drain plug HONDA CR-V 1999 RD1-RD3 / 1.G User Guide

[x] Cancel search | Manufacturer: HONDA, Model Year: 1999, Model line: CR-V, Model: HONDA CR-V 1999 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 677 of 1395

Pressure Testing

Changing

NOTE: Keep all foreign particles out of the transmis-

sion.

1. Bring the transmission up to operating temperature

(the radiator fan comes on) by driving the vehicle.

Park the vehicle on level ground. turn the engane

off. then remove the drain Plug.

NOTE: lf a cooler flusher is to be used, see page

14-264 and 14-265.

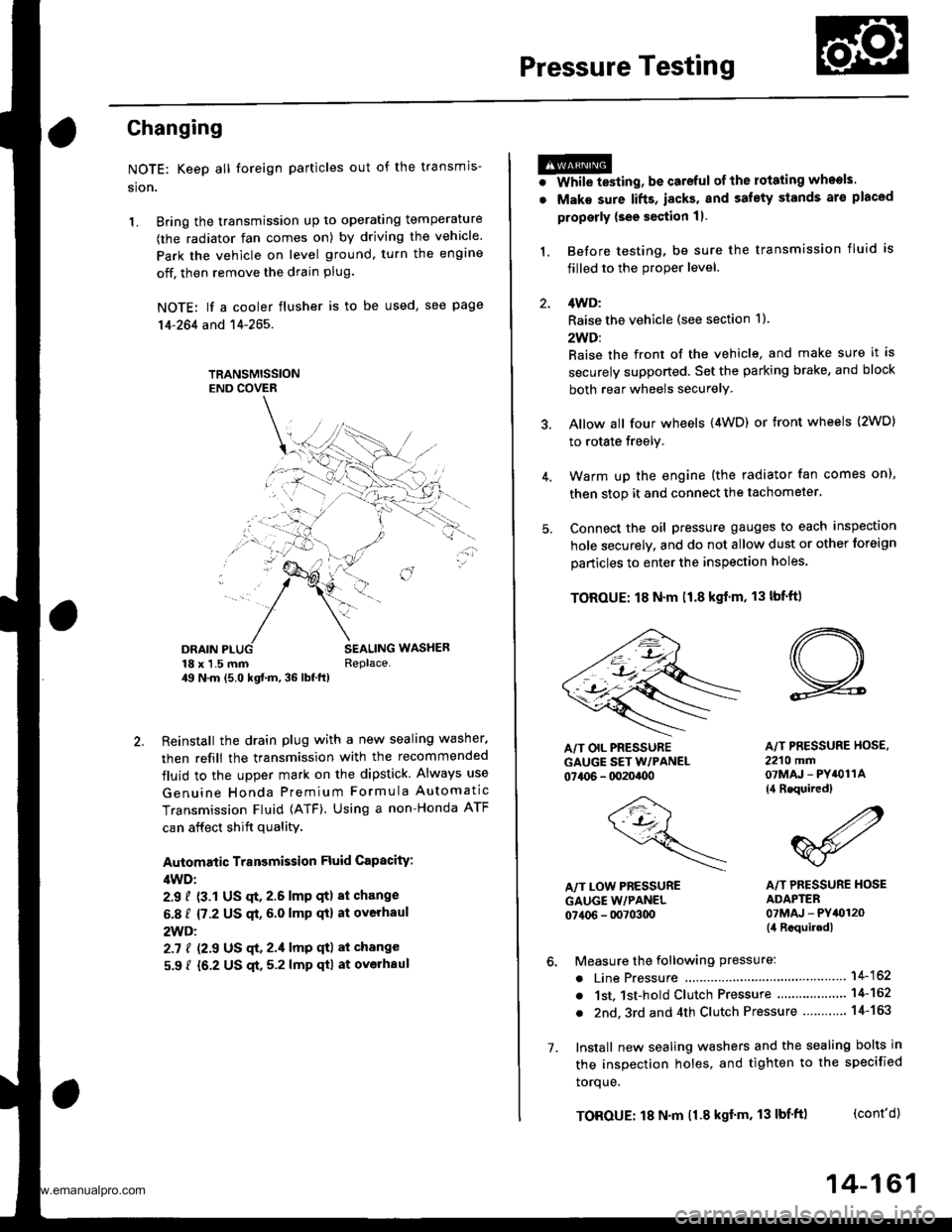

TRANSMISSIONEND COVER

DRAIN18 x 1.5 mmSEALING WASHEBReplace.49 N.m {5.0 kgt.m, 36 lbf.tl)

Reinstall the drain plug with a new sealing washer,

then refill the transmission with the recommended

fluid to the uDper mark on the dipstick. Always use

Genuine Honda Premium Formula Automatic

Transmission Fluid (ATF) Using a non-Honda ATF

can affect shift quality.

Automatic Transmission Fluid Capacity:

4WD;

2.9 { (3.1 US qt. 2.6 lmp qt) 8t change

5.8 ? {7.2 US $, 6.0 lmp qt} at ovethaul

2WD:

2.7 | l2.S US qt,2.1lmp qtl ai change

5.9 ? {6.2 US $, 5.2 lmp qtl at ovolhaul

2.

a

a

1.

Wlrile testing, be careful of the rotaling wheols.

Mako sure lifts, iacks, and safety stands ar€ placed

properly (see scction 11.

Before testing, be sure the transmission fluid is

filled to the proPer level.

4WD:

Raise the vehicle (see section 11.

2WD:

Raise the front of the vehicle, and make sure it is

securely supported. Set the parking brake, and block

both rear wheels securely.

Allow all four wheels {4WD) or front wheels (2wD}

to rotate freely.

Warm up the engine (the radiator fan comes on),

then stop it and connect the tachometer.

Connect the oil pressure gauges to each inspection

hole securely, and do not allow dust or other foreign

particles to enter the inspection holes.

TOROUE: 18 N'm ll.8 kgf'm, 13 lbf'ft)

5.

A/T PRESSURE HOS€,2210 mm07MAJ - PYiOllA

{4 Requircd}

,4'/"' ,a

W'

A/T PRESSURE HOSEADAPTER07MAJ - PYt0120(il Rcquiledl

6. Measure the following Pressure:. Line Pressure ..........,14-162

. 1st. 1st-hold Clutch Pressure .............'. 14-162

. 2nd,3rd and 4th Clutch Pressure .......... 14-163

7. Install new sealing washers and the sealing bolts in

the inspection holes, and tighten to the specified

toroue.

(cont'd)

A/T OIL PRESSUREGAUGE SET W/PANEL07{06 - 0020400

/4\\-J-- (

+..\.-.\-'-\

A/T LOW PBESSUREGAUGE w/PANEL07406 - 0070300

TOROUE: 18 N'm 11.8 kgf'm, 13 lbf'ft)

14-161

www.emanualpro.com

Page 681 of 1395

Transfer Assembly

Removal

@ Make sure the lifts, iacks, and safety

stands are placed properly (see section 11.

