Fault HONDA CR-V 1999 RD1-RD3 / 1.G Owner's Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1999, Model line: CR-V, Model: HONDA CR-V 1999 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 628 of 1395

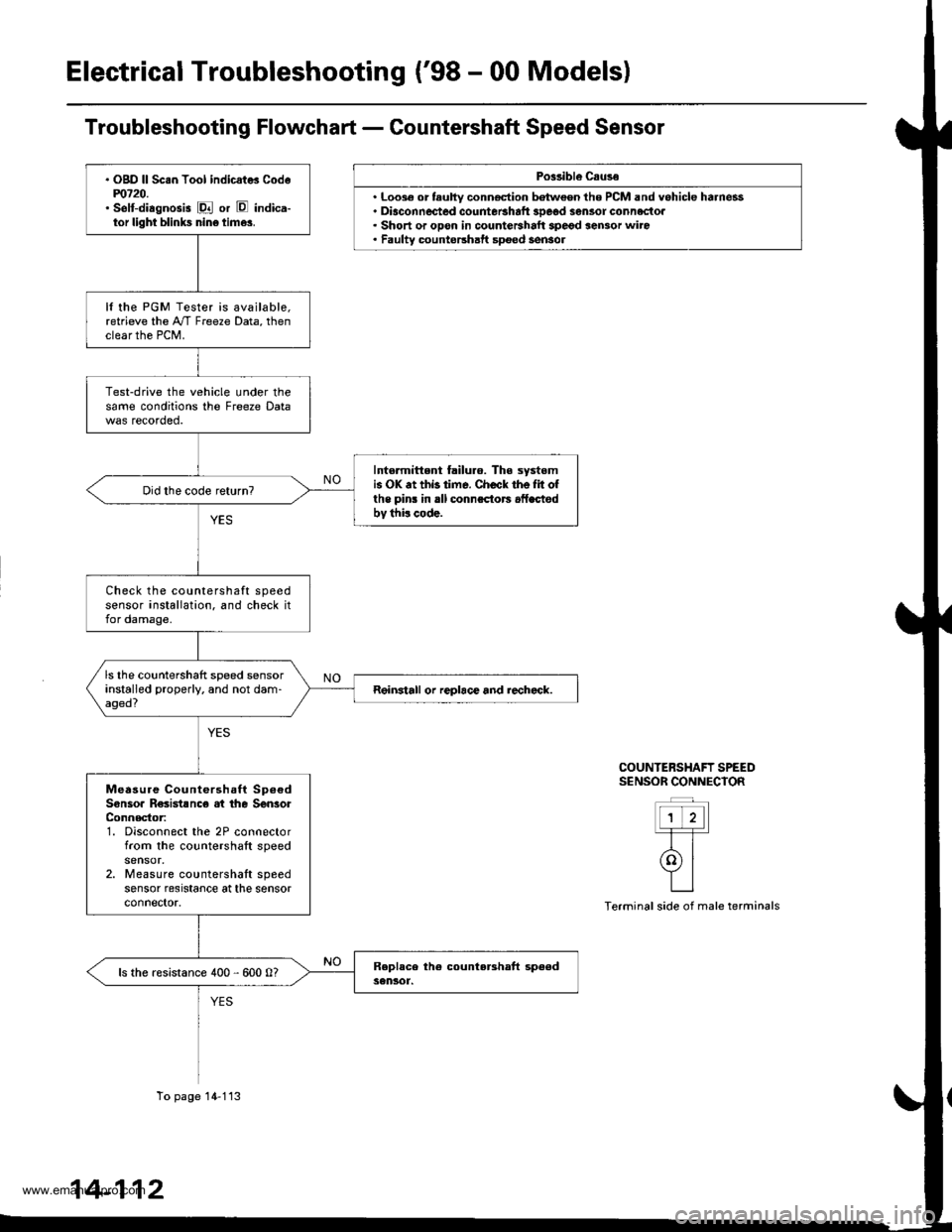

Electrical Troubleshooting ('98 - 00 Models)

Po$ibl€ Csuse

. Loo3€ or tauhy conn€ction batween the PCM and vehicle harness. Diaconnected countetshaft 3Deod sensor connectoa. Short or opon in countershalt spegd sensor wiro. Faulty countershatt spoed sensol

COUNTERSHAFT SPEEDS€NSOR CONNECIOR

ttt'l-T-T-

rolYILI

Terminal side of male terminals

. OgD ll Sc.n Tool indicat* Codem720.' selt-diagnosis E or E indica-tor light blinks nin6 time3.

It the PGM Tester is available,retrieve the A"/T Freeze Data, thenclear the PCM.

Test-drive the vehicle under thesame conditions the Freeze Data

Intormittent failuro. The systomis OK .t thb time. Check the Iit ofthe pins in rll connsctors .fLctodbv thi! code.

Check the countershaft speedsensor installation. and check itfor damage.

ls the countershaft speed sensorinstalled properly. and not dam-aged?Reinstall or replace and rechcck.

Measure Countershaft Sp6€dSonsoa R€sistsnc€ at the SenlorConnector:1. Disconnect the 2P connectorfrom the countershaft speed

2. Measure countershaft speedsensor resrstance at the sensorconnector.

ls the resistance 400 - 600 0?

