turn signal HONDA CR-V 1999 RD1-RD3 / 1.G User Guide

[x] Cancel search | Manufacturer: HONDA, Model Year: 1999, Model line: CR-V, Model: HONDA CR-V 1999 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 292 of 1395

PGM-FI System

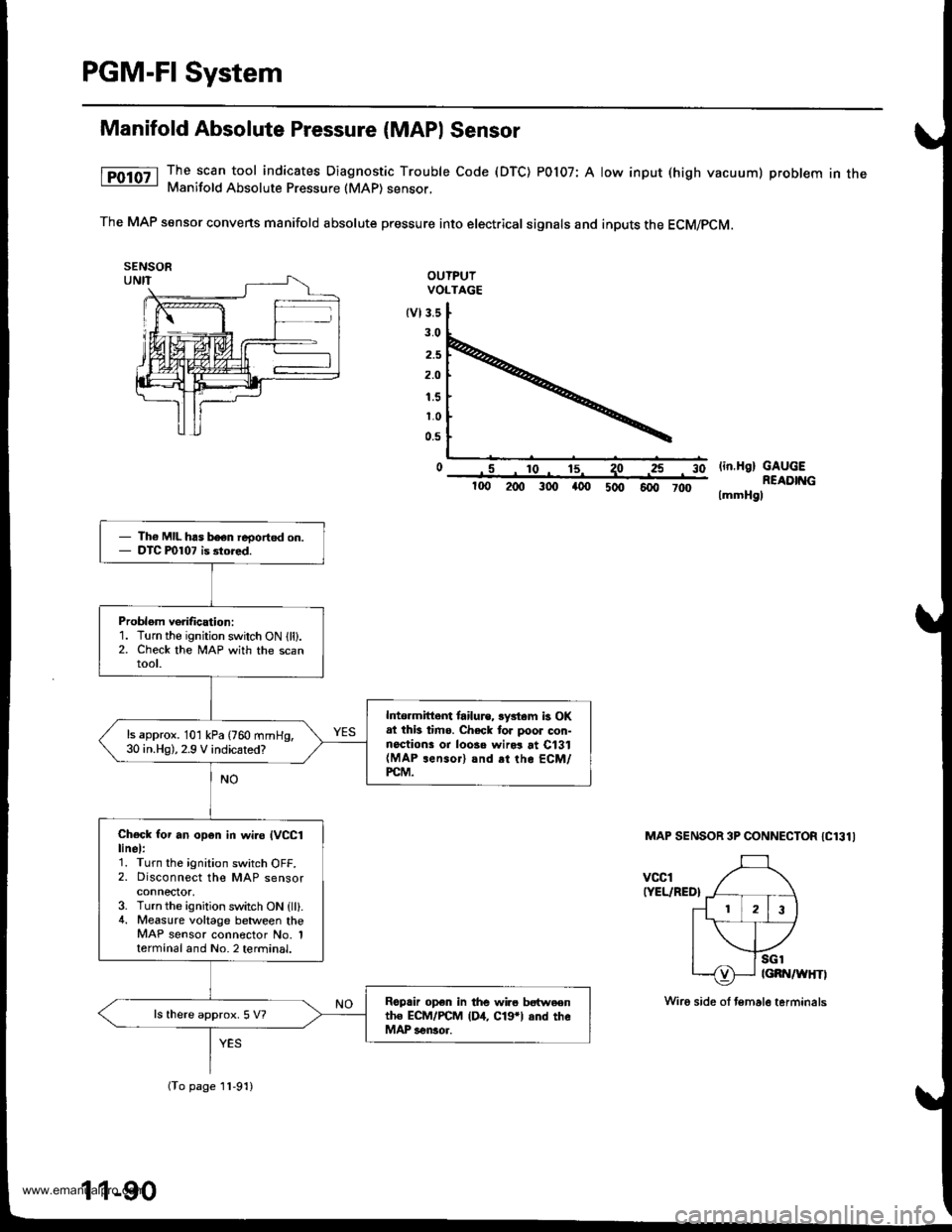

Manifold Absolute Pressure (MAPI Sensor

The scan tool indicates Diagnostic Trouble Code (DTC) POl07: A low input (high vacuum) problem in theManifold Absolute Pressure (MAP) sensor,

The MAP sensor convens manifold absolute pressure into electrical signals and inputs the ECM/pCM.

OUTPUIVOLTAGE

tvl3.s

3.0

2.5

2.O

1.5

1.0

0.5

o .5 ro- 15^ 1olin.H9) GAUGEREADIT{G

lmmHgl

3025

100 200 300 a00 5oo 6fi, 7d)

MAP SENSOR 3P CONNECTOR IC131I

vccl(YEL/RED}

Th6 MIL has b€en reoorted on.DTC P0107 is 3tored.

Problom verification:1. Turn the ignition switch ON lll).2. Check the lvlAP with the scanroot.

lrtormittem tailu.e, lystam b OKat thb timo. Check tor poor con-noctions or loosa wird at C131(MAP rensor) and rt the ECM/PCM.

ls approx. 101 kPa (760 mmHg,30 in.Hg),2.9 V indicated?

Check for an op6n in wi.o IVCC1linel:1. Turn the ignition switch OFF.2. Disconnect the MAP sensorconnector,3. Turn the ignition switch ON {ll}.4. Measure voltage between theMAP sensor connector No. 1termanal and No. 2 terminal.

Roprir op€n in the wir6 bstweentho ECM/PCM (D4, C19*l and theMAP sensor.

ls there approx. 5 V?

(To page 11-91)

