door switch HONDA CR-V 1998 RD1-RD3 / 1.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1998, Model line: CR-V, Model: HONDA CR-V 1998 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 299 of 1395

The scan tool indicates Diagnostic Trouble Code (DTC) P0113: A high voltage (low temperature) problem in the

Intake Air Temperature (lAT) sensor circuit.

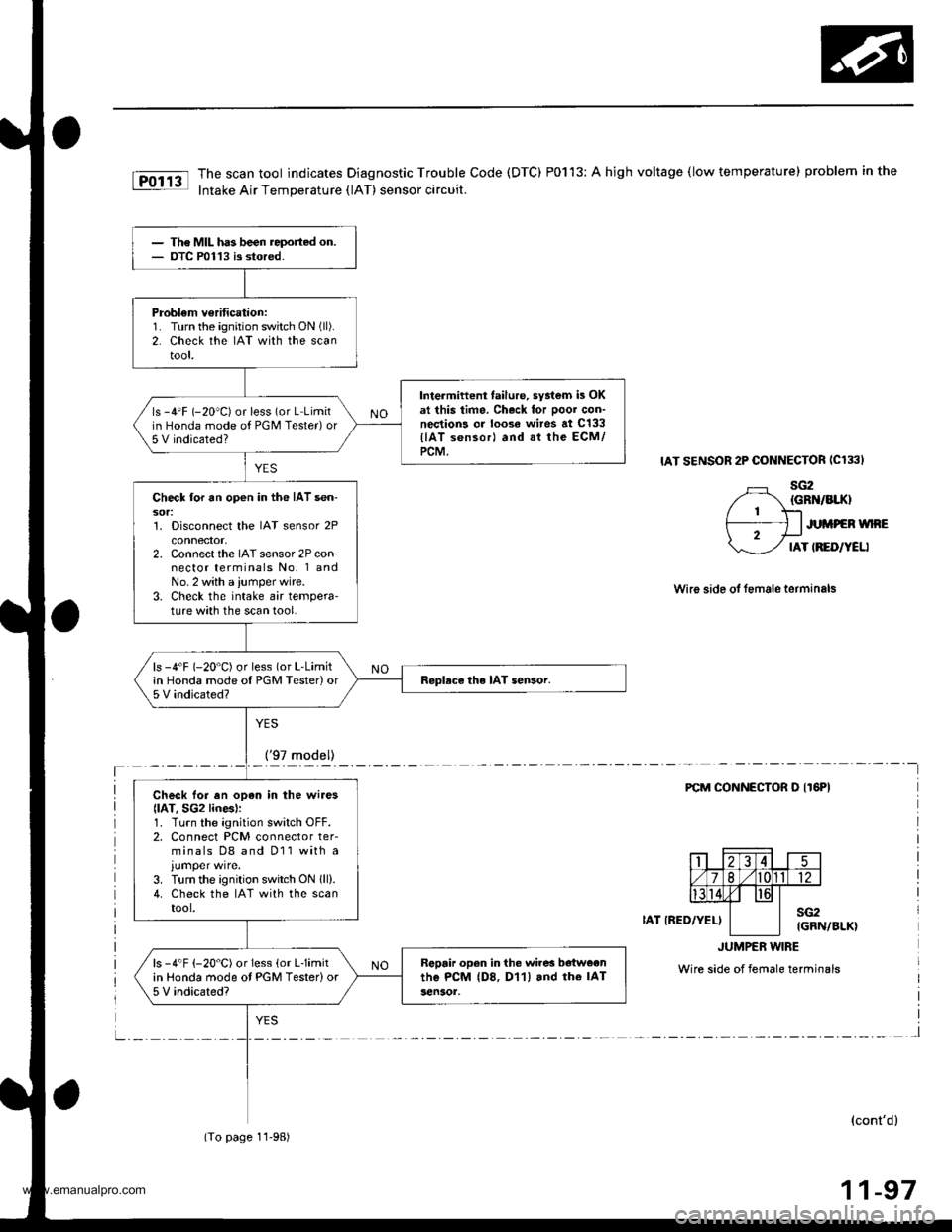

IAT SENSOR 2P CONNECTOR ICl33I

sG2{GRN/BIIO

JUMPEN WNE

IAT IRED/YELI

Wire side ol female terminals

YES

_!!7rqd9ll_____-

FCM CONNECTOR O IT6PI

IAT IRED/YEL)sG2IGRN/BLK}

JUMPER w|BE

Wire side of female terminals

l

(cont'd)

11-97

The MIL has been reported on.OTC P0113 is stored.

Problem v€rification:1. Turn the ignition switch ON (ll).

2. Check the IAT with the scantool,

Intermiftent failure, syatem is OKat this time. Ch.ck for Door con-nections or loose wires at c133

llAT s6nsorl and at the ECM/PCM.

ls -4'F (-20"C) or less (or L Limitin Honda mode of PGM Tester)or5 V indicated?

Check lor an open in the IAT sen-sor:1. Disconnect the IAT sensor 2Pconnector,2. Connect the IAT sensor 2P connector terminals No. 1 andNo. 2 with a ,umper wire.3. Check the intake air tempera'ture with the scan tool.

ls -4'F (-20"C) or less (or L-Limitin Honda mode oI PGM Tester)or5 V indicated?Replace the IAT sensor.

Check lor en opan in the wires

llAT, SG2 lines):1. Turn the ignition switch OFF.2. Connect PCM connector ter-minals D8 and D11 with a

3. Turn the ignition switch ON lll).4. Check the IAT with the scantool.

Rgpair open in the wires b€tweenthe PcM (D8. D11) and rhe IAT3en30r,

ls -4"F {-20"C) or Iess (or Llimitin Honda mode ot PGM Tester)or5 V indicated?

(To page 11-98)

www.emanualpro.com

Page 407 of 1395

'97 model:

The scan tool indicates Diagnostic Trouble Code (DTC) P0441: Evaporative Emission (EVAP) control system

insufficient purge flow.

Description

By monitoring the purge line vacuum with the MAP sensor, the PCM can detect insufficient EVAP control system purge

flow.

