ECM HONDA CR-V 1998 RD1-RD3 / 1.G Repair Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1998, Model line: CR-V, Model: HONDA CR-V 1998 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 336 of 1395

PGM-FI System

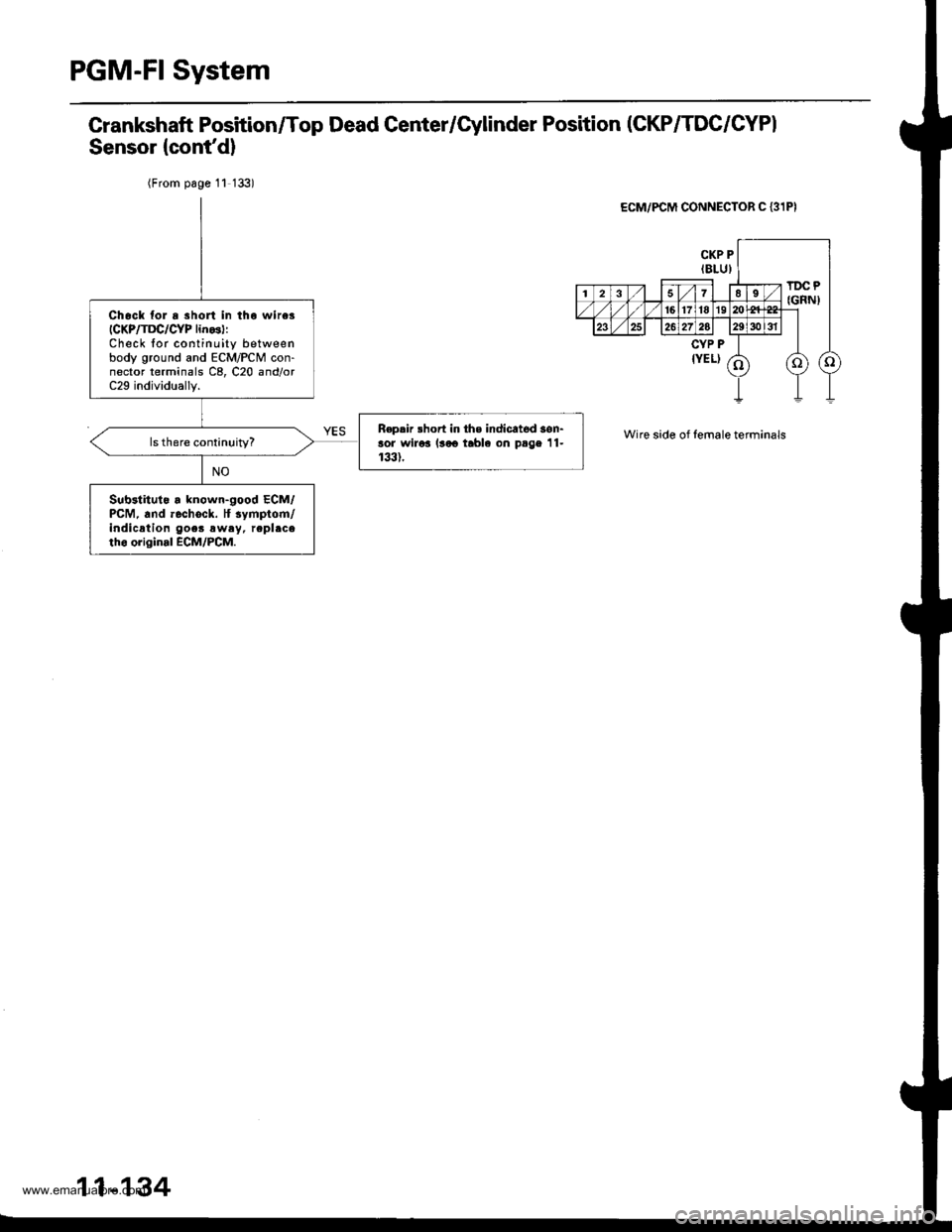

Grankshaft Position/Top Dead Center/Cylinder Position (CKP/TDC/CYPI

Sensor {cont'd}

(From page 11 133)

ECM/PCM CONNECTOR C {3IPI

Wire side of female terminals

Chock lor r 3hon in tho wirerICKP/TDC/CYP lin6):Check for continuity betweenbody ground and ECM/PCM con-nector terminals C8, C20 and/orC29 individually.

Rep.ir lhort in ths indicated son-aor wiroa 136o table on prge 11-133).

Substituto r known-good ECM/PCM, and .6chock. tf 3ymptom/indication goe3 swey, replrcetho original ECM/PCM.

