Lock HONDA CR-V 1998 RD1-RD3 / 1.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1998, Model line: CR-V, Model: HONDA CR-V 1998 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 893 of 1395

Power Steering Gearbox

Reassembly (cont'dl

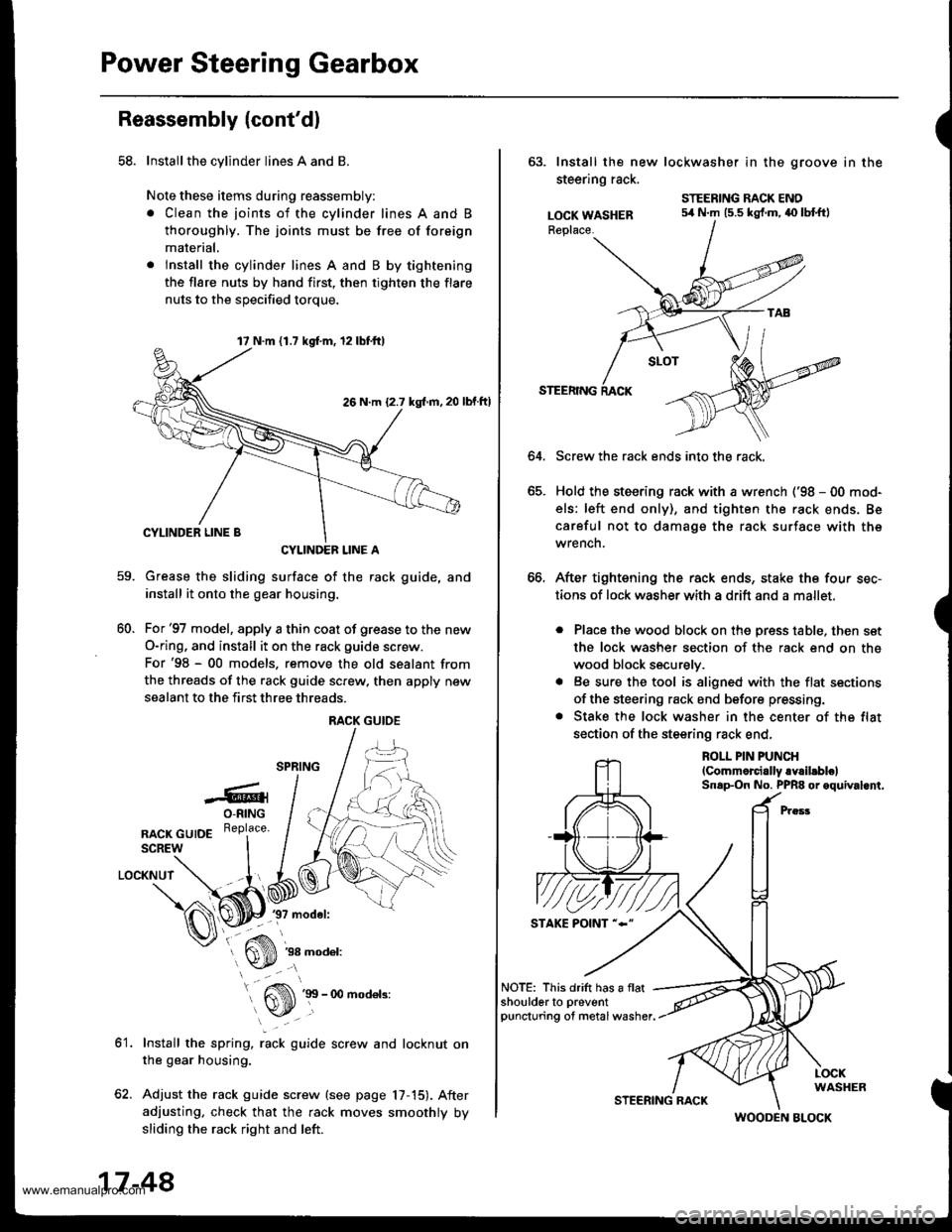

58. Installthe cylinder lines A and B

Note these items during reassembly:

. Clean the joints of the cylinder lines A and B

thoroughly. The joints must be free of foreign

material,

. lnstall the cylinder lines A and B by tightening

the flare nuts by hand first, then tighten the flare

nuts to the soecified torque.

CYLINDEF LINE A

Grease the sliding surface of the rack guide, and

install it onto the gear housing.

For'97 model, apply a thin coat of grease to the new

O-ring, and install it on the rack guide screw.

For'98 - 00 models. remove the old sealant from

the threads of the rack guide screw. then apply new

sealant to the first three threads.

-6rO-RING

nlcr cutDE R"Pl""u'

SCREW

LOCKNUT

37 model:

60.

ot.

38 model:

Install the spring, rack guide screw and locknut on

the gear housing.

Adjust the rack guide screw (see page 17,15). After

adjusting, check that the rack moves smoothly by

sliding the rack right and left.

17 N.m 11.7 kgd.m, 12lbf.ttl

26 N.m {2.7 kgl.m, 20

RACK GUIOE

17-48

STEERING RACK

(

63. Install the new lockwasher in the groove in the

steering rack.

LOCK WASHERReplace.

STEERING RACK ENO54 N.m (5.5 kgf.m,40 lbtftl

64.

STEERING

Screw the rack ends into the rack.

Hold the steering rack with a wrench ('98 - 00 mod-

els: left end only), and tighten the rack ends. Be

careful not to damage the rack surface with the

wrench.

After tightening the rack ends, stake the four sec-

tions of lock washerwith a drift and a mallet.

. Place the wood block on the press table, then set

the lock washer section of the rack end on the

wood block securely.

. Be sure the tool is aligned with the flat sections

of the steering rack end before pressing.

. Stake the lock washer in the center of the flat

section of the steering rack end,

ROLL PIN PUNCH

lCommorcially.Y.il.blelSnap-On No. PPR8 or oquival.nt.

NOTE: This drift has a flatshoulderto preventpuncturing of metal washer.

