Transmission front HONDA CR-V 1999 RD1-RD3 / 1.G Owner's Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1999, Model line: CR-V, Model: HONDA CR-V 1999 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 775 of 1395

Transmission

1.

lnstallation

Flush the ATF cooler as described on page 14-264

and 14-265.

Install the torque converter assembly on the main-

shaft with a new O-ring.

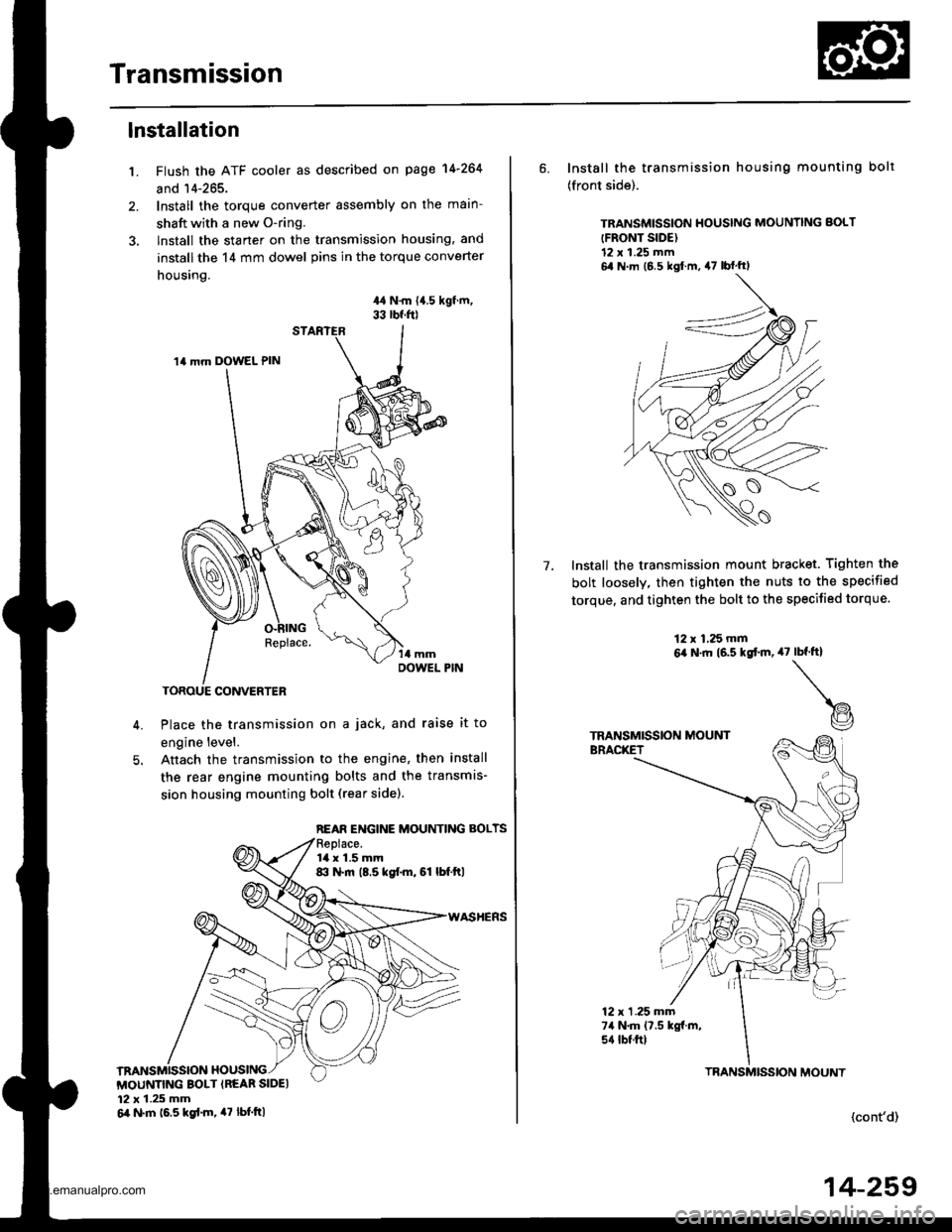

lnstall the starter on the transmission housing, and

install the 14 mm dowel pins in the torque converter

housing.

44 N.m {{.5 kgf.m,33 rbf.f0

Place the transmission on a jack, and raise it to

engine level.

Anach the transmission to the engine, then install

the rear engine mounting bolts and the transmis-

sion housing mounting bolt (rear sidel.

14 mm DOWEL PIN

REAR ENGINE MOUNTING BOLTS

la x 1.5 mm8:l N.m (8.5 kgf.m, 61 lbf.ftl

MOUNTING BOLT {REAR SIDEI12 x 1.25 mm6il N.m 16.5 kgd.m, 47 tbt.ttl

6. Install the transmission housing mounting bolt

(front side).

TRANSMISSION HOUSING MOUNNNG BOLT

{FRONT SIDE)12 x 1.25 mm6,1 N m (6 5 kgl m, 47 lbf'ftl

Install the transmission mount bracket. Tighten the

bolt loosely, then tighten the nuts to the specified

torque, and tighten the bolt to the specified torque.

7.

