Overhaul HONDA CR-V 1999 RD1-RD3 / 1.G Owner's Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1999, Model line: CR-V, Model: HONDA CR-V 1999 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 672 of 1395

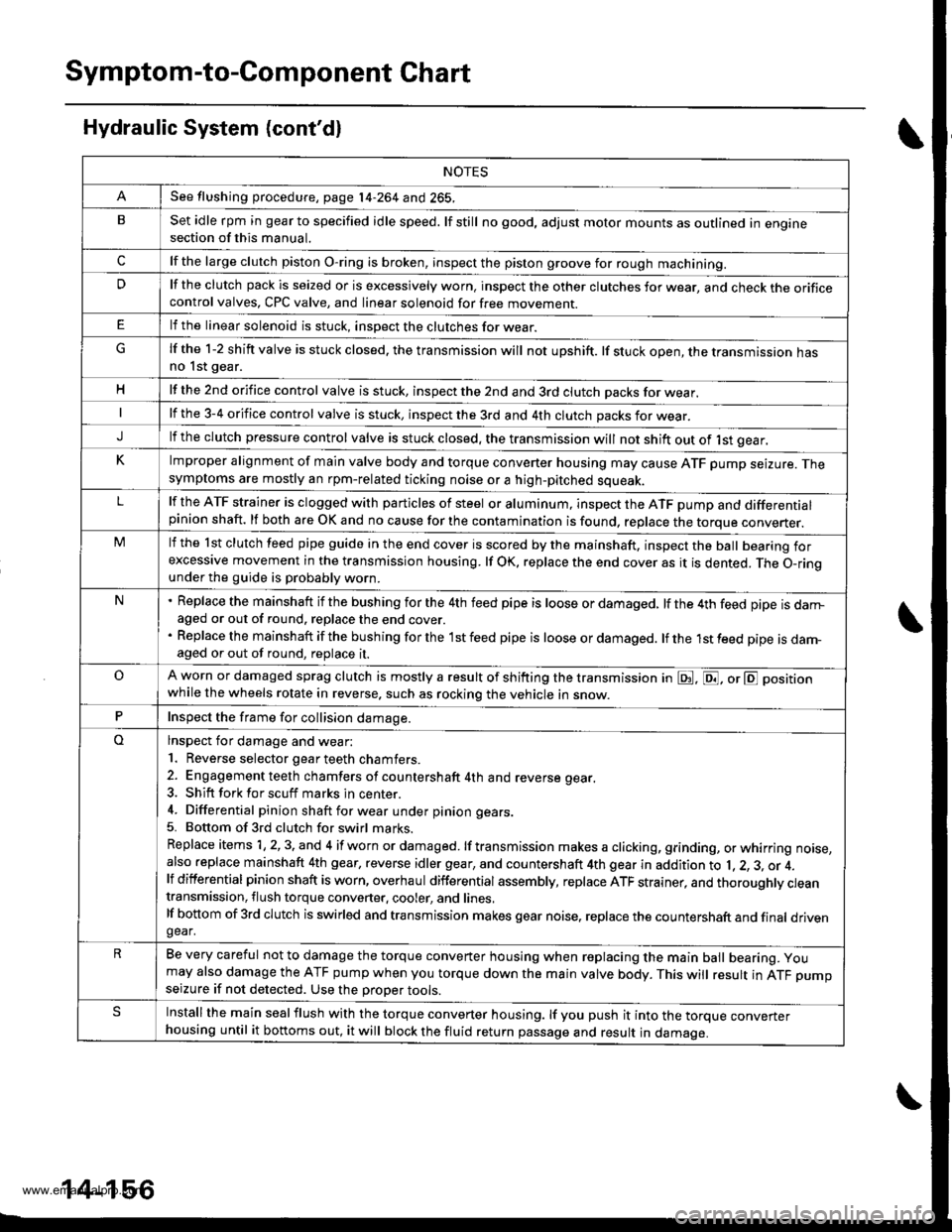

Symptom-to-Com ponent Chart

Hydraulic System (cont'd)

NOTES

See flushing procedure, page l4-264 and 265,

BSet idle rpm in gear to specified idle speed. lf still no good, adjust motor mounts as outlined in enginesection of this manual.

clf the large clutch piston O-ring is broken, inspect the piston groove for rough machining.

Dlf the clutch pack is seized or is excessively worn. inspect the other clutches fot wear, and check the orificecontrol valves, CPC valve, and linear solenoid for free movement.

lf the linear solenoid is stuck, inspect the clutches for wear.

lf the 1-2 shift valve is stuck closed. the transmission will not upshift. lf stuck open, the transmission hasno lst gear.

Hlf the 2nd orifice control valve is stuck, inspect the 2nd and 3rd clutch Dacks for wear.

lf the 3-4 orifice control valve is stuck, inspect the 3rd and 4th clutch packs for wear.

Jlf the clutch pressure control valve is stuck closed. the transmission will not shift out of lst gear.

Klmproper alignment of main valve body and torque converter housing may cause ATF pump seizure. Thesymptoms are mostly an rpm-related ticking noise or a high-pitched squeak.

Llf the ATF strainer is clogged with particles of steel or aluminum, inspect the ATF pump and differentialpinion shaft. lf both are OK and no cause for the contamination is found, replace the torque converter.

Mlf the lst clutch feed pipe guide in the end cover is scored by the mainshaft. inspect the ball bearing forexcessive movement in the transmission housing. lf oK, replace the end cover as it is dented. The o-rinounder the guide is probably worn.