WOODEN BLOCK

www.emanualpro.com

Page 894 of 1395

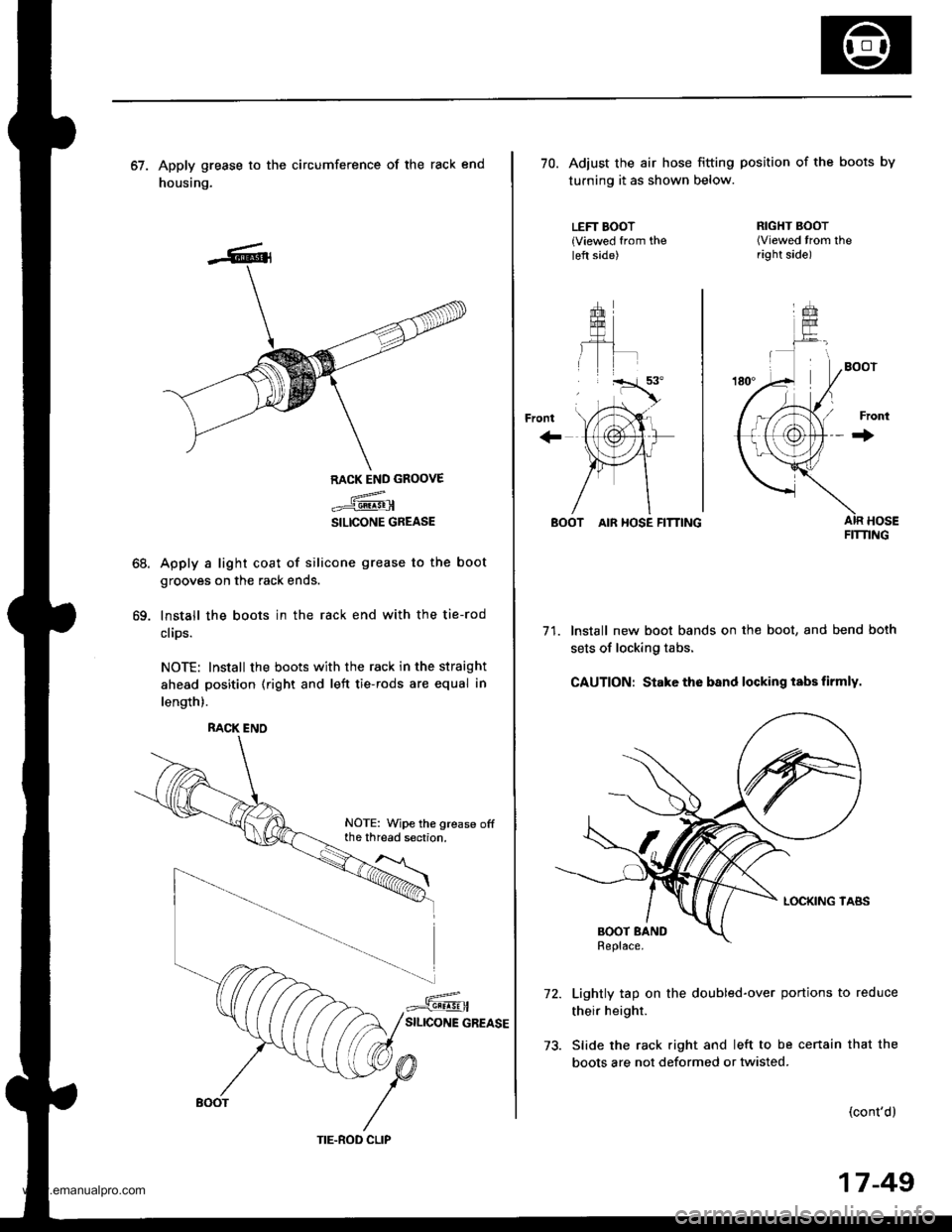

67. Apply grease to the circumference of the rack end

housing.

68.

69.

RACK END GROOVE

.={@

SILICONE GREASE

Apply a light coat of silicone grease to the boot

grooves on the rack ends.

lnstall the boots in the rack end with the tie-rod

clips.

NOTE: Install the boots with the rack in the straight

ahead position (right and left tie-rods are equal in

length).

RACK ENO

NOTE: Wipe the grease offthe thread section.

TIE.ROD CLIP

17-49

70. Adiust the air hose fitting position of the boots by

turning it as shown below.

LEFT BOOT{Viewed from theleft side)

+rom

''rT.a'.

, tri"

\,'tAr-

{,1@}tr

)Fr1

/\

RIGHT BOOT(Viewed trom theright side)

Front

+

BOOT AIR HOSE FITTING

71. Install new boot bands on the boot, and bend both

sets of locking tabs.

CAUTION: Stake the band locking tabs firmly.

Lightly tap on the doubled-over portions to reduce

their height.

Slide the rack right and left to be cenain that the

boots are not deformed or twisted.

(cont'd)

FIT'I'ING

www.emanualpro.com

Page 898 of 1395

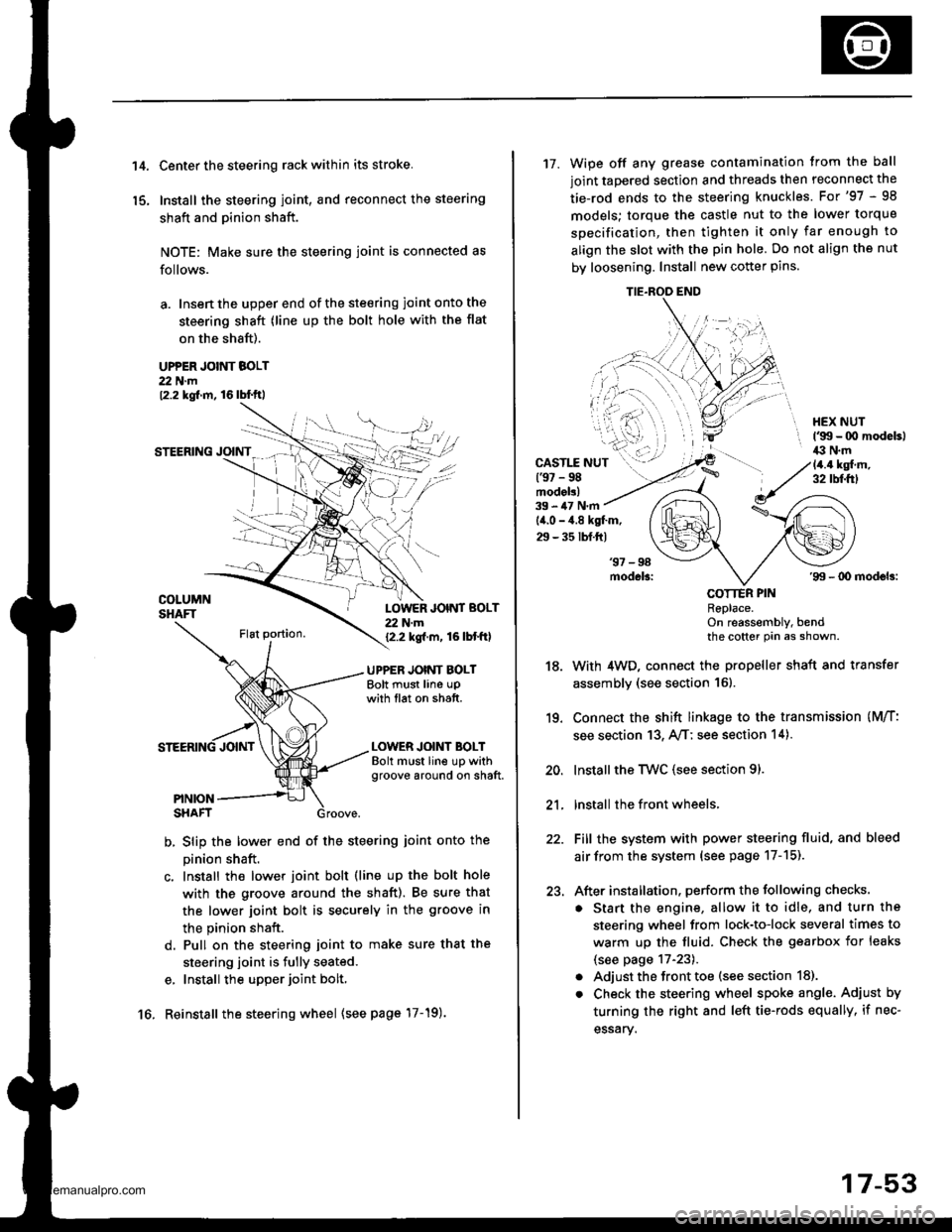

't 4.

