ECM HONDA CR-V 1998 RD1-RD3 / 1.G Repair Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1998, Model line: CR-V, Model: HONDA CR-V 1998 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 318 of 1395

PGM-FI System

Primary Heated Oxygen Sensor (Primary HO2S) lSensor 1) (cont'd)

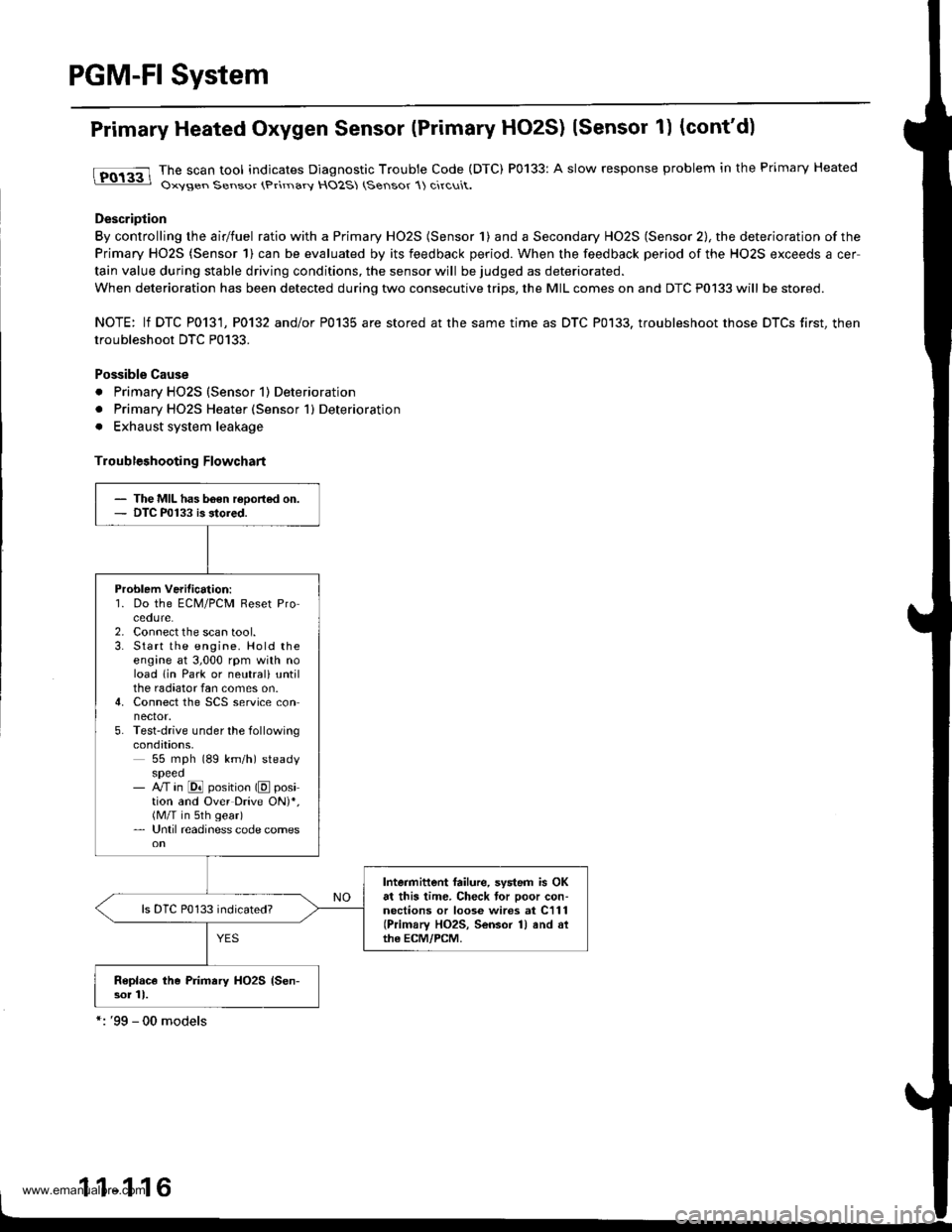

tFO133 lhe scan tool indicates Diagnostic Trouble Code (DTC) P0133: A slow response problem in the Primary Heated: Oxysen Sensor (Primarv HO2S (Sensor 1) circuit.

Description

By controlling the airlfuel ratio with a Primary HO2S (Sensor 1) and a Secondary HO2S (Sensor 2), the deterioration of the

Primary HO2S (Sensor 1) can be evaluated by its feedback period. When the feedback period of the HO2S exceeds a cer

tain value during stable driving conditions, the sensor will be judged as deteriorated.

When deterioration has been detected during two consecutive trips, the MIL comes on and DTC P0133 will be stored.

NOTE: lf DTC P0131, P0132 and/or P0135 are stored at the same time as DTC P0133. troubleshoot those DTCS first, then

troubleshoot DTC P0133.

Possible Cause

. Primary HO2S (Sensor 1) Deterioration

. Primary HO2S Heater (Sensor 1) Deterioration

. Exhaust system leakage

Troubleshooting Flowchart

- The MIL has b6€n reoorted on.- DTC P0133 is stored.

Problem Verilication:'1. Do the ECM/PCM Reset Procedure.2. Connect the scan tool.3. Start the engine. Hold theengine at 3,000 rpm with noload lin Park or neutrali untilthe radiator fan comes on.4. Connect the SCS service connector.5. Test-drive under the followingcondations,55 mph (89 km/h) steadyspeed- M in @ position (E position and Over Drive ON)*,(M/T in sth gear)- Until readiness code comes

Intermittent failure, system is OKat this time. Check tor poor con-nections or loose wires at C111(Primary HO2S, Sensor 1) and althe ECM/PCM.

Replace the Primary HO2S {Sen-sor 11.

1 1-1 16

www.emanualpro.com

Page 319 of 1395

Secondary Heated Oxygen Sensor (Secondary HO2S) (Sensor 2)

