Troubleshooting HONDA CR-V 1998 RD1-RD3 / 1.G Repair Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1998, Model line: CR-V, Model: HONDA CR-V 1998 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 598 of 1395

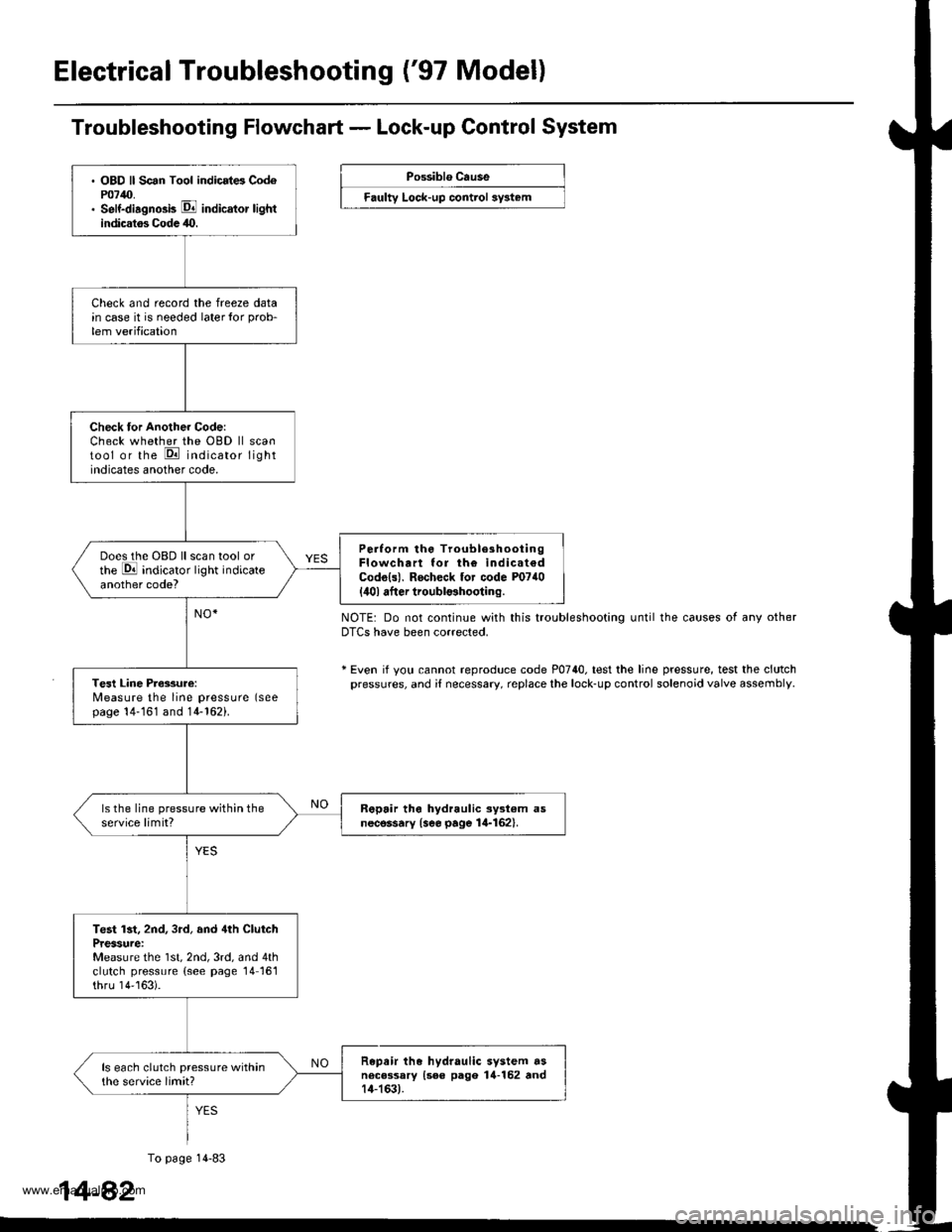

Electrical Troubleshooting ('97 Model)

. OBD ll Scan Tool indicrt6 Cod6P0740.. Self-diagno3b E indicator lightindicatos Codc 40.

Check and record the freeze datain case it is needed laterlor prob-

lem verification

Check tor Another Code:Check whether the OBD ll scantool or the E indicator lightindicates another code.

Perlorm the TroubleshootingFlowchart lor th€ indicat€dCodo{s). Rocheck tor code P0740

{ilol after troubl$hooting.

Does the OBD ll scan tool orthe E indicator light indicateanother code?

Tesl Line Pressure:Measure the line pressure (seepage 14-161 and 14-162).

ls the line pressure within theservice limit?R6pair tho hydraulic ayst€m asnecessary {see page 14-162}.

Test lst, 2nd, 3rd, and 4th ClutchPressure:Measure the 1st, 2nd, 3rd, and 4thclutch pressure (see page 14161thru 14''163).

Repair the hydraulic system dsnecessary {see pago 14-152 rnd14-163).

ls each clutch pressure withinthe service limit?

Troubleshooting Flowchart - Lock-up Control System

Possiblo Cause

Faulty Lock-up control sy3t6m

NOTE: Do not continue with this troubleshooting until the causes of any otherDTCS have been corrected.

* Even if yotl cannot reproduce code P0740. test the line pressure, test the clutchpressures, and i{ necessary, replace the lock-up control solenoid valve assembly

