cam HONDA CR-V 1998 RD1-RD3 / 1.G Owner's Guide

[x] Cancel search | Manufacturer: HONDA, Model Year: 1998, Model line: CR-V, Model: HONDA CR-V 1998 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 899 of 1395

Suspension

Special Tools ............. 18-2

Component Locations

lndex ................ ...... 18-3

Wheel Alignment

Service lnformation ......................,.. 18-4

Camber .................. 18-4

Caster ............... ...... 18-5

Front Toe Inspection/

Adiustment ........ 18-5

Rear Toe Inspection/

Adiustment ........ 18-6

Turning Angle Inspection/

Adiustment ........ 18-6

Wheel/Hub Inspection

Bearing End Play .......................,...... 18-7

Wheel Runout ....... 18-7

Front Suspension

Suspension Arms Replacement ..... 18-8

Knuckle/Hub Replacement ............. 18-9

Lower Ball Joint Replacement ....... 18-15

Ball Joint Boot Replacement .......... 18-16

Front Damper

Removal ................. 18-16

Disassembly/lnspection .................. 18-1 7

Reassembly ........... 18-18

lnstallation ............. 18-18

Rear Suspension

Suspension Arms Replacement ..... 18-19

Hub Bearing Unit Replacement ...... 18-20

Upper Arm Bushing

Replacement ..... 18-23

Rear Damper

Removal ................. 18-23

Disassembly/1nspection .................. 18-24

Reassembly ........... 18-25

lnstallation ............. 18-25

www.emanualpro.com

Page 902 of 1395

Wheel Alignment

Caster

For proper inspection/adjustment of the wheel align-ment, check and adjust these items before checkinq thealignment:

. Check that the suspension is not modified.. Check the tire size and tire pressure.

. Check th( runout of the wheels and t;res,. Check the suspension ball joints. (Hold a wheel withyour hands, and move it up and down and right andleft to check for wobbling.)

Inspection

Use commercially-available computerized four wheelalignment equipment to measure wheel alignment (cast-

er, camber, toe, and turning angle). Follow the equip-ment manufacturer's instructions.

Check the caster angle.

Caster angle: 2'10':t 1"

lf out of specification, check for bent or damagedsuspension components.

1.

18-4

Camber

Inspection

Use commercially-available computerized lour wheelalagnment equipment to measure wheel alignment (cast,

er, camber, toe, and turning angle). Follow the equip,ment manufacturer's instructions.

1. Check the camber angle.

Camber angle:

Front: 0'00' 1 1"

Rear: - 1' :! 1"

2. lf out of specification, check for bent or damagedsuspensron components.