15.

Center the steering rack within its stroke.

Install the steering joint, and reconnect the steering

shaft and pinion shaft.

NOTE: Make sure the steering joint is connected as

follows.

a. Insen the upper end of the steering joint onto the

steering shaft (line up the bolt hole with the flat

on the shaft).

UPPER JOINT BOLT22 N.m12.2 kgf.m, 16lbl.ft,

STEERING JOINT

COLUMNSHAFTLOWER JOINT BOLT22 N.m12.2 kgf.m, 16lbtftl

UPPER JOINT BOLTBolt must line upwith tlat on shatt.

LOWER JOINT BOLTBolt must line up withgroove around on shaft.

PINIONSHAFT

b, Slip the lower end of the steering ioint onto the

pinion shaft.

c. Install the lower joint bolt (line up the bolt hole

with ths groove around the shaft). Be sure that

the lower joint bolt is securely in the groove in

the pinion shaft.

d. Pull on the steering joint to make sure that the

steering joint is fully seated.

e, Install the upper joint bolt,

Reinstall the steering wheel {see page'17-19).16.

17-53

17. Wipe off any grease contamination trom the ball

joint tapered section and threads then reconnect the

tie-rod ends to the steering knuckles. For'97 - 98

models; torque the castle nut to the lower torque

specification, then tighten it only far enough to

align the slot with the pin hole. Do not align the nut

by loosening. Install new cotter pins.

CAST1T NUT(9t - 98modol!)

HEX NUTl'g!t - 00 modeb)il:l N.m14.4 ksl.m,32 tbf.f0

39 - iU N'm

lil.o - 4.8 kgl.m,

29 - 35 tbf.ftl

18.

19.

20.

21.

22.

23.

'99 - lD modeb:

COTTER PINRePlace.on reassembly, bendthe cotter Pin as shown.

With 4WD, connect the propeller shaft and transfer

assembly (see section 16).

Connect the shift linkage to the transmission (M/T:

see section 13, A,/T; see section 14).

Installthe Twc (see section 91.

lnstall the front wheels,

Fill the system with power steering fluid, and bleed

air from the system (see page 17-15).

After installation. perform the following checks.

. Start the engine, allow it to idle, and turn the

steering wheel from lock-to-lock several times to

warm up the fluid. Check the gearbox for leaks

(see page 17-23).

. Adjust the front toe (s€e section 18).

. Check the steering wheel spoke angl€. Adjust by

turning the right and left tie-rods equally, if nec-

essary.

TIE.ROO END

www.emanualpro.com

Page 903 of 1395

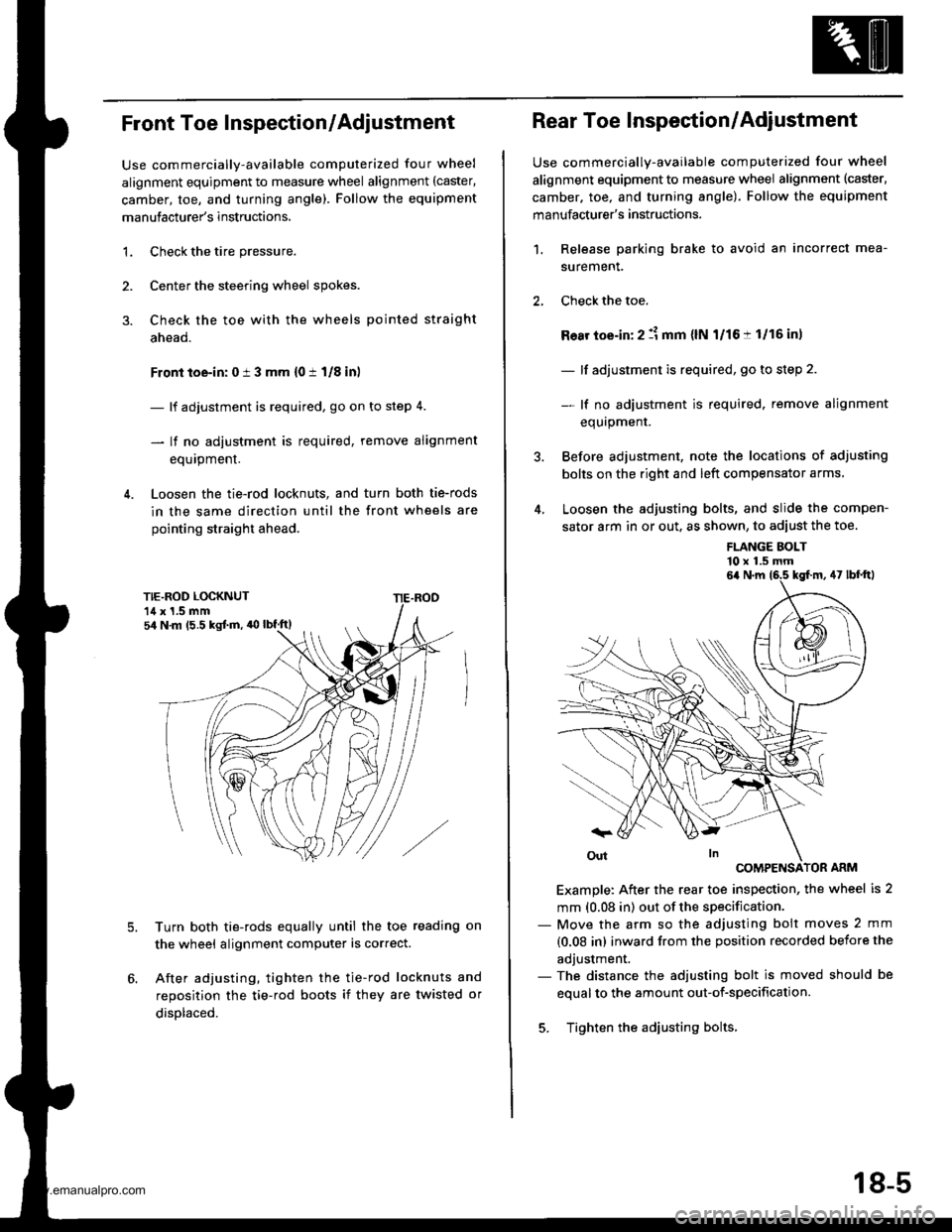

Front Toe Inspection/Adjustment

Use commercially-available computerized four wheel

alignment equipment to measure wheel alignment (caster,

camber, toe, and turning angle). Follow the equipment

manufacturer's instructions,

3.

1.Check the tire pressure.

Center the steering wheel spokes.

Check the toe with the wheels pointed straight

ahead.

Front toe-in: 0 i 3 mm {0 t 1/8 inl

- lf adjustment is required, go on to step 4.

- lf no adjustment is required, remove alignment

equipment.