1

To page 14-83

4-82

www.emanualpro.com

Page 600 of 1395

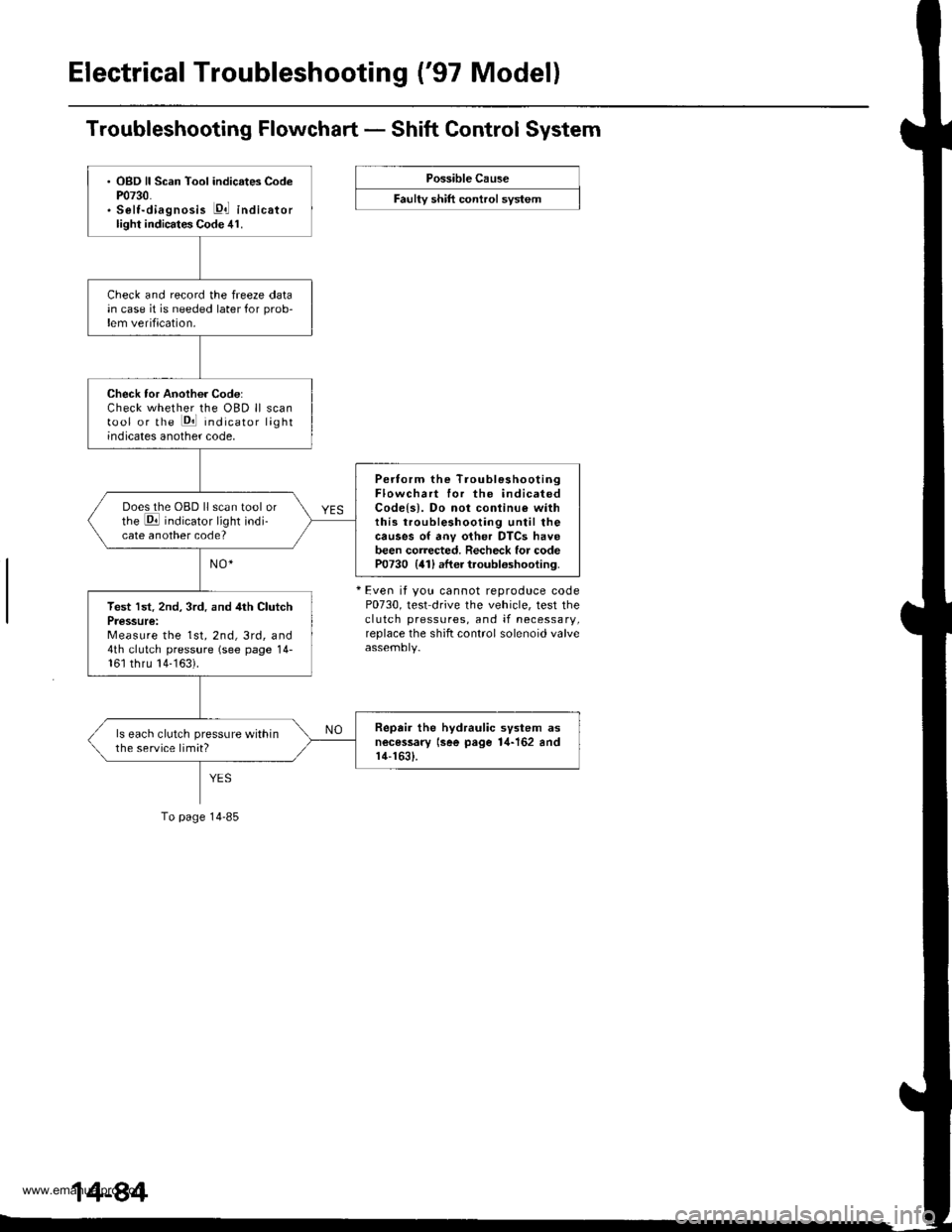

Electrical Troubleshooting ('97 Model)

Troubleshooting Flowchart - Shift Control System

Possible Cause

F""lty "t lft ".tttr"l "y"t..

+ Even it you cannot reproduce codeP0730, test drive the vehicle, test theclutch pressures, and if necessary,replace the shift control solenoid valve

. OBD ll Scan Tool indicates CodeP0730.. Selt-diagnosis E,l indicatorlight indicates Code 41.

Check and record the freeze datain case it is needed later for prob-lem verification.

Check tor Another Code:Check whether the OBD ll scantool or the Pll indicator lightindicates another code,

Pertorm the TroubleshootingFlowchart for the indicatedCodels). Do not conlinu€ withthis troubleshooting until thecauses of anv other DTCS havebeen corrected. Recheck for codeP0730 {41) after troubloshooting.

Does the OBD ll scan tool orthe E indicator light indi-cate another code?

Test lst. 2nd, 3rd. and 4th ClutchPressure:Measure the 1st, 2nd, 3rd, and4th clutch pressure (see page 14-161 thru 14-163).

Repair the hydraulic svstem asnecessary lsee page 1,1-162 andr4-1631.

ls each clutch pressure withinthe service limit?