www.emanualpro.com

Page 903 of 1395

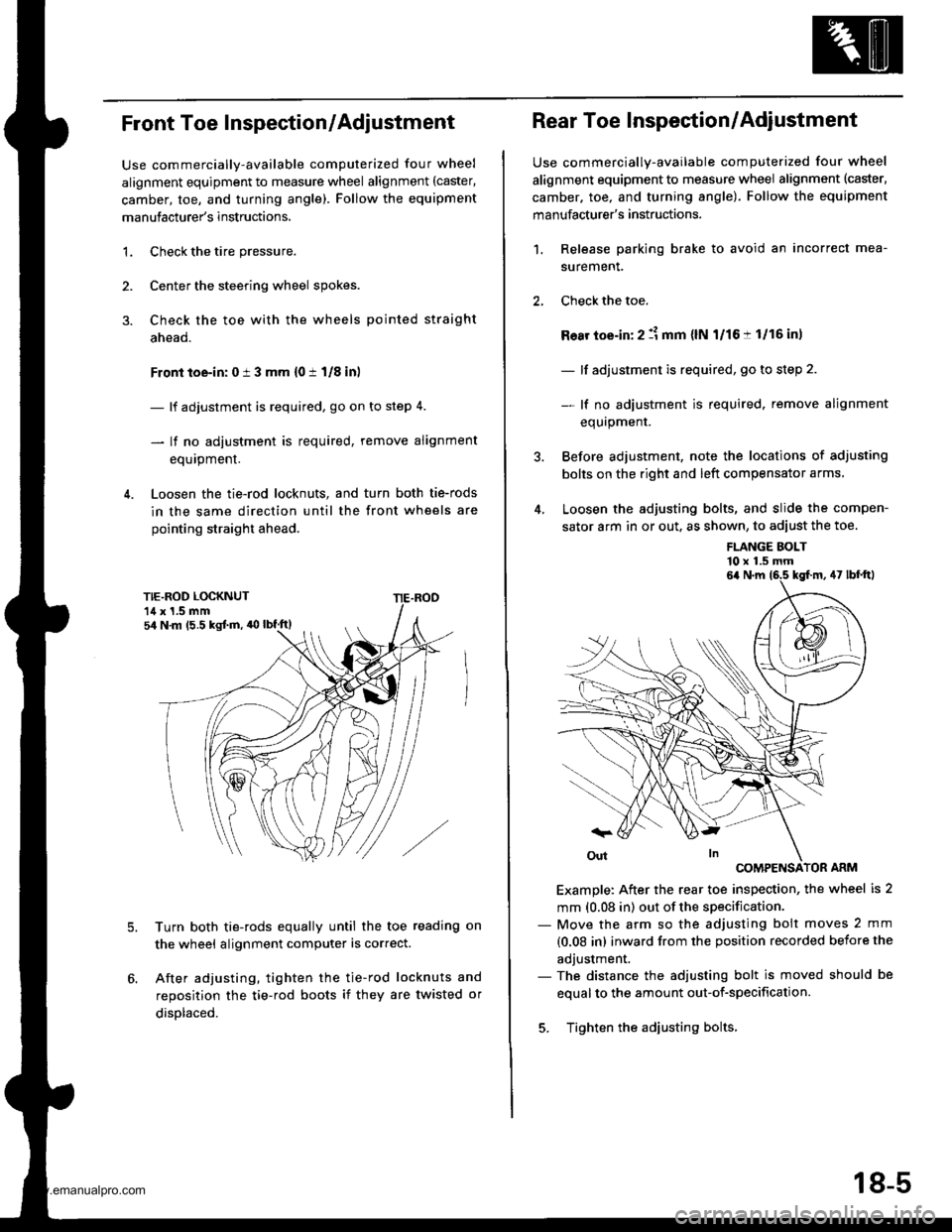

Front Toe Inspection/Adjustment

Use commercially-available computerized four wheel

alignment equipment to measure wheel alignment (caster,

camber, toe, and turning angle). Follow the equipment

manufacturer's instructions,

3.

1.Check the tire pressure.

Center the steering wheel spokes.

Check the toe with the wheels pointed straight

ahead.

Front toe-in: 0 i 3 mm {0 t 1/8 inl

- lf adjustment is required, go on to step 4.

- lf no adjustment is required, remove alignment

equipment.

Loosen the tie-rod locknuts, and turn both tie-rods

in the same direction until the front wheels are

pointing straight ahead.

5.Turn both tie-rods equally until the toe reading on

the wheel alignment computer is correct.

After adjusting, tighten the tie-rod locknuts and

reposition the tie-rod boots if they are twisted or

displaced.

sir N m (5.5 kgJ.m, 'O lbf.ft)

Rear Toe Inspection/Adjustment

Use commercially-available computerized four wheel

alignment equipment to measure wheel alignment (caster,

camber. toe, and turning angle). Follow the equipment

manufacturer's instructions.

Release parking brake to avoid an incorrect mea-

surement.

Check the toe.

Ro8r toe-in: 2 :1 mm {lN l/16:t 1/16 in,

- lf adjustment is required, go to step 2.

- lf no adiustment is required. remove alignment

equrpmenr.

Before adjustment, note the locations of adjusting

bolts on the right and left compensator arms.

Loosen the adjusting bolts, and slide the compen-

sator arm in or out. as shown, to adiust the toe.

1.

FLANGE BOLT'10 x 1.5 mm

COMPENSATOR ARM

Example: After the rear toe inspection, the wheel is 2

mm (0.08 in) out of the specification.- Move the arm so the adjusting bolt moves 2 mm

{0.08 in) inward from the position recorded before the

adjustment.- The distance the adjusting bolt is moved should be

equal to the amount out-of-specification.

5. Tighten the adjusting bolts.

6a N.m 16.5 kgf.m, 47 lbf'ftl

18-5

www.emanualpro.com

Page 904 of 1395

Wheel Alignment

Turning Angle Inspection

Use commercially-available computerized four wheelalignment equipment to measure wheel alignment (caster,

camber, toe, and turning angle). Follow the equipmentmanufacturer's instructions.