N' Replace the mainshaft if the bushing for the 4th feed pipe is loose or damaged, lf the 4th feed pipe is darrFaged or out of round. replace the end cover.' Replace the mainshaft if the bushing for the l st feed pipe is loose or damaged. lf the 1st feed pipe is dam-aged or out of round, replace it.

oA worn or damaged sprag clutch is mostly a result of shifting the transmission in E!. E, or E positionwhile the wheels rotate in reverse. such as rocking the vehicle in snow.

PInspect the frame for collision damage.

lnspect for damage and wear:

l. Reverse selector gear teeth chamfers.

2. Engagement teeth chamfers of countershaft 4th and reverse gear.

3. Shift fork for scuff marks in center.

4. Differential pinion shaft for wear under pinion gears.

5. Bottom of 3rd clutch for swirl marks.

Replace items 1, 2, 3. and 4 if worn or damaged. lf transmission makes a clicking, grinding, or whirring noise,also replace mainshaft 4th gear, reverse idler gear, and countershaft 4th gear in addition to 1,2, 3, or 4.lf differential pinion shaft is worn, overhaul differential assembly, replace ATF strainer, and thoroughly cjeantransmission, flush torque converter. cooler, and lines,lf bottom of 3rd clutch is swirled and transmission makes gear noise. replace the countershaft and final drivenoear,

Be very careful not to damage the torque converter housing when replacing the main ball bearing. you

may also damage the ATF pump when you torque down the main valve body. This will result in ATF pumpseizure if not detected. Use the Drooer tools.

SInstall the main seal flush with the torque converter housing. lf you push it into the torque converterhousing until it bottoms out, it will block the fluid return passage and result in damage.

www.emanualpro.com

Page 848 of 1395

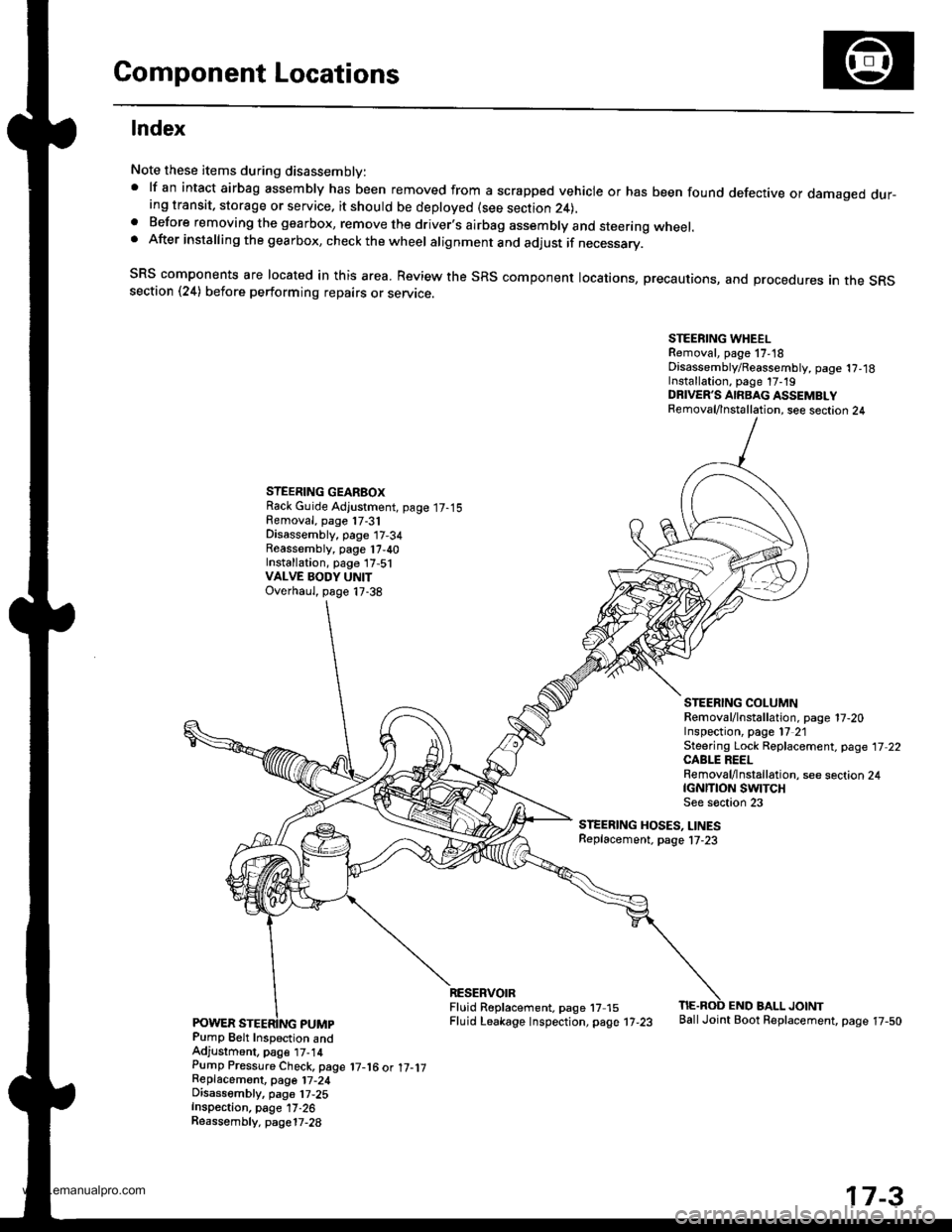

Component Locations

lndex

Note these items during disassembly:' lf an intact airbag assembly has been removed from a scrapped vehicle or has been found defective or damaged dur-ing transit, storage or service. it should be deployed (see section 24),a Before removing the gearbox, remove the driver.s airbag assembly and steering wheel.. After installing the gearbox, check the wheel alignment and adjust if necessary.