To page 14-85

www.emanualpro.com

Page 602 of 1395

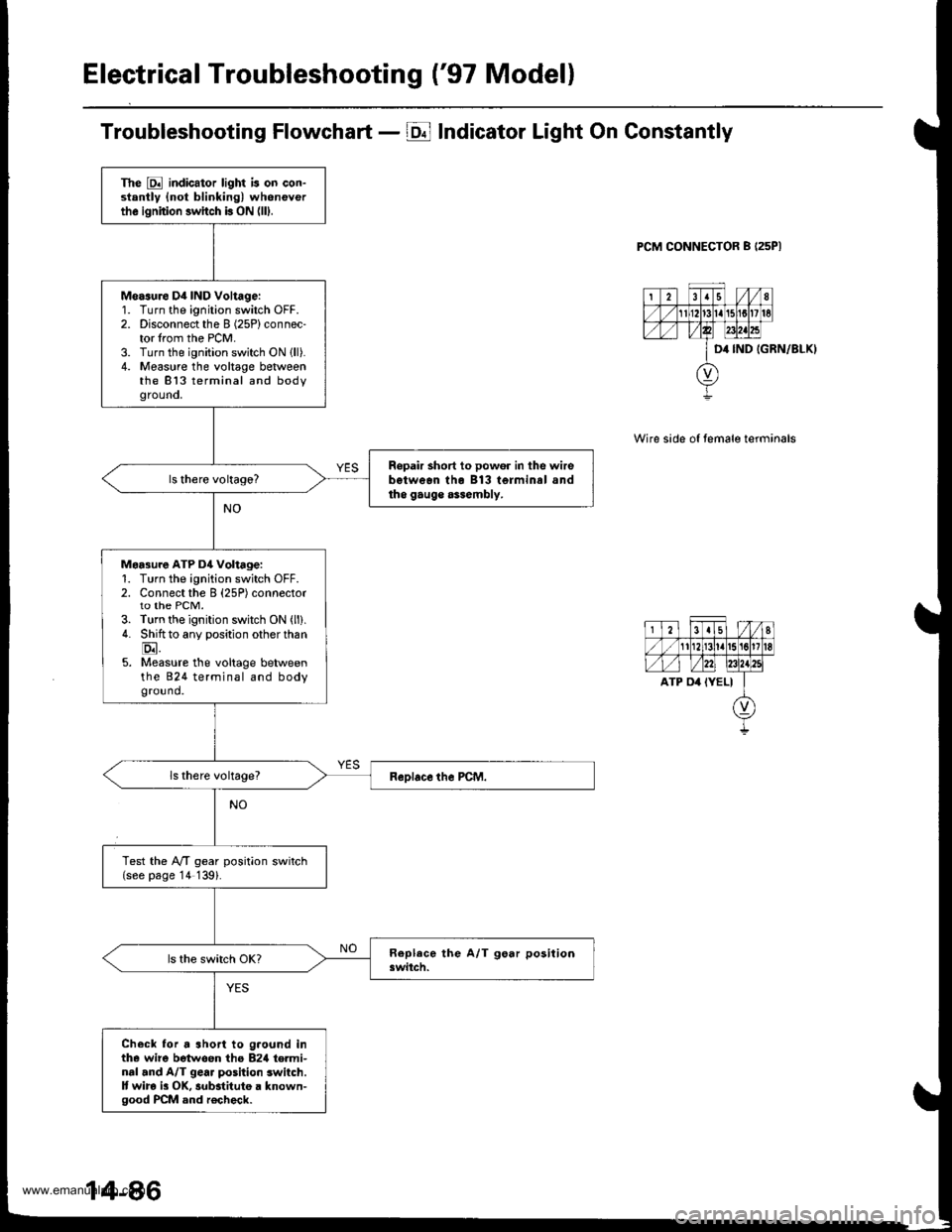

Electrical Troubleshooting ('97 Modell

Troubleshooting Flowchart - E Indicator Light On Constantly

PCM CONNECTOR B I25PI

IGRN/8LKI

Wire side of temale terminals

The E indicator light is on con-stantly {not blinking) wheneverthe ignition switch b ON (lll.

Measure D4 IND Voltage:'1.

2.

3.4.

Turn the ignition switch OFF.Disconnect the I (25P) connec-tor lrom the PCM.Turn the ignition switch ON lll).Measure the voltage betweenthe 813 terminal and bodygrouno,

Ropair short to powor in the wirebetwean tho B13 terminal andtho gauge assembly.

Maa3ure ATP D4 Voltage:1. Turn the ignition switch OFF.2. Connect the B (25P) connectorto the PCM.3. Turn the ignition switch ON (ll).

4. Shiftto any position other than

E.5. Measure the voltage betweenthe 824 terminal and bodyground.

Test the lVT gear position switch(see page '14 139).

Check lor a short to g.ound inthe wire betwoen tho B2rl te.minal and A/T gear position switch.It wira i3 OK, substitute a known-good PCM and r€check.

www.emanualpro.com

Page 603 of 1395

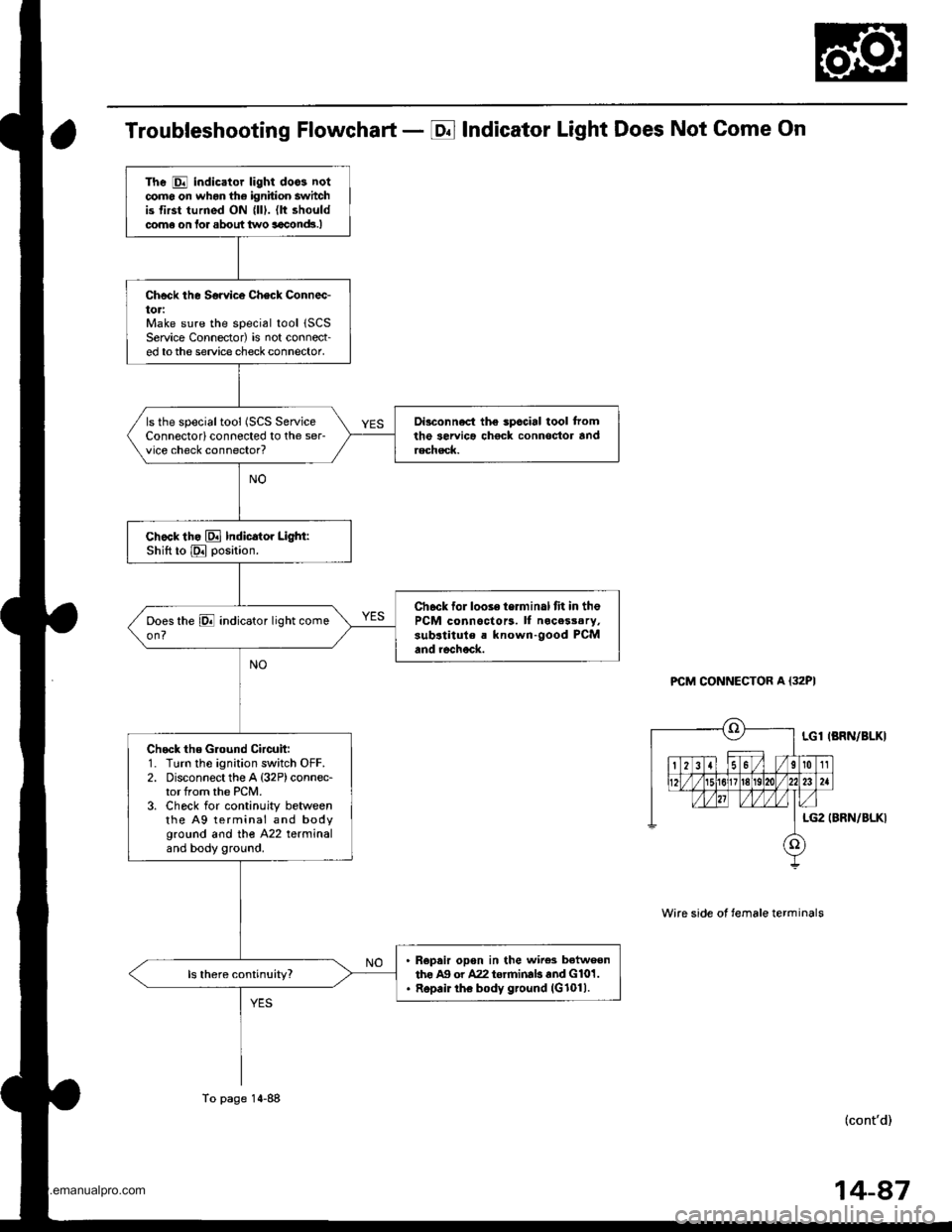

Troubleshooting Flowchart - E Indicator Light Does Not Come On

PCM CONNECTOR A {32PI

Wire side ot temale terminals

LGl IBRN/BLKI

LG2 (BRN/BLKI

(cont'd)