12 x 1,25 mm6,a N.ft (6.5 kgtm,47rbf.ft)

t@

TRANSMISSION MOUNTBRACKET

12 x 1 .25 mm74 N.m (7.5 kgf.m,s{ tbtftl

(cont'd)

TBANSMISSION MOUNT

14-259

www.emanualpro.com

Page 776 of 1395

Transmission

Installation (cont'dl

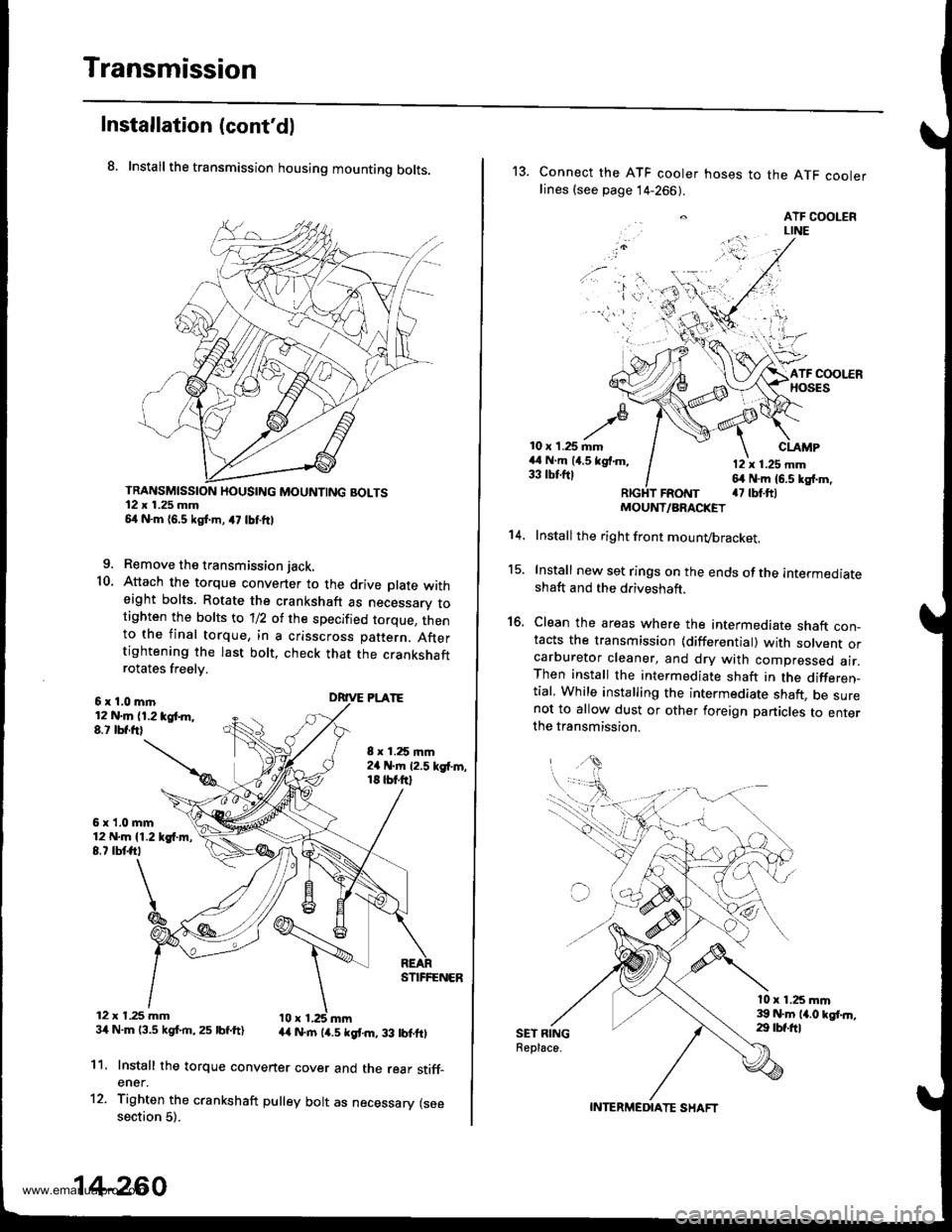

8. Install the transmission housing mounting bolts.

TRANSMISSION HOUSING MOUNTING BOLTS12 x 1.25 mm54 N.m 16,5 kgf.m, a7 lbtftl

9. Remove the transmission jack.

10. Attach the torque convener to the drive plate witheight bolts. Rotate the crankshaft as necessarv totighten the bolts to 'll2 of the specified torque, thento the final torque, in a crisscross pattern. Aftertightening the last bolt. check that the crankshaftrotates freelv.

6x1.0mln12 N.m (1.2 tgt m,8.t lbf.frl

6x1.0mm12 N.m {1.219{.m,8.7 tbtft,

12 x t.25 mm34 N.m 13.5 kgf.rn,25 lbf.ft)

8 x 1.25 mm2a N.m 12.5 kgf'm,18 tbt.ftl

DRIVE PLATE

STIFFENER

44 N.rn (4.5 kgt m, 33 lbtftl

11.

12.

Install the torque convener cover and the rear stiff_ener.

Tighten the crankshaft pulley bolt as necessary (seesection 5).

14-260

13. Connect the ATF cooler hoses to the ATF coolerlines (see page 14-266).

. ATF COOLERLINE

'i 'l'r',:,.) -

10 x 1.25 mm44 N.m (4.5 kgf.m,33 tbtftl

CLAMP

12 x 1.25 mm64 N.m 16.5 kg{.m,a7 tbt.ftlFRotrtT

15.

16.

't 4.

SET RINGReplace.

MOUNT/ARACKET

Install the right front mounvbracket.

Install new set rings on the ends of the intermediateshaft and the driveshaft.

Clean the areas where the intermediate shaft con_tacts the transmission {differential) with solvent orcarburetor cleaner, and dry with compressed air.Then install the intermediate shaft in the differen_tial, While installing the intermediate shaft, be surenot to allow dust or other foreign panicles to enterthe transmission.

l0 x 1.25 mm39 N.m 14.0 kgt.n,29 tbf.ftl

INTERMEDIATE SHAFT

www.emanualpro.com

Page 802 of 1395

Real-time 4WD-Dual Pump System

Troubleshooting (Automatic Transmission/Manual Transmission)

