Scs HONDA CR-V 1998 RD1-RD3 / 1.G Owner's Guide

[x] Cancel search | Manufacturer: HONDA, Model Year: 1998, Model line: CR-V, Model: HONDA CR-V 1998 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 796 of 1395

Description

Hydraulic Flow

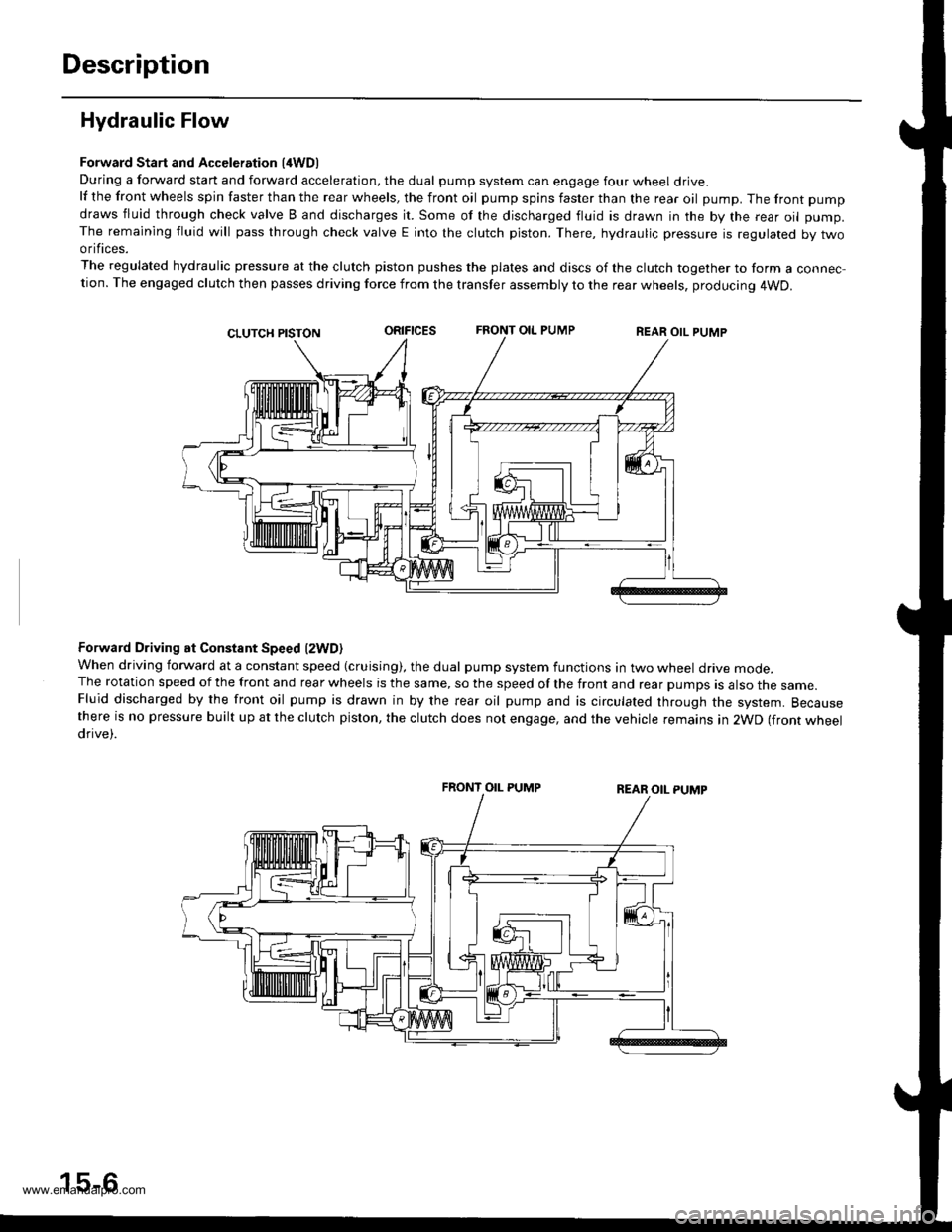

Forward Start and Acceleration l4WD)During a forward start and forward acceleration, the dual pump system can engage four wheel drive.lf the front wheels spin faster than the rear wheels, the front oil pump spins faster than the rear oil pump. The front pump

draws fluid through check valve B and discharges it. Some of the discharged fluid is drawn in the by the rear oil pump.The remaining fluid will pass through check valve E into the clutch piston. There, hydraulic pressure is regulated by twoorifices.

The regulated hydraulic pressure at the clutch piston pushes the plates and discs of the clutch together to form a connec-tion. The engaged clutch then passes driving force from the transfer assembly to the rear wheels, producing 4WD.

oRrFtcEsFRONT OIL PUMPREAR OIL PUMP

Forward Driving at Constant Speed lzWD)When driving forward at a constant speed (cruising), the dual pump system functions in two wheel drive mode.The rotation speed of the front and rear wheels is the same, so the speed of the front and rear pumps is also the same.Fluid discharged by the front oil pump is drawn in by the rear oil pump and is circulated through the system. Becausethere is no pressure built up at the clutch piston, the clutch does not engage, and the vehicle remains in 2WD (front wheeldrive).