SRS components are located in this area. Review the SRS component locations, precautions, and procedures an the SRssection (24) before performing repairs or servrce.

STEERING WHEELRemoval, page 17,18Disassembly/Reassembly, page 1?,18Installation, page 17-19DRIVER'S AIRBAG ASSEMBLYRemoval/lnstallation, see section 24

STEERING GEARBOXRack Guide Adjustment, page 17-15Removal, page 17-31Disassembly, page 17-34Reassembly, page 17,40Installation, page 17,51VALVE BODY UNITOverhaul, page 17-38

STEERING COLUMNRemoval/lnstallation. page 17-20Inspection, page l7 21Steering Lock Replacement, page 17 22CABLE REELRemoval/lnstallation, see section 24tcNrnoN swtTcHSee s€ction 23

STEERING HOSES, LINESReplacement. page l7-23

Pump Belt Inspection andAdjustment, pag€ t7-14Pump Pressure Check, page 17-16 ot 17-1jReplacemont, page 17-24Disassembly, pa96 17,25Inspection, page 17-26Reassembly. page17-28

RESERVOIRFluid R6placement. page 17 15Fluid Leakage lnspection, page 17-23

END BALL JOINTBallJoint Boot Replacement, page 17-50

17-3

www.emanualpro.com

Page 1091 of 1395

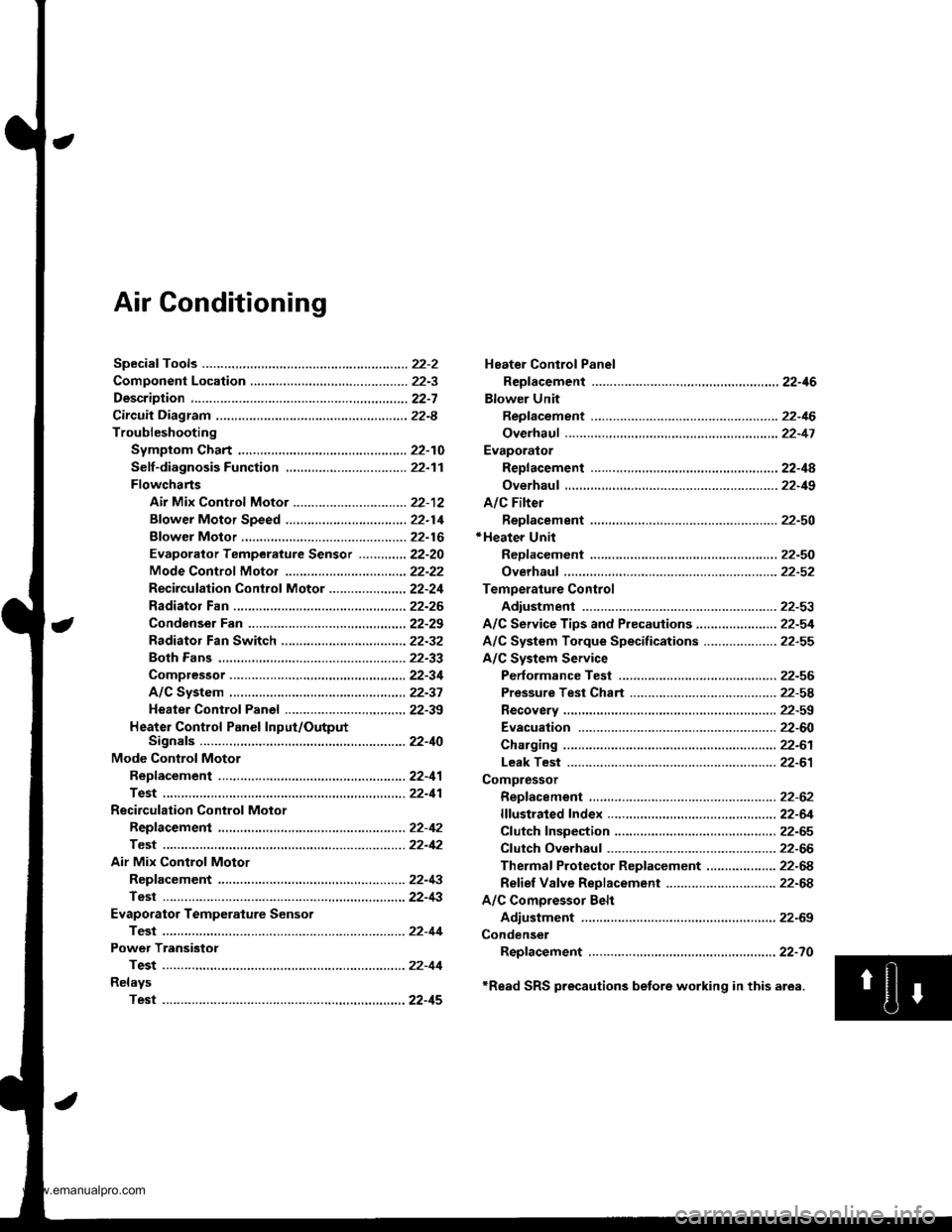

Air Conditioning

Heater Control Panel

Reofacement ,.,...,,.,..,.,.,,22-46

Blower Unit

Replacement .................. 22-46

Overhaul ...........,,,., .......-.22-17

Evaporalor

ReDlacement ...,.,.,..,......,22-4A

Overhaul ................ .........22-19

A/C Filter

Replacement ..................22-50*Heater Unit

ReDfacement ..................22-50

Overhaul ..,.,..,.,...,.. .........22-52

Temperature Control

Adiustment ....................22-53

A/C Service Tips and Precauiions............-....-.... 22-54

A/C System Torque Specifications .................... 22-55

A/C System Service

Performance Test ......,...22-56

Pressure Test Chart .-.....22-5a

Recovery ..............,. ...-.-...22-59

Evacuation -...........-........22-60

Charging ................ .......-.22-61

Leak Test ........................22-61

Compressor

Repfacement ..........-.......22-62

flfustrated Index .....,.......22-64

Cfutch fnspection .........,.22-65

Cfutch Overhaul ............- 22-66

Thermaf Protector Rep|acement ................... 22-68

Refief Valve Replacement .............................. 22-68

A/C Comoressor Belt

Adiustment .................... 22-69

Condenser

Repfacement .,.....,,.,..,.,..22-70

'Read SRS precautions betore working in this area.