1. Turn the wheel right and left while applying thebrake, and measure the turning angle of bothwneets.

Turning angle:

Inward wheel: 37.00'

Outward wheel lreference): 31.30'

2.lf the turning angle

check for be nt or

nenIs.

is not within the specifications,

damaged suspension compo-

18-6

www.emanualpro.com

Page 1019 of 1395

Glass

Ouarter Glass Replacement (cont'd)

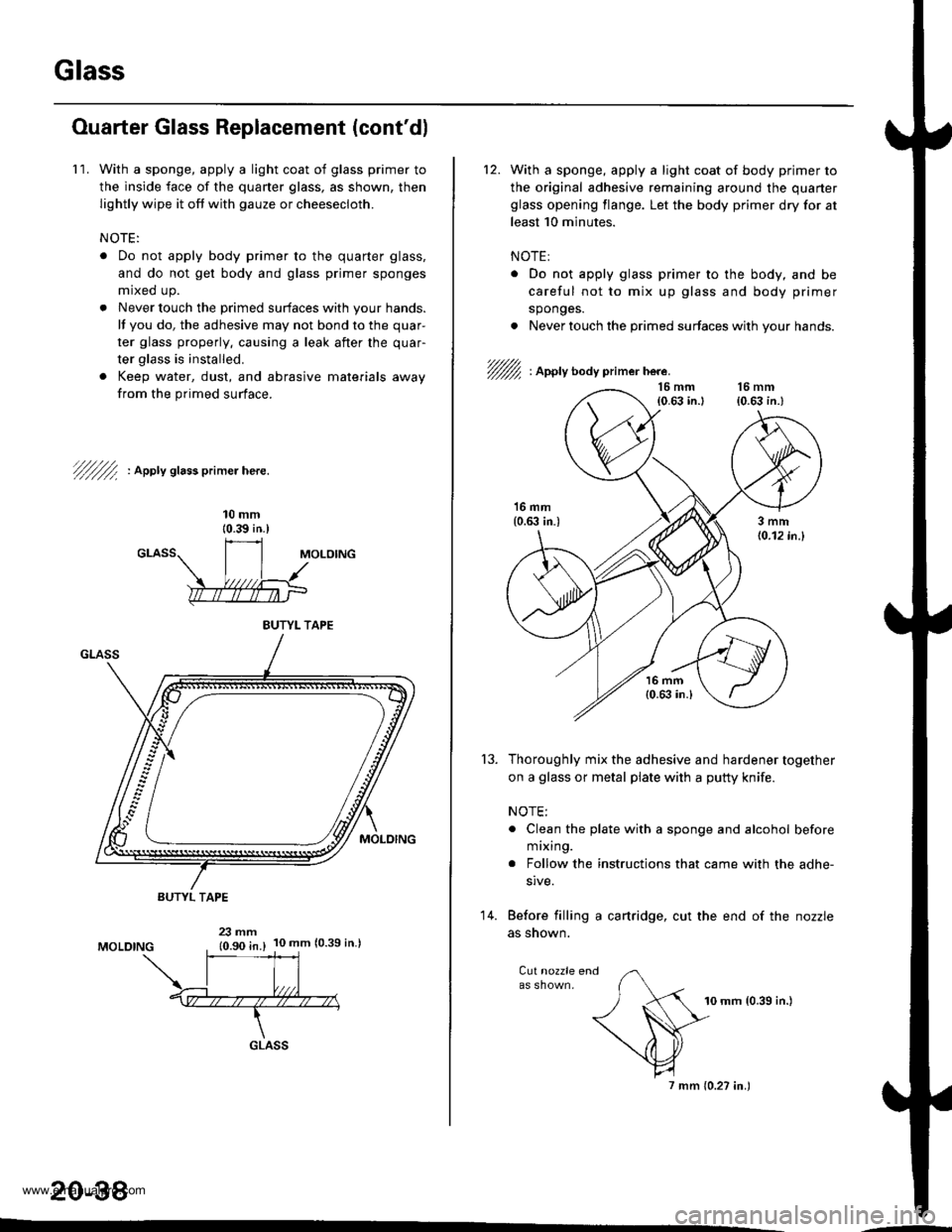

1 1. With a sponge, apply a light coat of glass primer to

the inside face of the quaner glass, as shown, then

lightly wipe it off with gauze or cheesecloth.

NOTE:

. Do not apply body primer to the quarter glass,

and do not get body and glass primer sponges

mrxed up.

. Never touch the primed surfaces with your hands.

It you do, the adhesive may not bond to the quar-

ter glass properly. causing a leak after the quar

ter glass is installed.