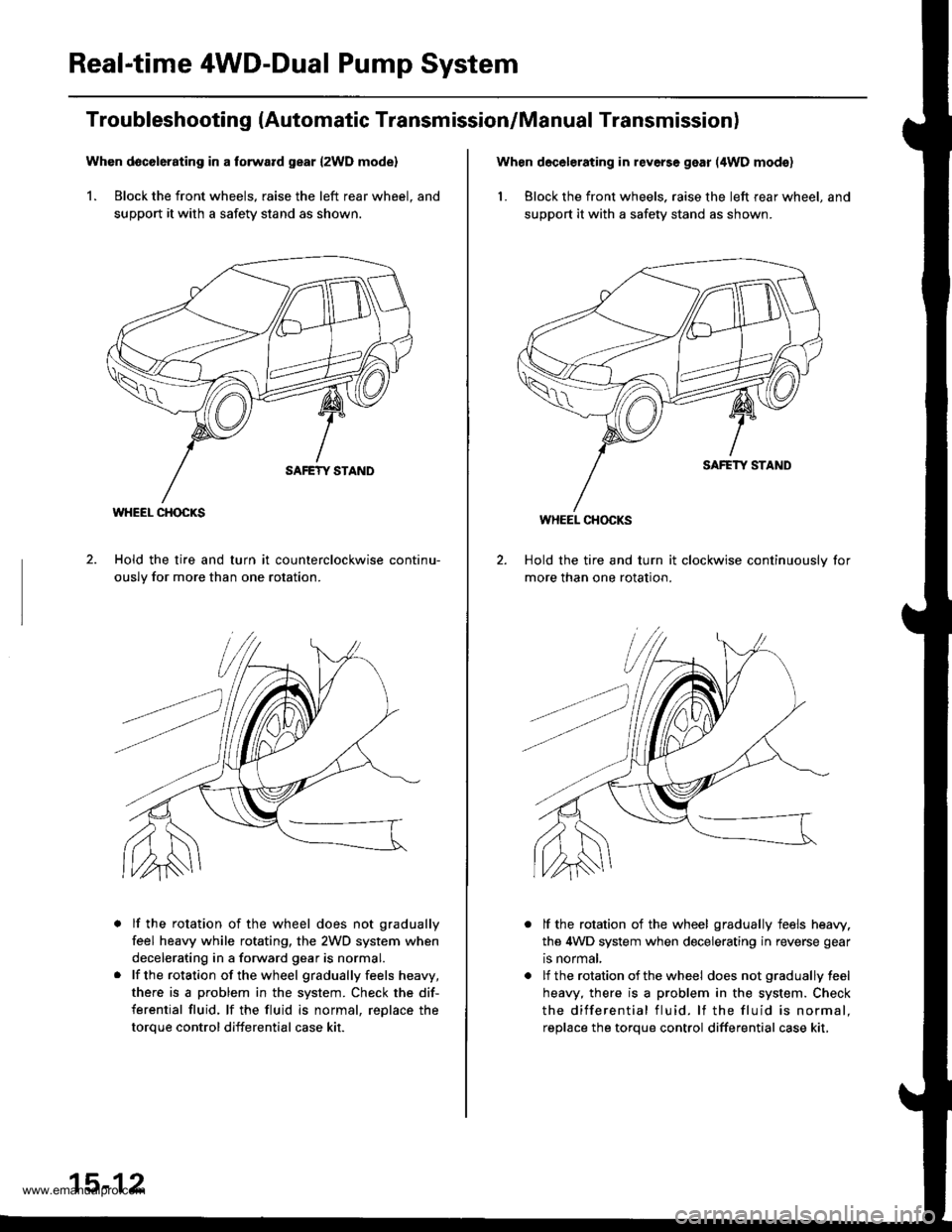

Whon d6c6l6rating in a torward gear {2WD mode}

1. Block the front wheels, raise the left rear wheel. and

support it with a safety stand as shown.

Hold the tire and turn it counterclockwise continu-

ouslv for more than one rotation.

lf the rotation of the wheel does not gradually

feel heavy while rotating, the 2WD system when

decelerating in a forward gear is normal.

lf the rotation of the wheel gradually feels heavy,

there is a problem in the system. Check the dif-

ferential fluid, lf the fluid is normal, reDlace the

toroue control differential case kit.

WHEEL CHOCKS

15-12

When decelerating in reverse gear (4WD mod€)

1. Block the front wheels. raise the left rear wheel, and

suppo( it with a safety stand as shown.

Hold the tire and turn it clockwise continuouslv for

more than one rotation.

lf the rotation of the wheel gradually feels heaw.

the 4WD system when decelerating in reverse gear

is normal,

lf the rotation of the wheel does not gradually feel

heavy, there is a problem in the system. Check

the differential fluid. lf the fluid is normal.