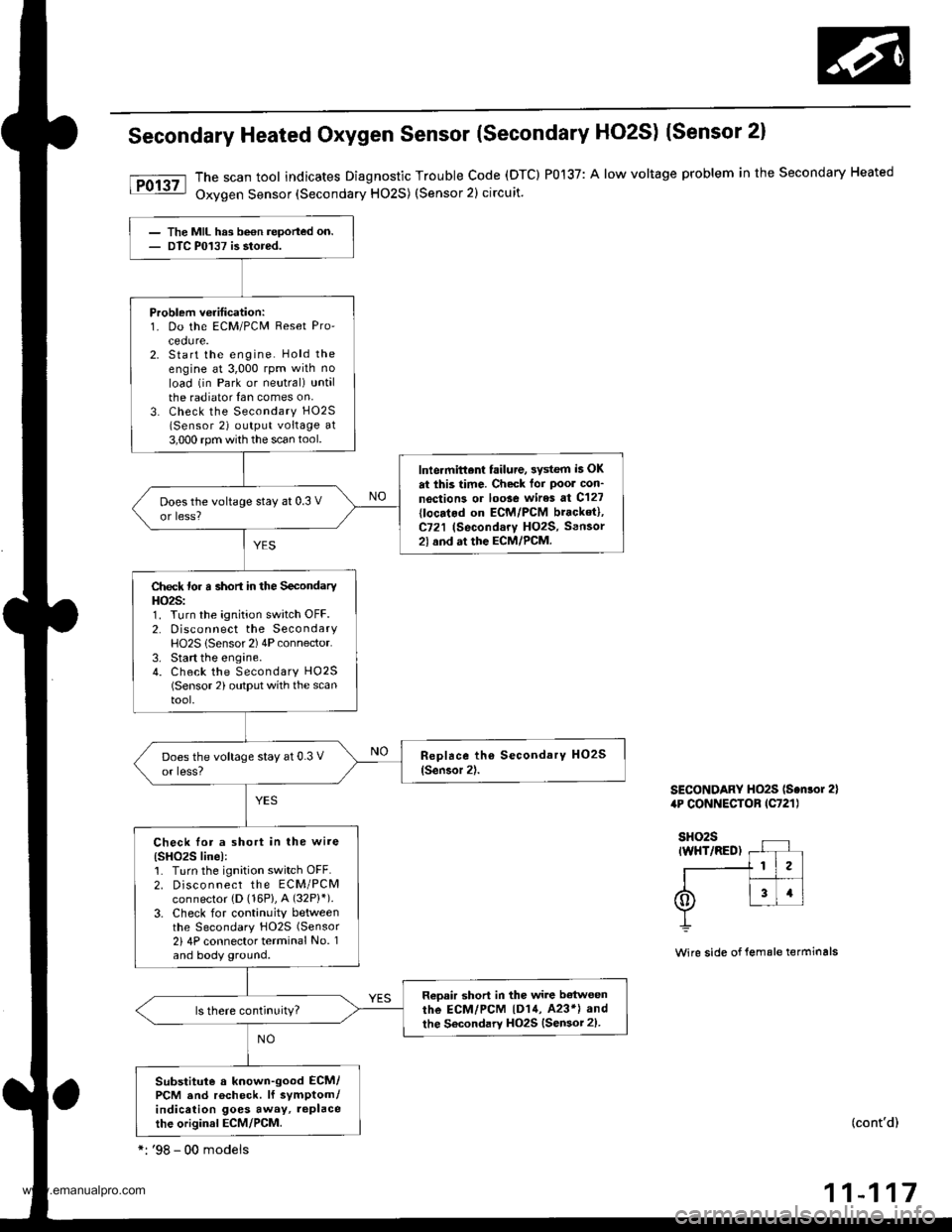

The scan tool indicates Diagnostic Trouble code (DTC) P0137: A low voltage problem in the secondary Heated

Oxygen Sensor (Secondary HO2S) (Sensor 2) circuit.

SECONDARY HO2S ls.nlor 2)4P CONNECTOB lC721l

Wire side of lemale terminals

(cont'd)

11-117

The MIL hrs been reported on.DTC P0137 is stored.

Problem veritication:1. Do the ECM/PCM Reset Pro'cedure.2. Start the engine. Hold theengine at 3,000 rpm wilh no

load (in Park or neutral) untalthe radiator {an comes on,3. Check the Secondary H02S

lSensor 2) output voltage at3,000 rpm with the scan tool.

lnlermittent failure, 3ystem i5 OK

at this time. Check tor Poor con'

noction3 or loose wires at C127

{locatod on ECM/PCM bracket},C721 (Secondary HO2S, Sensor2l and at the ECM/PCM.

Does the voltage stay at 0.3 V

or less?

Check for a short in the SecondaryHO2S:1. Turn the ignition switch OFF.2. Disconnect the SecondaryHO2S lSensor 2) 4P connector.3. Start the engine.4. Check the Secondary HO25(Sensor 2) output with the scantool.

Check lor a short in the wire(SHO2S linel:1. Turn the ignition switch OFF.2. Disco n nect the ECM/PCMconnector {D (16P}, A (32P}').

3. Check for continuity betweenthe Secondary HO2S (Sensor

2i 4P connector terminal No. 1and body ground.

Reoair short in the wire b€twoen

rhe ECM/PCM |D14, 423*l and

the Secondary HO2S {Sensor 2).

Substitute a known-good ECM/PCM and rocheck. lf symptom/indication goes away, replacethe original ECM/PCM.

