Lock HONDA CR-V 1998 RD1-RD3 / 1.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1998, Model line: CR-V, Model: HONDA CR-V 1998 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 832 of 1395

Front Driveshafts

lnstallation

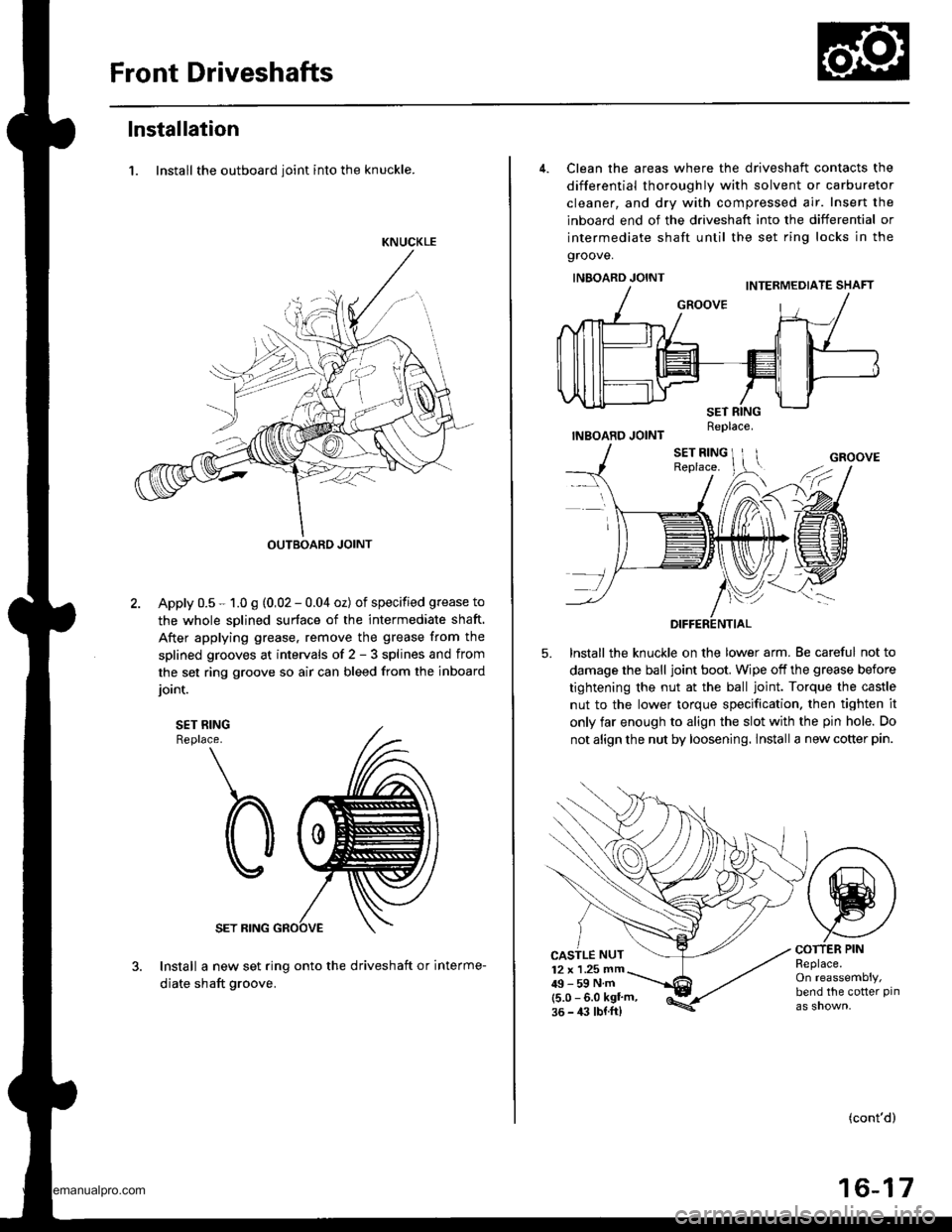

1. Install the outboard ioint into the knuckle.

KNUCKLE

OUTBOARD JOINT

Apply 0.5 - 1.0 g (0,02 - 0.04 oz) of specified grease to

the whole sDlined surface of the intermediate shaft.

After applying grease. remove the grease from the

splined grooves at intervals of 2 - 3 splines and from

the set ring groove so air can bleed from the inboard

ioint.

SET RINGReplace.

SET RING

Install a new set ring onto the driveshaft or interme-

diate shaft groove.

4. Clean the areas where the driveshaft contacts the

differential thoroughly with solvent or carburetor

cleaner, and dry with compressed air. Insert the

inboard end of the driveshaft into the differential or

intermediate shaft until the set ring locks in the

groove.

INBOARD JOINT

INBOARD JOINT

lnstall the knuckle on the lower arm. Be careful not to

damage the ball joint boot. Wipe off the grease before

tightening the nut at the ball joint. Torque the castle

nut to the lower torque specification. then tighten it

only far enough to align the slot with the pin hole. Do

not align the nut by loosening. lnstall a new cotter pin.

5.

CASTLE NUT12 x 1 .25 mm49-59Nm(5.0 - 6.0 kgl'm,36 - 4:l lbl.ft)

COTTER PINReplace.On reassembly,bend the cotter pin

(cont'd)

16-17

Replace.

