line HONDA CR-V 1999 RD1-RD3 / 1.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1999, Model line: CR-V, Model: HONDA CR-V 1999 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 1046 of 1395

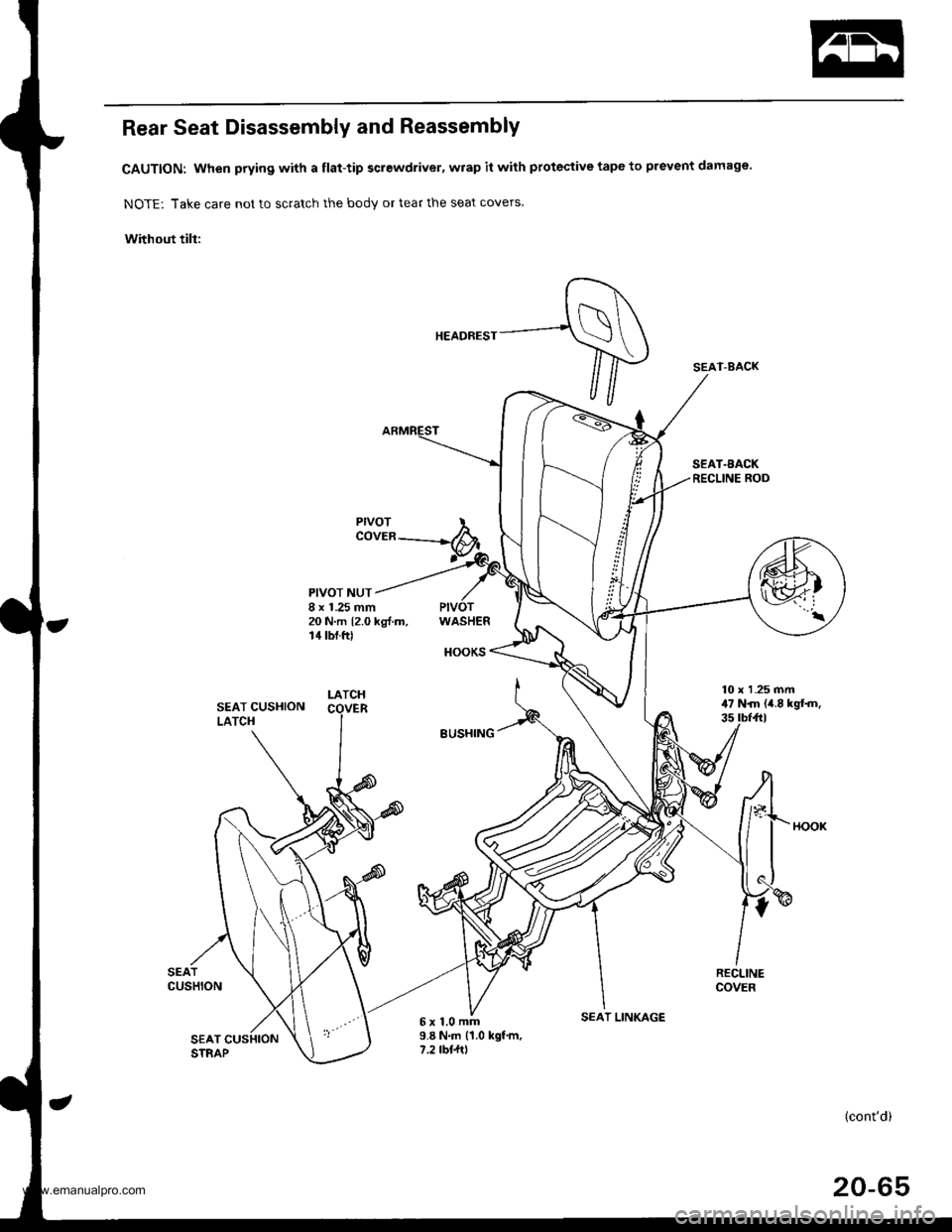

Rear Seat Disassembly and Reassembly

CAUTION: When prying with a flat-tip screwdriver, wrap it with protective tape to prevent damage.

NOTE: Take care not to scratch the body or tear the seat covers.

Without till:

SEAT.AACKRECLINE ROD

PIVOTCOVER

PIVOT NUT8 x 1.25 mm20 N.m 12.0 kg{.m.14 tbf.ftlWASHER

HOOKS

5x1.0mm9.8 N'm (1.0 kgf.m,7 .2 tbl.ltl

(cont'd)

