Troubleshooting HONDA CR-V 1998 RD1-RD3 / 1.G Owner's Guide

[x] Cancel search | Manufacturer: HONDA, Model Year: 1998, Model line: CR-V, Model: HONDA CR-V 1998 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 390 of 1395

![HONDA CR-V 1998 RD1-RD3 / 1.G Owners Guide

Fuel Supply System

PGM-FI Main Relay (contdl

Troubleshooting

lc(}21PGM.FI MAIN RELAY 7P CONNECTOR

GND

trTr]--Flq

FI,TilI A

Y

Wire side ot female terminals

- Engine will not start.- InsDection ol PG HONDA CR-V 1998 RD1-RD3 / 1.G Owners Guide

Fuel Supply System

PGM-FI Main Relay (contdl

Troubleshooting

lc(}21PGM.FI MAIN RELAY 7P CONNECTOR

GND

trTr]--Flq

FI,TilI A

Y

Wire side ot female terminals

- Engine will not start.- InsDection ol PG](/img/13/5778/w960_5778-389.png)

Fuel Supply System

PGM-FI Main Relay (cont'dl

Troubleshooting

lc(}21PGM.FI MAIN RELAY 7P CONNECTOR

GND

trTr]--Flq

FI,Til'I A

Y

Wire side ot female terminals

- Engine will not start.- InsDection ol PGM-FI mainrelay and relay harness,

Check fo. an open in the wireIGND linol:1. Turn the ignition switch OFF.2. Disconnect the PGM Fl mainrelay 7P connector.3. Check for continuity betweenthe PGM'FI main relay 7P con-nector terminal No. 3 and bodyground.

Repair opcn in th€ wire betweenthe PGM-FI main relav and G101.

Check tor an open or short in thewiro (BAT line):Measure voltage between thePGM'FI main relay 7P connectorterminal No. 7 and body ground.- Repai. open or short in lhewir6 belween the PGM-FImain relay and the Fl E/M (15Al fu3e.- Replace th6 FIE/M (15 Altus6in th€ under-hood fuse/.6lay

ls there baftery voltage?

Check lor an open or short in thewire (lGl line):L Turn the ignition switch ON (ll).2. Measure the voltage betweenthe PGM-FI main relay 7P connectorterminal No. 5 and bodyground.- Repair open or shorl in thewire between the FGM-FI mainrelay and the No. 13 FUELPUMP 115 A) tuse.- Replaco the No. 13 RJEL PUMP115 A) luse in the und6.-d$hfuso/ relav box.Check for an open or short in thewire {STS line):1. Turn the ignition switch to theSTART (lll) position.NOTE:. M/T: Clutch pedal must bedepressed.. A/T: Transmission in E orElposition.2. Measure the voltage betweenthe PGM-Fl main retay 7Pconnector terminal No. 2 andbody ground.- Repair open or short in thewire betwe€n the PIGM-FI m.inrclay and th€ No. 31 STARTERSlGllAL 17.5 A) tuse.- Repl.ce the No. 31 STARTERSIGNAL 17.5 Al tuse in theunder-dash tuse/relay box.('97 model: To page 11-189)('98 00models:To page 1l 190)

1 1-188

www.emanualpro.com

Page 402 of 1395

Emission Control System

Three Way Catalytic Converter {TWCI (cont'd}

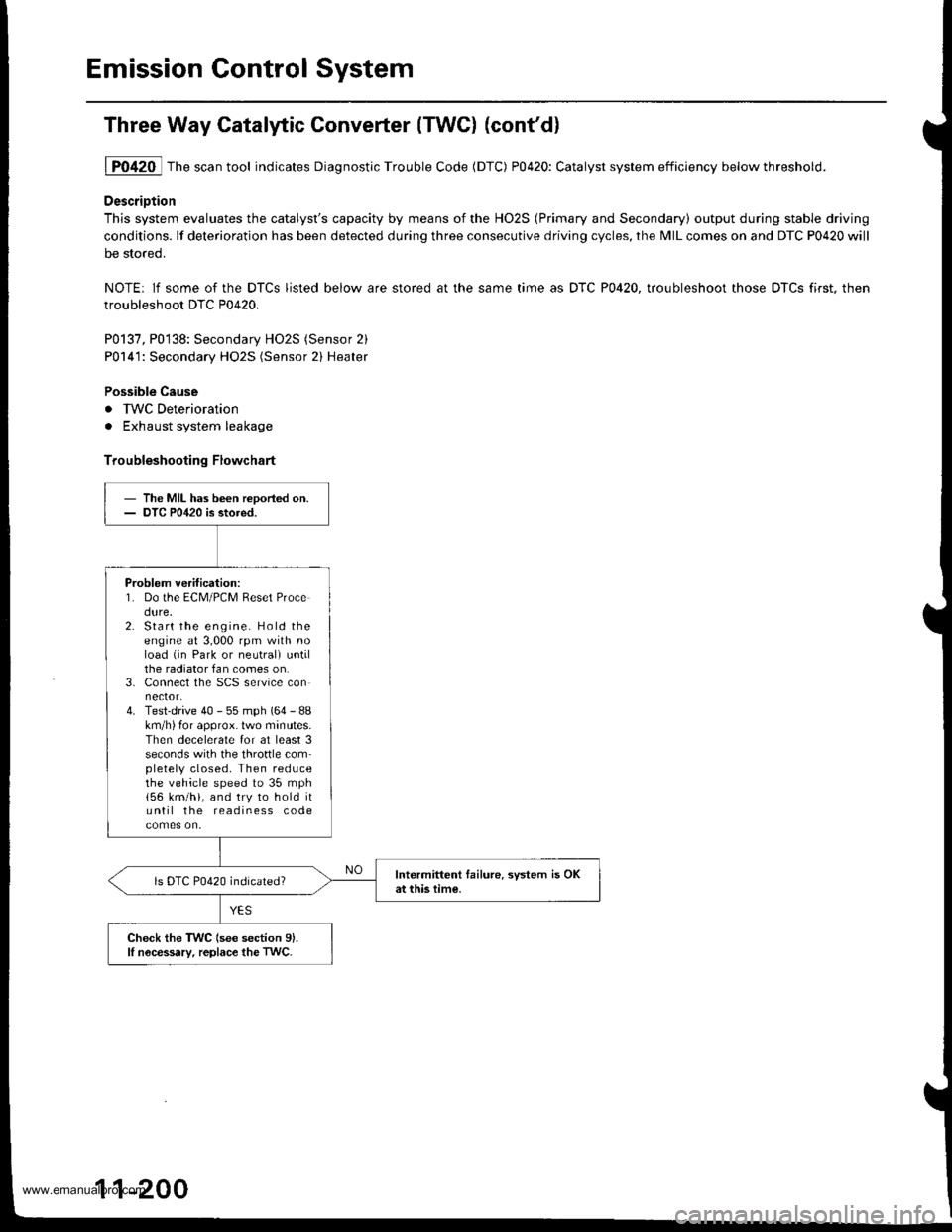

1P0420 Thescantool indicates Diagnostic Trouble Code (DTC) P0420: Catalyst system efficiency belowthreshold.