. Keep water, dust, and abrasive materials away

from the primed surface.

7///f ' aeery sra$ primer here.

10 mm{0.39 in.)

BUTYL TAPE

BUTYL TAPE

MOLOING23 mm10.90 in.)10 mm 10.39 in.)

GLASS

20-38

With a sponge, apply a light coat of body primer to

the original adhesive remaining around the quaner

glass opening flange. Let the body primer dry for at

least 10 minutes.

NOTE:

. Do not apply glass primer to the body, and be

careful not to mix up glass and body primer

sponges.

. Never touch the primed surfaces with your hands.

'/fu, : Apply body primer here.

'13.Thoroughly mix the adhesive and hardener together

on a glass or metal plate with a putty knife.

NOTE:

. Clean the plate with a sponge and alcohol before

m ixing.

. Follow the instructions that came with the adhe-

slve.

Before filling a cartridge, cut the end of the nozzle

as snown.

Cut nozzle end

10 mm {0.39 in.)

7 mm {0.27 in.)

14.

www.emanualpro.com

Page 1392 of 1395

SRS Unit

).0Replacement

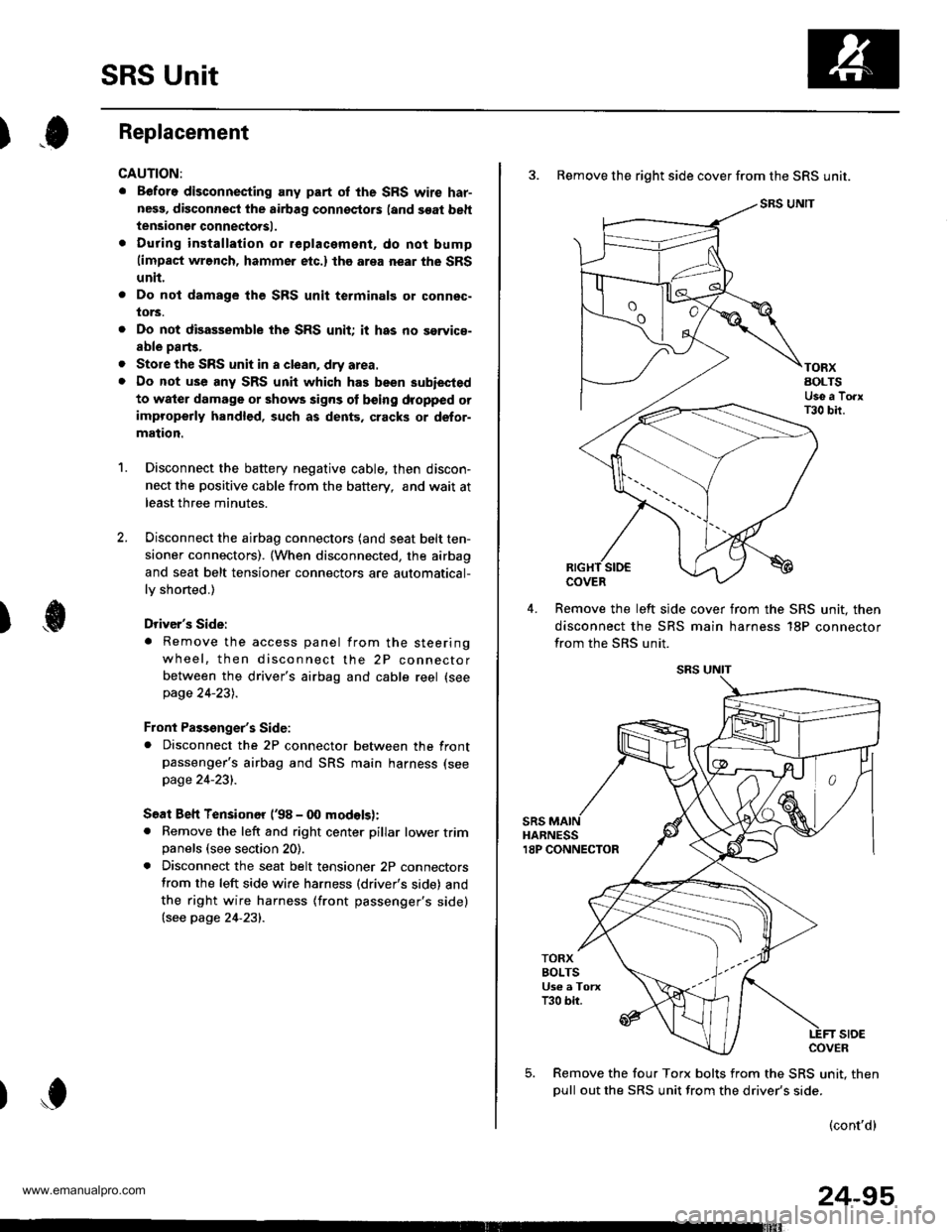

CAUTION:

. Before disconnecting any part of the SRS wire har-

nesg, disconnect the airbag connoctors (and soat beh

tensioner connectorsl.

