Overhaul HONDA CR-V 1999 RD1-RD3 / 1.G User Guide

[x] Cancel search | Manufacturer: HONDA, Model Year: 1999, Model line: CR-V, Model: HONDA CR-V 1999 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 72 of 1395

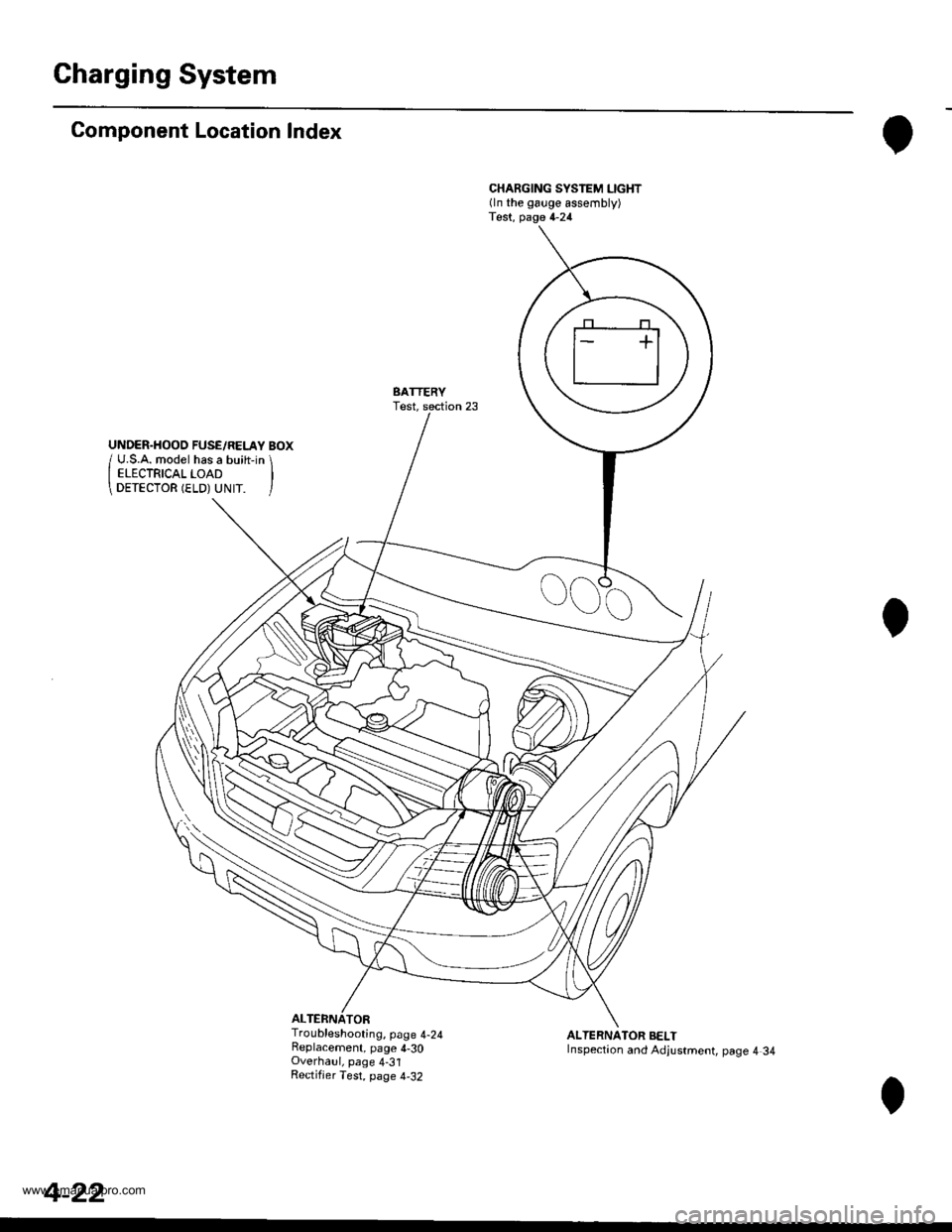

Charging System

Component Location Index

ALTERNATOR

CHARGING SYSTEM LIGHT(ln the gauge assembly)Test, page 4-24

BATTERYTest,

Troubleshooting, page 4-24Replacement, page 4-30Overhaul, page 4-31Rectifjer Test, page 4,32