DescriDtion

This system evaluates the catalyst's capacity by means of the HO2S (Primary and Secondary) output during stable driving

conditions. lf deterioration has been detected during three consecutive driving cycles, the MIL comes on and DTC P0420 will

be stored.

NOTE: lf some of the DTCS listed below are stored at the same time as DTC P0420, troubleshoot those DTCS first. then

troubleshoot DTC P0420.

P0137, P0138: Secondary HO2S (Sensor 2)

P0141: Secondary HO2S (Sensor 2) Heater

Possible Cause

. IWC Deterioration

. Exhaust system leakage

Troubleshooting Flowchart

- The MIL has been reDoried on.- DTC P0420 is stored.

Problem verification:1. Do the ECM/PCM Reset Procedure,2. Start the engine. Hold theengine at 3,000 rpm with noload (in Park or neutrali untilthe radiator fan comes on.3. Connect the SCS service connector.4. Test-drive 40 - 55 mph (64 - 88km/h) for approx. lwo minutes.Then decelerate for at least 3seconds with the throftle completely closed. Then reducethe vehicle speed to 35 mph

156 km/h), and try to hold ituntil the readiness code

Intermittent tailure. system is OKat this time.ls DTC P0420 indicated?

Check the TWC (see section 9).lI nocessary, replace the TwC.

11-200

www.emanualpro.com

Page 407 of 1395

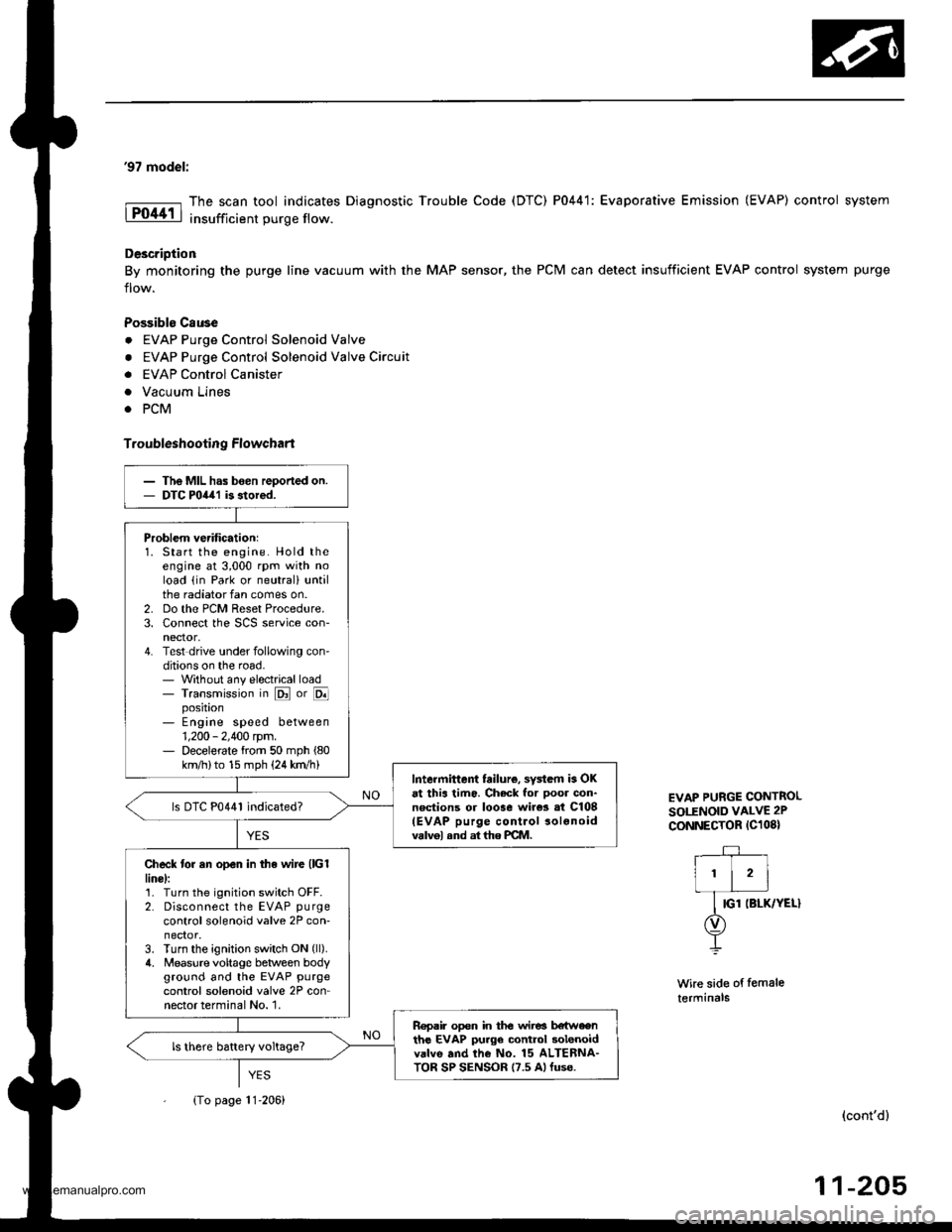

'97 model:

The scan tool indicates Diagnostic Trouble Code (DTC) P0441: Evaporative Emission (EVAP) control system

insufficient purge flow.

Description

By monitoring the purge line vacuum with the MAP sensor, the PCM can detect insufficient EVAP control system purge

flow.

Possiblo Cause

. EVAP Purge Control Solenoid Valve

. EVAP Purge Control Solenoid Valve Circuit

. EVAP Control Canister

. Vacuum Lines

. PCM

Troubleshooting Flowchart

EVAP PURGE CONTROL

SO1TNOID VALVE 2P

CoNNECTOR (C108)

(v)

YL

Wire side of female

termrnals

(cont'd)

11-205

Th€ MIL has b€en reooited on.DTC P0441 is .tored.

Problem verificationl1. Start the engine. Hold theengine at 3,000 rpm with noload (in Park or neut.al) untilthe radiator fan comes on.2. Do the PCM Reset Procedure.3. Connect the SCS service con-nector,4. Test drive under following con'ditions on the road.- without any electrical load- Transmission in @ or @position- Engine speed between1 ,2OO - 2,4OO rpfi.- Decelerate from 50 mph (80

km/h)to 15 mph (24 km/h)Intermittent trilure, sydern is OKat this time. Check for Door con-nections or loose wir€3 at C108

IEVAP purge control solonoidvalvol .nd at the PCM.

ls DTC P0441 indicated?

Check tor an open in the wire (lcl

linel:1. Turn the ignition switch OFF.2. Disconnect the EVAP purge

control solenoid valve 2P con-nector.3. Turn the ignition switch ON (ll).

4. Measure voltage between bodyground and the EVAP purge

control solenoid valve 2P con-nector terminal No. '1,

R€pafu open in thc wir6 b€tw€enthG EVAP purge control solenoidvalve and the No. 15 ALTEBNA-TOR SP SENSOR (7.5 A)fuse.

ls there batlery voltage?