20-65

SEAT-BACK

SEAT CUSHIONLATCH

SEATCUSHION

SEAT CUSHIONSTRAP

SEAT LINKAGE

www.emanualpro.com

Page 1047 of 1395

Seats

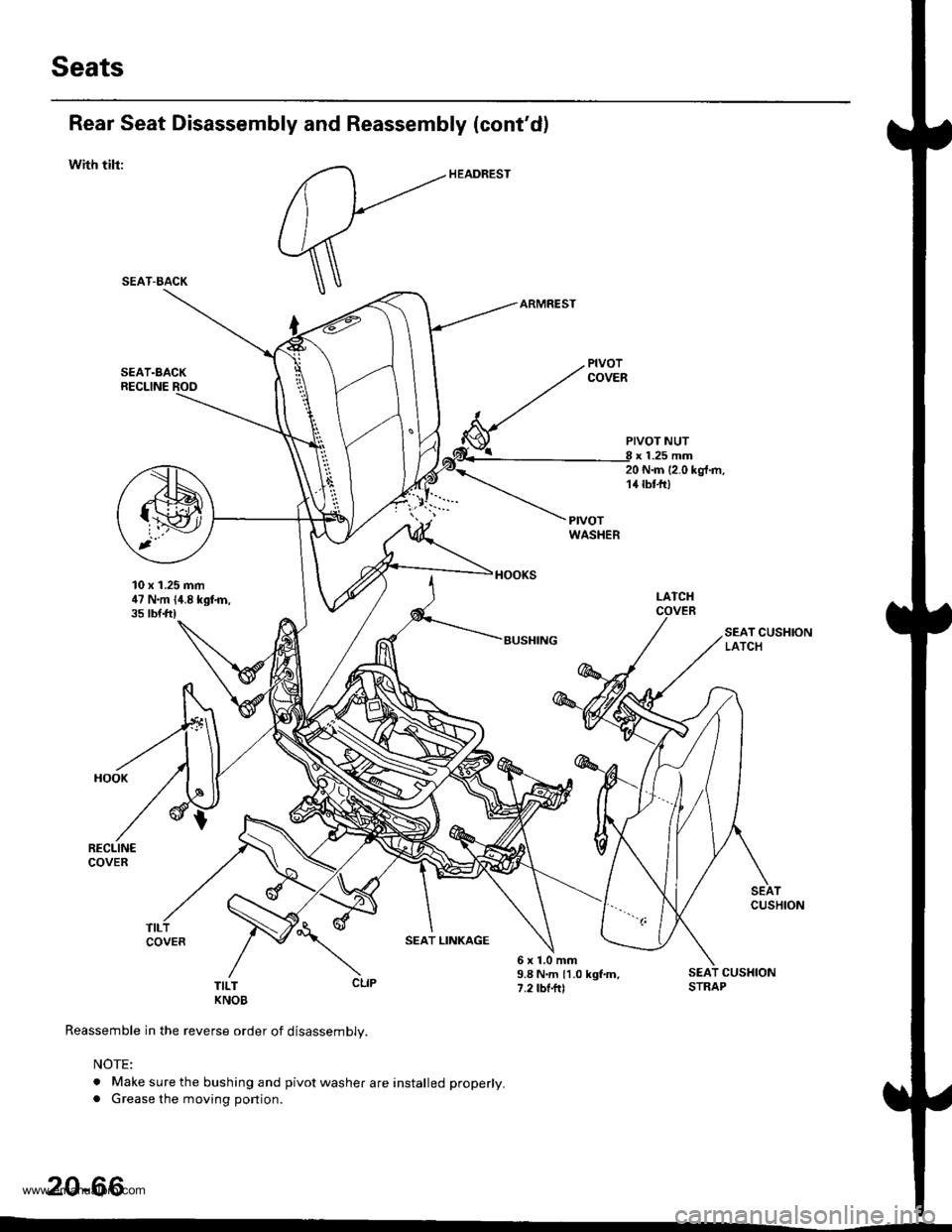

Rear Seat Disassembly and Reassembly (cont'd)

with tilr:

SEAT.BACKRECLINE ROO

10 x 1.25 mm47 N.m {4.8 kgfn,35 tbtft)

PIVOT NUTx 1.25 mm20 N{n (2.0 kgt.m,14 tbt-fr)

I-ATCHCOVER

SEAT CUSHIONLATCH

SEATCUSHION

SEAT LINKAGE

T;LT CLIP

KNOB

Reassemble in the reverse order of disassembly.

NOTE:

. Make sure the bushing and pivot washer are installed properly.. Grease the moving portion.

6x1.0mm9.8 N.m {1.0 kgf.m,7.2 tbf.ftl

SEAT CUSHIONSTRAP

20-66

SEAT-BACK

www.emanualpro.com

Page 1050 of 1395

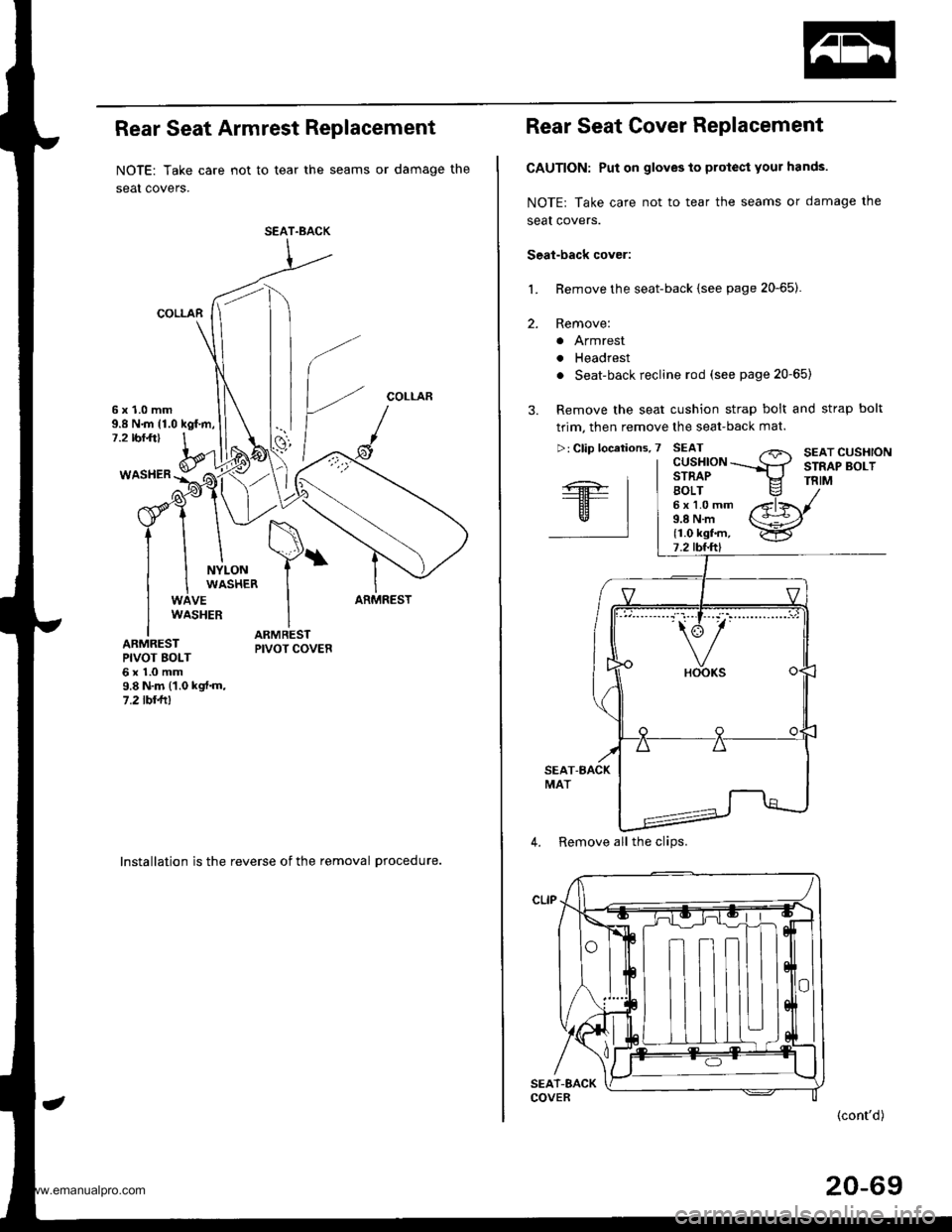

Rear Seat Armrest Replacement

NOTE: Take care not to tear the seams or damage the

seat covers.