Loosen the tie-rod locknuts, and turn both tie-rods

in the same direction until the front wheels are

pointing straight ahead.

5.Turn both tie-rods equally until the toe reading on

the wheel alignment computer is correct.

After adjusting, tighten the tie-rod locknuts and

reposition the tie-rod boots if they are twisted or

displaced.

sir N m (5.5 kgJ.m, 'O lbf.ft)

Rear Toe Inspection/Adjustment

Use commercially-available computerized four wheel

alignment equipment to measure wheel alignment (caster,

camber. toe, and turning angle). Follow the equipment

manufacturer's instructions.

Release parking brake to avoid an incorrect mea-

surement.

Check the toe.

Ro8r toe-in: 2 :1 mm {lN l/16:t 1/16 in,

- lf adjustment is required, go to step 2.

- lf no adiustment is required. remove alignment

equrpmenr.

Before adjustment, note the locations of adjusting

bolts on the right and left compensator arms.

Loosen the adjusting bolts, and slide the compen-

sator arm in or out. as shown, to adiust the toe.

1.

FLANGE BOLT'10 x 1.5 mm

COMPENSATOR ARM

Example: After the rear toe inspection, the wheel is 2

mm (0.08 in) out of the specification.- Move the arm so the adjusting bolt moves 2 mm

{0.08 in) inward from the position recorded before the

adjustment.- The distance the adjusting bolt is moved should be

equal to the amount out-of-specification.

5. Tighten the adjusting bolts.

6a N.m 16.5 kgf.m, 47 lbf'ftl

18-5

www.emanualpro.com

Page 906 of 1395

Front Suspension

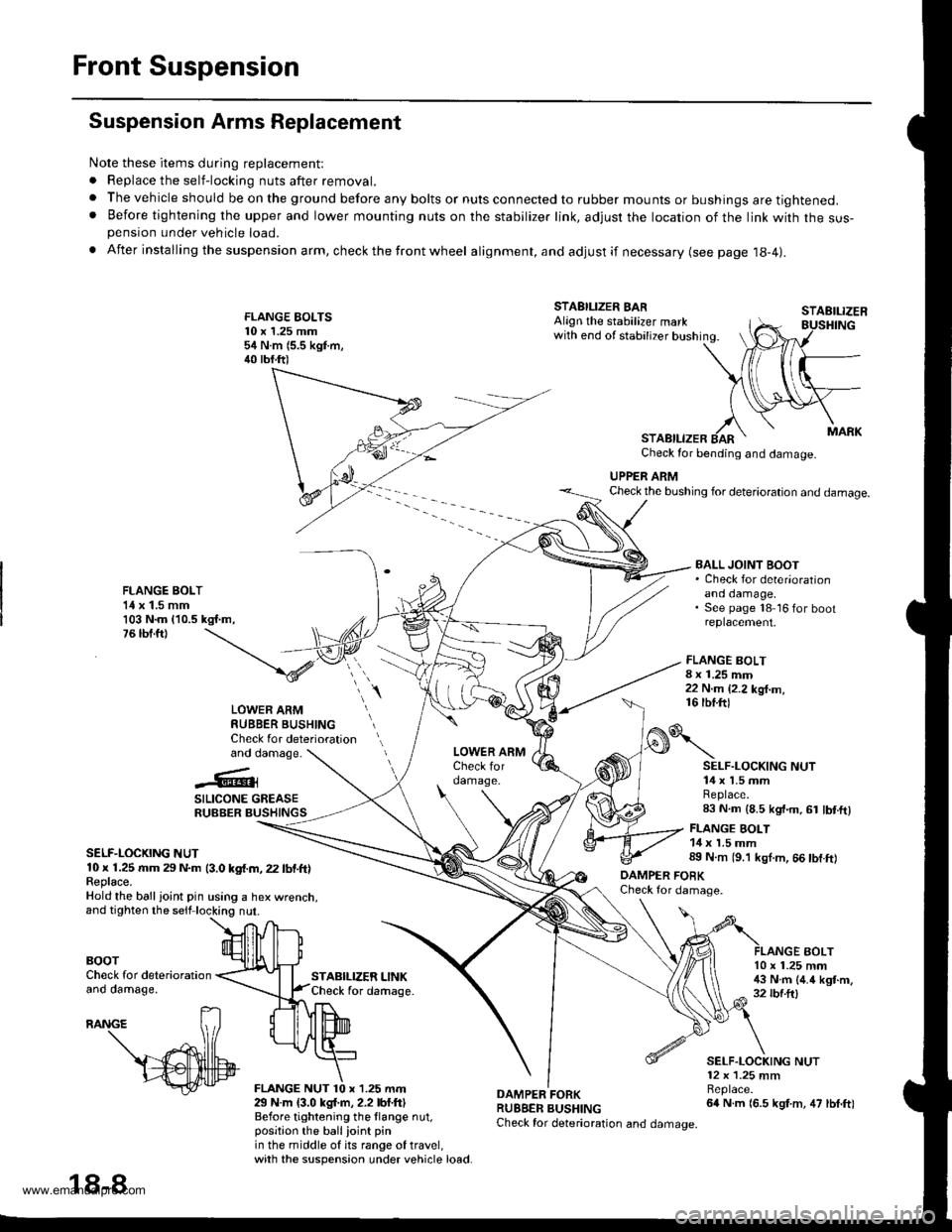

Suspension Arms Replacement

Note these items during replacement:

. Replace the self-locking nuts after removal.

. The vehicle should be on the ground before any bolts or nuts connected to rubber mounts or bushings are tightened.. Before tightening the upper and lower mounting nuts on the stabilizer link, adjusr the location of the link with the sus-pension under vehicle load.

. After insta lling the suspension arm, check the front wheel alignment, and adjust if necessary (see page 18-4|.

FLANGE EOLTS10 x 1.25 mm54 N.m (5.5 kgf.m,40 tbf.ft)

STABILIZER LINKCheck for daftage.

FLANGE BOLT8 x 1.25 mm22 N.m {2.2 kg{.m,16 tbf.ftl

STAEILIZER

AOLT

STABILIZER BARAlign the stabilizer markwith end of stabilizer bushing.

STABILIZERCheck for bending and damage.

UPPER ARMCheck the bushing for deterioration and damage.

FLANGE BOLT1{ x 1.5 mm103 N.m {10.5 kgf.m,76 tbf.ft)

BALL JOINT BOOT. Check for deter'orationano oamage,See page 18 16 for bootreplacement.

LOWER ARMRUBBER BUSHINGCheck for deteriorationand damage.

..'.{l@3

SILICONE GREASERUBBER BUSHINGS

SELF-LOCKING NUT10 x 1.25 rr|m 29 N.m (3.0 kgf.m, 22 lbf.ft)Feplace.Hold the ball ioint pin using a hex wrenct

BOOTCheck for deteriorationano oamage,

29 N.m {3.0 kgl.m, 2.2 lbf.ftlBefore tightening the llange nut,position the ballioint pinin the middle of its range of travel,with the suspension under vehicle load.

DAMPER FORKRUBBER BUSHINGCheck for deterioration and damage.

o\

DAMPER FOBKCheck for damage.