11-90

Wiro side ol temale terminals

www.emanualpro.com

Page 305 of 1395

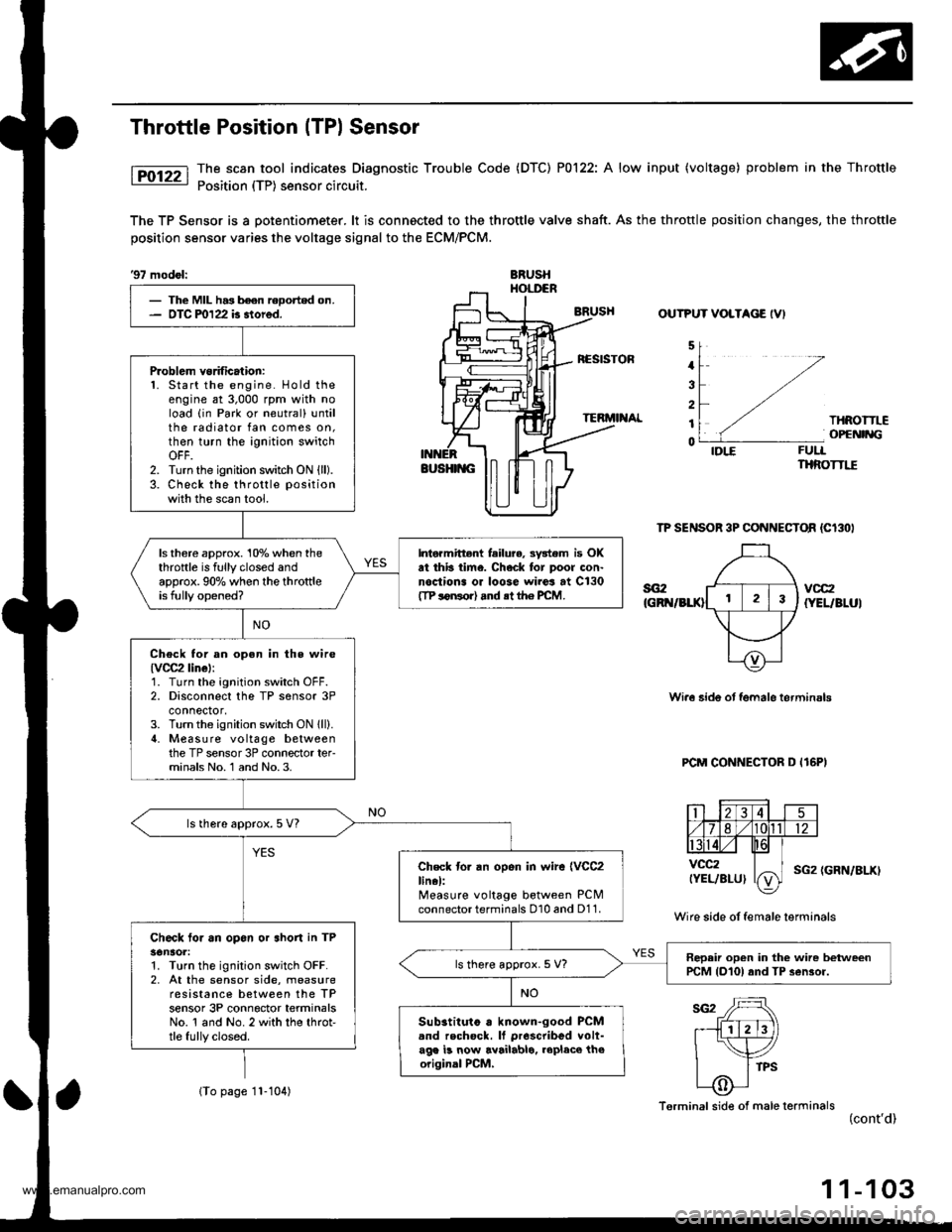

Throttle Position (TPl Sensor

The scan tool indicates Diagnostic Trouble Code (DTC) P0122: A low input (voltage) problem in the Throttle

Position (TP) sensor circuit.

The TP Sensor is a potentiometer. lt is connocted to the throttle valve shaft. As the throttle position changes, the throftle

position sensor varies the voltage signal to the ECM/PCM.

'97 mod6l:BRUSHHOI,I'ER

OUTPUT VOLTAGE IVI

5

4

3

2

1

0

THROITLEOPCNIiIG

FUTIIHROTTI"E

TP SENSOR 3P CONNECTOR {Cl3OI

vcc2IYEL/BLUI

Wi.6 6ide ot fgmale terminsls

PCM CONNECTOR D I16PI

Wire side of female terminals

(GRN/BLX)

- The MIL h.3 been reoorted on.- OTC m122 b 3tored.

Problem vorificalion:1. Start the engine. Hold theengine at 3,000 rpm with noload (in Park or neutrall untilthe radiator fan comes on,then turn the ignition switchOFF.2. Turn the ignition switch ON (ll).

3. Check the throttle position

with the scan tool.

ls there approx. 10% when thethrottle is fully closed andapprox.90% when the throttleis fully opened?

Intormittent feilu?e, 3y3tem is OKat thb iime. Check tor poor con-nodiona or loose wiros at C130tTP loNorl .nd rt th€ PCM.

Check tor an open in the wire{vOC2linel:1. Turn the ignition switch OFF.2. Disconnect the TP sensor 3Pconnector,3. Turn the ignition switch ON lll).il. Measure voltage betweenthe TP sensor 3P connector ter-minals No. 1 and No. 3.

ls there approx.5 V?

Check to. an open in wir6 {VCC2linel:Measure voltage between PCMconnector terminals 010 and D11.

Ch6ck to. an opon or shon in TPsonaol:1. Turn the ignition switch OFF.2, At the sensor side, measureresistance between the TPsensor 3P connector terminalsNo. 1 and No. 2 with the throt-tle fully closed.

Repair open in the wirc betweenPCM {D10} and TP 3ensor.ls there approx. 5 V?

Sub3tituto . known-good PCMand rechock. It proscribed volt-ag. b now availablo. rcplaco th6originsl PCM,

Terminal side of male terminals(cont'd)

(To page 11-104)