*: '98 - 00 modeis

www.emanualpro.com

Page 320 of 1395

PGM-FI System

Secondary Heated Oxygen Sensor (Secondary HO2SI (Sensor 2l (cont'dl

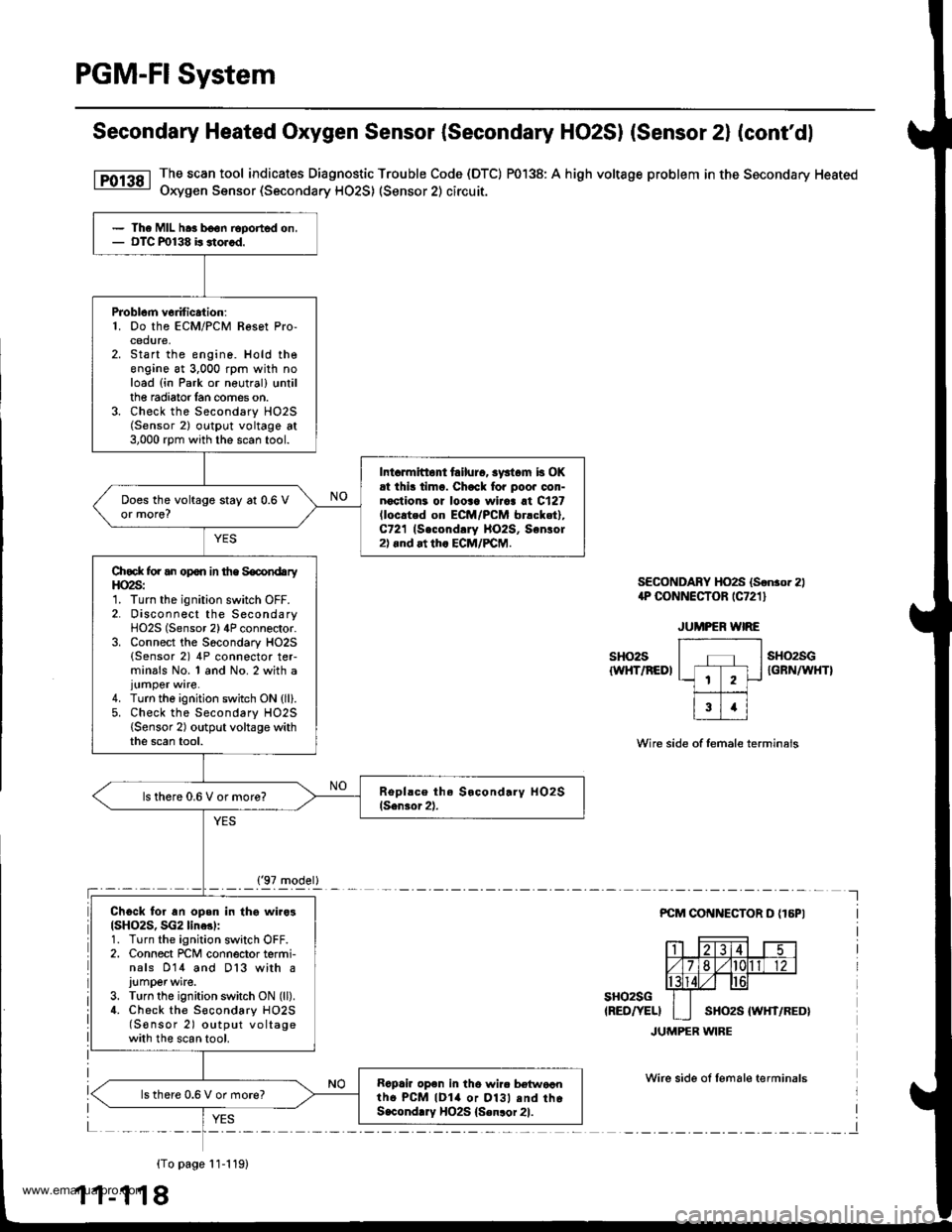

The scan tool indicates Diagnostic Trouble Code (DTC) P0138: A high voltage problem in the Secondary Heated

Oxygen Sensor (Secondary HO2S) (Sensor 2) circuit.

SECONDABY HO2S (Sonror 2)1P CONNECTOR rC721 l

sHo2s{WHT/REDI

sH()2sGIGFN/WHTI

Wire side of female terminals

PCM COI{NECTOR D {16PI

sHo2sG(RED/YELI

JUMPER WIRE

Wirc side ol lemale terminals

{To page 11-119)

1 1-1 18

The MIL hra b€on Eported on,OTC m138 b stor.d.

PJoblcm v6dtic.tion:1. Do the ECM/PCM Resot Pro-cedure,Start the engine. Hold theengine at 3,000 rpm with noload (in Park or neutral) trntilthe radiator lan comes on.Check the Secondary HO2S(Sensor 2) outpl.rt voltage at3,000 rpm with the scan tool.

Int.rmitto tailurc, syst.m b OKrt ihi! timo. Chack fo. poo. oon-noctioni or looaa wiiaa at C127lloc.ted on EcM/PcM br.cket),C721 (Second!ry llO2S, Sonlol2).nd at th. ECM/PCM.

Does the voltage stay at 0.6 Vor more?

Chock for an opon in the SocondaryHO2S:1. Turn the ignition switch OFF.2. Disconnect the SecondaryHO2S (Sensor 2) 4P connector.3. Connect the Socondary HO2S(Sensor 2) 4P connector ter-minals No. 1 and No. 2 with a

4. Turn the ignition switch ON {ll}.5. Check the Secondary HO2S{Sensor 2) output voltage withthe scan tool.

ls there 0.6 V or more?

Ch6ck for an open in thg wiro3(SH()2S, SG2 line3l:1. Turn the ignition switch OFF.2. Connect rcM connector termi-nals 014 and D13 with a

J!mper wite.3. Turn the ignition switch ON (ll).

4. Check the S€condary HO2S(S€nsor 2) output voltagewith the scan tool.

Rapair op6n in tho wir. b€{woantho PcM lDla or Dl3l .nd thoS.condlry HO2S {Senlor 21.

lsthere 0.6 V or more?

('97 model)

www.emanualpro.com

Page 321 of 1395

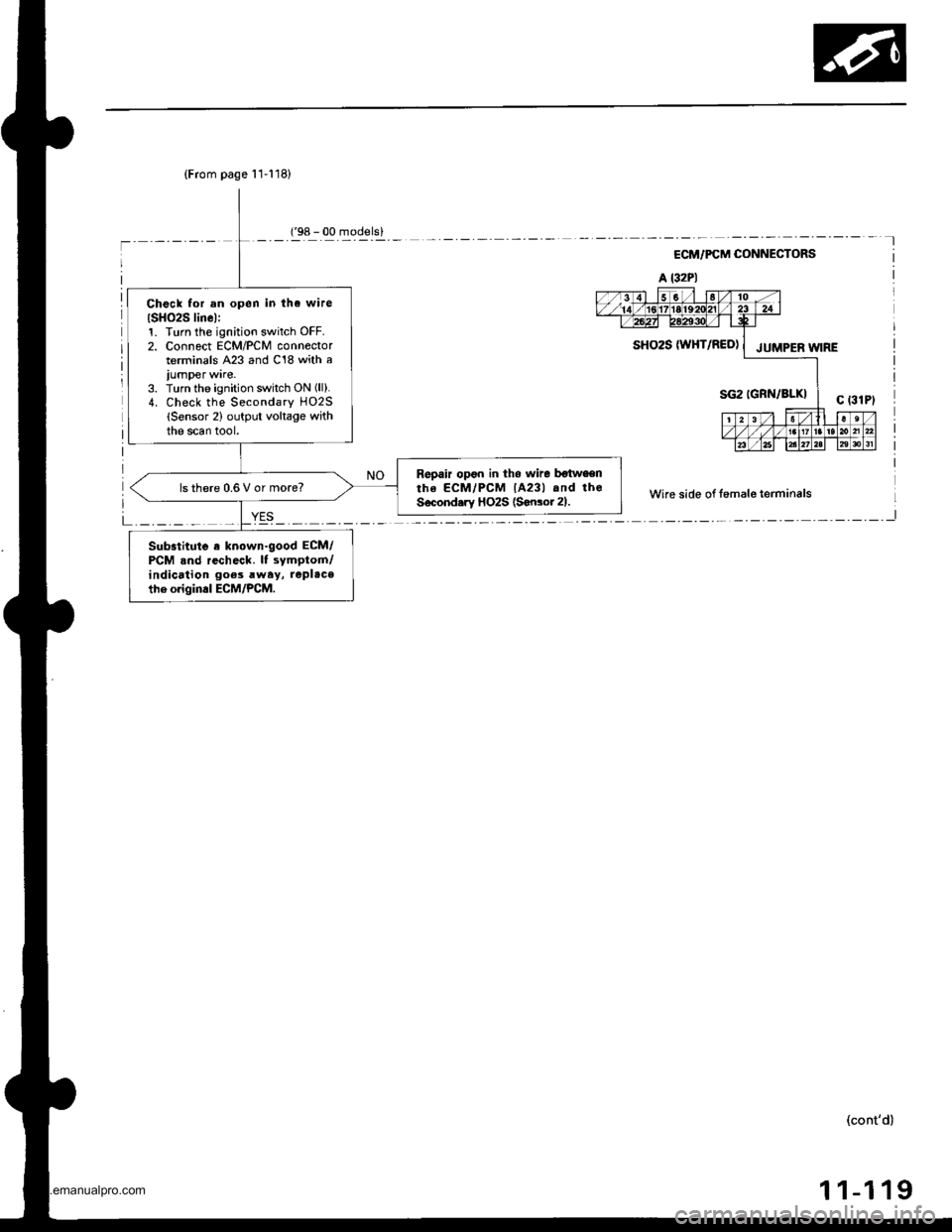

(From page 11-118)

Check for an open in tha wire

ISH()2S linel:1. Turn th€ ignition switch OFF.2. Connect ECM/PCM connectorterminals A23 and C18 with a

iumper ware.3. Turn the ignition switch ON (ll).