1. Raise the front of the vehicle, and make sure it is

supported securely.

2. Set the parking brake, and block both rear wheels

securelv.

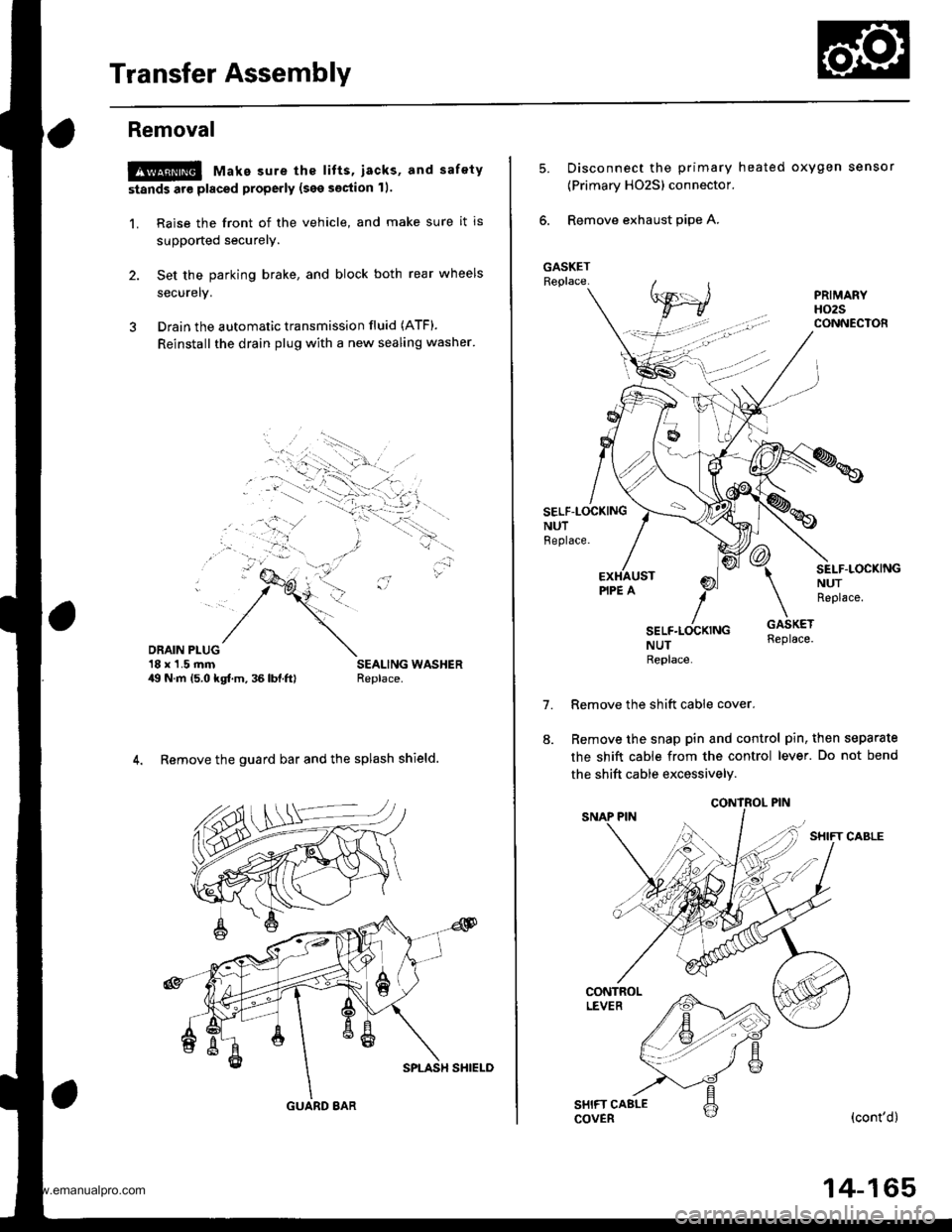

3 Drain the automatic transmission fluid (ATF).

Reinstall the drain plug with a new sealing washer'

DRAIN PLUG'18 x'1.5 rnm49 N.m 15.0 kgf.m, 36 lbl.ftl

4. Remove the guard bar and the splash shield.

GUARD 8AR

14-165

5.Disconnect the primary heated oxygen sensor

{Primary HO2S) connector.

Remove exhaust pipe A.

SELF-LOCKINGNUTBeplace.

7.

SEI-F.LOCKINGNUTReplace.

NUTReplace

Remove the shift cable cover.

Remove the snap pin and control pin, then separate

the shift cable from the control lever. Do not bend

the shift cable excessively.

(cont'd)

www.emanualpro.com

Page 686 of 1395

Transmission

Removal (cont'd)