COLLAR

COLLAR6x1.0mm9.8 N.m {1.0 kgf.m,7.2 rbr.ft)

WASHER

NYLONWASHER

VEARMRESTWASHER

ARMRESTPIVOT BOLT6x1.0mm9.8 N.m (1.0 kgt.m,7.2lbllll

lnstallation is the reverse of the removal procedure.

SEAT.BACK

Rear Seat Cover Replacement

CAUTION: Put on gloves to protect your hands.

NOTE: Take care not to tear the seams or damage the

seal covers.

Seal-back cover:

Remove the seat-back {see page 20-65).

Remove:

a Armrest

. Headrest

. Seat-back recline rod (see page 20-65)

Remove the seat cushion strap bolt and strap bolt

trim, then remove the seat-back mat.

L

2.

"'---.' t.-r" t-- i,': "" '

4. Remove all the clips.

(cont'd)

20-69

www.emanualpro.com

Page 1059 of 1395

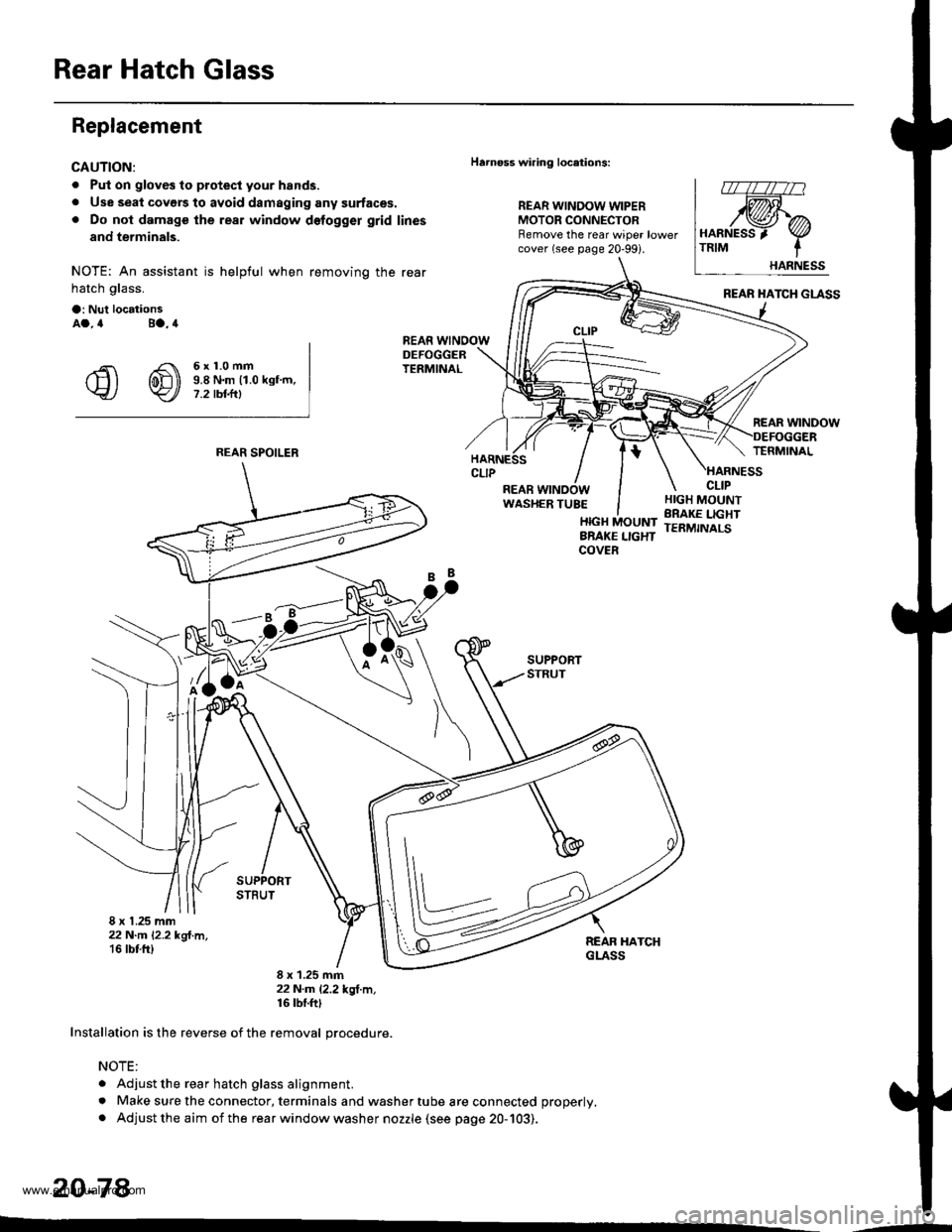

Rear Hatch Glass

Replacement

CAUTION:

. Put on gloves to protecl your hands.

. Use seal covers to avoid damaging any surfaces.. Do not damage the rear window delogger grid lines

and terminals.

NOTE: An assistant is helpful when removing the rear

hatch glass.

a: Nul locationsAa.4 Ba.4

€ @ i!iff*-"-

Harnoss wiring locations:

REAR WINDOW WIPERMOTOR CONNECTORRemove the rear wiper lowercover (see page 20-99i.

