cam HONDA CR-V 1998 RD1-RD3 / 1.G Owner's Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1998, Model line: CR-V, Model: HONDA CR-V 1998 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 146 of 1395

21.

22.

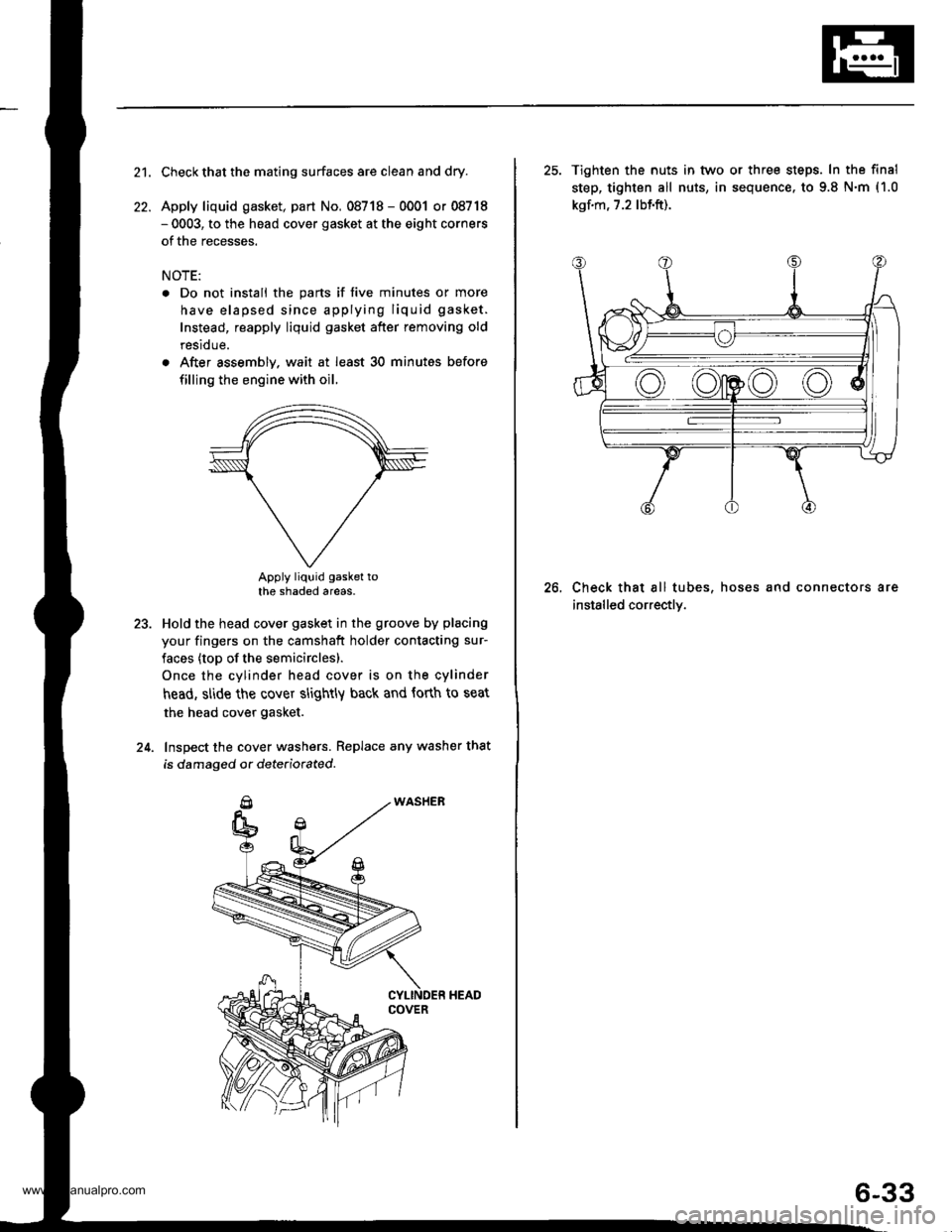

Check that the mating surfaces are clean and dry.

Apply liquid gasket, part No. 08718 - 0001 or 08718- 0003, to the head cover gasket at the eight corners

of the recesses.

NOTE:

. Do not install the parts if five minutes or more

have elapsed since applying liquid gasket.

Instead, reapply liquid gasket after removing old

residue.

. After assembly. wait at least 30 minutes before

filling the engine with oil.

Apply liquid gasket tothe shaded areas.

Hold the head cover gasket in the groove by placing

your fingers on the camshaft holder contacting sur-

faces (top of the semicirclesl.

Once the cylinder head cover is on the cylinder

head, slide the cover slightly back and forth to seat

the head cover gasket.

Inspect the cover washers. Replace any washer that

is damaged or dete(iorated.

23.

24.

25. Tighten the nuts in tvvo or three steps. In the final

step, tighten all nuts, in sequence. to 9.8 N.m (1.0

kgf.m, 7.2 lbf.ft).

Check that all tubes, hoses and connectors are

installed correctly.

26.

6-33

www.emanualpro.com

Page 377 of 1395

Fuel Tube/Ouick-Gonnect Fittings

Procautions

@ Do not smoke whils working on the fuel

syst6m, Koop open flames away from your work ar9a.