reolace the torque control differential case kit,

WHEEL CHOCKS

www.emanualpro.com

Page 818 of 1395

DriveshaftsFront Driveshafts

Inspection

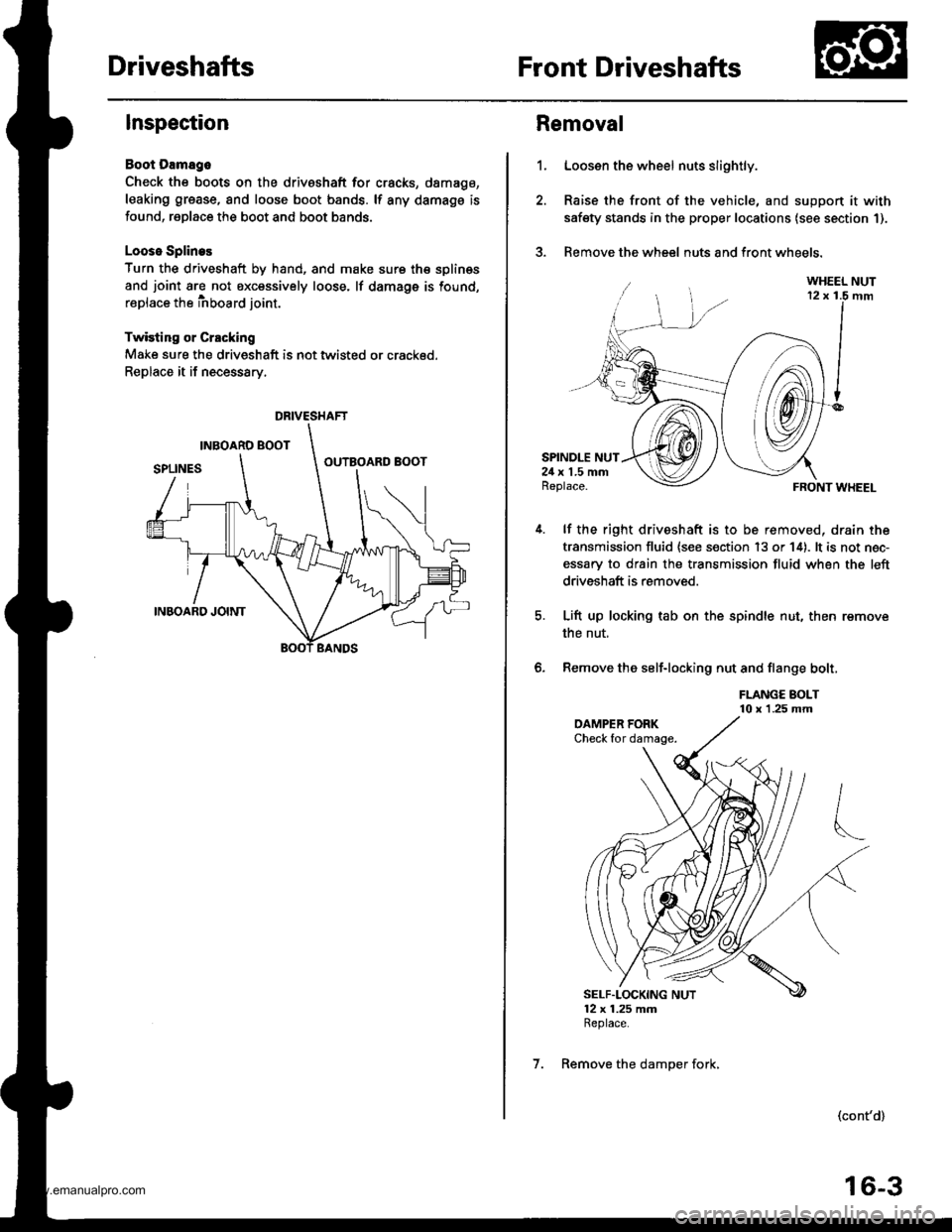

Boot Damago

Check the boots on the driveshaft for cracks, damago,

leaking grease, and loose boot bands. lf any damags is

found, replace the boot and boot bands.

Looso Splines

Turn the driveshaft by hand, and make sure th€ splin€s

and joint are not excessively loose. lf damage is found,

replace the inboard joint.

Twisting or Crscking

Make sure the driveshaft is not twisted or crackod.

Replace it if necessary.

DRIVESHAFT

1.

Removal

Loosen the wheel nuts slightly.

Raise the front of the vehicle, and suppon it with

safety stands in the proper locations (see section 1).

Remove the wheel nuts and front wheels.?

SPINDLE NUT24 x 1.5 mmReplace.

lf the right driveshaft is to be removed, drain the

transmission fluid {see s€ction 13 or 14). lt is not nec-

essary to drain the transmission fluid when the left

driveshaft is removed.

Lift up locking tab on the spindle nut, then remove

the nut,

Remove the self-locking nut and flange bolt,

FLANGE BOLT10 x 1.25 mm

FRONT WHEEL

(cont'd)

6.

SELF"LOCKING NUT12 x 1.25 mmReplace.