11-134

www.emanualpro.com

Page 338 of 1395

PGM-FI System

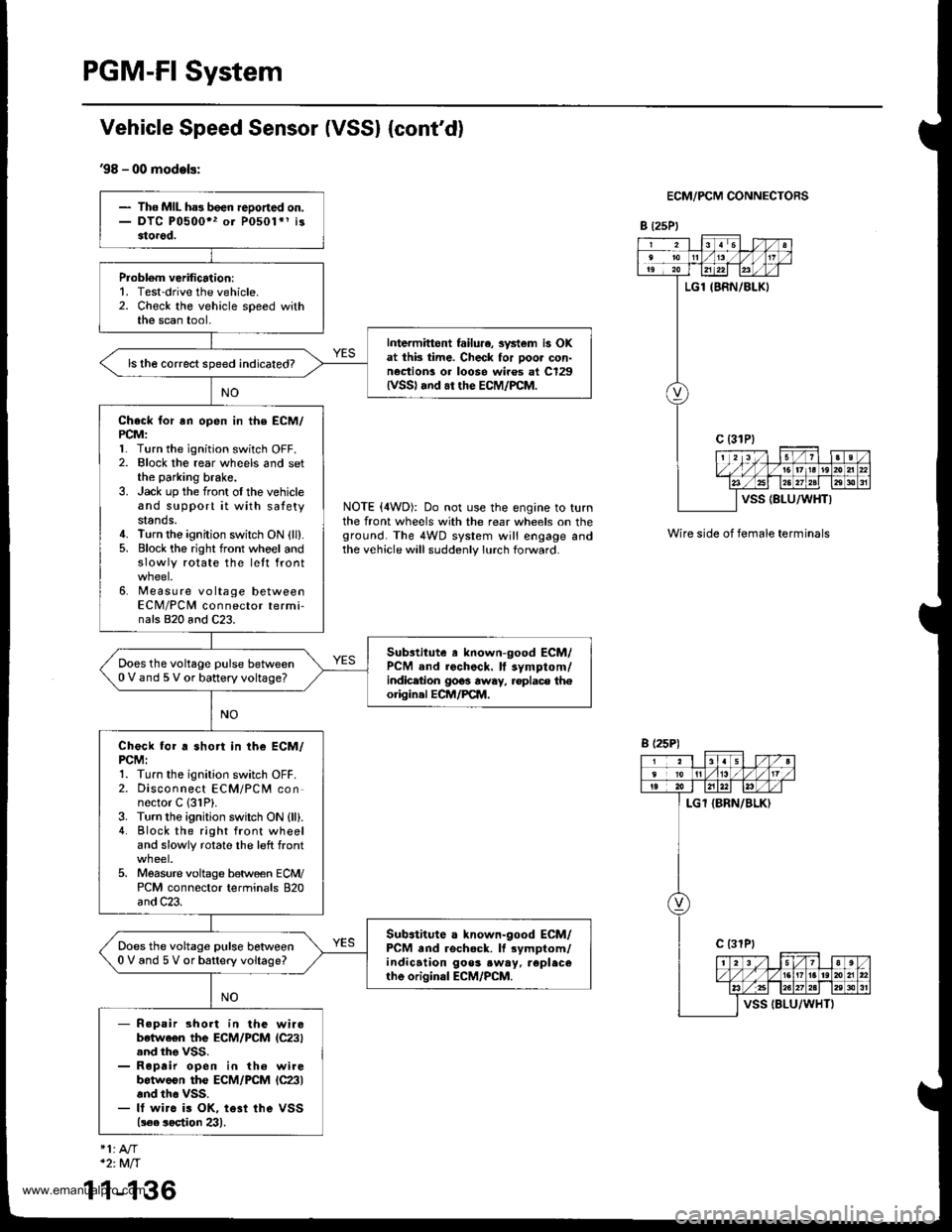

Vehicle Speed Sensor (VSSI {cont'd}

'98 - 00 models:

ECM/PCM CONNECTORS

B t25Pl

NOTE (4WD): Do not use the engine to turnthe front wheels with the rear wheels on theground. The 4WD system will engage andthe vehicle will suddenly lurch forward.

Wire side of female terminals

- The MIL ha3 been reDoned on.- DTC P0500" or P0501*1 i33torod.

Probl6m verification:1. Test-drive the vehicle.2. Check the vehicle speed withthe scan tool,

Intermittont failu.e, svstem is OKat thk time. Check for poor con-nection! or loose wiros at C129lvss) .nd ar the EcM/PcM.

ls the correct speed indicated?

Check for rn open in the ECM/PCM:l� Turn the ignition switch OFF.2. Elock the rear wheels and setthe parking brake.3. Jack up the front oI the vehicleand support it with satetystands.4. Turn the ignition switch ON {ll}.5. Block the right front whoel andslowly rotate the lett front

6. Measure voltage betweenECM/PCM connector termi-nals 820 and C23.

Substitute a known-good ECM/PCM and rochock. ll symptom/indicetion 9063 away, .oplace th€origin.l ECM/PCM.

Does the voltage pulse between0 V and 5 V or battery voltage?

Check for a short in the ECM/PCMI1. Turn the ignition switch OFF.2. Disconnect ECM/PCM connector C 131P).3. Turn the ignition swilch ON {ll).4. Block the right front wheeland slowly rotate the left front

5. Moasure voltage between ECM/PCM connector terminals 820and C23.

Sub.titute a known-good ECM/PCM and rschock. It rymptom/indication goos .w.y. replecerhe original ECM/PCM.

Does the voltage pulse betlveen0 V and 5 V or battery voltage?

- R.pair short in the wirobetwe€n the ECM/PCM lC23).nd tho VSS.- Roprir open in th6 wirebotweon the ECM/PCM lc23land th6 vss.- It wirc is OK, te3t ihe VSS(!€e soetion 23).

B (25P)