ALTERNATOR BELTInspection and Adjustment, page 4 34

4-22

www.emanualpro.com

Page 81 of 1395

,T

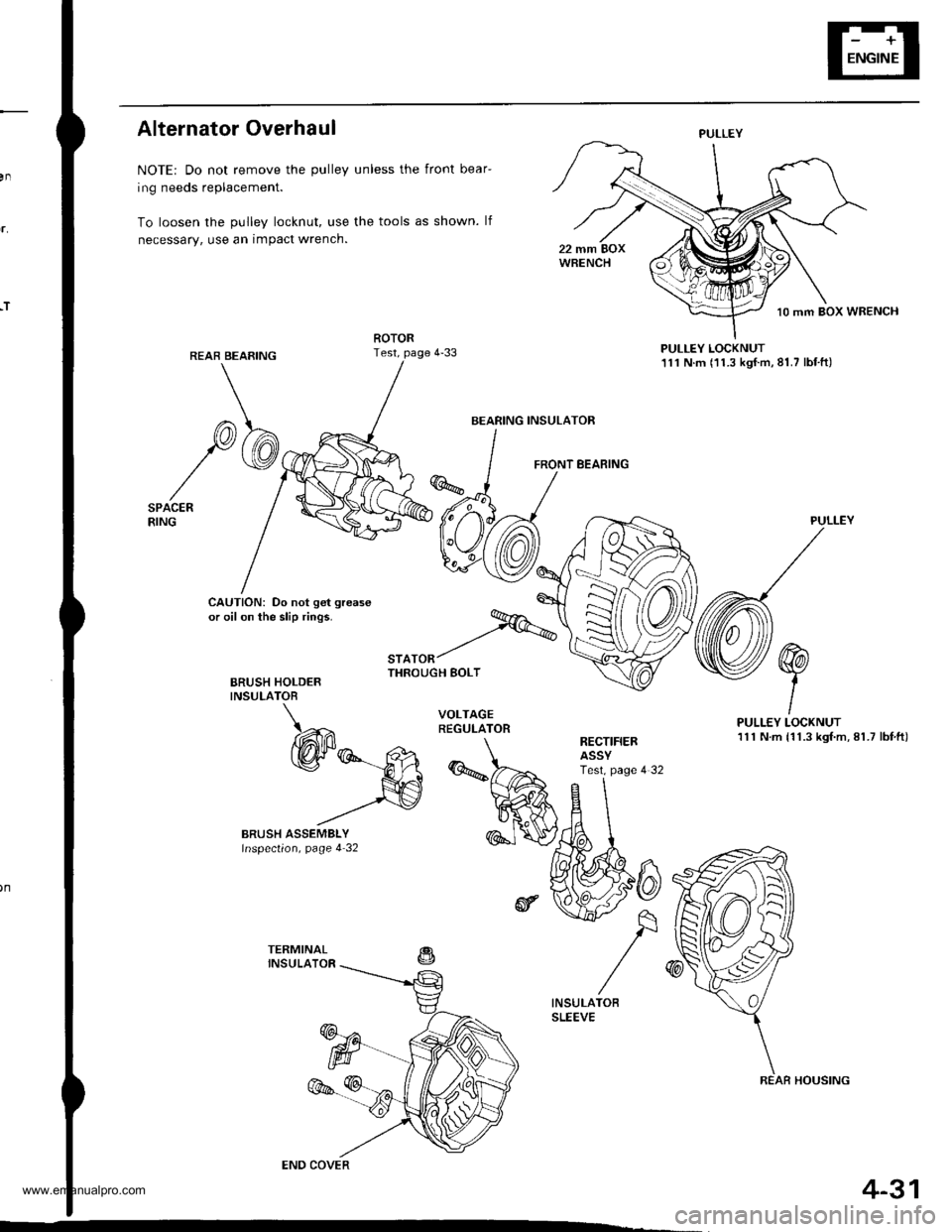

Alternator Overhaul

NOTE: Do not remove the pulley unless the front bear-

ing needs replacement.

To loosen the pulley locknut, use the tools as shown. lf

necessary, use an impact wrench.

PULLEY LOCKNUT111 N.m (11.3 kgf.m,81.7 lbf.ft)

FRONT BEARING

CAUTION: Do not get grease

or oil on the slip rings.