1 1-103

www.emanualpro.com

Page 333 of 1395

tro-rsl

1Tffi61

tF136t

fPfa6r-1

tF138tl

I-Pi382l

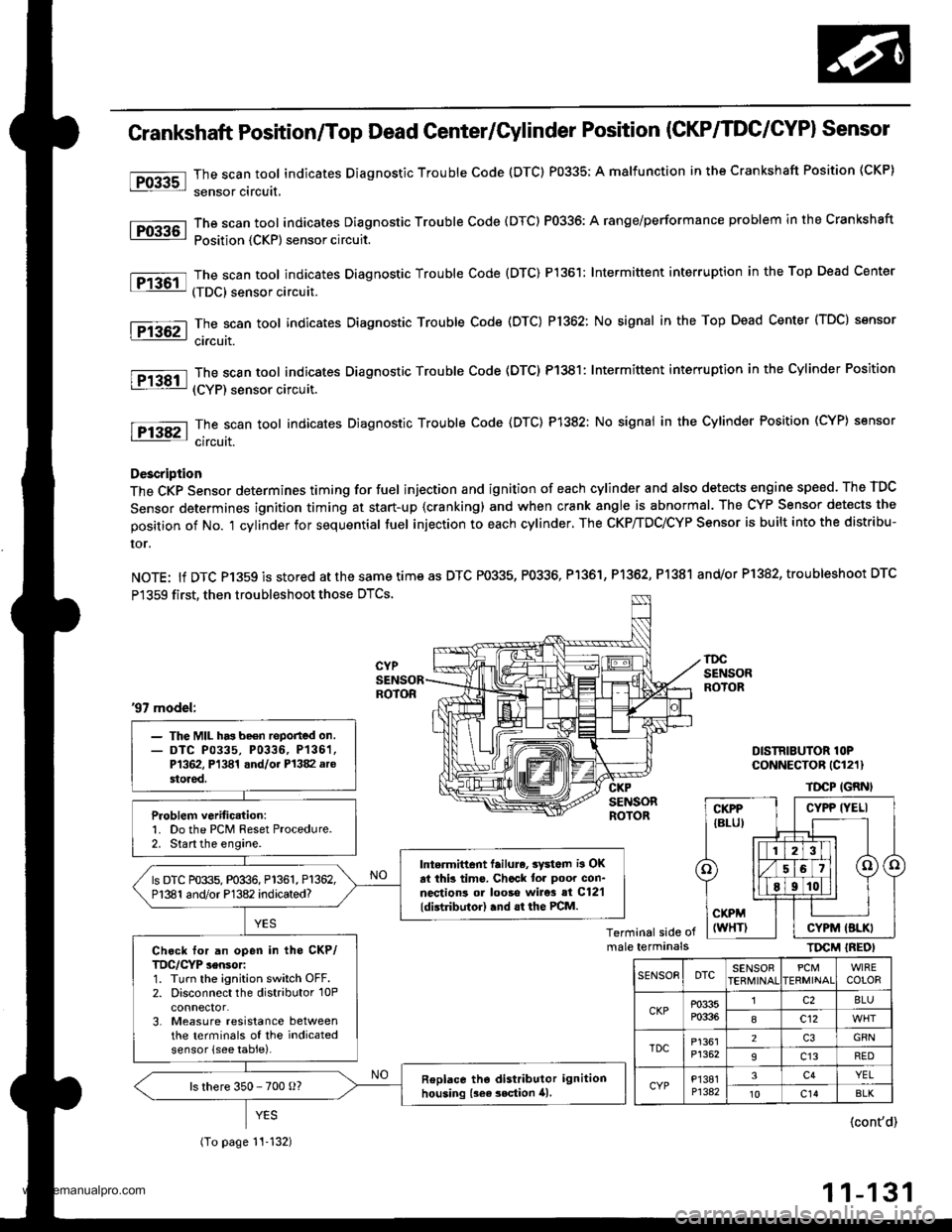

Crankshaft Position/Top Dead Genter/Gylinder Position (CKP/TDC/CYPI Sensor

The scan tool indicates Diagnostic Trouble Code (DTC) P0335; A malfunction in the Crankshaft Position (CKP)

sensor circuit,

The scan tool indicates Diagnostic Trouble Code (DTC) P0336: A range/performance problem in the Crankshaft

Position {CKP) sensor circuit.

The scan tool indicates Diagnostic Trouble Code {DTC) P1361: Intermittent interruption in the Top Dead Center

(TDC) sensor circuit.

The scan tool indicates Diagnostic Trouble Code (DTC) P1362: No signal in the Top Dead Center (TDC) sensor

ci.cuit.

The scan tool indicates Diagnostic Trouble Code (DTC) P1381: Intermittent interruption in the Cylinder Position

(CYP) sensor circuit.

The scan toot indicates Diagnostic Trouble Code {DTC) P1382: No signal in the Cylinder Position (CYP} sensor

circuit.

Description

The CKP Sensor determines timing for fuel injection and ignition of each cylinder and also detects engine speed. The TDC

Sensor determines ignition timing at start-up {cranking) and when crank angle is abnormal. The CYP Sensor detects the

position of No. 't cylinder for sequential fuel injection to each cylinder. The CKP/TDC/CYP Sensor is built into the distribu-

ror.

NOTE: lf DTC P1359 is stored atthesametimeas DTC P0335, P0336, Pl361, P1362, P1381 and/or P1382, troubleshoot DTC

P1359 first, then troubleshoot those DTCS.

DISTRIBUTOR lOPCoNNECTOR (Cl211

TDCP IGRNI

Terminal side ofmale terminalsTIrcM IREOI

'97 model:

- The MIL has be€n reported on.- DTC P0335, P0336, P136'�1,P1362, Pl341 and/oi P1382 arestored.

Problem verific.tion:1. Do the PCM Reset Procedure.2. Start the engine.

Intermittent lailure, 3yd6m i3 OKat thb tims. Chcck tor poor con-nections ol looso wire3 si C12'l

ldistributor) .nd .t the PCM.

ls DTC P0335, P0336, P1361, P1362,P1381 and/or P1382 indicated?

Ch.ck for an open in tho CKP/TDC/CYP sensor:1. Turn the ignition switch OFF.2. Disconnect the distributor 10Pconnector.3. Measure resistance betweenthe terminals of the indicatedsensor (see table).

Replace tho distributor ignitionhousing {sea 3ection 41.ls there 350 - 700 o?

(To page 11-132)

CYPP IYELI

CYPM (BLKI

SENSOEDTCSENSOBPCMERMINAIWIRECOLOR

CKPP0335P0336

lc28LU

8c12

TDCP1361P1352

2GRN

9c13RED

CYPP'�I381P1342

3c4YEL't0c14BLK

{cont'd)