1

*2:Mft

1-136

www.emanualpro.com

Page 339 of 1395

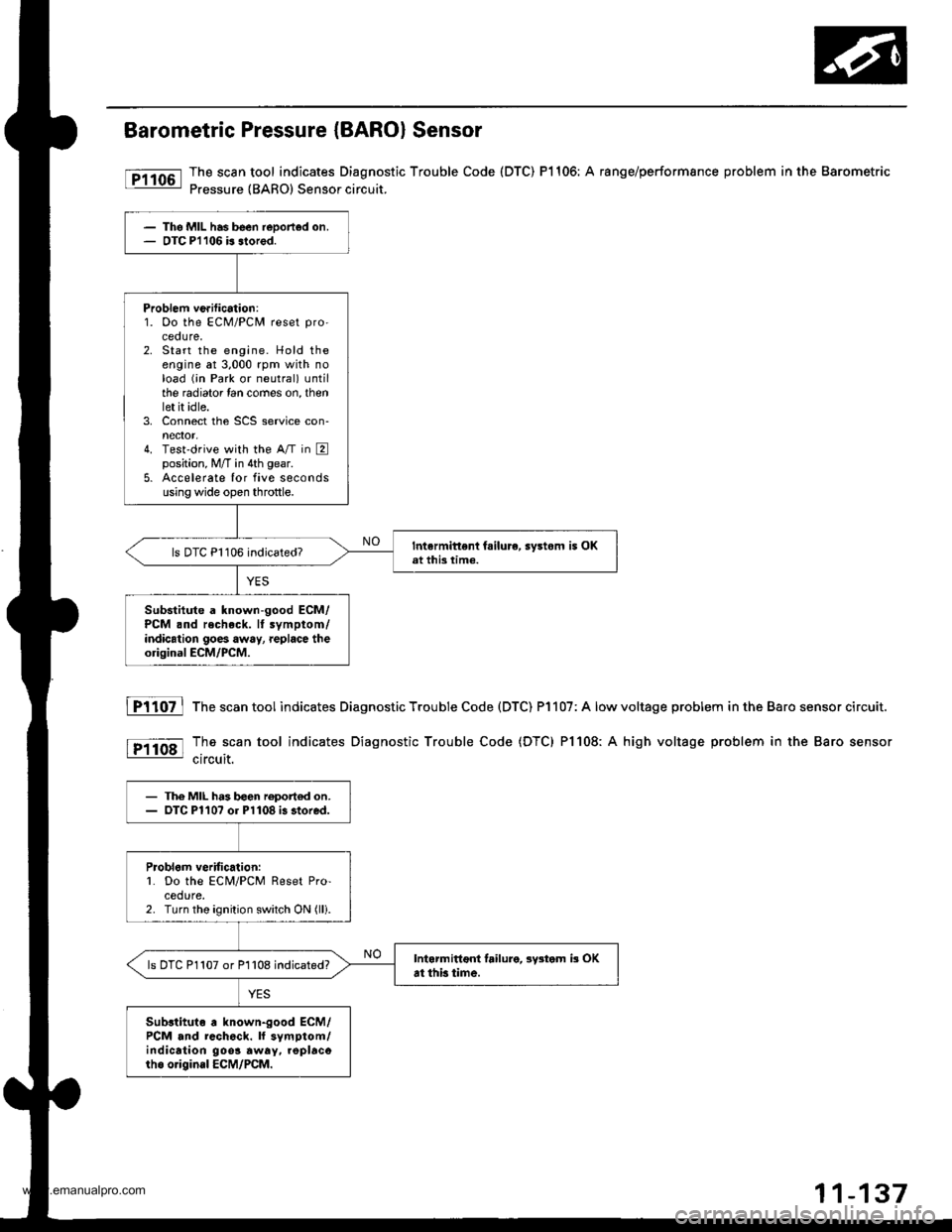

Barometric Pressure (BARO) Sensor

The scan tool indicates Diagnostic Trouble Code (DTC) P1106: A range/performsnce problem in the Barometric

Pressure {BARO) Sensor circuit.

The MIL has been reDorted on.OTC Pl106 b slored.

Problem ve.ification:1. Oo the ECM/PCM reset pro'

ceoure.2. Start the engine. Hold theengine at 3,000 rpm with noload (;n Park or neutral) untilthe radiator lan comes on, thenlet it idle.3. Connect the SCS service con-nector,4. Test'drive with the A/T in Eposition, M/T in 4th gear.

5. Accelerate Ior five secondsusing wide open throttle.

Intermittent fsilure, sy3tom i5 OKat this time.ls DTC P1106 indicated?

Substitute a known-good ECM/PCM .nd recheck. It symptom/indication goes away, replace theorigioal ECM/PCM.

fTiloz l

tP11o8l

The scan tool indicates Diagnostic Trouble Code (DTC) P1107: A low

The scan tool indicates Diagnostic Trouble Code (DTC) Pl108: A

circuit.

voltage problem in the Baro sensor circuit.

high voltage problem in the Baro sensor

- The MIL h.3 b€en roport€d on.- OTC Pl10? or Pl108 i3 stored.

Problom veritic.lion:L Do the ECM/PCM Reset Pro-cedure.2. Turn the ignition switch ON (lli.

Intarmittoni failure, lystom b OKat thb time.ls DTC P1107 or P1108 indicated?

Sub3tituto a known-good ECM/PCM and rcch6ck. ll symptom/indication 9oo3 away. .oplacorho o.igin.l ECM/PCM.