BRUSH HOLDERINSULATOB

"'^.^t%THROUGH BOLT

PULLEY

PULLEY LOCKNUT111 N.m {11.3 kgf.m, 81.7 lbf,ft)RECTIFIERASSYTest. page 4 32

PULLEY

BEARING INSULATOR

COVER

REAR HOUSING

4-31

www.emanualpro.com

Page 149 of 1395

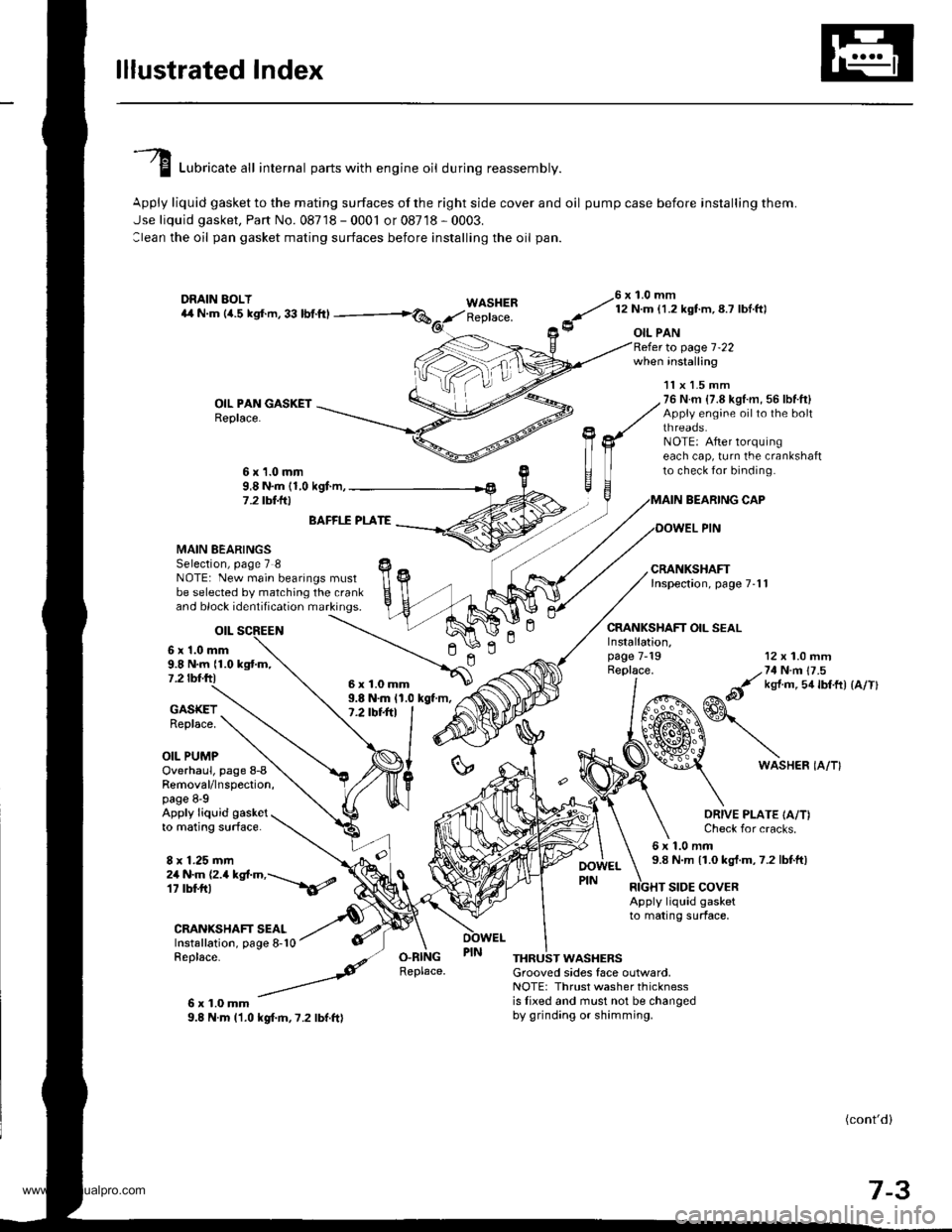

lllustrated lndex

I Luori""t" "tl internal parts with engine oil during reassembly.

Apply liquid gasket to the mating surfaces of the right side cover and oil pump case before installing them.

Jse liquid gasket, Part No. 08718 - 0001 or 08718 - 0003.

:lean the oil pan gasket mating surfaces before installing the oil pan.

WASHERReplace.

76 x 1.0 mm

y' t:n- l.zxstm, 8.7 lbl ftl

9 oIL PAN

OIL PAN GASKETReplace.

to page 1-22when installing

BEARING CAP

OOWEL PIN

CRANKSHAFT OIL SEAL

11x 1.5 mm76 N.m {7.8 kgl.m, 56 lbf.ft}Appiy engine oilto the boltthreaos.NOTE: After lorquingeach cap, turn the crankshaftto check for binding.6x1.0mm9,8 N.m (1,0 kgf.m,7 .2 tbt.lrl

n

MAIN BEARINGSSelection, page 7 8NOTE: New main bearings mustbe selected by matching the crankand block identification markings.

otL

6 x'1.0 mm9.8 N.m {1.0 kgtm,7.2 tbf.ftl

BAFFI.f PLATE

9.8 N.m 11.0 kgt m,7.2 tbt+tl

12 x 1.0 mm

/,71N n 17 .5

&it ks{ m 5a lbtft) {a/Tl

GASKETReplace.

OIL PUMP

Installation,page 7-19Replace.

ln

6WASHER IA/T}Overhaul, page 8-8Removal/lnspection,page 8-9Apply liquid gasketto mating surface.

8 x 1.25 mm

ORIVE PLATE IA/T)Check for cracks.

6x1.0mm9.8 N.m 11.0 kgt.m,7.2 lbtft)2a N.m (2.a kgt.m,---\6/

CRANIGHAFT SEALInstallation, page 8-10Replace-

6x1.0mm9.8 N.m l'1.0 kgf.m,7.2 lbf.ft)

RIGHT SIDE COVERApply liquid gasketto mating surface,

O.RINGReplace.THRUST WASHERSGrooved sides face outlvard,NOTE: Thrust washer thicknessis lixed and must not be changedby grinding or shimming.

(cont'd)