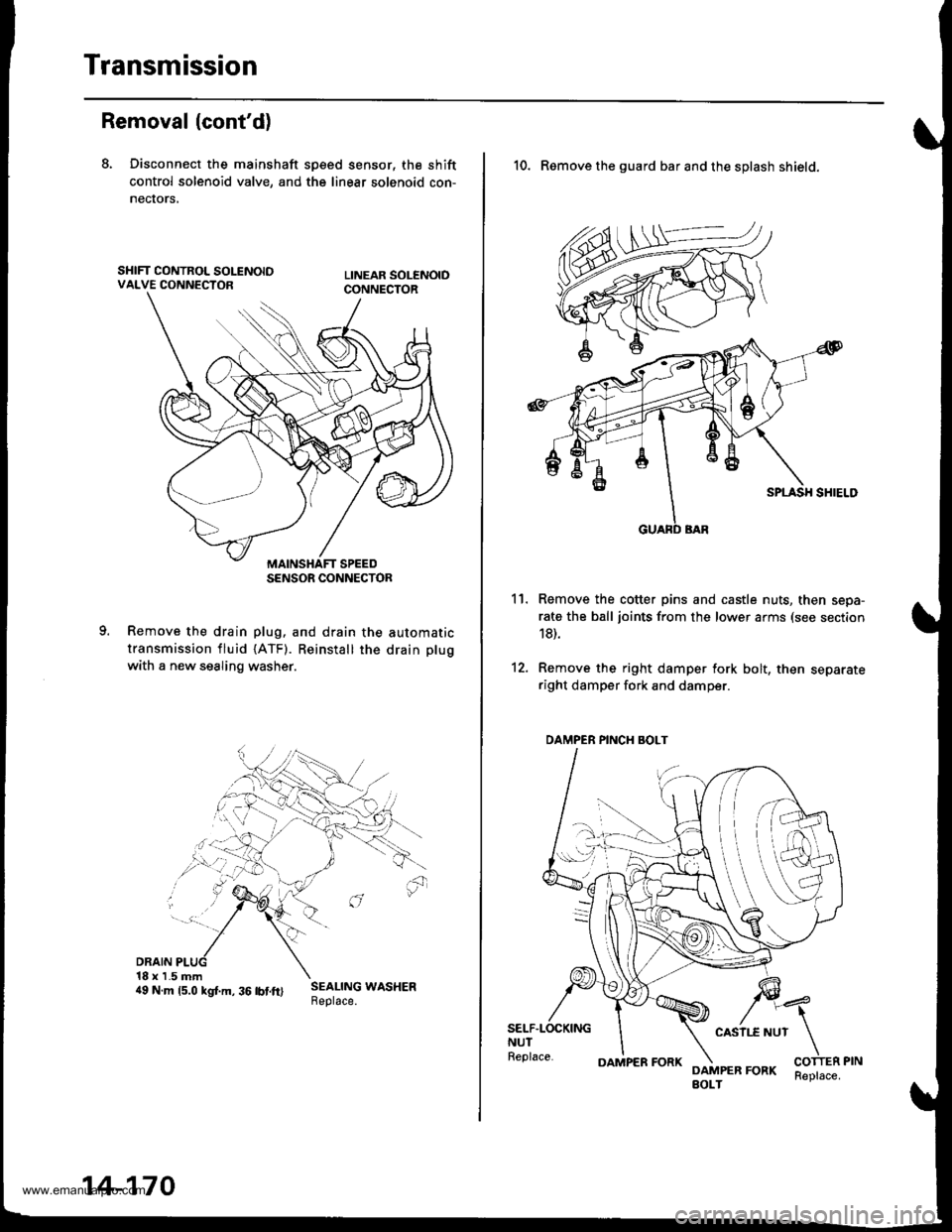

8. Disconnect the mainshaft sp€ed sensor, the shift

control solenoid valve, and the linear solenoid con-

necrors,

Remove the drain plug. and drain the automatic

transmission fluid {ATF). Reinstall the drain plug

with a new sealing washer.

DRAIN18 x 1.5 mm4e N.m rs.o ksr.m. 36 rbrft) ;:i:$: *o"*."

SENSOR CONNECTOR

14-170

OAMPER FORKReplace.

10. Remove the guard bar and the splash shield.

Remove the cotter pins and castle nuts, then sepa-

rate the ball joints from the lower arms (see section

18).

Remove the right damper fork bolt, then separateright damper fork and damper.

11.

12.

SELF.LOCKINGNUTReplace.

CASII.E NUT

DAMPER FORKBOLT

DAMPER PINCH BOLT

www.emanualpro.com

Page 691 of 1395

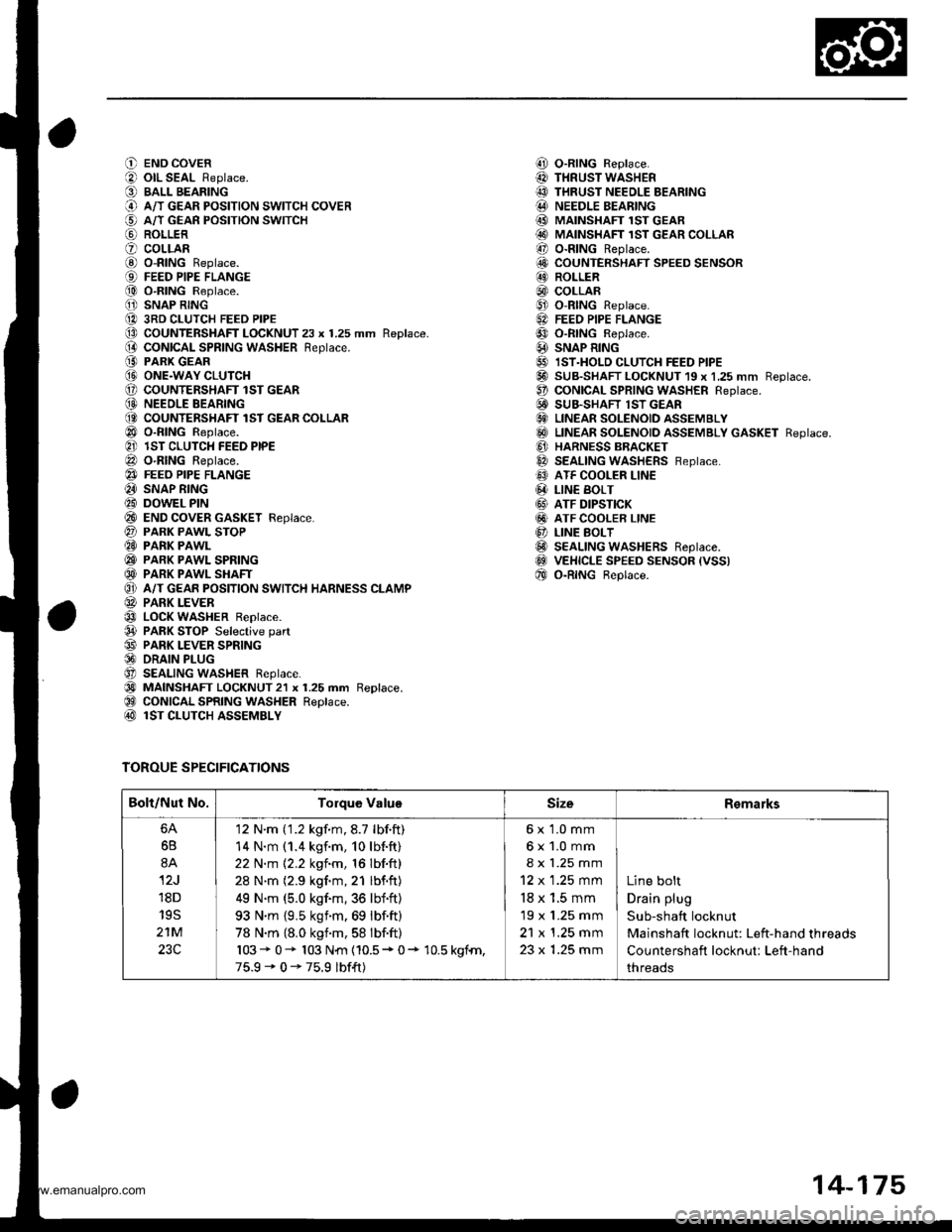

O END COVER

O olL SEAL Replace.

O BALL BEARING

@ A/T GEAR PoSITIoN swITcH coVER

€) A/T GEAn PosrloN swrrcH

@ ROLLER

O coLLARG) o-RING Replace.{9) FEED PIPE FLANGE

@ O-RING Replace.