To page 14-113

14-112

www.emanualpro.com

Page 630 of 1395

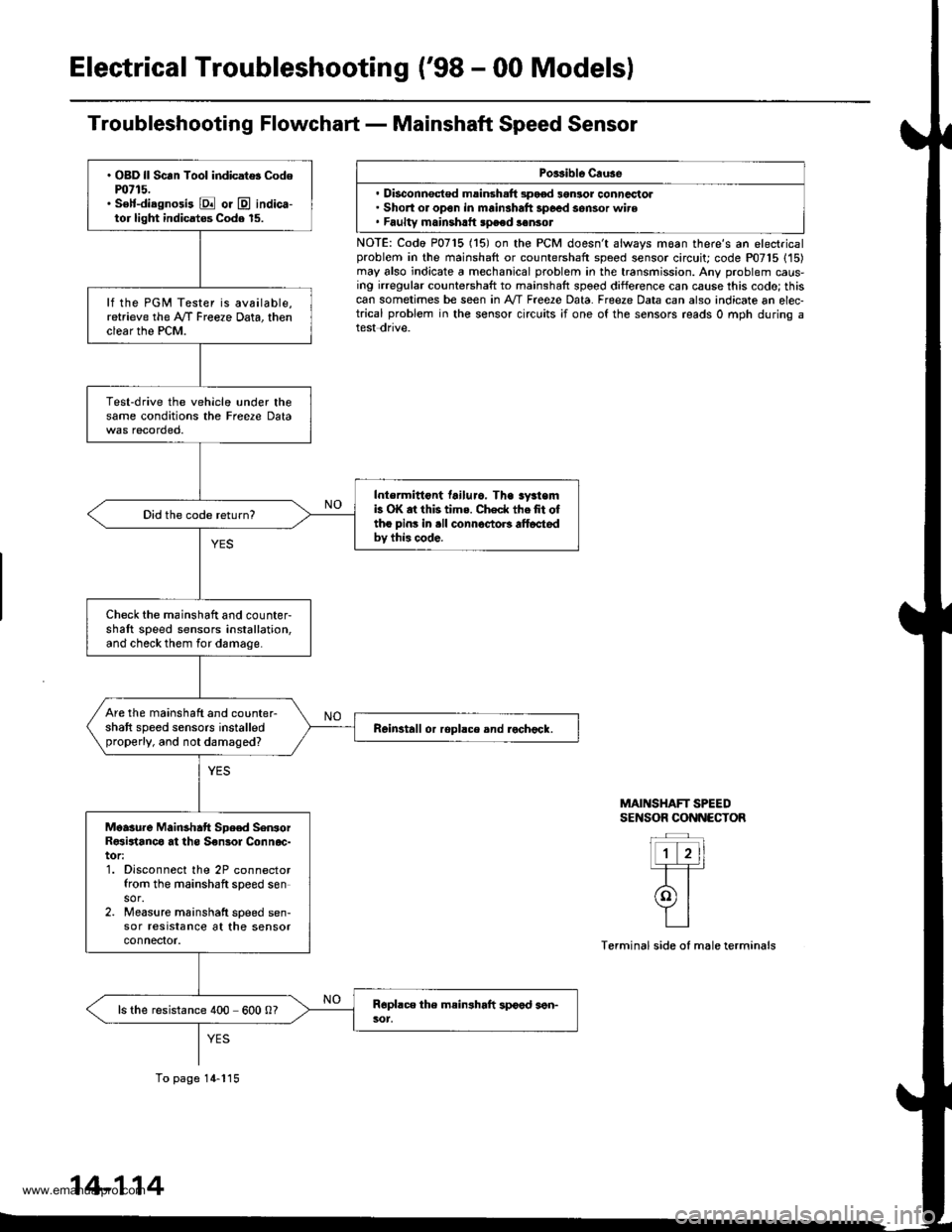

Electrical Troubleshooting ('98 - 00 Modelsl

Troubleshooting Flowchart - Mainshaft Speed Sensor

Porsible Cruse

. Disconnsct€d msinsh.ft 3pood 3gnlor conncctol. Short or open in mainshaft 3poed sensor wire. Faultv mainshrtt speed sonsot

NOTE: Codo P0715 (15) on the PCM doesn't always moan there's an electricalproblem in the mainshaft or countershaft speed sensor circuit; code P07'15 (15)may also indicate a mechanical problem in the transmission. Any problem caus-ing irregular countershaft to mainshaft spoed difference can cause this codo; thiscan sometimes be seen in A'/T Free2e Data. Freeze Data can also indicate an elec-trical problem in the sensor circuits ;f one of the sensors reads 0 mph during atest dnve.

MAINSHAFT SPEEDSENSOR CONNECTOR

Terminal side of male terminals

. OBD ll Scan Tool indicat$ Codem715.. S€lf-diagnosi3 E or @ indica-tor light indicatos Code 15.

lf the PGM Tester is available,retrieve the A/f Freeze Data, thenclear the PCM.

Test-drive the vehicle under thesame conditions the Freere Data

Intermittont tailuro. Tha sy3temb OK at this tims. Check thefit oftho pins in .ll connoctoB alt6ctedbv this code.

Did the code return?

Check the mainshaft and counter-shaft speed sensors installation,and check them for damage.

Are the mainshaft and counter-shaft speed sensors installedproperly, and not damaged?Reinstall or ropllce and rochock.

Moasure Mainshatt Spe€d SenrorR€sirtanco at ths S€nsol Connoc-tor:1. Disconnect the 2P connectorfrom the mainshaft speed sensor.2. Measure mainshatt speed sen-sor resrstance at the sensorconnefior.

ls the resistance 400 600 0?

