Troubleshooting HONDA CR-V 1998 RD1-RD3 / 1.G Service Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1998, Model line: CR-V, Model: HONDA CR-V 1998 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 575 of 1395

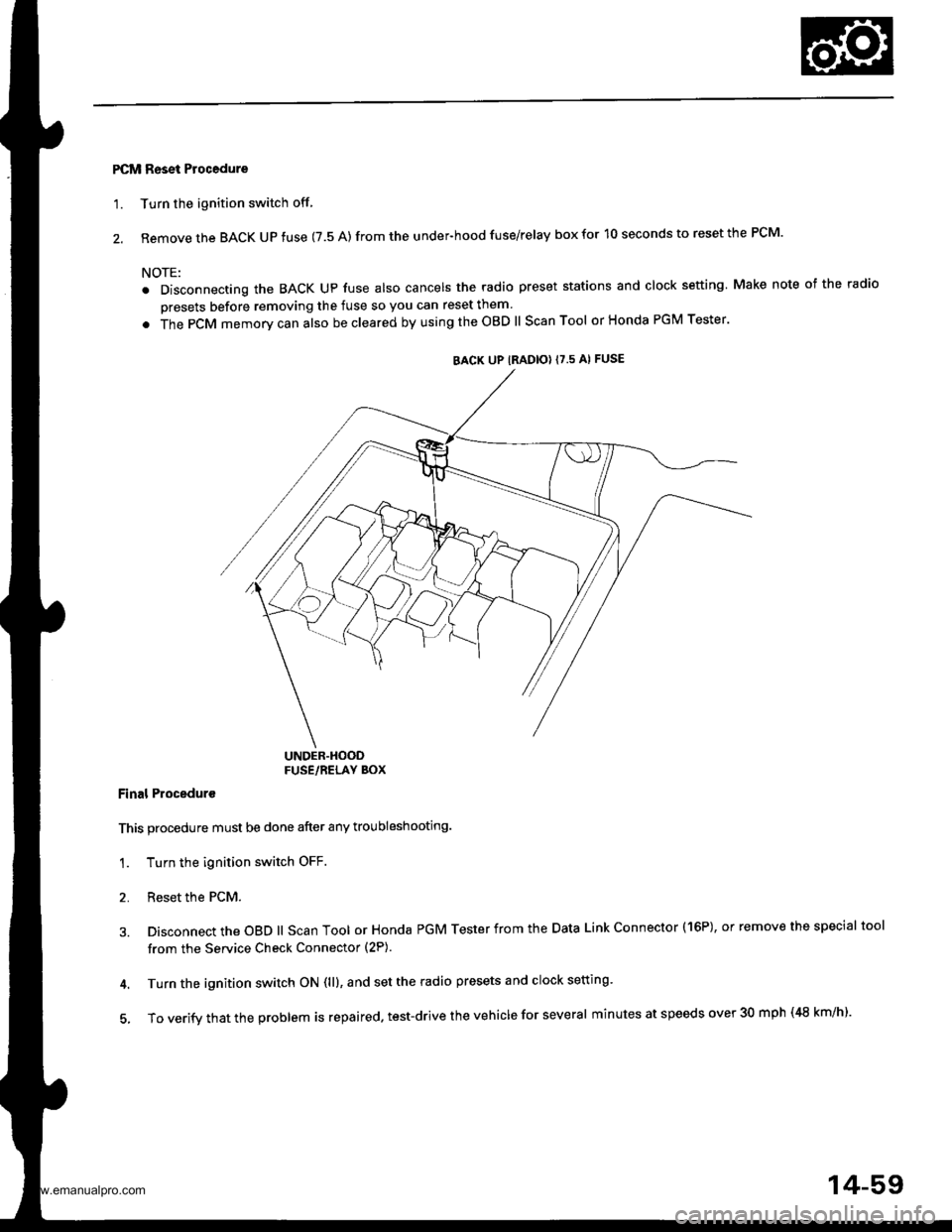

PCM Reset Procedure

'1. Turn the ignition switch off

2. Remove the BACK UP fuse (7.5 A) from the under-hood fuse/relay box for 10 seconds to reset the PCM.

NOTE:

. Disconnecting the BACK Up fuse also cancels the radio preset stations and clock setting Make note of the radio

presets before removing the fuse so you can reset them

. The PCM memorv can also be cleared by using the OBD ll Scan Tool or Honda PGM Tester'

UNDER.HOODFUSE/RELAY BOX

Final Proceduro

This procedure must be done after any troubleshooting.

1. Turn the ignition switch OFF.

2. Reset the PCM.

3. Disconnect the OBD ll Scan Tool or Honda PGM Tester from the Data Link Connector (16P), or remove the special tool

from the Service Check Connector (2P).

4. Turn the ignition switch ON (ll), and set the radio presets and clock setting'

5, To verify that the problem is repaired. test-drive the vehicle for several minutes at speeds over 30 mph (48 km/h).