Possiblo Cause

. EVAP Purge Control Solenoid Valve

. EVAP Purge Control Solenoid Valve Circuit

. EVAP Control Canister

. Vacuum Lines

. PCM

Troubleshooting Flowchart

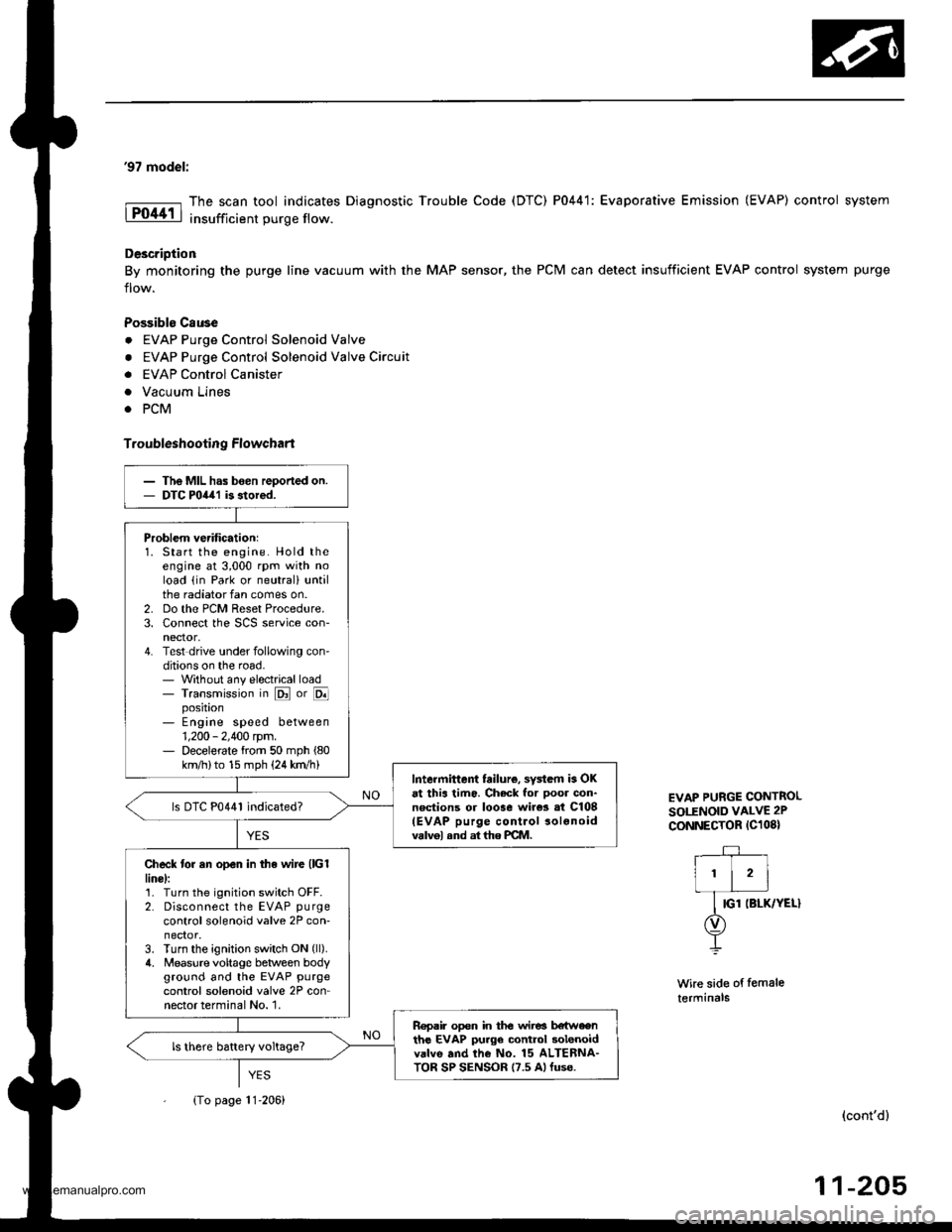

EVAP PURGE CONTROL

SO1TNOID VALVE 2P

CoNNECTOR (C108)

(v)

YL

Wire side of female

termrnals

(cont'd)

11-205

Th€ MIL has b€en reooited on.DTC P0441 is .tored.

Problem verificationl1. Start the engine. Hold theengine at 3,000 rpm with noload (in Park or neut.al) untilthe radiator fan comes on.2. Do the PCM Reset Procedure.3. Connect the SCS service con-nector,4. Test drive under following con'ditions on the road.- without any electrical load- Transmission in @ or @position- Engine speed between1 ,2OO - 2,4OO rpfi.- Decelerate from 50 mph (80

km/h)to 15 mph (24 km/h)Intermittent trilure, sydern is OKat this time. Check for Door con-nections or loose wir€3 at C108

IEVAP purge control solonoidvalvol .nd at the PCM.

ls DTC P0441 indicated?

Check tor an open in the wire (lcl

linel:1. Turn the ignition switch OFF.2. Disconnect the EVAP purge

control solenoid valve 2P con-nector.3. Turn the ignition switch ON (ll).

4. Measure voltage between bodyground and the EVAP purge

control solenoid valve 2P con-nector terminal No. '1,

R€pafu open in thc wir6 b€tw€enthG EVAP purge control solenoidvalve and the No. 15 ALTEBNA-TOR SP SENSOR (7.5 A)fuse.

ls there batlery voltage?

(To page 11'206)

www.emanualpro.com

Page 411 of 1395

'98 - 00 mod€ls:

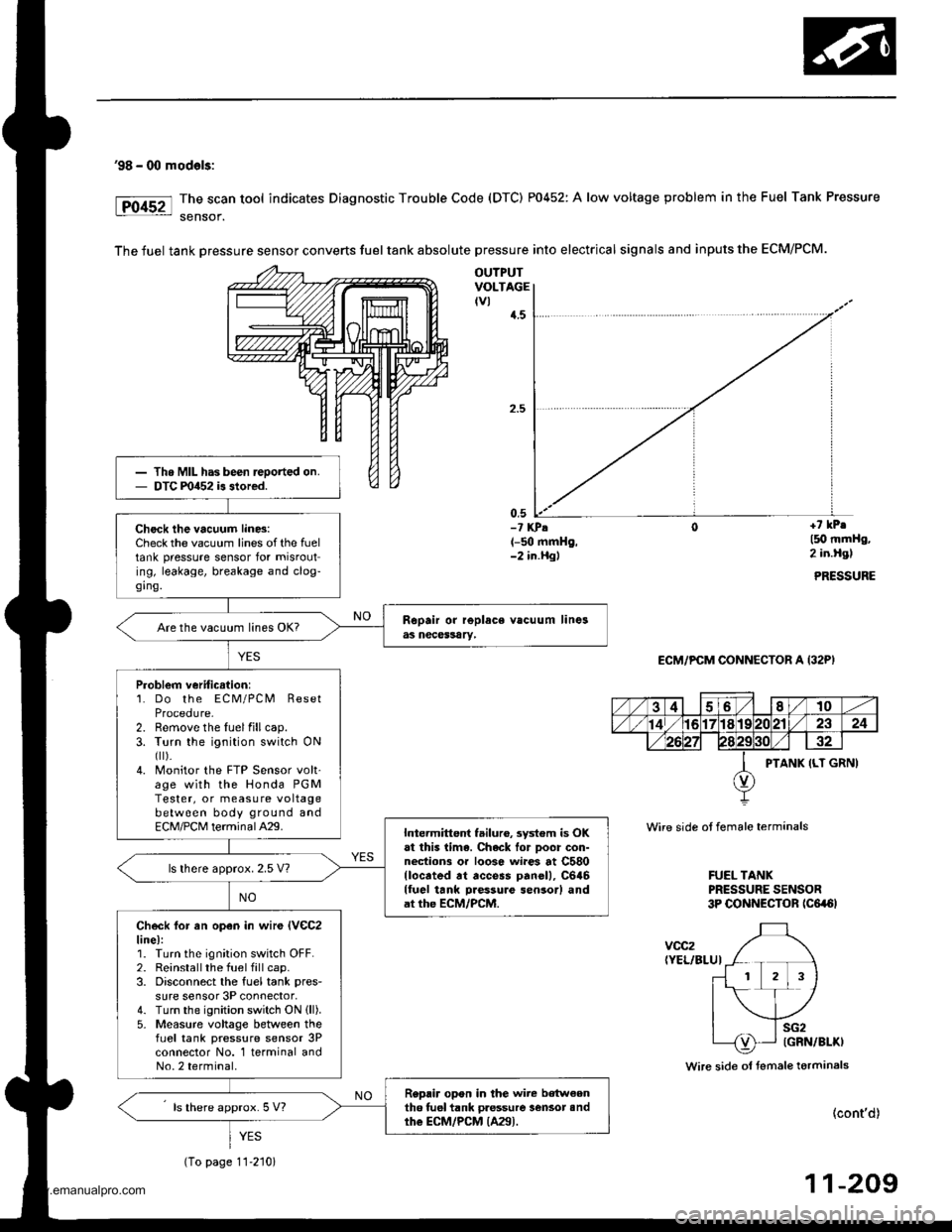

The scan tool indicates Diagnostic Trouble Code (DTC) P0452: A low voltage problem in the Fuel Tank Pressure

sensof.

The fuel tank Dressure sensor converts fuel tank absolute pressure into electrical signals and inputs the ECM/PCM.

OUTPUTVOLTAGEtvl{.5

0,5-? KPA(-50 mmHg,-2 in.Hgl

+7 kPr

l5O mmHg,2 in.Hgl

PRESSURE

ECM/PCM CONNECTOR A (32P)

Wire side ot female terminals

FUEL TANKPRESSURE SENSOR3P CONNECTOR tc6a6l

voc2(YEL/BLUI

Wire side ol fsmale terminals

(cont'd)

11-209

Th. MIL has been reoorted on.DTC m452 is stored.

Check the vacuum lin6:Check the vacuum lines of the fueltank pressure sensor for misrouting, leakage, breakage and clog-ging.

Are the vacuum lines OK?

Problem veriticstion:1. Do the ECM/PCM ResetProcedure-2. Remove the luelfillcap.3. Turn the ignition switch ONfl r).4. Monitor the FTP Sensor volt'age with the Honda PGMTester, or measure voltagebetween body ground andECM/PCM terminalA29.Intermittent failuro, system is OKat this lima. Chack lor Door con-nections or loose wi.es at C580llocrted rt access panell, C646lluel tank Daessure sensor) andat the ECM/PCM.

ls lhere approx. 2.5 V?

Check lor an open in wir€ lVeC2line):1. Turn the ignition switch OFF.2. Reinstallthe fuel fill cap.3. Disconnect the fuel tank pres-

sure sensor 3P connector,4. Turn the ignition switch ON (ll).

5- Measure voltage between thefLrel tank pressure sensor 3Pconnector No. 1 terminal andNo.2 terminal.

Replir opon in the wire b€tw€enth6 tuel tank pressure lensot andthe ECM/PCM {A29).ls there approx. 5 V?

YES

(To page 11-210)