The E indicator light doos notcomo on whon the ignition switchis first turned ON {lll. (lt shouldcome on lor about two aaclnd!.I

Check the Sorvice Check Connec-toriMake sure the special tool 1SCSService Connector) is not connect-ed tothe service check connector,

Di3connect the spccial tool tromthe servica chock connoctor andrechsck.

ls the specialtool (SCS ServiceConnectorlconnected to the ser-vice check connector?

chock th. El Indicator Light:Shift to E position.

Ch6ck for looie terminal fit in thePCM connoctors. ll nocesssry,sub.titule a known-good PCMand rechock.

Check the Ground Circuit:1. Turn the ignition switch OFF.2. Disconnect the A {32P)connec-tor from the PCM.3. Check for continuity betweenthe A9 terminal and bodyground and tho A22 terminaland body ground.

R€pair opon in the wire3 betweenthe Ag or A22 torrninab and G101.Repair the body ground (G1011.

To page 14-88

14-87

www.emanualpro.com

Page 604 of 1395

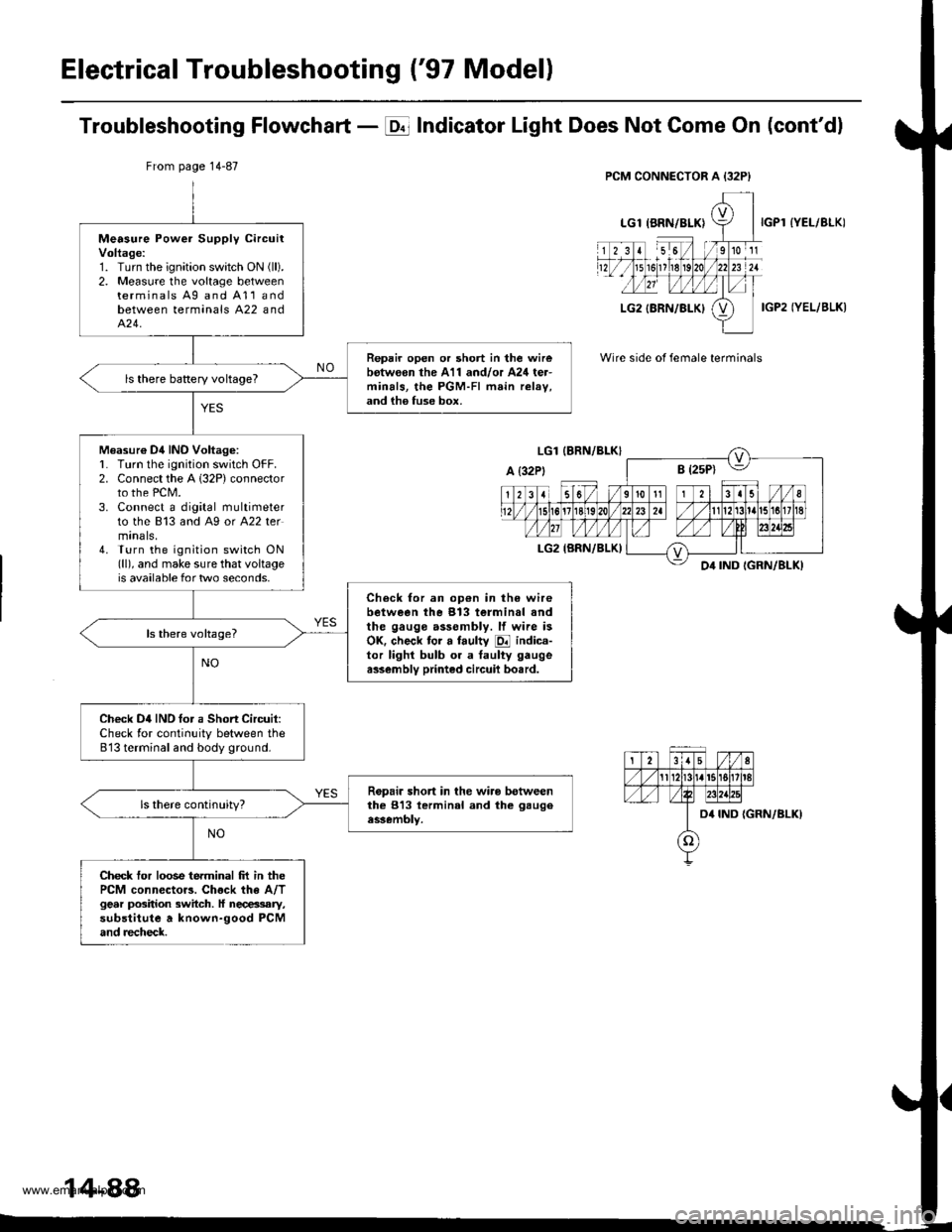

Electrical Troubleshooting ('97 Modell

Troubleshooting Flowchart - E Indicator Light Does Not Gome On (cont'dl

IYEL/BLK)

IGP2 IYEL/BLK)

Wire side of female terminals

From page 14-87

Measure Power Supply circuitVoltage:1. Turn the ignition swatch ON (ll).

2. Measure the voltage betweenterminals Ag and A11andbetween terminals A22 andA�24.

Repair open or short in the wirebotw€on the A11 and/or A24 ter-minals, the PGM-FI main relav,and ih6 fuse box.

ls there baRery voltageT

Measur€ Dil INO Voltag6:L Turn lhe ignition switch OFF.2. Connect the A 132P) connectorto the PCM.3. Connect a digital multimeterto the 813 and A9 or A22 termtnals,4. Turn the ignition switch ON(ll), and make sure that voltageis available for two seconds.