www.emanualpro.com

Page 833 of 1395

Front DriveshaftsIntermediate Shaft

Installation {cont'd}

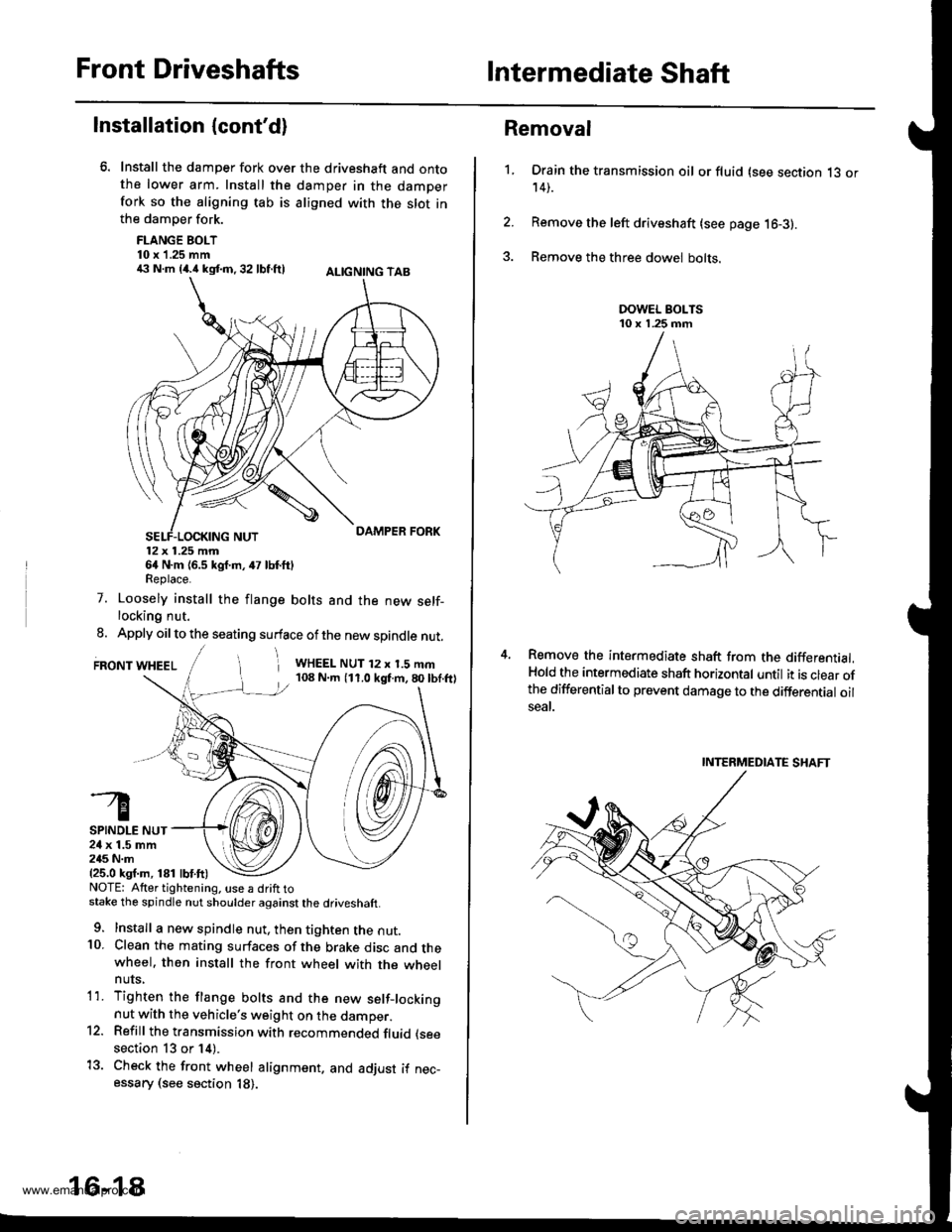

Install the damper fork over the driveshaft and ontothe lower arm. Install the damper in the damperfork so the aligning tab is aligned with the slot inthe damper fork.

FLANGE BOLT10 x 1.25 mm€ N.m {4.i1kst.n,32 lbf.ftl ALtcNtNG TAB

12x 1.25 mm64 N.m {6.5 kgf.m, 47 lbf.ftlReplace.

7. Loosely install the flange bolts and the new self-locking nut.

8. Apply oil to the seating surface of the new spindle nut.

FRONT WHEELi WHEEL NUT 12 x 1.5 mm108 N.m (11.0 kgf.m,80lbf.ftl

SPINDLE NUT24 x 1.5 mm245 N.m{25.0 ksf.m, 181 lbf.ft)NOTE: Atter tightening. use a drift tostake the spindle nut shoulder against the driveshaft.

9. Install a new spindle nut, then tighten the nut.10. Clean the mating surfaces of the brake disc and thewheel. then install the front wheel with the wheelnuts,

1'1. Tighten the flange bolts and the new setf-lockingnut with the vehicle's weight on the damper.12. Refill the transmission with recommended fluid (see

section 13 or 14).

13. Check the front wheel alignment. and adjust if nec-essary (see section 18).

16-18

1.

Removal

Drain the transmission oil or fluid (see section 13 or14).

Remove the left driveshaft (see page 16-3).

Remove the three dowel bolts.

Remove the intermediate shaft from the differential.Hold the intermediate shaft horizontal until it is clear ofthe differentialto prevent damage to the differential oilseal.