www.emanualpro.com

Page 982 of 1395

Body

Bumpers

Front Bumper Removal and

fnstaflation .........20-72

Rear Bumper Removal and

fnstaflation .........20-74

'Dashboard

lnstrument Panel Removal and

lnstallation .........20-47

Driver's Dashboard Lower Cover and

Knee Bolster Removal and

Installation .........20-48

Glove Box Removal and

lnstallation .........20-49

Center Pocket Removal and

lnstallation .........20-49

Center Dashboard Lower Cover

Removal and lnstallation ............ 20-50

Center Panel Removal and

lnstallation .........20-50

Power Window Switch Removal and

lnstallation .........20-51

Center Air Vent Removal and

lnstallation .........20-51

Side Air Vent Removal and

fnstallation .........20-52

Side Defogger Trim Removal and

fnstallation .........20-52

Dashboard Removal and

lnstallation .........20-53

Dashboard Frame Replacement ..... 20-55

Doors

Component Location Index

Front Door ,,...,,,,20-2

Rear Door ...........20-4

Tailgate Door ................................ 20-6

Fenderwell

Front Wheelwell Protector

Replacement .....20-89

Inner Fender Replacement .,.....,.,.... 20-89

Rear Wheelwell Protectol

Replacement .....20-90

Fuel Pipe Protector Replacement ... 20-90

Rear Air Outlet Replacement .......... 20-91

*Frame Repair Chart .............................. 20-106

Front Grille

Repf acement .........20-77

Glass

Component Location Index ............ 20-29

Hood

Replacement ......,,,20-75

Adjustment ............20-76

*lnterior Trim

Component Location Index ............ 20-40

Mirrors

Component Location Index .........,,, 20-26

Moldings

Roof Molding Replacement ............ 20-84

Door Moldings Replacement .......... 20-85

Openers

Component Location Index ............ 20-92

Rear Hatch Glass

Replacement .........20-74

Disassembly and Reassembly ........ 20-79

Adiustment ............20-81

Rear Weatherstrip Replacement .... 20-83

Seats

Component Location Index ............ 20-56

Side Sill Panel

Repfacement .........20-87

Spare Tire Cover

Emblem Installation ........................ 20-88

Sub-frame ..................20-104

Wiper/Washer

Component Location lndex ,,,,,....... 20-97

www.emanualpro.com

Page 1038 of 1395

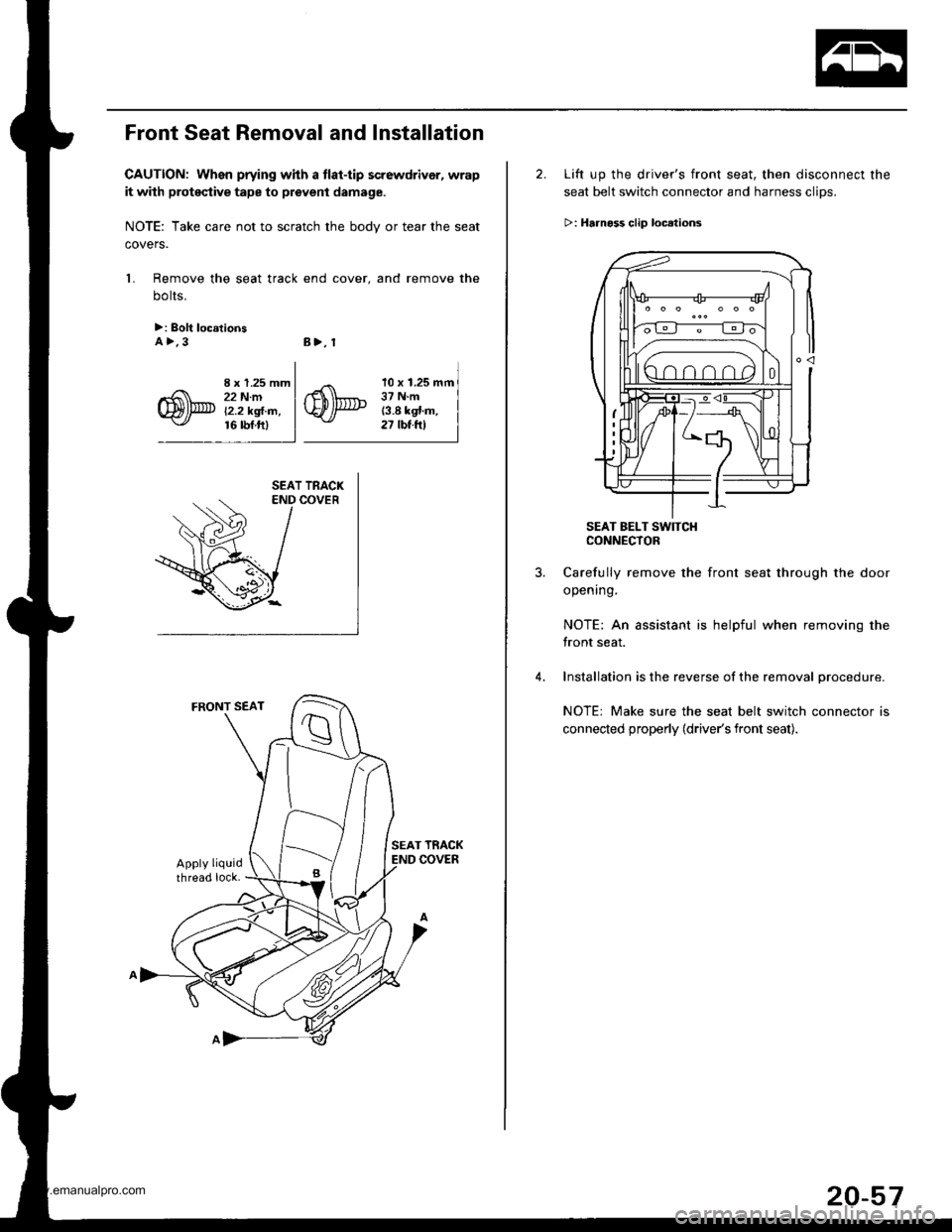

Front Seat Removal and Installation

CAUTION: When prying whh a tlat-tip screwdrivor, wrap

it with proteqtive tape to prevent damage.

NOTE: Take care not to scratch the bodv or tear the seat

covers.

1. Remove the seat track end cover, and remove the

bolts.

>: Bolt loc.tionsA>.3B>, 1

I x 1.25 mm22 N.mi'2.2 kgl.m,16 rbf.ftl

10 x 1.25 mm37 N.m13.8 kgt.m,27 tbt.ftl

2. Lift up the driver's front seat, then disconnect the

seat belt switch connector and harness clips.

>: Hrrnoss clip loc.lions

SEAT BELT SW]TCHCONNECTOR

Carefully remove the front seat through the door

opening.

NOTE: An assistant is helpful when removing the

front seat.

Installation is the reverse of the removal procedure.

NOTE: Make sure the seat belt switch connector is

connected properly (driver's front seat).