Check for an op€n in the wirebetween the 913 terminal andthe gauge assembly. lf wire isOK. check tor a faulty E indica-tor lighl bulb or a taulty gaugea$embly printed circuil bo.rd.

Check D4IND tor a Short Circuit:Check for continuity between the813 terminal and body ground.

Ropair short in the wiro betweenthe 813 lerminal and the gaugeassembly.

Check tor loose terminal frt in thePCM connector3. Chock the A/Tgear position switch. ll necessary,substitute a known-good PCMand recheck.

14-88

www.emanualpro.com

Page 605 of 1395

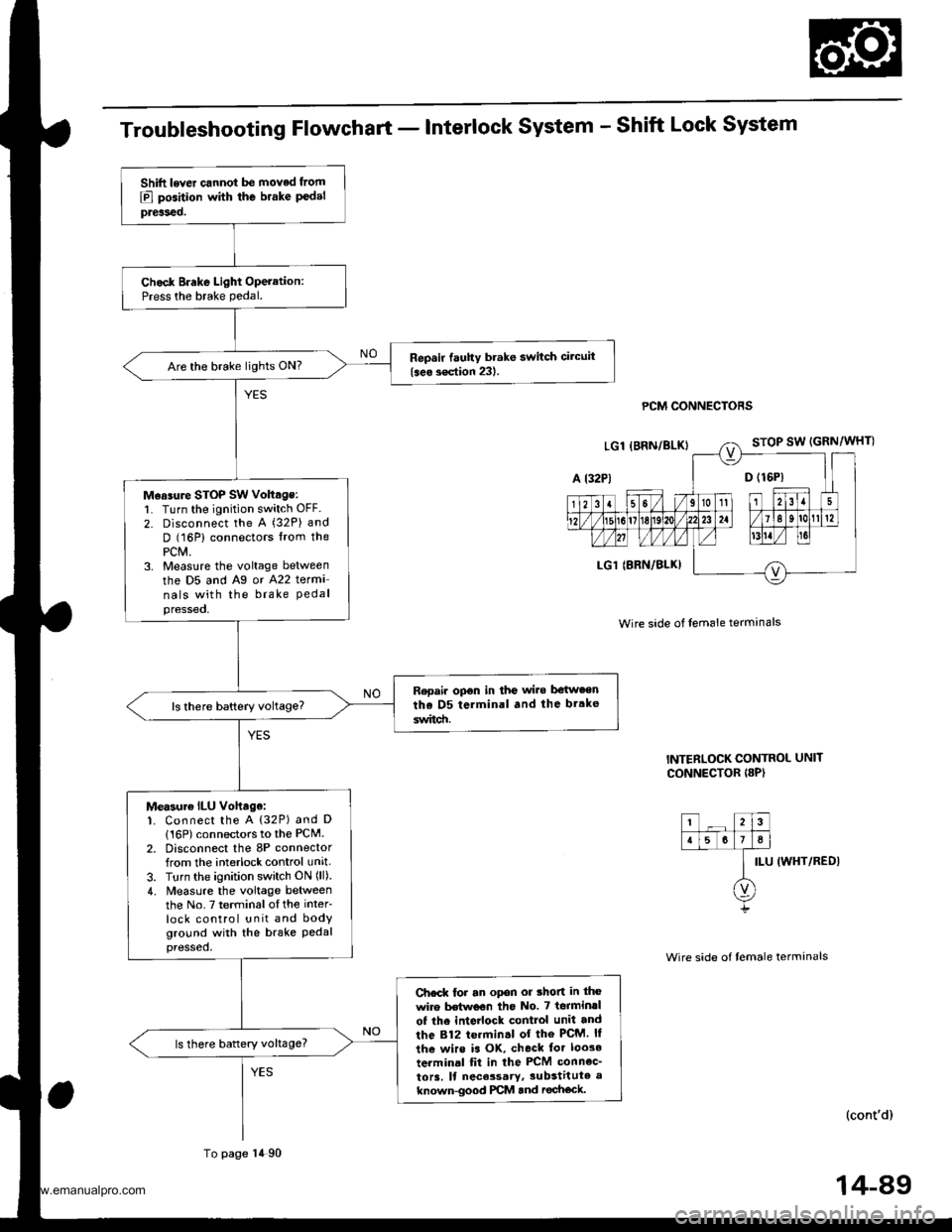

Troubleshooting Flowchart - Interlock System - Shift Lock System

PCM CONNECTORS

Wire side of lem6le termanals

INTERLOCK CONTROL UNIT

CONNECTOR I8P)

ILU IWHT/REDI

(cont'd)

Shift lever cannot be moved from

E] position with the brake P€delpreiseo.

Chock Brake Light Operation:Press the brake pedal.

Repsir fauhy brake switch circuit

{seo s€ction 231.Are the brake lights ON?

M€asure STOP SW voltage:l� Turn the ignition switch OFF.

2. Disconnect the A (32P) and

D (16P) connectors lrom thePCM.3. Measlre the voltage between

the D5 and Ag or A22 terma

nals with the brake Pedalpressed,

Repair opon in the wi.e be{w.enthe D5 terminal and the br.ke

switd!.

Measur€ ILU vohage:1. Connect the A {32P) and D

116P) connectors to the PCM.2. Disconnect the 8P connectorfrom the interlock control unit

3. Turn the ignition switch ON (ll).

4. Measure the voltage betweenthe No.7 terminalofthe inter

lock control unit and bodyground with the brake Pedalpressed,

Ch€ck for an opon or thon in the

wire Mwoon tho No. 7 terminrl

of the inte ock control unit and

the 812 termin.l of the PcM. ll

the wirs is OK, check tor loo3e

terminal fit in the PCM connec_

to13. ll nece3sary,3ubstitute a

known-good PCM and rechock.

ls there battery voltage?