11-131

www.emanualpro.com

Page 344 of 1395

PGM-FI System

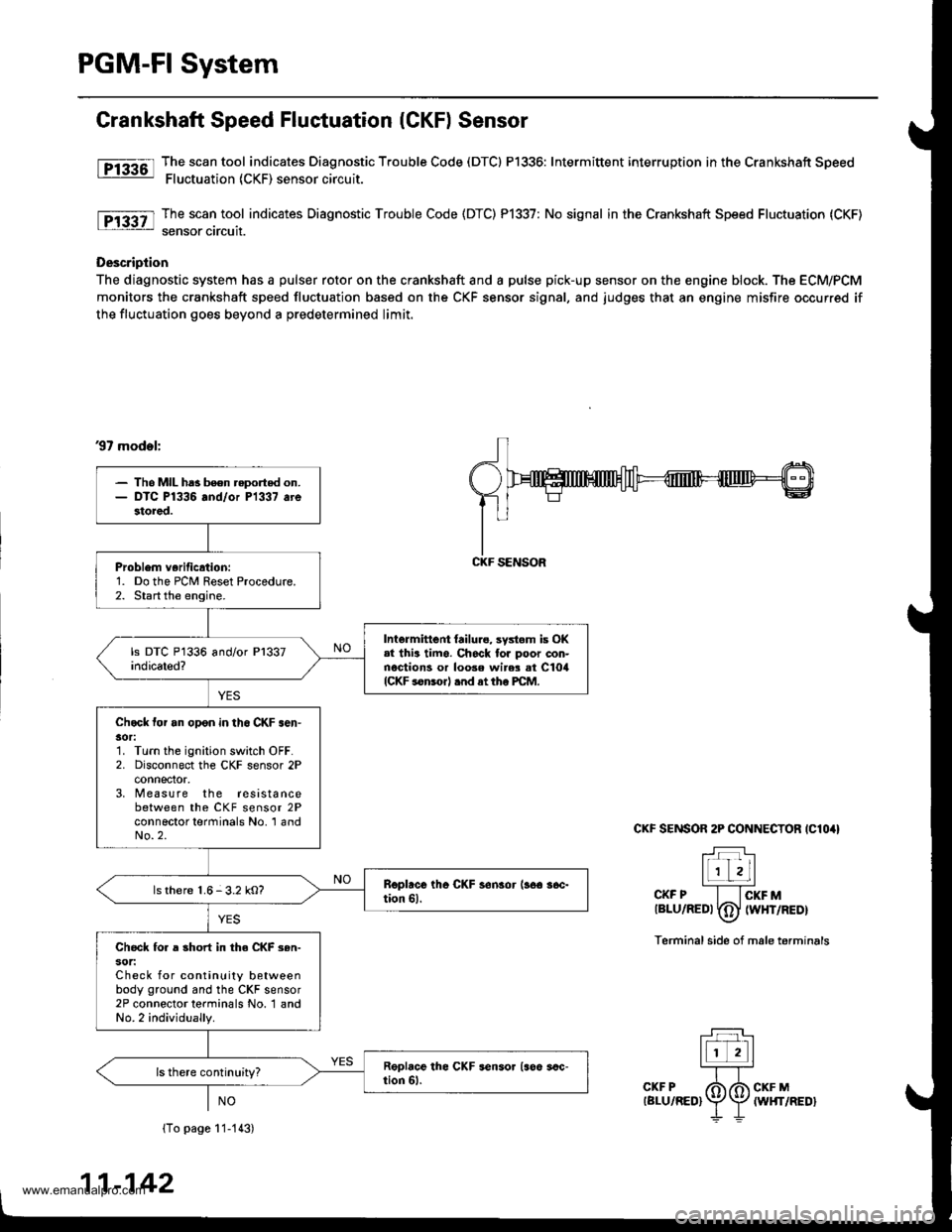

Grankshaft Speed Fluctuation (CKF) Sensor

fF13361l Tj":""l.tool indicates Diagnostic Trouble Code (DTCI P1336: Intermittent interruption inthe Crankshaft Speed: Fluctuation (CKF) sensor circuit.

The scan tool indicates Diagnostic Trouble Code (DTC) P1337: No signal in the Crankshaft Speed Fluctuation (CKF)

sensor circuit.

Description

The diagnostic system has a pulser rotor on the crankshaft and a pulse pick-up sensor on the engine block. The ECM/PCM

monitors the crankshaft speed fluctuation based on the CKF sensor signal, and judges that an engine misfire occurred if

the fluctuation goes beyond a predetermined limit.

37 mod.l:

CKF SENSOR 2P CONNECTOR IClO4I

T:]l-r'r Lll

l1 zLl''''CKF P I lcKF Mtalu/aeot fdJ twxrneor\-7

Terminal side of male terminals

(To page 11-113)

11-142

- Tho MIL ha3 been reported on.- DTC P1336 and/or P1337 arestored.

Problem verificrtion:1. Do the PCM Reset Procedure.2. Start the engine.

Intermittent {ailure, systom is OK.l thia timo. Ch6ck tor poor con-nections or loose wir$ at ClorlICKF sonsorl .nd at tho PCM.

Chock tor an opon in th6 CKF .en'30r:1. Turn the ignition switch OFF.2. Disconnect the CKF sensor 2Pconnector,3, M easure the resistancebetween the CKF sensor 2Pconnector terminals No. 'l andNo.2.

ls there 1.6-3.2 kO?

Check fo. a short in the CKF 3en-sot:Check for continuity betweenbody ground and the CKF sensor2P connector terminals No. 1 andNo.2 individually.

CKF SENSOR

www.emanualpro.com

Page 354 of 1395

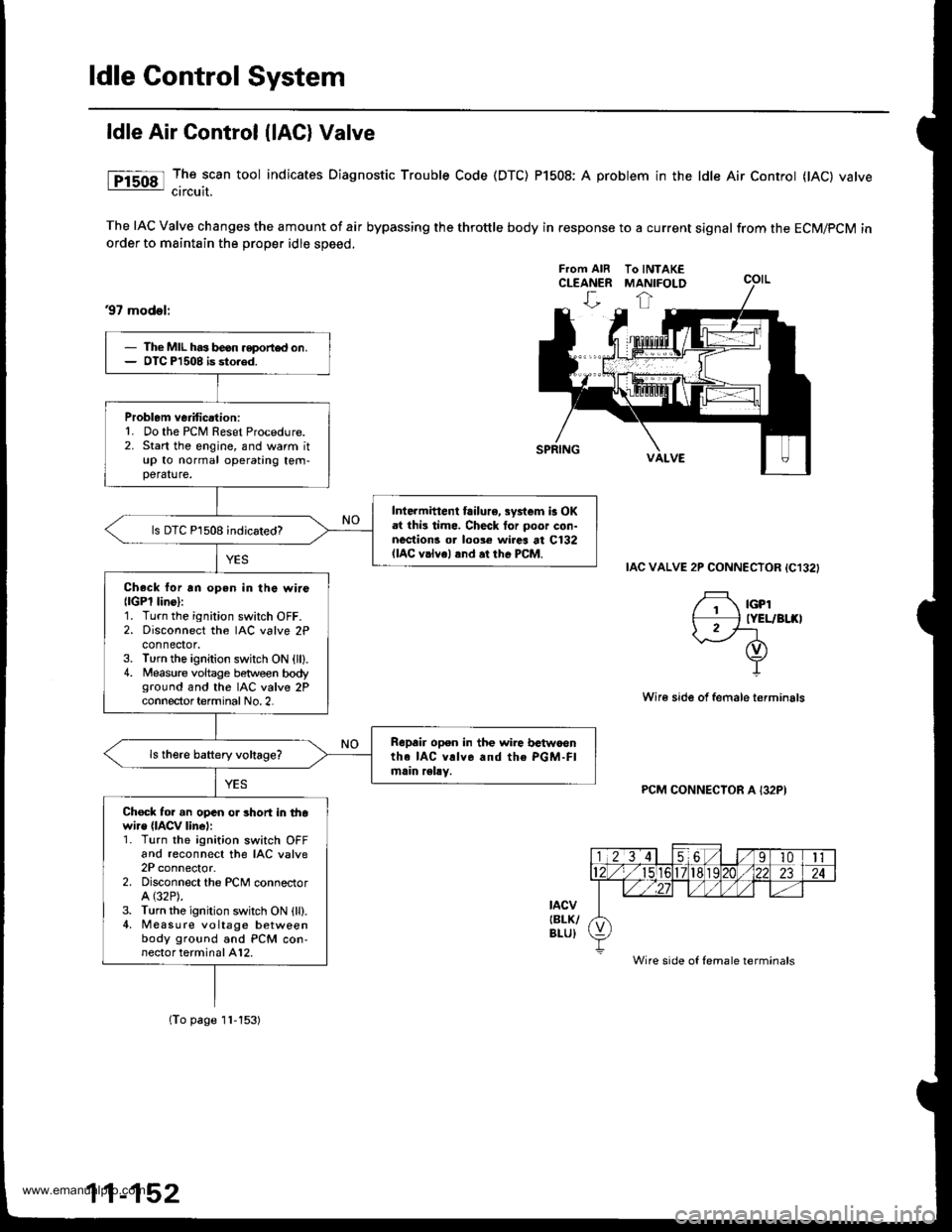

ldle Control System

ldle Air Control llAC) Valve

The scan tool indicates Diagnostic Trouble Code (DTC) Pl508: A probtem in the ldle Air Controt flAC) varvecircuit.