FRONT OIL PUMP

15-6

www.emanualpro.com

Page 797 of 1395

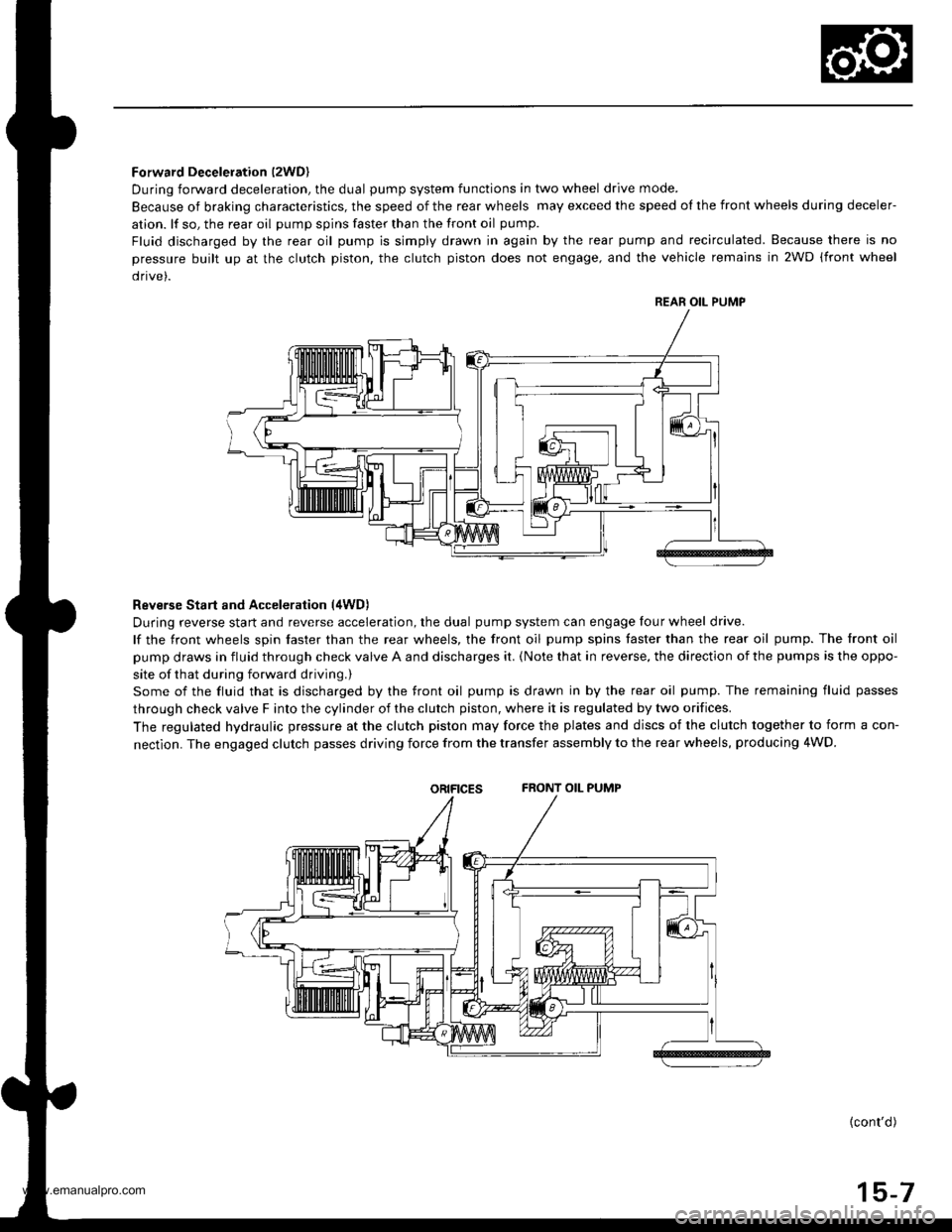

Forward Deceleration l2WDl

During forward deceleration, the dual pump system functions in two wheel drive mode.

Because of braking characteristics, the speed of the rear wheels may exceed the speed ol the front wheels during deceler-

ation. lf so, the rear oil pump spins faster than the front oil pump.

Fluid discharged by the rear oil pump is simply drawn in again by the rear pump and recirculated. Because there is no

pressure built up at the clutch piston. the clutch piston does not engage, and the vehicle remains in 2WD (front wheel

drive).

Reverse Start and Acceleration (4WD)

During reverse start and reverse acceleration, the dual pump system can engage four wheel drive.

lf the front wheels spin faster than the rear wheels, the front oil pump spins faster than the rear oil pump. The front oil

pump draws in fluid through check valve A and discharges it. {Note that in reverse, the direction of the pumps is the oppo-

site of that during forward driving.)

Some of the fluid that is discharged by the front oil pump is drawn in by the rear oil pump. The remaining fluid passes

through check valve F into the cylinder of the clutch piston, where it is regulated by two orifices.