HARNESS 'TRIM

.;=-

8 x 1.25 mm22 N-m l'2.2 kgl.m,'16 tbt fr)

8 x 1.25 mm22N.m l.2.2*ql.m,16 tbf.ft|

Installation is the reverse of the removal orocedure.

NOTE:

. Adjust the rear hatch glass alignment.

. Make sure the connector, terminals and washer tube are connected properly.

. Adjust the aim of the rear window washer nozzle (see page 20-103).

20-78

REAR SPOILER

'--

www.emanualpro.com

Page 1061 of 1395

Rear Hatch Glass

l,_ | r\

wl:

f\ALIGNMENT HARNESSMARK TRIM

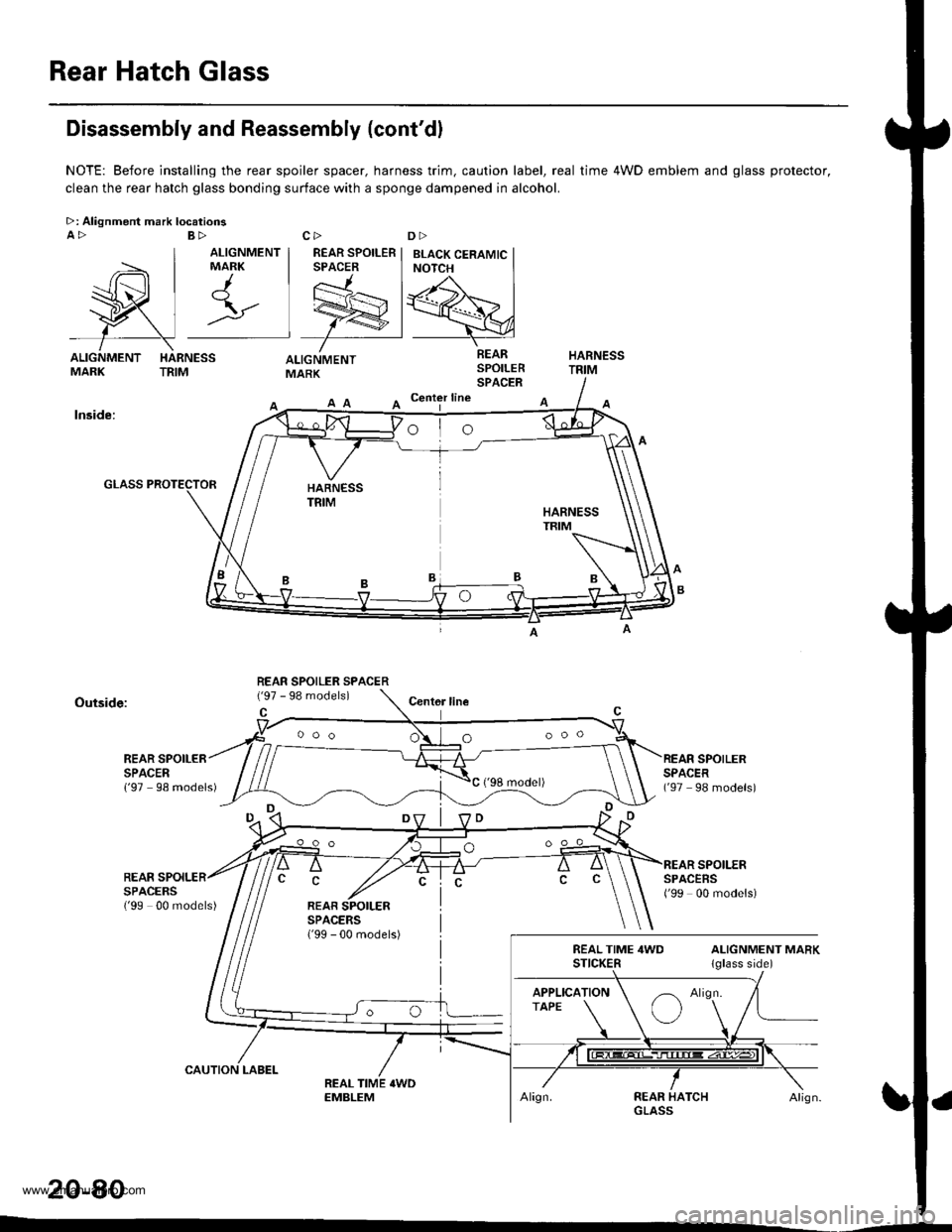

Disassembly and Reassembly (cont'dl

NOTE: Before installing the rear spoiler spacer, harness trim. caution label, real time 4WD emblem and glass protector,

clean the rear hatch glass bonding surface with a sponge dampened in alcohol.

>: Alignment mark locatioosA>

ALIGNMENTMARK

A Center line

lnside:

Outside:Centor line

REAR SPOILERSPACER{'97 98 models)

SPOILERREARSPACEBSSPACERS('99 00 models){'99 00 models)