To page 14 90

14-89

www.emanualpro.com

Page 606 of 1395

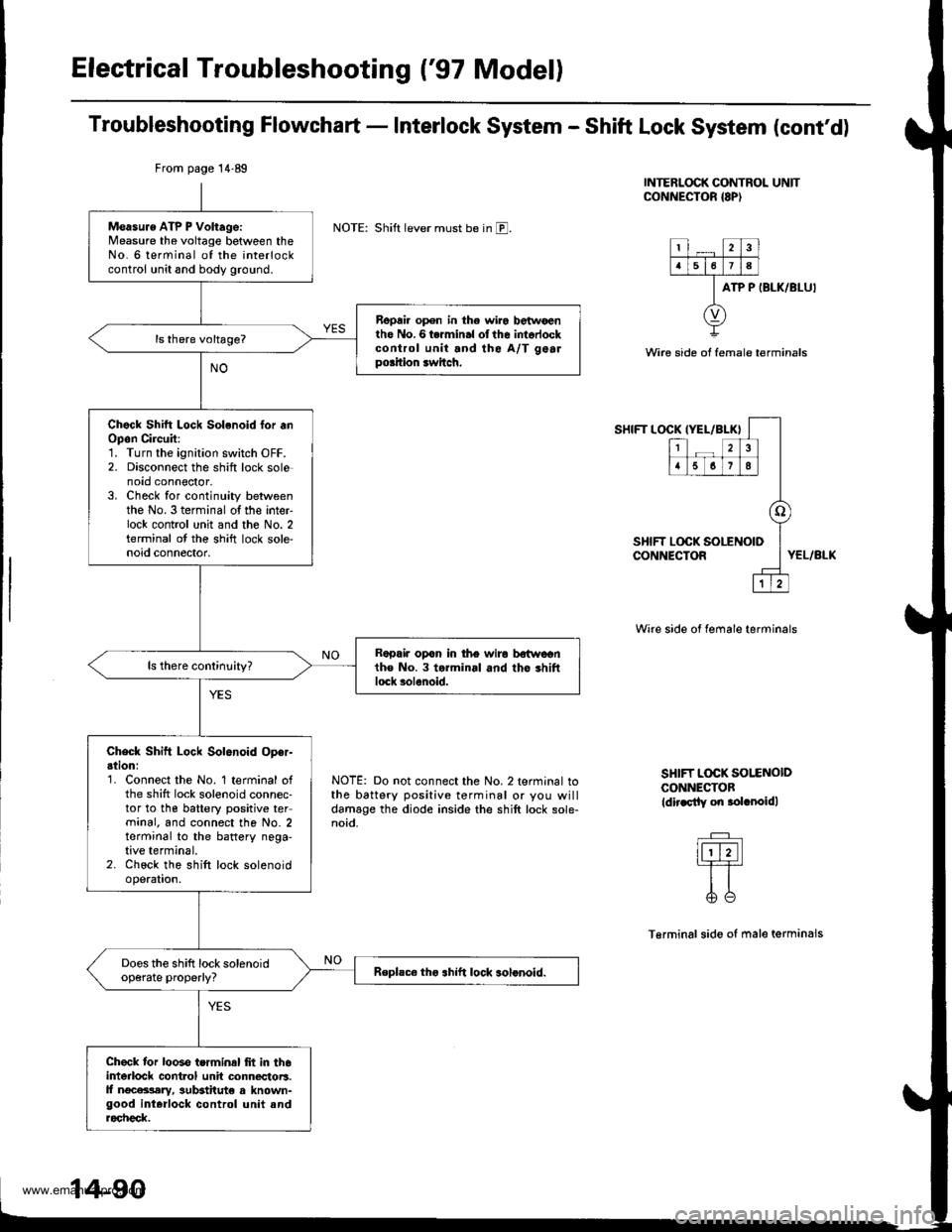

Electrical Troubleshooting ('97 Model)

Troubleshooting Flowchart - Interlock System - Shift Lock System (cont'd)

INTERLOCK CONTROL UNITCONNECTOR {8P)

NOTE: Shift lever must be in E.

ATP P IBLK/BLU'

Wire side ot female terminals

SHIFT LOCKIYEL/BLK}

12

5678

o

LOCK SOLENOID

1

SHIFT LOCK !CONNECTORYEL/BLK

NOTE: Do not connect the No. 2 terminal tothe battery positive terminal or you willdamage the diode inside the shift lock sole-noid.

Wire side of female terminals

SHIFT L@K SOI.ENOIDCONNECTOBldir.sily on .olrnoidl

Terminalsido of male terminals

From page 14.89

Measu.e ATP P Voltage:Measure the voltage between theNo. 6 terminal of the interlockcontrol unit and body ground.

Repai. open in the wir6 betwoentho No.6 termin.l olthe intorlockcontrol unit and the A/T gealpo.ition rwitch.

Chock Shitt Lock Solenoid lor .nOpon Circuit:1. Turn the ignition switch OFF.2. Disconnect the shift lock solenoto connoctor.3. Check for continuity betweenthe No. 3 terminal of the inter-lock contrcl unit and the No. 2terminal ot the shift lock sole-noid connector.

Rapair opon in the wiro bstwcentho No. 3 torminal and tho shiftlock solenoid.

Check Shift Lock Solenoid Oper-ation:'1. Connect the No. 1 terminal ofthe shift lock solenoid connec-tor to the battery positive terminal. and connect the No. 2terminal to the battery nega-tive terminal.2. Chock the shift lock solenoidoperation.

Does the shift lock solenoidop€rate properly?Replsc€ tho .hift lock solonoid.

Check tor looso terminal frt in th6interlock cont.ol unit connectoB.ll ngcara,lary, sutEtitut€ a known-good interlock control unit androcheck.

www.emanualpro.com

Page 607 of 1395

![HONDA CR-V 1998 RD1-RD3 / 1.G Repair Manual

Troubleshooting Flowchart - Interlock system - Key Interlock system

IGNITION SW]TCH 6P CONNECTOR

KEY LOCK SOL

{WHT/BLU)

ACC PUSH SW (WHT/YELI

Wire side oI female terminals

KEY LOCK SOL(WHT/BLUI

(cont HONDA CR-V 1998 RD1-RD3 / 1.G Repair Manual

Troubleshooting Flowchart - Interlock system - Key Interlock system

IGNITION SW]TCH 6P CONNECTOR

KEY LOCK SOL

{WHT/BLU)

ACC PUSH SW (WHT/YELI

Wire side oI female terminals

KEY LOCK SOL(WHT/BLUI

(cont](/img/13/5778/w960_5778-606.png)

Troubleshooting Flowchart - Interlock system - Key Interlock system

IGNITION SW]TCH 6P CONNECTOR

KEY LOCK SOL

{WHT/BLU)

ACC PUSH SW (WHT/YELI

Wire side oI female terminals

KEY LOCK SOL(WHT/BLUI

(cont'd)

lgnition key cannot be moved

Irom ACC (l) pGition to LOCK (0)

position while Pushing the igni-

tion kev with the shift lever in lllposifio;, and the shift lever but-

ton rcleased.