The regulated hydraulic pressure at the clutch piston may force the plates and discs of the clutch together to form a con-

nectlon. The engaged clutch passes driving force from the transfer assembly to the rear wheels, producing 4WD.

oRtFtcEsFRONT OIL PUMP

{cont'd)

15-7

REAR OIL PUMP

www.emanualpro.com

Page 798 of 1395

Description

Hydraulic Flow (cont'dl

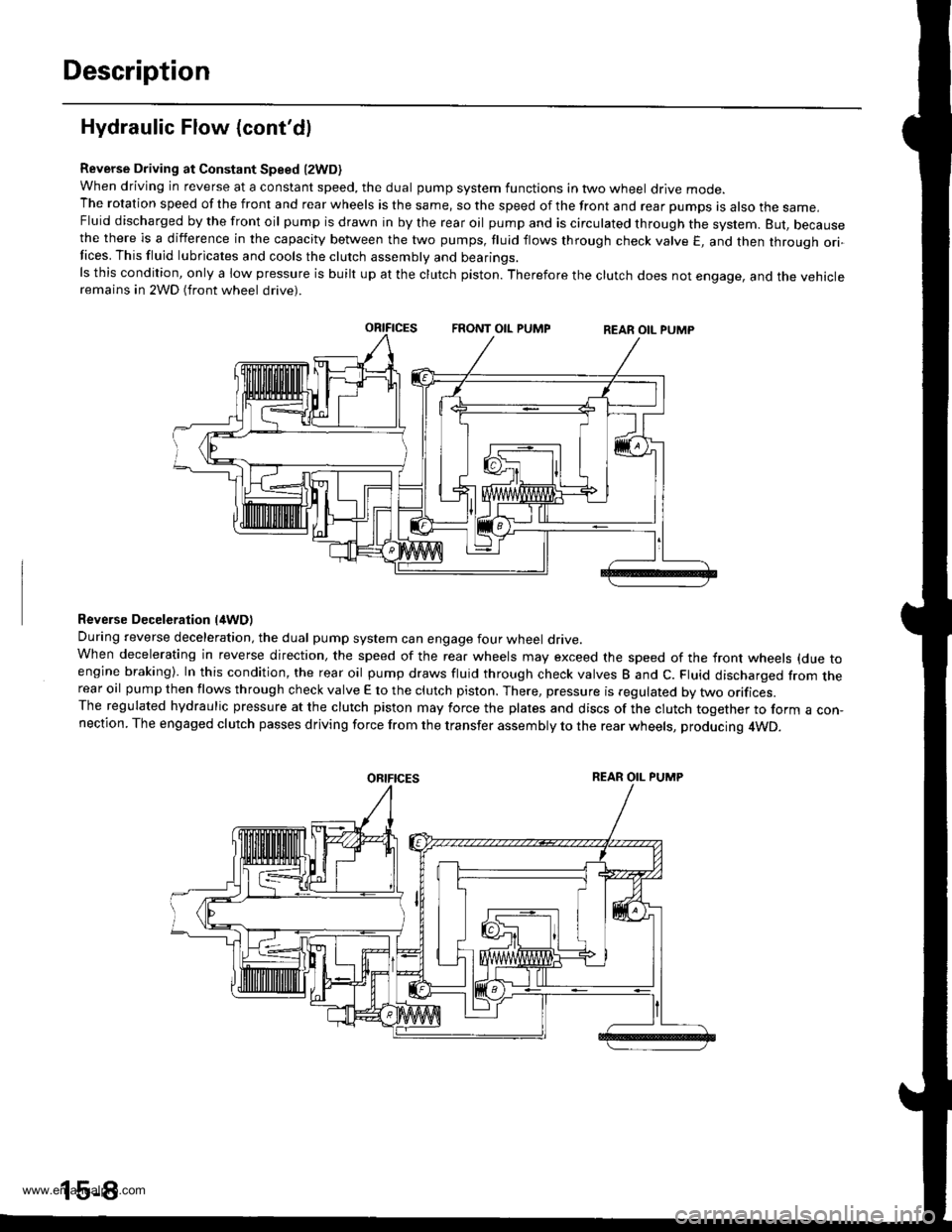

Reverse Driving at Constant Speed l2WD)when driving in reverse at a constant speed, the dual pump system functions in two wheel drive mode.The rotation speed of the front and rear wheels is the same, so the speed of the front and rear pumps is also the same,Fluid discharged by the front oil pump is drawn in by the rear oil pump and is circulated through the system. But, becausethe there is a difference in the capacity between the two pumps, fluid flows through check valve E, and then through ori-Iices. This fluid lubricates and cools the clutch assembly and bearings.ls this condition, only a low pressure is built up at the clutch piston. Therefore the clutch does not engage, and the vehicleremains in 2WD (front wheel drive).

Reverse Deceleration l/tWDl

During reverse deceleration, the dual pump system can engage four wheel drive.When decelerating in reverse direction, the speed of the rear wheels may exceed the speed of the front wheels (due toengine braking). In this condition, the rear oil pump draws fluid through check valves B and C. Fluid discharged from therear oil pump then flows through check valve E to the clutch piston. There, pressure is regulated by two orifices.The regulated hydraulic pressure at the clutch piston may force the plates and discs of the clutch together to form a con,nection. The engaged clutch passes driving force from the transfer assembly to the rear wheels, producing 4WD.