O SNAP RING

@ 3RD CLUTCH FEED PIPE(D CoUNTERSHAFT LOCKNUT 23 x 1.25 mm Replace.(} coNtcAL SPR|NG WASHER Reptace.

@ PARK GEAR@ ONE.WAY CLUTCH(, COUNTENSHAFT lST GEAR(D NEEOLE BEARING(O COUNTERSHAFT lST GEAR COLLAR

@ o-RING Reptace.

@ lST CLUTCH FEED PIPE

@ O-RING Reptace.

@} FEEO PIPE FLANGE

@ SNAP RING

@ DOWEL PIN

@ END coVER GASKET Feplace.

@ PARK PAWL SToP@ PARK PAWL

@ PARK PAWL SPRING

@ PARK PAWL SHAFT

O} A/T GEAR POSITION SWITCH HARNESS CLAMP

@ PARK LEVER

@ LOCK WASHER Replace.

@ PARK STOP Selective part

@ PARK LEVER SPRING@ DRAIN PLUG

O SEALING WASHER Reptace.

@) MAINSHAFT LOCKNUT2l x 1.25 mm Replace.@ CONICAL SPRING WASHER Replace.@ lST CLUTCH ASSEMBLY

TOROUE SPECIFICATIONS

i!, O-RING Replace.

@ THRUST WASHER

@ THRUST NEEDLE BEARING@ NEEDLE BEARING

@ MAINSHAFI 1ST GEAR@ MAINSHAFT 1sT GEAR coLLAR

@ o-RING Replace.

6!, COUNTERSHAFT SPEED SENSOR@ ROLLER

@) COLLAR@ o-RtNG Replace.

6A FEEo PIPE FLANGE

@ o-RtNG Reptace.

@ SNAP R|NG

@ IST.HOLD cLUTcH FEED PIPE@ SUB-SHAFT LOCKNUT 19 x 1,25 mm Reptace.O coNtCAL SPR|NG WASHER Reptace.E! SUB.SHAFT lST GEAR€} LINEAR SOLENOID ASSEMBLY

@ LTNEAR soLENotD aSSEMBLy GASKET Reptace.

@ HARNESS BBACKET

@ SEALING WASHERS Feptace.

@ ATF COOLER LINE

@ LIN€ BoLT

@ ATF DIPSTICK

@ ATF COOLER LINE

@ LINE BoLT@ SEALING WASHERS Reptace.@ VEHICLE SPEED sENsoR (vss)

@ o-RtNG Beptace.

Bolt/Nut No.Torque ValuoSizeRemarks

6B

8A

12J

18D

19S

21M

23C

'12 N'm ('1.2 kgf.m,8.7 lbf.ft)

14 N.m (1.4 kgf.m, 10lb{.ft}

22 N.m 12.2 kgf.m, 16 lbf.ft)

28 N'm (2.9 kgf.m,21 lbf.ft)

49 N.m (5.0 kgf.m,36 lbf'ft)

93 N'm {9,5 ksim.69 lbf.ft)

78 N.m {8.0 kgnm,58 lbf.ft)

103* 0- 103 N{n {10.5* 0+ 10.5 kgfn,

75.9-0-75.9 lbf{t)

6x 1.0 mm

6x1.0mm

8 x 1.25 mm

12 x 1.25 mm

18 x 1.5 mm

19 x 1.25 mm

21 x 1.25 mm

23 x 1.25 mm

Line bolt

Drain plug

Sub-shaft locknut

Mainshaft locknut: Left-hand threads

Countershaft locknut: Left-hand

threads

14-175

www.emanualpro.com

Page 697 of 1395

![HONDA CR-V 1999 RD1-RD3 / 1.G User Guide

O END COVERiLl OIL SEAL Beplace.

O BALL BEARINGi.) A/T GEAR POSITION SWITCH COVER

i5] A/T GEAR POSITION SWITCH

aq) RoLLER

? COLLABi0 o-BtNG Replace.

€) FEED PIPE FLANGE

f,o) o-RING Replace.

1 SNAP HONDA CR-V 1999 RD1-RD3 / 1.G User Guide

O END COVERiLl OIL SEAL Beplace.

O BALL BEARINGi.) A/T GEAR POSITION SWITCH COVER

i5] A/T GEAR POSITION SWITCH

aq) RoLLER

? COLLABi0 o-BtNG Replace.

€) FEED PIPE FLANGE

f,o) o-RING Replace.

1 SNAP](/img/13/5778/w960_5778-696.png)

O END COVERiLl OIL SEAL Beplace.

O BALL BEARINGi.) A/T GEAR POSITION SWITCH COVER

i5] A/T GEAR POSITION SWITCH

aq) RoLLER

? COLLABi0 o-BtNG Replace.

€) FEED PIPE FLANGE

f,o) o-RING Replace.

1' SNAP RING

1A 3RD CLUTCH FEED PIPE

O COUNTERSHAFT LOCKNUT 23 x 1.25 mm Replace.

[} coNtcal SPRING WASHER Replace.iO PARK GEAR(!I ONE.WAY CLUTCH

E COUNTERSHAFT lST GEAR

@ NEEDLE BEARING

@ COUNTERSHAFT 1ST GEAR COLLAR

Or o-RtNGS Reptace.

?] lST CLUTCH FEED PIPE

@ o-RING Replace.

e3 FEED PIPE FLANGE

4I SNAP RING

€i DOWEL PINi?0 END COVER GASKET Replace.

?7) PARK PAWL STOP

E9 PARK PAWL

C9 PARK PAWL SPRING

€D PARK PAWL SHAFT

OI A/T GEAR POSITION SWITCH HARNESS CIAMP

@ PARK LEVER

€3 LoCK WASHER Replace.

04 PARK sToP Selective part(!' PARK LEVER SPRING

@ DRAIN PLUG

Ot SEALING WASHER Replace.

60 MA|NSHAFT LocKNuT 21 x 1.25 mm Replace.(9 CONICAL SPRING WASHER Replace.

@ lST CLUTCH ASSEMBLY

TOROUE SPECIFICATIONS

,!4! O-RING Replace.

@I THRUST WASHER@ THRUST NEEDLE BEARINGi.!' NEEDLE BEARINGi MAINSHAFT lST GEAR

@i MAINSHAFT 1ST GEAR COLLAR!r, O-RING Replace.iO COUNTERSHAFT SPEED SENSOR

E ROLLER

@, coLLAR

Ct o-RING Replace.5.] FEED PIPE FLANGE

09 o-RING Replace.

6A SNAP RING

5' IST.HOLD CLUTCH FEED PIPE

@-] SUB-SHAFT LOCKNUT 19 x 1.25 mm Replace.

!t CONICAL SPRING WASHER Replace.