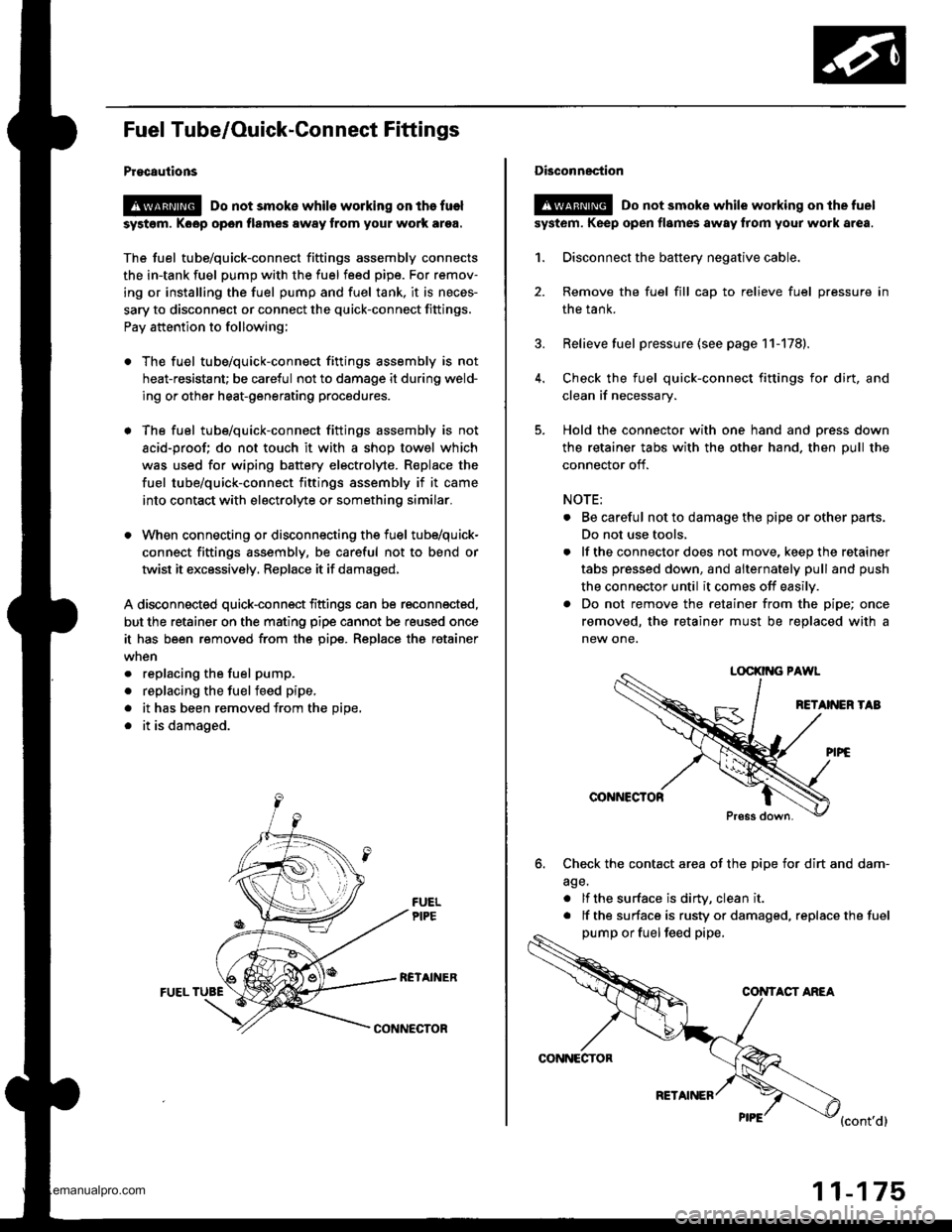

The fuel tube/quick-connect fittings assembly connects

the in-tank fuel pump with the fuel feed pipe. For remov-

ing or installing the fuel pump and fuel tank, it is neces-

sary to disconnect or connect the quick-connect fittings.

Pay attention to following;

. The fuel tube/quick-connect fittings assembly is not

heat-resistant; be careful not to damage it during weld-

ing or other heat-generating procedures.

. The fuel tube/quick-connect fittings assembly is not

acid-proof; do not touch it with a shop towel which

was used for wiping battery electrolyte. R€place the

fuel tube/quick-connect fittings assembly if it came

into contact with electrolyte or somethino similar.

. When connecting or disconnecting the fuel tube/quick-

connect fittings assembly, be careful not to bend or

twist it excessively, Replace it if damaged,

A disconnected quick-connect fittings can be reconnected,

but the retainer on the mating pipe cannot be reused once

it has been removed from the pipe. Replace tha retainer

. replacing the fuel pump.

. replacing the fuelfeed pipe,

. it has been removed from the Dioe,

. it is damaged.

RCTAINERFUEL TUBE

CONNECTOR

CONNECTOR

RETAINER

11-175

Disconnection

!@ Do not smoke while working on the fuel

syst6m. Keep open flames away from your work area.

1. Disconnect the battery negative cable.

2. Remove the fuel fill cap to relieve fuel pressure in

the tank.

3. Relieve fuel pressure (see page 11-178).

4. Check the fuel quick-connect fittings for dirt, and

clean if necessary.

5. Hold the connector with one hand and press down

the retainer tabs with the other hand. then pull the

connector off.

NOTE:

. Be careful not to damage the pipe or other parts.

Do not use tools,

. lf the connector does not move, keep the retainer

tabs pressed down, and alternately pull and push

the connector until it comes off easily.

. Do not remove the retainer from the pipe; once

removed, the retainer must be replaced with a

new one.

LOCKII{G PAWL

RETANEN TAB

@NNCCTOR

Press down.

6. Check the contact area of the pipe for dirt and dam-

age.