To page 14-115

14-114

www.emanualpro.com

Page 633 of 1395

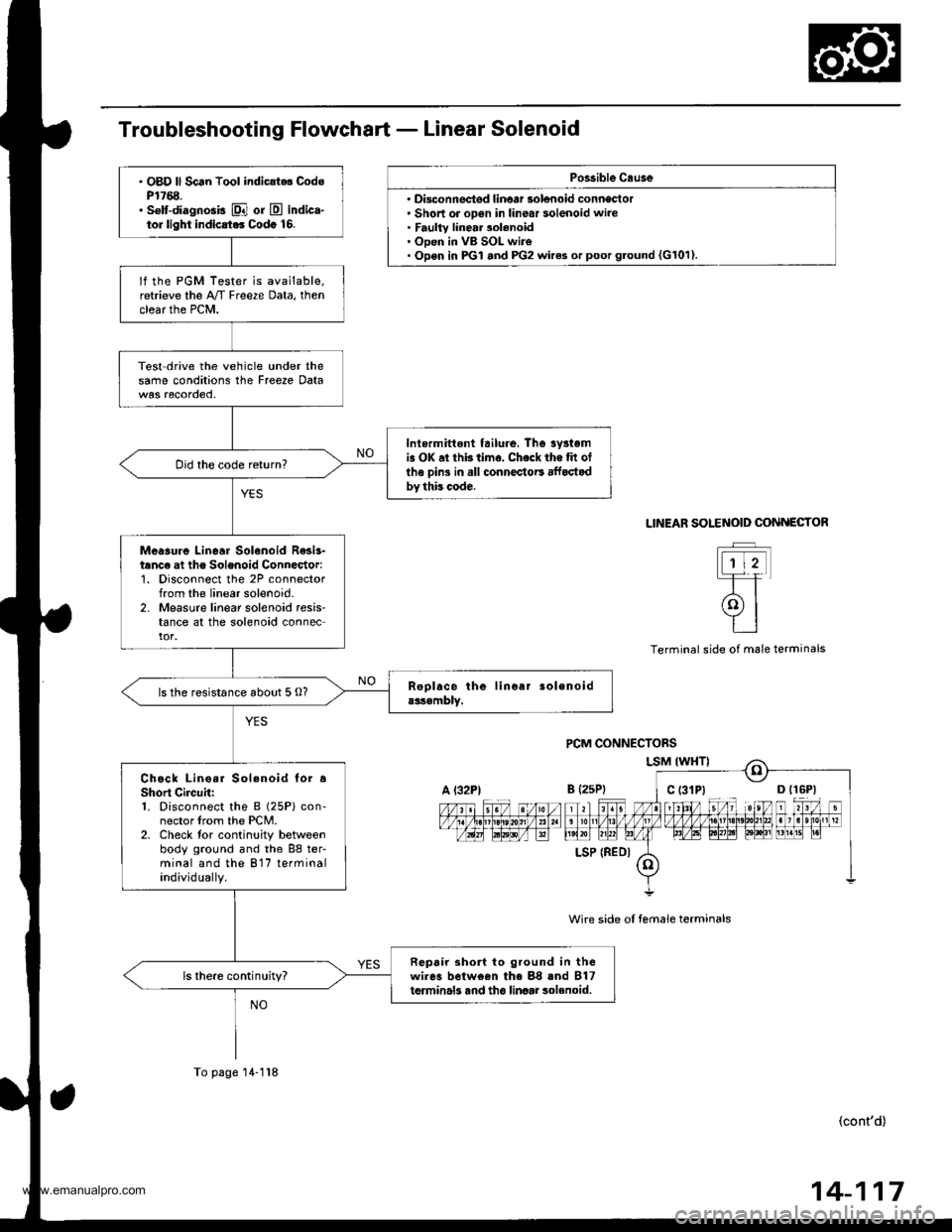

Po$ible Cau3e

' Disconnectsd linoar solenoid conneclol. Short or open in linear solenoid wire. Faulty linear 3olenoid. Open in VB SOL wire. Open in PGI and PG2 wires or poot g.ound {G101).

. OBD ll Scan Tool indic{t.. CodsP1768.. selt-diagnosis El or E indica-tor light indicrt.. Codo 16.

lf the PGM Tester is available.retrieve the A/T Freeze Data, thenclear the PCM.

Test drive the vehicle under thesame conditions the Freeze Data

Inlermittont tailure, The 3yrtomis OK at thb time. Check the tit otlhe oins in all connectoE affoctodby this code.

Did the code return?

Meaaure Linear Solenoid R€sis-tanc€ at the Solenoid Connector:1. Disconnect the 2P connectorfrom the linear solenoid-2. Measure linear solenoid resis-tance at the solenoid connector.

ls the resistance about 5 O?

Chock Lino.r Sol.noid to. aShort Circuh:1. Disconnect the B (25P) con-nector lrom the PCM.2. Check tor continuity betweenbody ground and the 88 ter-minal and the 817 terminalindividually.

Repair 3ho to ground in thewires belween the 88 rnd B17terminals and tho linaar 3olenoid.ls there continuity?

A l32PtB {2sP)

LSP (REDI

To page 14-118

SOLENOID COiINECTOR

t-rtt

(9l

tt

LINEAR

Terminal side ol male terminals

wire side oI temale terminals

(cont'd)