SELF.LOCKING NUT14 x 1.5 mmReplace.83 N.m (8.5 kgt.m, 61 lbt.ftl

FLANGE BOLT14 x 1.5 mm89 N.m (9.'l kgl.m, 66 tbf.ft)

10 x 1.25 mm!$ N.m (4.4 kgt.m,32 rbf.ftl

SELF.LOCKING NUT12 x 1.25 mmBeplace.64 N.m (6.5 kgt.m, 47 lbf.ft)

18-8

www.emanualpro.com

Page 907 of 1395

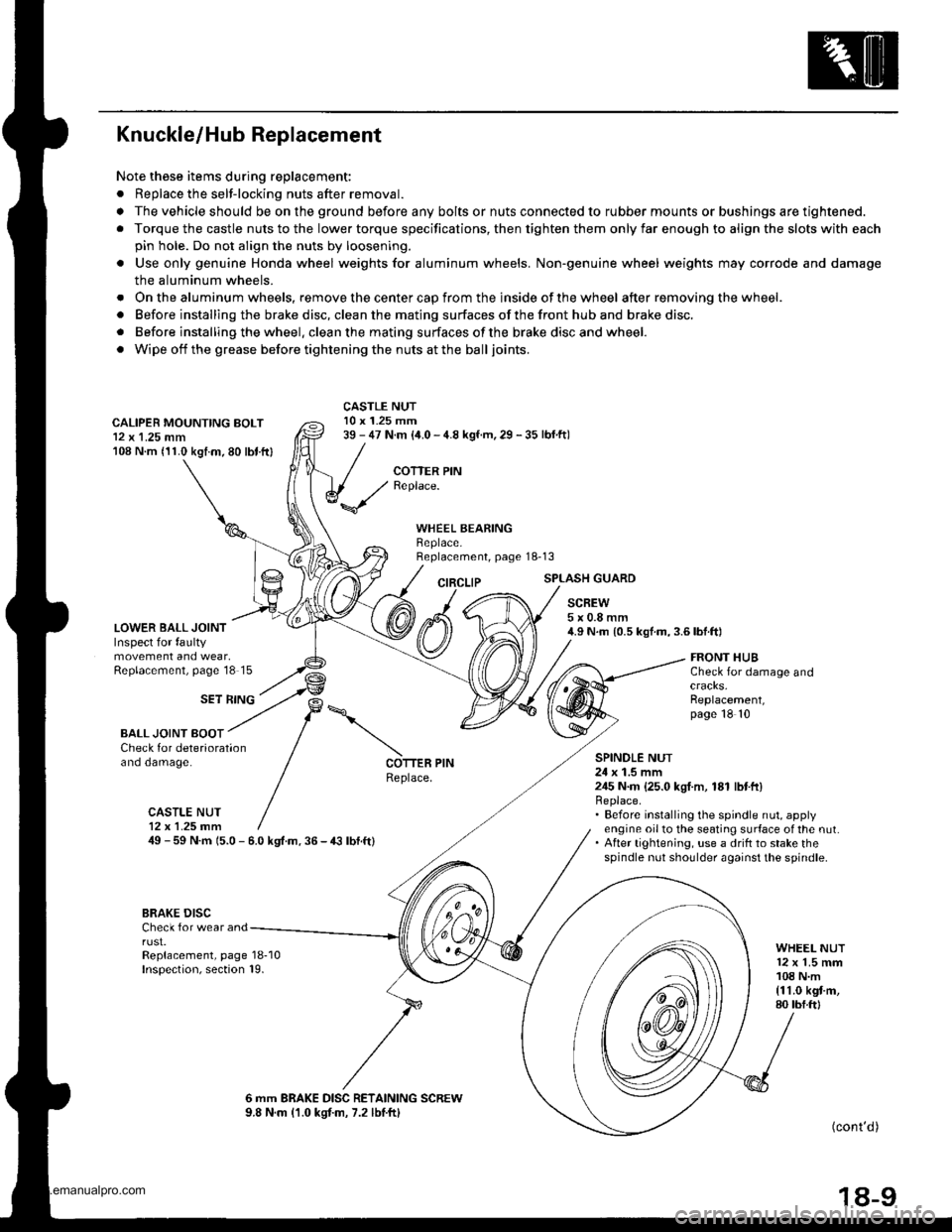

Knuckle/Hub Replacement

Note these items during replacement:

. Replace the selt-locking nuts after removal.

. The vehicle should be on the ground before any bolts or nuts connected to rubber mounts or bushings are tightened.

. Torque the castle nuts to the lower torque specifications, then tighten them only far enough to align the slots with each

pin hole. Do not align the nuts by loosening.

o Use only genuine Honda wheel weights for aluminum wheels. Non'genuine wheel weights may corrode and damage

the aluminum wheels.

. Onthealuminum wheels, remove the center cap from the inside of the wheel after removing the wheel.

. Before installing the brake disc, clean the mating surfaces of the front hub and brake disc.

. Before installing the wheel. clean the mating surfaces ofthe brake disc and wheel.

. Wipe off the grease before tightening the nuts at the balljoints.

CALIPER MOUNTING BOLT12 x 1.25 mm108 N.m (11.0 kgtm.80 lbt.ftl

LOWER BALL JOINTInspect for faultymovement and wear,Replacement, page'18 15

CASTLE NUT10 x 1.25 mm39 - 47 N.m (i1.0 - 4.8 kgf.m, 29 - 35 lbf.ftl

COTTER PINReplace.

WHEEL BEARINGBeplace.Replacement, page 18-13

CIRCLIPSPLASH GUARD

SCREW5x0.8mm4.9 N.m {0.5 kgf.m,3.6lbf.ft)

SET RING

FRONT HUBCheck for damage and

Replacement,page 18 10

BALL JOINT BOOTCheck for deteriorationano oamage.SPINOLE NUT24 x 1.5 mm245 N.m {25.0 kgI.m, 181 lbtft}Replace.. Before installing the spindle nut, applyengine oil to the seating surface of the nut.. After tightening, use a drift to stake thespindle nut shoulder against the spindle.

COTTER PINReplace.

CASTLE NUT12x 1.25 fim49 - 59 N.m 15.0 - 6.0 kgt.m. 36 - € lbf.ft)

BRAKE DISCCheck for wear andrust.Replacement, page 18-10Inspection, section 19.