. lf the surface is dirW, clean it

. lf the surface is rusty or damaged, replace the fuel

pump or fuel feed pipe,

CONTACT ANEA

{cont'd}

www.emanualpro.com

Page 384 of 1395

Fuel Supply System

Fuel Filter

Replacamont

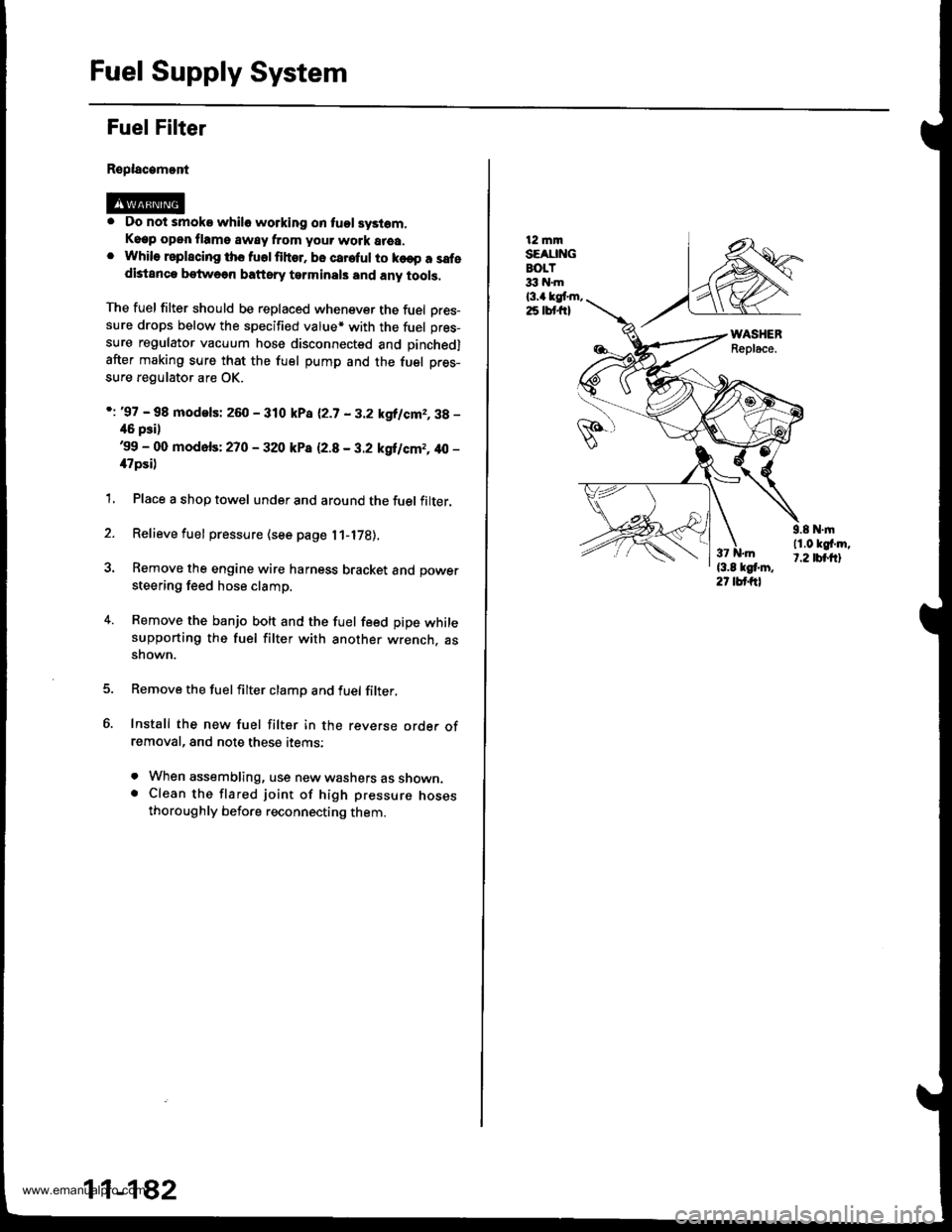

. Do not smoke whilo working on tuol syslom,Keep open flame away from your work area.. While rsplscing ths fuolfihor. bo careful to ko€p a safedistanca betweon baftsry tarminals and any tools,

The fuel filter should be replaced whenever the fuel Dres-sure drops below the specified value* with the fuel pres-

sure regulator vacuum hose disconnected and pinchedl

after making sure that the fuel pump and the fuel pres-

sure regulator are OK.

i: '97 - 98 modelsi 260 - 310 kPa 12.7 - 3.2 kgllcm2,3g -

46 psil'99 - 00 mod6fs: 270 - 320 kP8 12.8 - 3.2 kgilcm2, 40 -

il7psi)

1, Place a shop towel under and around the fuel filter.

2. Relieve fuel pressure (see page l1-l7B).

3. Remove the engine wire harness bracket and power

steering feed hose clamp.

4. Remove the banjo bolt and the fuel feed pipe whilesupporting the fuel filter with another wrench. assnown.

Remove the fuelfilter clamp and fuel filter,

Install the new fuel filter in the reverse orde. ofremoval, and note these items:

. When assembling, use new washers as shown.. Clean the flared joint of high pressure nosesthoroughly before reconnecting them.

11-182

12 mmSEAUNGBOLT33 hl.m

l3.a kgt m,25 lbt frl

9.8 N.|n11.0 kgf'm,t.2 tbt.ftl

www.emanualpro.com

Page 451 of 1395

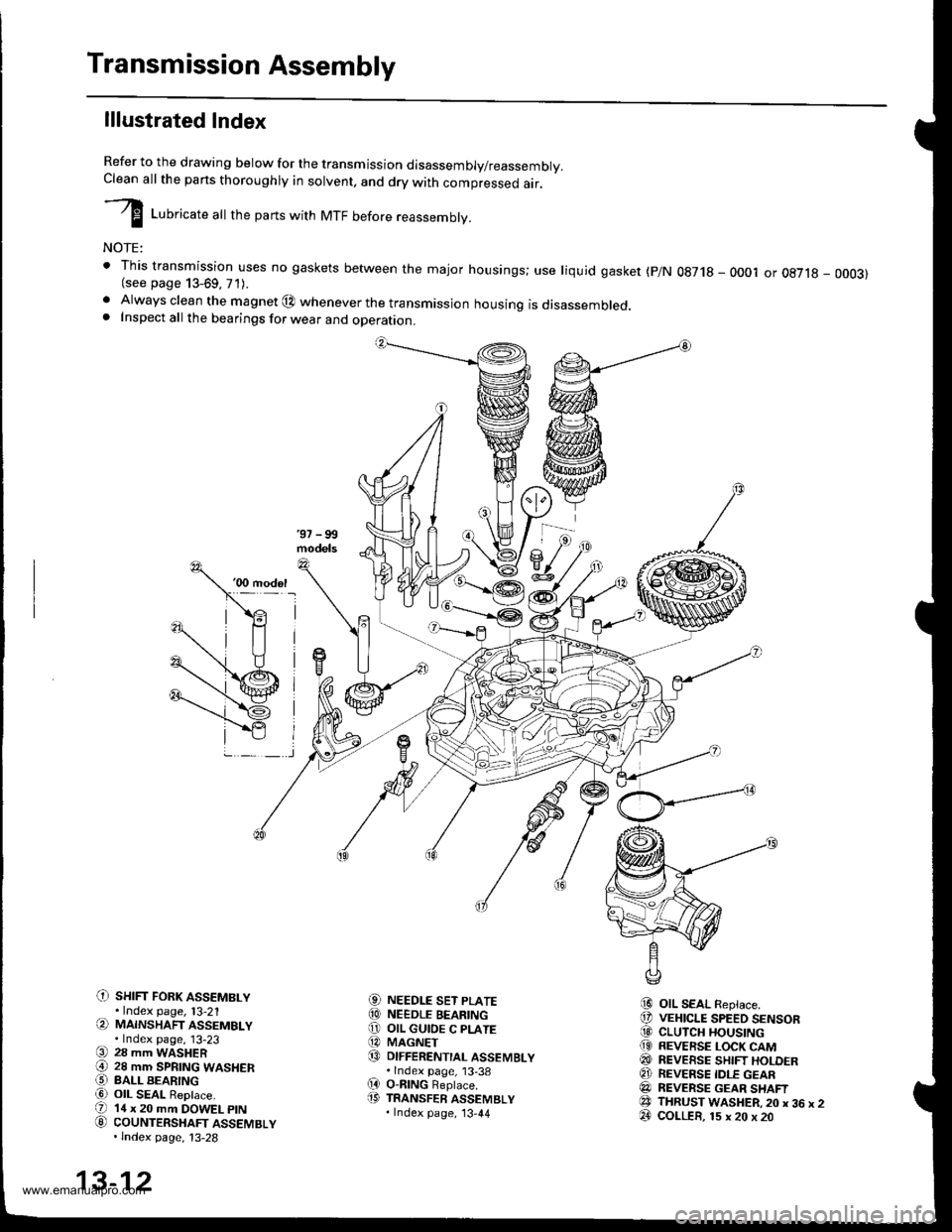

Transmission Assembly

lllustrated Index

Refer to the drawing below for the transmission disassembly/reassembly.Clean all the pans thoroughly in solvent, and drv with comoressed air.