. During installation or replacament, do not bump(impact wrench, hammer etc.) the area near the SRS

unit.

Do not damage the SFS unit terminalg or connsc-

lors.

Do not disassemble the SRS unit it has no saryice-

able parts,

Store the SRS unit in a clean, dry area.

Do not use any SRS unit which has been subiected

to water damage or shows signs ot being dropped orimproperly handlgd, such as dents, cracks or defor-

mation.

Disconnect the battery negative cable, then discon-

nect the positive cable from the battery, andwaitat

least three minutes.

Disconnect the airbag connectors (and seat belt ten-

sioner connectors). (When disconnected, the airbag

and seat belt tensioner connectors are automatical-

ly shorted.)

Driver's Side:

. Remove the access panel from the steering

wheel, then disconnect the 2P connector

between the driver's airbag and cable reel (see

page 24-231.

Front Passenger's Side:. Disconnect the 2P connector between the frontpassenger's airbag and SRS main harness (see

page 24-231.

Soat Beh Tensionor ('98 - 00 modelsr:. Remove the left and right center pillar lower trimpanels (see section 20).

. Disconnect the seat belt tensioner 2P connectors

from the left side wire harness (driver's side) and

the right wire harness (front passenger's side)(see page 24'231.

2.

a

a

'1.

)

)o

24-95

3. Remove the right side cover from the SRS unit.

SRS UNIT

TORXAOLTSUse a TorxT30 bir.

COVER

Remove the left slde cover from the SRS unit. then

disconnect the SRS main harness 18P connector

from the SRS unit.

sRsHARNESS18P CONNECTOR

TORXBOLTSUs€ a TorxT30 bir.

stoECOVER

Remove the four Torx bolts from the SRS unit. then

oull out the SRS unit from the driver's side.

(cont'd)

www.emanualpro.com

Page 1395 of 1395

Airbag/Seat Belt Tensioner

1.