BACK UP IRADIO} {7.5 AI FUSE

14-59

www.emanualpro.com

Page 580 of 1395

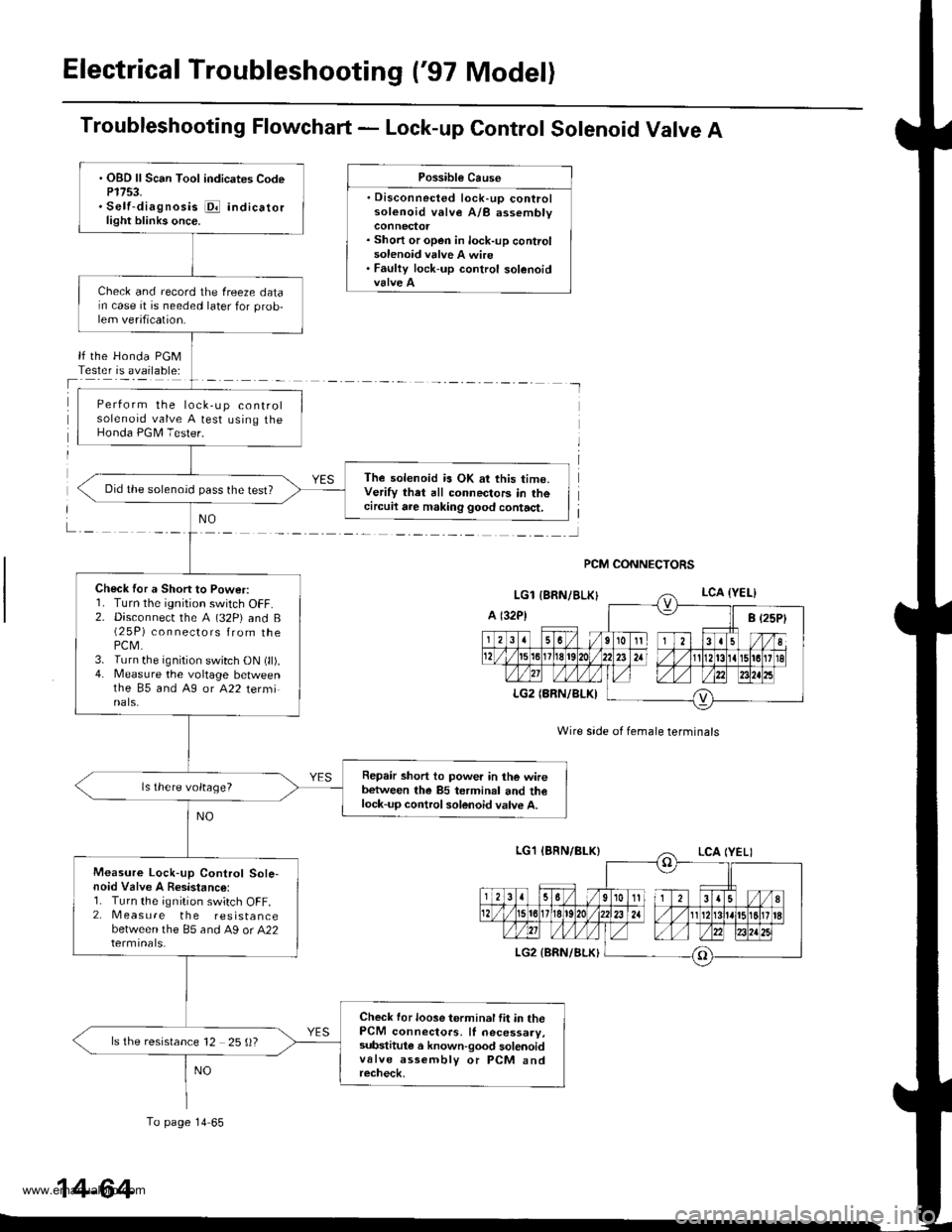

Electrical Troubleshooting ('97 Model)

Troubleshooting Flowchart - Lock-up Control Solenoid Valve A

Possible Cause

. Disconnected lock-up controlsolenoid valve A/B assembly

. Short or open in lock-up controlsolenoid valve A wire. Faulty lock-up control solenoid

lf the Honda PGMTester is available:

NO

Wire side of female terminals

PCM CONNECTORS

. OBD ll Scan Tool indicates CodeP1753.. Self-diagnosis i@ indicatorlight blinks once.

Check and record the freeze datarn case it is needed later for prob-lem verification.

Perform the lock,up controlsolenoid valve A test using theHonda PGM Tester.

The solenoid is OK at this time.Verify that all connectors in thecircuil are making good contact,

Did the solenoid pass the test?

Check for a Short to Power:r. I urn rne tgntUon swttch ut-f.2. Disconnecr the A (32P) and B(2 5P) connectors from thePCM.3. Turn the ignition switch ON (ll).4. Measure the voltage betweenthe 85 and A9 or A22 terminals.

Repair short to power in the wirebetween the 85 terminal and thelock-up control solenoid valve A.

ls there voltage?

Measure Lock-up Control Sole-noid Valve A Resistance:1. Turn the ignition switch OFF.2. Measure the resistancebetween the 85 and A9 or A22

Check for loose terminal fit in thePCM connectors, ll necessary,substitule a known-good solenoidvalve assembly or PCM andrecheck,

ls the resistance 12 25 ()?

To page 14 65

14-64

www.emanualpro.com

Page 582 of 1395

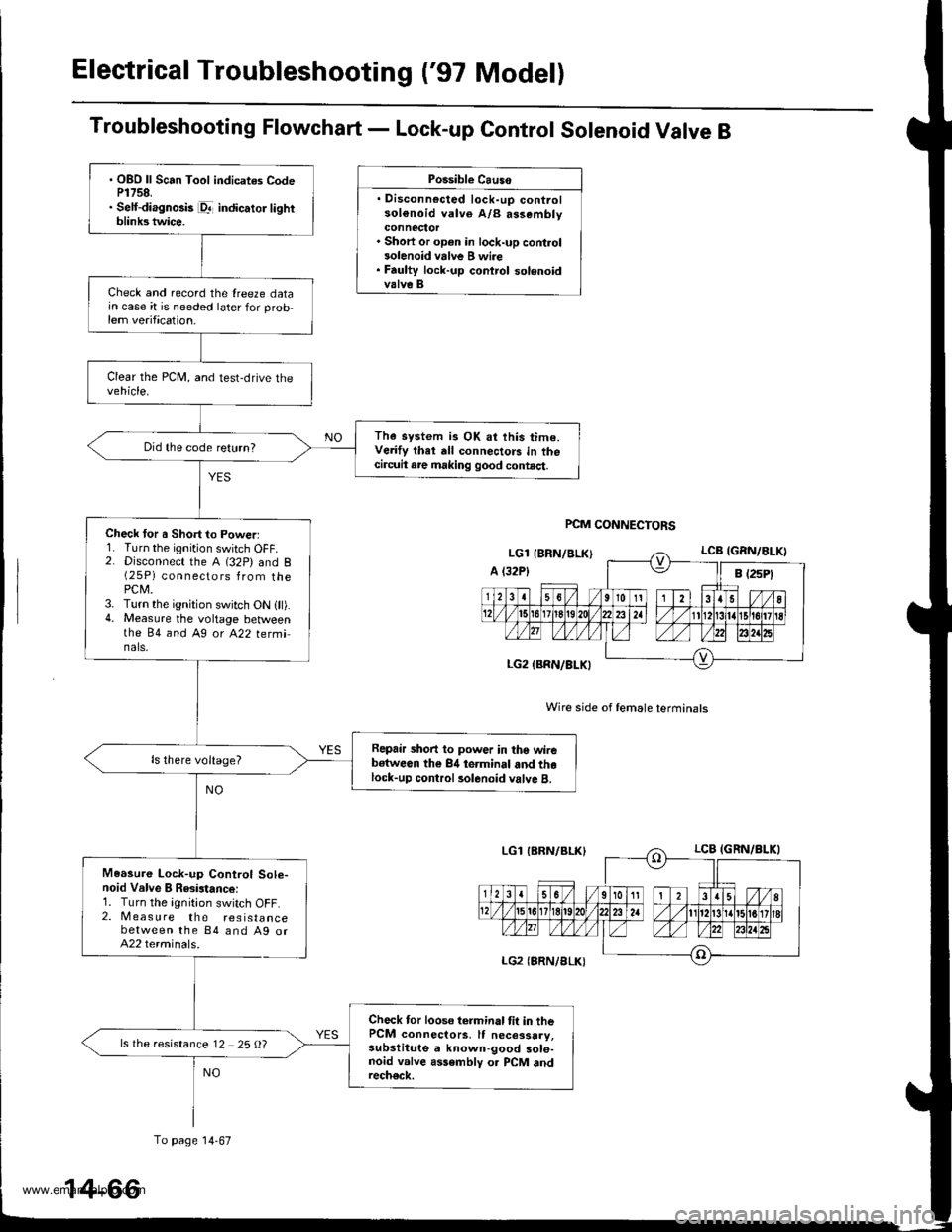

Electrical Troubleshooting ('97 Model)