(To page 11'206)

www.emanualpro.com

Page 415 of 1395

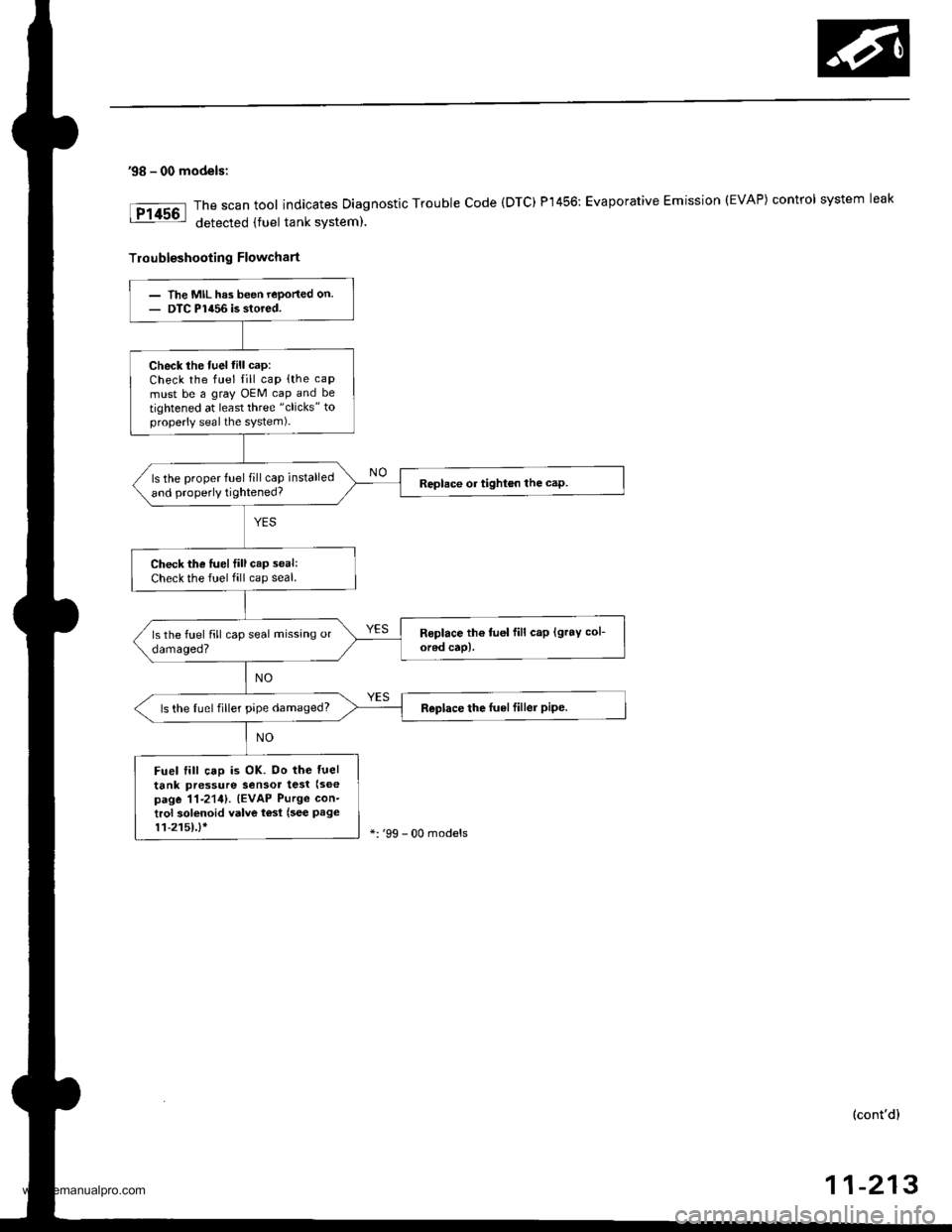

'98 - 00 models:

The scan tool indicates Diagnostic Trouble code (DTC) P1456: Evaporative Emission (EVAP) control system leak

detected {fuel tank system).

Troubleshooting Flowchart

- The MIL has been reported on.- DTC P1456 is stored.

Check the fuel fill cap:Check the fuel fill cap (the caP

must be a gray OEM cap and be

tightened at least three "clicks" toproperly seal the system)-

ls the proper fuel fill cap installed

and properly tightened?Replace or tighton the cap.

Check the lueltill cap seal:

Check the fuel fill cap seal.

Replace the luelfiller pipe.ls the tuel filler pipe damaged?

Fuel till caD is OK. Do the luel

tank pressure Sensor test (see

page 11-2111. (EVAP Purge con-

trol solenoid valve t€sl (see Page11-2151.1r':'99 - 00 models

(cont'd)

11-213

www.emanualpro.com

Page 418 of 1395

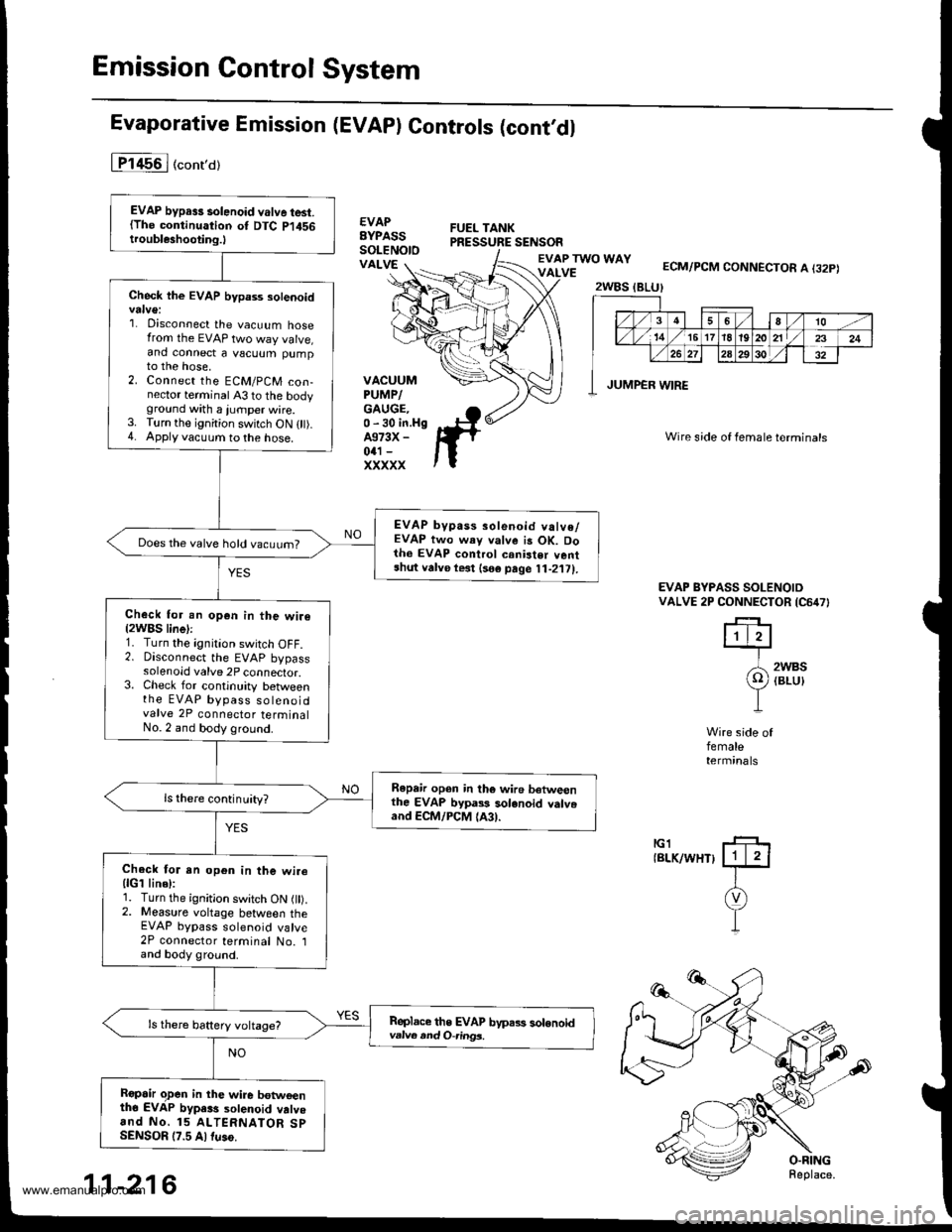

Emission Control System

Evaporative Emission (EVAPI Controls (cont,dl

1T1456I (conro)