20-57

www.emanualpro.com

Page 1101 of 1395

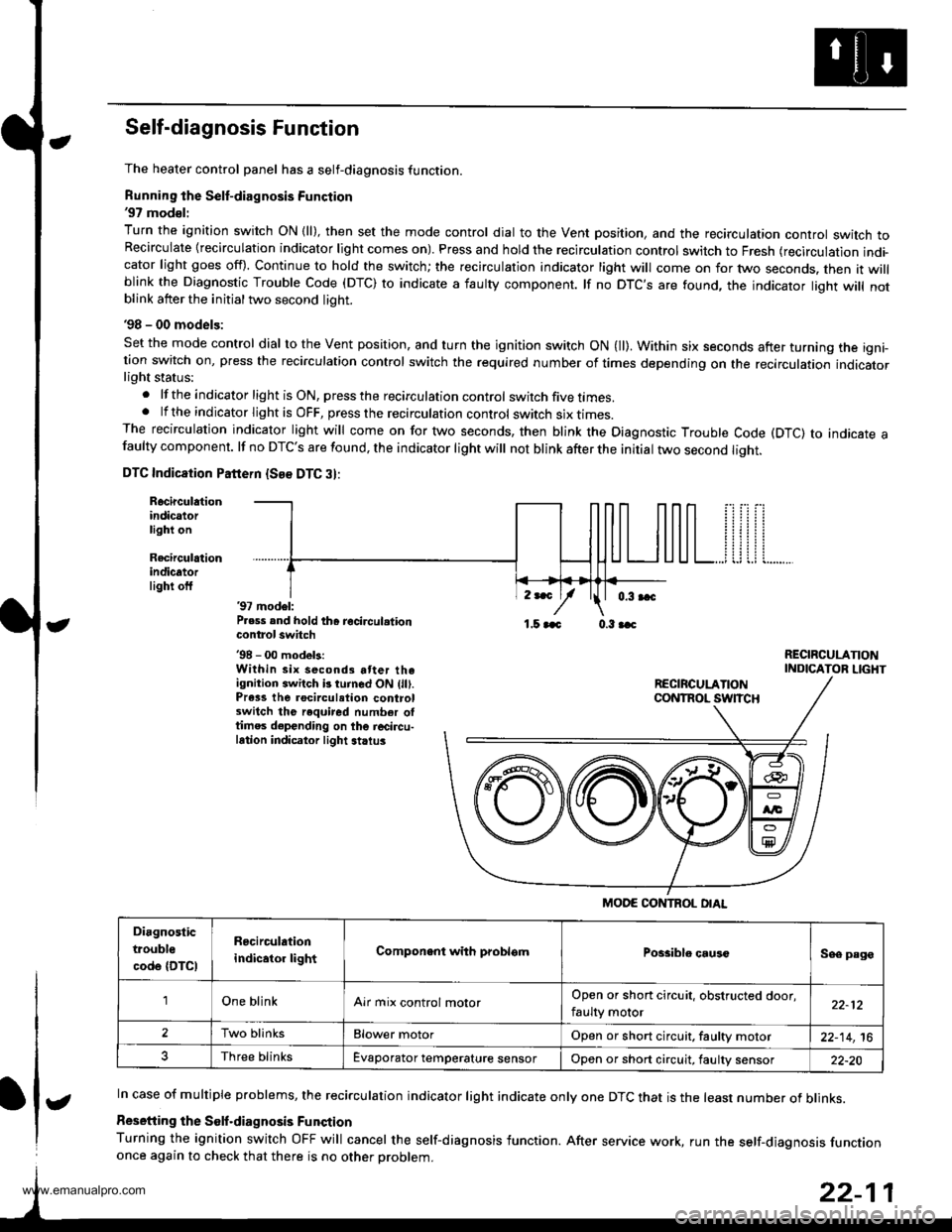

Self-diagnosis Function

The heater control panel has a self-diagnosis function.

Running the Self-diagnosis Function'97 mod€l:

Turn the ignition switch ON {ll), then set the mode control dial to the Vent position, and the recirculation controt switch toRecirculate {recirculation indicator light comes on). Press and hold the recirculation control switch to Fresh (recirculation indi-cator light goes off). Continue to hold the switch; the recirculation indicator light will come on for two seconds. then it willblink the Diagnostic Trouble Code (DTC) to indicate a iaulty component. lf no DTC'S are found, the indicator liqht will notblink atter the initial two second light.

'98 - 00 models:

Set the mode control dial to the Vent position, and turn the ignition switch ON (ll). Within six seconds after turning the igni-tion switch on, press the recirculation control switch the required number of times depending on the recirculation indicatorlight status:

.lftheindicatorlightisON,presstherecirculationcontrol switch five times..lftheindicatorlightisOFF,presstherecirculationcontrol switch six I|mes.The recirculation indicator light will come on for two seconds, then blink the Diagnostic Trouble Code (DTC) to indicate afaulty component. lf no DTC'S are found, the indicator light will not blink after the initial two second liqht.

DTC Indicaiion Pattern {See DTC 3}:

Rocirculationindicatorlight on

Recirculrtionindicatorlighi off'97 model:P.ess and hold th6 recircul.tioncontrol switch'98 - 00 modek:Within six second3 atter theignition switch b turned ON (lll.Prass the rocirculation controlswitch the required number oltimes depending on the r6circu-lation indicator light striu3

,r*

/1.5 aaa 0.3 aac

RECIRCULANONINDICATOR LIGHT

In case of multiple problems, the recirculation indicator light indicate only one DTC that is the least number of blinks.

Resetiing the Solf.diagnosis Funqtion

Turning the ignition switch OFF will cancel the self-diagnosis function. After service work, run the self-diaqnosis functiononce again to check that there is no other Droblem.

MODE CONTROL OIAL

Diagnostic

trouble

code {DTCI

R6circulation

indicator lightComponent with problsmPossiblo causcSee page

'lOne blinkAir mix control molorOpen or short circuit, obstructed door,

faulty motor22-12

2Two blinksElower motorOpen or short circuit, faultv motor22-14,16

Three blinksEvaporator temperature sensorOpon or short circuit, faulty sensor22-20