I LuUri""r" utt the parts with MTF before reassembly.

NOTE:

t This transmission uses no gaskets between the major housings; use liquid gasket (p/N 0g718 - 0001 or oE7l8 - 0003)(see page 13-69, 71).. Always clean the magnet @ whenever the transmissjon housing is disassembled.. Inspect all the bearings for wear and operation.

C) sHrFr FoRK ASSEMBLY.Index page, l3-21(a MAINSHAFT ASSEMBLY.Index page, 13-23(9 28 mm WASHER€) 28 mm SPRTNG WASHERO BALL BEARINGa6) OIL SEAL ReDlace.(D 14 x 20 mm DOWEL ptN

G) couNTERSHAFT ASSEMBLY.lndex page, 13-28

NEEDLE SET PLATENEEDLE BEARINGOIL GUIOE C PLATEMAGNETDIFFERENTIAL ASSEMBLY.lndex page, 13-38O-nlNG Beplace.TRANSFER ASSEMBLY.Index page, '13,44

OIL SEAL Replace.VEHICLE SPEED SENSORCLUTCH HOUSINGREVERSE LOCK CAMREVEESE SHIFT HOLDERREVERSE IDLE GEARREVERSE GEAR SHAFTTHRUST WASHER,20 x 36 x 2COLLER, 15 x 20 x 20

aol

@o@@

(D

i9

@@@(9

@@@e3@

13-12

www.emanualpro.com

Page 456 of 1395

20.

2't.

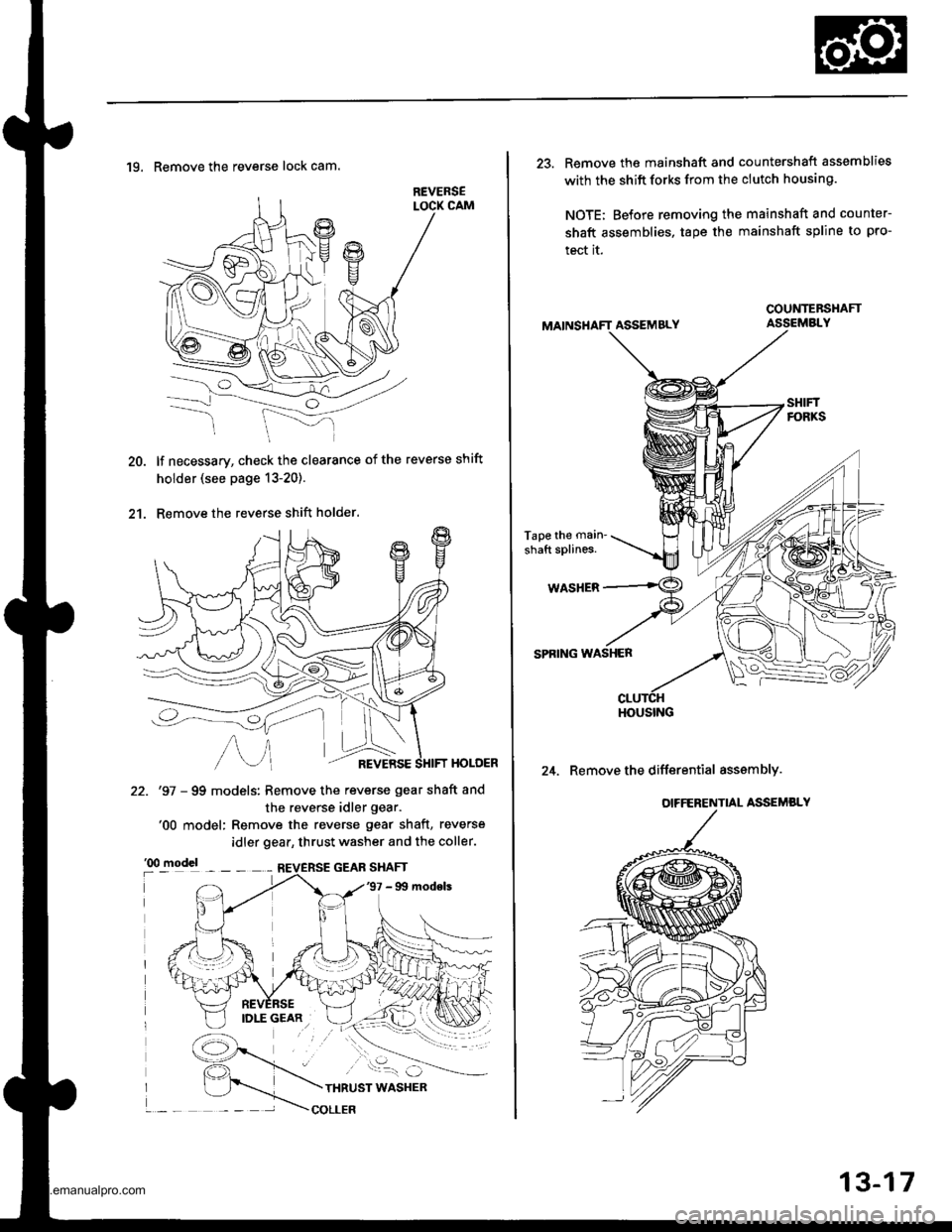

19. Remove the reverse lock cam.

lf necessary, check the clearance of the reverse shift

holder (see page 13-20).

Remove the reverse shift holder.

HOLOER

22. '97 - 99 models: Remove the reverse gear shaft and

the reverse idler gear.'00 model: Remove the reverse gear shaft, reverse

idler gear, thrust washer and the coller.

13-17

23. Remove the mainshaft and countershaft assemblies

with the shift forks from the clutch housing.