oRtFtcEsREAR OIL PUMP

www.emanualpro.com

Page 805 of 1395

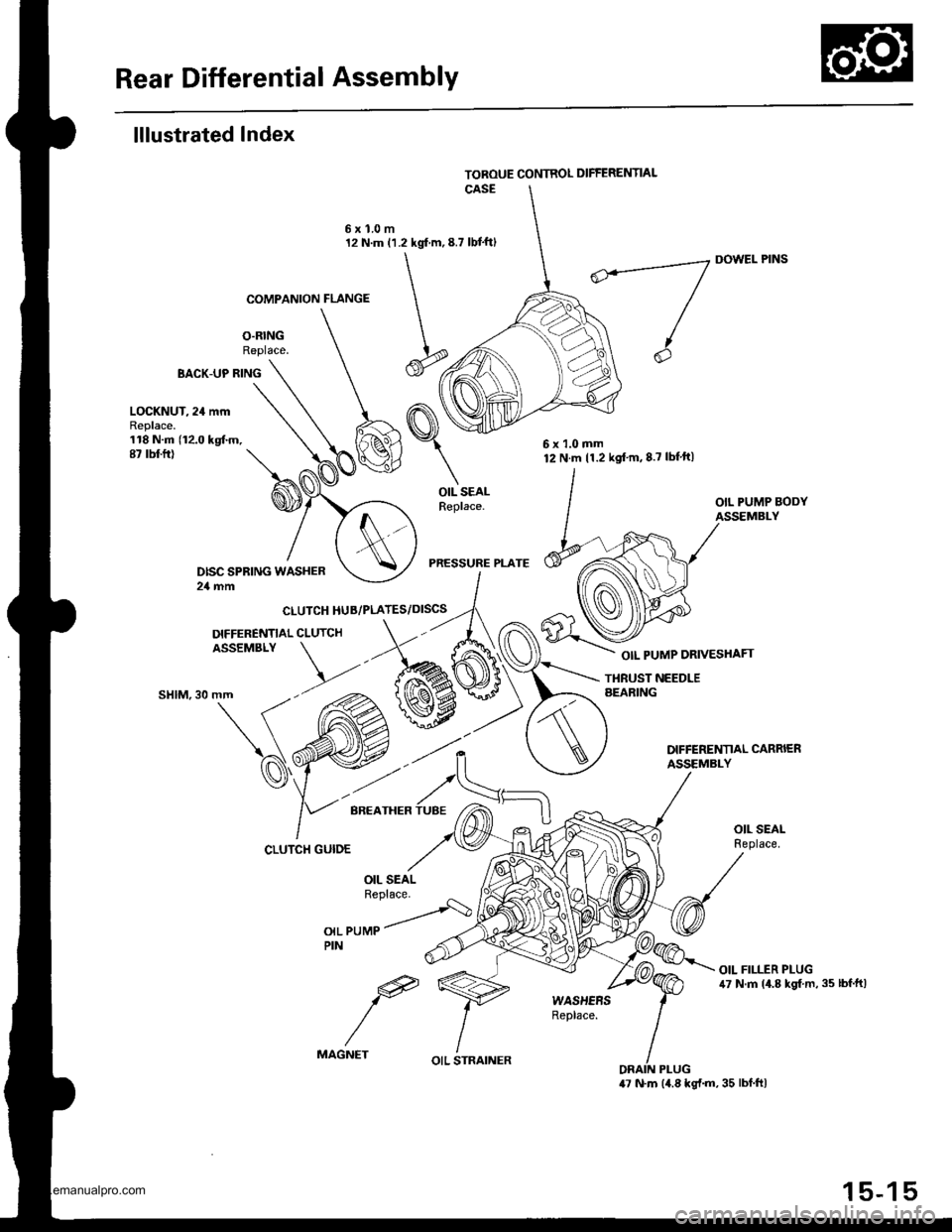

Rear Differential Assembly

lllustrated Index

O.RINGReplace.

6xl.0m12 N.m (1.2 kgf m,8.7 lbt'ftl

BACK-UP RING

COMPANION FLANGE

CLUTCH HUB/PLATES/DISCS

DIFFERENNAL CLUTCHASSEMBLY

DOWEL PINS

OIL PUMP DRIVESHAFT

LOCKNUT, 24 mmReplace.118 N.m (12.0 kgtm.87 rbt ft)

OIL SEALReplace.

PRESSURE PLATE

THBUST NEEDLEAEARING""t",at\(

'd'