The IAC Valve changes the amount of air bypassing the throttle body in response to a current signal from the ECM/PCM inorder to maintain the proper idle speed.

37 model;

IAC VALVE 2P CONNECTOR {C132}

,f rcp'# IYEL/BI.(II2f-1-d)

Y

Wir€ side of female terminals

PCM CONNECTOR A I32PI

tacvIBLK/BLU)

From AIR To INTAKECLEANER MANIFOLD

Wire side of female terminals

The MIL has beon .eport€d on.OIC Pl508 is sto.ed.

Problem veiification:1. Do the PCM Reset Procedure.2. Start the engine, and warm itup to normal operating tem-perature.

Inte.mittent failure, systcm b OKat thi3 time. Check tor poo. con-nections or loose wircs at C132(lAC v.lvel and at the PCM.

ls DTC Pl508 indicated?

Check lor an open in the wir6{lGPl lins}:1. Turn the ignition switch OFF.2. Disconnect the IAC valve 2Pconnector.3. Turn the ignition switch ON {ll).4. Measure voltage between bodyground and the IAC valve 2Pconnector term inal No.2.

Repair open in the wire trctwoontha IAC v!lv6 and the PGM-Flmain relly.

Chock for an opan o. short in thowi.e (lACv linel:1. Turn the ignition switch OFFand reconnect the IAC valve2P connector.2. Disconnect the PCM conneclorA (32P).

3. Turn the ignition switch ON {ll).4, Measure voltage betweenbody ground and PCM con-nector terminal A12.

{To page 1l-153)

www.emanualpro.com

Page 357 of 1395

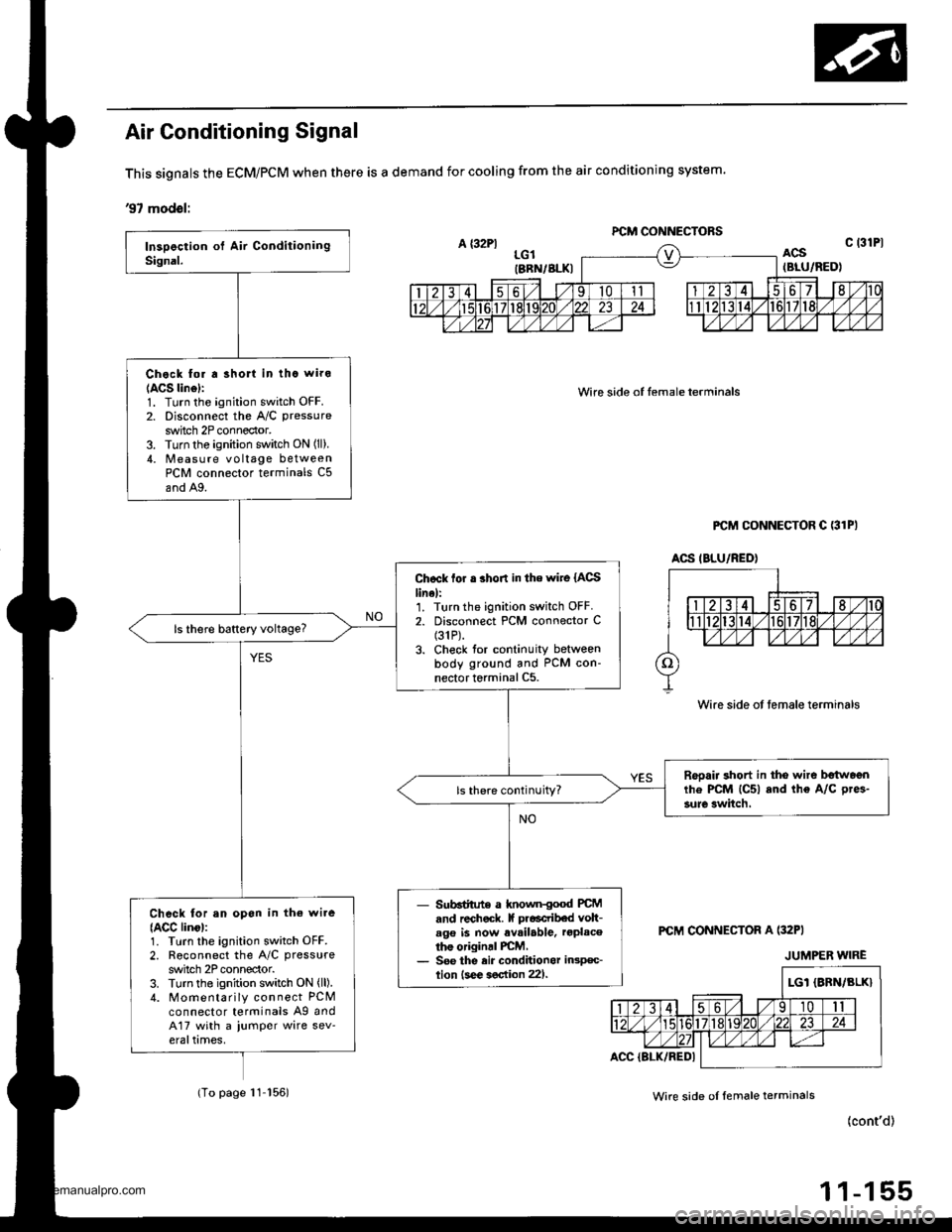

Air Conditioning Signal

This signals the EcM/PcM when there is a demand for cooling from the air conditioning system.

'97 modol:

Wire side of lemale terminals

PCM CONNECTOR C (31PI

ACS IBLU/RED)

PCM CONNECTOR A (:TIPI

(cont'd)

1 1-1 55

Chock for a shorl in thc wiro(ACS linol:1. Turn the ignition switch OFF.2. Disconnect the A/C pressure

switch 2Pconneclor.3. Turn the ignition switch ON (ll).,1. [Ieasu re voltage betweenPCM connector terminals C5

and A9.

Check for . .hon in the wire IAGSlinel:1. Turn the ignition switch OFF.2. Disconnect PCM connector C(31P).

3. Check for continuity betweenbody ground and PCM con-nector torminal C5.

Reoaii short in tho wire b€twoenrh6 PCM (Csl and the A/C pres-

3urc 3witch.