NOTE; Before removing the mainshaft and counter-

shaft assemblies, tape the mainshaft spline to pro-

tect it.

ASSEMBLY

Tape the main'

shaft splines.

WASHER

SPRING WASHER

24. Remove the differential asssmbly.

COUNTEBSHAFT

HOUSING

www.emanualpro.com

Page 507 of 1395

Transmission Assembly

Reassembly (cont'dl

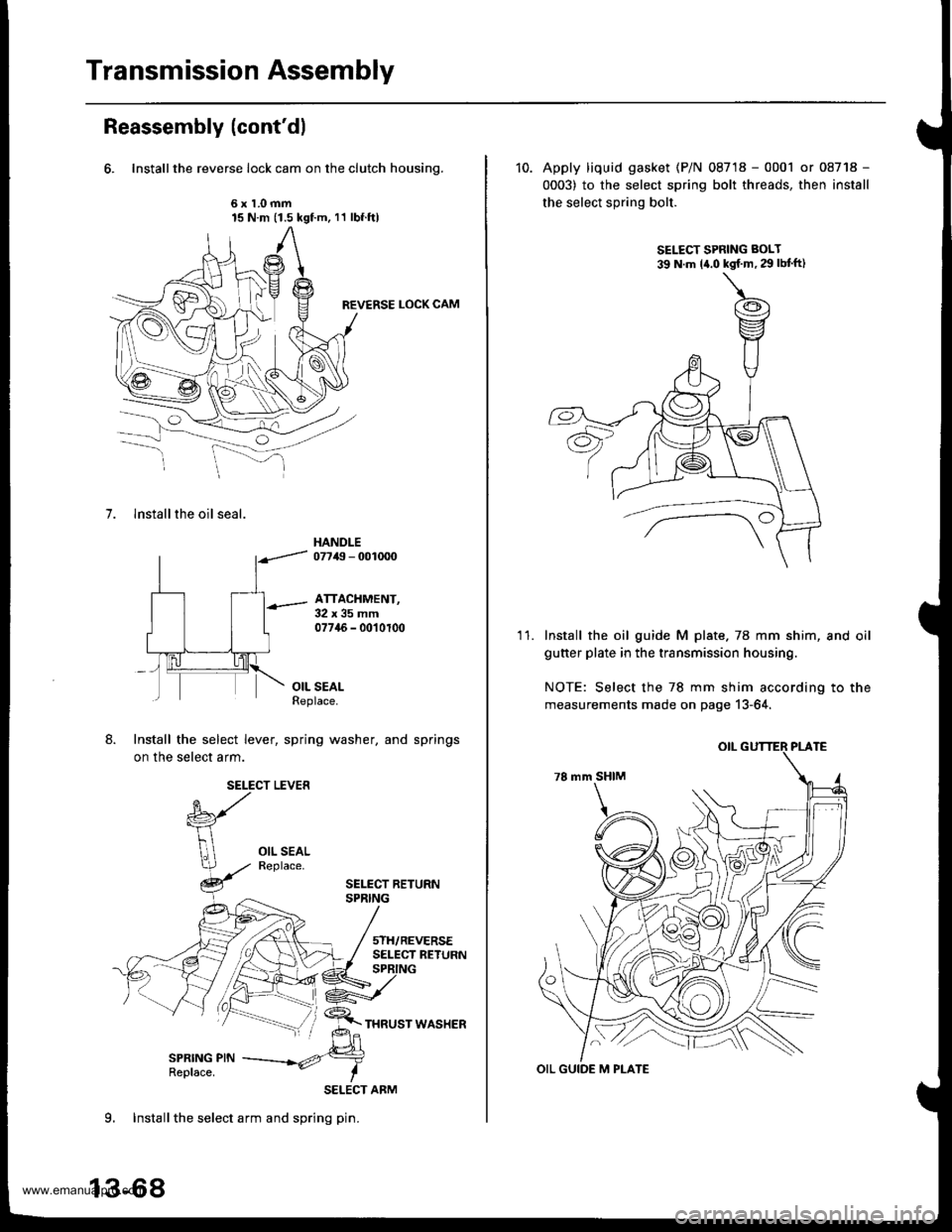

6. Installthe reverse lock cam on the clutch housing.

6x1.0mm15 N.m (1.5 kgf.m, 11 lbf.ftl

REVERSE LOCK CAM

7. lnstall the oil seal.

HANDLE07749 - 001mO

ATTACHMENT,32x35mm07745 - 0010100

OIL SEALReplace.

Install the select lever, spring washer, and springs

on the select arm.

SELECT LEVER

SELECT BETURNSPRING

5TH/REVERSESELECT RETURN

SPRING PINReplace.

SELECT ARM

9. Installthe select arm and spring pin.

13-68

10. Apply liquid gasket (P/N 08718 - 0001 or 08718 -

0003) to the select spring bolt threads, then install

the select spring bolt.

SELECT SPRING BOLT

39 N.m la.o kgf'm,29lbtft)

'I 1.Install the oil guide M plate.78 mm shim, and oil

guner plate in the transmission housing.