www.emanualpro.com

Page 1093 of 1395

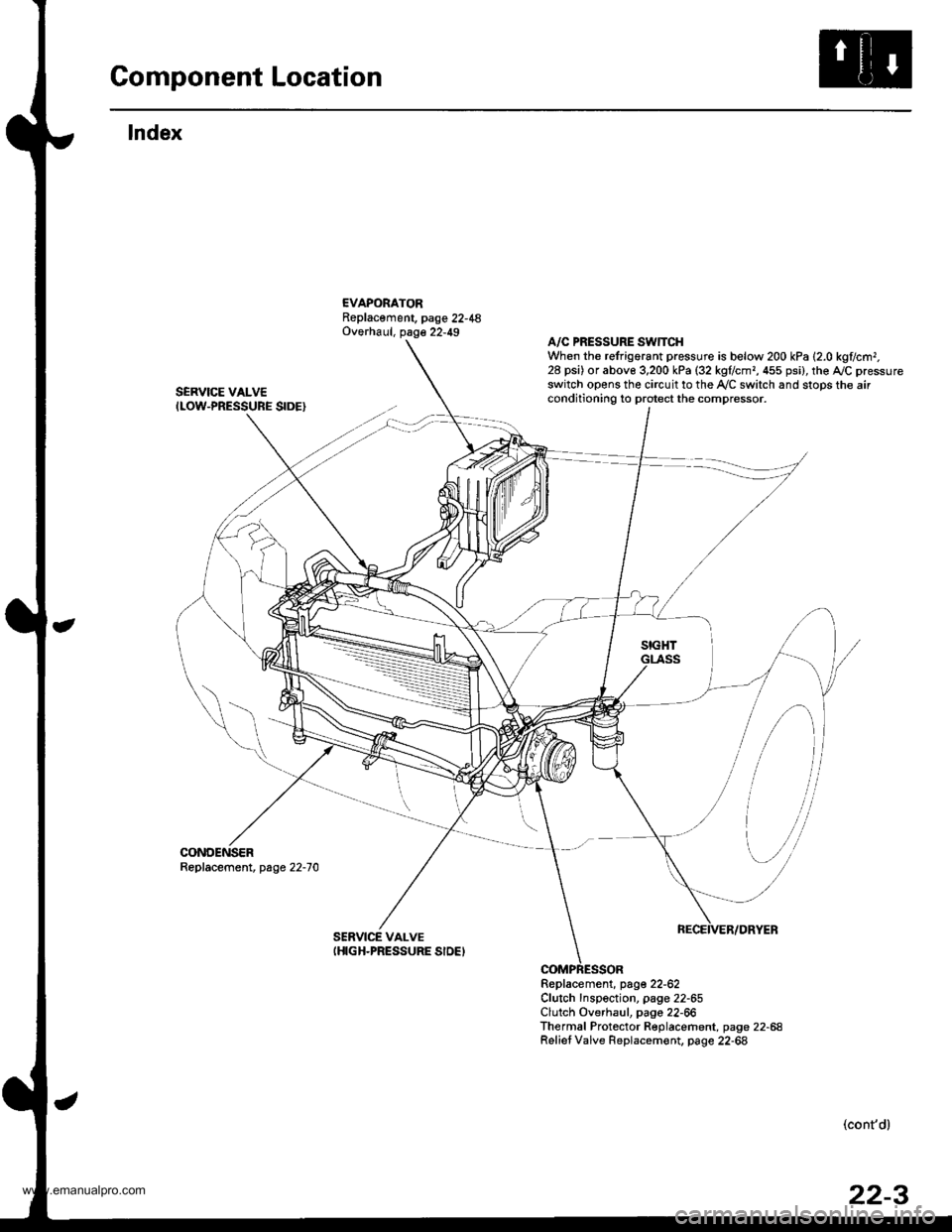

Component Location

lndex

EVAPORATORReplacement, page 22-48Overhaul, page 22-49

SERVICE VALVEILOW-PRESSURE SIDE}

CONDENSERReplacement, page 22-70

A/C PRESSURE SWTTCHWhen the refrigorant pressure is below 200 kPa 12.0 kglc.r|r,28 psi) or abov€ 3,200 kPa (32 kgflcmr, 455 psi), the AJC pressureswitch opens the circuit to the Ay'C switch and stops the airconditioning to protect the compressor.