- Subcdtrte a known{ood PCMand recheck. lf pr6actibed volt-age is now av{ilable, roplacethe origind PCM,- Soe the eir conditionor in3p€c-lion lsee soction 221.

Check tor an opon in the wite(ACC lino):1. TLrrn the ignition switch OFF.2. Roconnect the A/C pressure

switch 2P connector.3. Turn the ignition switch ON (ll).

4. Momenta rily connect PCMconnector terminals A9 and417 with a iumper wire sev'eraltimes,

Wire side of female terminals

JUMPER WIRE

(To page 11-156)Wire side oI Iemale terminals

www.emanualpro.com

Page 358 of 1395

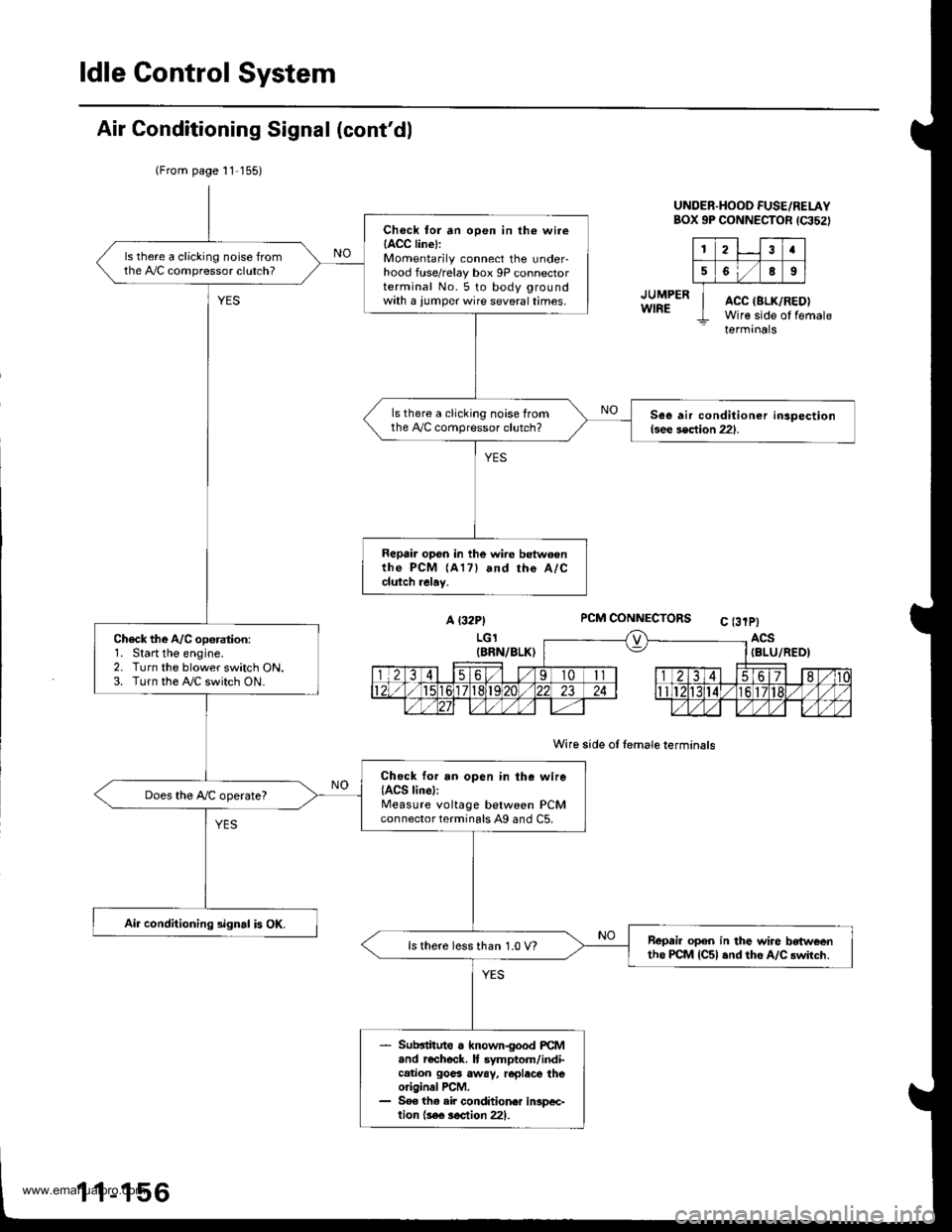

ldle Gontrol System

Air Conditioning Signal (cont'dl

(From page 11-'155)

JUMPERWIRE

UNOER.HOOD FUSE/RELAYBOX 9P CONNECTOR tqt52)

123I

56I

ACC IBLK/RWire side ofACC IBLK/REDIWire side of femaletermrnats

A t32PlPCM CONNECTORS C t3rp)

Wire side ol lemale terminals

Ch6ck for an open in th€ wire(ACC linel:Momentarily connect the under-hood fuse/relay box 9P connectorterminal No.5 to body groundwith a jumper wire several times.

ls there a cl;cking noise fromthe 4!/C compressor clutch?

ls there a clicking noise fromthe 4!/C compressor clutch?See air condiiioner inspection{see section 221.

Repai. op6n in the wire betwoenthe PcM (A17) and tho A/Cclutch relay.

Check the A/C operation:1. Start the engine.2. Turn the blower switch ON.3. Turn the A"/C switch ON.

Check for an open in the wire(ACS line):Measure voltage between PCMconnector terminals Ag and C5.

Does the A,/C operate?

Air conditioning signal is OK.

Repair open in the wire betweenthe PCM lCSl and the A/C awitch.ls there less than 1.0 V?

- Subqtitute a known-good FCM.nd r€ch6ck. lt 3ymptom/indi-cation goes awav, replece theoriginal rcM.- Soe th€ eir conditioner in3pec-tion (s6€ aec.tion 22).