6i' SUB-SHAFT lST GEAR

G) LINEAR SOLENOID ASSEMBLY(6!) LINEAR SOLENOID ASSEMBLY GASKET Replace

G] HARNESS BRACKET

6a SEALING WASHERS Replace.

C' ATF COOLER LINE

@ L|NE BoLT

GI ATF DIPSTICK

GI ATF COOLER LINE

O LINE BOLT

@ SEALING wasHERs Replace.aoo VEHICI.E SPEED SENSOR IVSS)

f,E O-RING Replace.

Bolt/Nut No.Torque ValueSizeRemarks

6A

6B

8A

12J'18D

195

21M

12 N.m (1.2 kgf.m,8.7 lbf.ft)

14 N.m (1.4 kgf.m, 10lbf.ft)

22 N.m 12.2 kgim, 16lbf.ft)

28 N.m (2.9 kgim,21 lbf.ft)

49 N'm (5.0 kgim,36 lbf.ft)

93 N.m (9.5 kgf.m,69 lbf.ft)

78 N.m (8.0 kgf.m,58 lbf.ft)

103+ 0+ 103 N{n (10.5 + 0+ 10.5 kSfm,

75.9' 0 - 75.9 lbfft)

6x1.0mm

6x1.0mm

8 x 1.25 mm

12 x 1 .25 mm

18 x 1.5 mm

19 x 1.25 mm

21 x 1.25 mm

23 x 1.25 mm

Line bolt

Drain plug

Sub-shaft locknut

Mainshaft locknut: Left-hand threads

Countershaft locknut: Left-hand

threads

14-181

www.emanualpro.com

Page 780 of 1395

Transmission

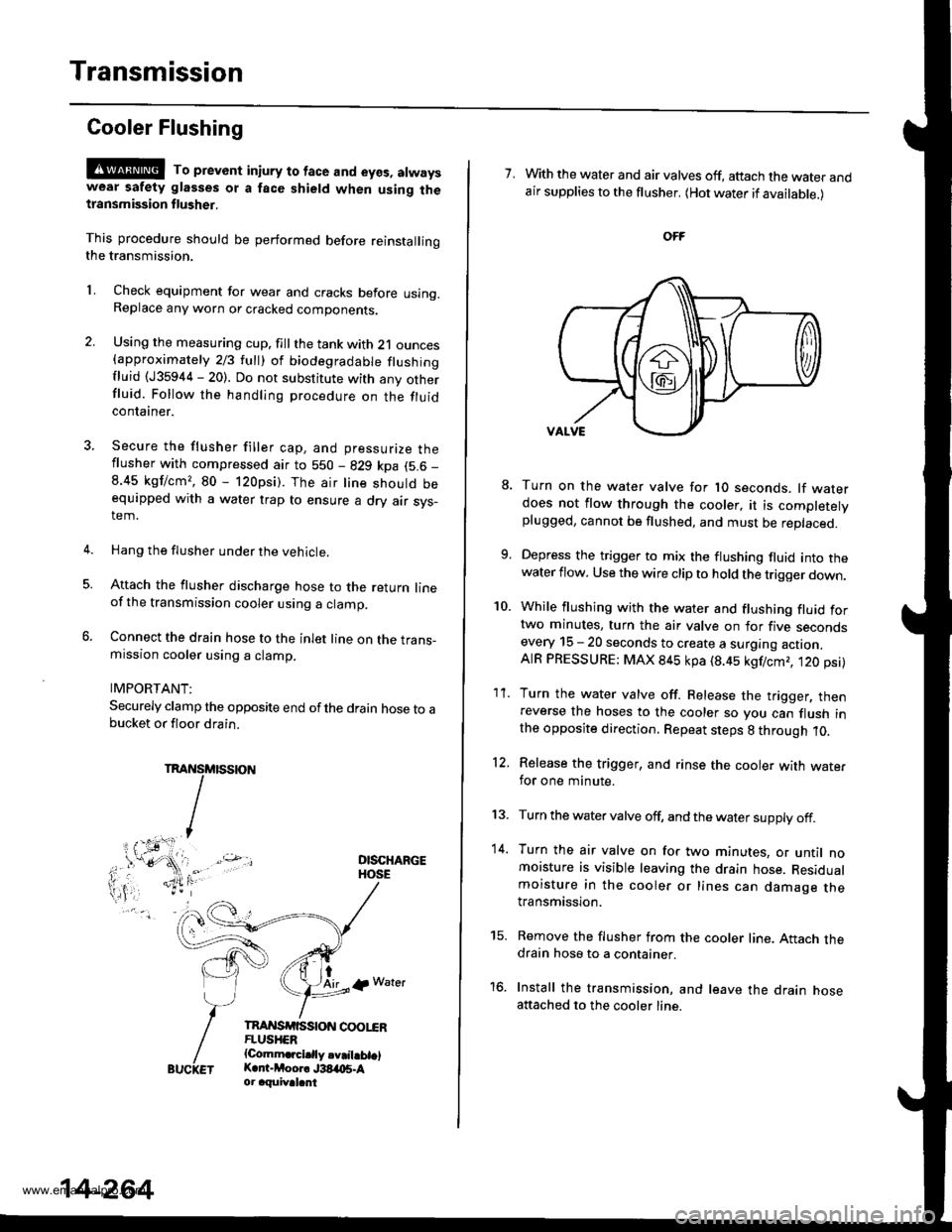

Cooler Flushing

@@ To prevent in;ury to face and eyos, atwayswear safety glasses ot a face shield when using thetlansmission flusher.

This procedure should be performed before reinstallingthe transmission.

2.

LCheck equipment for wear and cracks before using.Replace any worn or cracked components.

Using the measuring cup. fill the tank with 21 ounces{approximately 213 lull) ol biodegradable flushingfluid (J35944 - 20). Do not substitute with any otherfluid. Follow the handling procedure on the fluidcontaaner.

Secure the flusher filler cap, and pressurize theflusher with compressed air to 550 - 829 kpa (5.6 _

8.45 kgf/cm,, 80 - 120psi). The air line should beequipped with a water trap to ensure a dry air sys-tem.

Hang the flusher under the vehicle.

Attach the flusher discharge hose to the return lineof the transmission cooler using a clamp.

Connect the drain hose to the inlet line on the trans-mission cooler using a clamp.

IMPORTANT:

Securely clamp the opposite end ofthe drain hose to abucket or floor drain.

DISCHARGEHOSE

tAirlp Water

TnAI{SrfiSStoN coot"€RFLUSHER{Comm.rcidly.v.il.bt.lK.r -Moor. J38,t{15.Aor aquival.nt

5.

14-264

7. With the water and air valves off, attach the water andair supplies to the flusher. (Hot water if available.)

10.

8.

1'�I.