7. Remove the damper fork,

16-3

www.emanualpro.com

Page 833 of 1395

Front DriveshaftsIntermediate Shaft

Installation {cont'd}

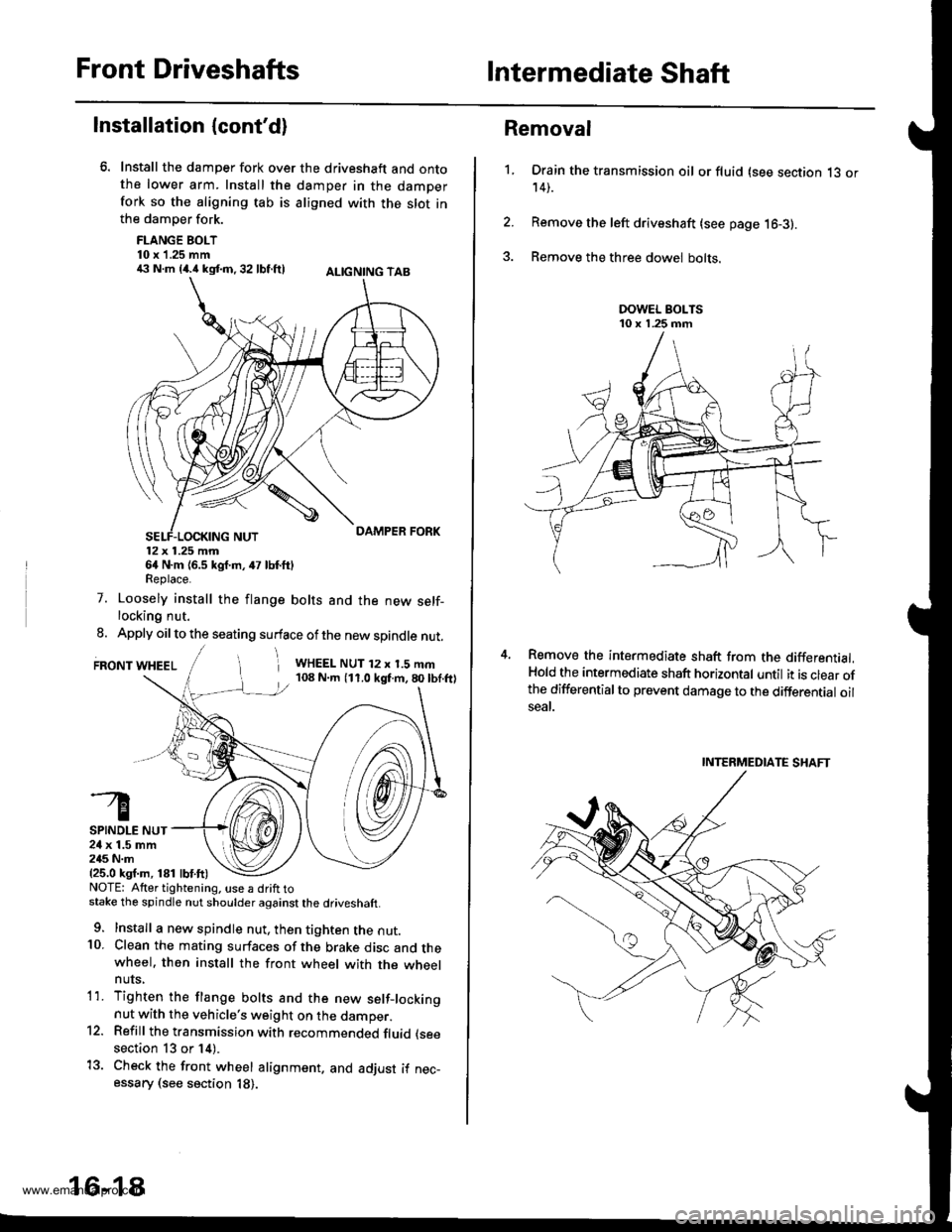

Install the damper fork over the driveshaft and ontothe lower arm. Install the damper in the damperfork so the aligning tab is aligned with the slot inthe damper fork.

FLANGE BOLT10 x 1.25 mm€ N.m {4.i1kst.n,32 lbf.ftl ALtcNtNG TAB

12x 1.25 mm64 N.m {6.5 kgf.m, 47 lbf.ftlReplace.

7. Loosely install the flange bolts and the new self-locking nut.

8. Apply oil to the seating surface of the new spindle nut.

FRONT WHEELi WHEEL NUT 12 x 1.5 mm108 N.m (11.0 kgf.m,80lbf.ftl

SPINDLE NUT24 x 1.5 mm245 N.m{25.0 ksf.m, 181 lbf.ft)NOTE: Atter tightening. use a drift tostake the spindle nut shoulder against the driveshaft.

9. Install a new spindle nut, then tighten the nut.10. Clean the mating surfaces of the brake disc and thewheel. then install the front wheel with the wheelnuts,

1'1. Tighten the flange bolts and the new setf-lockingnut with the vehicle's weight on the damper.12. Refill the transmission with recommended fluid (see

section 13 or 14).

13. Check the front wheel alignment. and adjust if nec-essary (see section 18).

16-18

1.

Removal

Drain the transmission oil or fluid (see section 13 or14).

Remove the left driveshaft (see page 16-3).

Remove the three dowel bolts.

Remove the intermediate shaft from the differential.Hold the intermediate shaft horizontal until it is clear ofthe differentialto prevent damage to the differential oilseal.

INTERMEDIATE SHAFT

www.emanualpro.com

Page 876 of 1395

Power Steering Gearbox

Removal

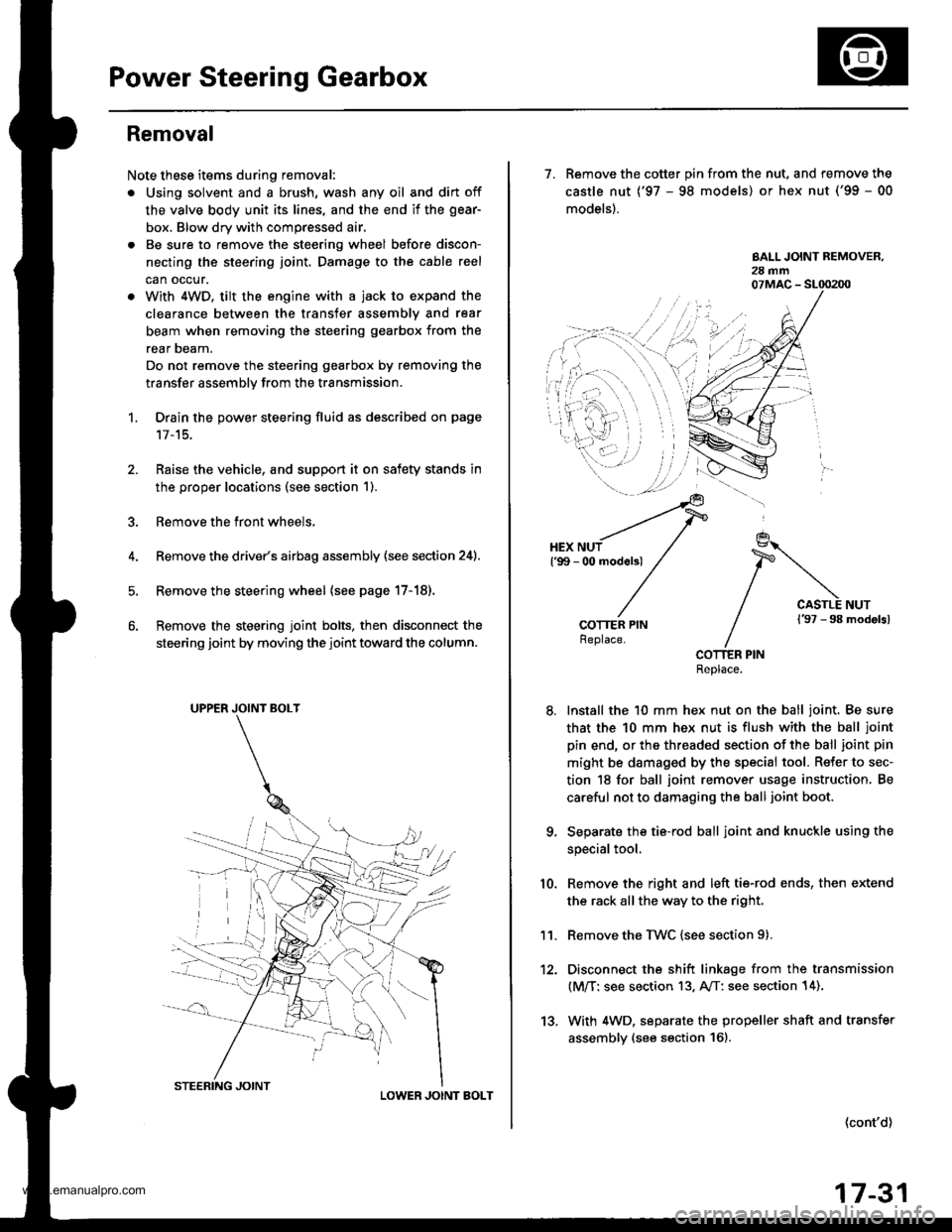

Note these items during removal:

. Using solvent and a brush, wash any oil and dirt off

the valve body unit its lines, and the end if the gear-

box. Blow dry with compressed air.