www.emanualpro.com

Page 360 of 1395

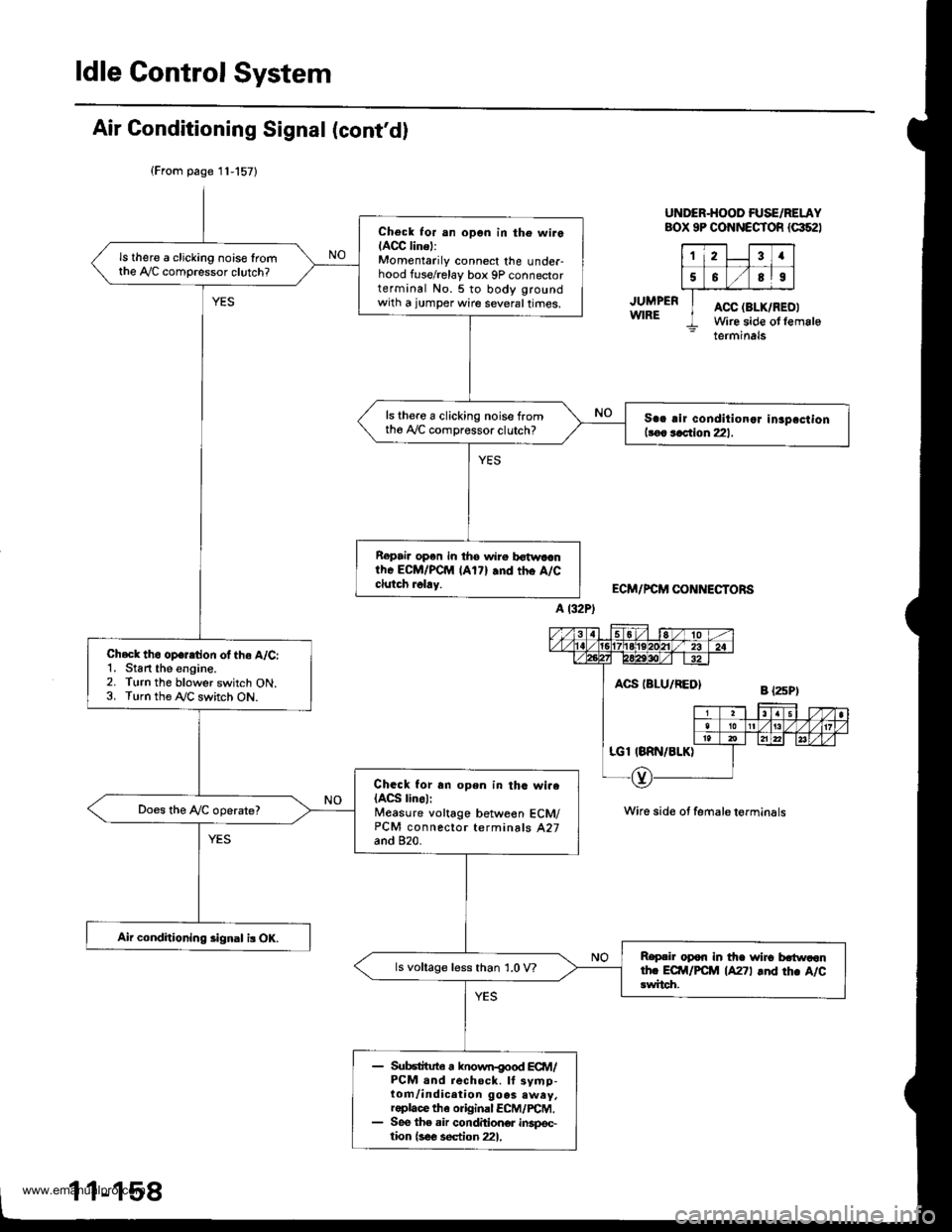

ldle Control System

Air Gonditioning Signal (cont'd)

JUMPERWIRE

UNDER-HOOD FUSE/RELAYBOX 9P CONNECTOR {G'52I

23a

5589

ACC (BLK/R

Wire side otACC (BLK/RED'

Wire side otfemaleterminals

ECM/PCM CONNECTORS

Wire sid€ of female torminals

(From page '11,157)

Check Ior dn opon in the wiroIACC linel:Momentarily connect the under-hood fuse/relay box 9P connectorterminal No. 5 to body groundwith a jumper wire several times.

ls there a clicking noise lromthe y'y'C compressor clutch?

ls there a clicking noise fromtho A,/C comprossor clutch?Sae rir conditional in3pactionlroa saction 221.

Repai. open in th6 wiro lr€twlanthe ECM/PCM lAl7l .nd tho A/Cclutch rolay.

Check tho op.ration of tho A/C:1. Stan the engine.2. Turn the blower switch ON.3. Turn the Ay'C switch ON.

ChGGk for an open in the wi.eIACS linel:Measure voltage betweon ECM/PCM connector terminals A27and 820.

Does the !y'C operate?

Air conditioning 3ignal i3 OK.

Rap.ir opon in the wir6 bdtunaanrh. Ecil/FcM lA27l rnd rh. A/crwitch.

ls voltage less than 1.0 V?

Sub6lftna a known{ood ECM/PCM and rechock. lf symp-tom/indicetion goes away.roplace the original ECM/rcM.See the ah conditionor inspoc-tion {3e€ section 22},