7-3

6x1.0mm

www.emanualpro.com

Page 171 of 1395

Engine Lubrication

Speciaf Tools .......... ...".""'8-2

lllustrated Index ........... .'...8-3

Engine Oil

Inspection ............'..'...'..' 8-4

Replacement ............................'........... 8-4

OilFilter

Rep1acement........................................ 8-5

Oil Pressure Switch

Testing ".....8-7

Oil Pressure

Testing ....'.' 8-7

OilPump

Overhaul..... ...........,......... 8-8

Removal/lnspection/lnstallation ....'.' 8-9

www.emanualpro.com

Page 173 of 1395

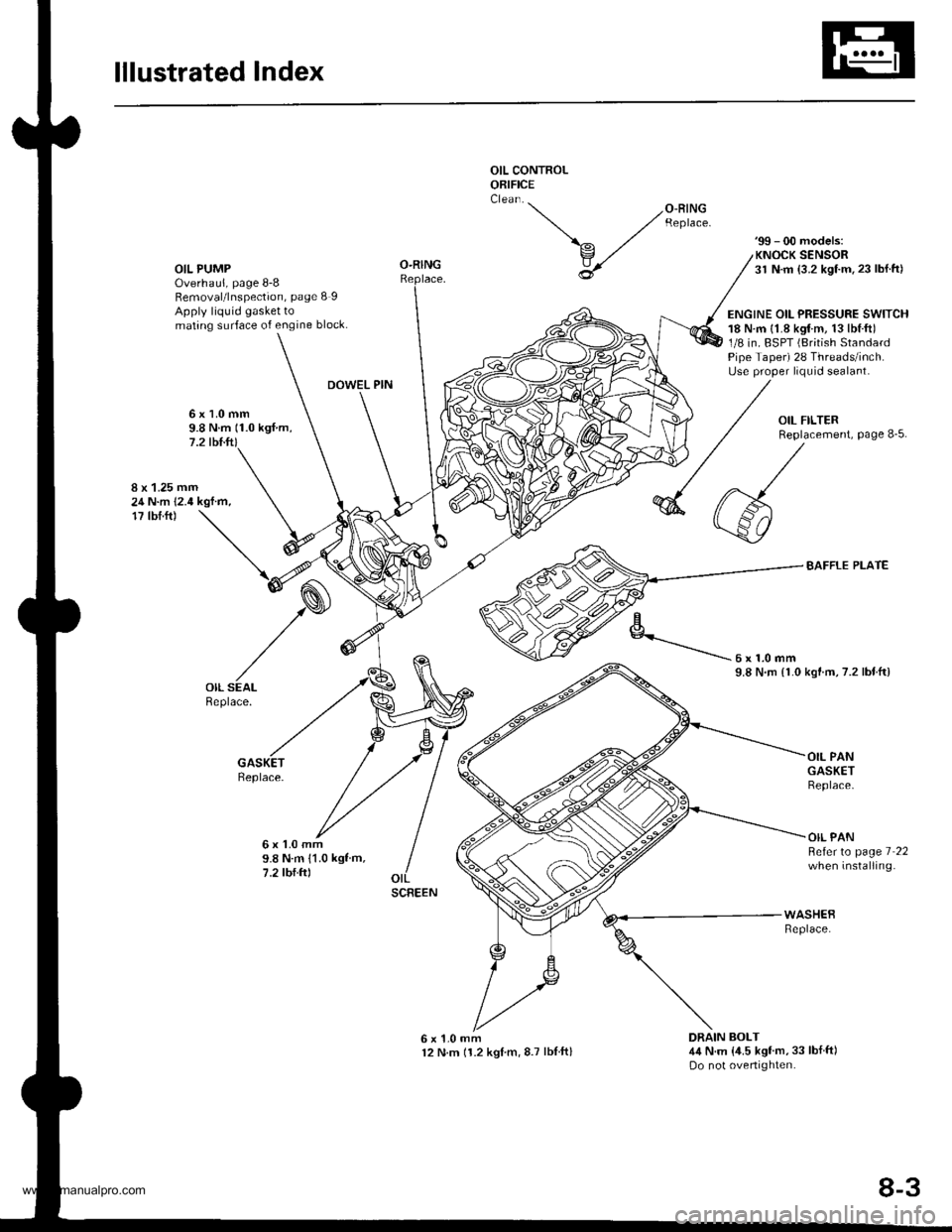

lllustrated Index

OIL CONTROLORIFICE

OIL PUMPOverhaul, page 8-8Removal/lnspection, page 8 IApply liquid gasket tomating surface of engine block.

'99 - 00 models:KNOCK SENSOR31 N.m {3.2 kgf.m.23 lbl.ft)

ENGINE OIL PRESSURE SWITCH18 N.m {1.8 kgtm, 13lbl.ft)1/8 in. BSPT (British StandardPipe Taper) 28 Threads/inch.Use proper liquid sealant.

O-RING

DOWEL PIN

6x1.0mm9.8 N.m (1.0 kgf.m,7.2 tbl.ft)

8 x 1.25 mm24 N.m 12.4 kgf.m,17 tbf.ft)

BAFFLE PLATE

kgtm,7.2 lbtftl

Replace.

6x1.0mm9.8 N.m 11.0 kgf m,7.2 tbf.ftl

OIL PANGASKETReplace.

OIL PANBeferto page 7 22when installing.

6x1.0mm12 N.m 11.2 kglm,8.7 lblftl

WASHEBReplace.

DRAIN BOLT4,1N.m {,1.5 kgf'm,33 lbf ft)Do not overtighten.

'-- /o-RrNG ,/ Reptace.