20-80

REAR SPOILER SPACER

ooo O

www.emanualpro.com

Page 1062 of 1395

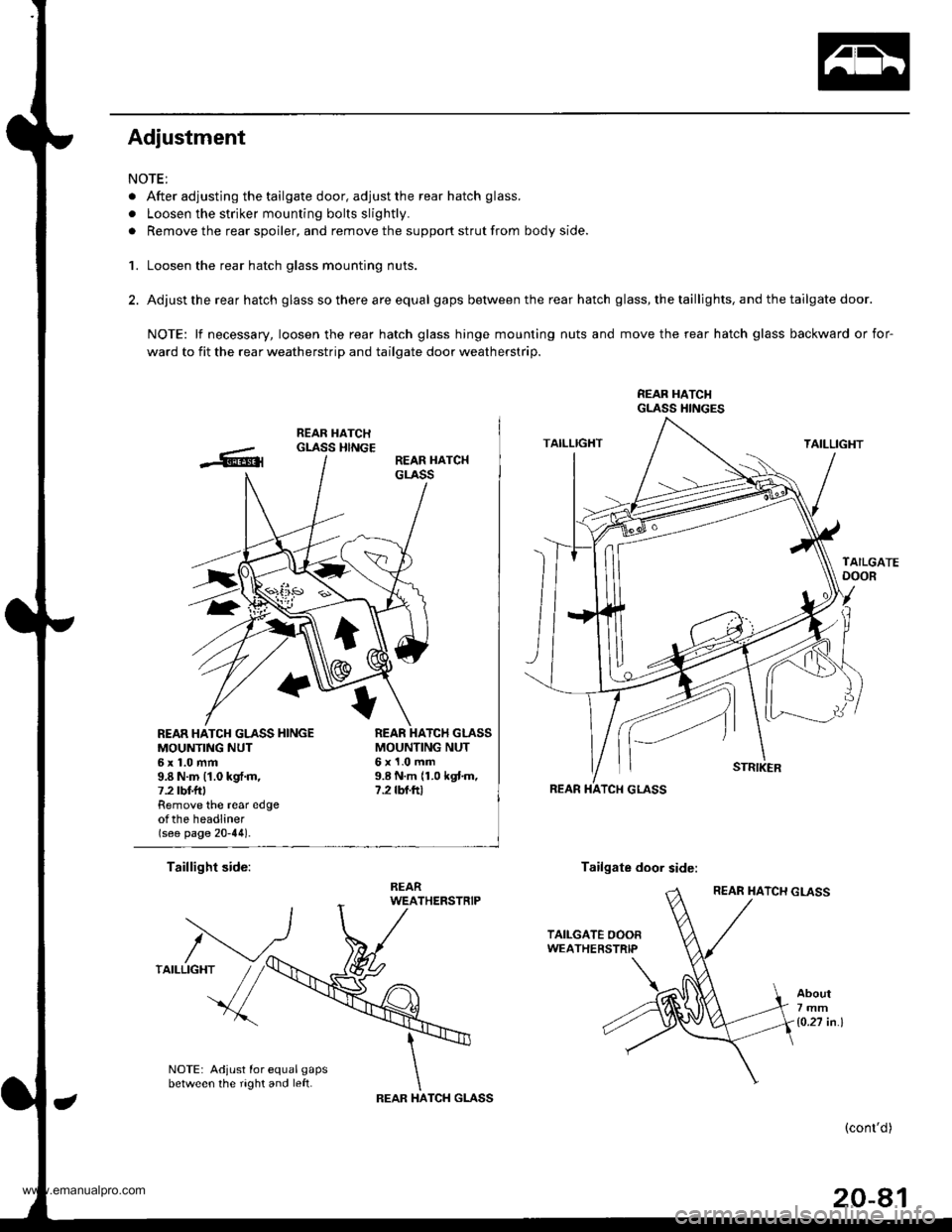

Adjustment

NOTE:

. After adjusting the tailgate door, adjust the rear hatch glass.

. Loosen the striker mounting bolts slightly.

. Remove the rear spoiler, and remove the support strut from body side.

1. Loosen the rear hatch glass mounting nuts.

2. Adjust the rear hatch glass so there are equal gaps between the rear hatch glass, the taillights, and the tailgate door.

NOTE: lf necessary, loosen the rear hatch glass hinge mounting nuts and move the rear hatch glass backward or for-

ward to fit the rear weatherstrip and tailgate door weatherstrip.

REAR HATCI{GLASS HINGES

REAR HATCH GLASS HINGEMOUNTING NUT6x1.0mm9.8 N.m (1.0 kgf.m,7.2 tbt f Remove the rear edgeotthe headliner(see page 20-44).

MOUNTING NUT6x1.0mm9.8 N.m 11.0 kgtm,7.2 rbf.ftt

Taillight side:Tailgate door side:

About7mm

1o.27 in.l

NOTE: Adjust for equal gapsbetween the right and left.TCH GLASSIHAREAR

(cont'd)