www.emanualpro.com

Page 341 of 1395

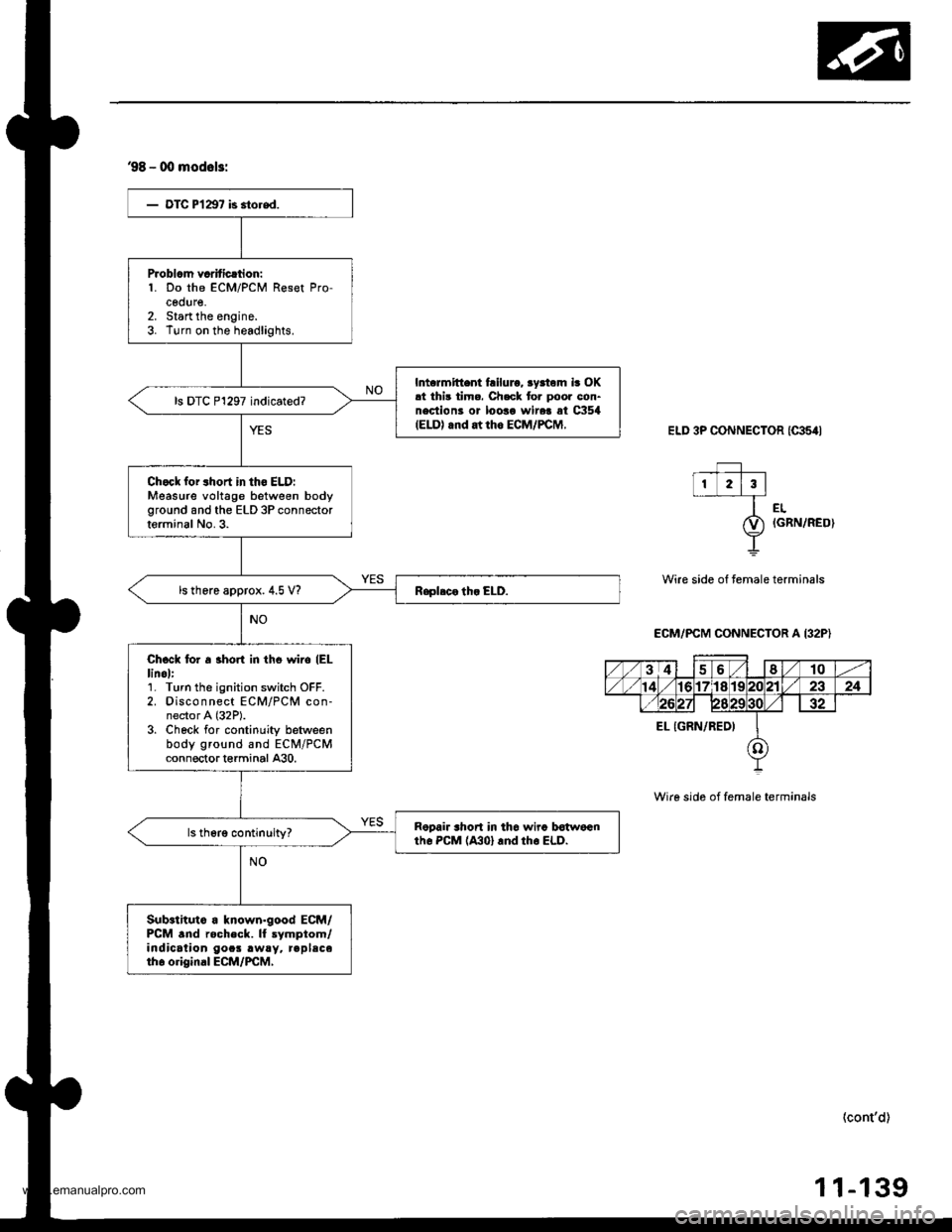

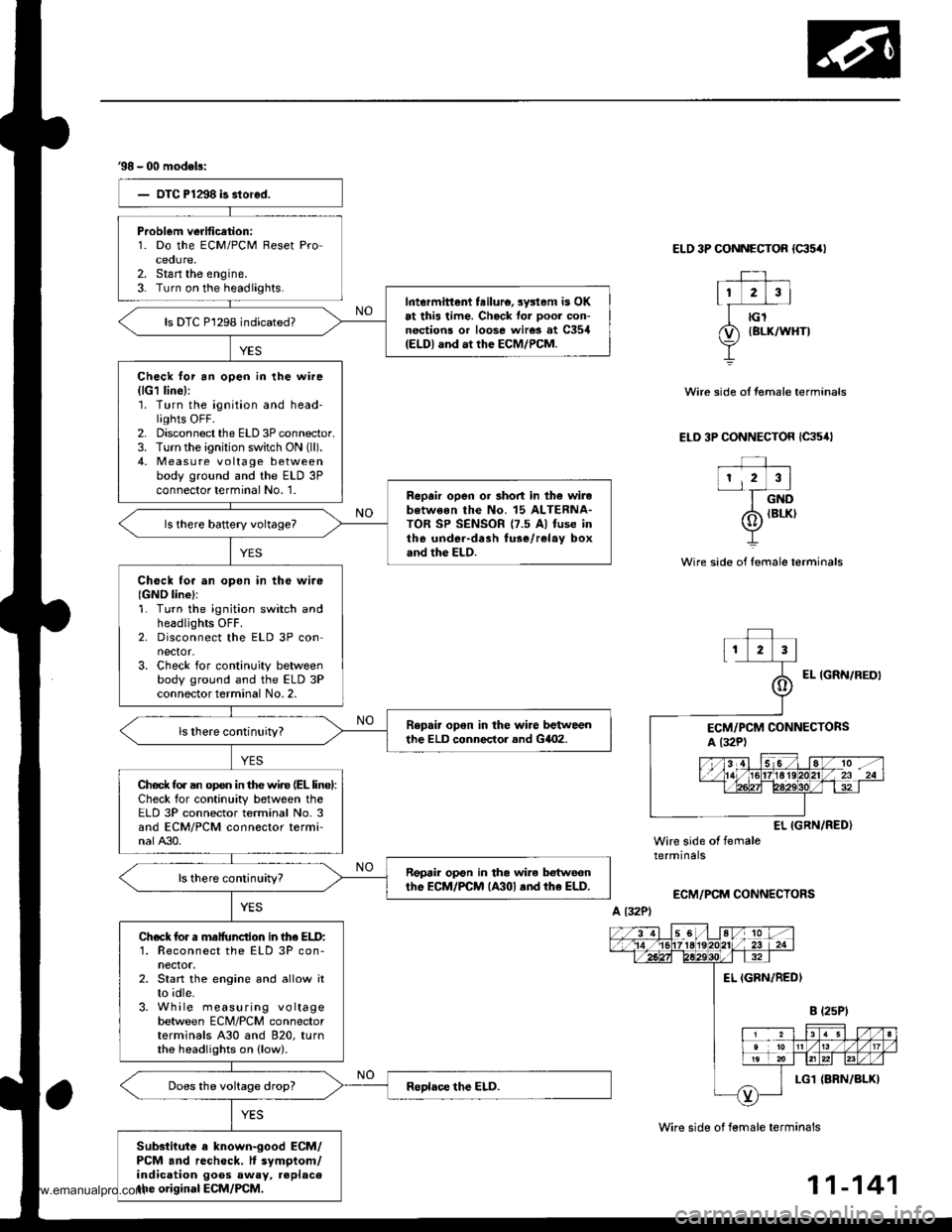

98 - 00 mod6l3:

- OTC P l1€7 is 3tored.

Problcm vcrificrtion:1. Do the ECM/PCM Reset Pro-cedure,2. Start the engine.3. Turn on the headlights.

Intcrmittent tailuro, ryrtom ir OK!t thi3 timo. Ch.ck tor poor con-nectiont or looao wire! at CXl54IELD) rnd at rh6 ECM/PCM,

ls DTC P1297 indicated?

Chock for 3hort in tho ELD:Measure voltage between bodyground and the ELD 3P connectorterminal No.3.

ls there approx. 4.5 V?

Chcck lor a 3horl in tho wiio (EL

linol:1. Turn the ignition switch OFF.2. Disconnect ECM/PCM con-nector A (32P).

3. Check for continuity betweenbody ground and ECM/PCMconn€ctort€rminal A30.

Ropair shon in thc wira botwocntho PcM (A301 rnd rho ELD.

Sub.tituto a known.good ECM/PCM .nd rocheck. ll lymptom/indication gocs .w!y. replsceth6 o.iginal ECM/PCM,

ELD 3P CONNECTOR ICAs4I

f_l,I 2l3l-

l--- r'.

&) iGRN/RED)

T

Wire side of temale terminals

ECM/PCM CONNECTOR A I32P)

Wire sid6 of female terminals

(cont'd)