Check Key Interlock Solenoid

Op€ration:1. Disconnect the ignition switch

connector (6P).

2. Connect the No. 4 terminal of

the ignition switch 6P connec-

tor to the battery Positive ter

minal, and connect the No. 3

terminal to the battery nega

tive terminal.3. Check the key interlock sole

noid operation A clicking

so!nd sho!ld be heard.

Faulty koy interlock solenoid.

Replace the ignition key cylinder/

steedng lock as36mbly

Does the key interlock

solenoid operate properly?

Check Key Interlock Switch OPer'

adon:1. Connect the No. 5 terminal of

the ignition switch connector

to the battery Positive termi

nal, and connect the No 3 ter

minal to the baftery negative

termrnal,2. Turn the ignition switch to

ACC (l), then push rt.

3. Check the key interlock sole'

noid operation. A clicking

sound should be heard whilepushing the ignition key.

Faulty key inte.lock switch

Replaco the ignition key cylindor/

stoering lock a3r.mblY.

Does the key interlocksolenoid operate ProPerlY?

To page 14 92

14-91

www.emanualpro.com

Page 608 of 1395

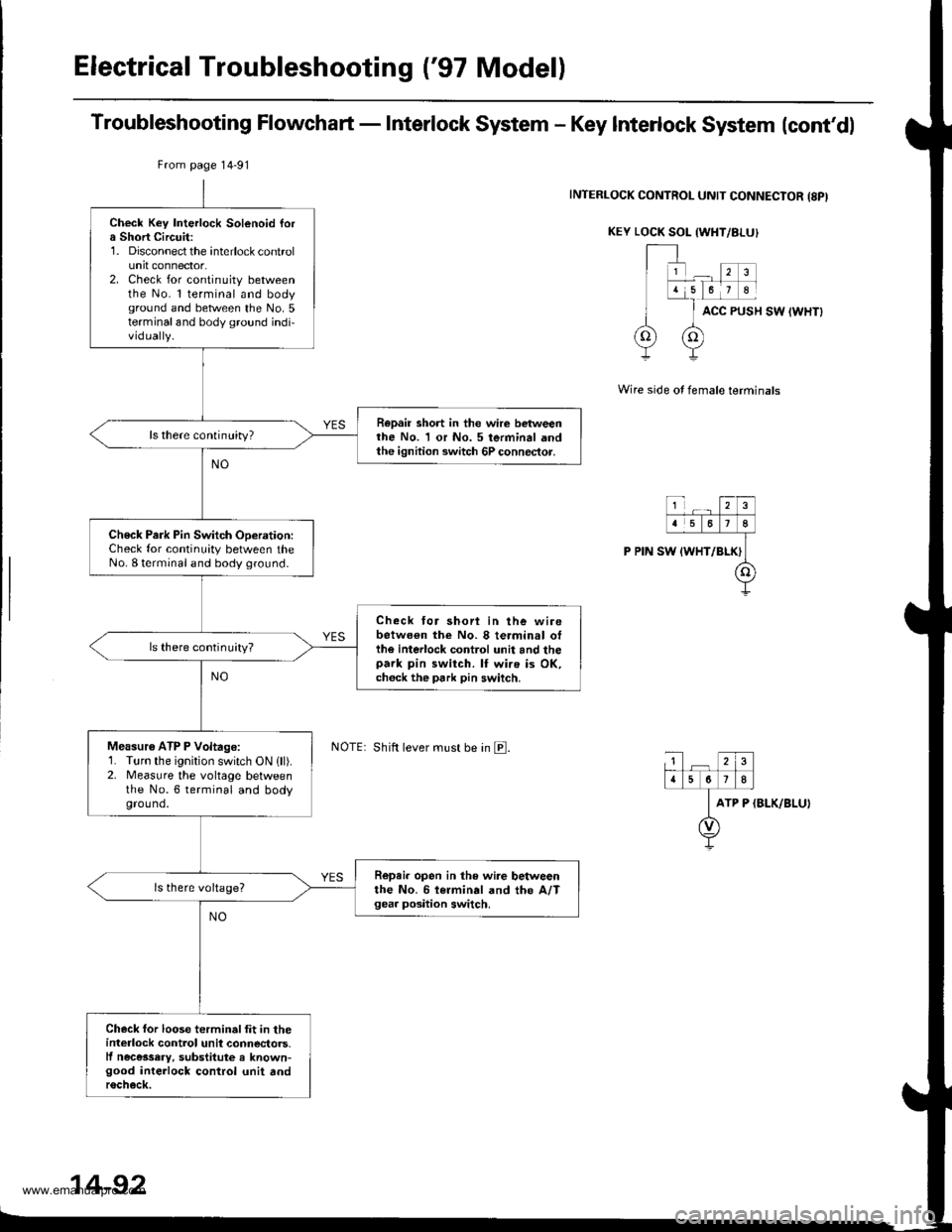

Electrical Troubleshooting {'97 Model)

Troubleshooting Flowchart - Interlock System - Key Interlock System lcont'dl

INTERLOCK CONTROL UNIT CONNECIOR {8PI

KEY LOCK SOL {WHT/8I-UI

ACC PUSH SW IWHTI

Wire side of female terminals

ATP P (BLK/BLU)

Check Key Interlock Solenoid fora Short Circuit:1. Disconnect the interlock controlunit connector.2. Check for continuity betweenthe No. l terminal and bodyground and between the No.5terminaland body ground indi-vidually.

Repair short in the wire betweenthe No. 1 or No. 5 terminal andthe ignition switch 6P connector.

ls there continuity?