€VAPBYPASSSoLENOtOVALVEECM/PCM CONNECTOR A I32P)

Wire side of female terminals

VACUUMPUMP/GAUGE.0 -30 in.HgA373X -

041 -

xxxxx

EVAP BYPASS SOLENOIDVALVE 2P CONNECTOR lcorlTl

2WBS(BLU}

II

Wire side offemaletermrnats

tGlIBLK/WHT}

EVAP bypa3s solenoid valve test.(The continuation ot DTC P1456troubleshooting.l

Check the EVAP bypass sotenoid

1. Disconnect the vacuum hosefrom the EVAP two way valve,and connect a vscuum pumpto the hose,2. Connect the ECM/PCM con-nector terminal 43 to the bodyground with a jurnper wire.3. Turn the ignition switch ON 0t).4. Apply vacuum to the hose.

EVAP bypass solenoid valve/EVAP two way valve is OK. Doth6 EVAP control crnister ventshut vafve le3t lso€ page 11-2'111.

Does the valve hold vacuurn?

Check for an op€n in the wir€(2WBS line):1. Turn the ignition switch OFF.2. Disconnect the EVAP bypasssolenoid valve 2P connector.3. Check for continuity betweenthe EVAP bypass so teno idvalve 2P connector terminalNo. 2 and body ground.

Repair open in the wire betweenthe EVAP bypass solenoid valv.and ECM/PCM lA3).

Chack tor an op6n in the wirellcl line):1. Turn the ignition switch ON l).2. Measure voltage between theEVAP bypass solenoid valve2P connector terminal No. land body ground.

Replace the EVAP byps.,s solonoidvatus and O-ring3.

Ropair o,pen in the wire botwoenth6 EVAP bypa$ sotenoid vatvoand No. 15 ALTERNATOR SpSENSOR (7.5 Altuso.

2WBS (BLU}

/3

7,x

4l6o/to -/

,/ 16 1718't920 211/z3

26 272A29solT32

JUMPER WIRE

11-216

www.emanualpro.com

Page 419 of 1395

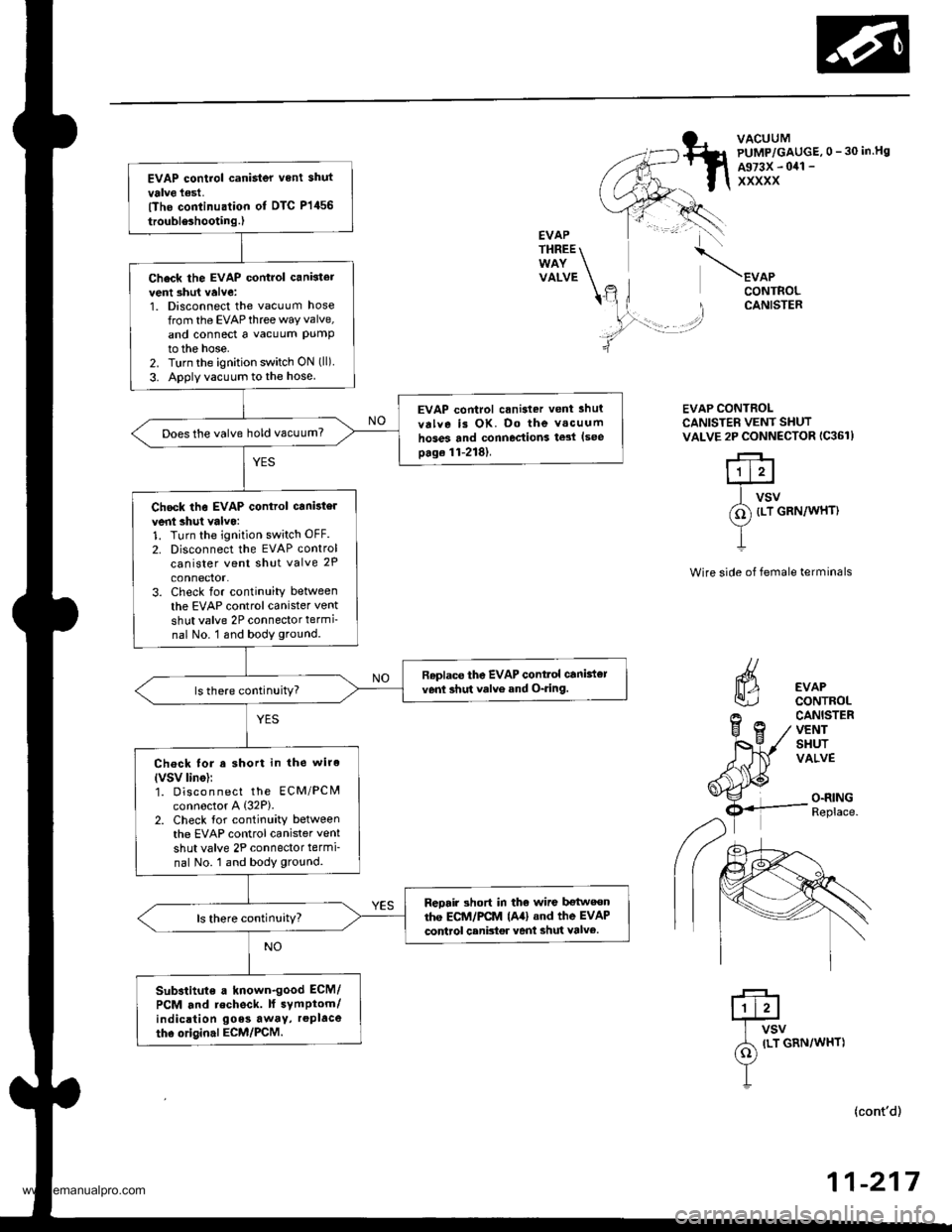

EVAP control canister vent shut

valve l€st,lThe conlinualion ot DTC P1456

troubleshooting.)

Check the EVAP control cankter

vent 3hut valve:1. Disconnect the vacuum hose

from the EVAPthree way valve,

and connect a vacuum PUmPto the hose.2. Turn the ignition switch ON (ll).