Replacement, page 22-62Clutch Inspection, page 22-65Clutch Overhaul, pago 22-66Thermal Protector Replacement, page 22-68Relief Valve Replacem€nt. page 22-68

SERVICE VALVEIHIGH-PRESSURE SIDEI

,

[\,

-il

(cont'd)

www.emanualpro.com

Page 1094 of 1395

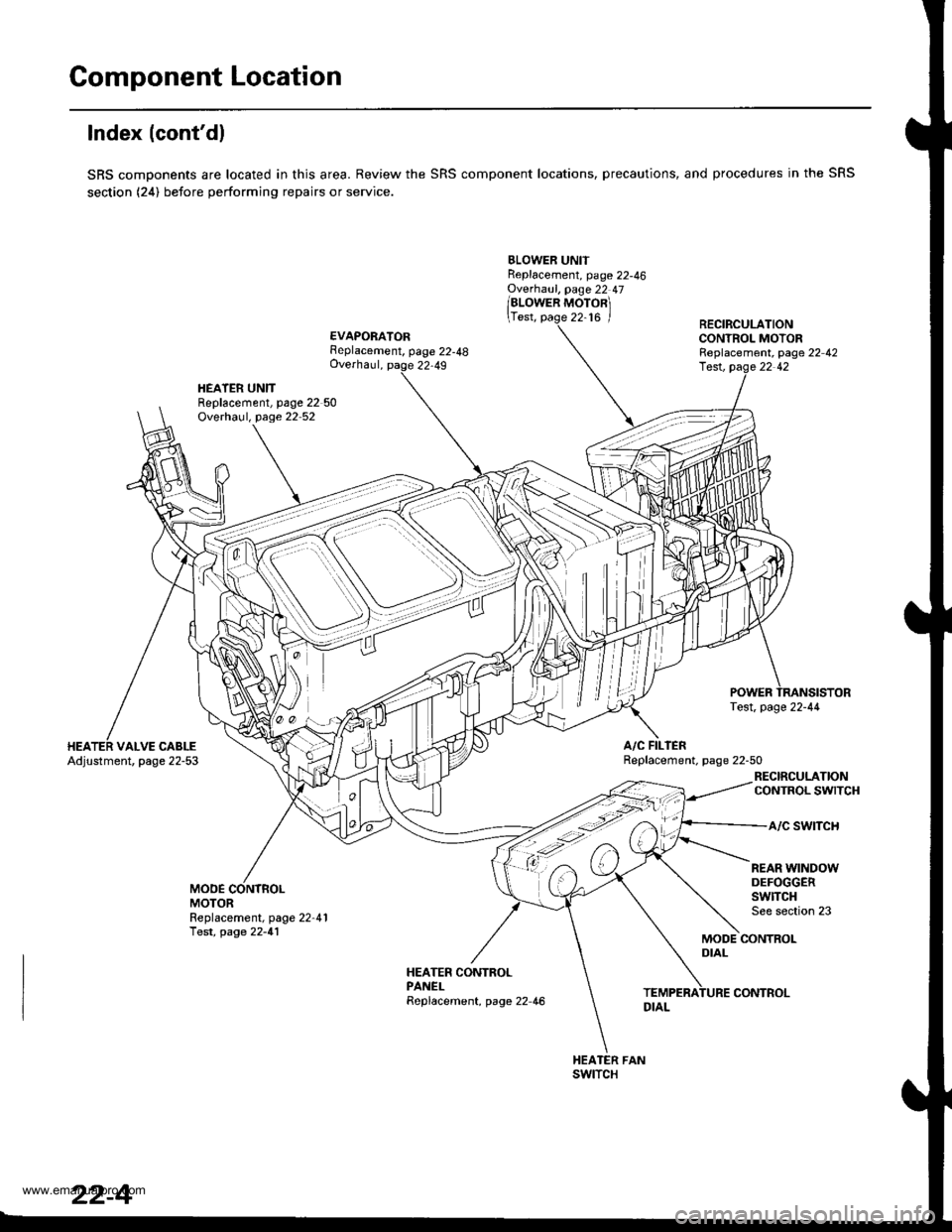

Component Location

lndex (cont'dl

SRS components are located in this area. Review the SRS component locations, precautions, and procedures in the SRS

section (24) before performing repairs or service.

BLOWER UNITReplacement, page 22-46Ovethaul, page 22 47

/alowen ruoronl

\Test, page 22-16 /

EVAPORATORFeplacement, page 22-48Overhaul, page 22,49

RECIRCULATIONCONTROL MOTORReplacement, page 22 42

HEATER UNITReplacement, page 22 50Overhaul, page 22 52

lest, pag.e 22 42

A/C FILIERReplacement. page 22-50VALVE CABLEAdjustment, page 22-53

RECIRCULATIONCONTROL SWITCH

a/c swtTcH

MODEMOTOR

REAR WINDOWDEFOGGERSwlTCHSee section 23Replacement, page 22-41Test, page 22-41MODE CONTROLDIAL