Turn on the water valve for 1O seconds. lf waterdoes not flow through the cooler, it is completelyplugged, cannot be flushed, and must be replaced.

Depress the trigger to mix the flushing fluid into thewater flow. Use the wire clip to hold the trigger down.

While flushing with the water and flushing fluid fortwo minutes, turn the air valve on for five secondsevery 15 - 20 seconds to create a surging action.AIR PRESSURE: MAX 845 kpa (8.45 kgf/cmr, t20 psi)

Turn the water valve off. Release the trigger, thenreverse the hoses to the cooler so you can flush inthe opposite direction. Repeat steps 8 through 10.

Release the trigger, and rinse the cooler with wate.for one minute.

Turn the water valve off, and the water supply off.

Turn the air valve on for two minutes, or until nomoisture is visible leaving the drain hose. Residualmoisture in the cooler or lines can damage thetransmission.

Remove the flusher from the cooler line. Attach thedrain hose to a container.

Install the transmission, and leave the drain hoseattached to the cooler line.

12.

13.

14.

to.

www.emanualpro.com

Page 804 of 1395

Maintenance

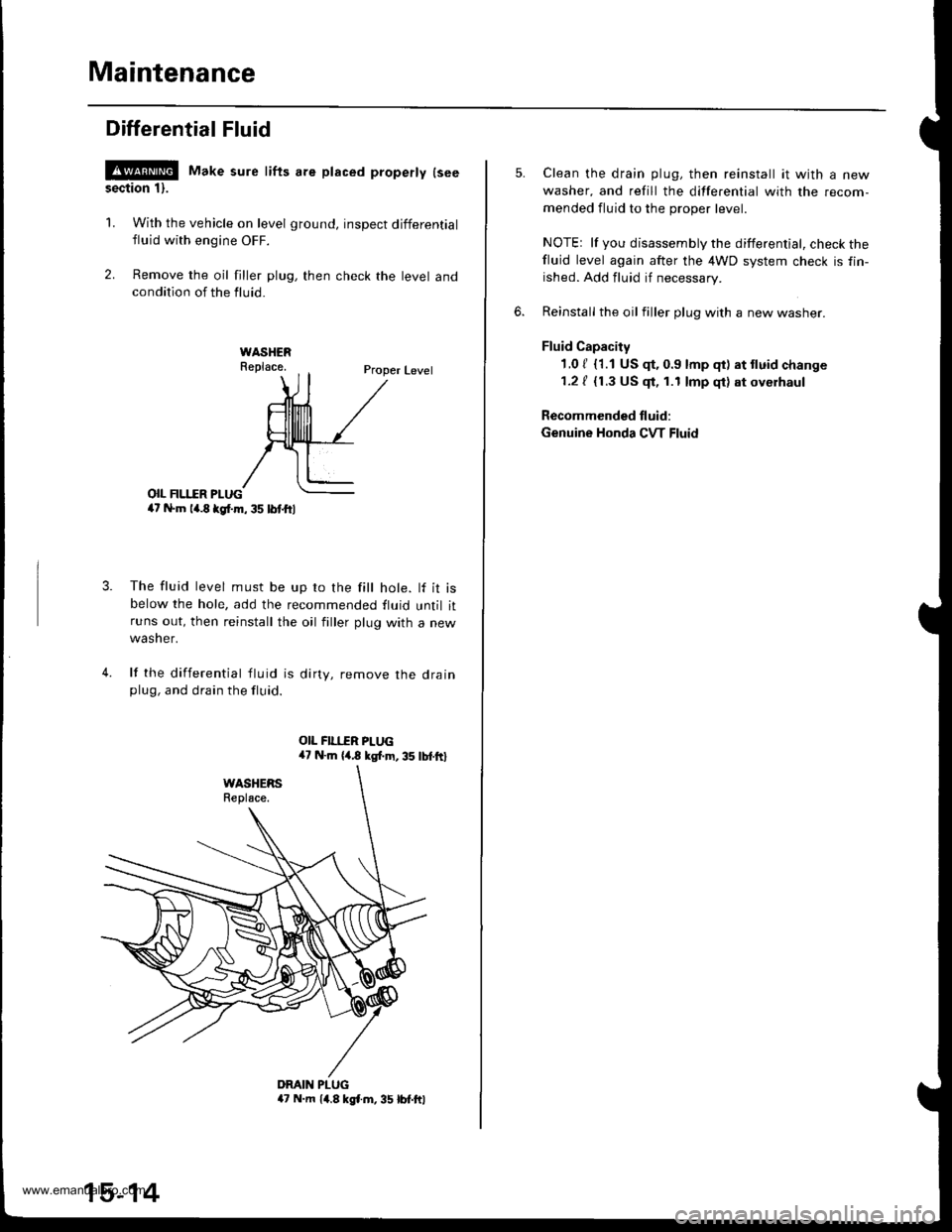

Differential Fluid

!@ Make sure lifts are placed properly lseesection 1).

1. With the vehicle on level ground, inspect differential

fluid with engine OFF.

2. Remove the oil filler plug, then check the level andcondition of the fluid.

Proper Level

o|I FII.IIR PI-UG4t N.m la.8 kgl.m, 35 lbl.ftl

The fluid level must be up ro the fill hole. lf it isbelow the hole, add the recommended fluid until itruns out, then reinstall the oil filler plug with a new

wasner.

lf the differential tluid is dirty, remove the drainplug, and drain the fluid.

4.

DMIN PLUGa7 N.m 14.8 kgl.m, 35 lbt.ftl

15-14

Clean the drain plug, then reinstall it with a new

washer, and refill the differential with the recom-

mended fluid to the proper level.

NOTEr lf you disassembly the differential, check thefluid level again after the 4WD system check is fin-

ished. Add fluid if necessary.

Reinstall the oil filler plug with a new washer.