3. Apply vacuum to the hose

EVAP control crnisier vent lhul

valve is OK. Do the v.cuum

hoses and connections te3l lseepage 11-218).

Does the valve hold vacuum?

Chock the EVAP control canbtel

vent shul valvo:1. Turn the ignition sw;tch OFF.

2. Disconnect the EVAP controlcanister vent shut valve 2P

connector.3. Check for continuity betlveen

the EVAP control canister vent

shut valve 2P connector termi-nal No. 1 snd body ground.

Roplac€ the EVAP contlol canbt€]venl shut valve and O-ring.

Chock lor a short in the wire(VSV lino)r1. Disco n nect the EcM/PCN4connoctor A (32P).

2. Check for continuity betweenthe EVAP control canister vent

shut valve 2P connector termi-

nal No. 1 and body ground.

Reorir 3hort in tho wiro bgtweonthe EC1I/I/PCM lAal .nd the EVAP

codrol canbtor vent shut valv6.

Substitute a known.good ECM/

PCM and recheck. lf symptom/indicrtion goes awaY, replace

the original ECM/PCM.

VACUUMPUMP/GAUGE,0 - 30 in.Hg

A973X - 041 -

XXXXX

EVAPTHREE

VALVEEVAPCONTROLCANISTER

EVAP CONTROLCANISTER VENT SHUTVALVE 2P CONNECTOR IC361)

r+l1t2l

f1 VSV

(o) tLT cnrulwxrt

1

Wire side of female terminals

EVAPCONTROLCANISTERVENTSHUTVALVE

O.RINGReplace.

ILT GRN/WHT)

(cont'd)

-21711

www.emanualpro.com

Page 423 of 1395

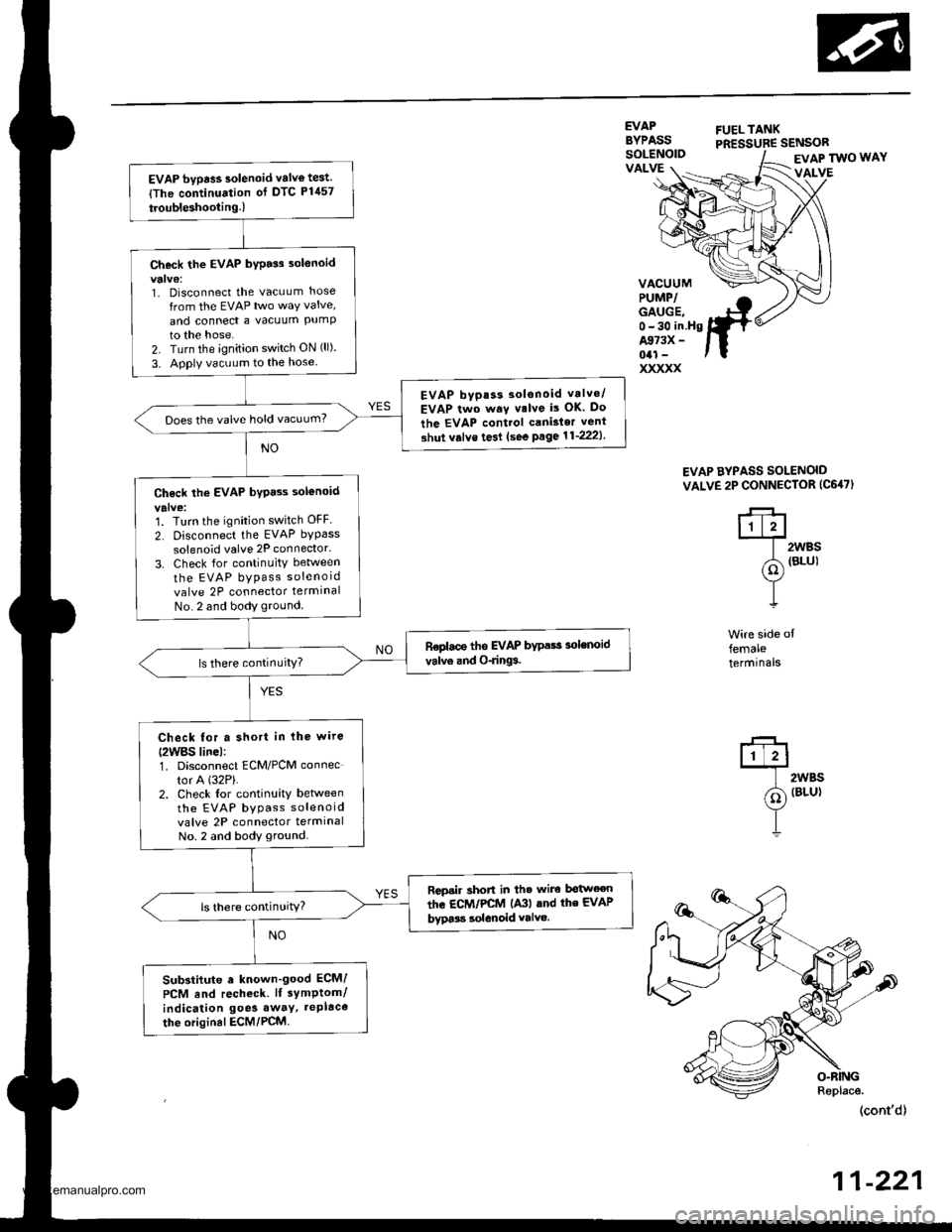

EVAP bypass solenoid valv€ test.

{The continuation of DTC P1457

troubleshooting.l

Check the EVAP bypass 3olenoid

1. Disconnect the vacuLlm hose

from the EVAP two way valve,

and conned a vacuum PUmPto the hose.2. Turn the ignition switch ON (ll).

3. Apply vacuum to the hose

EVAP bvpas3 30lsnoid vrlvo/

EVAP two way v.lve is OK. Do

the EVAP control canisler vent

3hut v.lve te3l (see Psge11'2221.

Does the valve hold vacuum?

Ch6ck the EVAP byp.ss solenoid

'1. Turn the ignition switch OFF

2. Disconnect the EVAP bypass

solenoid valve 2P connector.

3. Check {or continuity between

the EVAP bypass soleno id

valve 2P connector termlnal

No. 2 and body ground

ReDlace the EVAP bypass 3olenoid

valve and O-rings.

Check for a short in lhe wire

{2WBS linel:1. Disconnect ECM/PCM connec

tor A (32P).

2. Check lor continuity betlveenthe EVAP bypass soleno id

valve 2P connector termrnalNo. 2 and body ground.

Rcpsir short in th. wire bgtwoen

the EcM/PCtrl lA3l lnd the EVAP

bypa$ solenoid valvo.ls there continuitY?

Sub3tiiute . known'good ECM/

PCM End recheck. lI sYmptom/

indication goe3 away, tePlace

the original ECM/PCM.