t

www.emanualpro.com

Page 1105 of 1395

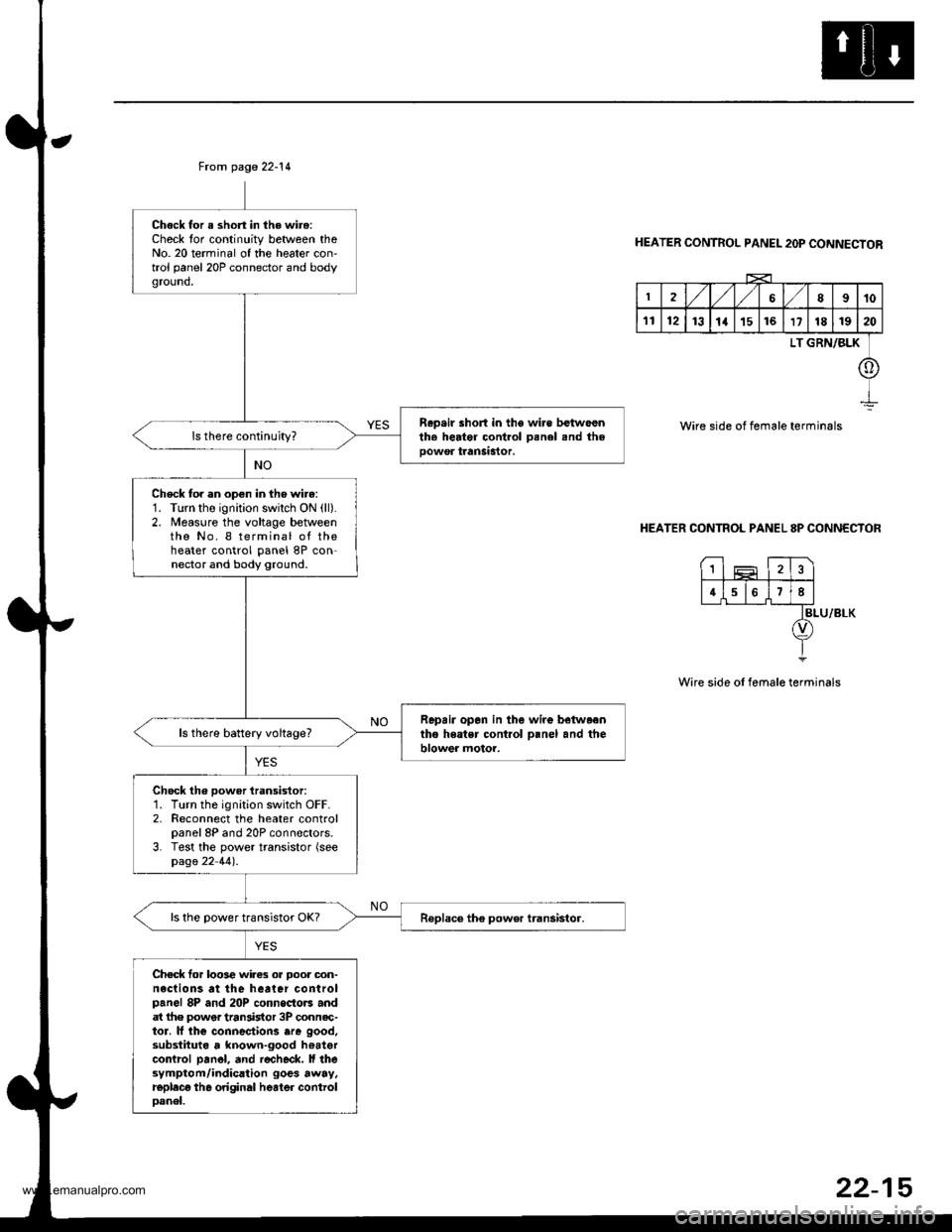

From page 22-14

Chock for a short in the wire:Check tor continuity between theNo. 20 terminal of the heater con'trol panel 20P connector and bodyground,

R.p.ir short in the wire betwoenth. herter control Denel snd theoowor tranSastor.

Check to. an open in the wire:1. Turn the ignition swilch ON (ll).

2. Measure the voltage betweenthe No. I terminal of theheater control panel 8P con-nector and body ground.

Repair opan in the wire betwaentho heatsr cont.ol o.nel and theblower motor.ls there battery voltage?

Chock th6 power iransistor:1. Turn the ignition switch OFF.2. Reconnect the heater controlpanel 8P and 20P connectors.3. Test the power transistor (seepage 22 44).

ls the power transistor OK?

Chec* for loo3e wires or Door oon-neclions at the heater controlpanel 8P and 20P connoctors andat lhe power tran3istor 3P connec-tor. lf lhe connectiorc are good,substituta , known-good hoatercontrcl pan6l, and r€check. ll thesymptom/indication goes away.replecg th6 original heater controloanel.