HEATER CONTROLPANELReplacement, page 22 46

swtTcH

22-4

CONTROL

www.emanualpro.com

Page 1137 of 1395

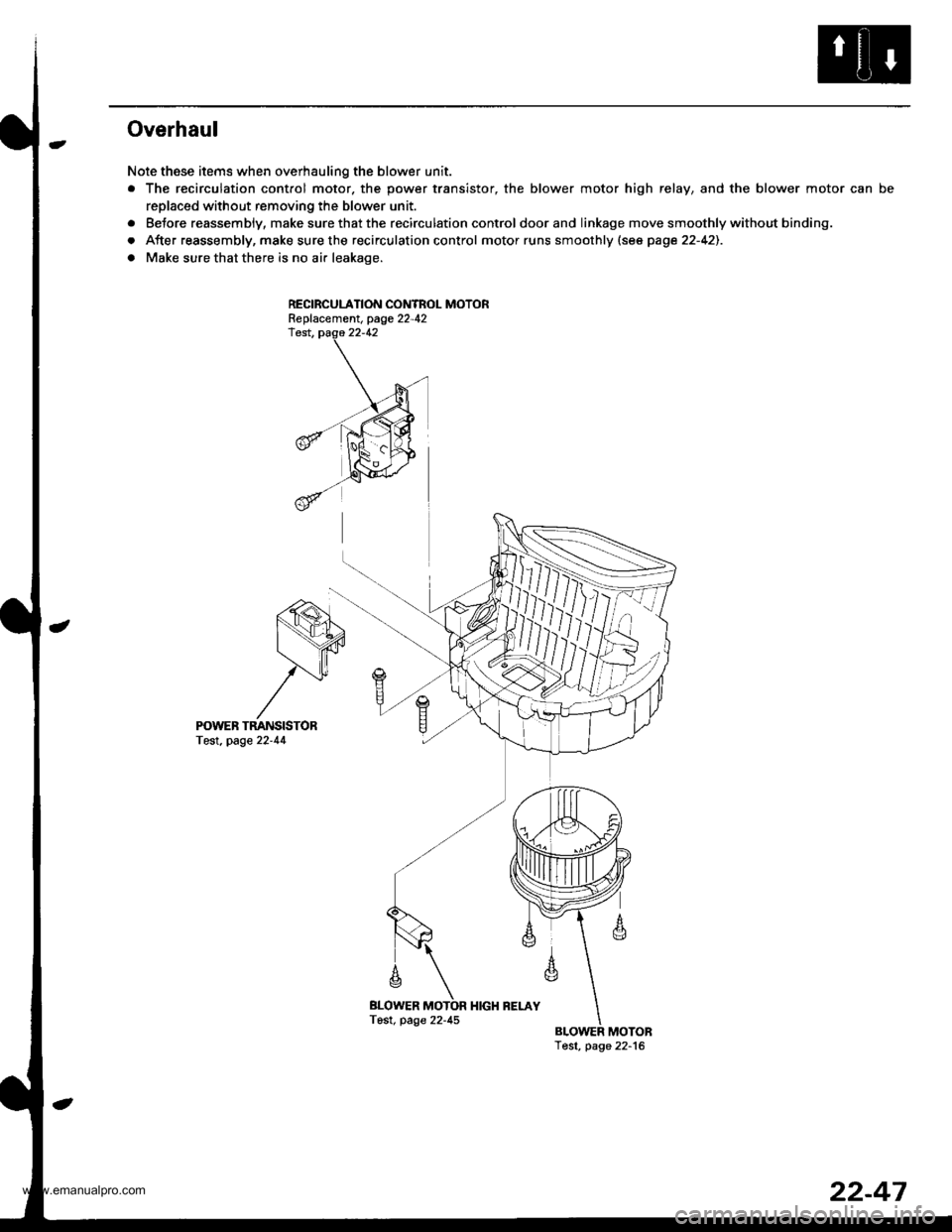

Overhaul

Note these items when overhauling the blower unit.

. The recirculation contfol motor. the power transistor, the blower motor high relay, and the blower motor can be

replaced without removing the blower unit.

. Betore reassembly, makesurethatthe recirculation control doorand linkage move smoothly without binding.

o After reassembly, make sure the recirculation control motor runs smoothly (se€ page 22-42).

o Make sure that there is no air leakage.