INTERMEDIATE SHAFT

www.emanualpro.com

Page 837 of 1395

Rear Driveshafts

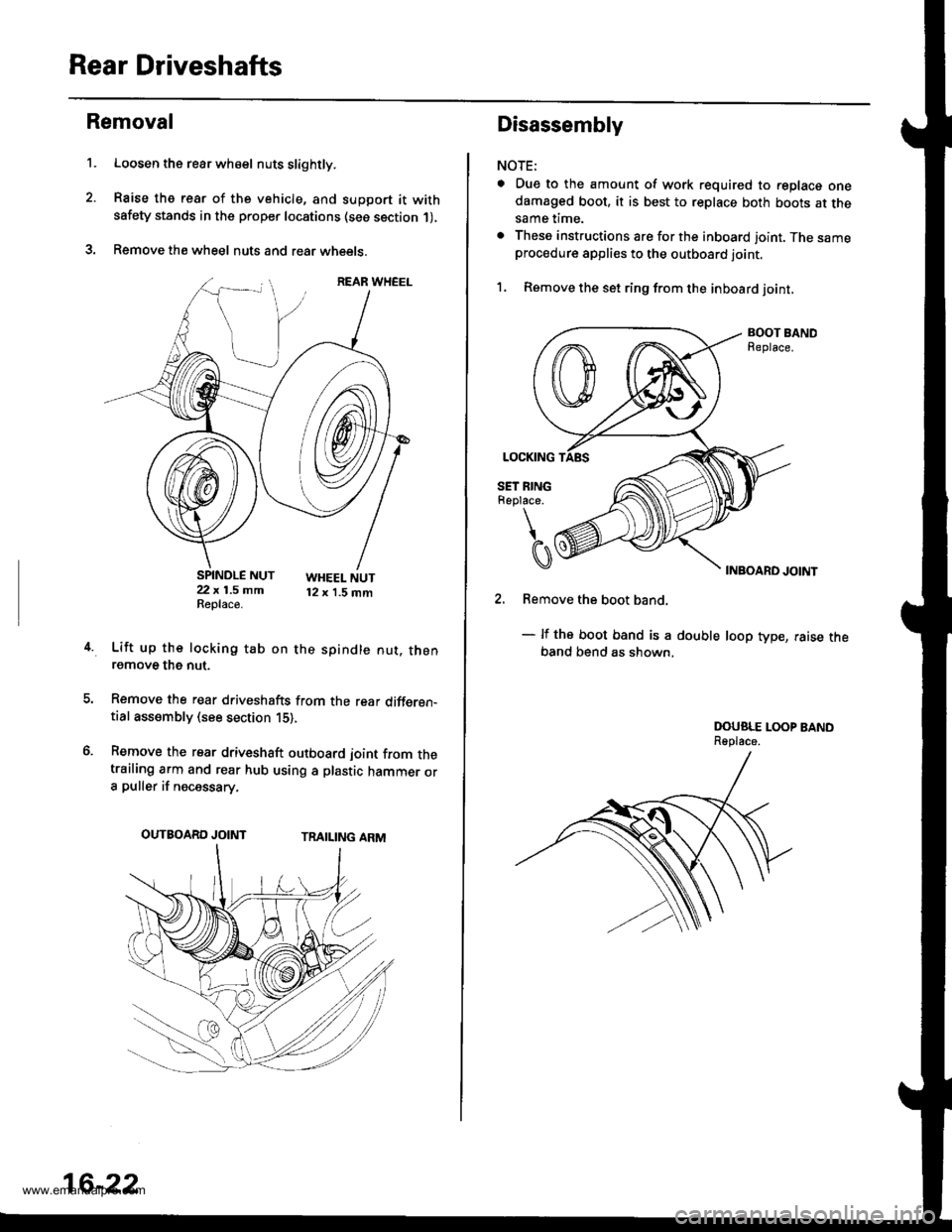

't.

Removal

Loosen the rear wh€el nuts slightly.

Raise the rear of the vehicle, and support it withsafety stands in the proper locations (see section 1),

Remove the wheel nuts and rear wheets.

SPINDLE NUT22 x 1.5 mmReplace.

WHEEL NUT12 x 1.5 mm

4.Lift up the locking tab on the spindle nut. thenremove the nut.

Remove the rear driveshafts from the rear differen-tial assembly (see section 15),

Remove the rear driveshaft outboard joint from thetrailing arm and rear hub using a plastic hammer ora puller if necessary.

TRAILING ARMOUTBOARD JOINT

16-22

Disassembly

NOTE:

a Due to the amount of work required to replace onedamaged boot, it is best to replace both boots at thesame time.

. These instructions are for the inboard joint. The sameprocedure applies to the outboard joint.

1, Remove the set ring from the inboard joint,

BOOT BANDReplace.

INBOARD JOINT

2. Remove the boot band.

- lf the boot band is a double loop type, raise theband bend as shown,

DOUSLE LOOP BANDReplace.

www.emanualpro.com

Page 845 of 1395

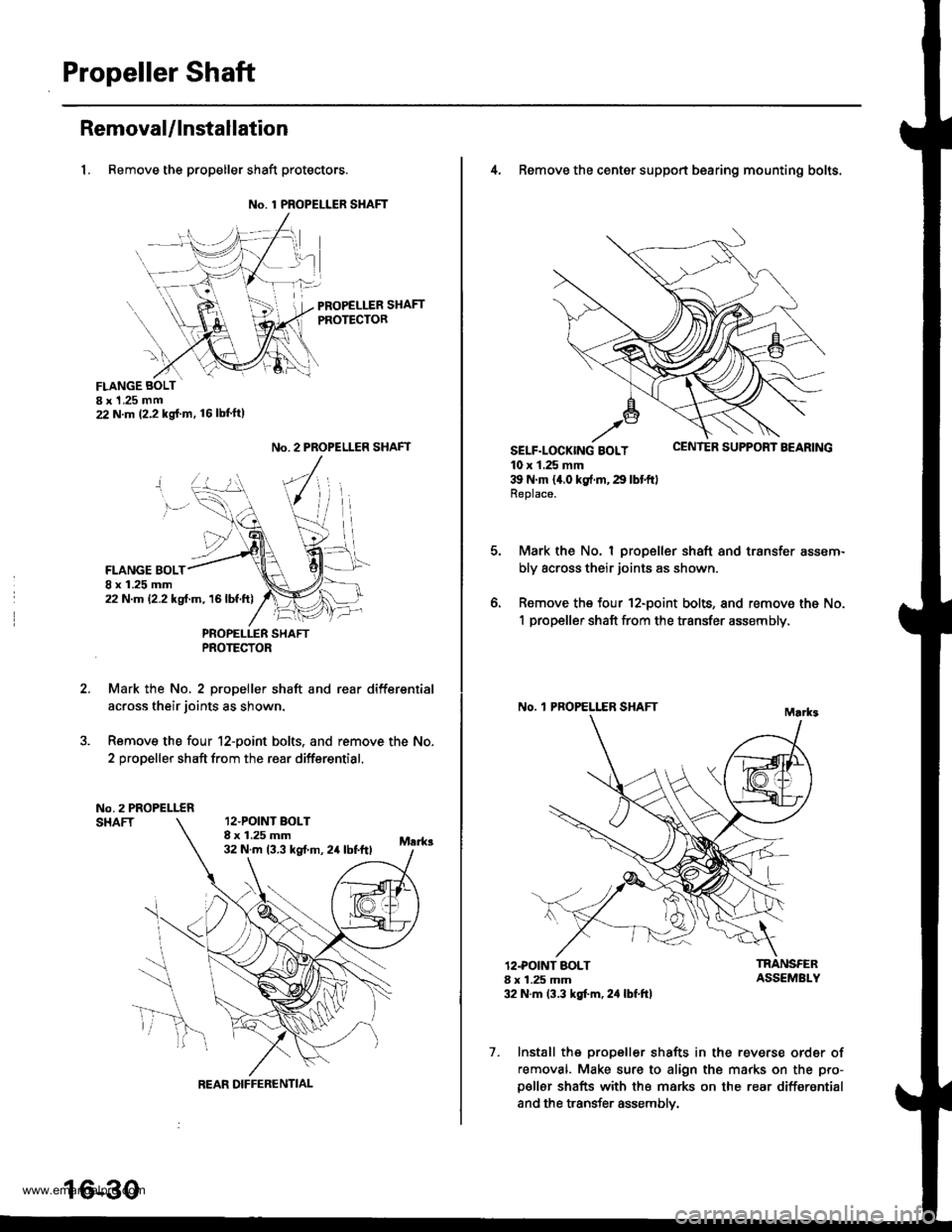

Propeller Shaft

RemovaUlnstallation

1, Remove the propeller shaft protectors.

No. 1 PROPELLER SHAFT

PROPELLER SHAFTPROTECTOR

FLANGE BOLTI x 1 .25 mm22 N.m (2.2 kg{.m. 16lbl'ft)

2.