Troubleshooting Flowchart - Lock-up Control Solenoid Valve B

Possible Causo

. Disconnocted lock-up controlsol€noid valve A/B assembly

. Short or op€n in lock-up control3olenoid vrlve B wi.e. Faulty lock-up control solenoidvalve B

Wire side of female terminals

PCM CONNECTORS

. OBO ll Scan Tool indicates CodeP1758.. Self-diagnosis pr- indicator lightblink3 twice.

Check and record the {reeze datajn case it is needed later for prob,lem verification.

The system is OK at this time.Verify thet dll connectors in thecircuit are making good contact.

Did the code return?

Check tor a Short to Powerl1. Turn the ignition switch OFF.2. Disconnect the A (32P) and B(25P) connectors from thePCM.3. Turn the ignition switch ON {ll).4. Measure the voltage betweenthe 84 and Ag ot A22 tetminals,

Repair short to power in tho wirebstween the 84 terminal and thelock-up control rolenoid valve B.

Measure Lock-up Control Sole-noid Valve B Resistance:1. Turn the ignition switch OFF.2. Measure the resistancebetween the 84 and Ag orA22 terminals.

Check tor loose terminal tit in thePCM connectors, It necessary,subslitute a known-good sole-noid valve assembly o. PCM andrech€ck.

ls the resistance 12 25 O?

To page 14-67

14-66

www.emanualpro.com

Page 584 of 1395

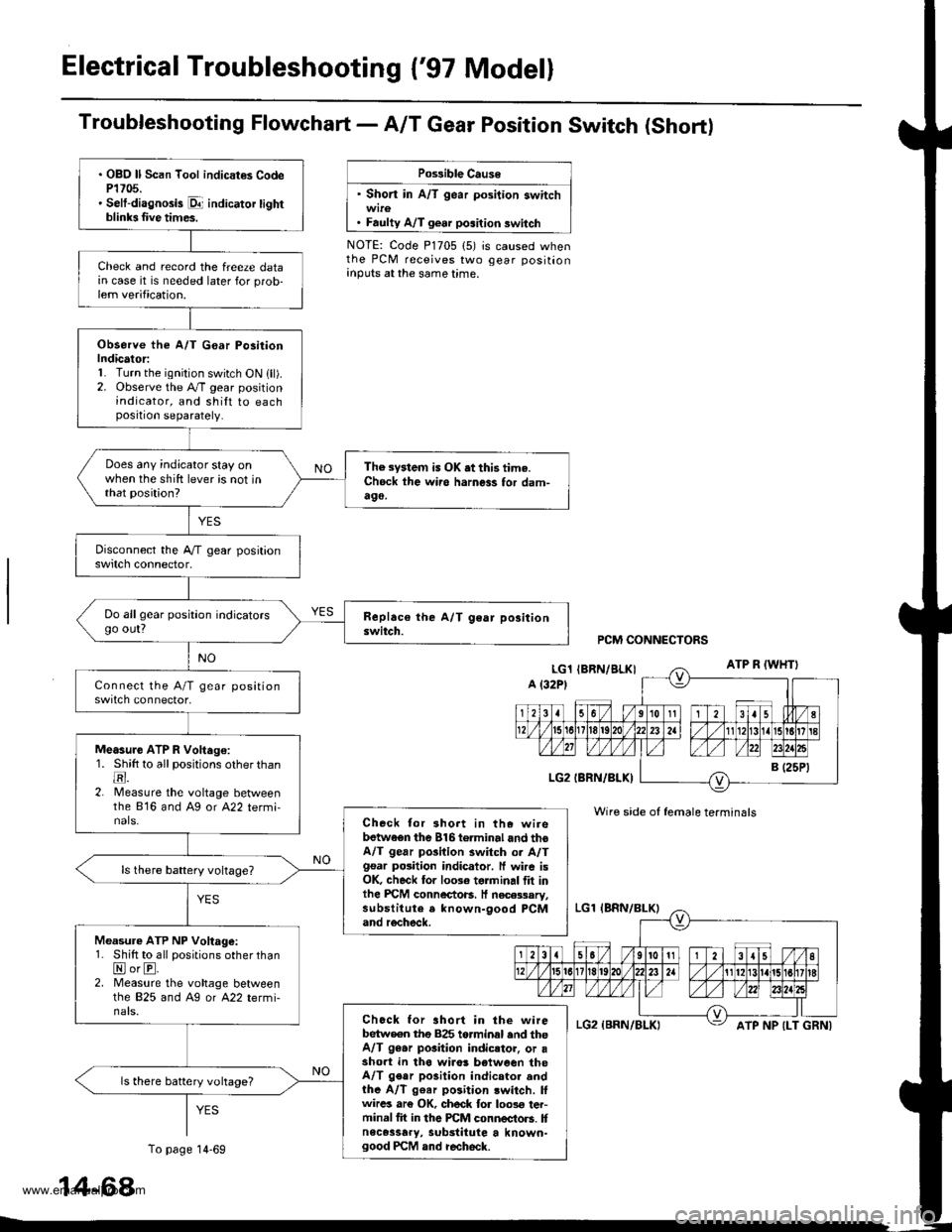

Electrical Troubleshooting {'97 Model}

Troubfeshooting Flowchart- AIT Gear Position Switch (Short)

Po$ible Cause

' Short in A/T gear position switch

. Faulty A/T gear position switch

NOTE: Code P1705 (5) is caused whenthe PCM receives two gear positionanputs at the same time.

. OBO ll Scan Tool indicat€s CodeP1705.' Selt-diagnosis p1- indicator tightblinb Iive times.

Check and record the freeze datain case it is needed later for prob-lem verification.

Observe the A/T G€ar Po3itionIndicator:1. Turn the ignition switch ON lll).2. Observe the A./T gear positionindicator, and shilt to eachposition separately.