4. Check the Secondary HO2S(Sensor 2) output voltage withthe scan tool.

Repair opon in tho wire botwaenthe ECM/PCM lA23l and theSecond.ry HO2S (Sonsot 21.ls there 0.6 V or more?

Substitute a known.good ECM/PCM .nd recheck. It symptom/indication goes rway, replace

the origin.l ECM/PCM.

('98 - 00 models)

ECM/PCM CONNECTORS

A l32Pl

Wire side of fomale terminals

L _._._ _ _I

SHO2S W}iT/RED) | JUMpER W;RE

(cont'd)

1 1-1 19

www.emanualpro.com

Page 322 of 1395

PGM-FI System

Secondary Heated Oxygen Sensor (secondary HO2SI (sensor 2l (cont,d)

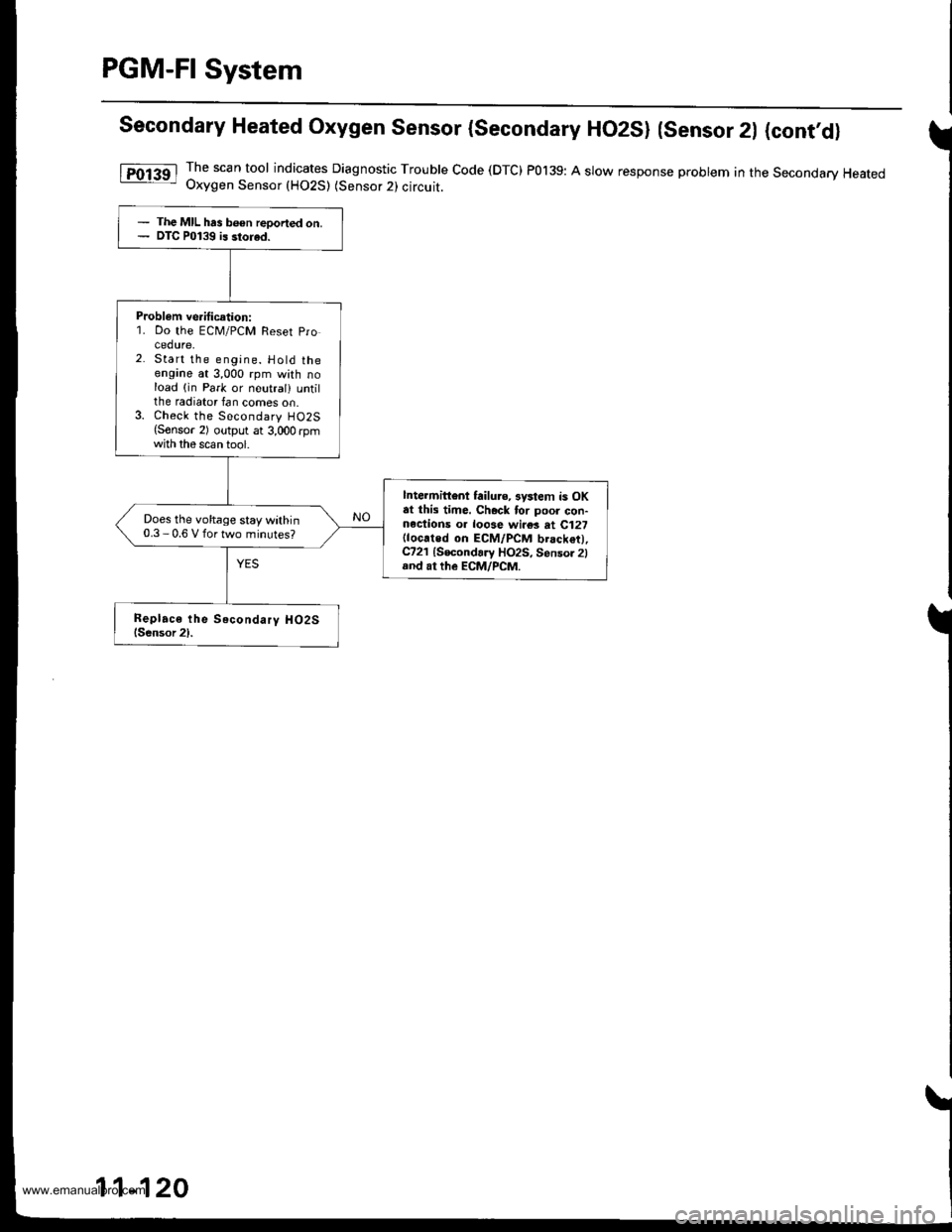

lTol3al The scan tool indicates Diagnostic Trouble Code (DTC) P0139: A slow response probtem in the Secondary Heated- Uxygen Sensor (HO2S) (Sensor 2l circuit.

- The MIL has b€en reoorted on.- DTC P0139 is storad.

Probl€m ve.itication:1. Do the ECM/PCM Reset Procedure,Start the engine. Hold theengine at 3,000 rpm with noload (in Park or neutral) untilthe radiator fan comes on.Check the Secondary HO2S(Sonsor 2) output at 3,000 rpmwith the scan tool.

lntehittont failure, 3ystem is OKat this time. Chock for poor con-nections o. loose wi.es at C127(located on ECM/PCM brack€t),C721 {Secondary HO2S, Sensor 2land at the EcM/PcM.

Does the voltage stay within0.3 - 0.6 V for two minutes?