HEATER CONTROL PANEL 2OP CONNECTOR

2,/1,/l/68910

1112131a151617181920

LT GRN/BLK

o

Wire side of female terminals

HEATER CONTROL PANEL 8P CONNECTOR

BLU/8LK

Wire side of female terminals

1

4678

22-15

www.emanualpro.com

Page 1112 of 1395

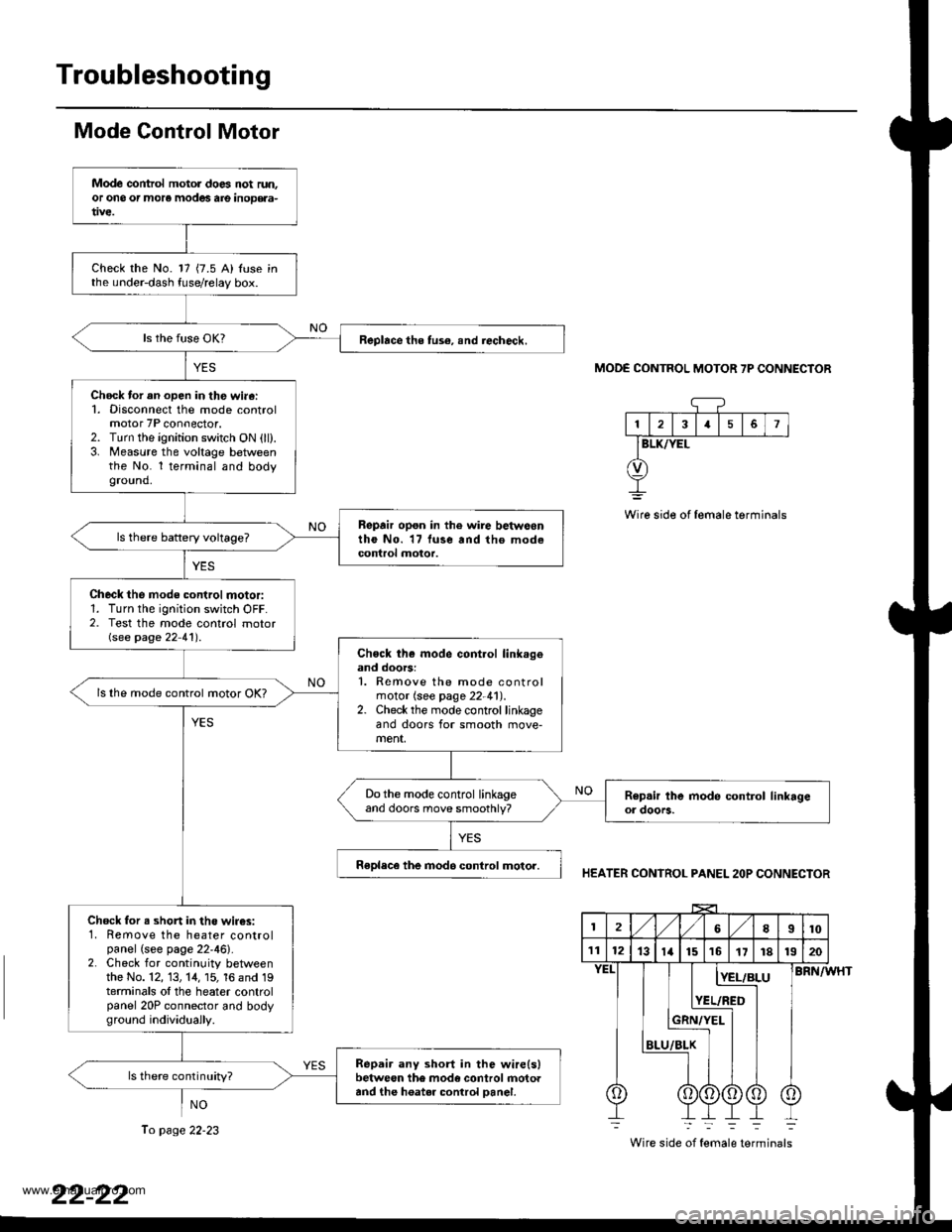

Troubleshooting

Mode Control Motor

NO

MODE CONTROL MOTOR 7P CONNECTOR

13I5

BLK/YEL

Wire side of female terminals

HEATER CONTROL PANEL 2OP CONNECTOR

BRN/WHT

Wire side of female terminals

Mode control motol does not run.or ono or more modes are inoD€aa-

Check the No. 17 {7.5 A) Iuse inthe under-dash fuse/relay box.

Replace the tus€, snd iecheck.

Chock tor an open in th€ wi.6:1. Disconnect the mode controlmotor 7P connector.2. Turn the ignition switch ON (ll).3. Measure the voltage betweenthe No. l terminal and bodyground.

Repair opon in the wire betwoontho No. 17 luse and tho modecontrol motor.

Check the mode control motor:1. Turn the ignition switch OFF.2. Test the mode control motorGee page 22 41') .

Chock th€ mode cont.ol link.geand doors:1. Remove the mode controlmotor (see page 22-41).2. Check the mode control linkageand doors for smooth move-ment,

ls lhe mode control motor OK?

Do the mode control linkageand doors move smoothly?

Replece the inod6 control motor.

Chock for s shon in the wir€s:1. Remove the heater controlpanel (see page 22'46).2. Check for continuity betweenthe No. 12, 13, 14, 15, 16 and 19terminals ol the heater controlpanel 20P connector and bodyground individuaily.

Repair any short in the wire(slbetween the mode control rnotoaand the h6ater control Danel.

ls there continuity?

2l,/1,/8I10

111213ta151617r81320

BLU

[E!r!

YEL/RED

Ii

To page 22-23

www.emanualpro.com

Page 1114 of 1395

Troubleshooting

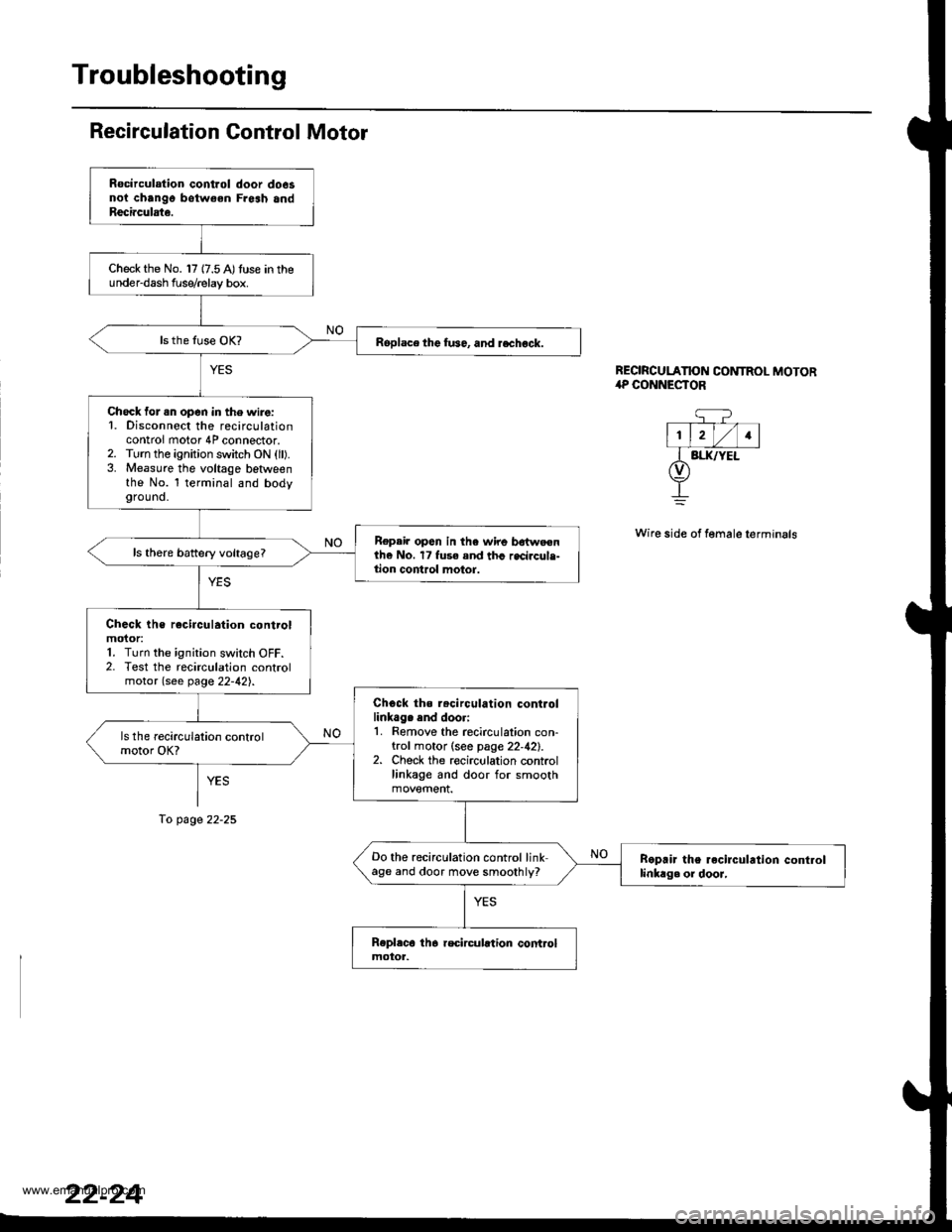

Recirculation Gontrol Motor

YES

To page 22-25

REORCULATION CONTROL MOTOR,rP CONNESTOR

q?- T--- V-l

l1, lrl/l1lI BI.IUYEL(v)

+

Wire side of female terminals

Rocirculation control door do6snoi chango botw€en Fresh andReci.culate.