No. 2 PROPELLER SHAFT

FLANGE BOLT8 x 1.25 mm22 N.m 12.2 kgf.m, 16lbf.ft)

PNOPELLER SHAFTPROTECTOR

Mark the No. 2 propeller shaft and rear differsntial

across their joints as shown.

Remove the four 12-point bolts. and remove the No.

2 propeller shaft from the rear differential.

No.2 PROPELLERSHAFT12.POINT BOLT8 x 1.25 mm32 N.m 13.3 kst m, 24 lbtftl

REAR DIFFERENTIAL

16-30

4, Remove the center support bearing mounting bolts.

SELF-LOCK|NG BOLT uErr rEn Durrr.r'r I I'EAnrNu

10 x 1.25 mm39 N'm 14.0 kg{.rn,29 lbtftlReplace.

Mark the No. I propeller shaft and transfer assem-

bly across their joints as shown.

Remove the four 12-point bolts, and remove the No.

1 propeller shaft from the transfer assembly,

No. 'l PROPELLER SHAFT

o.

12.POINT BOLT8 x 1.25 mm32 N.m 13.3 kgt'm, 2,1 lbf.ft)

TRANSFERASSEMBLY

7. Install the propeller shafts in the reverse order of

removal. Make sure to align the marks on the pro-

p€ller shafts with the marks on the rear differential

and the transfer assemblv.

www.emanualpro.com

Page 846 of 1395

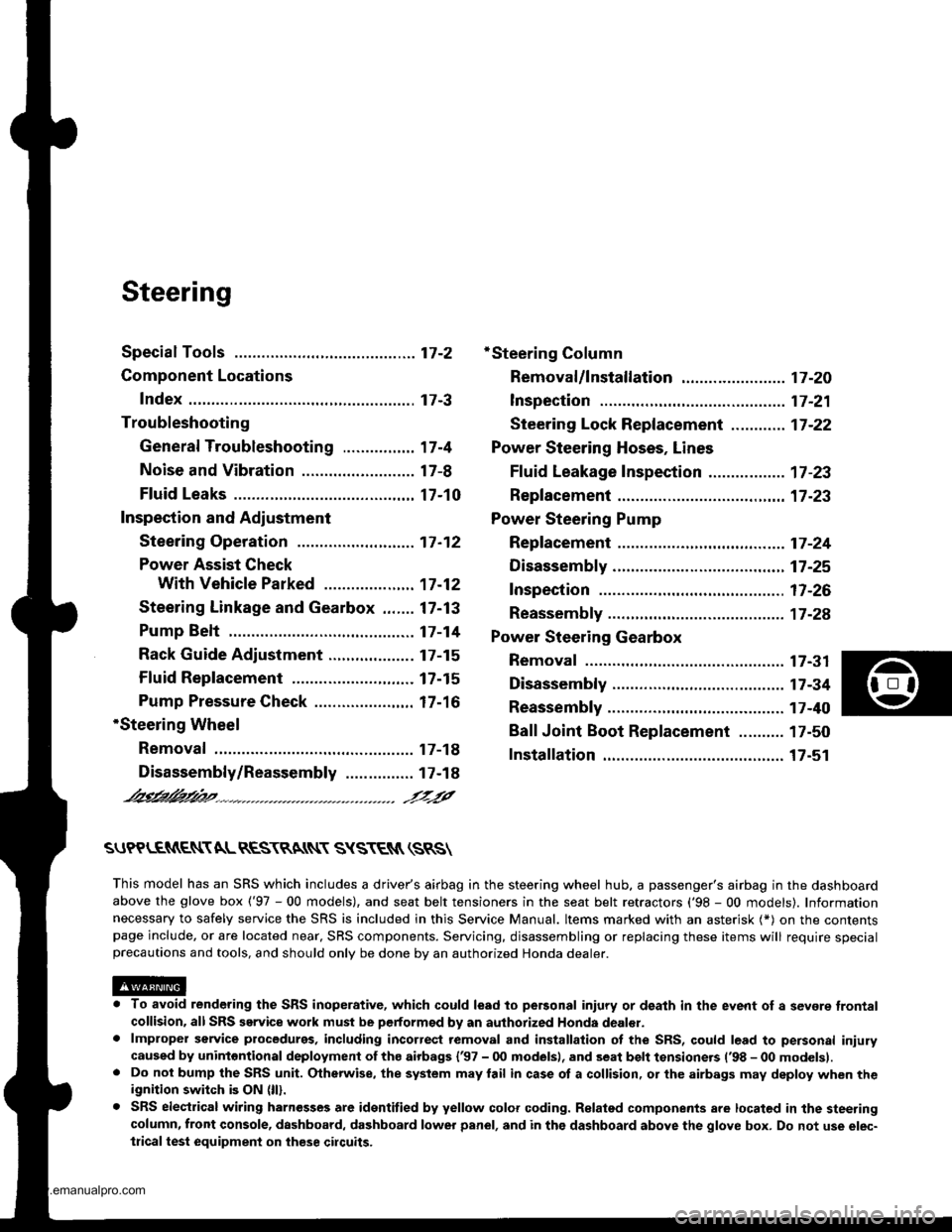

Steering

Special Toofs ............. 17-2

Component Locations

Index ................ ....... 17-3

Troubleshooting

General Troubleshooting ................ 1 7-4

Noise and Vibration ......................... 17-8

Fluid Leaks ............. 17-10

Inspection and Adiustment

Steering Operation .......................... 17-12

Power Assist Check

With Vehicle Parked ....................

Steering Linkage and Gearbox .......

Pump Belt

Rack Guide Adjustment ...................

Fluid Rep|acement ...................,,.,....

Pump Pressure Check .................,,...

*Steering Wheel

Removal ................. 17-18

*Steering Column

Removal/lnstallation ................ ....... 17 -2O

lnspection .............. 17-21

Steering Lock Replacement ............ 17 -22

Power Steering Hoses, Lines

Ffuid Leakage Inspection ................. 17 -23

Repfacement .......... 17-23

Power Steering Pump

Repfacement .......... 17-24

Disassembly ...........17-25

fnspection .............. 17-26

Reassembly ............ 17-28

Power Steering Gearbox

Removal ................. 17-31

Disassembly ........... 17-34

Reassembly ............ 17-40

Ball Joint Boot Replacement .......... 17-50

Installation ............. 17-51

17-12

17-13

17-14

l7-15

17-15

17-16

Disassembly/Reassembly............... 17-18

4'%/b.......... -r'-7--a/

SUPPLEN\EN AL RES\RA(N SYSTES{ (SRS\

This model has an SRS which includes a driver's airbag in the steering wheel hub. a passenger's airbag in the dashboardabove the glove box ('97 - 00 models), and seat belt tensioners in the seat belt retractors ('98 - 00 models). Informationnecessary to safely service the SRS is included in this Service Manual. ltems marked with an asterisk (*) on the contentspage include, or are located near, SBS components. Servicing. disassembling or replacing these items will require specialprecautions and tools, and should only be done by an authorized Honda oearer.