. Be sure to remove the steering wheel before discon-

necting the steering joint. Damage to the cable reel

can occur.

. With 4WD. tilt the engine with a jack to expand the

clearance between the transfer assembly and rear

beam when removing the steering gearbox from the

rear oeam.

Do not remove the steering gearbox by removing the

transfer assembly from the transmission.

1. Drain the power steering fluid as described on page'17-15.

Raise the vehicle, and suppon it on safety stands in

the proper locations (see section 1).

Remove the front wheels,

Remove the drive/s airbag assembly {see section 24).

Remove the steering wheel {see page 17-18).

Remove the steering joint bolts, then disconnect the

steering joint by moving the joint toward the column.

UPPER JOINT BOLT

LOWER JOINT BOLT

13.

7. Remove the cotter pin from the nut, and remove the

castle nut {'97 - 98 models) or hex nut ('99 - 00

models).

COTTER PINReplace.

Install the 10 mm hex nut on the ball joint. Be sure

that the 10 mm hex nut is flush with the ball joint

pin end, or the threaded section of the ball joint pin

might be damaged by the special tool. Refer to sec-

tion 18 for ball joint remover usage instruction, Be

careful not to damaging the ball joint boot.

Separate the tie-rod ball joint and knuckle using the

special tool.

Remove the right and left tie-rod ends, then extend

the rack all the way to the right.

Remove the TWC (see section 9).

Disconnect the shift linkage from the transmission

(M/T: see section 13, A/T: see section 14).

With 4WD. separate the propeller shaft and transfer

assembly (see section 161.

10.

11.

(cont'd)

17-31

www.emanualpro.com

Page 877 of 1395

Power Steering Gearbox

AN'USTABLE HOSE CLAMP

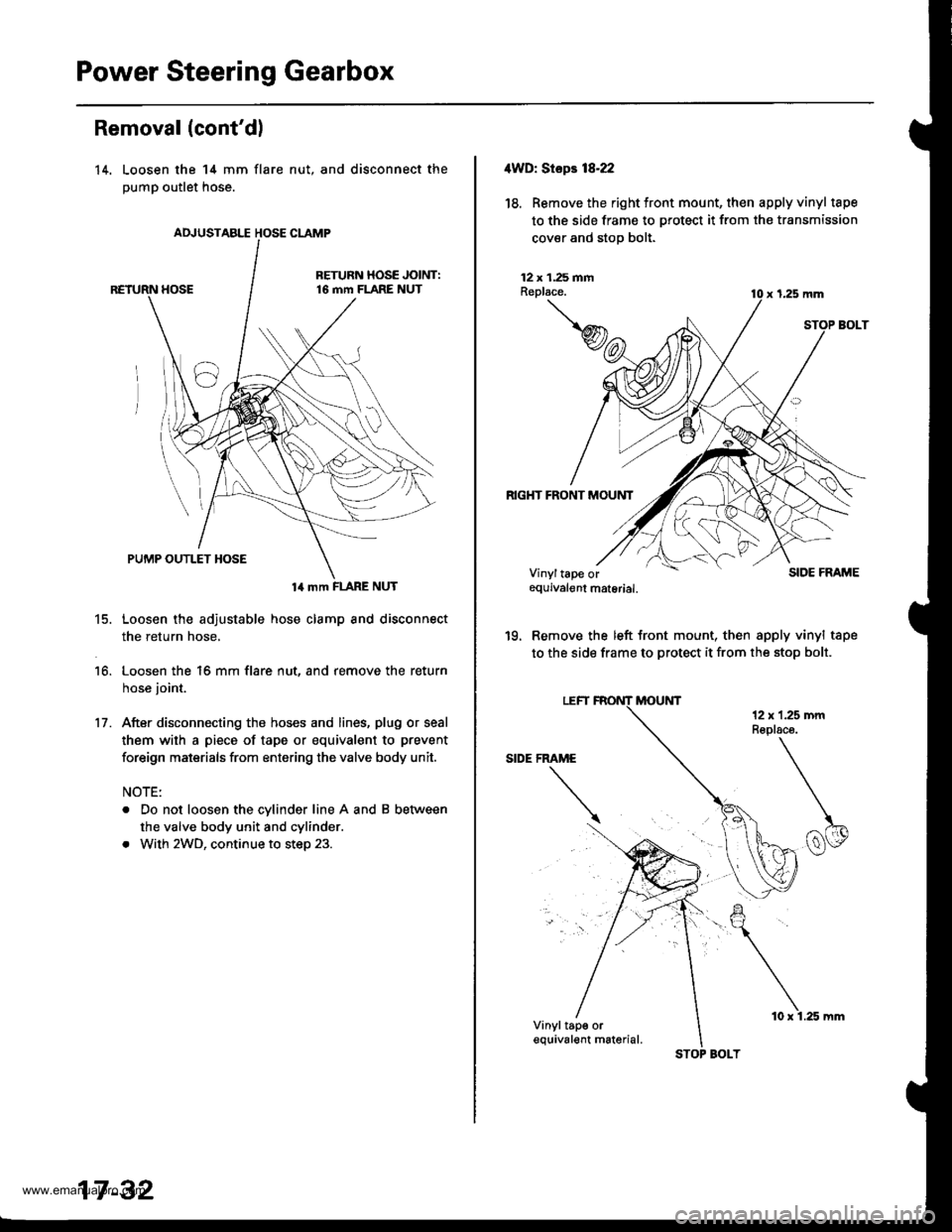

Removal (cont'dl

14. Loosen the 14 mm flare

pump outlet hose.

nut, and disconnect the

14 mm FLARE NUT

15. Loosen the adjustable hose clamp and disconnect

the return hose,

16. Loosen the 16 mm flare nut, and remove the return

hose joint.