-13911

www.emanualpro.com

Page 343 of 1395

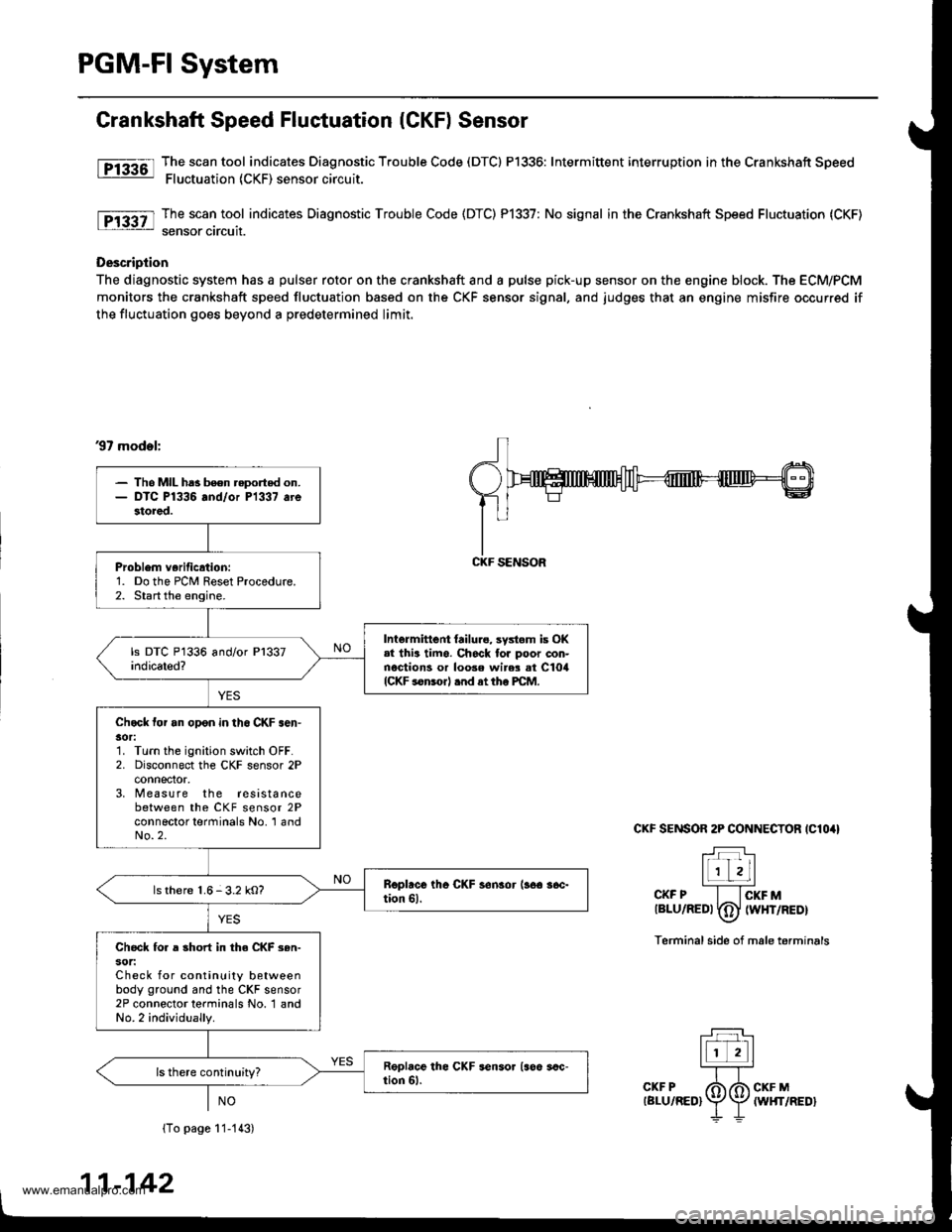

38 - 00 modeb:

Problem verification:1. Do the ECM/PCM Reset Proceoure.2. Stan the engine.3- Turn on the headlights.Intermittent feilure, sysl.m is OKat this time. Check for ooor con-nections or loose wires at C354(ELDI and at the ECM/PCM.

ls DTC P1298 indicated?

Check lor an open in the wire(lG1 line):'1. Turn the ignition and head-lights OFF.2. Disconnect the ELD 3P connector.3. Turn the ignition switch ON (ll).

4, Measu re voltage betweenbody ground and the ELD 3Pconnector terminal No. '1.Reprir open or short in th6 wirebotweon the No. 15 ALTERNA-TOR SP SENSOR {7.5 Al fuse inthe under-drah fuse/relay boxand the ELD.

Check tor an opon in tho wire{GND line}:1. Turn the ignition switch andheadlights OFF.2. Disconnect the ELD 3P connector.3. Check for continuity betweenbody ground and the ELD 3Pconnector terminal No. 2,

Repair opon in the wire betweenthe ELD conneclor and GilO2.

Ched( fo. an op€n in the wir€ (EL linel:Check for continuity between theELD 3P connector terminal No. 3and ECM/PCM connector termi-nalA30.

Repair op€n in tha wile botwecnthe EcM/PCM lA30l .nd rhe ELD.

Check for s malfunction in lhe ELD:1. Reconnect the ELD 3P con-nector.2. Start the engine and allow itto idle.3. While measuring voltagebetween ECM/PCM connectorterminals A30 and 820, turnthe headlights on (low).

Substiiute a known-good ECM/PCM and recheck. It symptom/indication goos away, replacethe original ECM/PCM.

ELO 3P CONNECTOR {c35/rl

Wire side of female terminals

Wire side of female terminals

Wire side ot temale terminals

ELD 3P CONNECTOR {C35,lt

EL IGRN/RED}Wire side of femaletermrnars

ECM/PCM CONNECTORS

A l32P)