To avoid rendering the SRS inoperative, which could lead to peFonal iniury or death in the event of a sevore trontalcollision. allSRS service work must be performod by an authorized Honda dealer.lmproper service procedurgs, including incorrect removal and installalion of the SRS, could lead to personal iniurycaused by unintontional deployment of th€ airbags {'97 - 00 models), and seat belt tensioners ('98 - 00 modelsl.Do not bump the SRS unit. Otherwise, the system may lail in case ot a collision, or the airbags may deploy when theignition switch is ON (lll.

SRS electrical wiring harnesses are identitied by yellow colof coding. Ralated components are located in the steeringcolumn, front console, dashboard, dashboard lower panel, and in the dashboard above the glove box. Do not use elec-trical test equipment on these cilcuits,

www.emanualpro.com

Page 847 of 1395

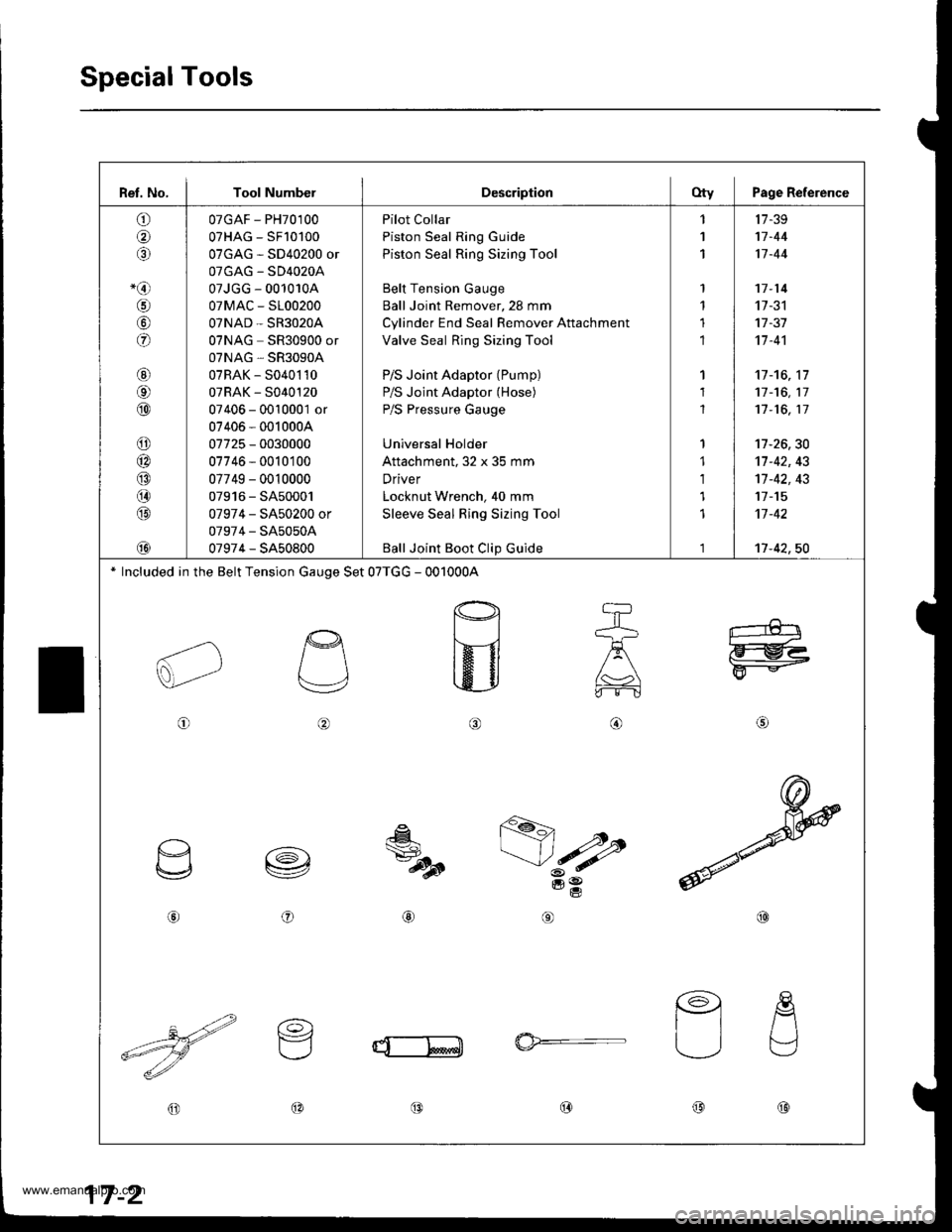

Ret. No, I Tool NumbelDescriptionfty Page Reference

o

o

-@

€r

o

@rol

@

o

@

@(}

@

@

07GAF - PH70100

07HAG - SF10100

07GAG - SD40200 or

OTGAG - SD4O2OA

07JGG - 001010A

07MAC - S100200

OTNAD _ SR3O2OA

07NAG SR30900 or

07NAG , SR3OgOA

07RAK - 50401 10

07RAK - 5040120

07406 - 0010001 or

07406 - 0010004

07725 - 0030000

07746 - 0010100

07749 - 0010000

07916 - SA50001

07974 - SA50200 or

07974 - SA5050A

07974 - SA50800

Pilot Collar

Piston Seal Ring Guide

Piston Seal Ring Sizing Tool

Belt Tension Gauge

Ball Joint Remover,23 mm

Cylinder End Seal Remover Attachment

Valve Seal Ring Sizing Tool

P/S Joint Adaptor (Pump)

P/S Joint Adaptor (Hose)