NOTE: Select the 78 mm shim according to the

measurements made on page 13-64,

OIL GUIDE M PLATE

www.emanualpro.com

Page 870 of 1395

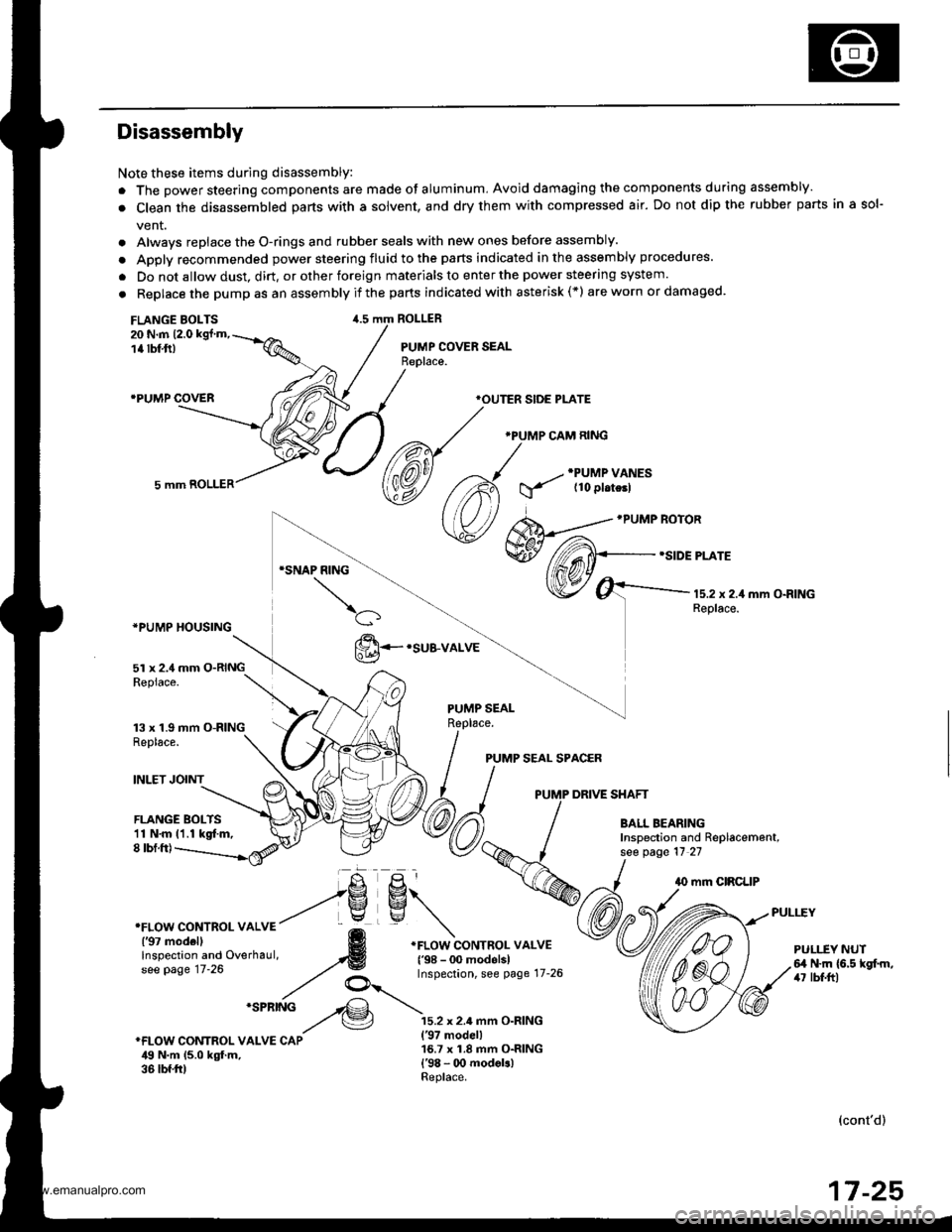

Disassembly

Note these items during disassembly:

. The power steering components are made of aluminum, Avoid damaging the components during assembly.

. Clean the disassembled parts with a solvent, and dry them with compressed air. Do not dip the rubber parts in a sol-

vent.

. Always replace the O-rings and rubber seals with new ones before assembly.

. Apply recommended power steering fluid to the parts indicated in the assembly procedures.

. Do not allow dust, dirt, or other foreign materials to enter the power steering system.

. Replace the pump as an assemblyif the parts indicated with asterisk(*) areworn ordamaged.

FLANGE BOLTS20 N.m 12.0 kgt'm,

1a tbf,ft)

.PUMP COVER

ROLLER

PUMP COVER SEAL

*PUMP HOUSING

5l x 2.4 mm O-RINGRepiace.

13 x 1.9 mm O-RINGReplace.

INLET JOINT

*OUTER SIDE PLATE

.PUMP CAM RING

PUMP SEAL SPACER

PUMP DRIVE SHAFT

FLANGE BOLTS11 N.m 11.1 kgt m,8 tbf.ft)

PULI.-EY NUTfl N.m (6.5 kgf.m,/r7 lbf.ftl

(cont'd)