14-117

www.emanualpro.com

Page 635 of 1395

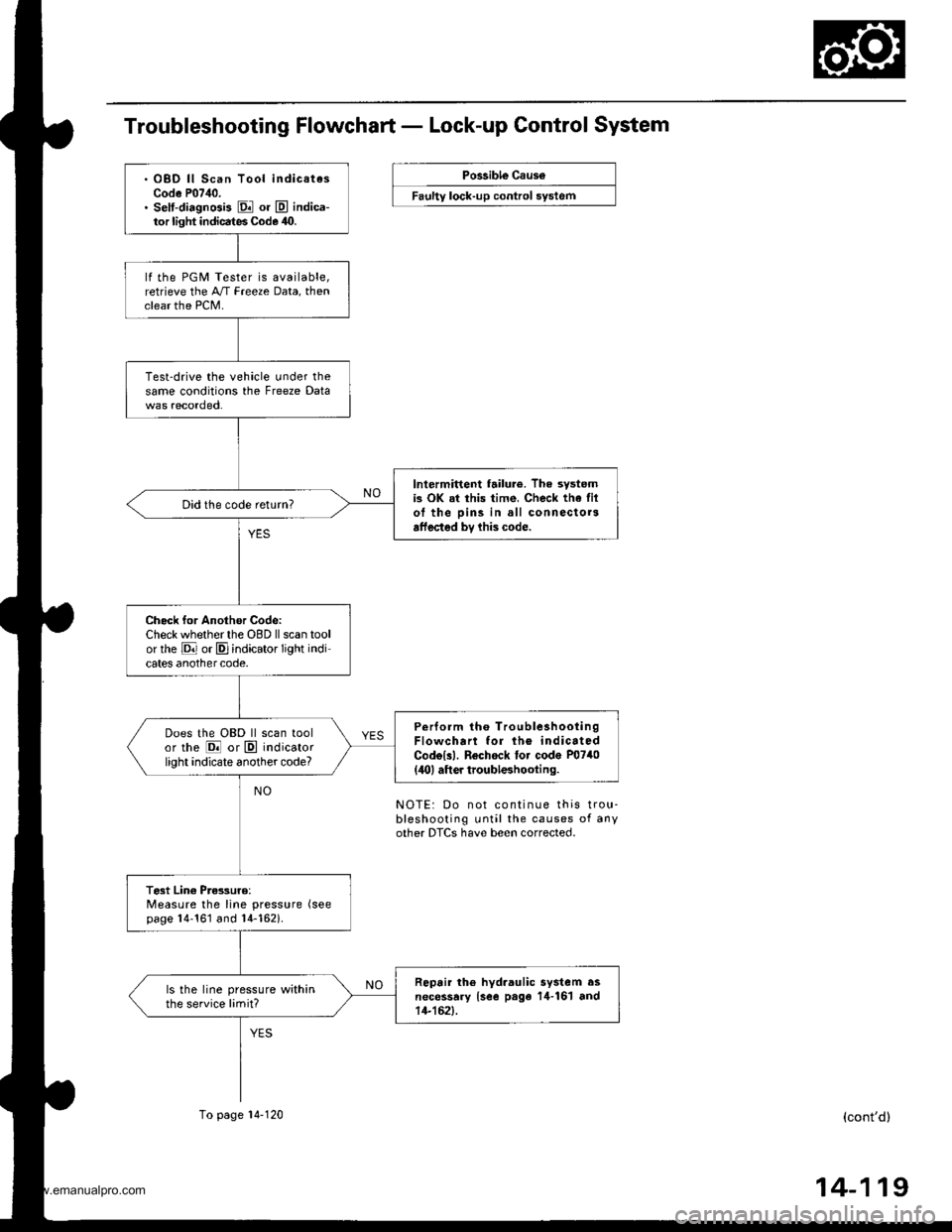

Troubleshooting Flowchart - Lock-up Control System

Possible Caus6

Faulty lock-up control system

. OBD ll Scan Tool indicatesCode P07,10.. selt-diagnGis El or E indica-tor light indicates Code 40.

lf the PGM Tester is available,retrieve the A/T Freeze Data, thenclear the PCM.

Test-drive the vehicle under thesame conditions the Freeze Data

lntermittent failur6. The systemis OK at this time, Check the filol the pins in all connectorsaffected bv lhis code.

Did the code return?

Check for Another Codc:Check whether the OBD ll scan toolor rhe E or E]indicator light indicates anothercode,

Perform tho TroubleshootingFlowchart for lh6 indicatedCodolll. Rechock tor code P0740(,lO) aft er troubleshooting.

Does the OBD ll scan toolor the @ or E indicatorlight indicate another code?

Test Lin€ Pres3uro:Measure the line pressure (see

page 14'161 and 14-162i.

Repair th6 hyd.aulic system asnecessary {see page 14-161 and14-152).

ls the line pressure withinthe service limit?

To page 14-120

NOTE: Do not continue this trou-bleshooting until the causes of anyother DTCS have been corrected.

(cont'd)

14-119

www.emanualpro.com

Page 637 of 1395

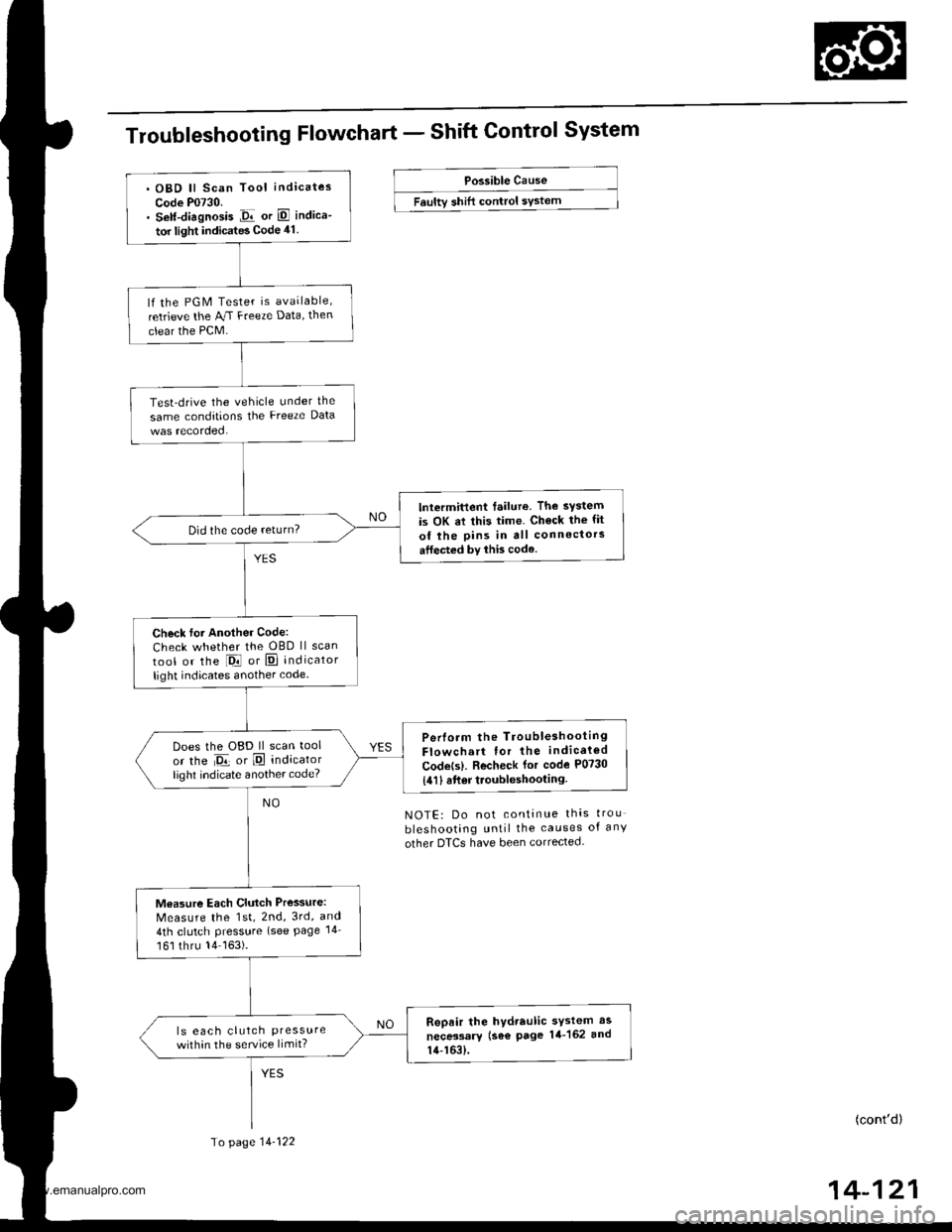

Troubleshooting Flowchart - Shift Control System

Possible Cause

Faultv shift control sYstem

NOTE: Do not continue thas trou

bleshooting until the causes of any

other DTCS have been corrected.