P/S Pressure Gauge

Universal Holder

Attachment, 32 x 35 mm

Driver

Locknut Wrench, 40 mm

Sleeve Seal Ring Sizing Tool

Ball Joint Boot Clip Guide

'l

1

1

1

1

1

1

1

1

1

1

1

1,l

1

1

11-39

17-44

11-44

17 -14't]-31

17 -37't7 -4'l

17-'t6, 17

17-16, 17

11-16, 17

17-26,30't]-42, 43't1-42, 43

11-15't]-42

11-42, 50

* Included in the Belt Tension Gauge Set 07TGG - 001000,4

o@

\J

,/:\

I

o

,€l-

=tt

@@

aA)

l:I/\L----.--.--------_

@o(D(9@@

17-2

www.emanualpro.com

Page 848 of 1395

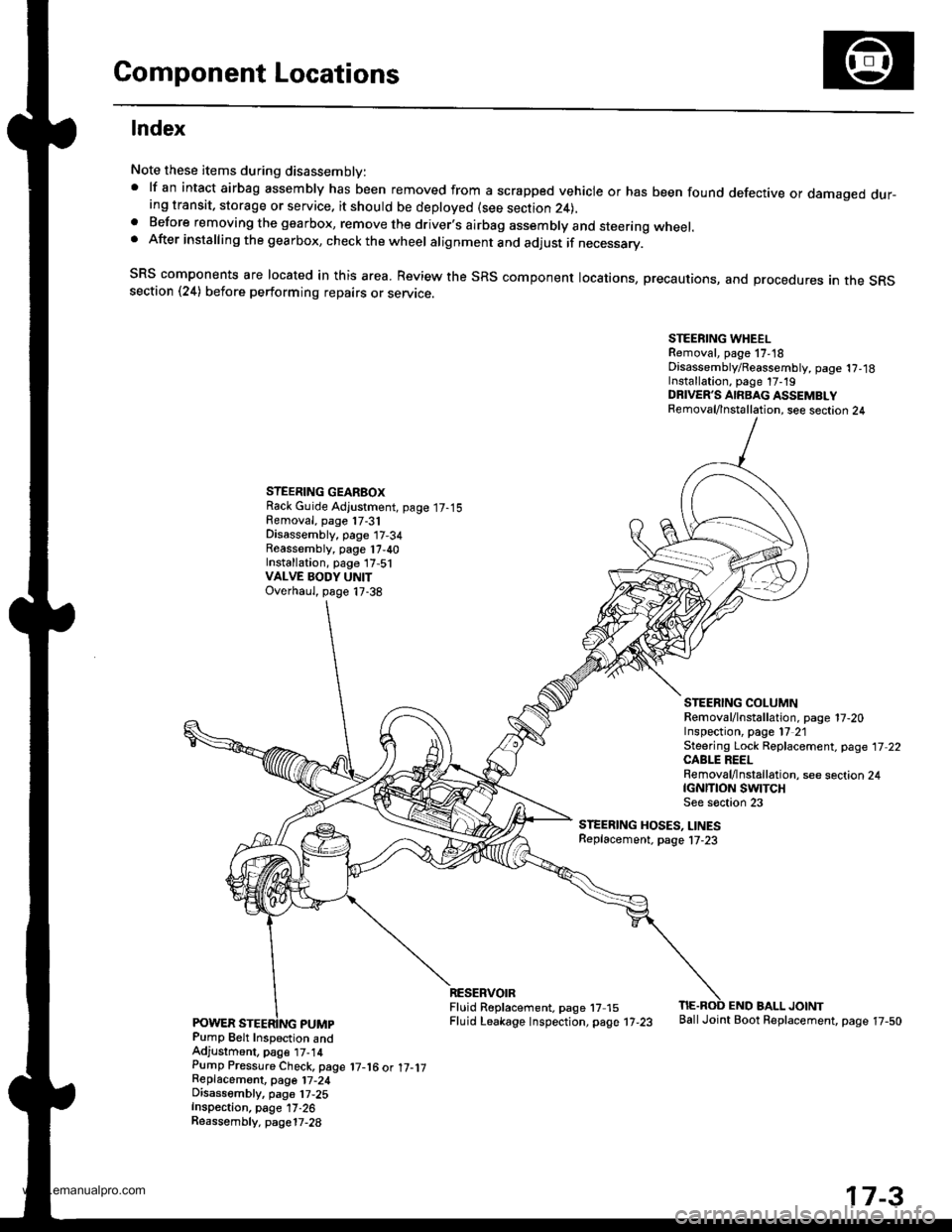

Component Locations

lndex

Note these items during disassembly:' lf an intact airbag assembly has been removed from a scrapped vehicle or has been found defective or damaged dur-ing transit, storage or service. it should be deployed (see section 24),a Before removing the gearbox, remove the driver.s airbag assembly and steering wheel.. After installing the gearbox, check the wheel alignment and adjust if necessary.

SRS components are located in this area. Review the SRS component locations, precautions, and procedures an the SRssection (24) before performing repairs or servrce.

STEERING WHEELRemoval, page 17,18Disassembly/Reassembly, page 1?,18Installation, page 17-19DRIVER'S AIRBAG ASSEMBLYRemoval/lnstallation, see section 24

STEERING GEARBOXRack Guide Adjustment, page 17-15Removal, page 17-31Disassembly, page 17-34Reassembly, page 17,40Installation, page 17,51VALVE BODY UNITOverhaul, page 17-38

STEERING COLUMNRemoval/lnstallation. page 17-20Inspection, page l7 21Steering Lock Replacement, page 17 22CABLE REELRemoval/lnstallation, see section 24tcNrnoN swtTcHSee s€ction 23

STEERING HOSES, LINESReplacement. page l7-23

Pump Belt Inspection andAdjustment, pag€ t7-14Pump Pressure Check, page 17-16 ot 17-1jReplacemont, page 17-24Disassembly, pa96 17,25Inspection, page 17-26Reassembly. page17-28