CLUTCH GUIDE

OIL PUMPPIN

e

MAGNET

6x1.0mm12 N.m 11.2 kgt'm,8.7 lbf'ft|

OIL STRAINER

15-15

www.emanualpro.com

Page 812 of 1395

Rear Differential Assembly

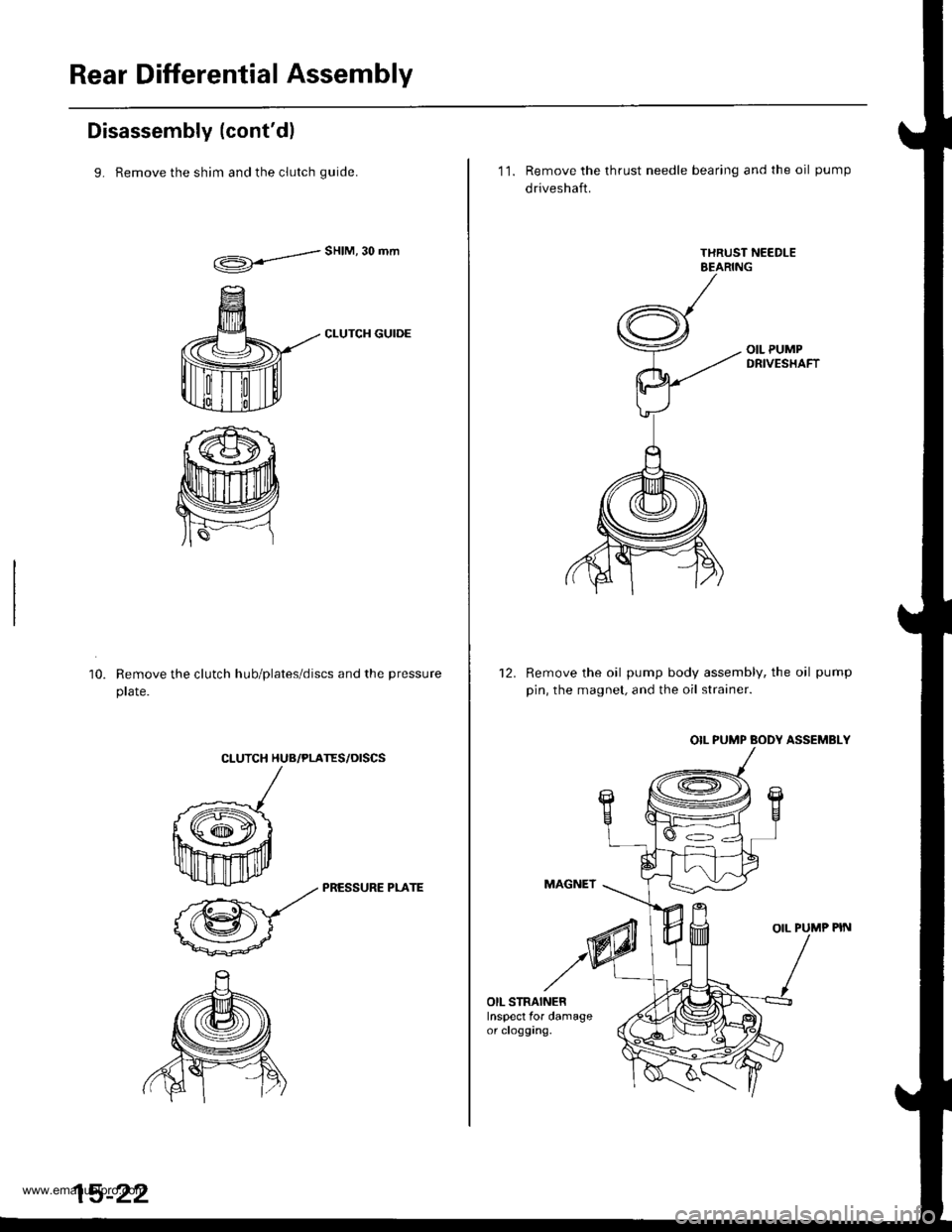

Disassembly (cont'dl

9. Remove the shim and the clutch quide.

d"HIM'30mm

CLUTCH GUIDE

Remove the clutch hub/plates/discs and the pressure

prare.

10.

CLUTCH HUB/PLATES/OISCS

k

ffi-:*

_zz PRESSURE PLArE

@-

15-22

11. Remove the thrust needle bearing and the oil pump

driveshaft.

Remove the oil pump body assembly, the oil pump

pin, the magnet, and the oil strainer.

OIL PUMP BODY ASSEMBLY

MAGNET

OIL PUMP PIN

12.

OIL STRAINERInspect for damageor clogging.