\^ ./

v,/

U

6x1.0mm9.8 N.rn {1.0

SCREEN

8-3

www.emanualpro.com

Page 174 of 1395

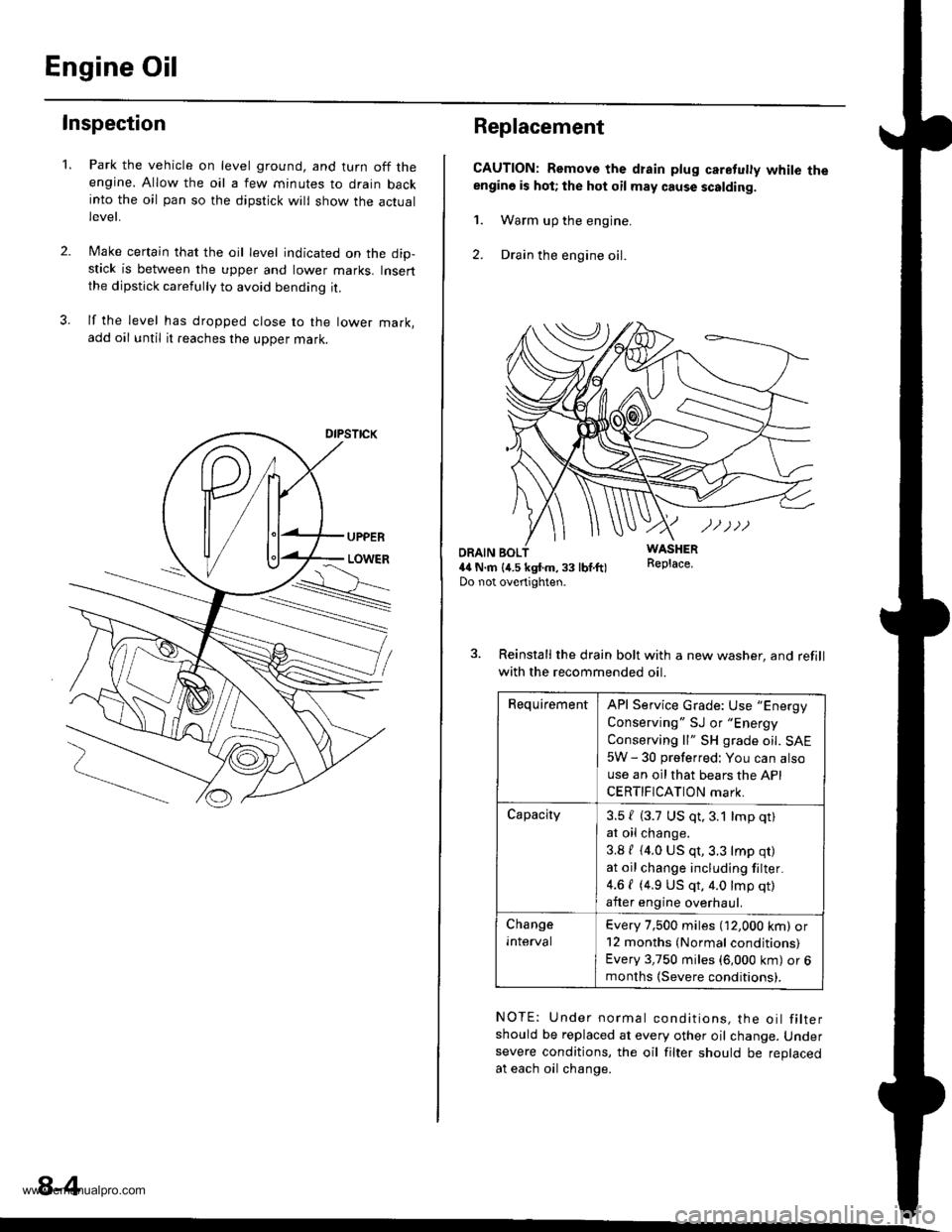

Engine Oil

Inspection

2.

1.Park the vehicle on level ground, and turn off theengine. Allow the oil a few minutes to drain backinto the oil pan so the dipstick will show the actuallevet,

Make certain that the oil level indicated on the dip-stick is between the upper and lower marks. Insertthe dipstick carefully to avoid bending it.

lf the level has dropped close to the lower mark,add oil until it reaches the upper mark.

8-4

Replacement

CAUTION: Remove the drain plug caretuly white theengino is hot; the hot oil may cause scalding.

1. Warm up the engine.

2. Drain the engine oil.

WASHERR€place.ORAIN BOL4il N.m {4.5 kgtm,33 lbf.ft)Do not overtighten.

3. Reinstall the drain bolt with a new washer, and refill

with the recommended oil.

RequirementAPI Service Grade: Use "Energy

Conserving " SJ or "Energy

Conserving ll" SH grade oil. SAE

5W - 30 preferred: You can also

use an oil that bears the API

CERTIFICATION mark.

Capacity3.5 { (3.7 US qt,3.1 lmp qt)

at oil change.

3.8 / (4.0 US qt,3.3 lmp qr)

at oil change including filter.

4.6 { (4.9 US qt, 4.0 lmp qt)

after engine overhaul.

Change

Inlerval

Every 7,500 miles (12,000 km) or12 months (Normal conditions)

Every 3,750 miles (6,000 km) or 6months (Severe conditions).