Disposal (cont'dl

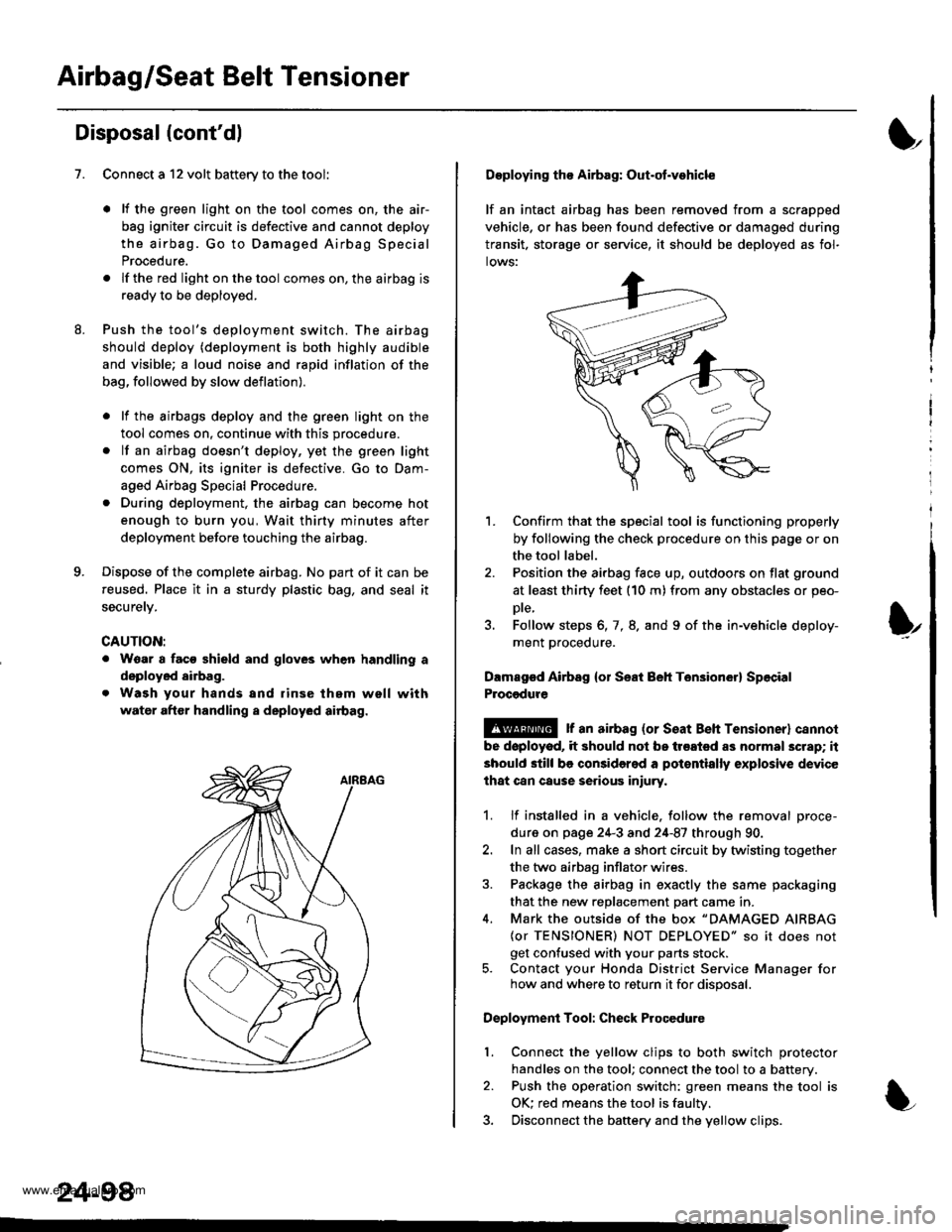

Connect a 12 volt battery to the tool'

. It the green light on the tool comes on, the air-

bag igniter circuit is defective and cannot deploy

the airbag. Go to Damaged Airbag Special

Procedure.

.lftheredlightonthetool comes on, the airbag is

ready to be deployed.

Push the tool's deployment switch. The airbag

should deploy (deployment is both highly audible

and visible; a loud noise and rapid inflation of the

bag, followed by slow deflation).

. lf the airbags deploy and the green light on the

tool comes on, continue with this procedure.

. lf an airbag doesn't deploy, yet the green light

comes ON, its igniter is defective. Go to Dam-

aged Airbag Special Procedure.

. During deployment, the airbag can become hot

enough to burn you, Wait thirty minutes after

deployment before touching the airbag.

Dispose of the complete airbag. No part of it can be

reused. Place it in a sturdy plastic bag, and seal it

securety.

CAUTION:

. Wear a faco shield and gloves when handling a

deployed airbag.

. Wash your hands and rinse them well with

water after handling a deployed airbag.

24-98

Deploying tho Airbag: Out-ot.vohicle

lf an intact airbag has been removed from a scrapped

vehicle, or has been found defective or damagsd during

transit. storage or seryice, it should be deployed as fol-

lows:

'L Confirm that the special tool is functioning properly

by following the check procedure on this page or on

the tool label.

2. Position the airbag face up, outdoors on flat ground

at least thirty feet (10 m) from any obstacles or peo-

Dte,

3. Follow steps 6, 7, 8. and 9 of the in-vehicle deploy-

ment proceoure.

Dlmaged Airbsg {or Seat Beh Ten3ion6r} Sp6cial

Procgdure

!@ r an airbag {or seat Beh rensioner} cannol

be doployod, it should not be treated as normal scrap; it

should still be considered a pot€ntially explosive device

lhat can cause serious iniury.

1. lf installed in a vehicle. follow the removal proce-

dure on page 24-3 and 24-87 through 90.

2. In all cases, make a short circuit by twisting together

the two airbag inflator wires.

3. Package the airbag in exactly the same packaging

that the new reDlacement Dart came in.

4. Mark the outside of the box "DAMAGED AIRBAG

{or TENSIONER) NOT DEPLOYED" so it does not

get confused with your parts stock.5. Contact your Honda District Service Manager forhow and where to return it for disposal.

Deployment Tool: Check Procedure

Connect the yellow clips to both switch protector

handles on the tool; connect the tool to a battery.

Push the operation switch: green means the tool is

OK: red means the tool is faultv.

Disconnect the baftery and the yellow clips.

I

t

l.

www.emanualpro.com