www.emanualpro.com

Page 814 of 1395

Rear Differential Assembly

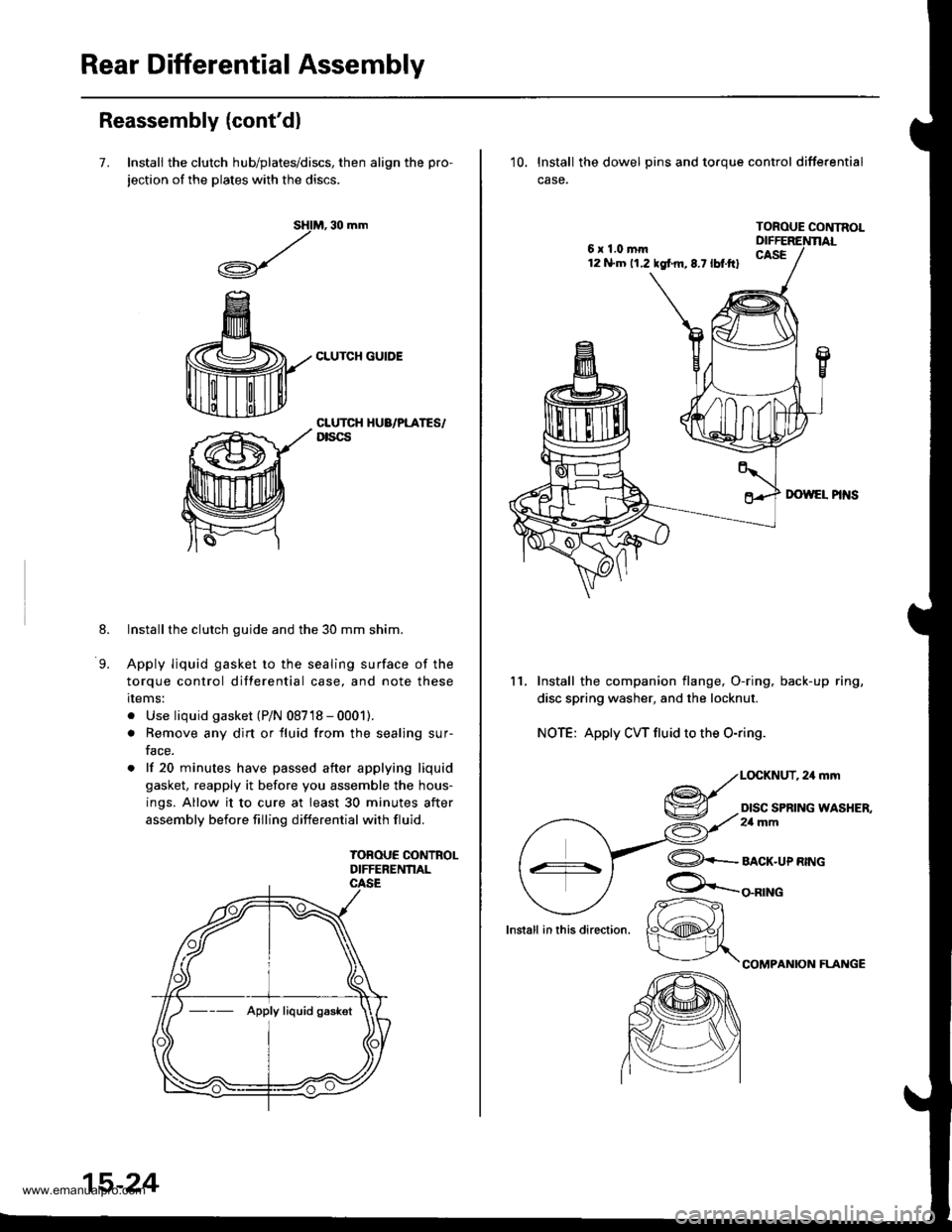

Reassembly (cont'dl

7. Install the clutch hub/plates/discs, then align the pro-

jection of the plates with the discs.

M, 30 mm

CLUTCH GUIDE

sHl

,/

.A-\,/r\-7

8.

9.

CLUTCH HUA/PLATES/Dtscs

Installthe clutch guide and the 30 mm shim.

Apply liquid gasket to the sealing surface of the

torque control differential case, and note these

rlems:

. Use liquid gasket (P/N 08718 - 0001).

. Remove any dirt or fluid from the sealing sur-

face.

. lf 20 minutes have passed after applying liquid

gasket, reapply it before you assemble the hous-

ings. Allow it to cure at least 30 minutes after

assembly before filling differential with fluid.

TOBOUE CONTROLDIFFERENNAL

--- Apply liquid gaskot

15-24

6x1.0mm12 N.m 11.2 tgf m,8.7lbt.ftl

10. lnstall the dowel pins and toroue control differential

case.

TOROUE CONTNOL

11. Install the companion flange, O-ring, back-up ring,

disc spring washer, and the locknut.

NOTE: Apply CW fluid to the O-ring.

,24mm

DISC SPRING WASHER,2a mm

lnstall in this direction.