NOTE: Under normal conditions, the oil filtershould be replaced at every other oil change. Undersevere conditions, the oil filter should be replacedat each oil change.

www.emanualpro.com

Page 178 of 1395

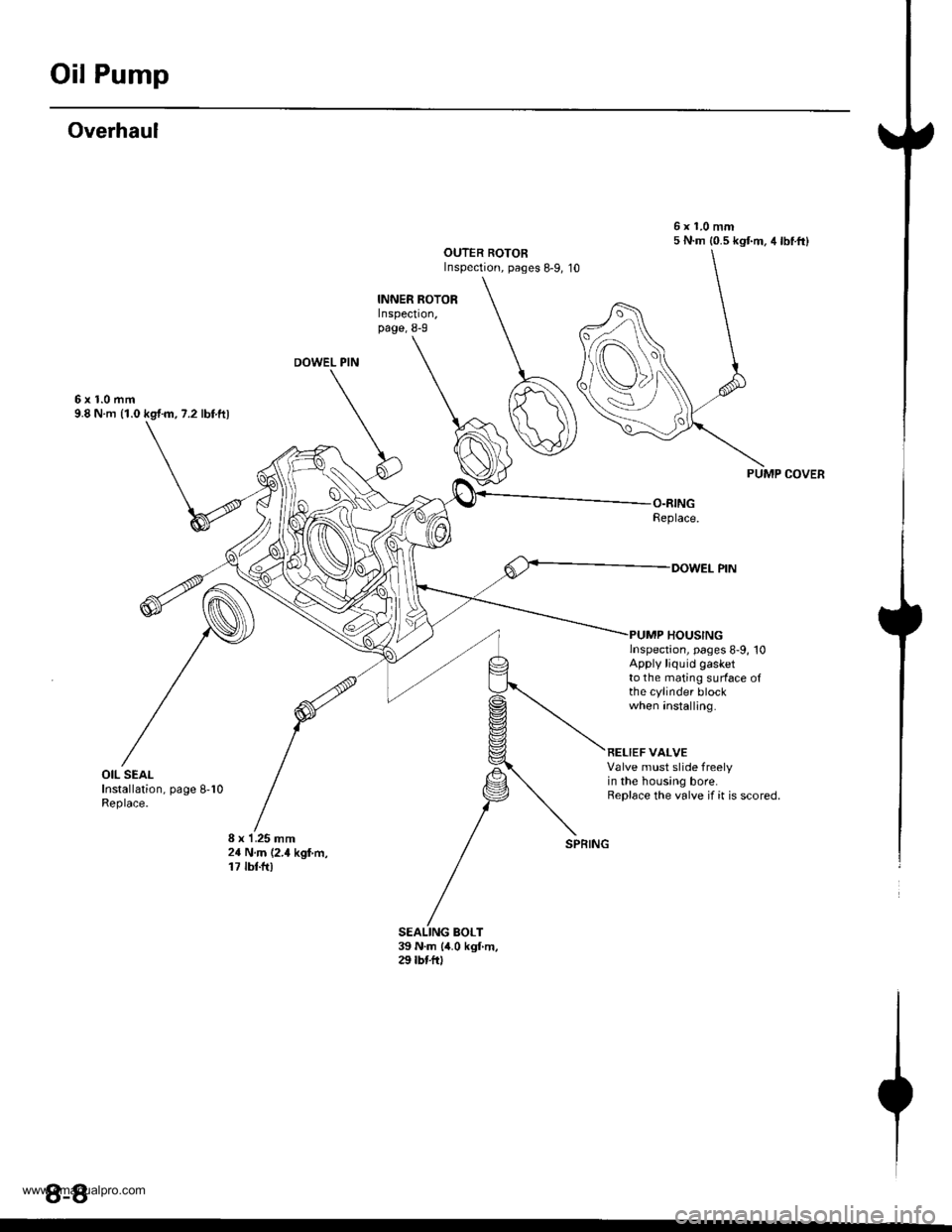

Oil Pump

Overhaul

6xl.0mm9.8 N m (1.0 kg,t m, 7.2 lbf ftl

6x1.0mm5 N.m {0.5 kgt m. 4lbtft}OUTER ROTORInspection, pages 8-9, 1O

PUMP COVER

lnspection, pages 8-9, 10Apply liquid gasketto the mating surface ofthe cylinder blockwhen anstalling.

REI-IEF VALVEValve must slide freelyin the housing bore.Replace the valve if it is scored.

8 x 1.25 mm2{ N.m (2.4 kgf m,17 tbf.fi)

DOWEL PIN

8-8

www.emanualpro.com

Page 440 of 1395

Manual Transmission

Diff€rential

lndex ...................... ......... 13-38

Backlash Inspestion ..,....,.,.....................,......, 13-38

Final Driven Gear Replacement .................... 13-39

Tapered Roller BearingReplacement ............. 13-39

Bearing Outer Race Replacement ......,.,........ 13-i10

Tapered Roller Bearing PreloadAdiustment ............... 13-il1

Oil Seal Reolacement .................................... 13-/l:}

Transfer Assembly

lllustrated Index ............. 13-il4

Inspection ..,....,.,......,...... 13-46

Disassembly ................... 13-47

Transfer Drive Gear BearingReplacement ...,..................,....................... 13-ilg

Transfer Driven Gear Shaft BearingReplacement .............................................. 13-ilg

Transfer Shaft Disassembly/Reassembly .............. 13-50

Transler Cover A Bearing Outer RaceRep1acement.........,.,.,..........,....,...,.........,., 13-50

Transter Housing Bearing Outer RaceReD1acement.............................................. 13-51