11-141

www.emanualpro.com

Page 344 of 1395

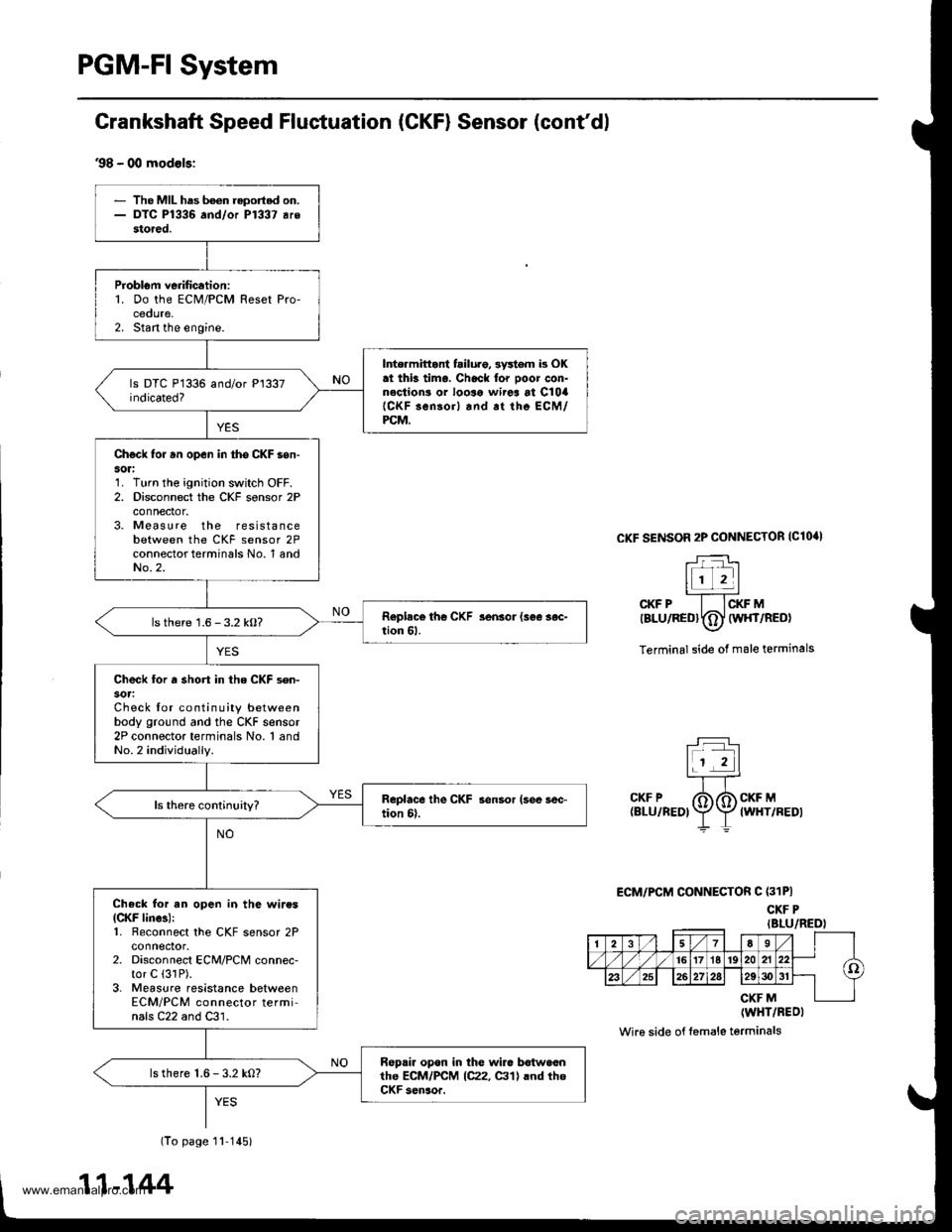

PGM-FI System

Grankshaft Speed Fluctuation (CKF) Sensor

fF13361l Tj":""l.tool indicates Diagnostic Trouble Code (DTCI P1336: Intermittent interruption inthe Crankshaft Speed: Fluctuation (CKF) sensor circuit.

The scan tool indicates Diagnostic Trouble Code (DTC) P1337: No signal in the Crankshaft Speed Fluctuation (CKF)

sensor circuit.

Description

The diagnostic system has a pulser rotor on the crankshaft and a pulse pick-up sensor on the engine block. The ECM/PCM

monitors the crankshaft speed fluctuation based on the CKF sensor signal, and judges that an engine misfire occurred if

the fluctuation goes beyond a predetermined limit.

37 mod.l:

CKF SENSOR 2P CONNECTOR IClO4I

T:]l-r'r Lll

l1 zLl''''CKF P I lcKF Mtalu/aeot fdJ twxrneor\-7

Terminal side of male terminals

(To page 11-113)

11-142

- Tho MIL ha3 been reported on.- DTC P1336 and/or P1337 arestored.

Problem verificrtion:1. Do the PCM Reset Procedure.2. Start the engine.

Intermittent {ailure, systom is OK.l thia timo. Ch6ck tor poor con-nections or loose wir$ at ClorlICKF sonsorl .nd at tho PCM.

Chock tor an opon in th6 CKF .en'30r:1. Turn the ignition switch OFF.2. Disconnect the CKF sensor 2Pconnector,3, M easure the resistancebetween the CKF sensor 2Pconnector terminals No. 'l andNo.2.

ls there 1.6-3.2 kO?

Check fo. a short in the CKF 3en-sot:Check for continuity betweenbody ground and the CKF sensor2P connector terminals No. 1 andNo.2 individually.