Does any indicator stay onwhen the shift lever is not inthat position?

The system is OK .t this time.Ch6ck ihe wii6 harness for dam-490,

Do allgear position indicatorsgo out?

Measure ATP R Voltago:1. Shitt to all positions other thantr.2. lMeasure the voltage betweenthe 816 and Ag or A22 termi-nals.Check tor 3hort in the wirebetwaen the 816torminal and thoA/T gear pGilion switch or A/Tgsar posiiion indicator. ff wire isOK, check for 10036 torminal flt inlhe PICM connectoB. It necessary,substitute a known-9ood PCMand recheck.

Measure ATP NP Voltage:1. Shift to all positions other thanNorE.2. Measure the vohage betweenlhe 825 and Ag or A22 termi-nals.Chock for ahort in the wirebetw€en tho 825 torminal end theA/T 96.r pGition indicstor, or asho.t in tha wiro! b€tween theA/T gear po3ition indicator andthe A/T g€ar position lwitch. lfwircs ar€ OK, ch6ck for loos€ ter-minal fit in the PCM connectors. Itnece3sary, substitute a known-good PCM and recheck.

ls there battery vohage?

PCM CONNECTORS

Wire side of female terminals

ATP NP {LT GRNI

14-68

To page 14-69

www.emanualpro.com

Page 586 of 1395

Electrical Troubleshooting ('97 Model)

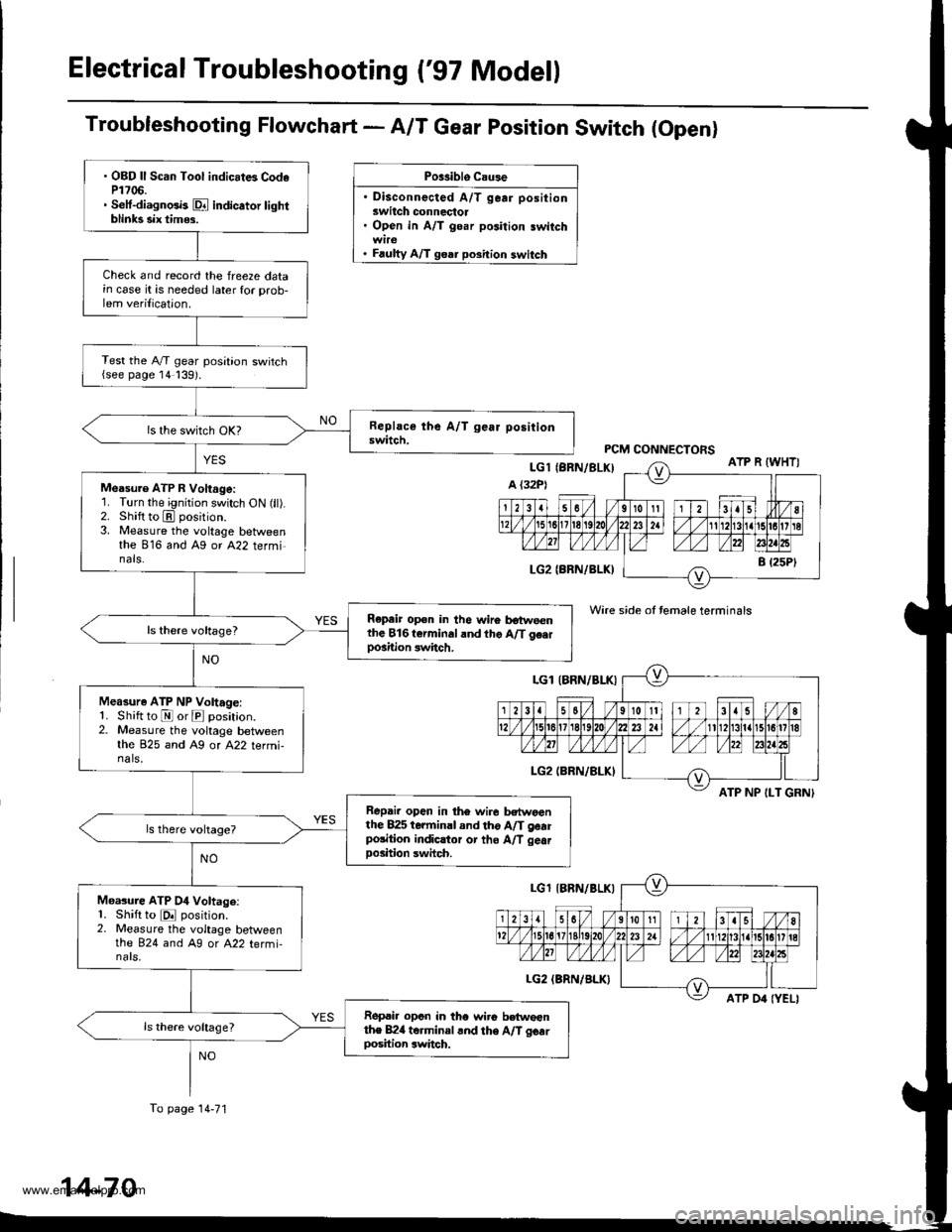

Troubleshooting Flowchart - A/T Gear position Switch (Openl

Po$iblo C.u3e

. Disconnected A/T gear positionswitch connectol. Open in A/T goar position switch

. Faulty A/T goar position switch

Wire side ot temale terminals

ATP NP ILT GRNI

. OBD ll Scan Tool indicat6 CodeP1706.. Setf-diagnGb Dl indicator tightblinks six tim$.

Check and record the freeze datain case it is needed later for prob-lem verilication.

Test the A,/T gear position switch{see page 14139).

Measu.e ATP R Voltage:'1. Turn the ignition switch ON (ll).2. Shift to E position.3. Measure the voltage betweenthe 816 and Ag or A22 termi-nals.

Repeir op€n in the wire botweenthe 816t€rminaland the A/T g€.rpo3ition switch.

Measure ATP NP Voltage:1. Shift to E or E position.2. Measure the voltage betweenthe 825 and A9 or A22 termi-na ls,

Repai. open in th6 wir6 bctwoanthe 825 terminal and tho A/T gearpolition indicltor or tho A/T gea.Doshion swhch.

Moasure ATP 04 Voltage:1. Shift to E position.2. Measure the voltage betweenthe 824 and A9 or A22 termi-nars,

Ropai. opcn in tho wiro betwoenthe B24 torminal .nd the A/T gcarDosition switch.