17. After disconnecting the hoses and lines, plug or seal

them with a piece of tape or equivalent to prevent

foreign maisrials from entering the valve body unit.

NOTE:

. Do not loosen the cylinder line A and B between

the valve body unit and cylinder.

. With 2WD, continue to step 23.

17 -32

STOP BOLT

10 x 1.25 mm

4WD: Stepr 18-22

18. Removethe right tront mount, then apply vinyl tape

to the side frame to protect it from the transmission

cover and stop bolt.

12 x 1.25 fiiAReplace.

RIGHT FRONT MOUNT

x 1,25 mm

SIDE FRAME

'19. Remove the left front mount, then apply vinyl tape

to the side frame to protect it from the stop bolt.

Vinyltape orequivalgnt material.

Vinyltap€ orequival€nt m6terial.

www.emanualpro.com

Page 898 of 1395

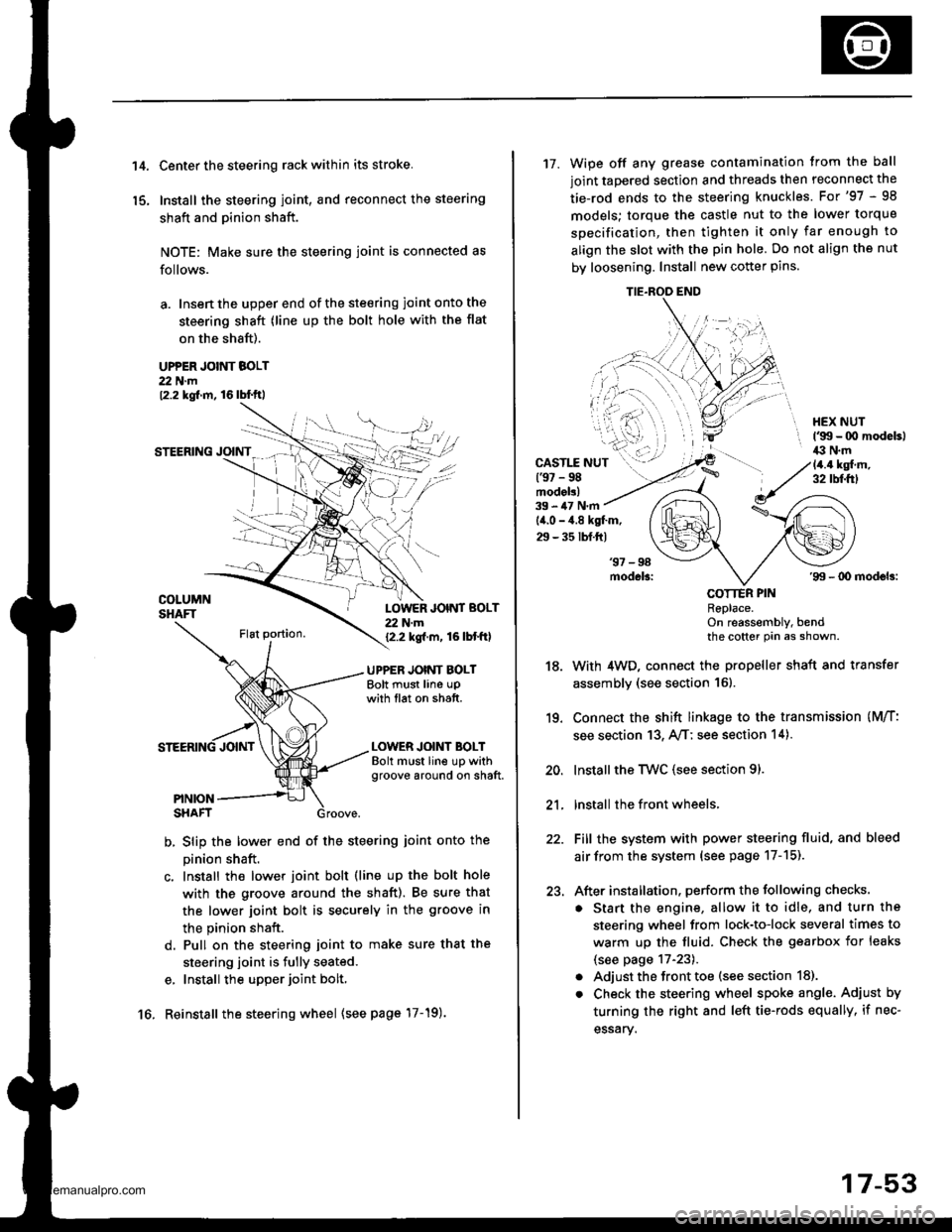

't 4.

15.

Center the steering rack within its stroke.

Install the steering joint, and reconnect the steering

shaft and pinion shaft.

NOTE: Make sure the steering joint is connected as

follows.

a. Insen the upper end of the steering joint onto the

steering shaft (line up the bolt hole with the flat

on the shaft).

UPPER JOINT BOLT22 N.m12.2 kgf.m, 16lbl.ft,

STEERING JOINT

COLUMNSHAFTLOWER JOINT BOLT22 N.m12.2 kgf.m, 16lbtftl

UPPER JOINT BOLTBolt must line upwith tlat on shatt.

LOWER JOINT BOLTBolt must line up withgroove around on shaft.

PINIONSHAFT

b, Slip the lower end of the steering ioint onto the

pinion shaft.

c. Install the lower joint bolt (line up the bolt hole

with ths groove around the shaft). Be sure that

the lower joint bolt is securely in the groove in

the pinion shaft.

d. Pull on the steering joint to make sure that the

steering joint is fully seated.

e, Install the upper joint bolt,

Reinstall the steering wheel {see page'17-19).16.