(cont'd)

14-121

. OBD ll Scan Tool indicates

Code P0730.. Self-diagnosis Jir or E indica-

tor light indicates Code 41.

lf the PGM Tester is available,

retrieve the AJ.I Freeze Data, then

clear the PCM.

Test-drive the vehicle under the

same conditions the Freeze Data

lntermittent failure. The system

is OK at this time. Ch€ck the fit

of the pins in all connectors

atfected by this code.

Did the code return?

Check for Another Code:

Check whether the OBD ll scan

tool or the l-Drl or E] indicator

light indicates another code.

Perlorm the TroubleshootingFlowchart for the indicaled

Codets). Recheck for code P0730

{411 6ft6r troubleshooting.

Does the OBD ll scan tool

or the Da or E indicatorlighl indicate another code?

Measure Each Clutch Pressure:

Measure the 1st, 2nd, 3rd, and

4th clutch Pressure (see Page 14

161 thru 14163).

Repair the hydraulic sYstem as

necessary (se€ page 14-162 and

14-163).

ls eac h clutch Pressurewithin the service limit?

To page 14-122

www.emanualpro.com

Page 640 of 1395

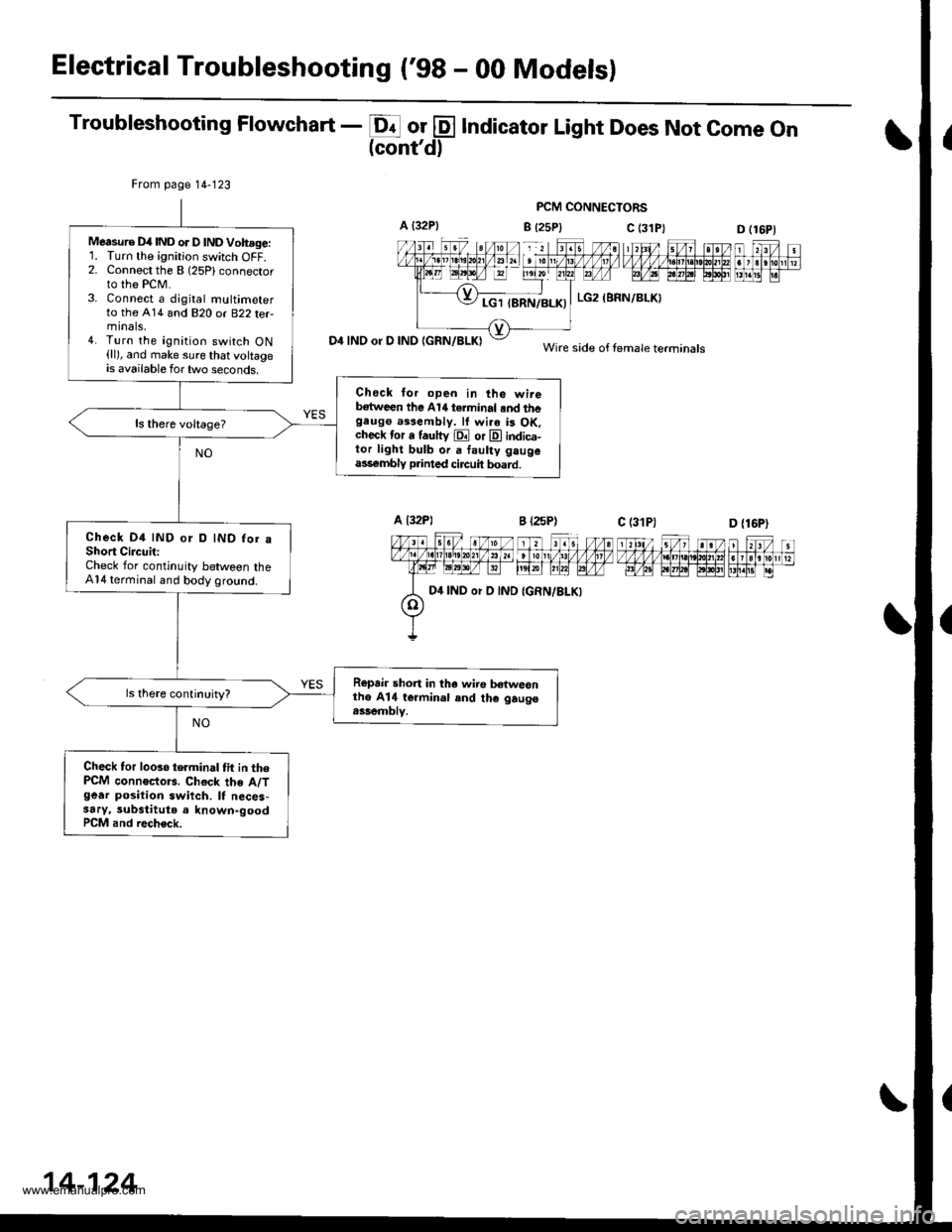

Electrical Troubleshooting ('98 - 00 Modelsl

Troubleshooting Flowchart - E or @ Indicator Light Does Not come on(cont'd)

PCM CONNECTORS

B {25P} C (3D (16P1

n f,-ff nt f,Fjrti.trnnmflnr

D4 INO or D IND IGRN/BLKI

From page 14-123

Measure D4IND or D lNDVoh.ge:'L Turn the ignition switch OFF.2. Connect the B (25Plconnector

to the PCM.3. Connect a djgital multimeterto the A14 and 820 or B22 terminals,4. Turn the ignition switch ON(ll), and make sure that voltageis available for two seconds.

Check lor open in the wireb€tween the Al/t terminal .nd thegeugo a$eftbly. lf wi.a is OK.check tor a fautty E or E indica-tor light bulb or a faulty gaugeass€mbly p.inted circuit board.

Check D4 IND or D IND for aShort CircuitiCheck for continuity between theA14 terminal and body ground.

Ropair short in tha wiro b€twesnthe A14 termin.l and th€ gaugo.ssemblv.