WHEEL NUT12 x 1.5 mm108 N.m{11.0 kgt m,80 tbf.ftl

6 mm BRAKE DISC RETAINING SCREW9.8 N.m (1.0 kgtm, 7.2 lbtftl(cont'd )

18-9

www.emanualpro.com

Page 908 of 1395

Front Suspension

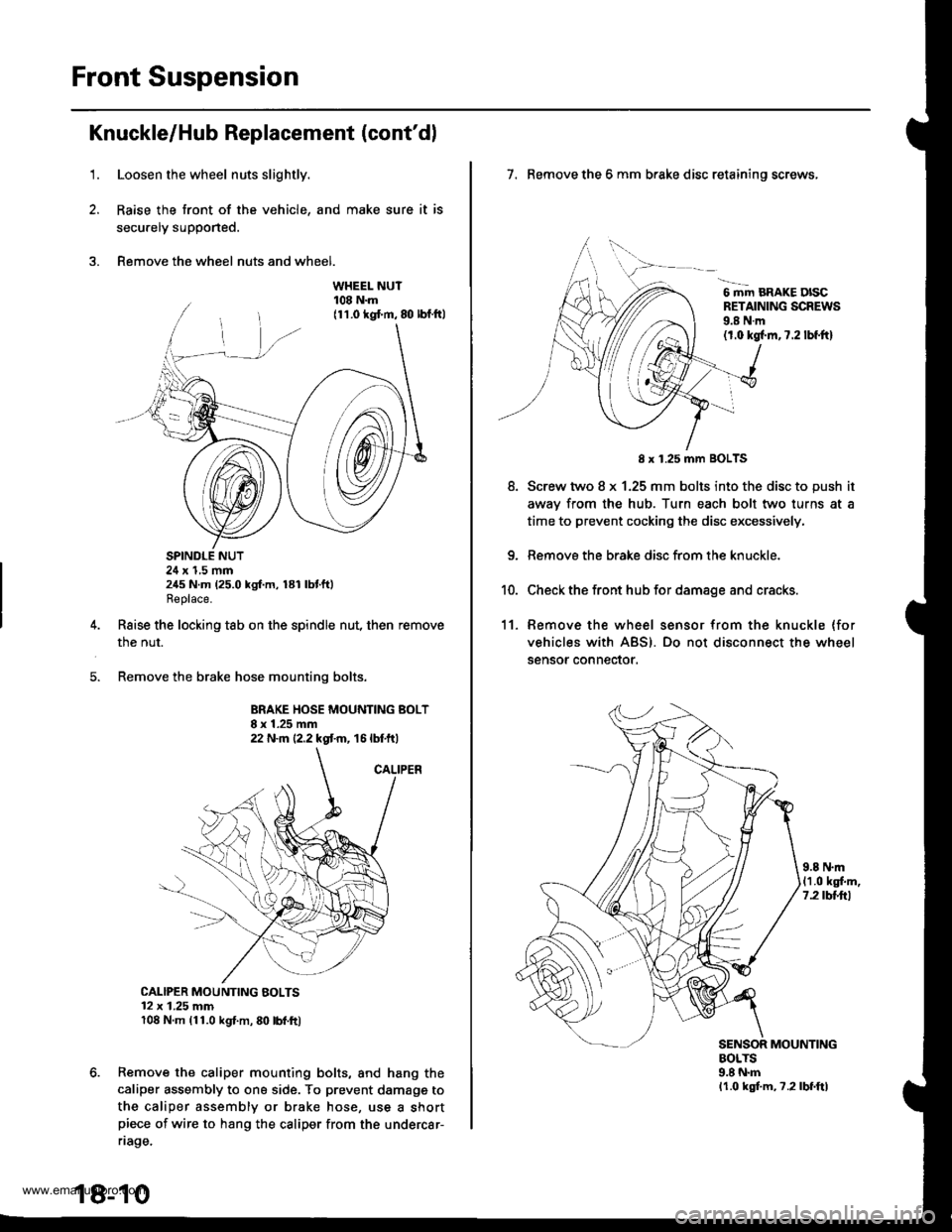

Knuckle/Hub Replacement (cont'dl

1.Loosen the wheel nuts slightly.

Raise the front of the vehicle, and make sure it is

secu.ely supported.

Remove the wheel nuts and wheel.

SPINDLE NUT24 x 1,5 mm245 N.m (25.0 kgf.m, 181 lbtft)Replace.

Raise the locking tab on the spindle nut, then remove

the nut.

Remove the brake hose mounting bolts.

BRAKE HOSE MOUNTING BOLT8 x 1.25 mm22 N.m {2.2 kgt m, 16 lbtft)

CALIPER MOUNTING BOLTS12 x 1.25 mm108 N.m (11.0 kgl.m, 80 lbl.ft)

Remove the caliper mounting bolts, and hang the

caliper assembly to ona side. To prevent damagg to

the caliper assembly or brake hose, use a shortpiece of wire to hang the caliper from the undercar-

riage.

18-10

7. Remove the 6 mm brake disc retaining screws,

6 mm BRAKE DISCRETAINING SCREWS9.8 N.m(1.0 kgl.m,7.2 lbf.ftl

8.

8 x 1.25 mm BOLTS

Screw two 8 x 1.25 mm bolts into the disc to push it

awav from the hub. Turn each bolt two turns at a

time to prevent cocking the disc excessively,

Remove the brake disc from the knuckle.

Check the front hub for damage and cracks.

11. Remove the wheel sensor from the knuckle (for

vehicles with ABS). Do not disconnect the wheel

sensor connector.