RECIBCULATION CONTBOL MOTORReplacement. page 22-42

BLOWER

m

Tost, page 22-45

POWEB TMNSISTORTest. page 22'44

22-47

www.emanualpro.com

Page 1139 of 1395

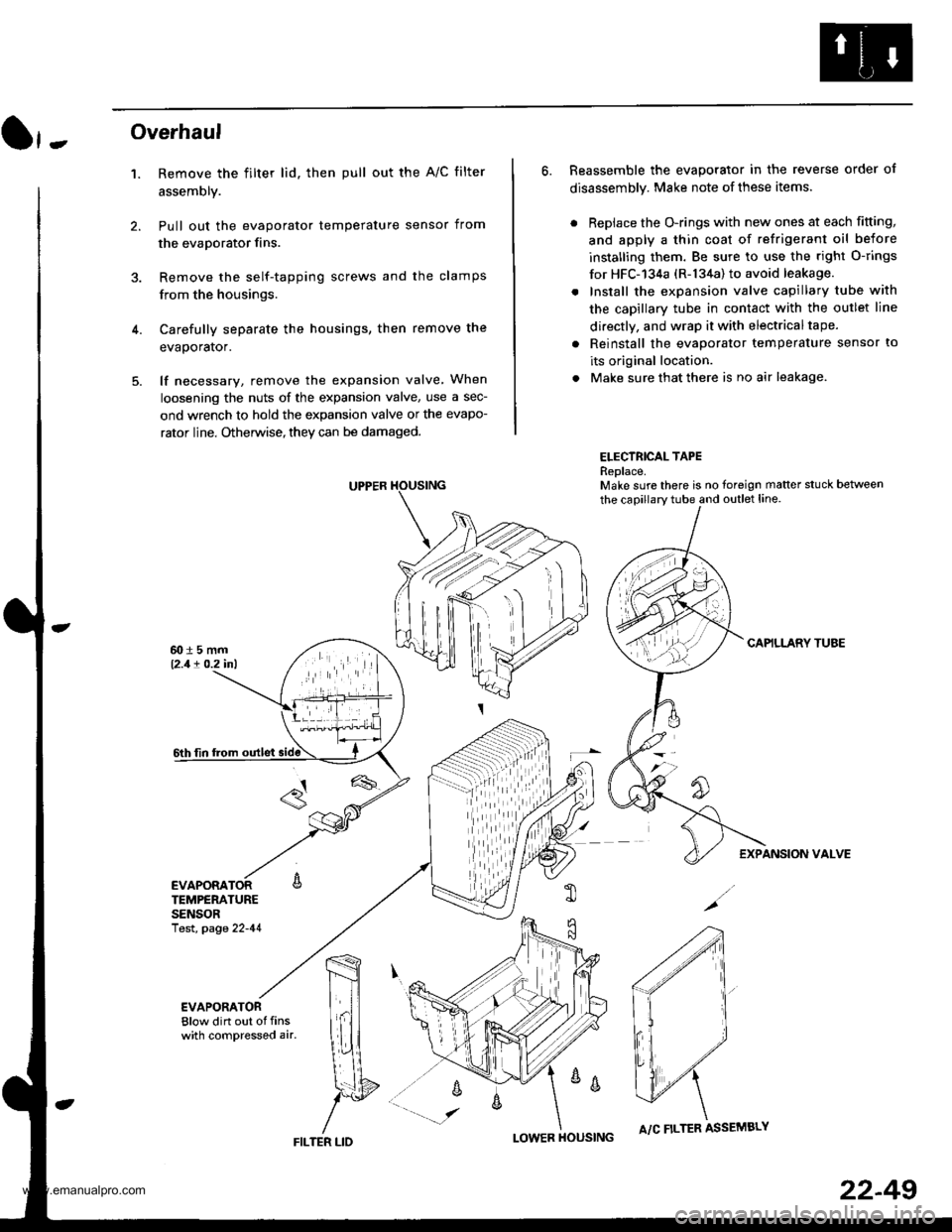

}-Overhaul

1. Remove the filter lid. then pull out the A/C filter

assembly.

Pull out the evaporator temperature sensor from

the evaporator fins.

Remove the self-tapping screws and the clamps

from the housings.

Carefully separate the housings, then remove the

evaporator.

lf necessary, remove the expansion valve When

loosening the nuts of the expansion valve, use a sec-

ond wrench to hold the expansion valve or the evapo-

rator line. Otherwise, they can be damaged.

6. Reassemble the evaporator in the reverse order of

disassembly. Make note of these items.

. Replace the O-rings with new ones at each fitting,

and apply a thin coat of refrigerant oil before

installing them. Be sure to use the right O-rings

for HFC-'134a (R-134a) to avoid leakage.

. Install the expansion valve capillary tube with

the capillary tube in contact with the outlet line

directly, and wrap it with electricaltape.

. Reinstall the evaporator temperature sensor to

its original location.

. Make sure that there is no air leakage.

ELECTRICAL TAPEReplace.Make sure there is no foreign matter stuck between

the capillary tube and outlet line.

CAPILLARY TUAE

EXPANSION VALVE

4.

TEMPERATURESENSORlest, page 22-41

,m

\!{

YFILTER LID

;

I-OWER HOUSINGA/C FILTER ASSEMBLY

22-49

www.emanualpro.com

Page 1142 of 1395

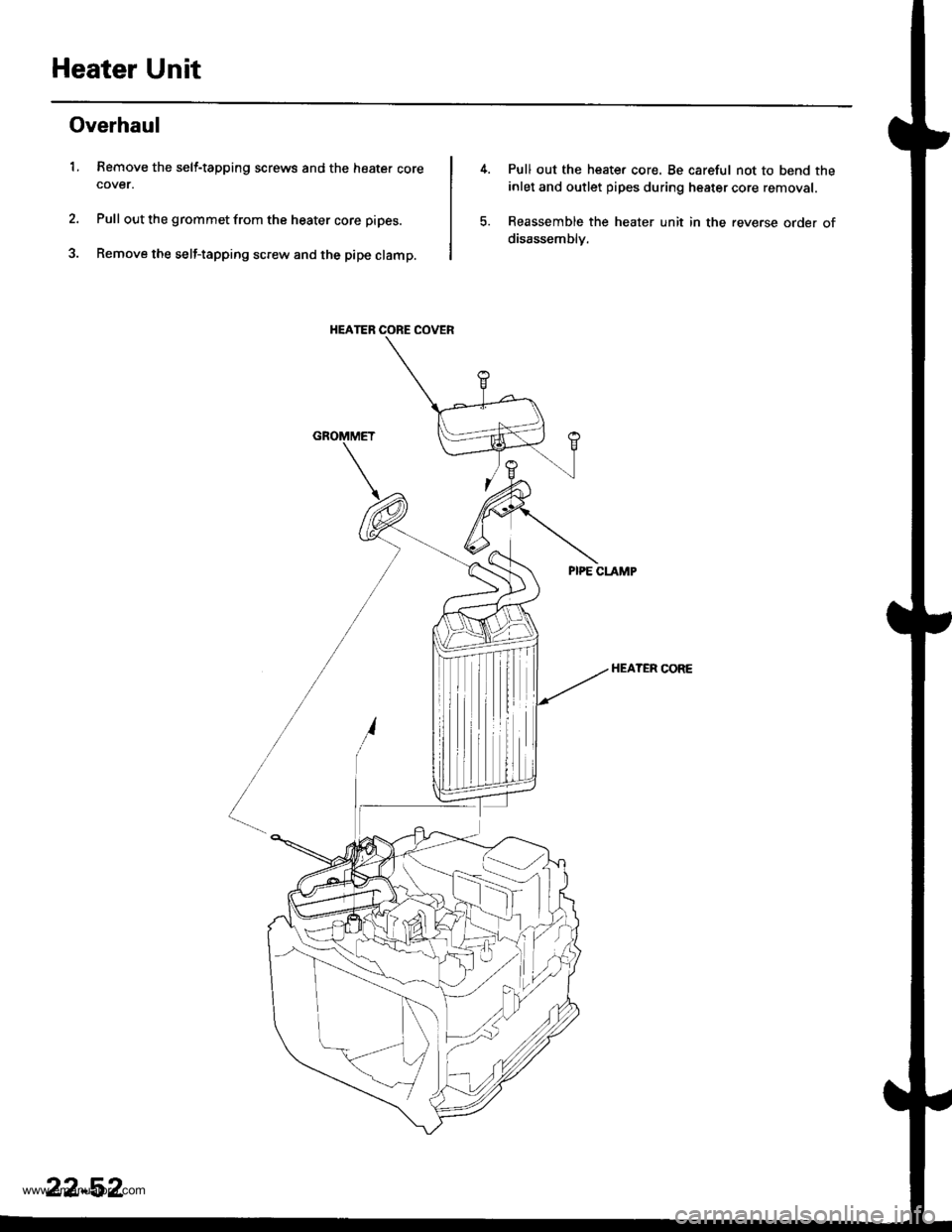

Heater Unit

Overhaul

1. Remove the self-tapping screws and the heater corecover.

Pull out the grommet from the heater core pipes.