20-81

www.emanualpro.com

Page 1079 of 1395

Wiper/Washer

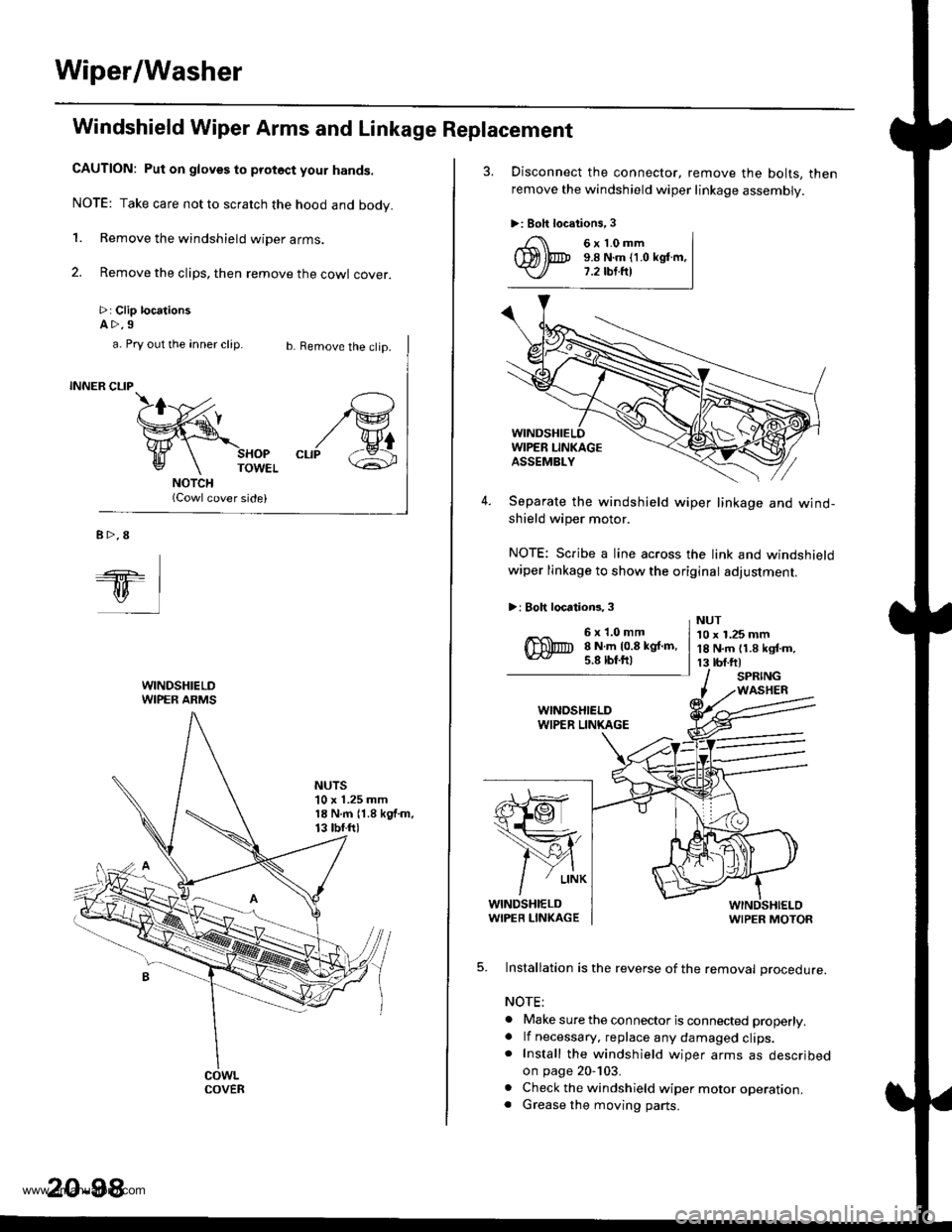

Windshield Wiper Arms and Linkage Replacement

CAUTION: Put on gloves to protoct your hands.

NOTE: Take care not to scratch the hood and body.

1. Remove the windshield wiper arms.

2. Remove the clips, then remove the cowl cover.

>: Clip locationsA>.9

b. Remove the clip.

SHOPTOWEL

(Cowl cover side)

/G

"rr/ &

a. Pry out the anner clip.

INNER CLIP

B>.8

ql

WINDSHIELDWIPER ARMS

NUTS'10 x 1.25 mm18 N.m 11.8 kgf.m.13 tbf.ftl

COVER

20-98

3. Disconnect the connector, remove the bolts, then

remove the windshield wiper linkage assembly.

>: Boh locations,3

4. Separate the windshield wiper linkage and wind-shield wiper motor.

NOTE: Scribe a line across the link and windshieldwiper linkage to show the original adjustment.

>: Boh locations, 3

s}@

1ffi,

/Y{

/

' L|NK

WINDSHIELDWIPER LIN(AGEWIPER MOTOR

5. Installation is the reverse of the removal procedure.

NOTE:

. Make sure the connector is connected properly.. lf necessary. replace any damaged clips.. Install the windshield wiper arms as describedon page 20-103.

. Check the windshield wiper motor operation.. Grease the moving parts.

6x1.0mm9.8 N.m (1.0 kglm,7.2 tbt.fr)

6x1.0mm8 N.m 10.8 kgf.m,5.8 lbf.ftl

NUT10 x 1.25 mm18 N.m 11.8 kgf.m,13 tbf.ftlSPRINGWASHER

www.emanualpro.com

Page 1082 of 1395

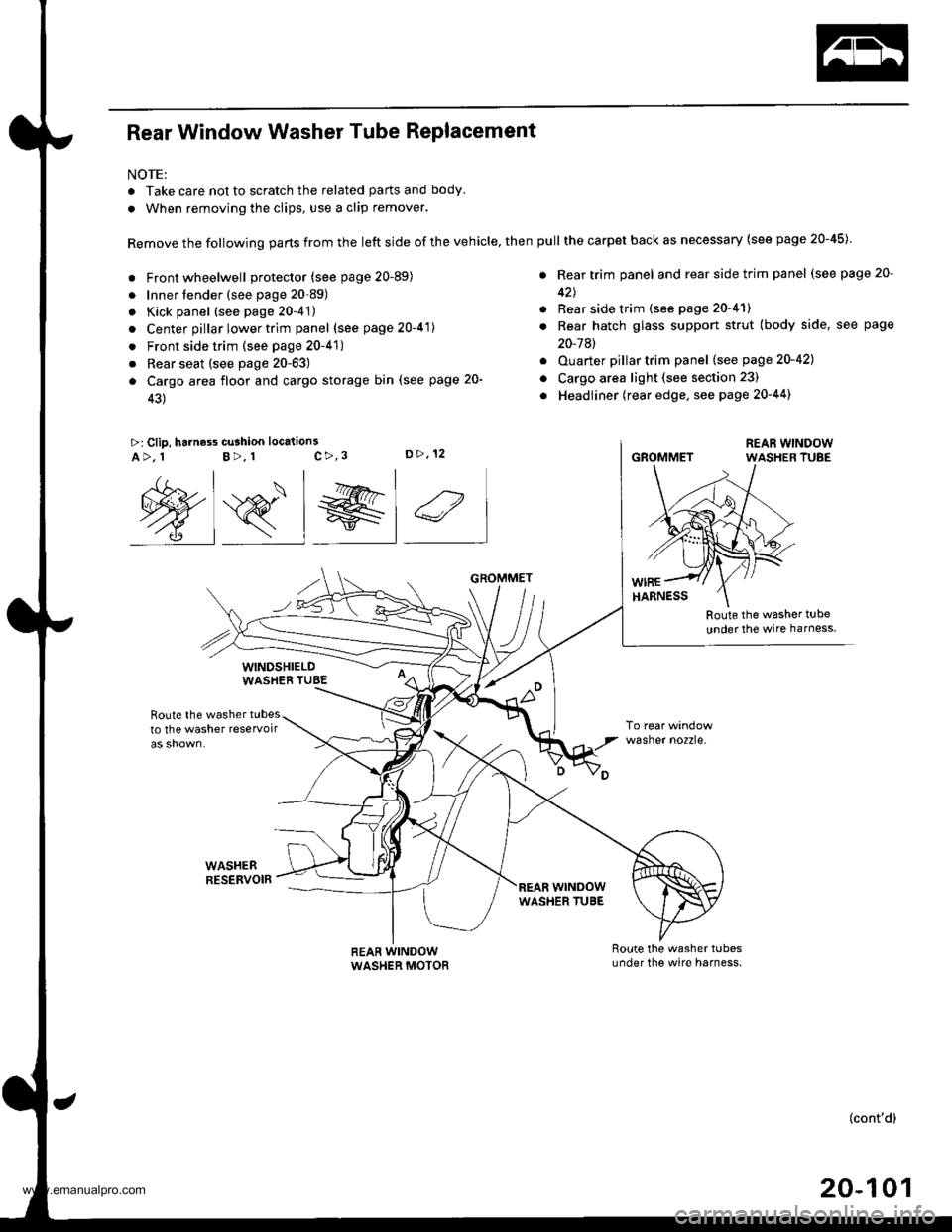

Rear Window Washer Tube Replacement

NOTE:

. Take care not to scratch the related parts and body.