EVAPBYPASSFUELTANKPRESSUBE SENSORSOLENOIDVALVEEVAP TWO WAY

VALVE

VACUUMPUMP/GAUGE,0-30 in.HgA973X -

041 -

xxxxx

EVAP AYPASS SOLENOID

VALVE 2P CONNECTOR (C647}

q

@)

T

t.'-+lt1t?l

| 2wBs

(d1 terul

Y-L

Wire side offemaleterminals

2WBS(BLU}

(cont'd)

11-221

www.emanualpro.com

Page 517 of 1395

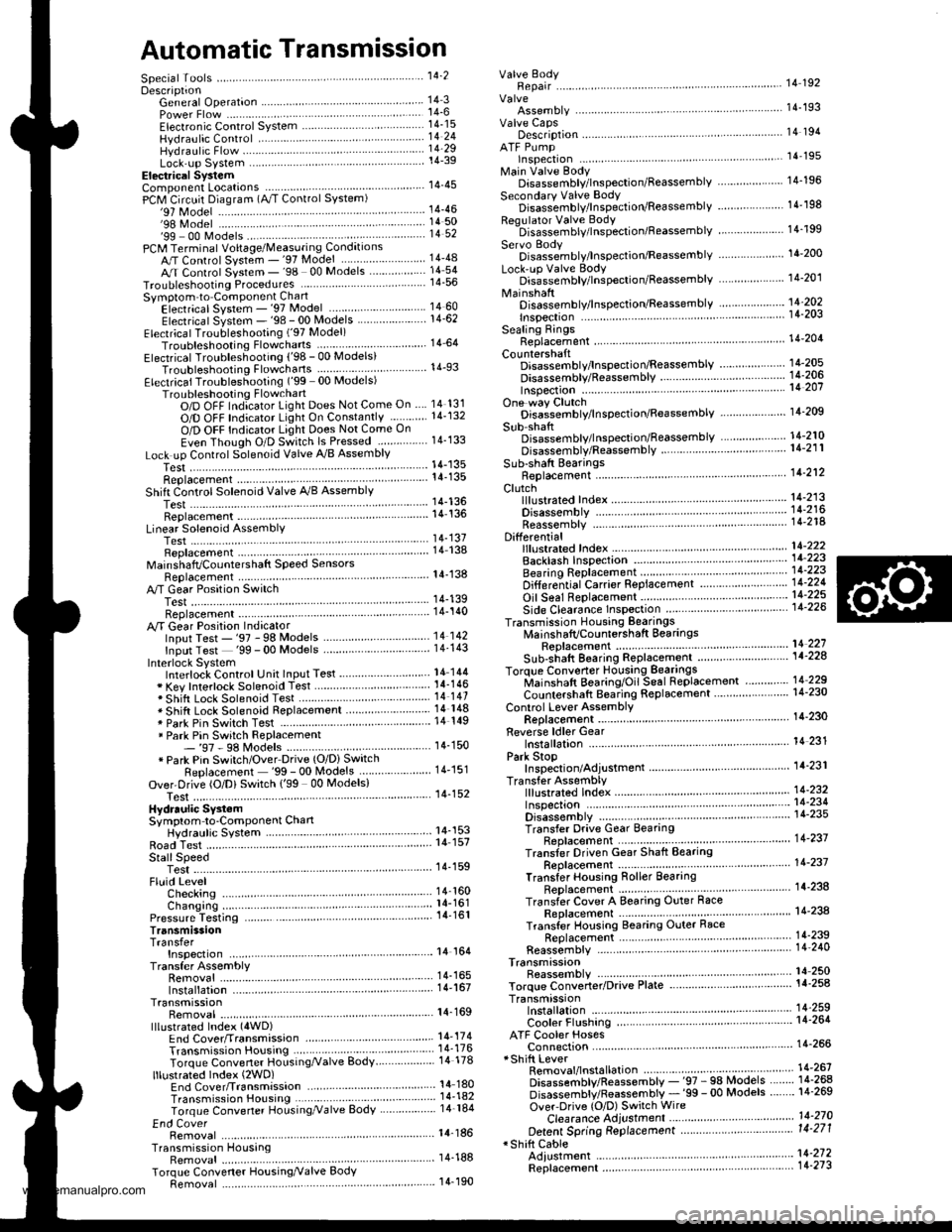

Automatic Transmission

Special Tools . 14'2OescriptionGeneral Operation . .... 14 3Power Flow . . .. '14_6

Electronic Control System .. .. . . .. .14_15Hydraulic Control .. 14 24Hydraulic Flow....-....... .. . .... .. .. . 14_29Lock'up Syslem .. .'t4'39Electrical SystemComponenl Locdlrons 14 45

PCM Circuil Dragram (A/T Control Svstem)'97 Model ....................... . . .. - . ... .14-46'98Model ................. . ... .. .. .1450'99 00Models.... . .... . . . 1452

PCM Terminal Voltage/Measuring ConditionsA"/T Control System-'97Model ...... ..14'48A,/T Control System -'98 00 Models . . .. . . 14 54

Troubleshooting Procedures .. ..... ... - 14_56Svmotom to comoonent CharlEiectr,cal Syslem -'97 Model . . 14 60Electrical System -'98 - OO Models . .. . . 14_62Electrical Troubleshooting ('97 Model)Troubleshooting Flowaharts .... ..... . .. . . 14_64

Electrical Troubleshooting ('98 - 00 Models)Troubleshootinq Flowclt"n" .... . ....- . .14-93ElectricalTroublesliooting('99 00Models)Troubleshootino FlowchartO/D OFF Indicator Light Does Not Come On 14 131

O/D OFF Indicator Liaht On ConstantlY . . . .1!-132O/D OFF Indicator Light Does Not Come OnEven Though O/D Switch ls Pressed . .... - 14_133

Lock up Control Solenoid Valve A,/B AssemblyTest....................-......... . .14-135Replacement . .ll_135Shifr ControlSolenoid Valve Ay'B Assembl,Test .............................. . .. 14-136

Replacement..............- . .14'136Linear Solenoid AssemblYTest.............................................. .. .... . 14_137Replacement .. . 14138Marnshaftlcountershafl Speed SensorsReplacement ...-... 14_138A/T Gear Position SwitchTest ..........................-... . .. 14-139ReplacementA/T Gear Positionlndicator.................. 14-140

Valve Eodynepair ............................... ..... . . .. - . .. ... 14 192

Assembly .................... .. 1{_193

Valve CapsDesciiption....-........................ .. ...... 14194

tnspeition ................... .. 14' 195

N4ain Valve BodyDisassembly/lnspection/Reassemblv - ...... .. 14_196

Secondarv Valve BodYDisassemblv4nspectron/ReassemblY .. . 14 198

Reoulator Valve Bodvbisassembtv,lnspiction/Reassemblv . 14199

Servo EodvDisassembly/lnspection/Reassembly ... ....14'200

Lock'uo Valve BodYDis;ssembly/lnspection/Reassembly .... . 14_201

MainshaftDisassembly/lnspection/Reassembly .. .. .. ..14'202

Inspection ....-.............. ..11_203

Sealing RingsReilaceient ...... ..... . 14'204

CountershaftDisassembly/lnspection/Reassembly .. . . . . . 11-205

Disassembly/Reassemb|y . . ........ ...... . .. 14_206Inspedron ................ . .... . 14 207

One wav ClutchDisassembly/lnspection/ReassemblY ... 11_209

Sub-shaftDisassembly/lnspection/Reassembly ... . .. . 14-210

oisassembly/Re6ssembly . . ... .-...... . . ..14-211

Sub-shaft BearingsReplacement .......14'212

Clutchllfustrated Index .......... . . .14-213

Disassembly .... .. .....14-216Reassembfy .... . .. .. . 14'218

Differentialllfustrated Index " 14-222Backlash Inspection . .... . .14'223

Bearing Repiacement .. 11-223

Differe-ntial Carrier Replacement .. .. . . . .. ..11-2?4

OifSeal Replacement. . .. 14'225

Side Clearance lnspection . . - .. ... . - ...... . .. 11'226

Transmission Housing BearingsMainshaJVCountershaft EearingsRepfacement .......14221Sub'siralt Eearing Replacement . . . . . . . . . ..11'224

Toroue Converter Housing BearingsMainshattEearing/OilSe6lReplacement . .. l4229

Countershaft Bea;ing Replacement.. .... .. ..14-230

Input Test - '97 - 98 ModelsInput Test '99 - 00 Models

Symptom to-Component ChartHydraulic System ...............