To page 14-71

14-70

www.emanualpro.com

Page 588 of 1395

Electrical Troubleshooting ('97 Model)

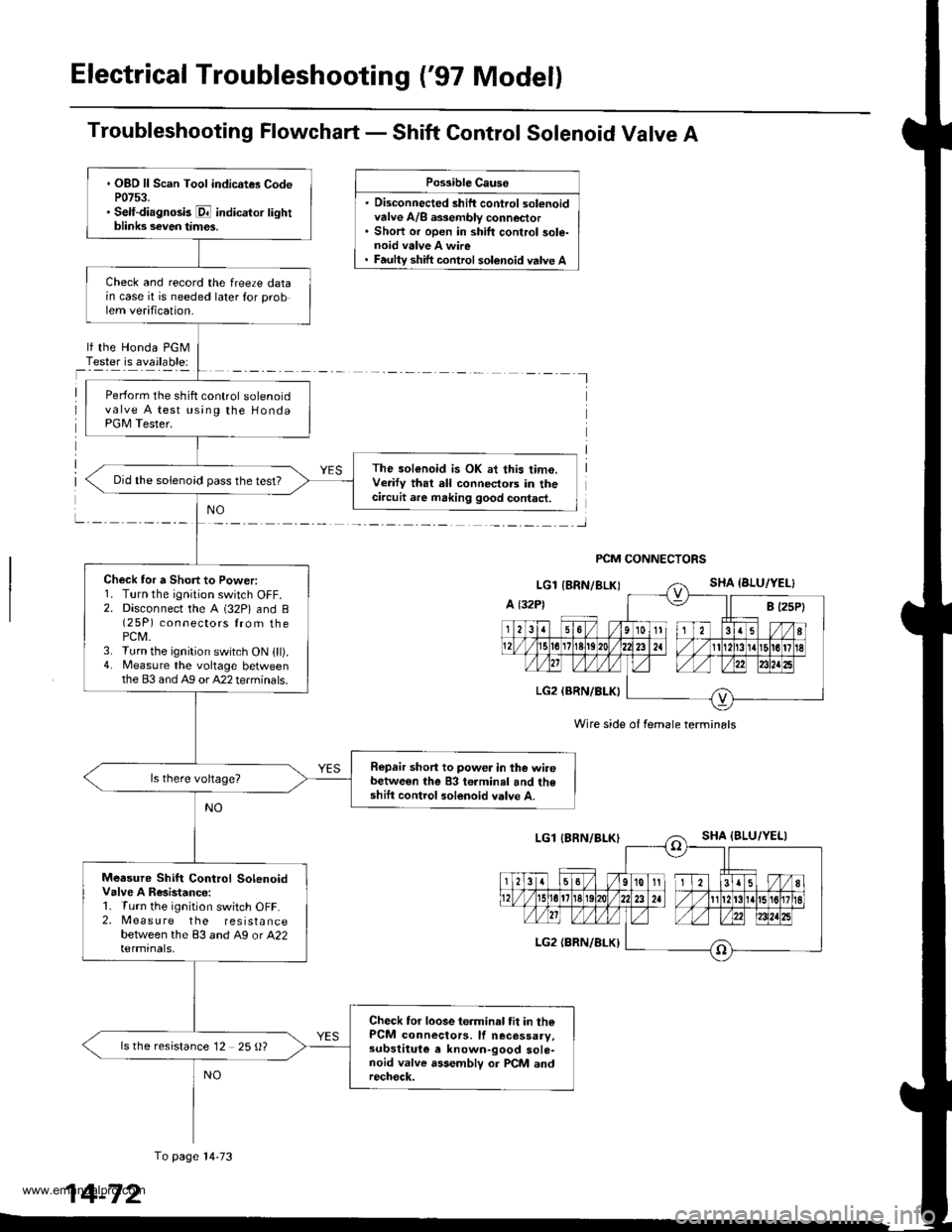

Troubleshooting Flowchart - Shift Control Solenoid Valve A

. Disconnected shift control solenoidvalve A/8 a$embly connector. Short or open in shift control sole-noid valve A wire

Possible Causo

shift control solenoid valve A

lf the Honda PGMTester is available:

I

PCM CONNECTORS

Wire side of female termin6ls

. OBD ll Scan Tool indicates CodeP0753.. Self-diagnosk E indicator lightblinks seven tim€s.

Check and record the freeze datain case it is needed later for problem verification.

Perform the shift control solenoidvalve A test using the HondaPGM Tester.

The sol€noid is OK at this time.Verify that all connectors in thecircuit are making good contact.

Did the solenoid pass the test?

Check tor a Short to Power:1. Turn the ignition switch OFF.2. Disconnect the A (32P) and B(2 5P) connectors from thePCM.3. Turn the ignition switch ON lll).4. Measure the voltage betweenthe 83 and Ag or A22 terminals.

Repair short to power in the wirebetween the 83 terminal and theshift control solenoid valve A.

Measure Shift Control SolenoidValve A Resistanco:1. Turn the ignition switch OFF.2, Measure the resistancebetween the 83 and A9 or A22termrnals,

Check tor loose terminal tit in thePCM connectors, lf necessaay,subslituie e known-good sole-noid valve assemblv or PCM andrech€ck.

ls the resistance 12 25 {)?