. When removing the clips, use a clip remover.

Remove the following parts from the left side of the vehicle, then

. Front wheelwell protector (see page 20-89)

. Innertender (see page 20-89)

. Kick panel (see page 20-4't)

. Center pillar lower trim panel (see page 20-41)

. Front side trim (see page 20-41)

. Rear seat (see page 20-63)

a Cargo area floor and cargo storage bin (see page 20-

43)

>: Clip, harness cu3hion location3c>,3D>,12A>, 1B>, 1

Route the washer t!be

under the wire harness

Route the washer tubesto the washer reservoir

WASHEBRESERVOIR

wasner no2zre.

@s_l el 4

WINDSHIELDWASHEB TUBE

REAR WINDOWWASHER MOTOR

GROMMET

wrNoowWASHER TUBE

pull the carpet back as necessary (see page 20-45)

. Rear trim panel and rear side trim panel (see page 20-

42J

. Rear side trim (see page 20-41)

. Rear hatch glass support strut (body side, see page

20-7Al

. Ouarter pillartrim panel (see page 20-421

o Cargo area light (see section 23)

. Headliner (rear edge, see page 20-44)

GROMMET

(cont'd)

20-101

www.emanualpro.com

Page 1084 of 1395

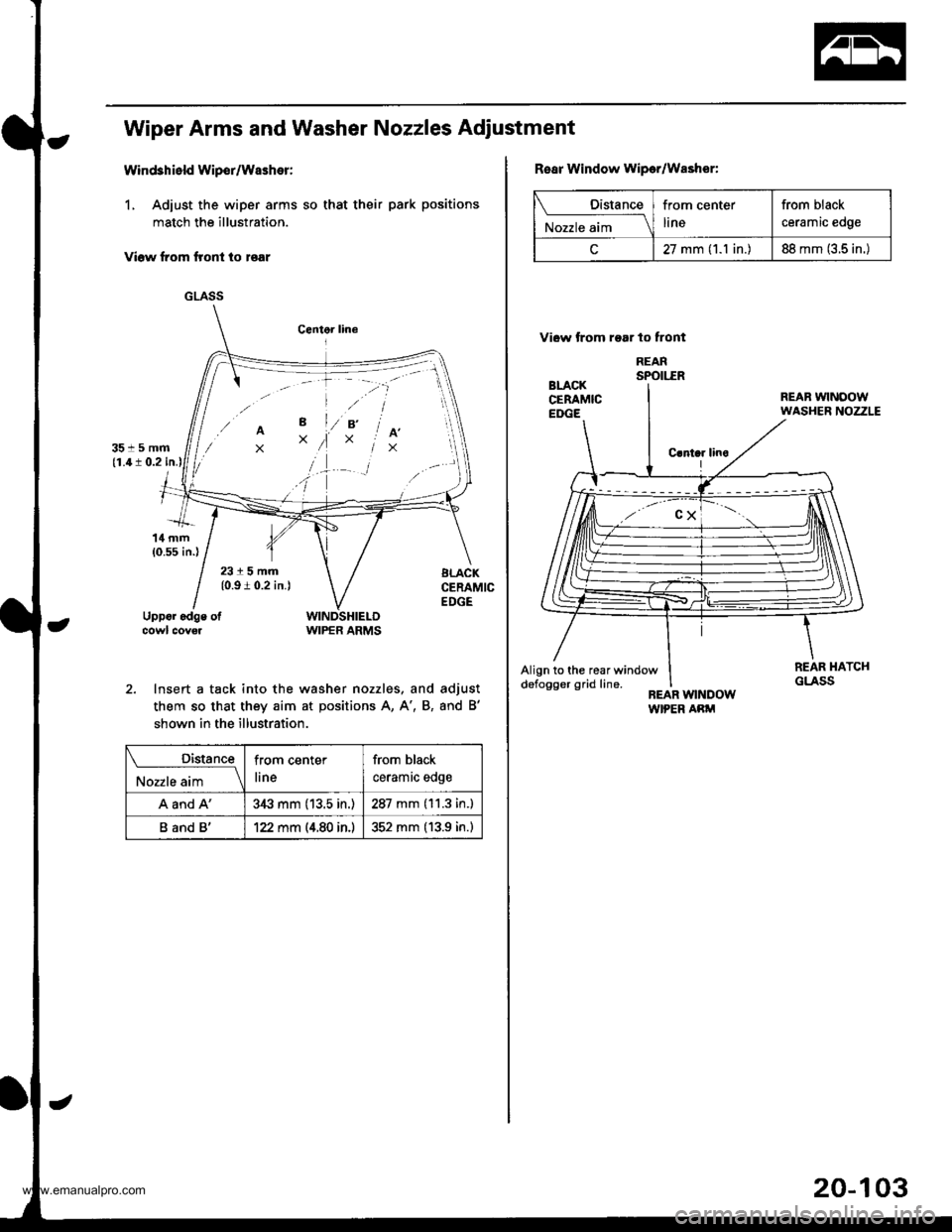

Wiper Arms and Washer Nozzles Adiustmenl

Wind3hield Wipor/Washer:

1, Adiust the wiper arms so that their park positions

match the illustration.

Viow from flont io roar

GLASS

2. Insert a tack into the washer nozzles. and

them so that they aim at positions A, A', B,

shown in the illustration.

adjust

and B'

Distance

^,J;-ll\

from center

line

from black

ceramic edge

A and A'3,$ mm (13.5 in.)287 mm (11.3 in.)