Reassembly ..-............,... 13-52

Mainshaft Bearing/Oil Seal

Beplacement .................. 13-62

Countershaft Bearing

Replacement .,,.,.,., ..,...... 13-63

Mainshaft Thrust Clearance

Adiustment .................... 13-6,1

Transmission Assembly

Reassembly .,.,.,.,..,.,....,., 13-67

fnstaffation .,.,.............,... 13-72

Gearshift Mechanism

Overhaul ................ .........13-17

www.emanualpro.com

Page 442 of 1395

MaintenanceBack-up Light Switch

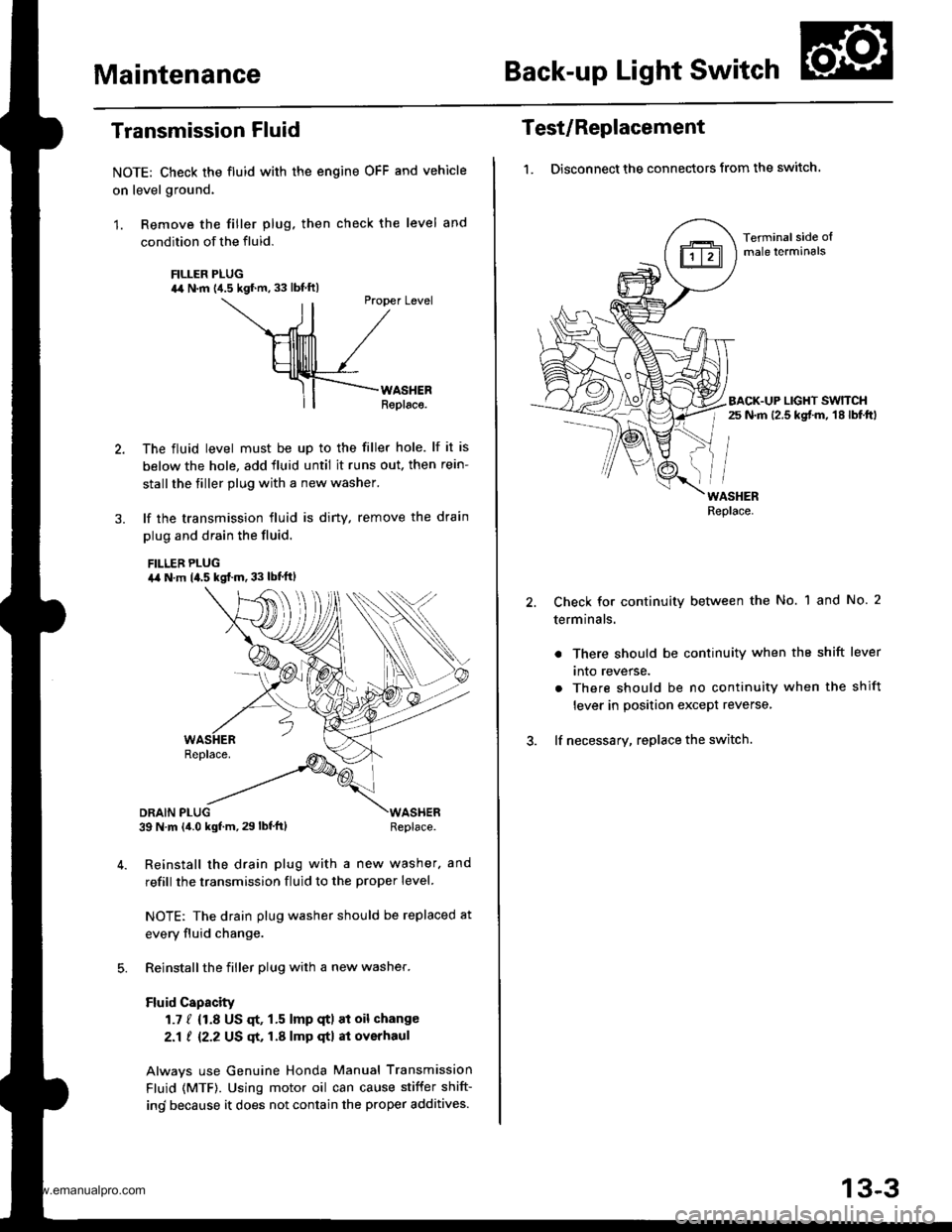

Transmission Fluid

NOTE: Check the fluid with the engine OFF and vehicle

on level ground.

1. Remove the filler plug. then check the level and

condition of the fluid.

FILLER PLUG44 N.m {4.5 kgf.m. 33 lbf ftl

ll

Ptopet Level

\--ril /

HllllllTl /

Hllllrlll /_rf-F{--rno."."

ll| | Replaco.

The fluid level must be up to the filler hole. lf it is

below the hole, add fluid until it runs out. then rein-

stall the tiller plug with a new washer.

lf the transmission fluid is diny, remove the drain

plug and drain the fluid.

FILLEB PLUGa,a N.m 14.5 kgf..n. 33 lbt'ftl

DRAIN PLUG39 N m (4.0 kgf.m, 29 lbf'ft)WASHERReplace.

Reinstall the drain plug with a new washer. and

refill the transmission fluid to the proper level.

NOTE: The drain plug washer should be replaced at

every fluid change.

Reinstall the filler plug with a new washer.

Fluid Capacity

1.7 / {1.8 US qt, 1.5 lmp qtl at oil change

2.1 ! 12.2 US qt, 1.A lmp qtl at overhaul

Alwavs use Genuine Honda Manual Transmission

Fluid (MTF). Using motor oil can cause stiffer shift-

ind because it does not contain the proper additives.