Fluid Capacity

1.0 / {1.1 US $, 0.9 lmp qt) at tluid change

1.2 / {1.3 US $, 1.1 lmp qt) at oyerhaul

Recommended fluid:

Genuine Honda CVT Fluid

www.emanualpro.com

Page 810 of 1395

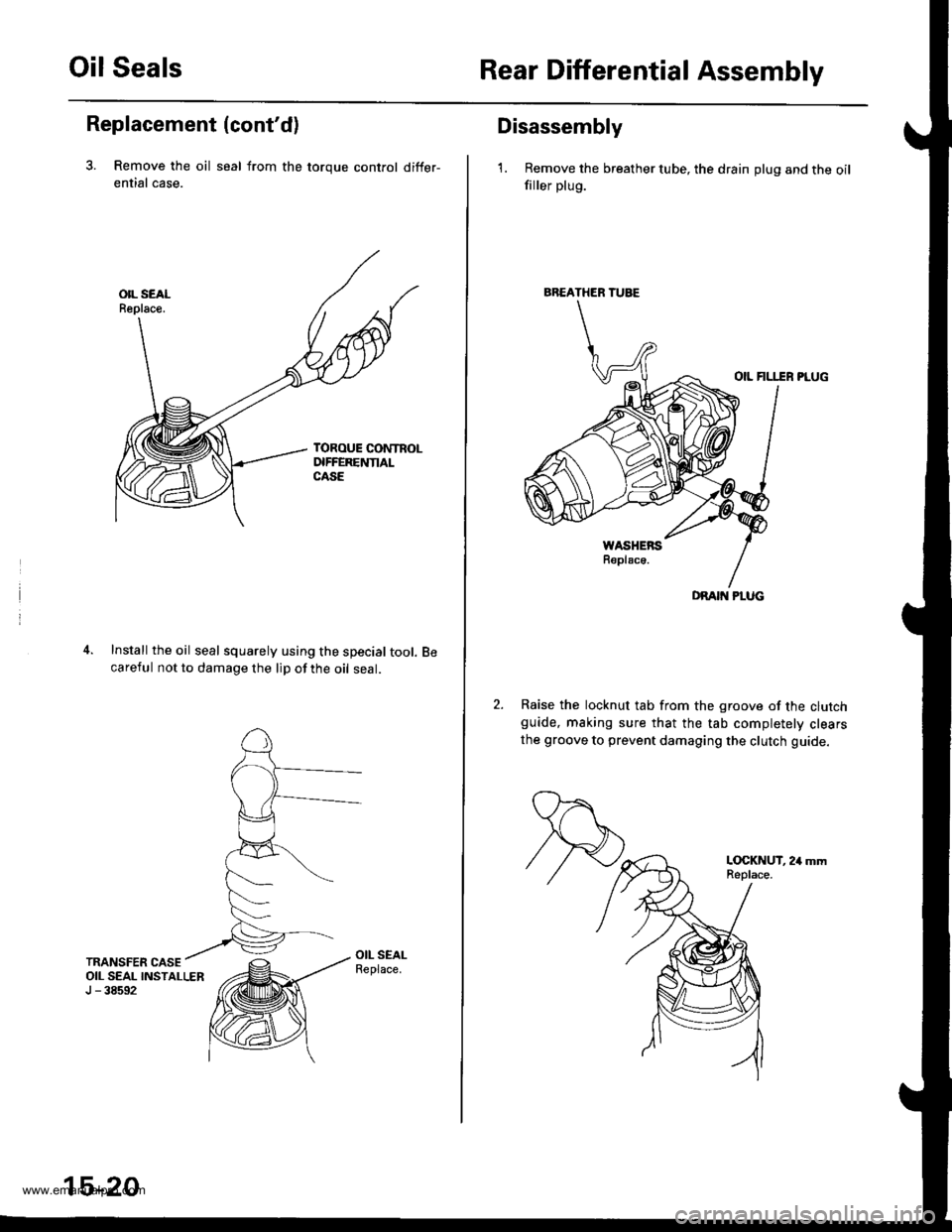

Oil SealsRear Differential Assembly

Replacement (cont'd)

3. Remove the oil seal from the toroue control differ-

ential case.

Install the oil seal squarely using the special tool.careful not to damage the lip of the oil seal.

15-20

BREATHER TUBE

DRAIT{ PLUG

Disassembly

1. Remove the breather tube, the drain plug and the oilfiller plug.

OIL FILI.IR PLUG

Raise the locknut tab from the groove of the clutchguide, making sure that the tab completelv clearsthe groove to prevent damaging the clutch guide.

L(rcKNUT, 24 mmReplace.

www.emanualpro.com

Page 815 of 1395

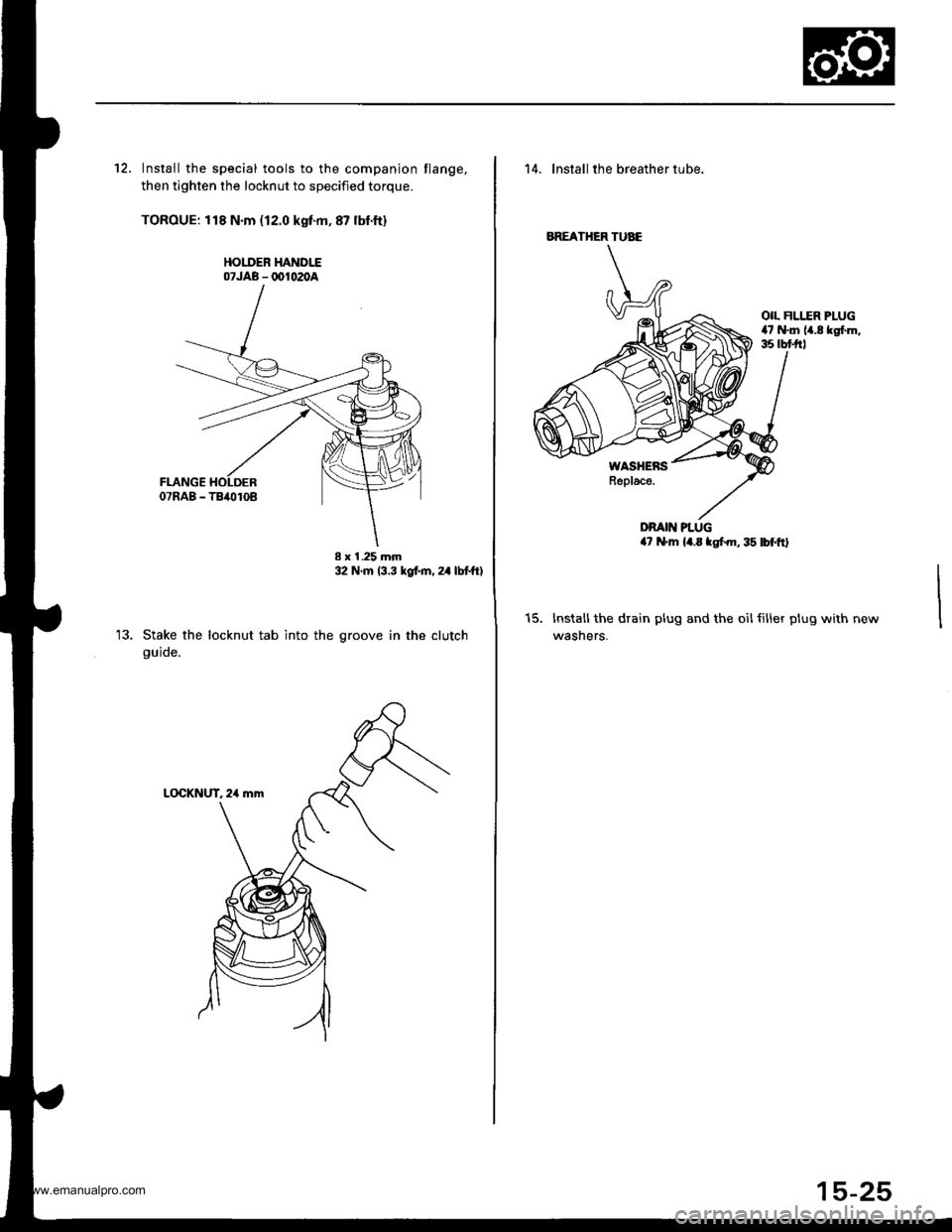

12. Install the special tools to the companion flange,

then tighten the locknut to specified torque.