Check tor looso telminal tit in thePCM connoctors. Chock the A/Tgear position swiich. It neces-3ary, substitute a known-goodPCM and rech€ck.

c (31P)

LG2 (BRN/BLKI

Wire side of female terminals

D {16P)

D4 IND or D IND

14-124

www.emanualpro.com

Page 645 of 1395

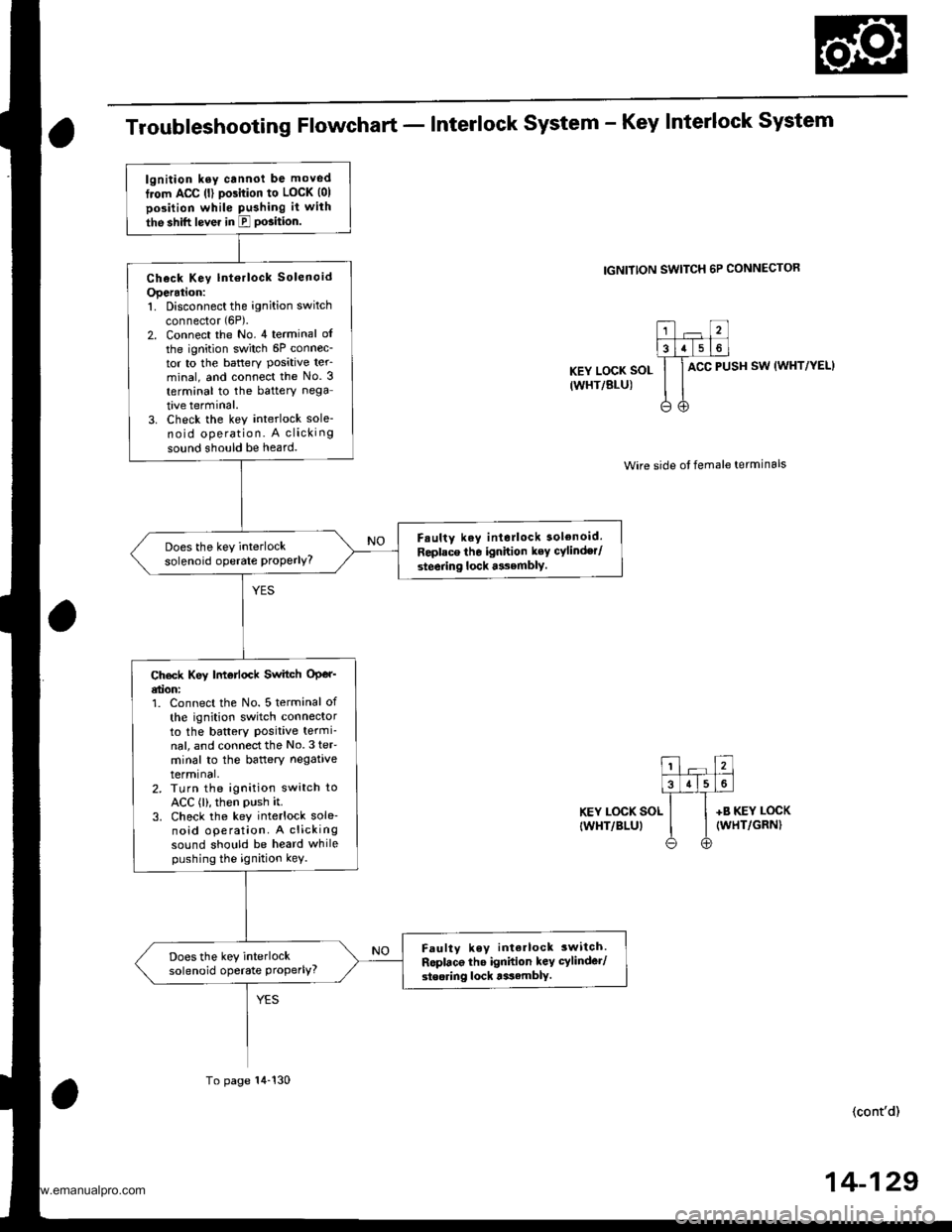

Troubleshooting Flowchart - Interlock system - Key Interlock system

IGNITION SWITCH 6P CONNECTOR

KEY LOCK SOL

IWHT/BLU)

ACC PUSH SW (WHT/YEL}

Wire side ot female terminals

KEY LOCK SOL

IWHT/BLUI

+B KEY LOCK(WHT/GRN)

(cont'd)

lgnition ksy cannot be moved

from ACC (l) pGition to LOCK (01

position while Pushing it with

the shift lever in E PGition.

Check Key lntorlock Solenoid

Operation:1. Disconnect the ignition switch

connector (6P).

2. Connect the No. 4 terminal of

the ignition switch 6P connec-tor to the battery Posative ter_minal, and connect the No. 3

terminal to the battery nega

tive terminal.3. Check the key interlock sole-no id operation. A clicking

sound should be heard.

F.ulty key interlock solenoid.

Replace tho ignition key cylinder/

steering lock asembly.

Does the key interlocksolenoid operate ProPerlY?

Ch€ck Key |motlock Switch OPer'etion:1. Connect the No. 5 terminal of

th€ ignition switch connectorto the battery Positive termi-nal, and connectthe No.3 teF

minal to the baftery negativetermrnal,2. TLrrn the ignition switch toACC (l), then PUsh it.3. Check the key interlock sole-noid operation. A clickingsound should be heard whilepushing the ignition kev.

Faulty key interlock 3witch.

Roplaco the ignidon key cylinder/

steoring lock tssamblY.

Does the key interlocksolenoid operate Properly?