@+-_alcr-upnwc

COMPANION FLAI{GE

/r-

K@#/

www.emanualpro.com

Page 934 of 1395

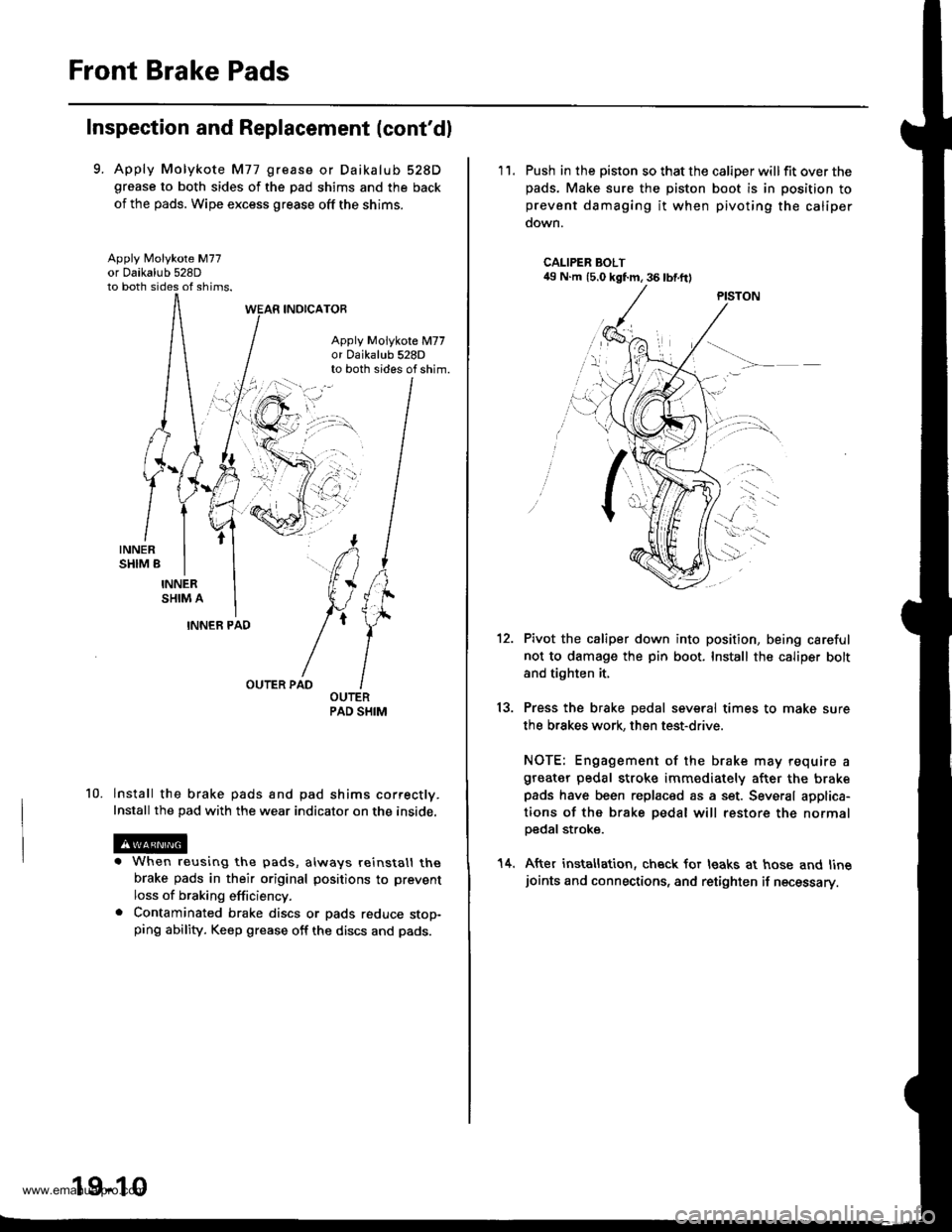

Front Brake Pads

Inspection and Replacement (cont'dl

9. Apply Molykote M77 grease or Daikalub 528Dgrease to both sides of the pad shims and the back

of the pads. Wipe excess grease off the shims.

Apply Molykote M77

to both sides of shims.

INOICATOR

Apply Molykote M77or 0aikalub 528Dto both sides of shim.

10.

INNER PAD

OUTER PAD

lnstall the brake pads and pad shims correctly.

Install the pad with the wear indicator on the inside.

. When reusing the pads, always reinstall thebrake pads in their original positions to prevent

loss of braking efficiency.. Contaminated brake discs or pads reduce stop-ping ability. Keep grease off the discs and pads.

19-10

'11. Push in the piston so that the caliper willfit over thepads. Make sure the piston boot is in position toprevent damaging it when pivoting the caliper

down.

CALIPER BOLT49 N.m (5.0 kgf.m, 36 lbf.ftl

13.

Pivot the caliper down into position, being careful

not to damage the pin boot. Install the caliper bolt

and tighten it,

Press the brake pedal several times to make sure

the brakes work, then test-drive.

NOTE: Engagement of the brake may require agreater pedal stroke immediately after the brakepads have been replaced as a set. Several applica-

tions of the brake pedal will restore the normalpedal stroke.

After installation, check for leaks at hose and linejoints and connections, and retighten if necessary.

14.

