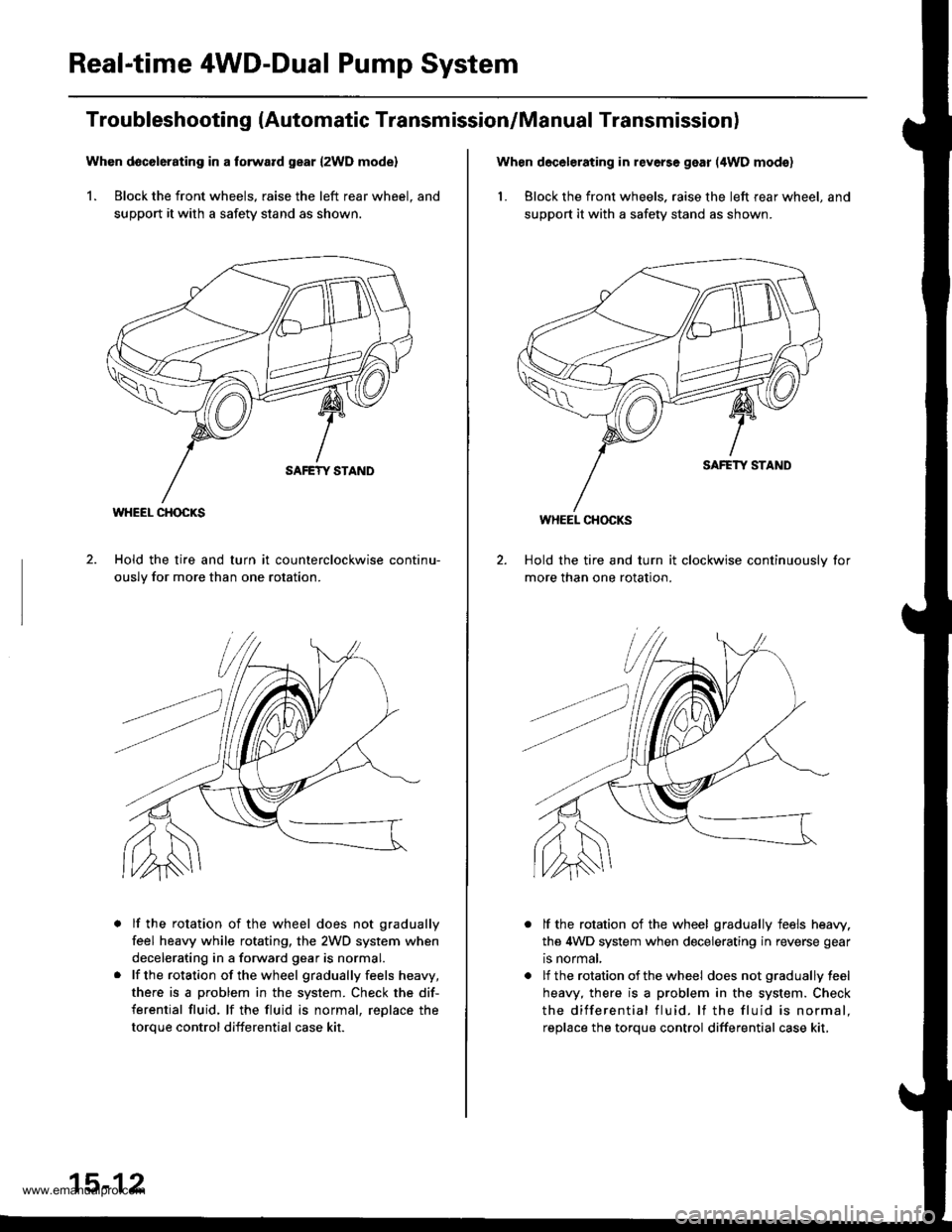

Whon d6c6l6rating in a torward gear {2WD mode}

1. Block the front wheels, raise the left rear wheel. and

support it with a safety stand as shown.

Hold the tire and turn it counterclockwise continu-

ouslv for more than one rotation.

lf the rotation of the wheel does not gradually

feel heavy while rotating, the 2WD system when

decelerating in a forward gear is normal.

lf the rotation of the wheel gradually feels heavy,

there is a problem in the system. Check the dif-

ferential fluid, lf the fluid is normal, reDlace the

toroue control differential case kit.

WHEEL CHOCKS

15-12

When decelerating in reverse gear (4WD mod€)

1. Block the front wheels. raise the left rear wheel, and

suppo( it with a safety stand as shown.