To page 14-130

14-129

www.emanualpro.com

Page 658 of 1395

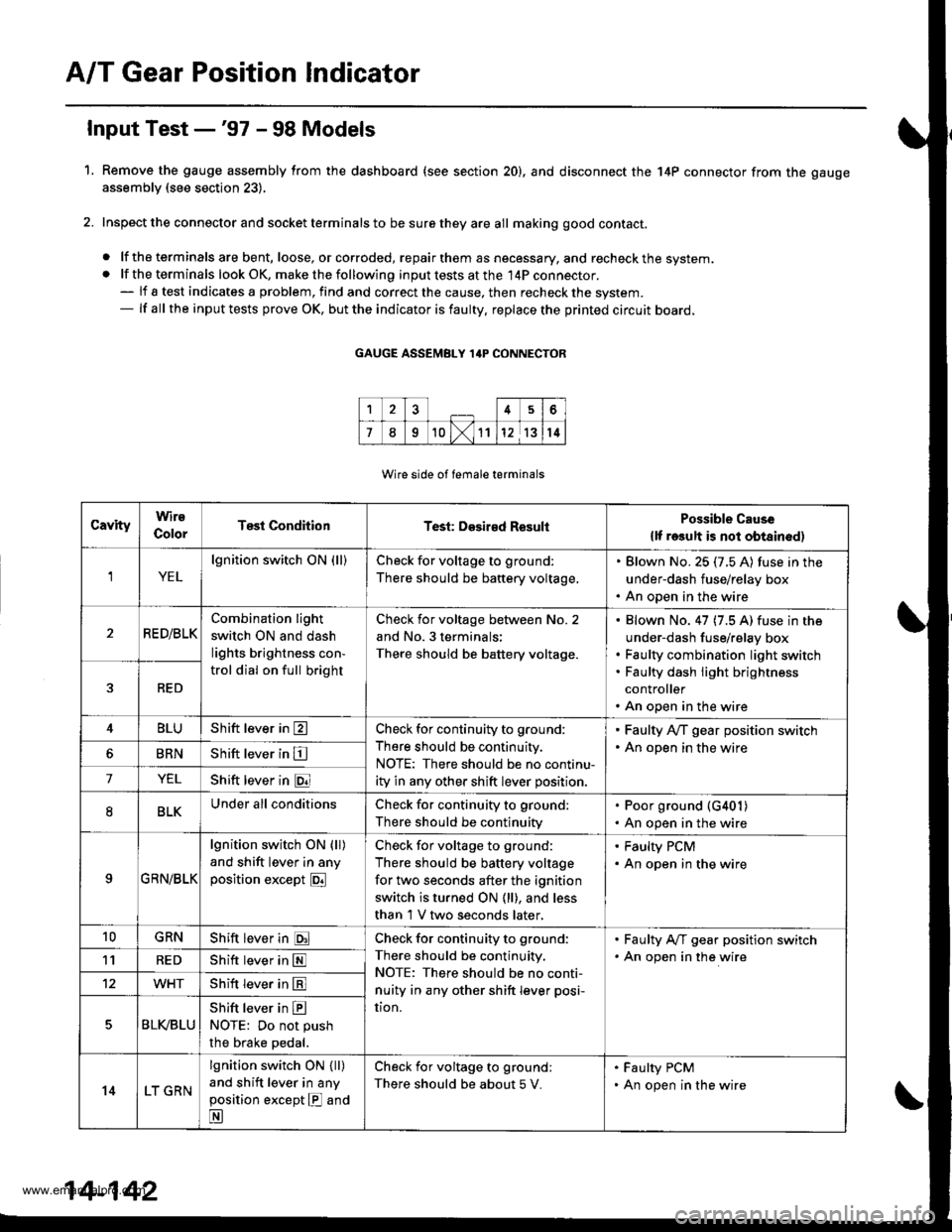

A/T Gear Position Indicator

1.

f nput Test -'97 - 98 Models

Remove the gauge assembly from the dashboard (see section 20). and disconnect the 14P connector from the gauge

assemblv (see section 23),

Inspect the connector and socket terminals to be sure they are all making good contact.

. lf the terminals are bent, loose, or corroded, repairthem as necessary, and recheck the system.. lf the terminals look OK, make the following input tests at the 14P connector.- lf I test indicates a problem, find and correct the cause, then recheck the system.- lf all the input tests prove OK, but the indicator is faulty. replace the printed circuit board,

GAUGE ASSEMBLY 14P CONNECTOR

Wire side of female terminals

CavityWirs

ColorTest ConditionTest: Desir€d ResultPossible Cause

{lf rosult is not obtainod)

YEL

lgnition switch ON (ll)Check for voltage to ground:

There should be battery voltage,

. Blown No. 25 (7.5 A) fuse in the

under-dash fuse/relay box. An open in the wire

RE D/BLKCombination light

switch ON and dash

lights brightness con-

trol dial on full bright

Check for voltage between No. 2

and No. 3 terminals;

There should be battery voltage.

Blown No. 47 (7.5 A) fuse in the

under-dash fuse/relay box

Faulty combination Iight switch

Faulty dash iight brightness

controller

An open in the wire

RED

4BLUShift lever in ECheck for continuity to ground:

There should be continuity.

NOTE: There should be no continu-

ity in any other shift lever position.

' Faulty Ay'T gear position switch. An open in the wireBRNShift lever in E

7YELShift lever in @

8BLKUnder all conditionsCheck for continuity to ground:

There should be continuity

. Poor ground {G401). An open in the wire

9GRN/BLK

lgnition switch ON {ll)

and shift lever in any

position except E

Check for voltage to ground:

There should be battery voltage

for two seconds after the ignition

switch is turned ON {ll), and less

than 1 V two seconds later,

' Faulty PCM. An open in the wire

10GRNShift lever in ECheck for continuity to ground:

There should be continuity.

NOTE: There should be no conti-

nuity in any other shift lever posi-

UOn.

. Faulty A,ff gear position switch. An open in the wire1'lREDShift lever in @

12WHTShift lever in E

BLVBLU

Shift lever in ENOTE: Do not push

the brake pedal.

14LT GRN

lgnition switch ON { ll)

and shift lever in any

position except E and

E

Check for voltage to ground:

There should be about 5 V.