To page l4-73

14-72

www.emanualpro.com

Page 590 of 1395

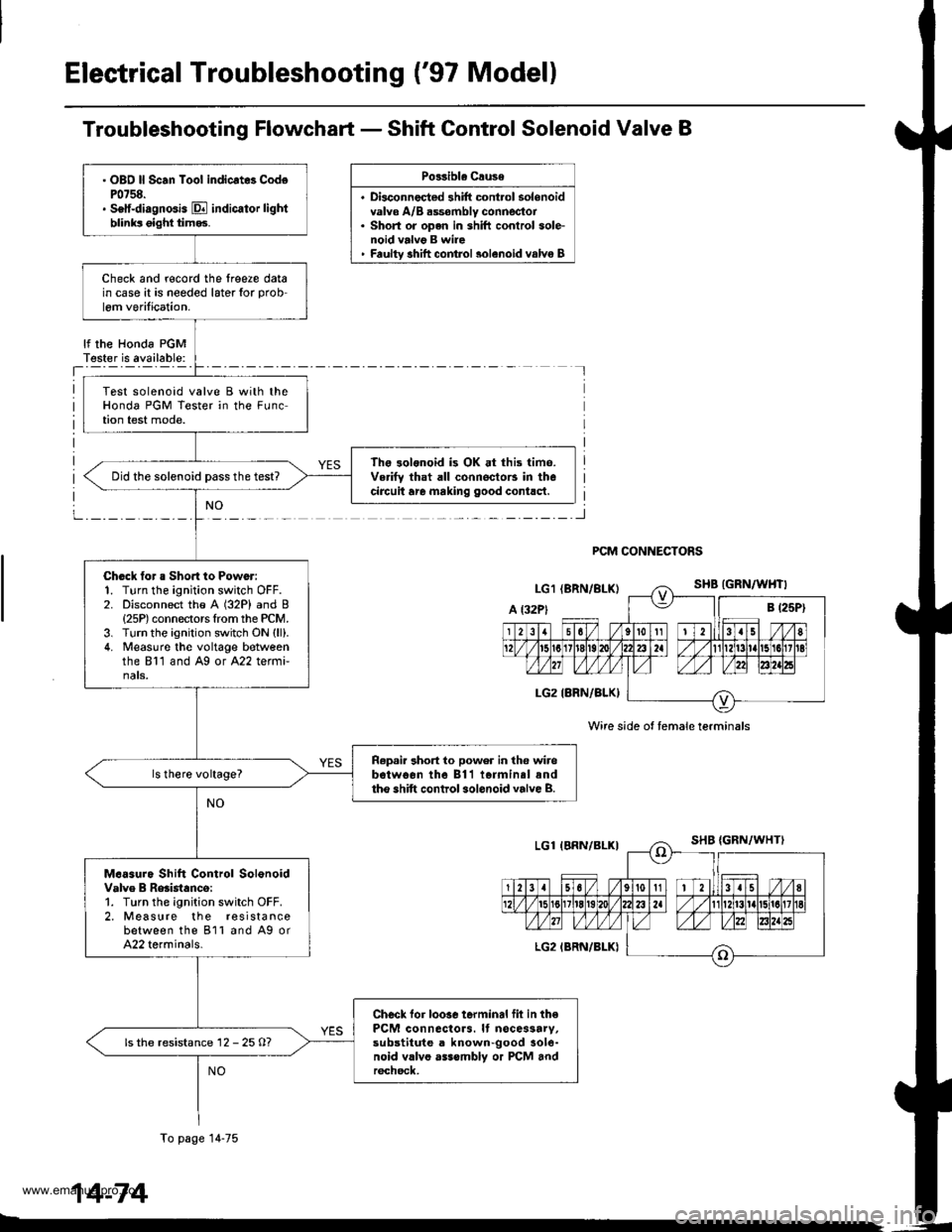

Electrical Troubleshooting ('97 Model)

Troubleshooting Flowchart - Shift Control Solenoid Valve B

Po33ibla Crusa

. Disconnec{ed shift cont.ol solenoidvalve A/B dssombly connector. Short or open in shift conlrol sole-noid valvg B wire' Faultv shift comrol 3olenoid valvo B

lf the Honda PGMT€ster is available:

PCM CONNECTORS

Wire side ot female terminals

. OBO ll Scan Toot indicrt8 CodoP0758.. Setf-diagnGis E indicator lightblinks oight tim93.

Check and r€cord the lreere datain case it is needed later for prob

lem verilication.

Test solenoid valve B with theHonda PGM Tester in the FLrnction test mode.

The 3olonoid is OK at this time.Verifv that all connoctors in thecircuit are making good contlct.Did the solenoid Dass the test?

Chock tor a Sho.t to Power:1. Turn the ignition switch OFF.2. Disconnect the A (32P) and B{25P) connectors Irom the PCM.3. Turn the ignition switch ON (ll).

4. Measuro the voltage botveenthe 811 and Ag or A22 termi-nats.

R.p.ir 3hort to power in the wirebotwo€n the 811 iormin.l andtho shift control sol.noid valve B.

M.6sure Shift Control SolonoidValve B Reaistanco:1. Turn the ignition switch OFF.2. Measure the r€sistancebetween the 811 and A9 orA22 terminals.

Checl lor loosc terminal fil in thePCM connactors. It nocessarv,substitute a known-good aole-noid vllvo asssmbly or PCM andr6chsck,

ls the resistance 12 - 25 O?