17 -25

www.emanualpro.com

Page 871 of 1395

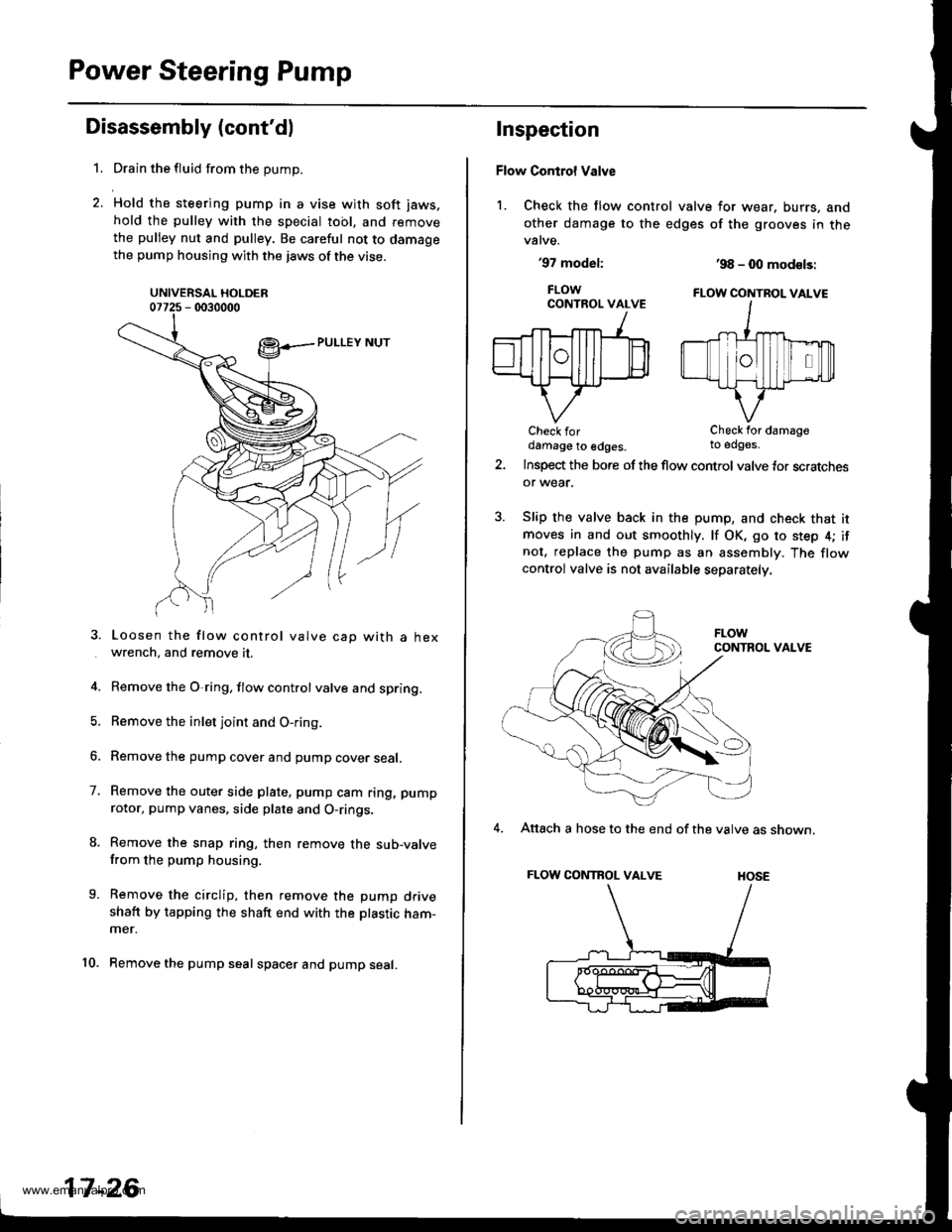

Power Steering Pump

Disassembly (cont'dl

1.

7.

9.

10.

Drain the fluid from the pump.

Hold the steering pump in a vise with soft jaws.

hold the pulley with the special tool, and remove

the pulley nut and pulley. Be careful not to damagethe pump housing with the jaws of the vise.

UNIVERSAL HOLDER07725 - 0030000

Loosen the flow control valve cap with a hexwrench, and remove it.

Remove the O,ring, flow control valve and spring.

Remove the inlet joint and O-ring.

Remove the pump cover and pump cover seal.

Remove the outer side plate, pump cam ring, pump

rotor, pump vanes, side plate and O-rings.

Remove the snap ring, then remove the sub-valvefrom the pump housing.

Remove the circlip, then remove the pump driveshaft by tapping the shaft end with the ptastic ham-mer.

Remove the pump seal spacer and pump seal.

17-26

Inspection

Flow Control Valve

1. Check the flow control valve for wear, burrs, and

other damage to the edges of the grooves in thevalve.

'97 model:

FLOWCONTROL VALVE

Check fordamage to edges.

'98 - 0O mod€ls:

FLOW CONTBOL VALVE

Check for damageto edges.

Insp€d the bore of the flow control valve tor scratchesor wear.

Slip the valve back in the pump, and check that itmoves in and out smoothly. lf OK, go to step 4; ifnot, replace the pump as an assembly. The flowcontrolvalve is not available separately.

CONTROL VALVE

4. Attach a hose to the end of the valve as shown.

FLOW CONTROL VALVE HOSE

www.emanualpro.com

Page 873 of 1395

Power Steering Pump

Reassembly

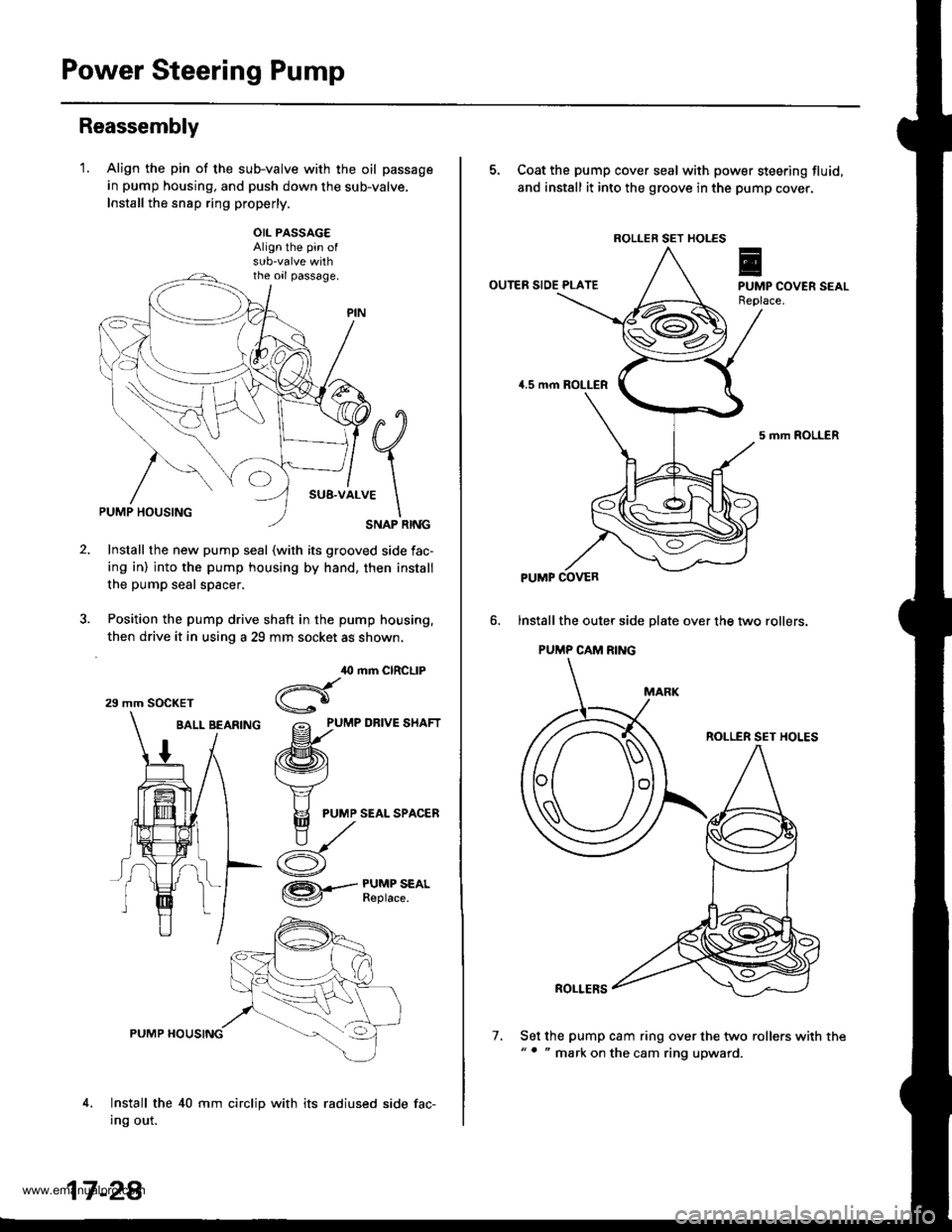

'1.Align the pin of the sub-valve with the oil passage

in pump housing, and push down the sub-valve.

Install the snsp ring properly.