www.emanualpro.com

Page 361 of 1395

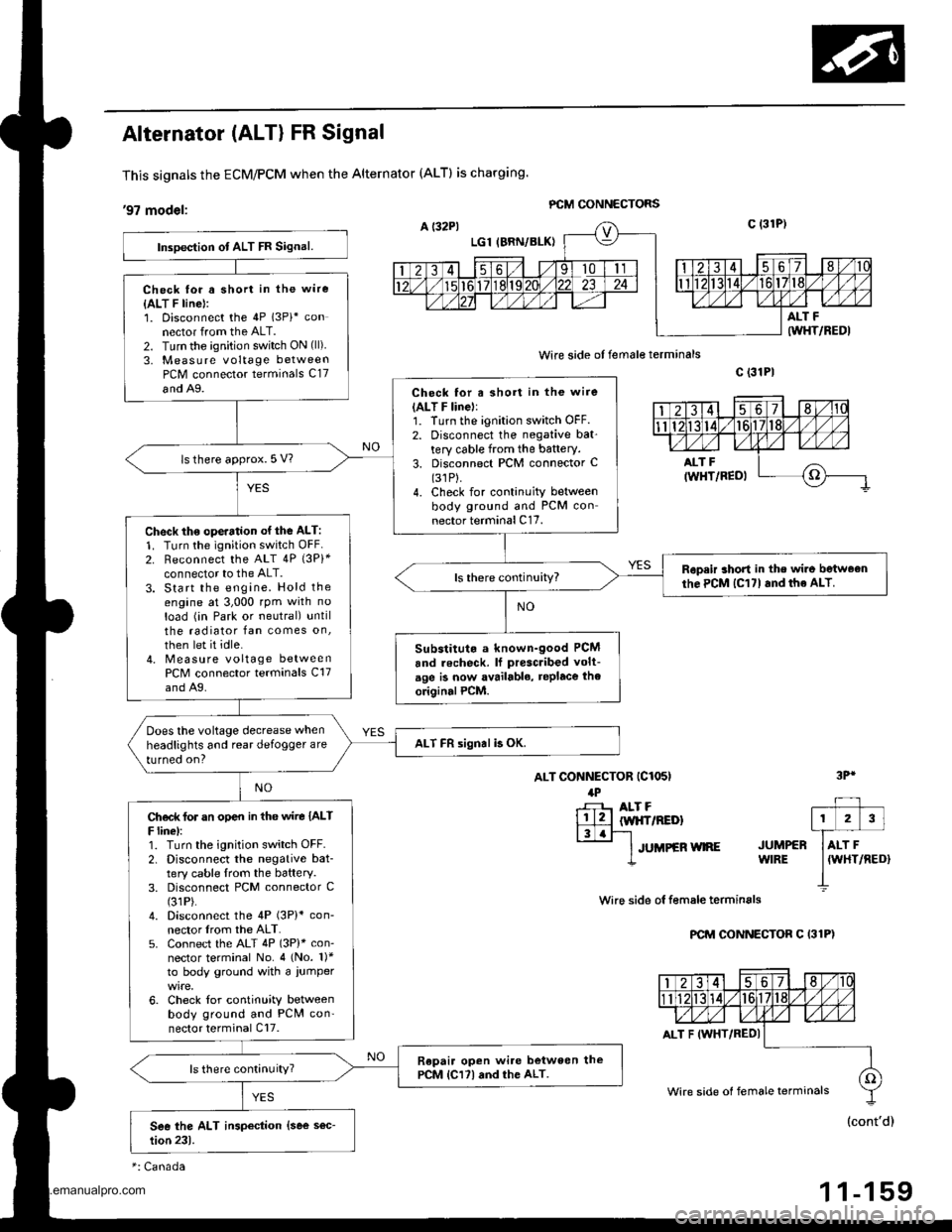

Alternator (ALT) FR Signal

This signals the ECM/PCM when the Alternator (ALTI is charging.

,97 modet: PCM GONNECTORS

wire side of female terminals

ALT CONNECTOR (C1O5I

lPr-F- ALT F

lll2llw|{frREDl|3.r-'l-

lruueen wne

c (31P|

wire side ol f€male terminals

PCM CONNECTOR C I31P)

3Pr

JUMPERWIRE

Inspection ot ALT FR Signal.

Check lor a short in the wire

{ALT F line}:1. Disconnect the 4P 13Pi* connector from the ALT.2. Turn the ignition switch ON (ll)

3, Measure voltage betweenPCM connector terminals C17

and A9.Check for a short in the wire(ALT F linel:1. Turn the ignition switch OFF.2. Disconnect the negative bat'tery cable from the battery.3. Disconnect PCM connector C(31P).

4. Check for continuity betweenbody ground and PCM connector terminal C17.

ls there approx. 5 V?

Check th€ ope.ation of the ALT:

1. Turn the ignition switch OFF2. Reconnect the ALT 4P {3Pi*connector to the ALT.3. Start the engine. Hold theengine at 3,000 rpm with no

load (in Park or neutral) untilthe radiator fan comes on,

then let it idle.4. Measure voltage betweenPCM connector terminals C17and A9.

Ropeir short in the wir6 betweonthe PCM lC17l and the ALT.

Substitut. a known-good PCM

and recheck. lf prescribed volt-

age is now availablo, replace the

originalPCM.

Does the voltage decrease when

headlights and rear defogger are

turned on?ALT FR signal b OK.

Ch€d( for an op€n in tho wire IALTF linel:1. Turn the ignition switch OFF.2. Disconnect the negative bat-tery cable lrom the battery.3. Disconnect PCM connector C(31P).

4. Disconnect the 4P (3P)* con-nector lrom the ALT.5. Connect the ALT 4P (3P)* con-nector terminal No. 4 (No. 1)*to body ground with a iumper

6. Check for continuity betweenbody ground and PCN4 con'nector terminal Cl7.

Repair open wi.e between thePCM lCl7l and the ALT.ls there continuity?

ALT F IWHT/REDI

Wire side of female terminals

1 1-159

www.emanualpro.com

Page 362 of 1395

![HONDA CR-V 1999 RD1-RD3 / 1.G User Guide

ldle Gontrol System

Alternator (ALT) FR Signal (contdl

98 - 00 modols:

ALT CONNECTOR (C1I}5I

4P

rH] Arr FllltwHr/REo)l3laF1

I JUMPER WIRE JUMPER+ WIRE

ECM/PCM CONNECTORS

Wire side of female termi HONDA CR-V 1999 RD1-RD3 / 1.G User Guide

ldle Gontrol System

Alternator (ALT) FR Signal (contdl

98 - 00 modols:

ALT CONNECTOR (C1I}5I

4P

rH] Arr FllltwHr/REo)l3laF1

I JUMPER WIRE JUMPER+ WIRE

ECM/PCM CONNECTORS

Wire side of female termi](/img/13/5778/w960_5778-361.png)

ldle Gontrol System

Alternator (ALT) FR Signal (cont'dl

'98 - 00 modols:

ALT CONNECTOR (C1I}5I

4P

rH] Arr Fl'l'ltwHr/REo)l3laF1

I JUMPER WIRE JUMPER+ WIRE

ECM/PCM CONNECTORS

Wire side of female terminals

ECM/PCM CONNECTOR C {31PI

Wire side of female terminals

Wire side of female terminals

ECM/PCM CONNECTOR C {31P}

": Canada

1 1-160

B (25P)

Insp€ction of ALT FR Signsl.

Check fo. a shon in th. wire {ALTF linel:1. Disconn6ct the 4P (3P)* con-nector from the ALT.2. Turn the ignition switch ON {ll).3. Measure voltage between ECM/PCM connector terminals C5and 820.Ch€ck for a sho.t in iho wirc lAlTF lino):1. Turn the ignition switch OFF.2. Disconnecl the negative bat,tery cable from the battery.3. Disconnect ECM,PCM connec-torC (31P).

4. Check for continuity betwoenbody ground and ECM/PCMconnector terminal c5.

ls there approx. 5 V7

Check the opcration of the ALT:1. Turn the ignitioo switch OFF.2. Reconnect rhe ALT 4P (3P)*connector to the ALT.3. Start the engine. Hold theengine at 3,000 rpm with noload (in Park or neutral) untilthe radiator lan comes on,then let it idle.4. Measure voltage between ECM/PCM connector terminals C5and 820.

Roprir lhort in tho wirc bstweentho ECM/PCM {Csl and the ALT.

Substitut. r known-good ECM/PCM and roch.ck. It Droscrib.dvoltage b now lvrilabls, .eplaccth. o.igin!l ECM/PCM.

Does the voltage decrease whenheadlights and rear defogger areturned on?ALT FR 3ignol is OK,

Chock lor an opon in tha wire (ALTF linel:1. Turn the ignition switch OFF.2. Disconnect the negative bat-tery cable from the battery.3. Disconnect ECM/PCM con-nector C (31P).4. Disconnect the 4P 13P)* con,nector from the ALT.5. Connect the ALT 4P {3P)* con-nector terminal No. 4 1No. 1)*to body ground with a jumper

6. Check for continuity betwe€nbody ground and ECM/PCMconnector terminal C5.

Rsprir opan wiro batw.en thoECM/PCM lcsl .nd th. ALT.ls there continuity?

AI.T F IWHT/REDI

ALT F {WHT/REDI

Wire side ot Iemale terminals

www.emanualpro.com