B and B'122 mm (4.80 in.)352 mm (13.9 in.)

Rear Window wipor/Washer:

Vi6w trom roar to lront

REARsPo[.-ER

C.nlar linoL

Align to the rear windowdefogger grid line.

Distance

ru"rrr. "i.

'_\from center

ltne

from black

ceramic edge

27 mm (1.1 in.)88 mm (3.5 in.)

20-103

www.emanualpro.com

Page 1097 of 1395

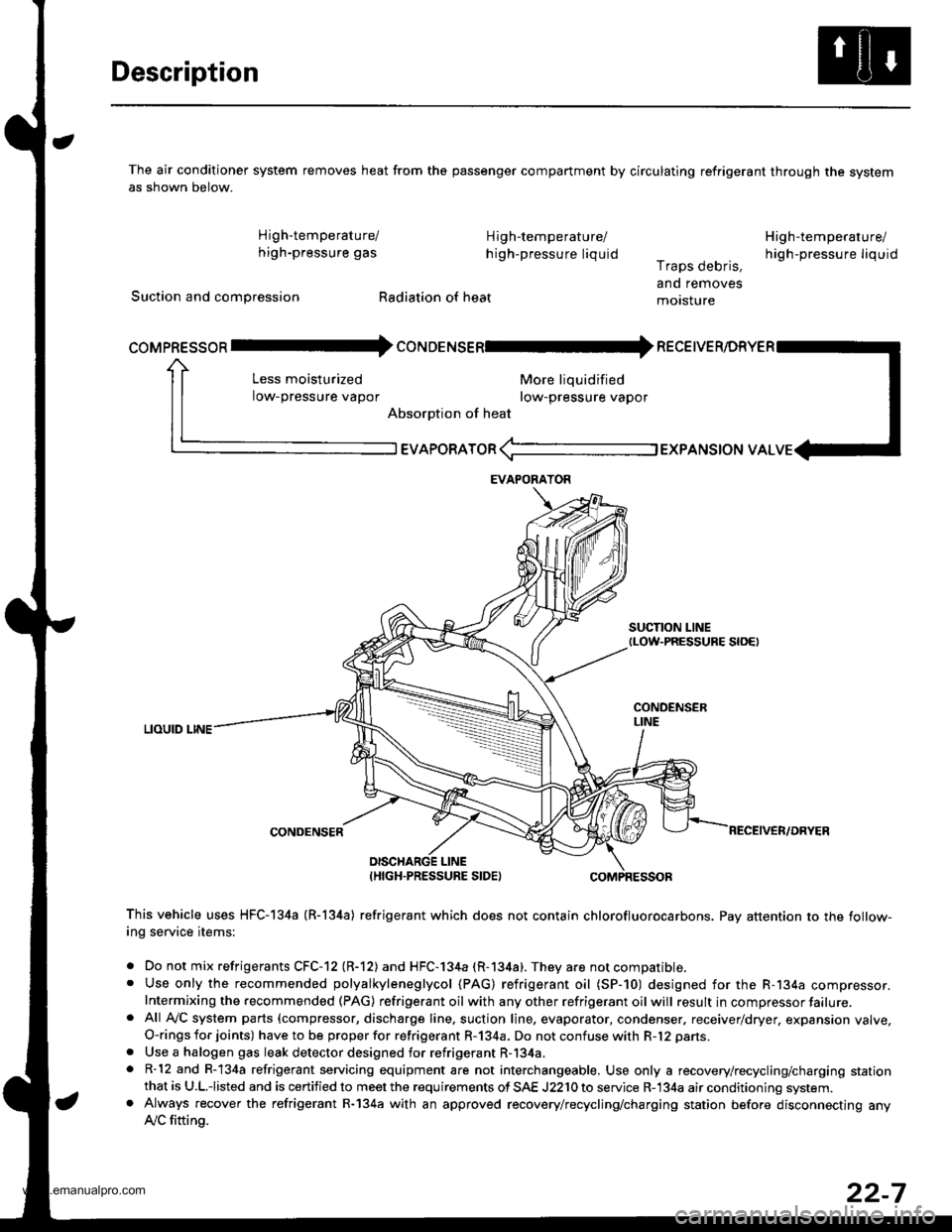

Description

The air conditioner system removes heat from the passenger compartment by circulating refrigerant through the systemas shown below.

High'temperature/ High-temperature/

high-pressure gas h igh-pressure liquid

Suction and compression Radiation of heat

High-temperature/

high-pressu re liq uidr raps oeons,

and removes

motsture

More liquidified

row-pressure vapor

EVAPoRAToR (-l EXPANSToN vAL

SUCTION LINEtLow-PRESSURE S|OEt

LIOUID LINE

CONDENSER

coMpREssoR Il- coruoerusenl* necetve

Less moisturized

low-pressure vapor

Absorption of heat

DISCHARGE LINEIHIGH.PRESSURE SIDEI

This vehicle uses HFC-I34a (R-l34a) refrigerant which does not contain chlorofluorocarbons. Pay attention to the follow-ing service items:

. Do not mix refrigerants CFC-12 (R-12) and HFC-l34a (R-134a). They are not compatible.. Use only the recommended polyalkyleneglycol (PAG) refrigerant oil (SP-10) designed for the R-134a compressor.Intermixing the recommended (PAG) refrigerant oil with any other refrigerant oil will result in compressor failure.. Afl Ay'C system parts (compressor, discharge line. suction line, evaporator, condenser. receiver/dryer, expansion valve,O-rings for joints) have to be proper for refrigerant R-134a. Do not confuse with R-12 parts.

. Use a halogen gas leak detector designed for refrigerant R-134a.. R-12 and R-134a refrigerant servicing equipment are not interchangeable. Use only a recovery/recycling/charging stationthat is U.L.iisted and is certified to meet the requirements of SAE J2210 to service R-134a air conditioning system.. Always recover the refrigerant R-134a with an approved recovery/recycling/charging station before disconnecting anylVC fitting.

EVAPORAYOR

22-7

www.emanualpro.com