To page 14-75

14-74

www.emanualpro.com

Page 592 of 1395

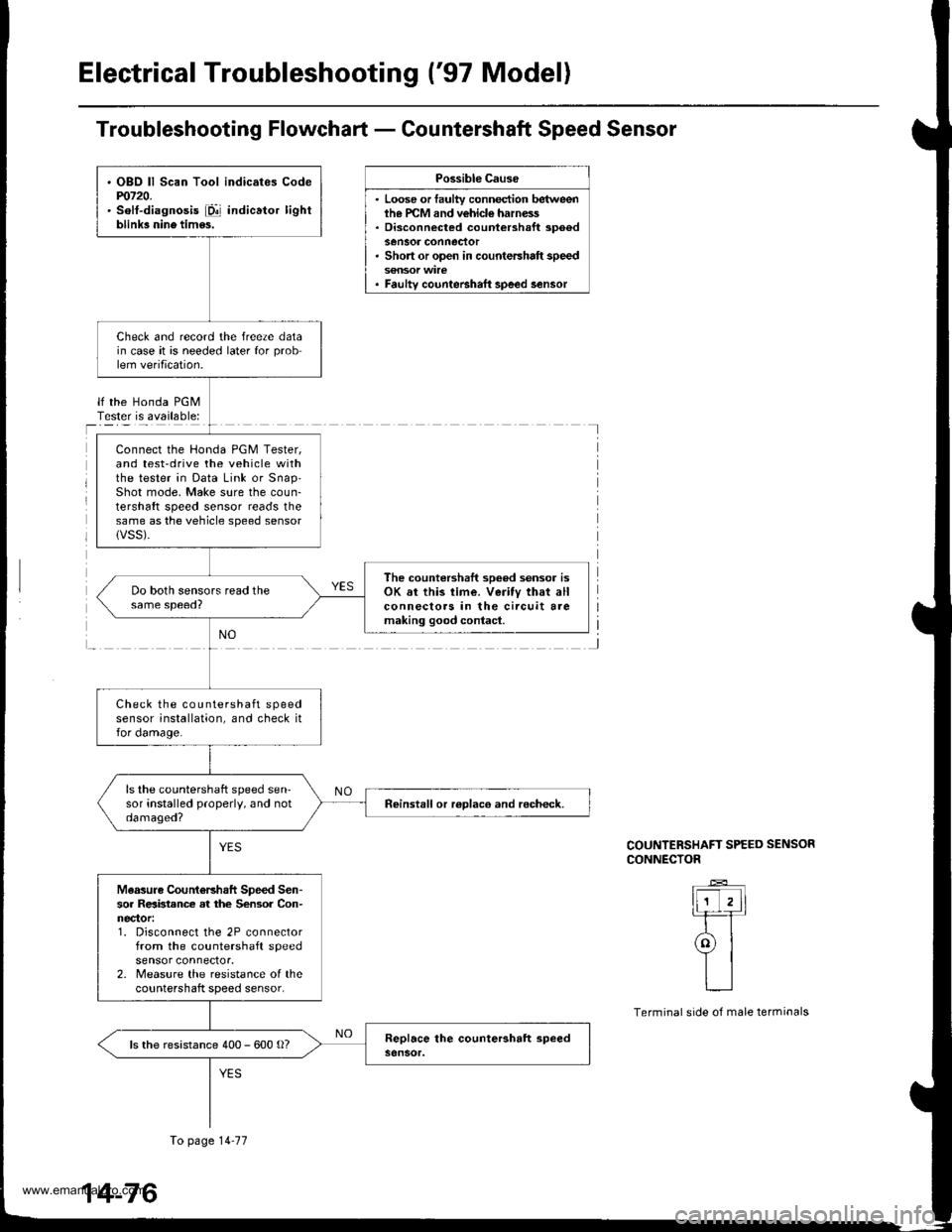

Electrical Troubleshooting ('97 Model)

Troubleshooting Flowchart - Countershaft Speed Sensor

Possible Cause

. Loose or faulty connection betweenih€ PCM and vehicle harness. Disconnected countershaft spoedsensor conneclor. Short or open in countershaft speed

. Faulty counteBhaft speed lensor

lf the Honda PGMTester is available:I

J

COUNTERSHAFT SPEED SENSOR

CONNECTOR

ll-'T,ll-rT

ral

YIL__l

Terminal side of male terminals

. OBO ll Scan Tool indicates Codem720.' solt-diagnosis iD!' indicator lightblink3 nine tim6s.

Check and record the freeze datain case it is needed later for problem verification.

Connect the Honda PGM Tester,and test-drive the vehicle withthe tester in Data Link or snap'Shot mode, Make sure the coun-tershaft speed sensor reads thesame as the vehicle speed sensorlVSS).

The countershaft sooed sensor isOK sr this time. Veritv that allconnecloas in the circuit aremaking good contacl.

Check the countershaft speedsensor installation, and check itfor damage.

ls the countershaft speed sen-sor installed properly, and notdamaged?neinstall or roDlaco and recheck.

Measuro CountoBhaft Speed Sen-sor Relbtance at the Sensor Con-nector:1. Disconnect the 2P connectorfrom the countershaft speedsensor connector.2. Measure the resistance of thecountershaft speed sensor.

ls the resistance 400 - 600 o?

To page 14-77

14-76

www.emanualpro.com

Page 594 of 1395

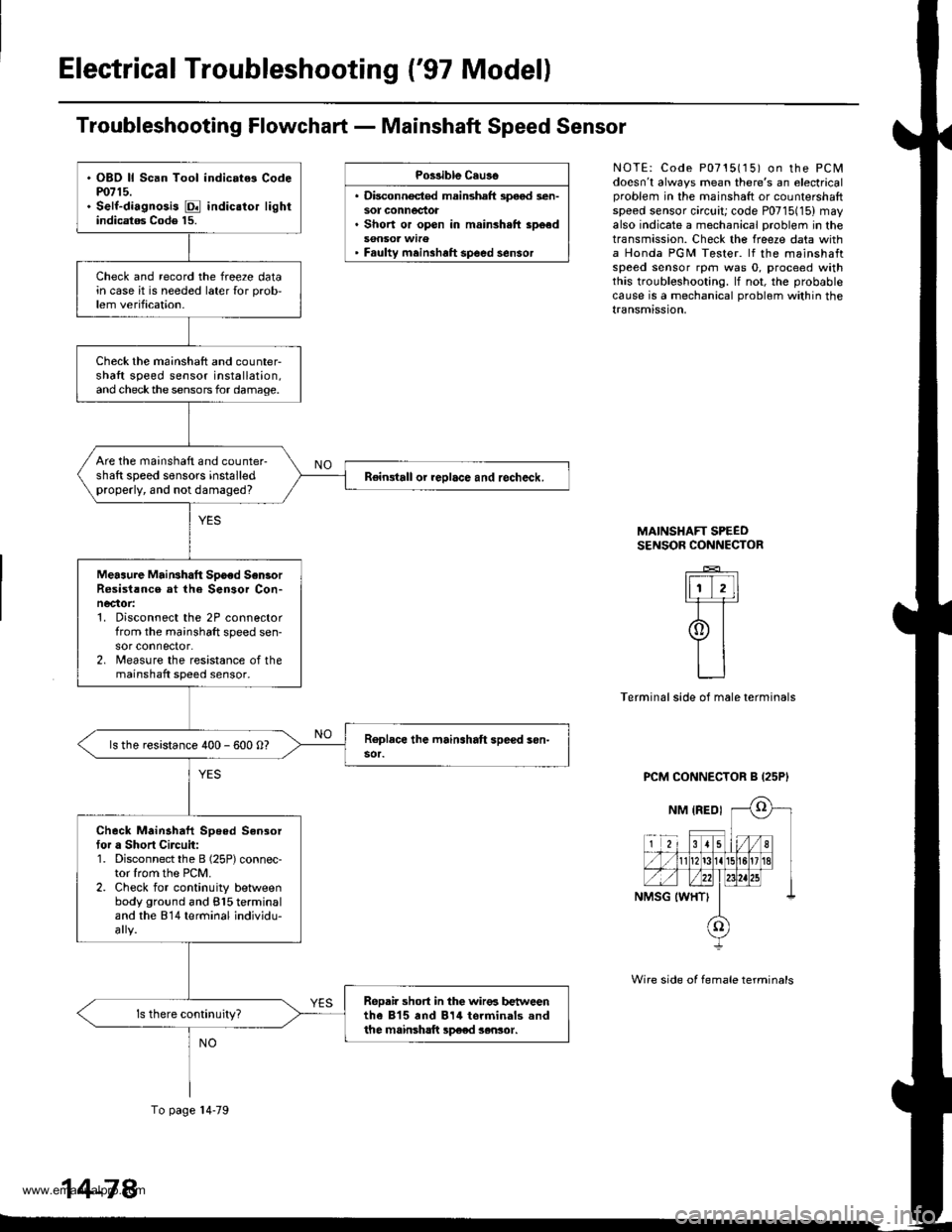

Electrical Troubleshooting {'97 Model)

Troubleshooting Flowchart - Mainshaft Speed Sensor

Po$ible Cau3o

. Disconnocted mainshaft speod sen-sot connectot. Short or open in mainsh.ft sp6ed

' Faulty meinshaft spoed sensor

NOTE: Code P0715115) on the PCMdoesn't always mean there's an electricalproblem in the mainshaft or counlersharlspeed sensor circuit; code P0715(15) mayalso indicate a mechanical problem in thetransmission. Check the freeze data witha Honda PGM Tester. lf the mainshaftspeed sensor rpm was 0, proceed withthis troubleshooting. lf not, the probablecause is a mechanical problom within thetransmission,

MAINSHAFT SPEEOSENSOR CONNECTOR

_E_

ItiT,ll-F=r

9t

LJ

Terminal side of male terminals

PCM CONNECTOR B {25P'

Wire side of female terminals

. OBD ll Scan Tool indic.t6 Codem715.. Self-diagnosis E indic.tor lightindicatag Code 15.