Test/Replacement

1. Disconnect the connectors from the switch.

Terminal side oImale lerminals

BACK.UP LIGHT SWTTCHr 25 N.m 12.5 kgt m, 18 lbf.ftl

WASHERReplace.

Check for continuity between the No. 1 and No. 2

terminals.

. There should be continuity when the shift lever

tnto reverse.

. There should be no continuity when the shift

lever in position except reverse,

lf necessary, replace the switch.

13-3

www.emanualpro.com

Page 516 of 1395

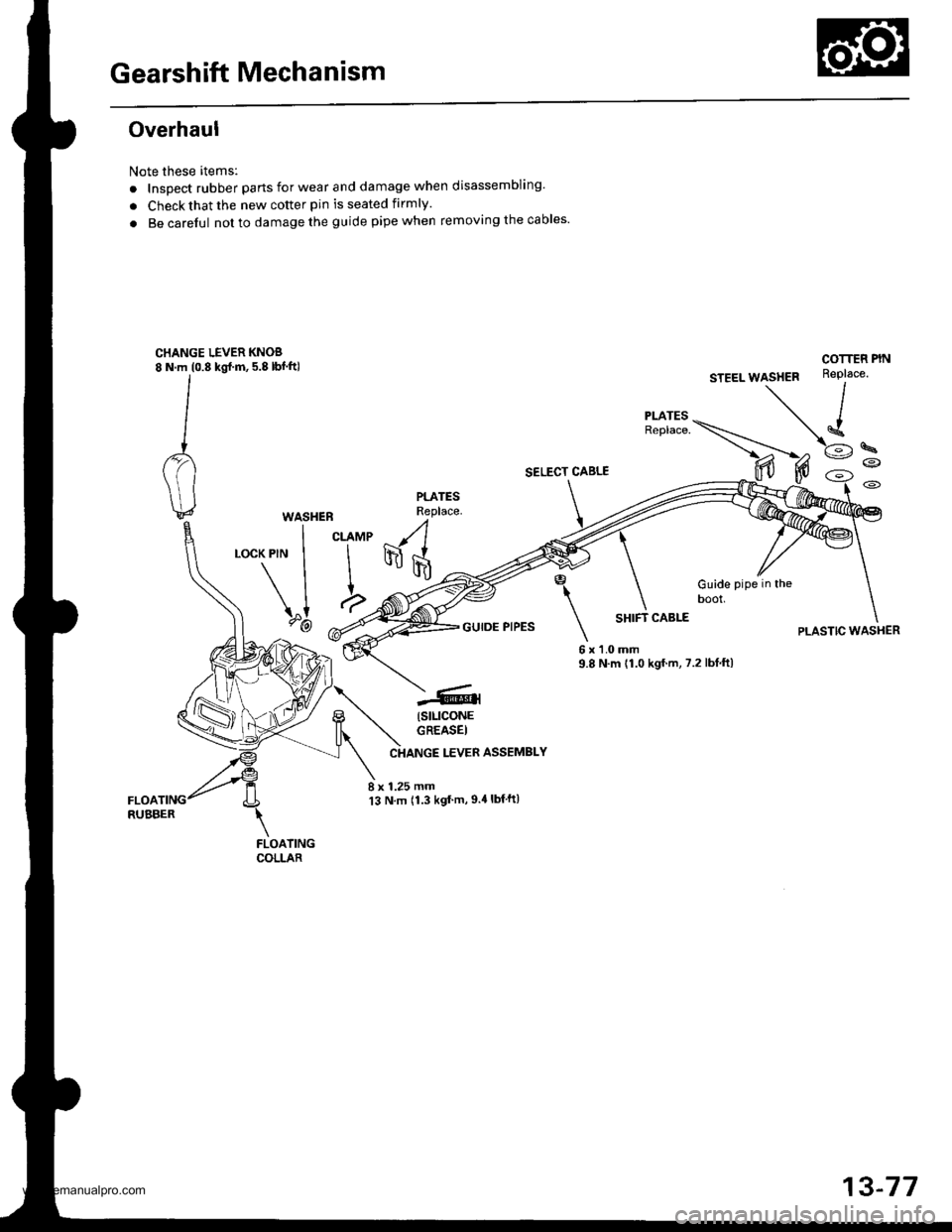

Gearshift Mechanism

Overhaul

Note these itemsl

. InsDect rubber parts for wear and damage when disassembling'

. Check that the new cotter pin is seated firmly.

. Be carelul not to damage the guide pipe when removing the cables'

CHANGE LEVER KNOS8 N.m (0.8 kgl.m, 5.8 lbf.ft)

SELECT CABLE

PLATESReplace.WASHEB

I curur(PlN I I

\II

\"1 a,?-@ -.4'

-(

I

\

6x9.8

Guide pipe in theDOOI,

COTTEF PIN

PLASTIC WASHERGUIDE PIPESSHIFT CABLE

'l.0 mmN.m {1.0 kgf.m, 7.2 lbf.ftl

(stLlcoNE

GREASEI

LEVER ASSEMBLY

8 x 1.25 mm13 N.m 11.3 kgt'm,9.4lbf ft)

FLOATINGCOLLAR

13-77

www.emanualpro.com