9.8 N.m(1.0 kgf.m,7.2 tbttrl

MOUNTINGBOLTS9.8 N.mlr.0 kgf.m, ?.2lbf.ftl

www.emanualpro.com

Page 914 of 1395

Front SuspensionFront Damper

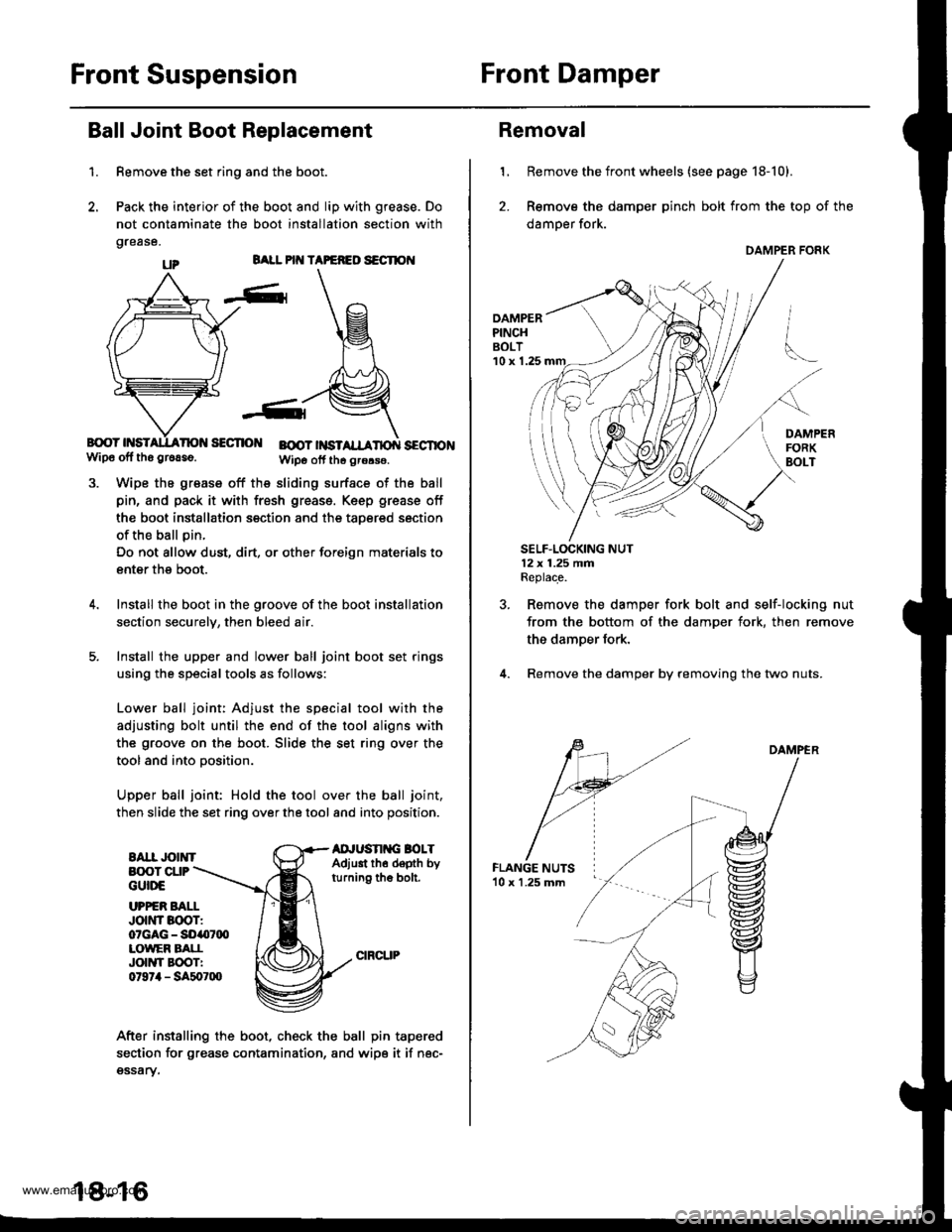

Ball Joint Boot Replacement

1.

BALL PIT{ TAPEFEO S€CTION

B{rcY HSISECTIO BOOT |NSTSECTIONwip6 off tho gr6aso.Wipo otf th6 grors€.

Wipe the grease off the sliding surface of the ball

pin, and pack it with fresh greass. Keep grease off

the boot installation section and the taoered section

of the ball pin.

Do not allow dust, dirt, or other foreign materials to

enter the boot.

Install the boot in the groove of the boot installation

section securelv, then bleed air.

Install the upper and lower ball joint boot set rings

using the special tools as follows:

Lower ball joint: Adjust the special tool with the

adjusting bolt until the end of the tool aligns with

the groove on the boot. Slide the set ring over the

tool and into oosition.

Upper ball joint: Hold the tool over the ball joint,

then slide the set ring over the tool and into position.

EAII JOINTAD'USN G BOLTAdjust th6 depth byturning the bolt.

Remove the set ring and the boot.

Pack the interior of the boot and lip with grease. Do

not contaminate the boot installation section with

grease.

B(X)T CUPGUttrE

UPPER BAI.IJott'tr Boor:07GAG - SO407q)LOWEF BATIJOIIYI EOOTI0t97il - SA507lXl

After installing the boot, check the ball pin tapered

section for grease contamination, and wipe it if nec-gssary.

18-16

Removal

1, Remove the front wheels (see page 18-10).

2. Remove the damper pinch bolt from the top of the

damper fork.

DAMPERPINCHBOLT'10 x 1.25

SELF.LOCKING NUT12x 1.25 fifiReplace.

Remove the damper fork bolt and self-locking nut

from the bottom of the damper fork, then remove

the damper fork.

Remove the damper by removing the two nuts.

DAMPER

DAMPER FORK

www.emanualpro.com

Page 915 of 1395

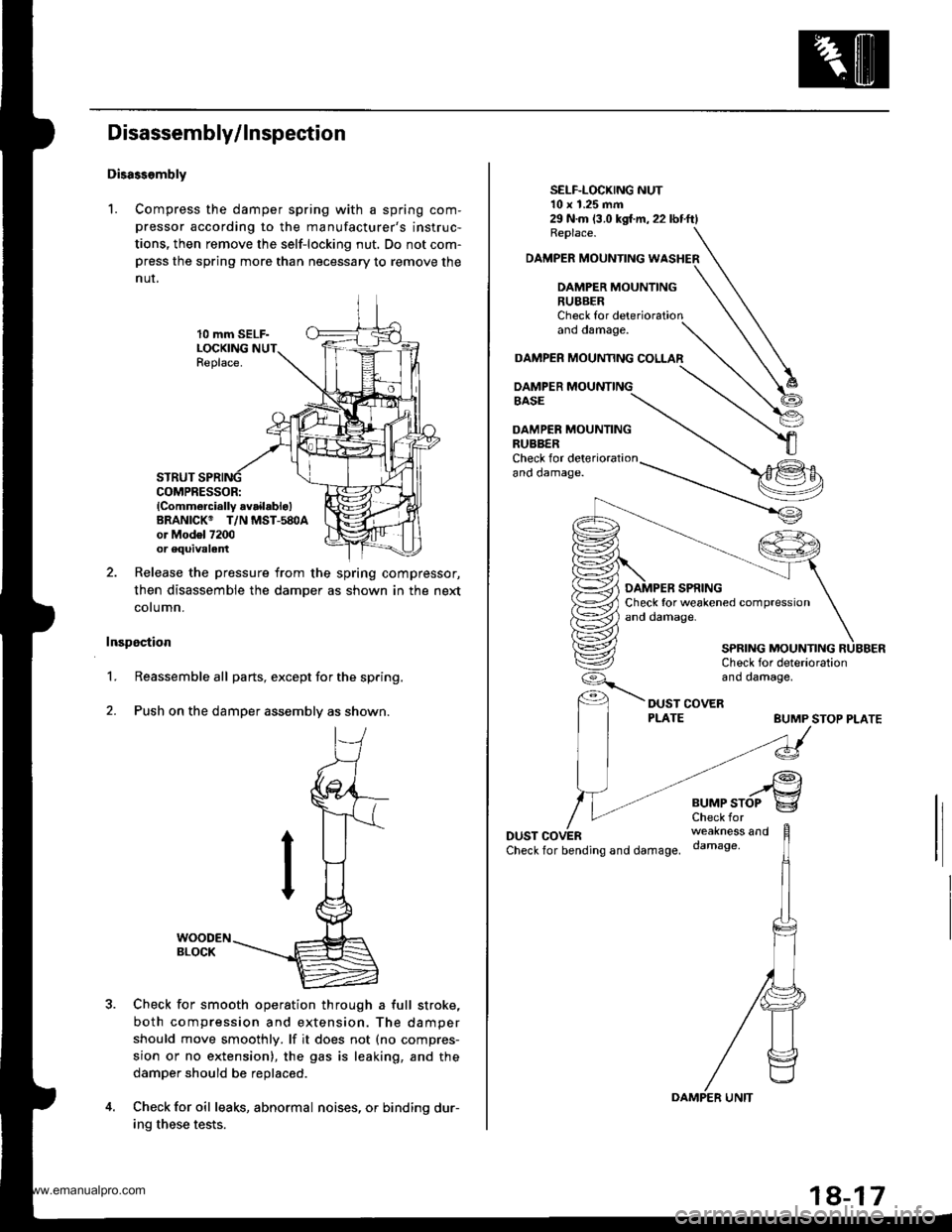

Disassembly/ Inspection

Disass.mbly

1. Compress the damper spring with a spring com-

pressor according to the manufacturer's instruc-

tions, then remove the self-locking nut. Do not com-press the spring more than necessary to remove the

nur.