Check the No. 17 {7.5 A)tuse in theunder-dash f use/relay box.

Roplace the fu36, and rechock.

Check for .n open in the wire:1. Disconnect the recirculationcontrol motor 4P connector.2. Turn the ignition switch ON (ll).3. Measure the voltage betlveenthe No. l terminal and bodyground.

Repair op6n in the wire bdtweenthe No. 17 fuse and thc recircule-tion control motor.

Check the rocirculation controlmoior:1. Turn the ignition switch OFF.2. Test the recirculation controlmotor (see page 22-42).

Chock ths r.circulation controllinkag. end doori1. Remove the recirculation con-trol motor (see page 22,42).2. Check the recirculation controllinkage and door for smooth

Do the recirculation control linkage and door move smoothly?Boprir the recirculrtion controllinkag. or dooJ,

www.emanualpro.com

Page 1126 of 1395

Troubleshooting

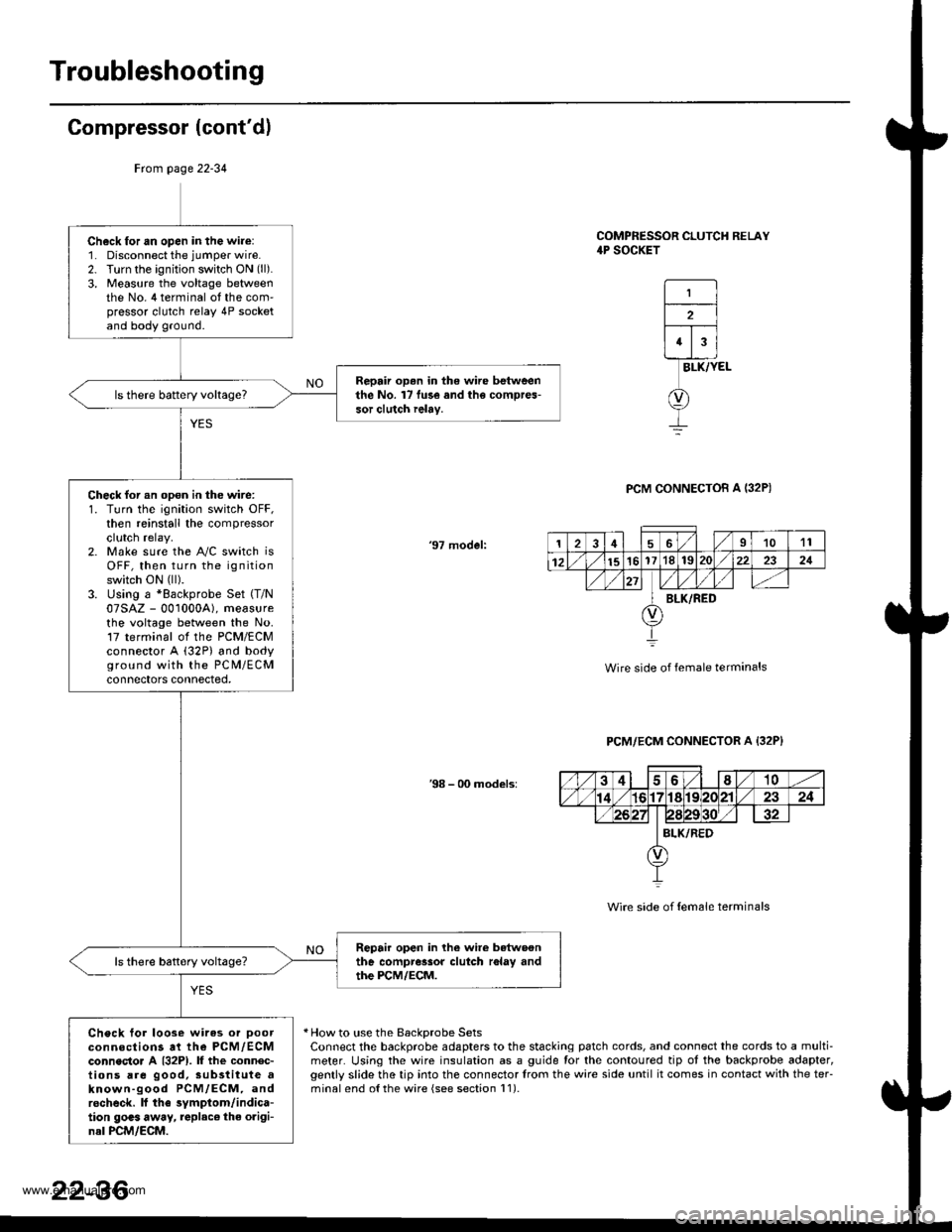

Compressor (cont'dl

COMPRESSOR CLUTCH RELAY4P SOCKET

1

2

43

BLK/YEL

PCM CONNECTOB A I32P)

'97 model:

Wire side of female terminals

PCM/ECM CONNECTOR A {32P}

38 - 00 models:

Wire side of {em6le terminals

* How to use the BackDrobe SetsConnect the backprobe adapters to the stacking patch cords, and connect the cords to a multi-meter. Using the wire insulation as a guide for the contoured tip ot the backprobe adapter,gently slide the tip into the connector trom the wire side until it comes in contact with the teFminalend o{the wire {see section l1).

Frcm page 22-34

Ch6ck for an open in the wire:1. Disconnect the jumper wire.2. Turn the ignition switch ON (ll).

3, Measure the voltage betweenthe No. 4 terminal ot the com'pressor clutch relay 4P socketand body ground.

Repair op.n in the wire betweenthe No. l7 fu3e and the compres-sor clutch ielay.

Check for an opon in the wire:1. Turn the ignition switch OFF,then reinstall the compressorclutch relay.2. Make sure the A"/C switch isOFF, then turn the ignitionswitch ON (ll).

3. Using a *Backprobe Set (T/N

07SAZ - 001000A), measurethe voltage between the No.17 terminal ol the PCM/ECMconnector A (32P) and bodyground with the PC M/ECMconnectors connected,

Repair open in lhe wire betwoonthe compressor clutch r6lay andthe PCM/ECM.

Check tor loose wires or Doorconnections at the PCM,/ECMconnecto. A {32P1. lf the connec-tions are good, sub3titute aknown-good PCM/ECM, androcheck. lf the symptom/indica-tion goas away, replac€ the origi-nal PCM/ECM.

126I1011

12151617'181S222321

BLK/RED

22-36

www.emanualpro.com