www.emanualpro.com

Page 936 of 1395

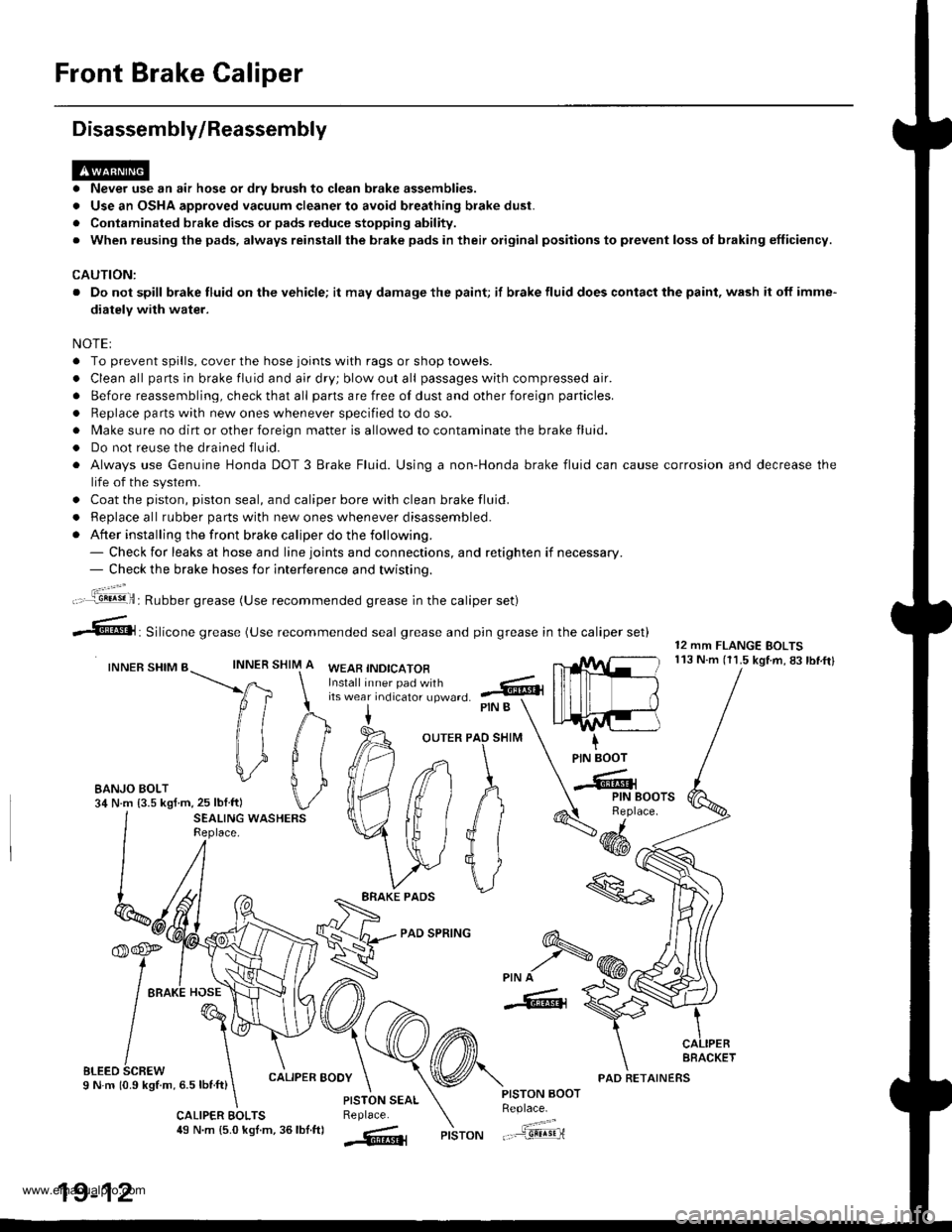

Front Brake Caliper

Disassembly/Reassembly

. Never use an air hose or dry brush to clean brake assemblies.

. Use an OSHA approved vacuum cleaner to avoid breathing brake dust.

. Contaminated brake discs or pads reduce stopping ability.

. When reusing the pads, always reinstallthe brake pads in their original positions to prevent loss ol braking efficiency.

CAUTION:

. Do not spill brake fluid on the vehicle; it may damage the paint; if brake fluid does contact the paint, wash it off imme-

diatelY with water.

NOTEI

. To prevent spills, cover the hose joints with rags or shop towels.

. Clean all pans in brake fluid and air dry; blow out all passages with compressed air.

. Before reassembling, check that all parts are free of dust and other foreign particles.

. Replace parts with new ones whenever specified to do so.

. Make sure no dirt or other foreign matter is allowed to contaminate the brake fluid.

. Do not reuse the drained fluid.

. Always use Genuine Honda DOT 3 Brake Fluid. Using a non-Honda brake fluid can cause corrosion and decrease the

life of the system.

. Coat the piston, piston seal, and caliper bore with clean brake fluid.

. ReDlace all rubber oarts with new ones whenever disassembled.

. After installing the front brake caliper do the following.- Check for leaks at hose and line joints and connections, and retighten if necessary.- Check the brake hoses for interference and twistinq.

SHIM

12 mm FLANGE BOLTS113 N.m (11.5 kgtm,83lbf.ftlINNER

ft

il1

#

\i

#

PIN B

OUTER PAO SHIM

PAD SPRING

IPIN BOOT

-Cr

SEALING WASHERSReplace.4dd*

ERAKE PADS

'f,-rre

/ tto*l "o"\

t@I

/\'

sLreo 6cnew \I N m 10.9 kStm, 6.5 lbnft)

\

6-

>PIN A

-6, {

CALIPER BOOY

CALIPER EOLTS49 N.m {5.0 kgl.m, 36lbf.ftl

PISTON AOOTReplace.

"..-a=a-...,--"sEqriPISTON

t".:jil,,.'.1!!!!9!il: Rubber grease (Use recommended grease in the caliper set)

irf"i:;;T::fl,-J'I",0 .@

--6, Silicone grease (use recommended seal grease and p,n grease in the caliper set)

INNER SHIM BWEAB INDICATOR

EANJO BOLT34 N.m {3.5 kgf m,25 lblftl

PISTON SEALReplace.

AFACKET

19-12

PAD RETAINERS

www.emanualpro.com

Page 948 of 1395

Anti-lock Brake System (ABSI,'97 - 00 Models

Special Tools ............. 19-26

Component Locations ......................... 19-27

Anti-lock Brake System (ABS)

Features/Construction ............. ......, 19-2A

Circuit Diagram ......... 19-32

ABS Control Unit Terminal

Arrangement ......... 19-34

Troubleshooting Precautions ............. 19-36

Diagnostic Trouble Gode (DTC)

Diagnostic Trouble Code (DTC)

Indication (SCS Model ................ 19-38

DTG Erasure (MES Mode) ............... 19-39

Troubleshooting lndex .................... 19-40

Troubleshooting

ABS Indicator Light Does Not

Come On ............ 19-41

ABS Indicator Light Does Not

Go Off (No DTC) ........................... 19-43

DTC 1r - 18:

Wheel Sensor .... 19-45

DTC 31 - 38:

Solenoid ............. 19-47

DTC 51 - 53:

ABS Pump Motor ......................... 19-49

DTC 54:

Main Relay ......... 19-52

DTC 61:

lgnition Voltage ........................... 19-54

DTC 81:

Central Processing Unit (CPU) .... 19-55

Modulator Unit

Removal/lnstallation ....................... 19-56

ABS Control Unit

Replacement ..,...... 19-57

Pulsers/Wheel Sensors

Inspection .............. 19-57

Wheel Sensor Replacement ............ 19-58

www.emanualpro.com

Page 949 of 1395

SpecialTools

Rel. No. I Tool NumberDescriptionOty Page Relerence

o07PAZ - 0010100SCS Service Connector119-38

19-26

www.emanualpro.com