. Faulty PCM. An open in the wire

14-142

www.emanualpro.com

Page 659 of 1395

L

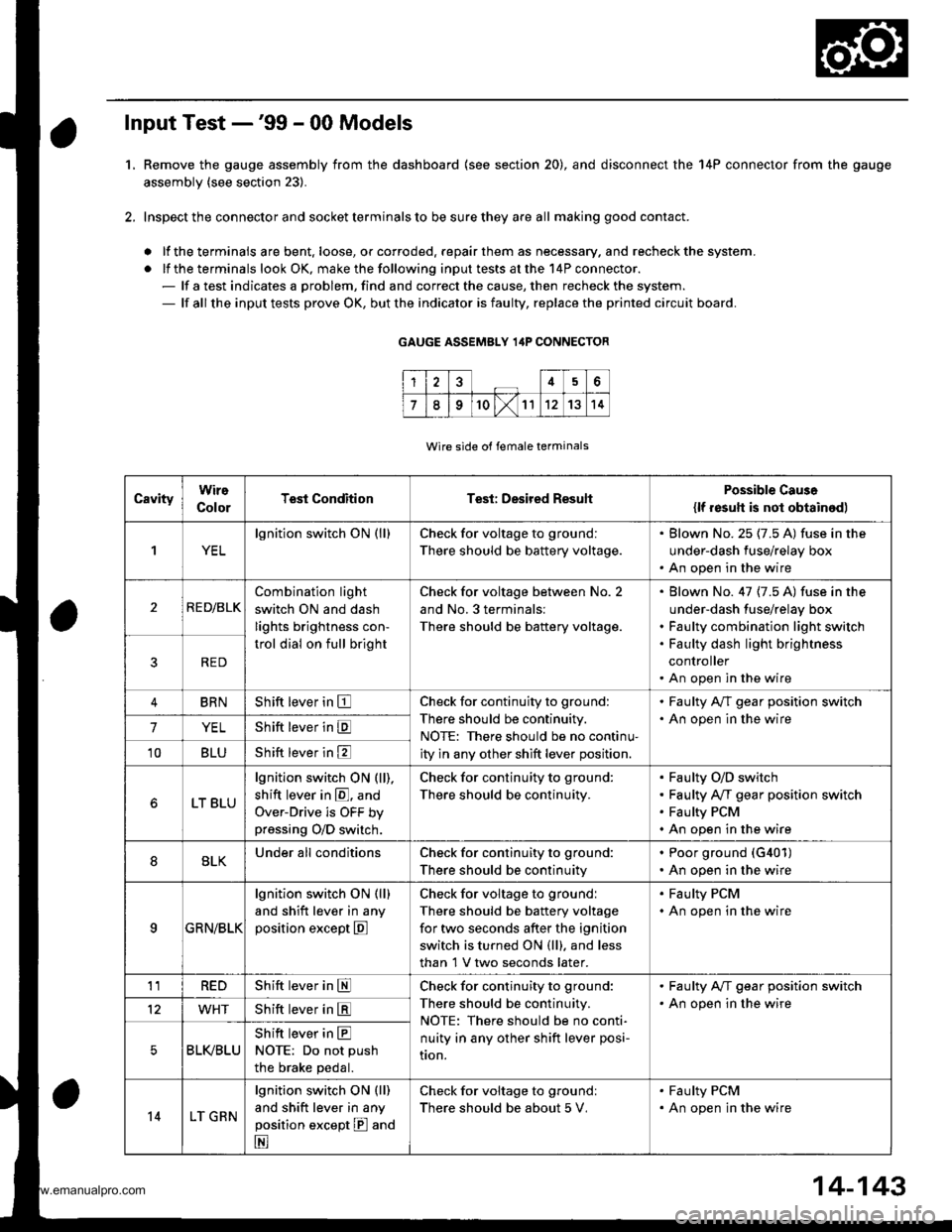

Input Test -'99 - 00 Models

Remove the gauge assembly from the dashboard {see section 20), and disconnect the 14P connector from the gauge

assembly (see section 23).

Inspect the connector and socket terminals to be sure they are all making good contact.

a lf the terminals are bent. loose, or corroded. repair them as necessary. and recheck the system.

. lf the terminals look OK, make the following input tests at the 14P connector.- lf a test indicates a problem, find and correct the cause, then recheck the system.- lf all the input tests prove OK, but the indicator is faulty, replace the printed circuit board.

GAUGE ASSEMBLY 14P CONNECTOR

Wire side of female terminals

CavityWire

ColorTest ConditionTest: Desired ResuhPossible Caus6

{lf resutt is not obtainod)

1YEL

lgnition switch ON (ll)Check for voltage to ground:

There should be battery voltage.

. Blown No.25 (7.5 A) fuse in the

under-dash fuse/relay box. An open in the wire

2RE D/BLK

Combination light

switch ON and dash

lights brightness con-

trol dial on full bright

Check for voltage between No. 2

and No.3 terminals:

There should be battery voltage.

Blown No. 47 {7.5 A) fuse in the

under-dash fuse/relay box

Faulty combination light switch

Faulty dash light brightness

controller

An open in the wire

5RED

BRNShift lever in ECheck for continuity to ground:

There should be continuity.

NOTE: There should be no continu-

ity in any other shift lever position.

. Faulty A/T gear position switch. An open in the wire7YELShift lever in E

'10BLUShift lever in E

LT BLU

lgnition switch ON (ll),

shift lever in E. and

Over-Drive is OFF bypressing O/D switch.

Check for continuity to ground:

There should be continuity.

Faulty O/D switch

Faulty A/T gear position switch

Faulty PCM

An open in the wire

8BLKUnder all conditionsCheck for continuity to ground:

There should be continuity

. Poor ground (G401)

. An open in the wire

9a:FI\|/Et| ta

lgnition switch ON (ll)

and shift lever in any

position except E

Check for voltage to groundl

There should be battery voltage

for two seconds after the ignition

switch is turned ON (ll). and less

than 1 V two seconds later.

. Faulty PCM. An open in the wire

11REDShift lever in SCheck for continuity to ground:

There should be continuity.

NOTE: There should be no conti-

nuity in any other shift lever posi-

Iton.

. Faulty A/T gear position switch. An open in the wire12WHTShift lever in E

BLI(BLU

Shift lever in ENOTE: Do not push

the brake pedal.

14LT GRN

lgnition switch ON (ll)

and shift lever in any

position except E and

E

Check for voltage to groundl

There should be about 5 V,

. Faulty PCM. An open in the wire

14-143

www.emanualpro.com

Page 660 of 1395

Interlock System

Interlock Control Unit Input Test

SRS components are located in this area. Review the SRS component locations, precautions, and procedures in the SRS

section (24) before performing repairs or service.

'1. Remove the instrument panel lower cover (see section 20).

2. Disconnect the 8P connector from the interlock control unit.

3. Inspect the connector and connector terminals to be sure they are all making good contact.

. lf the terminals are bent, loose, or corroded, repair them as necessary, and recheck the system

. lf the terminals look OK, make the following input tests at the connector.

- lf a test indicates a problem, find and correct the cause, then recheck the system

- lf all the input tests prove OK, substitute a known-good control unit, and recheck the system. lf the check is OK,

the control unit must be faulty; replace it.

NOTE: lf the shift lock solenoid clicks when the ign ition switch is tu rned ON (ll) while pressing the brake pedal withthe

shift lever in E position, the shift lock system is OK. lf the shift lever cannot be shifted from E position. test the A/T

gear position switch.

14-144

www.emanualpro.com