RESERVOIRFluid R6placement. page 17 15Fluid Leakage lnspection, page 17-23

END BALL JOINTBallJoint Boot Replacement, page 17-50

17-3

www.emanualpro.com

Page 851 of 1395

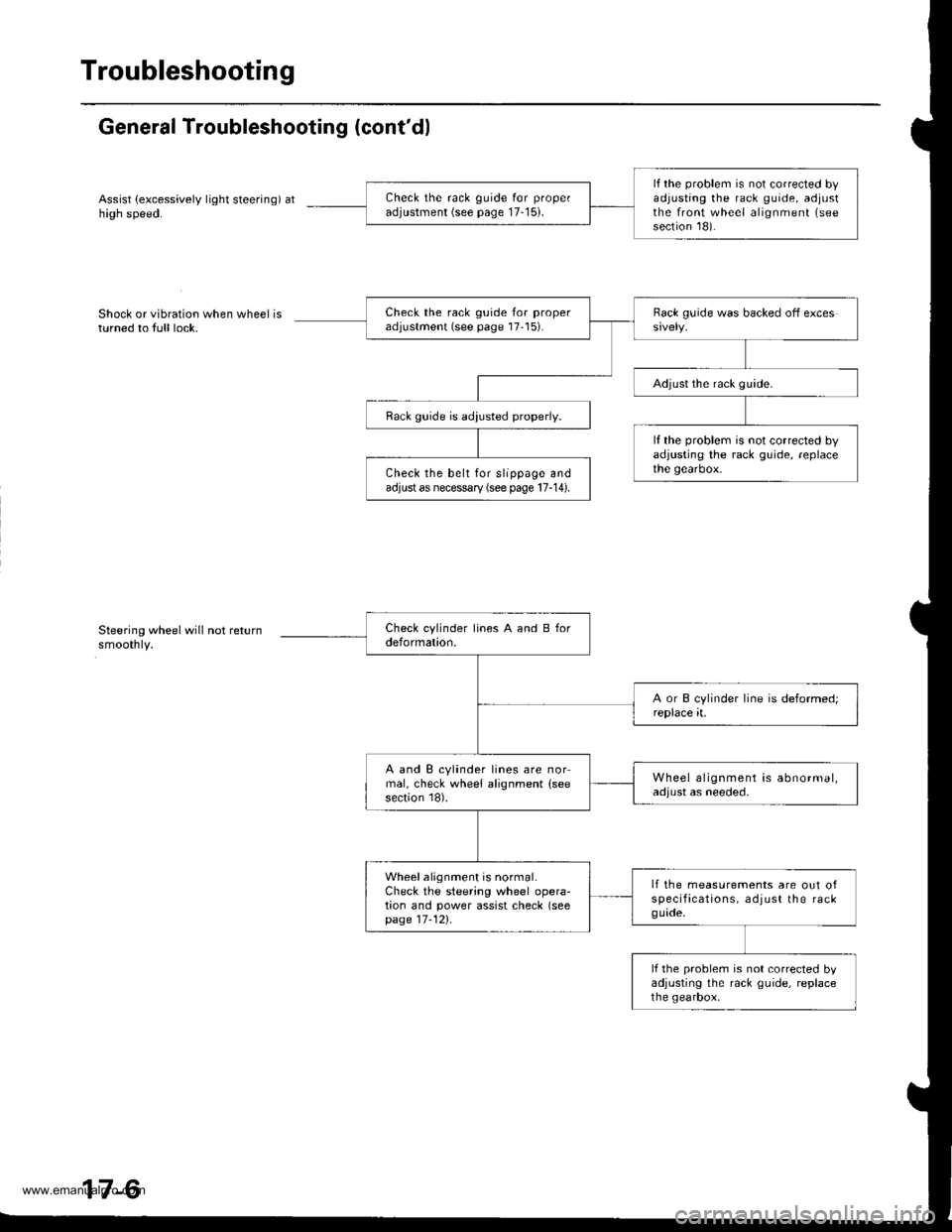

Troubleshooting

General Troubleshooting (cont'dl

Assist (excessively light steering) athigh speed.

Shock or vibration when wheel isturned to full lock.

Steering wheel will not returnsmoothly.

lf the problem is not corrected byadjusting the rack guide, adjustthe front wheel alignment (see

section 18).

Check the rack guide for proper

adjustment (see page 17-15).

Check the rack guide for properadjustment (see page 17'15).

Adjust the rack guide.

Rack guide is adiusted properly.

lf the problem is not corrected byadjusting the rack guide, replacethe gearbox.Check the belt for slippage andadjust as necessary (see page 17-14).

A and B cylinder lines are normal, check wheel alignment (see

section 18).

Wheel alignment is abnormal,adjust as needed.

Wheel alignment is normal.Check the steering wheel opera-tion and power assist check (seepage 17-121.

lf the measurements are out ofspecifacations, adjust the rackguade.

lf the problem is not corrected byadjusting the rack guide, replacethe gearbox,

www.emanualpro.com

Page 853 of 1395

Troubleshooting

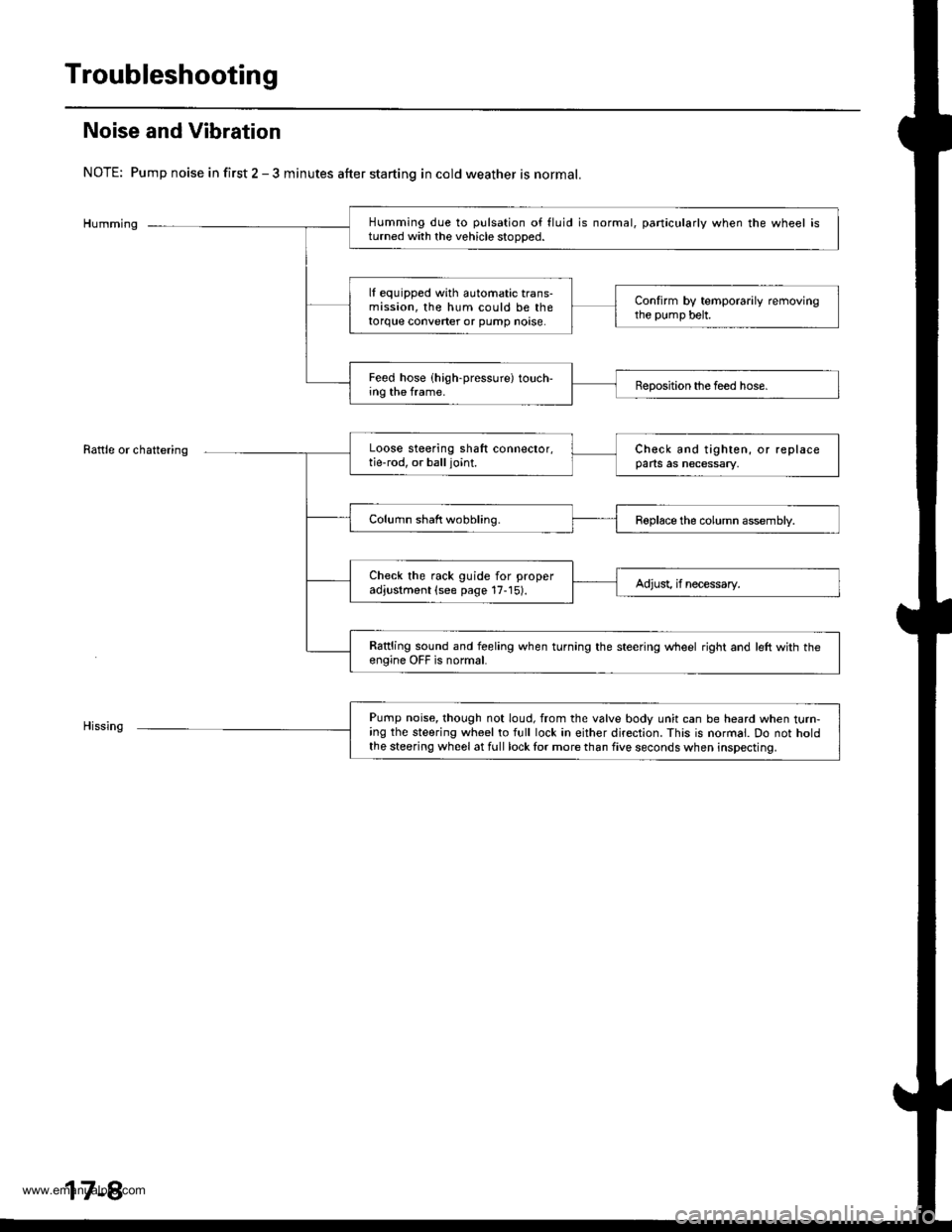

Noise and Vibration

NOTE: Pump noise in first 2 - 3 minutes after starting in cold weather is normal.