11-120

www.emanualpro.com

Page 323 of 1395

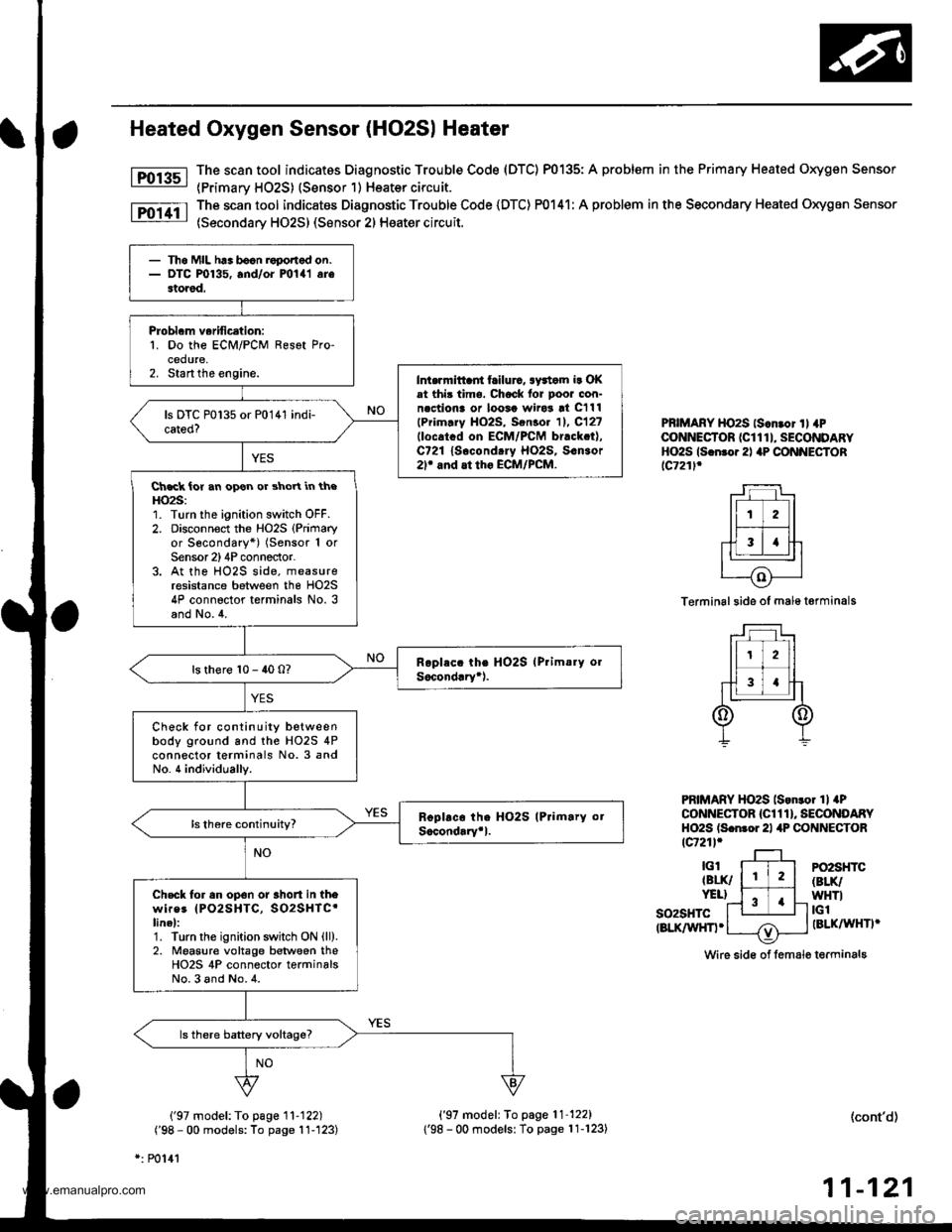

Heated Oxygen Sensor (HO2S| Heater

The scan tool indicatos Diagnostic Trouble Code (DTC) P0135: A problem in the Primary Heated Oxygen Sensor

{Primarv HO2S) (Sensor 1) Heater circuit.

The scan tool indicates Diagnostic Trouble Code (DTC) P0141: A problem in the Secondary Heated Oxygen Sensor

(Secondary HO2S) (Sensor 2) Heater circuit.

Fol3sl

Fo11tl

PBIMARY HO2S ls.n.or ll 4PCONNECTOR (CI 1 1 I, SECONDARYHO2S ls.n.o.2l aP CONNECTORlc721l.

Terminal side of male t€rminals

PRIMARY HO2S lson.o. 1l aPCONNECTOR {Cl 1 1 }, SECONDARYHO2S ls.nror 21 4P CONNECTORtcr21l.

so2sHTctBLK/WHn.

PO2SHTC(BLK/

WHTItGlIBLKAAIHTI'

Wire sid€ of lemale terminals

('97 model: To page '11-122)

('98 - 00 models: To page 11-'123)

*: P0141

('97 model: To page'11-122)

1'98 - 00 modelsl To page 11-123)(cont'd)

11-121

- Th6 MIL h.. bocn roponod on.- DTC P0135, and/oi mlal arestored.

Probl.m verification:1. Do the ECM/PCM Resot Pro-cedure,2. Start the engine.Int.rrnittaii frilurc, awtom ir OKat thi3 time. Chock lor poor con-n.ctiona or loosa wiro3 !t C111

lPrim.ry HO2S, Sen3o. 11. C12?llocatcd on ECM/PCM br.ck.t),C721 lsocond.ry Ho2s, s.n3or2r and at tho ECM/PCM.

Ch.ck ior an opon or shoYt in theHO2S:1. Turn the ignition switch OFF.2. Disconnoct the Ho2s (Primary

or Secondary*) (Sensor 1 orSensor 2)4P conneclor.3. At the HO2S side, measureresistance between the HO2S4P connector terminals No. 3and No.4.

ls there 10 - 40 0?

Check for continuity betweenbody ground and the HO2S 4Pconnector terminals No. 3 andNo. 4 individually.

Check tor an op6n or 3hort in thewires IPO2SHTC, SO2SHTC'linel:1. Turn the ignition swhch ON {ll).2. Moasure voltage between theHO2S 4P connector terminalsNo.3 and No.4.