Checking

Removal ...,lllustrated Index (4WD)

Interlock SystemInterlock ControlUnit lnputTest. -..... -.. .... . - 14 144* Key Interlock Solenoid Test .- .. . . . - . . . ..... 14_146* Shift Lock Solenoid Test ..............-.-. . .. . ... .... 14 147*Shift LockSolenoidReplacement...... .. . .. .. 14 148* park pin Switch Test ......... 14 119' Park Pin Switch Replacement- '97 - 98 Models ....... 14-150* Park Pin Swirch/Over Drive (O/Di SwitchReplacemenl '99-00Models . .. 14_151over-Drive (O/D) Switch {'99 00 [4odels]Test........_..................... .......14-152Hydr.ulic System

..............._............... t4 142.................................. 14-143

Control Lever AssemblyR6placement ......,.,Reverse ldler Gear

lllustrated lndex

.......... 14-230

14 231

11-231

1nsta1|ation ..................Park StopInspeclion/AdjustmenlTransfer AssemblY.......14.232

RoadTest.............-.... ........ .StallSpeedTest ....._........................ ....... 14-159Fluid Level......_................... 14'160

Disessembly .................... 14-235Transfer Drive Gear BearingReplacementTrans{er Driven Gesf Shaft BearingReplacementTransfer Housing Roller BearingReplacementTransfer Cov€r A Bearing Outer RaceReplacementTransfer Housing Bearing Outer RaceReplacement ......-..,,,,,.....ReassemblvTransmassaonBeassembly ... -.. .... .14 250

Torque Converier/Drive Plate . .-. .... .. . ... .....14_258

Transmissionlnstatlation .................. ....... 14'259

Cooler Flushing . . ......11-261ATF Cooler HosesConnection.................. ....... 14-266I Shift LeverRemoval/lnstallation . .. 14'261

Disassemblv/Reassemblv - '97 - 98 Models . . 14_264

Disassembli/Reassemblv -'99 - 00 Models . 14-269

Over'Orive (O/D) Switch WireClearanceAdjustment. - ... . . . .. .. . 14'270

Detent Spring Replscement . . -.. ... .14'271*Shift CableAdiustment ....... 14'272

Repfacement.............. . 11'273

14 15711-237

11-237

14-238

$-234

11-23914-240

Transmigrion

Inspeclron ....., ...........Transfer AssemblyRemova1,.,,,..............,lnstallalion ........... .. ...Transmission

14 164

14-16514,167

14-169

End Cover/Transmissio . 14'174Transmission Housing .... ... .. . . .... .. 14-176Torque Converter Housingly'alve Body.. - ... -. 14 178

lllustrated lndex (2WD)End Cover/Transmissio ....... 14 180Transmission Housing . . ... . .. .... ... 14'182Torque Convener Housing/r'alve Body ......- 14-184

End CovefRemovat ...................... ....... 14'186Transmission HousingRemoval ...................... .. 14_188Torque Convener HousingA/alve BodYRemovat ................-..... .-..... 14-190

www.emanualpro.com

Page 572 of 1395

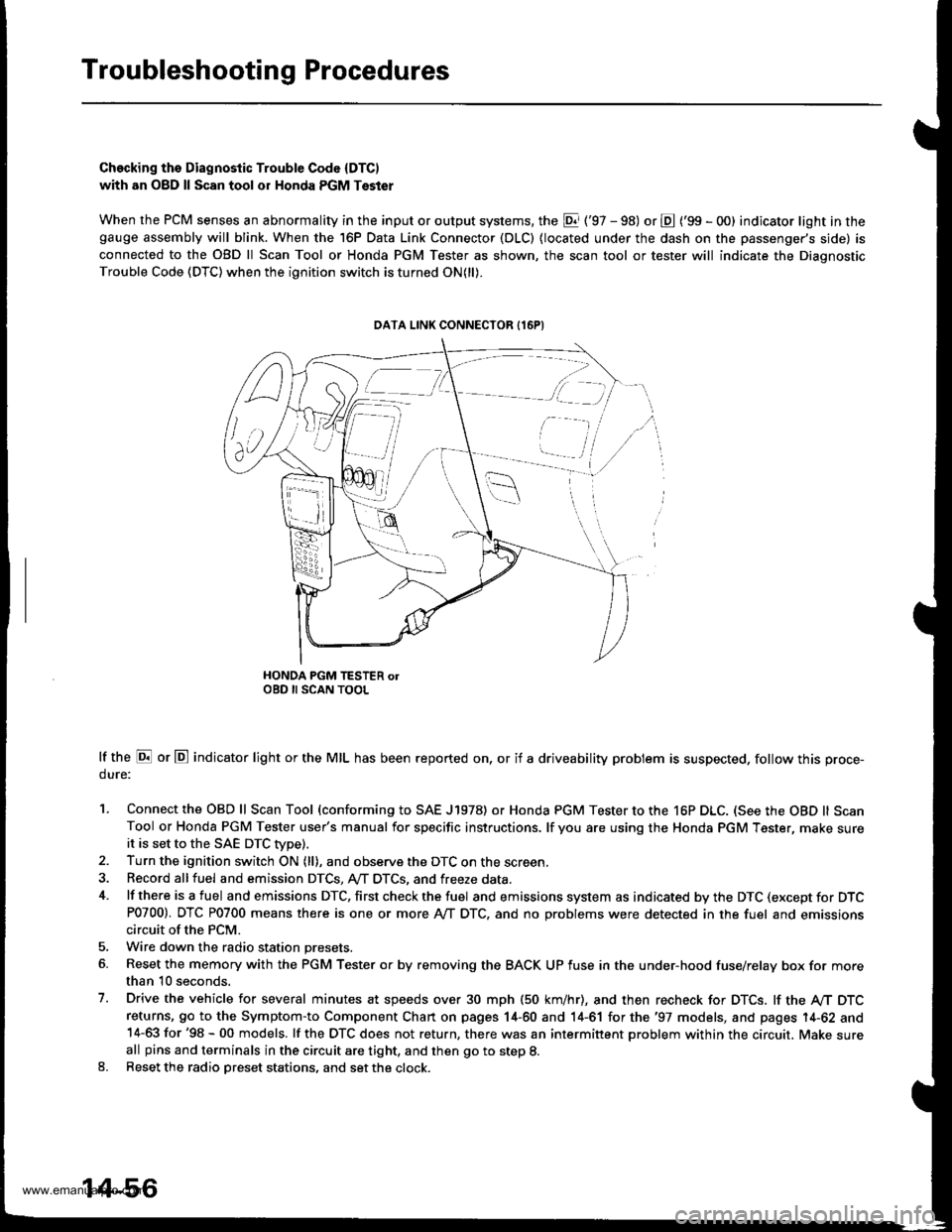

Troubleshooting Procedures

Checking ths Diagnostic Trouble Code (DTC)

with an O8D ll Scan tool or Honda PGM Tsster

When the PCM senses an abnormality in the input or output systems, the El ('97 - 98) or E ('99 - O0) indicator light in thegauge ass€mbly will blink. When the 16P Data Link Connector (DLC) {located under the dash on the passenger's side) is

connected to the OBD ll Scan Tool or Honda PGM Tester as shown, the scan tool or tester will indicate the Diagnostic

Trouble Code (DTC) when the ignition switch is turned ON(ll).