Hold the tire and turn it clockwise continuouslv for

more than one rotation.

lf the rotation of the wheel gradually feels heaw.

the 4WD system when decelerating in reverse gear

is normal,

lf the rotation of the wheel does not gradually feel

heavy, there is a problem in the system. Check

the differential fluid. lf the fluid is normal.

reolace the torque control differential case kit,

WHEEL CHOCKS

www.emanualpro.com

Page 803 of 1395

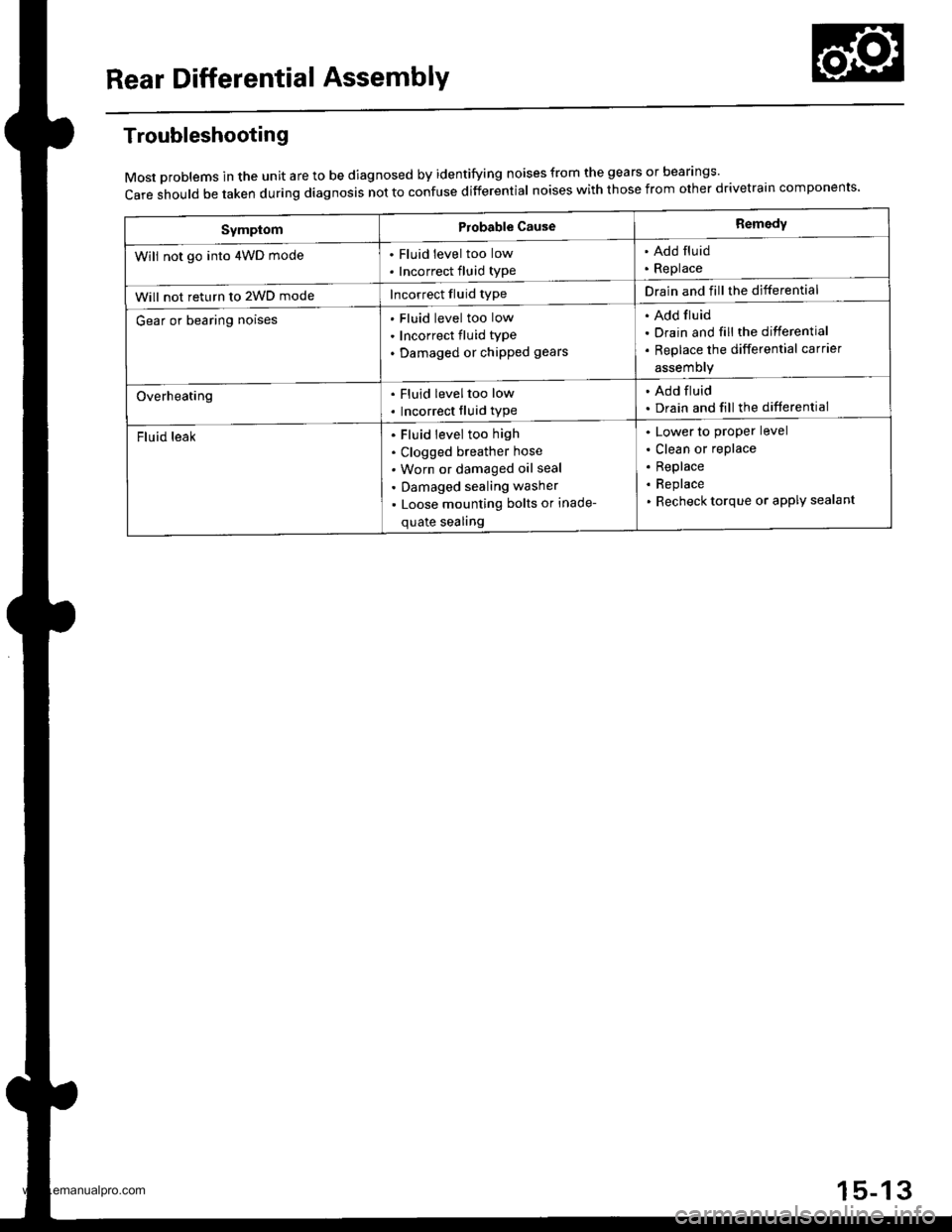

Rear Differential AssemblY

Troubleshooting

Most problems in the unit are to be diagnosed by identifying noises from the gears or bear'ngs'

care should be taken during diagnosis not to confuse differential noises with those from other drivetra'n components'

SymptomProbable CauseRemedy

Will not go into 4WD mode. Fluid level too low

. Incorrect fluid type

. Add fluid. Replace

Will not return to 2WD modeIncorrect fluid typeDrain and fill the differential

Gear or bearing noisesFluid level too low

Incorrect fluid type

Damaged or chipped gears

Add fluid

Drain and fill the differential

Replace the differential carrier

assemory

Overheating. Fluid leveltoo low

. Incorrect fluid type

. Add fluid. Drain and fill the differential

Fluid leakFluid level too high

Clogged breather hose

Worn or damaged oil seal

Damaged sealing washer

Loose mounting bolts or inade-

quate sealing

Lower to proper level

Clean or replace

Replace

Replace

Recheck torque or aPPIY sealant

15-13

www.emanualpro.com