Check and record the freeze datain case it is needed later {or prob,lem verification.

Check the mainshaft and counter-shaft speed sensor installation,and checkthe sensors for damage.

Are the mainshaft and counter-shaft speed sensors installedproperly, and not damaged?Reingtall or reolace and recheck.

Meaaure MaiNhatt Spoed Sen3orR6sist!nce at the Sensor Con-necaor:1. Disconnect the 2P connectorfrom the mainshaft speed sen-sor connector.2. lreasure the resistance of themainshaft speed sensor.

ls the resistance 400 - 600 O?

Check Mainahaft Speed Sensortor a Short Circuit:1. Disconnect the B (25P) connec-tor lrom the PCM.2. Check for continuity betlveenbody ground and 815 terminaland the 814 terminal individu-

ReDair short in the wir€6 b€t reenthe 815 and 814 torminals andthe mainsh!ft sp€ed sensor.

To page l4-79

14-78

www.emanualpro.com

Page 596 of 1395

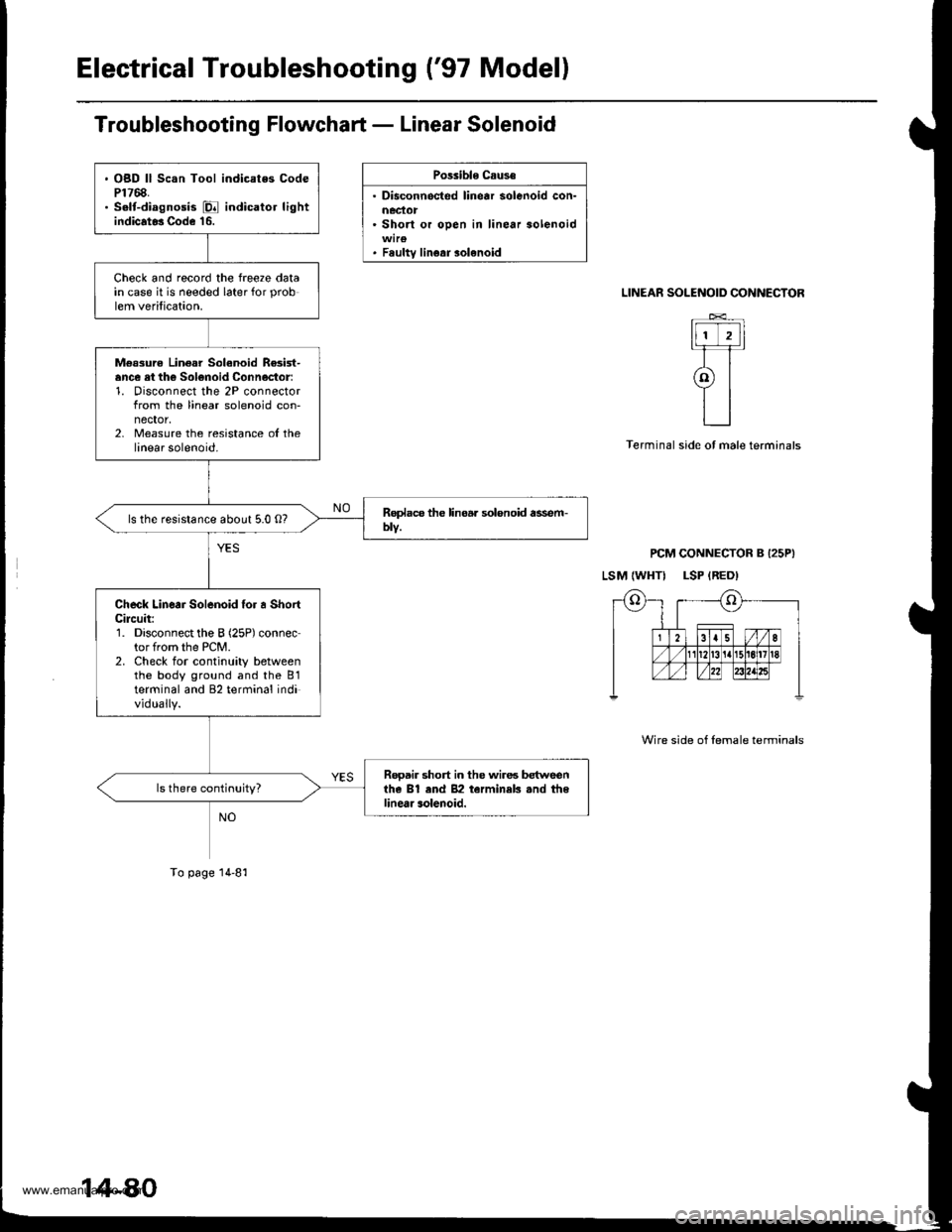

Electrical Troubleshooting ('97 Modell

Troubleshooting Flowchart - Linear Solenoid

Possible Caus€

. Disconnocted linear solenoid con-

. Short or oDen in linear solenoid

. Fsultv linear solenoid

SOLENOID CONNECTOR

t-TTI�t]]lt

tl I ? rl-T�r

atll

L_l

PCM CONNECTOR B I25PI

LSM {WHTI LSP {RED)

LINEAR

Terminal side ot male terminals

Wire side of lemale terminals

. OBD ll Scan Tool indicates CodeP1768.. S.lt-diagnosis E indicator lightindicat* Code 16.

Check and record the freeze datain case it is needed later for prob

lem verification.

M€ssurc Linear Solanoid Re3ist-ance ei th€ Solonoid Connoctor:1. Disconnect the 2P connectorfrom the linear solenoid con-nector,2, Measure the resistance ol thelinear solenoid.

ls the resistance about 5.0 O?

Check Linear Solenoid {or a ShortCileuit:1. Disconnect the B (25P) connector from the PCM.2. Check for continuity betweenthe body ground and the B1terminal and 82 terminal individually.

Rooair short in the wires betweenthe Bl end 82 terminek .nd thelinear solenoid.

To page 14-81

www.emanualpro.com