HONDA PGM TESTER olOBD II SCAN TOOL

lf the E or E indicator light or the MIL has been reported on, or if a driveability problem is suspected, follow this proce-

dure:

1. Connect the OBD ll Scan Tool (conforming to SAE J1978) or Honda PGM Tester to the 16P DLC. (See the OBD ll ScanTool or Honda PGM Tester user's manual for specific instructions. lf you are using the Honda PGM Tester, make sureit is set to the SAE DTC Wpe).2. Turn the ignition switch ON (ll), and observe the DTC on the screen

3. Record allfuel and emission DTCS, A,,/T DTCS, and freeze data.

4. lf there is a fuel and emissions DTC, first check the fuel and emissions system as indicated by the DTC (except for DTCP0700). DTC P0700 means there is one or more Ay'T DTC, and no Droblems were detected in the fuel and emissionscircuit of the PCM.

5. Wire down the radio station presets.

6. Reset the memory with the PGM Tester o. by removing the BACK UP fuse in the under-hood fuse/relay box for morethan 10 seconds.

7. Drive the vehicle for several minutes at speeds over 30 mph (50 km/hr), and then recheck for DTCS. lf the A/T DTCreturns, 9o to the Symptom-to Component Chart on pages 14-60 and 14-61 for the '97 models, and pages 14-62 and14-63 for '98 - 00 models. lf the OTC does not return, there was an intermittent problem within the circuit. Make sureall pins and terminals in the circuit are tight, and then go to step 8.8. Reset the radio Dreset stations, and set the clock.

DATA LINK CONNECTOR {16PI

[ -=.r,

ili,i /i,

v,., i

14-56

www.emanualpro.com

Page 574 of 1395

Troubleshooting Procedures

(cont'dl

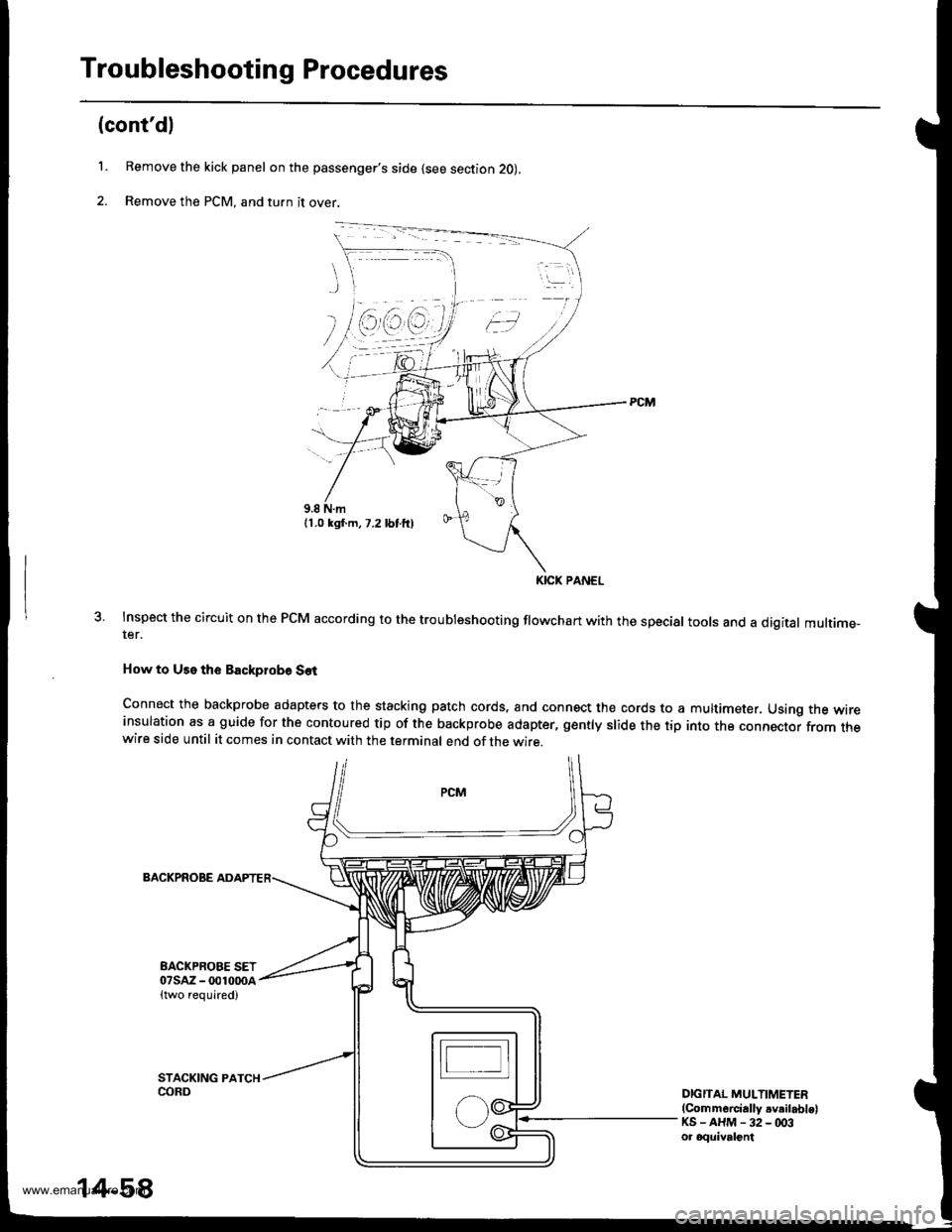

L Remove the kick panel on the passenger's side (see section 2O),

2. Remove the PCM, and turn it over.

Inspect the circuit on the PCM according to the troubleshooting flowchart with the special tools and a digital multime-ter.

How to Use the Backplobe Set

Connect the backprobe adapters to the stacking patch cords, and connect the cords to ainsulation as a guide for the contoured tip of the backprobe adapter, gently slide the tipwire side until it comes in contact with the terminal end of the wire.

multimeter. Using the wire

into the connector from the

BACKPROBE

EACKPROBE SET07sAz - 001000a{two required)

DIGITAL MULTIMETER(Commercially .v.ilablelKS-AHM-32-003ot oquivalont

KICK PANEL

14-58

www.emanualpro.com