www.emanualpro.com

Page 325 of 1395

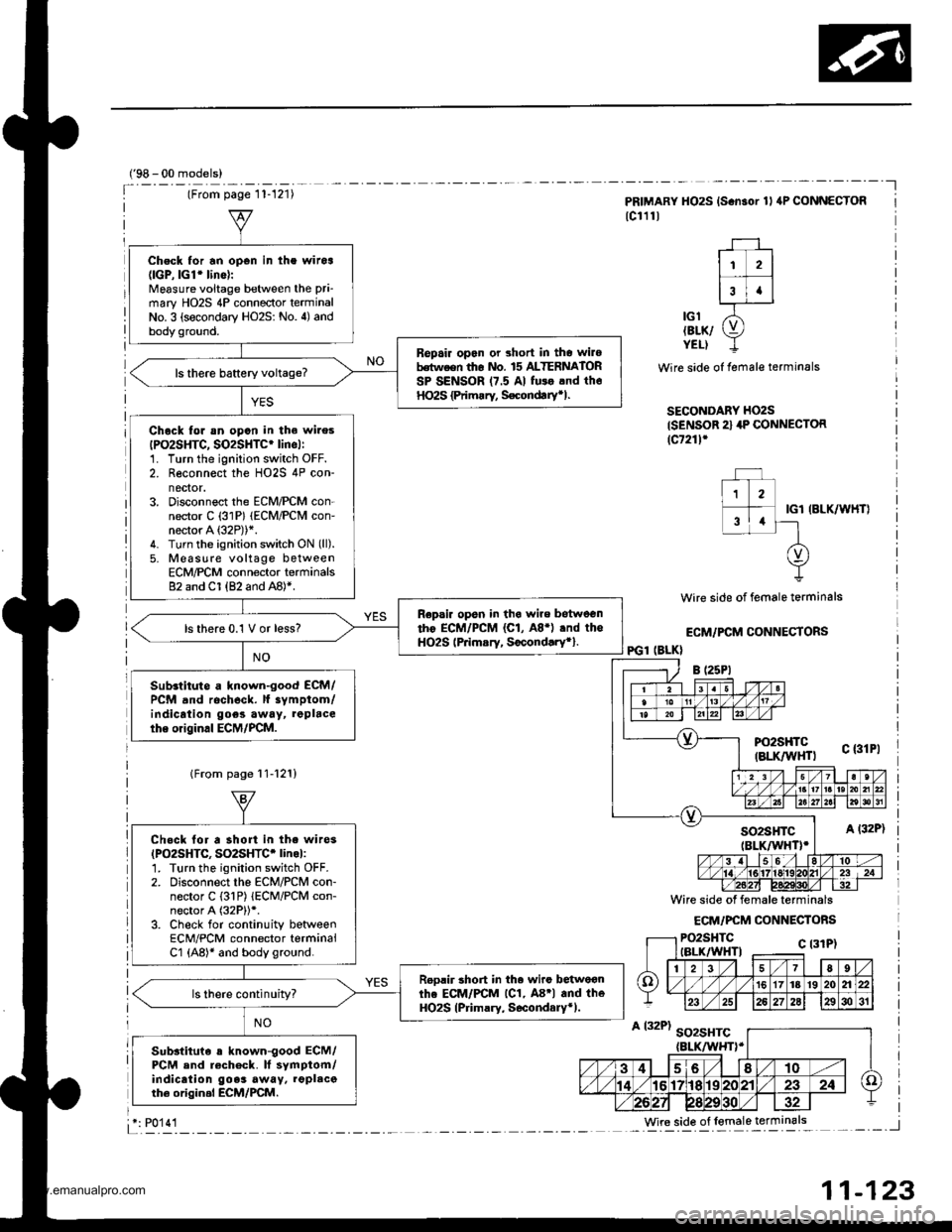

Check for an open in the witoa(lGP,lGl'lino):

Mgasure voitage between the pri-

mary HO2S 4P connector terminalNo. 3 (secondary HO2S: No. 4) andbody ground.

Bepair opan or short in tho wilobdtween th6 nlo. 15 ALTERNATORSP SENSOR 17.5 Al fu$ .nd th6HO2S {Primrry, S€condtrytl.

Chock lor sn opon in the wires

IPO2SHTC, SO2SHTC' lincl:1. Turn the ignition switch OFF.2. Reconnect the HO2S 4P con-nector.3. Disconnect the ECM/PCM con-nector C (31P) (ECM/PCM con-neaor A (32P))*.

4. Turn the ignition switch ON (ll).

5. Moasure voltage betweenECM/PCM connector terminals82 and Cl (82 and A8)*.

Repsir opsn in tha wire betweentho ECM/PCM (C1, A8.) .nd theHO2S lPrimsry, Socond.ry*}.ls there 0.1 V or less?

Sub.titute a known-good ECM/PCM and rocheck. lf iymptom/indicrtion goes away, repbcethe original ECM/PCM.

('98 - 00 models)

Wire side of female terminals

ECM/FCM CONNECTORS

IGl IBLK/WHT}

PRIMARY HO2S {S.n3or 1l aP CONNECTOR

lc111l

11 2l

r--T -l3t.lL-.IJ------J

lcl /5'tErK/ g,YELI I

Wire side of female terminals

SECONDARY HO2S

{SENSOR 2} 4P CONNECTOR(c7211'

PGl (BLK}

lFrom page 11-12'!)

Chock lor a short in the wi.es(PO2SHTC, SO2SHTC' linol:1. Turn the ignition switch OFF.2. Disconnect the EcM/PcM con-nector C {31P) lECM/PCM con-nector A (32P))*.

3. Check for continuity betweenECM/PCM connector terminalCl (A8)* and body ground.

Roolir 3hort in th. wiro betwoonthe ECM/PCM lC1, A8'l and theHO2S (Primary, S6condary*).ls there continuity?

Sub3tituie s known-good ECM/PCM and rech6ck. It symptom/indicaiion goes away. lgplacoth6 origin.l ECM/PCM.

Wire side of lemale terminals: P0'14'l

11-123

www.emanualpro.com

Page 330 of 1395

PGM-FI System

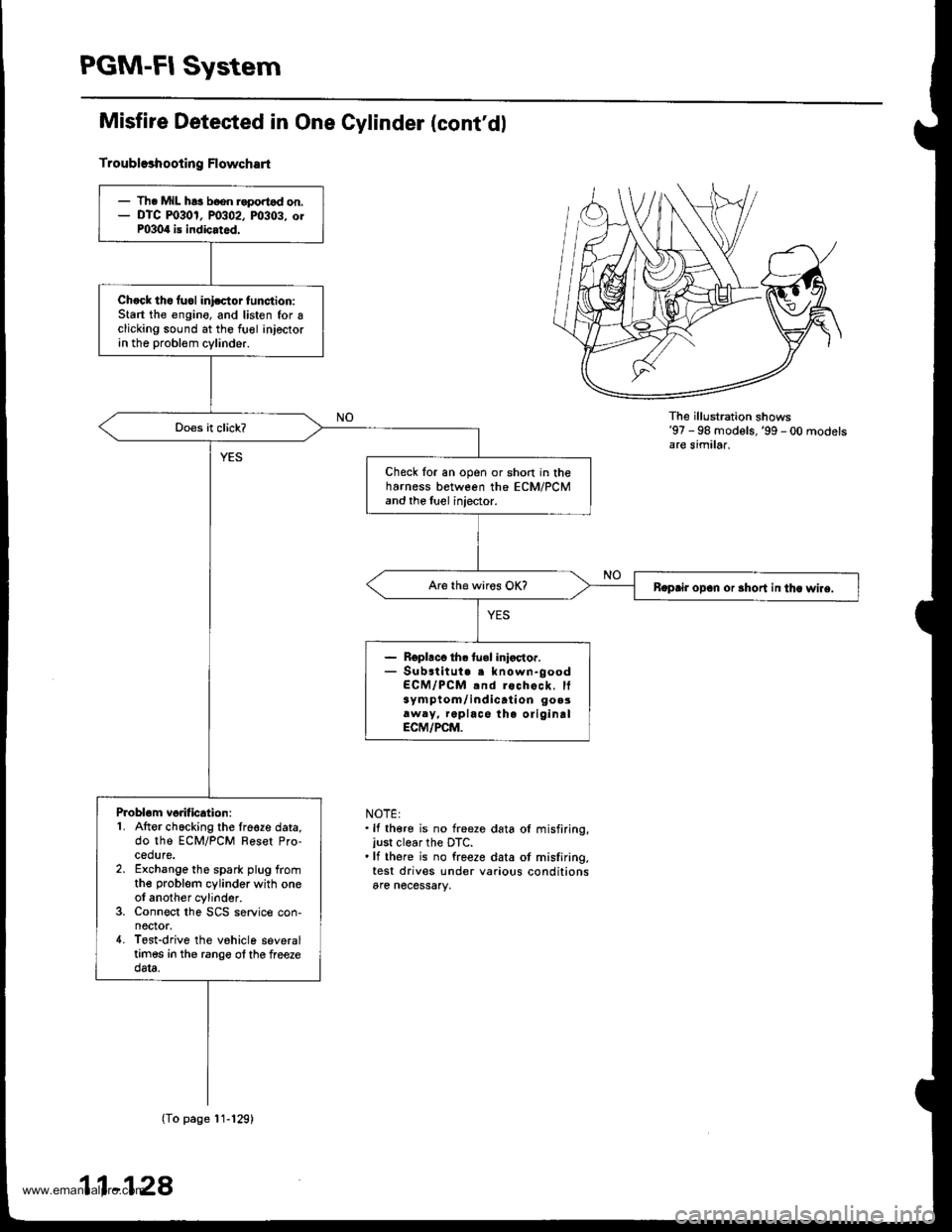

Misfire Detested in One Cylinder (cont'dl

Troubl93hooting Flowchart

The illu stration shows'97 - 98 models,'99 - 00 modelsare similar.