Humming

Rattle or chattering

Humming due to pulsation of fluid is normal, particularly when the wheel isturned with the vehicle stooDed.

lf equipped with automatic trans-mission, the hum could be thetorque converter or pump noase.

Confirm by temporarily removingthe pump belt.

Feed hose (high-pressure) touch-ing the frame.Beposition the feed hose.

Loose steering shaft connector,tie-rod, or balljoint.Check and tighten, or replaceparts as necessary,

Column shaft wobbling.Roplace the column assembly.

Check the rack guide for properadjustment (see page 17-15).Adjust, if necessary.

Rattling sound and feeling when turning the steering wheel right and left with th€engine OFF is normal.

Pump noise, though not loud, from the valve body unit can be heard when turn-ing the steering wheel to full lock in either direction. This is normal. Do not holdthe steering wheel at full lock lor more than five seconds when inspecting.

17-8

www.emanualpro.com

Page 857 of 1395

Inspection and Adjustment

Steering Operation

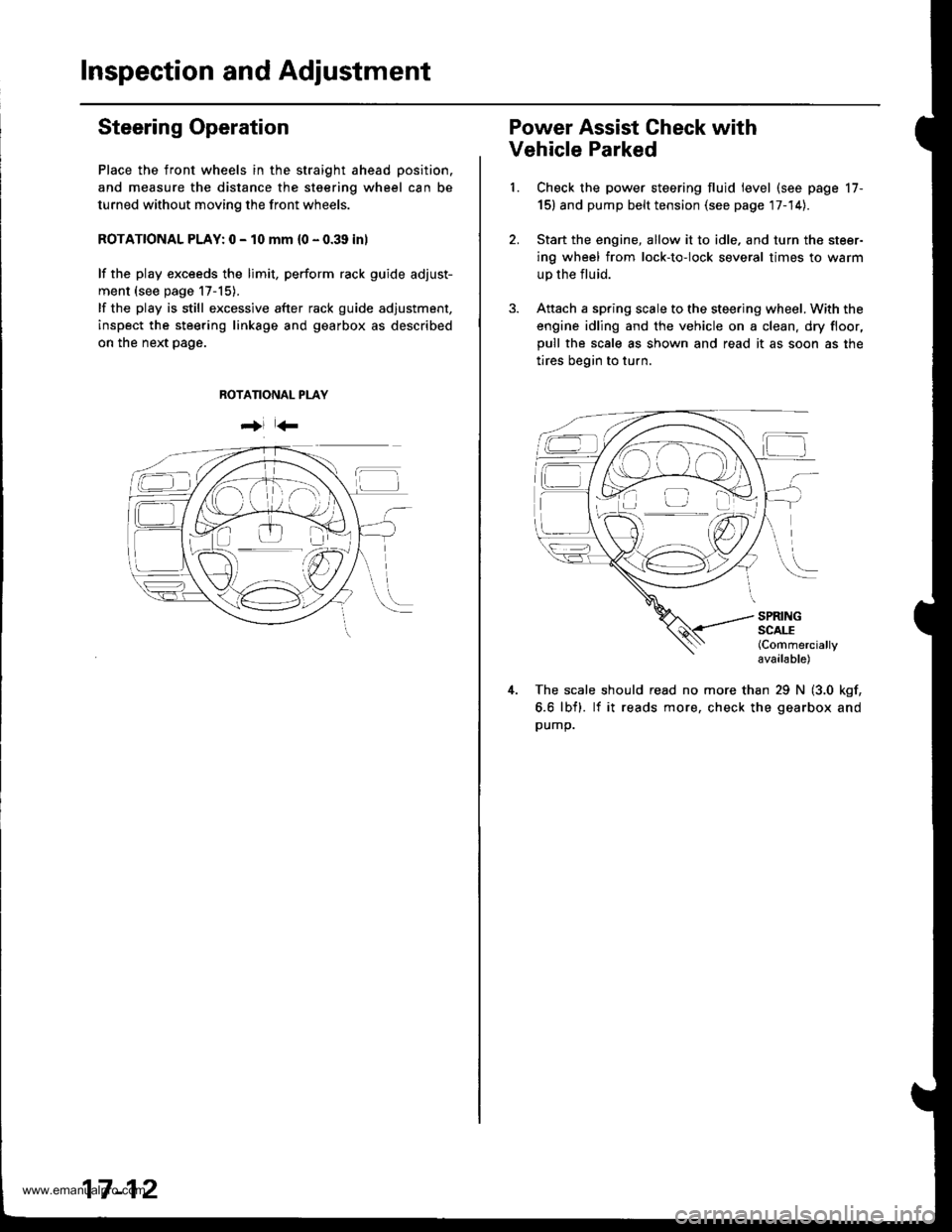

Place the front wheels in the straight ahead position.

and measure the distance the steering wheel can be

turned without moving the front wheels.

ROTATIONAL PLAY: 0 - 10 mm (0 - 0.39 inl

lf the play exceeds the limit, perform rack guide adjust-

ment (see page 17-15).

lf the play is still excessive after rack guide adjustment,

inspect the steering linkage and gearbox as described

on the next page.

ROTANONAL PLAY

+i r

17-12

Power Assist Check with

Vehicle Parked

1. Check the power steering fluid level (see page 17-

15) and pump belt tension (see page 17-14).

2. Start the engine, allow it to idle, and turn the steer-

ing wheel from lock-toiock several times to warm

up the fluid.

3. Aftach a spring scale to the steering wheel, With the

engine idling and the vehicle on a clean. dry floor,

pull the scale as shown and read it as soon as the

tires begin to turn.

SPRINGSCALE(Commercially

available)

The scale should read no more than 29 N (3.0 kgf,

6.6 lbfl. lf it reads more, check the gearbox and

oumo.

f::1-tE

www.emanualpro.com