Check Park Pin Switch ODeration:Check for continuity between theNo. I terminal and body ground.

Check tor shori in the wirebetwo€n the No. 8 terminal otthe interlock control unit and thepark pin switch. lf wire is OK,ch6ck the park pin switch.

ls there continuity?

Measu16 ATP P Voltage:1. Turn the ignition switch ON lll).2. Measure the vohage betweenthe No.6 terminal and bodyground.

R6pei. open in the wire betweenthe No. 6 i€rminal and the A/Tgea. position switch.

Check for loose terminalfit in theinterlock control unil connectors.lf necessery, substitute a known-good interlock control unit andr6check.

From page 14-91

Shift lever must be in E.

14-92

www.emanualpro.com

Page 609 of 1395

Electrical Troubleshooting ('98 - 00 Models)

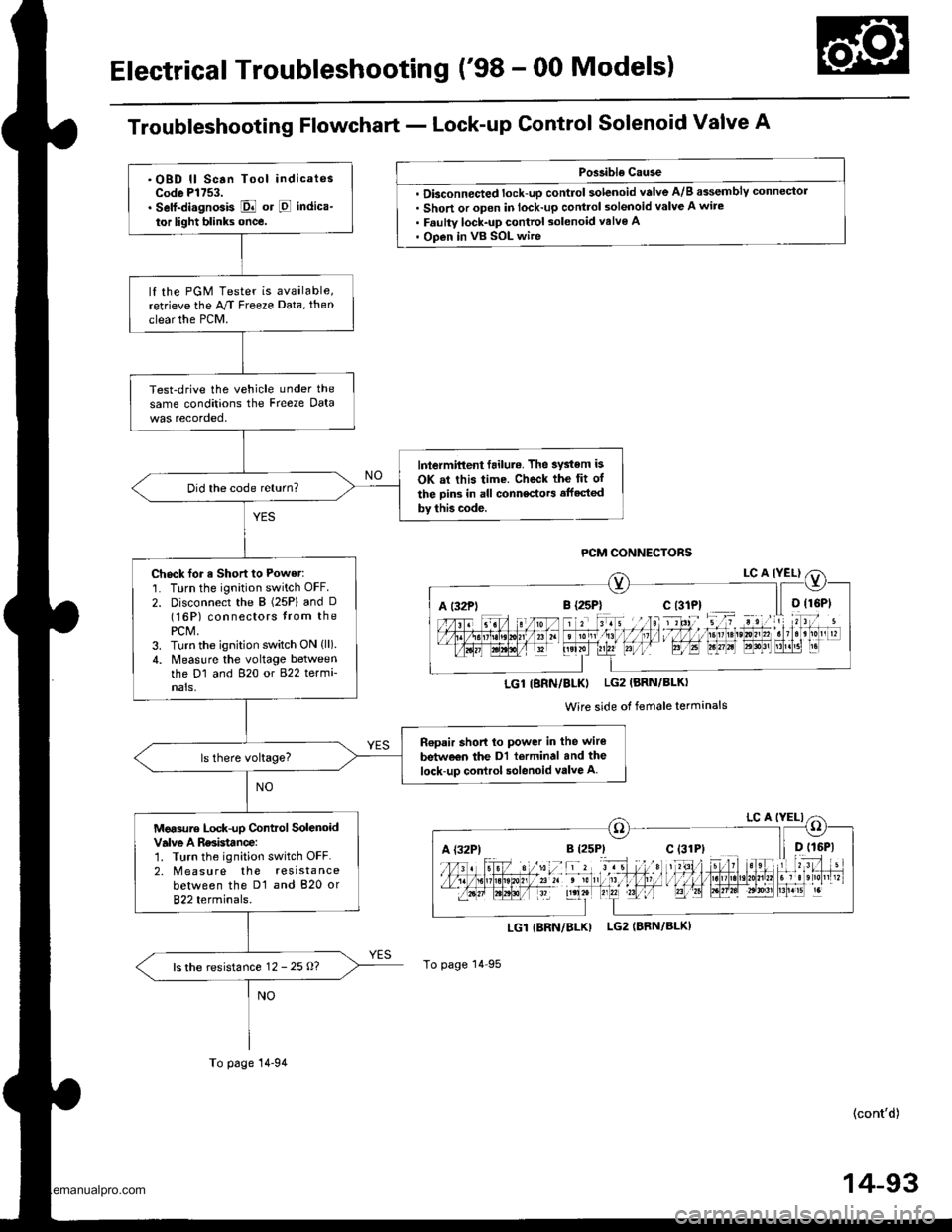

Troubleshooting Flowchart - Lock-up Control Solenoid Valve A

Poslible Cause

. Dbconnected lock-up control solenoid valve A/B assemblY connector. Short or open in lock-up control solenoid valve A wire. Faulty lock-up control solenoid valve A' Open in vB SOL wire

LGI|BRN/BLK) LG2IBRN/BLK)

To page 14 95

(cont'd)

14-93

A t32Pli r rriltI l,1 I I ltDrste,0n,,2. t3r B'r!51 r.

LGl IBRN/BLKI LG2 (BRN/BLKI

Wire side of female terminals

A {32P)

.OBD ll Scan Tool indicatesCode Pl753.. Self-di.gnosis E or E indica-

tor light blinks once.

lf the PGM Tester is available,retrieve the M Freeze Data, then

clear the PCM.

Test-drive the vehicle under the

same conditions the Freeze Data

lntermittent failul.. The system is

OK at this time. Check the fit of

the Din3 in all connectors affected

by thb code.

Did the code return?

Check for a Short to Power:'1. Turn the ignition switch OFF.

2. Disconnect the B (25P) and D(16P) connectors trom thePCM,3. Turn the ignition switch ON (ll).

4. Measlre the voltage betweenthe D1 and 820 or 822 termi-nals,

n€pair short lo power in the wire

betw€€n the Dl terminal and the

lock-up control solenoid valve A

Mg.sure Lock-up Control SolenoidValve A Rssistance:1. Turn the ignition switch OFF.2. M easu re the resistancebetween the D1 and 820 or822 terminals.

ls the resistance 12 - 25 o?

To page 14-94

www.emanualpro.com