NOTE:.lf there is no freeze data ol misfiring,just clear the DTC..lf there is no freeze data ot misfiring,test drives under various conditionsare necessary,

- Th. MIL h!3 b6on r.portod on.- DTC m30r, P0302, m303. orP0304 is indicated.

Ch.ck tho fuol inicctor tunction:Start the engino, and listen for Iclicking sound at the fuol injectorin the probl€m cylinder.

Check for an open or short in theharness between the ECM/PCMand the luel injector.

Boprir opan or 3hort in tha wlre.

- Roplaco th. tuel inioctor.- Substitut. . known-goodECM/PCM .nd rochock. It3ym ptom/ indicati on go.3aw.y, replace the oliginalECM/PCM.

Problom vorification:1. Atter chacking the lre€ze data,do the ECM/PCM Reset Pro-cedure.2. Exchange the spark plug fromthe problem cylinder with oneol another cylinder.3. Connect the SCS service con-nector.4. Tost-drive the vohicle severaltimes in the rango ol the freezedata.

(To page'11-129)

11-128

www.emanualpro.com

Page 332 of 1395

PGM-FI System

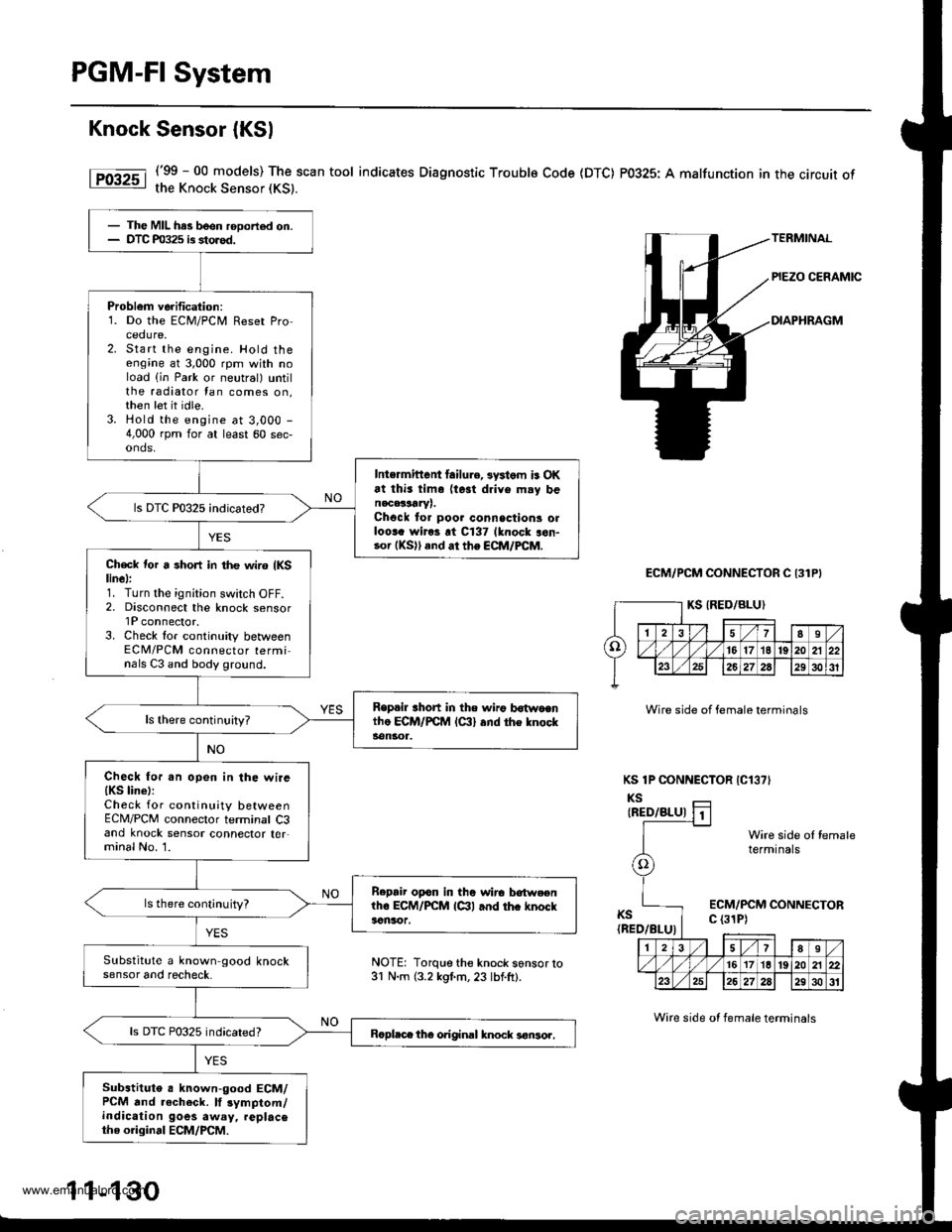

Knock Sensor {KSl

('99 - 00 models) The scan tool indicates Diagnostic Troublo Code (DTC) P0325: A malfunction in the circuit ofthe Knock Sensor (KS).

ECM/PCM CONNECTOR C 131P}

Wire side of female terminals

KS 1P CONNECTOR IC13?'

KSIRED/BLU)

KS(BED/BLU)

Wire side ol femaletermtnals

ECM/PCM CONNECTORc (31P)

- The MIL has been rooorted on.- DTC m325 is storod.

Problem verification:1. Do the ECM/PCir, Reset Procedure,2. Start the engine. Hold theengine at 3,000 rpm with noload (in Park or neutral) untilthe radiator tan comes on,then let it idle.3. Hold the engine at 3,000 -

4,000 rpm for at least 60 sec-onds,

Intermittent lailu.e, 3ystom is OKat thi3 tim. (te3t drive m.y benacalLrYr.Chock to. poor connsctions olloora wiros rt C137 lknock aon-.o. (KS)) and ar the ECM/FCM.

Ch€ck tor a short in the wir6 {KSlinel:1. Turn the ignition switch OFF.2, Disconnect the knock sensorlP connector.3. Check lor continuity betweenECM/PCM connector terminals C3 and body ground.