OIL PASSAG€Align the pin of

the oil passage.

#q

;1..*

\SNAP RINGPUMP HOUSING

Install the new pump seal (with its grooved side fac-

ing in) into the pump housing by hand, then install

the pump seal spacer.

Position the pump drive shaft in the pump housing,

then drive it in using a 29 mm socket as shown,

BALL BEARfNG grlu,e un.t

/ /ffi\

1 / t\v4

t/ Y

# I F

PUMP SEALSPAC,ER

ry^

i- d

,O mm CIRCLIP

Hgo

/= PUMP DRIVE SHAFT

@.--#$i":*'

4,

PUMP HOUSING

Install the 40 mm circlip with its radiused side fac-

Ing out.

29 mm SOCKET

17 -2A

7.

5. Coat the pump cover seal with power steering fluid,

and install it into the groove in the pump cover.

OUTER SIDE PLATE

5 mrh ROLLER

lnstall the oute. side plate over the two rollers.

PUMP CAM RING

ROLLER SET HOLES

ROLLERS

Set the pump cam ring over the two rollers with the"' " mark on the cam ring upward.

ROLLER SET HOLES

PUMP COVER

www.emanualpro.com

Page 874 of 1395

8.

9.

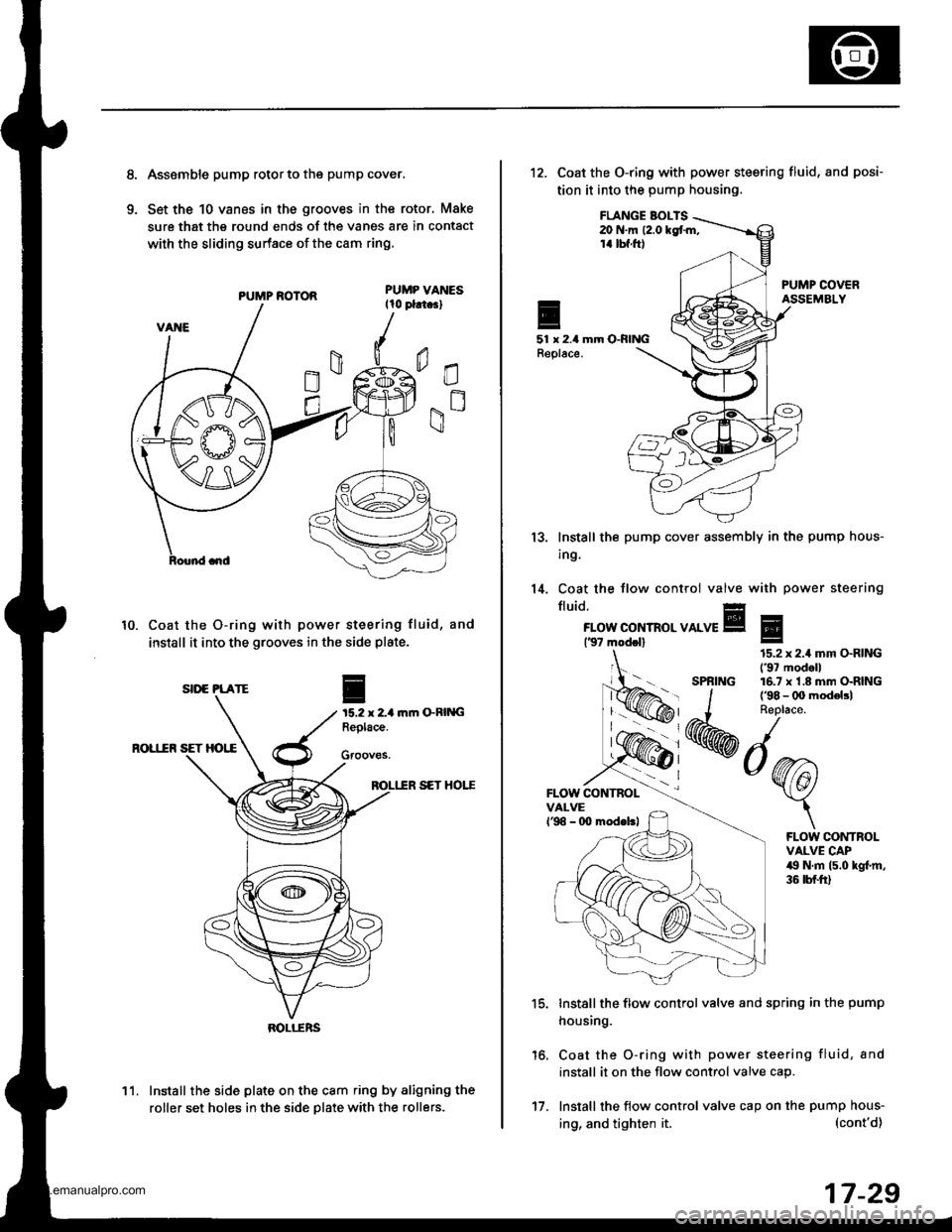

Asssmble pump rotor to the pump cover,

Set the 10 vanes in the grooves in the rotor, Make

sure that the round ends of the vanes are in contact

with the sliding surface of the cam ring.

PUMP ROTOR

Coat the O-ring with power steering fluid, and

install it into the grooves in the side plate.

ftm GRING

ROL1IR SET HOI,E

SET HOTT

Install the side plate on the cam ring by aligning the

roller set holes in the side Dlate with the rollers.

10.

I

15.2 x 2-1Replace.

Gfooves.

SII'E PLATE

BOLI-ERS

11.

17.

ing, and tighten it.

12. Coat the O-ring with power steering fluid,

tion it into the pump housing.

and posi-

FLANGE BOI-TS20 N.m (2.0 kgt m,14 tbf.ft)

51 x 2.4 mm O-RINGReplace.

13.

14.

lnstall the

ing.

Coat the

fluid.

pump cover assembly in the pump hous-

tlow control valve with power steering

FLOW CONTROL VALVE137 modol)

FLOW CONTBOLVALVEl'98 - 0O modeltl

'15.

16.

Install the flow control valve and spring in the pump

housing.

Coat the O-ring with power steering fluid, and

install it on the flow control valve cap.

Install the flow control valve cap on the pump hous-

Eg

SPRING

15.2 x 2.4 mm O.RING('97 modell16.7 x'1.8 mm O-RING

FLOW CONTROLVALVE CAP49 N.m (5.0 kgl.m,36 tbf.ft)

(cont'd)

17-29

www.emanualpro.com