CKF SENSOR

www.emanualpro.com

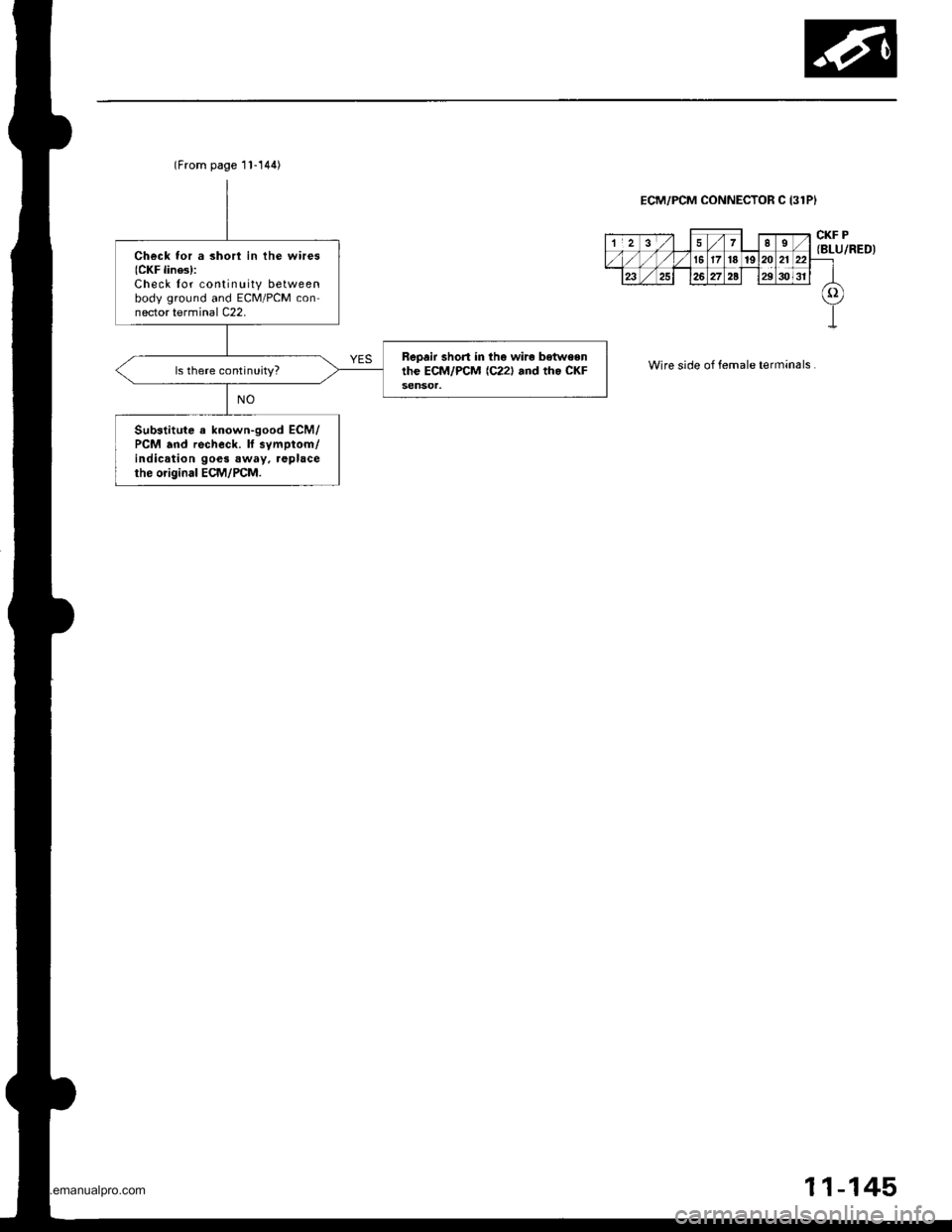

Page 346 of 1395

PGM-FI System

Grankshaft Speed Fluetuation (CKFI Sensor (cont'dl

.98 - 00 modols:

CKF SENSOR 2P CONNECTOR IClO'I

r-:-i-_ltr_- |l1 2ll,,-'CKF P I ICKF MtsLuneotTOl wlrrneo)\7

Terminal side of male terminals

r:l

t! El

.KFP XA"*."talu rneor \:f

f rwxvneor

ECM/PCM CONNECTOR C (31P)

CKF PIBLU/REDI

CKF M(WHT/BEOI

Wi16 side of l6male terminals

1278__l

-lI(o

T

161716't9202122

,/ 2s262728293()3l

M

- The MIL has boon reported on.- DTC P1336 and/or P1337 arestored.

ProblGm verification:1. Do the ECM/PCM Reset Pro-cedure,2. Stan the engine.

Inte.mittant failuro, 3y*om b OKat thb tima. Chack lor ooor con-nections or looso wirea at C10a{CKF sensorl and.t the ECM/PCM,

Chgck forun open in tho CKF son-sori1. Turn the ignition switch OFF.2. Disconnect the CKF sensor 2Pconnector.3. Measure the resistancebetween the CKF sensor 2Pconnector terminals No. 1 andNo.2.

lsthere 1.6 - 3.2 kO?

Check for a short in the CKF sen-

Check lor continuity betweenbody ground and the CKF sensor2P connector terminals No. 1 andNo.2 individually.

Check for an open in the wiresICKF linca):1. Feconnect the CKF sensor 2Pconnector.2. Disconnect ECM/PCM connec-tor C (31P).

3. Measure resistance betweenECM/PCM connector termi'nals C22 and C31.

Repair opon in the wir6 botwoonthe ECM/PCM 1C22, glll lnd th6CKF s6n3or.

ls there 1.6 - 3.2 kO?

(To page 11'1451

11-144

www.emanualpro.com

Page 347 of 1395

(From page 11-144)

Check for a shorl in the wires(CKF lines):Check lor continuity betweenbody ground and ECM/PCM connector terminal C22.

Repair short in tho wire betweenthe ECM/PCM {C221 and rh. CKFls there continuity?

Substitute a known-good ECM/PCM and recheck. lf svmptom/indication goes away. replacethe original ECM/PCM.

ECM/PCM CONNECTOR C (31PI

Wire side of female terminals

CKF P{BLU/RED)