TOROUE: 118 N.m (12.0 kgf-m,87 lbf'ft)

HOLDEB HANDLE07JAB - @1020A

Stake the locknut tab into the

guide.

I x I .25 mm32 N'm (3.3 kgt m, 24 lbtftl

groove in the clutch

14. lnstall the breather tube.

OIL FILI..ER PLUG47 N.m 14.8 kgf.m,35 tbt frl

WASHENSReplace.

DRAIN PLUG4? N'm l4.E tgf.m, 35 lbf'ftl

t5.Installthe drain plug and the oilfiller plug with

wasners.

BREATHER TUAE

www.emanualpro.com

Page 869 of 1395

Power Steering Pump

Replacement

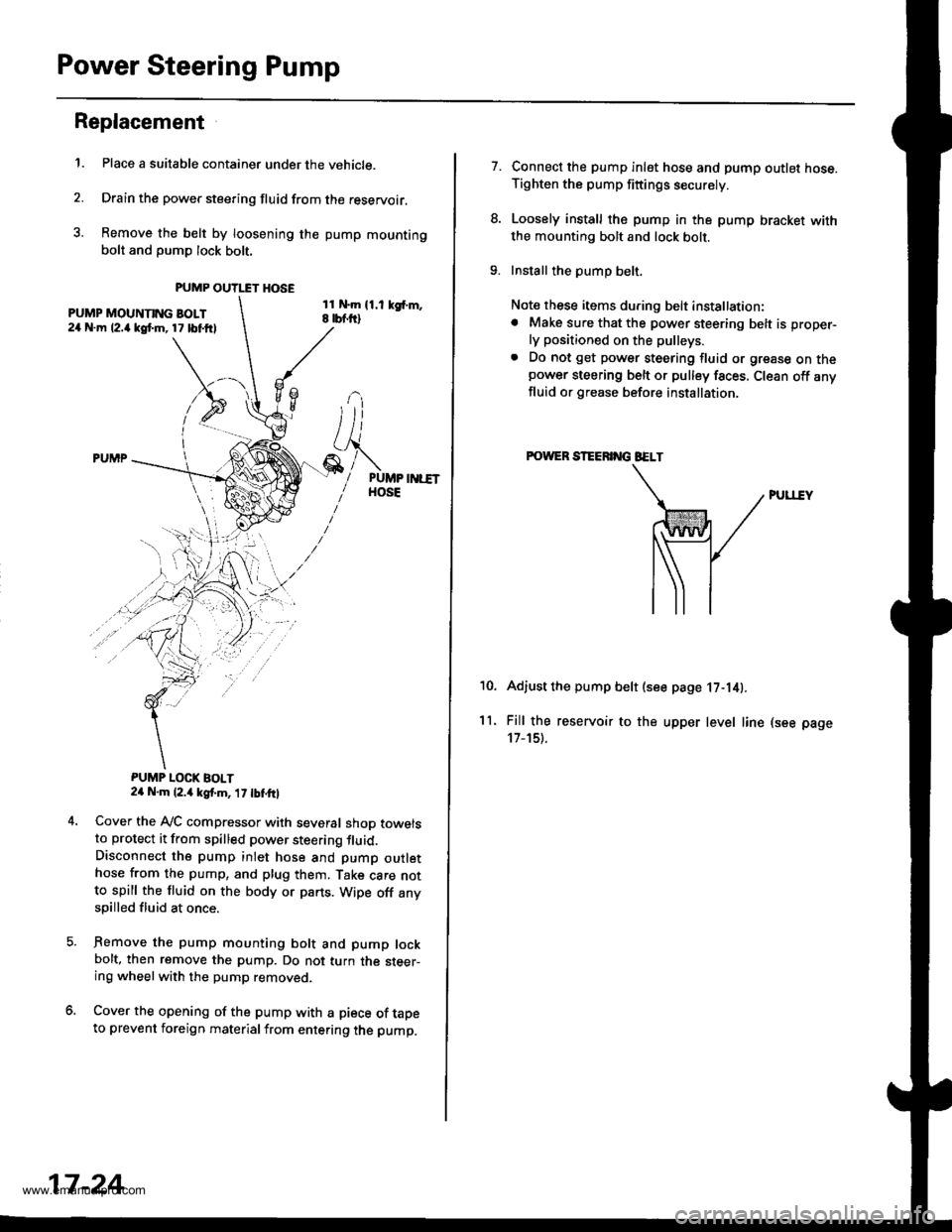

1.Place a suitable container under the vehicle.

Drain the power steering fluid from the reservoir.

Remove the belt by loosening the pump mountingbolt and pump lock bolt.

PUMP MOUNNNG BOI.T24 N.m 12.4 kgt m, 17 lbl.ftl

PUMP LOCK BOLT24 N.m (2.4 kg{.m, 1, tbfttl

Cover the IVC compressor with several shop towelsto protect it from spilled power steering fluid.Disconnect the pump inlet hose and pump outlethose from the pump, and plug them. Take care notto spill the lluid on the body or parts. Wipe off anyspilled fluid at once.

Remove the pump mounting bolt and pump lockbolt, then remove the pump. Do not turn the steer-ing wheelwith the pump removed.

Cover the opening of the pump with a piece of tapeto prevent foreign materialfrom entering the pump.

PUMP OU'I.TT HOSE

11 N.m (1.1 kgf.m,E rbf.ti)

17-24

7.Connect the pump inlet hose and pump outlet hose.Tighten the pump fittings securely.

Loosely install the pump in the pump bracket withthe mounting bolt and lock bolt.

Install the pump belt.

Note these items du.ing belt instsllation:. Make sure that the power steering belt is proper-

ly positioned on the pulleys.

. Do not get power steering fluid or grease on thepower steering belt or pulley faces, Clean off anyfluid or grease before installation

FOWER STEER G EELT

PUTrlY

Adiust the pump belt (see page 17-141.

Fill the reservoir to the upper level line (see page't7 -151..

10.

'l l.

www.emanualpro.com