10 mm SELF-LOCKINGReplace.

STRUTCOMPRESSOR:lComm6rcially availablo)BRANICK@ T/N MST-580Aor Mod6l 7200or equivalent

Release the pressure from the spring compressor,

then disassemble the damper as shown in the next

cotumn.

Inspection

1.Reassemble all parts, except for the spring.

Push on the damper assembly as shown.

Check for smooth operation through a full stroke,

both compression and extension. The damper

should move smoothly. lf it does not (no compres-

sion or no extension), the gas is leaking, and the

damper should be replaced.

Check for oil leaks, abnormal noises, or binding dur-

ing these tests.

2.

29 N.m (3.0 kgl.m,22lbtftlReplace.

DAMPER MOUNTING WASHER

DAMPER MOUNTING

SELF-LOCKING NUT10 x 1.25 mm

RUBBERCheck forano oamage.

DAMPER MOUAMNG COLLAR

DAMPER MOUNTINGBASE

DAMPER MOUNTINGRUBBERCheck for det€riorationano oamage.

BUMP STOP PLATE

DUSTCheckfor bending and damage.

..rgBUMPSTOP g

weakness anddamage,

SPRING MOUNTING

www.emanualpro.com

Page 916 of 1395

Front Damper

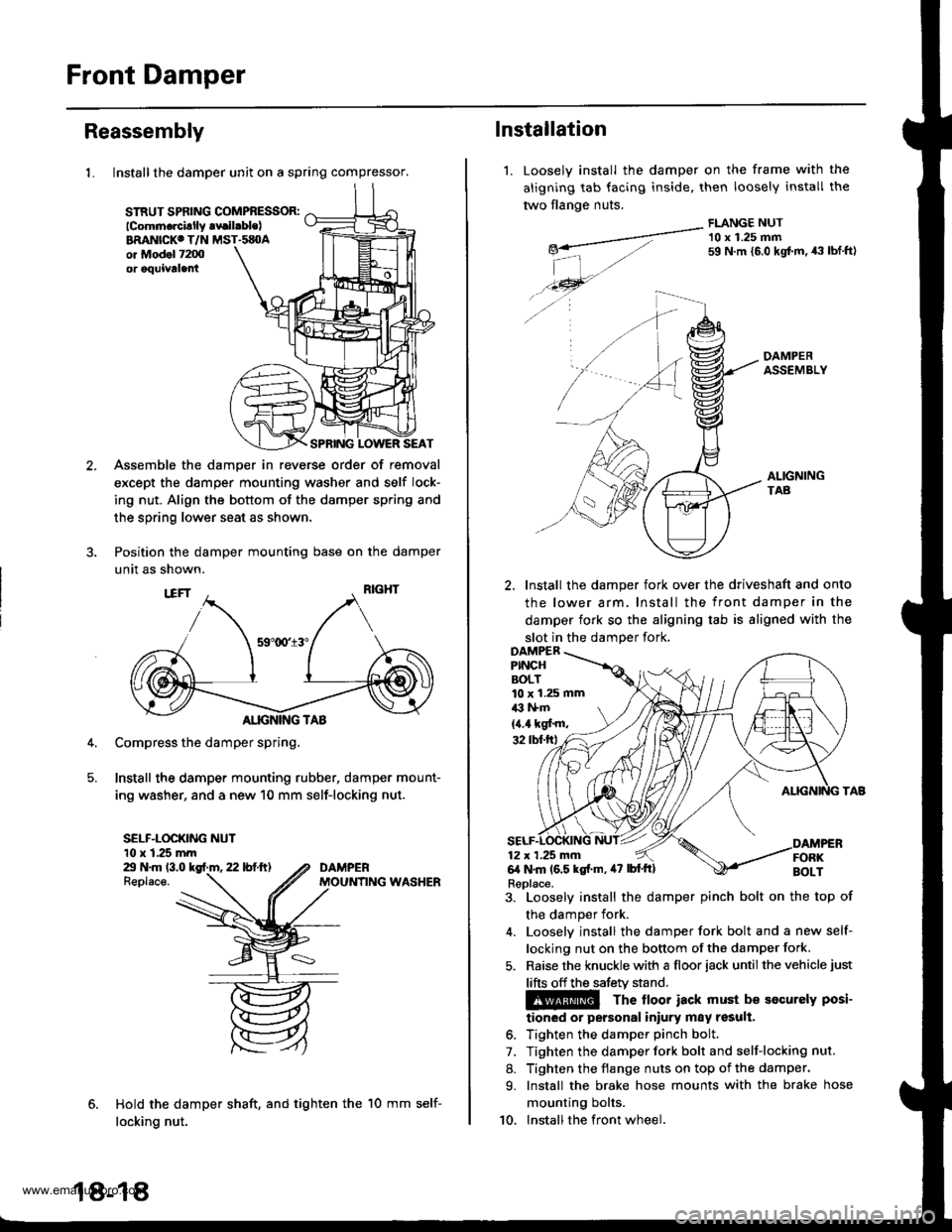

Reassembly

1. Install the damper unit on a spring compressor.

STRUT SPflNG COMPBESSOR:lcomm.rcillly .vrilrble)BRANICKC T/N MST.sEOAor Mod.l 7200or oquivtla

SPRING LOWER SEAT

Assemble the damper in reverse order of removal

except the damper mounting washer and self lock-

ing nut. Align the bottom of the damper spring and

the spring lower seat as shown.

Position the damper mounting base on the damper

unit as shown.

Compress the damper spring,

Install the damper mounting rubber, damper mount-

ing washer, and a new 10 mm self-locking nut.

SELF-LOCKING NUT10 x 1.25 mmZt N.m 13.0 kgf.m, 22 lbf.ft)Replace.

Hold the damper shaft, and tighten the

locking nut.

DAMPERMOUNfING WASHER

18-18

10 mm self-

1.

lnstallation

Loosely install the

aligning tab facing

two flange nuts.

damper on the frame with

inside, then loosely install

FLANGE NUT

the

tne

-__---a-"- 10 x 1.25 mmg*- 59 N.m {5.0 kgt m, 43 tbf.ftl

| -,./.46- --...

./ -4 A-

DAMPERASSEMBLY

ALIGNINGTAB

2, Install the damper fork over the driveshaft and onto

the lower arm. Install the front damper in the

damper fork so the aligning tab is aligned with the

slot in the damDer fork,

3. Loosely install the damper pinch bolt on the top of

the damper fork.

4. Looselv install the damper fork bolt and a new self-

locking nut on the bottom of the damper fork.

5. Raise the knuckle with a floor iack until the vehicle just

lifts off the safetv stand.

The lloor iack must b€ socurely posi-

tioned or personal iniury may result.

6. Tighten the damper pinch bolt.

7. Tighten the damper fork bolt and self-locking nut.

8. Tighten the flange nuts on top of the damper.

9. Install the brake hose mounts with the brake hose

mounting bolts.

10. Installthe front wheel.

10 x 1.25 mmil3 l+m

{4.4 kgf'm,

Replace.

www.emanualpro.com