11-145

www.emanualpro.com

Page 348 of 1395

PGM-FI System

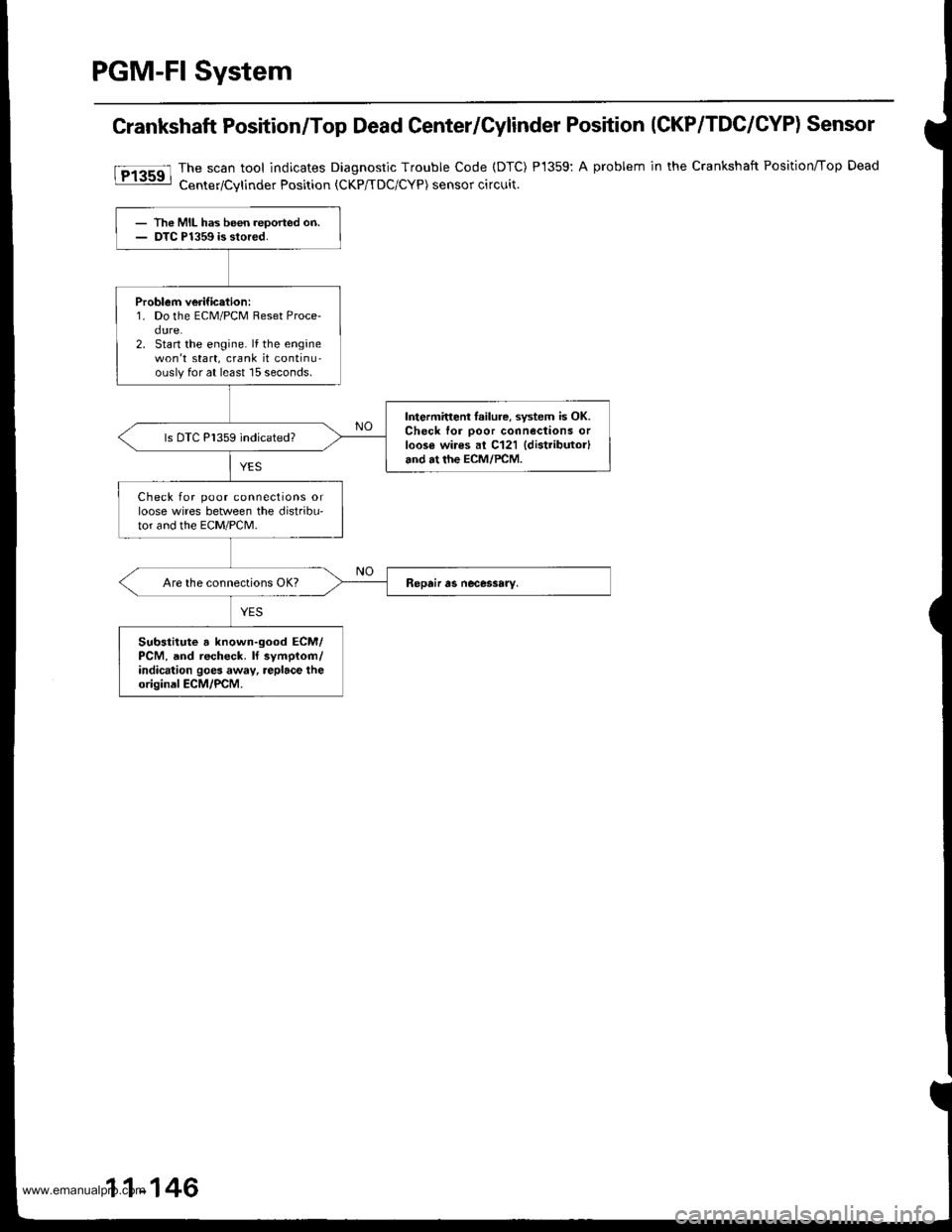

Crankshaft Position/Top Dead Center/Cylinder Position (CKP/TDC/CYP) Sensor

The scan tool indicates Diagnostic Trouble Code (DTC)

Center/Cvlinder Position tCKP/TDC/CYP) sensor circuit.

P1359:A problem in the Crankshaft Position/Top Dead

- The MIL has been reoorted on.- DTC P1359 is stored.

Problem verific.tion:1. Do the ECM/PCM Reset Proce-dure.2. Start the engine. lf the enginewon't start, crank it continu-ouslyfor at least 15 seconds.

Intermitteni lailure, system is OK.Check for ooor connections orloos€ wires al C121 {distributor}and at the ECM/PCM.

ls DTC P1359 indicated?

Check for poor connections orloose wires between the distribu'tor and the EcM/PcM.

Substitute a known-good ECM/PCM, and recheck. ll symplom/indication goes away, replace theoriginal ECM/PCM.

11-146

www.emanualpro.com

Page 349 of 1395

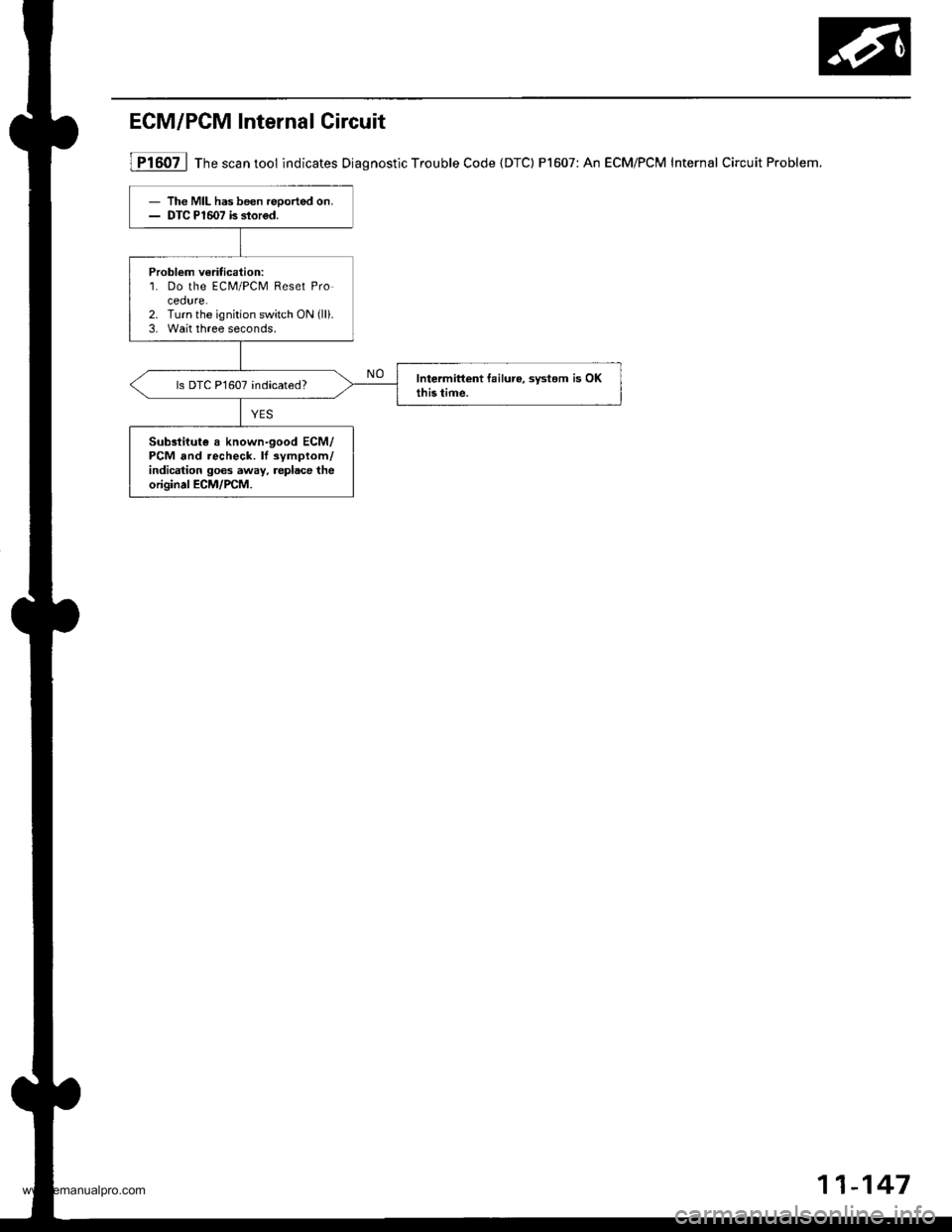

ECM/PCM Internal Circuit

lFi6oil Th" """n tool indicates Diagnostic Trouble Code {DTC) P1607: An ECM/PCM Internal Circuit Problem.

- The MIL has been reoorted on.- DTC PlmT is slor6d.

Problom veritication:1. Do the ECM/PCM Reset Pro

2. Turn the ignition switch ON (ll).

3, Wait three seconds,

ls DTC P1607 indicated?

Sub3tiiut€ a known-good ECM/PCM and recheck. lf symptom/indication goes away, replace theoriginal ECM/rcM.

11-147

www.emanualpro.com