Replil rhort in the n irg b6{wocntho ECM/PCM lc:ll and the knocks€ngr1.

Check fo..n open in the wire{KS line):Check for continuity betweenECM/PCM connector terminal C3and knock sensor connector ter,minal No. 1.

B.pair opon in the wirc lrotweenlho ECM/PCM lctl and thc knockacnsor.

ls there cont;nuity?

Substitute a known-good knocksensor and recheck.

ls DTC P0325 indicated?Bcpl.ce the original knock 3€nsor,

Substituto a known-good ECM/PCM and .echeck. lf 3ymptom/indication goes away, replacethe original ECM/PCM.

NOTE: Torque the knock s6nsor to31 N.m (3.2 kgl.m, 23 lbf.ft).

1 1-130

Wire side ot female terminals

www.emanualpro.com

Page 335 of 1395

TDCP (GRN)

CYPP (YEL}

TDCM (REDI

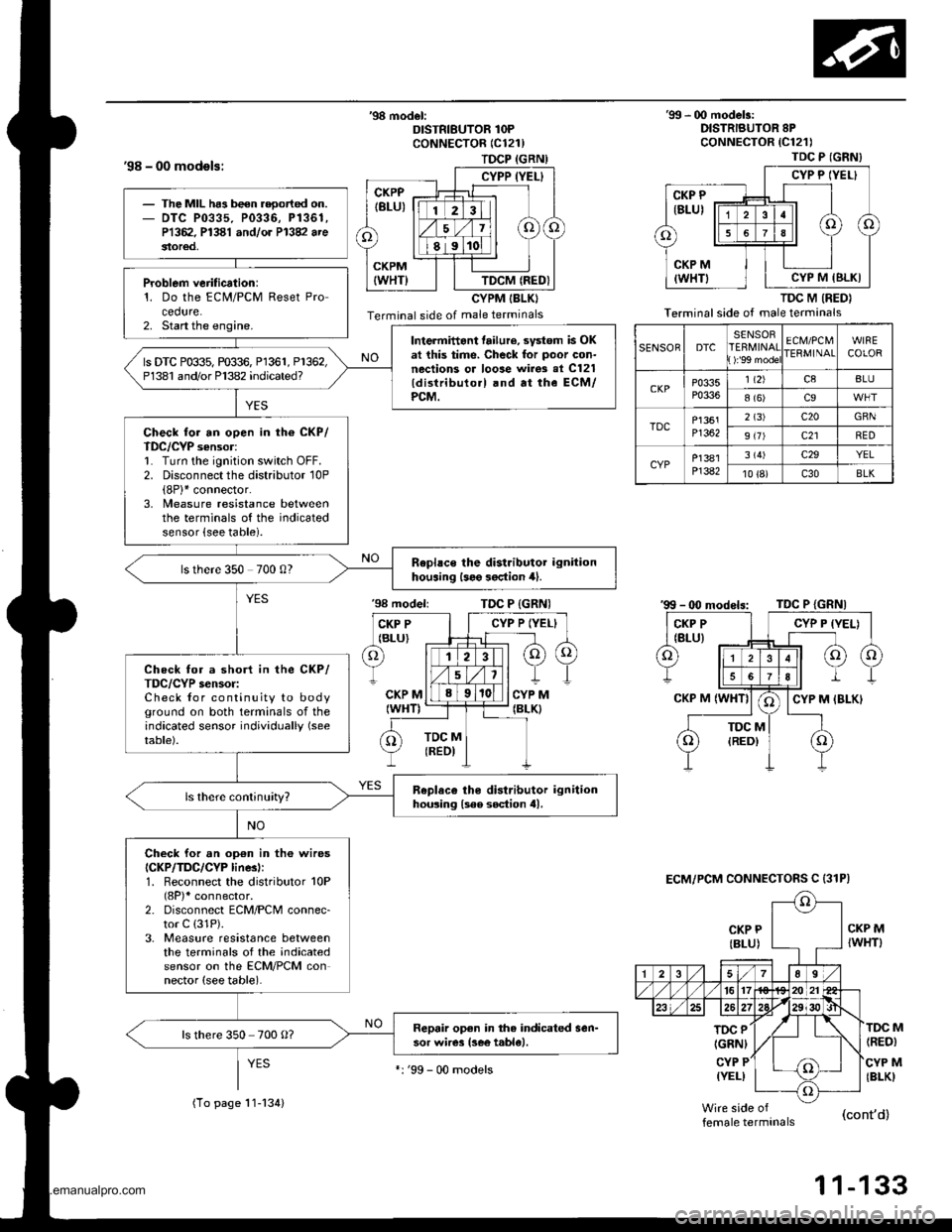

'98 - 00 models:

'98 model:DISTRIBUTOR 1OPCoNNECTOR (C121)

CYPM IBLKI

Terminal side of male terminals

'99 - 00 modelr:DISTRIBUTOR 8PcoNNECTOR {C121)

TDC M (RED}

Terminal side of male terminals

CKP P

{BLU)

'98 modeliTDC P {GRNI

CKP MIWHT)

TOC P

IGRNI

CYP P(YEL)

(RED)

CYP M(BLKI

M

female terminals(cont'd)

1 1-133

TDC P (GNN}

CYP P IYEL}

CYP M IBLKI

SENSORDTCSENSORERMINAT):'99 mode

ECM/PCMIERMINAIWIRECOLOR

CKPP0335P0336

1 t2)c8BLU

8 (6)c9

TDCP1361Pl362

2 (3)c20GBN

9 (7)c21RED

CYPP]381P]382

3 (4)c29YEL

10 {8)c30BLK

ECM/PCM CONNECTOFS C {31P)

The MIL ha3 been reoorted on.DTC P0335. P0336, P1361,P1362. P1381 andlor P13V arestor€d,

Problem verification:1. Do the ECM/PCM Reset Procedure.2. Start the engine.Intermittant tailure, svstom is OKat this time. Check for poor con-nections or loose wirgs al C121{distributo.l .nd at the ECM/PCM.

ls DTC P0$5, m$6, Pl361, P1362,P1381 and/or Pl382 indicated?

Check for an open in th6 CKP/TDC/CYP sensor:1. Turn the ignition switch OFF.2. Disconnect the distributor 10P(8P)* connector.3, Measure resistance betweenthe terminals of the indicatedsensor {see table).

Rephce the distributor ignitionhouaing l3e9 3oction 4).ls there 350 700 0?

Check for a short in the CKP/TDC/CYP s€nsor:Check for continuity to bodyground on both terminals of theindicated sensor individually (see

table).

Replaco tho distributor ignitionhousing lsee soction tll.

Check for an op€n in th6 wiresICKP/TDC/CYP linesl:1. Reconnect the distributor 10P(8P)* connector.2. Disconnect ECM/PCM connec-tor C (31P).

3. Measure resistance betweenthe terminals of the indicatedsensor on the ECM/PCM connector (see table).

Repair open in the indicated sen-sor wires lsee t.ble).ls there 350 700 O?

(To page 11-134)

':'99 - 00 models

www.emanualpro.com