Remove the self-tapping screw and the pipe clamp.

HEATER CORE COVER

Pull out the heate. core. Be careful not to bend the

inlet and outlet pipes during heater core removal.

Reassemble the heater unit in the reverse order of

disassemblv.

HEATER CORE

22-52

www.emanualpro.com

Page 1156 of 1395

Compressor

Glutch Overhaul

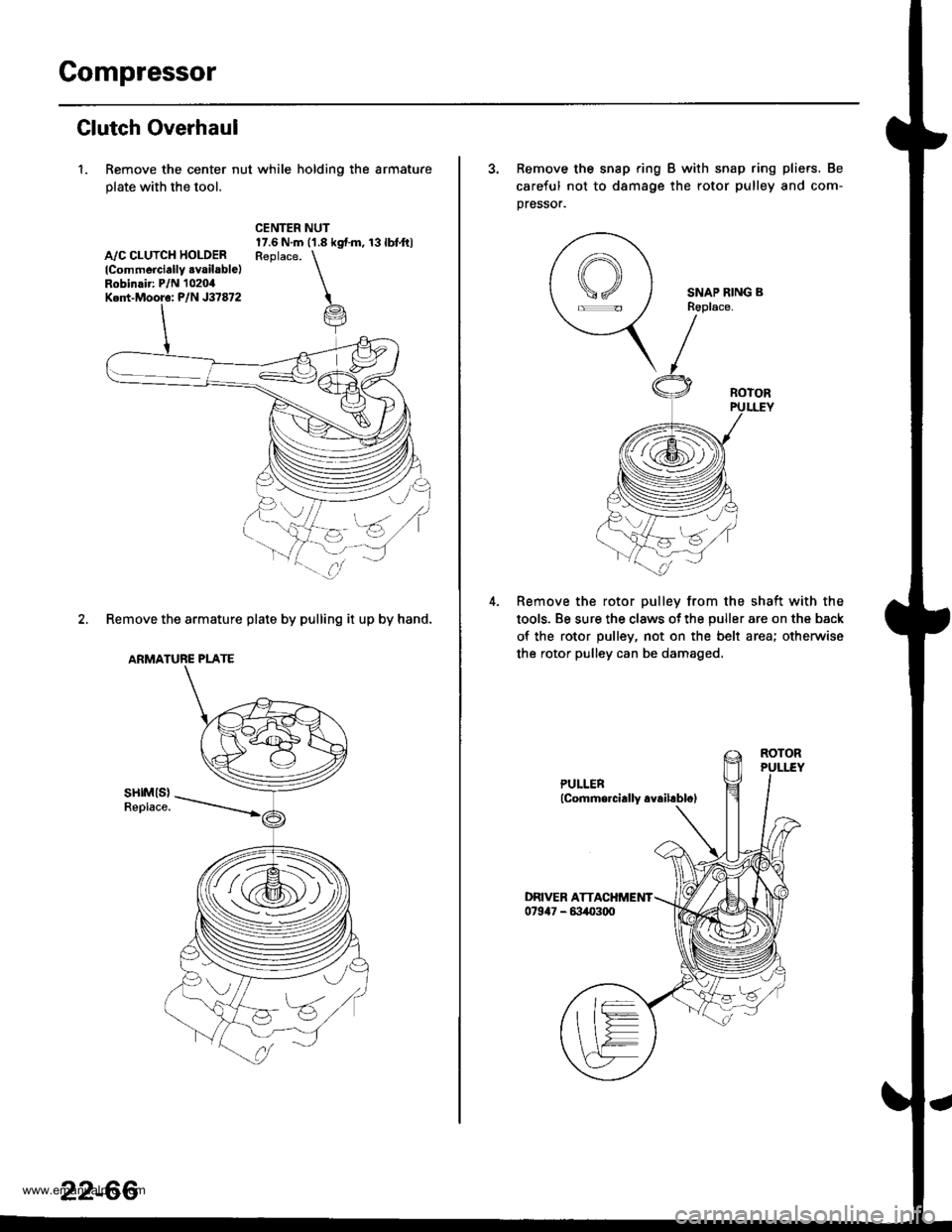

1. Remove the center nut while holding the armature

plate with the tool.

A,/C CLUTCH HOLOERlCommerciallY .vailable)Robinair: P/N 1020,0Ked-Mooro: P/N J37872

CENTER NUT17.6 N.m ('1.8 kgf.m, 13lbfft)Reolace. \

i

2. Remove the armature plate by pulling it up by hand.

ARMATURE PLATE

sHtMls)Replace.

za:s

(i@,

22-66

3. Remove the snap ring B with snap ring pliers. Be

careful not to d8mage the rotor pulley and com-

pressor.

SNAP RING BR6place.

Remove the rotor pulley from the shaft with the

tools. Be sure the claws ot the puller are on the back

of the rotor pulley, not on the belt area; otherwise

the rotor pulley can be damaged.

www.emanualpro.com