17-53

17. Wipe off any grease contamination trom the ball

joint tapered section and threads then reconnect the

tie-rod ends to the steering knuckles. For'97 - 98

models; torque the castle nut to the lower torque

specification, then tighten it only far enough to

align the slot with the pin hole. Do not align the nut

by loosening. Install new cotter pins.

CAST1T NUT(9t - 98modol!)

HEX NUTl'g!t - 00 modeb)il:l N.m14.4 ksl.m,32 tbf.f0

39 - iU N'm

lil.o - 4.8 kgl.m,

29 - 35 tbf.ftl

18.

19.

20.

21.

22.

23.

'99 - lD modeb:

COTTER PINRePlace.on reassembly, bendthe cotter Pin as shown.

With 4WD, connect the propeller shaft and transfer

assembly (see section 16).

Connect the shift linkage to the transmission (M/T:

see section 13, A,/T; see section 14).

Installthe Twc (see section 91.

lnstall the front wheels,

Fill the system with power steering fluid, and bleed

air from the system (see page 17-15).

After installation. perform the following checks.

. Start the engine, allow it to idle, and turn the

steering wheel from lock-to-lock several times to

warm up the fluid. Check the gearbox for leaks

(see page 17-23).

. Adjust the front toe (s€e section 18).

. Check the steering wheel spoke angl€. Adjust by

turning the right and left tie-rods equally, if nec-

essary.

TIE.ROO END

www.emanualpro.com

Page 1171 of 1395

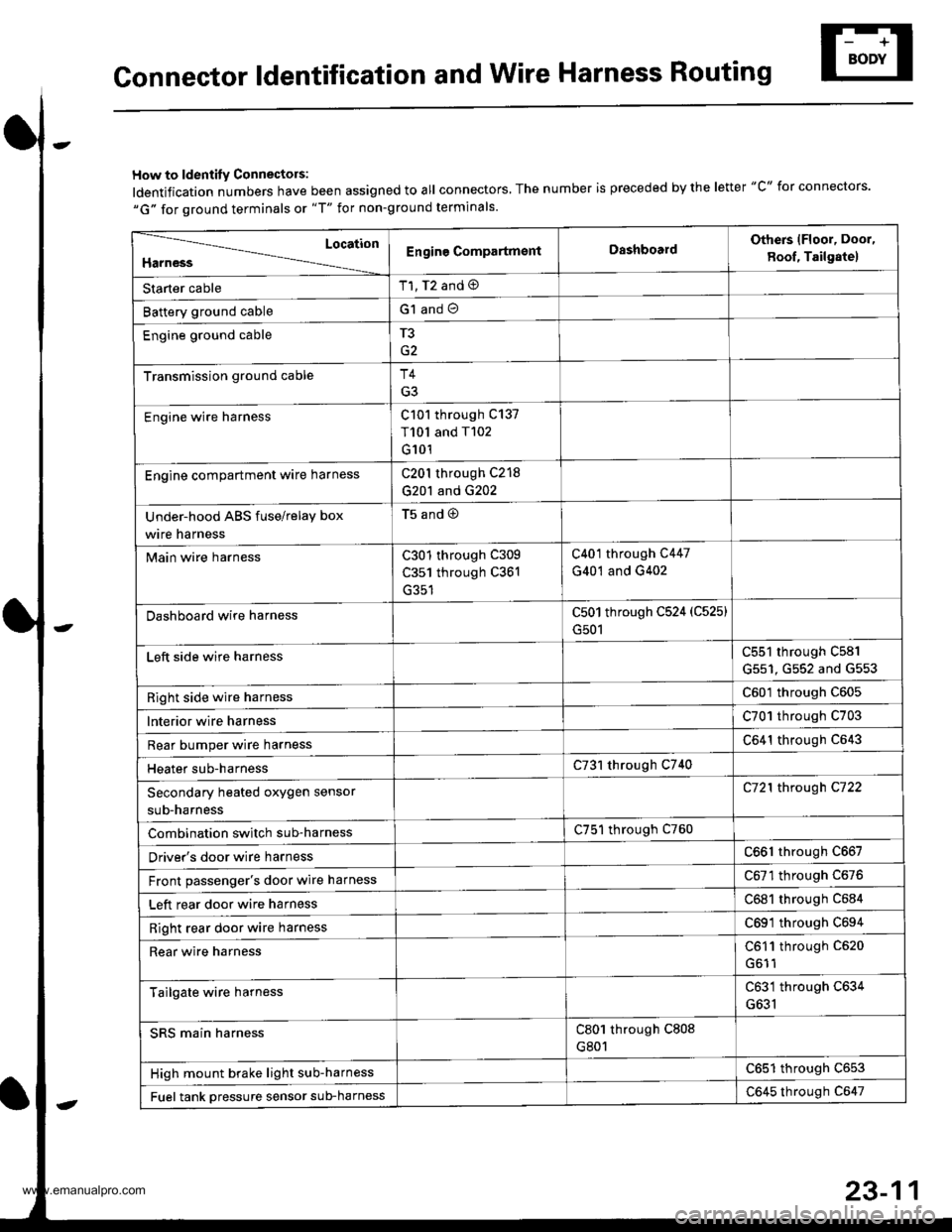

Gonnector ldentification and Wire Harness Routing

How to ldentity Connectors:

ldentification numbers have been assigned to all connectors, The number is preceded by the letter "C" for connectors.

"G" for ground terminals or "T" for non-ground terminals.

Location

HarnessEngine CompartmsntDashboardOthers lFloor, Door,

8oof, Tailgate)

Starter cableT1, T2 and @

Battery ground cableG1 and O

Engine ground cableT3

Transmission ground cableT4

G3

Engine wire harnessC101 through C137

T101 and T102

G101

Engine compartment ware harnessC201 through C218

G201 and G202

Under-hood ABS fuse/relay box

wire harness

t5ano9

Main wire harnessC301 through C309

C351 through C361

C401 through C447

G401 and G402

Dashboard wire harnessC501 through C524 (C525)

G501

Left side wire harnessC551 through C581

G551, G552 and G553

Right side wire harnessC601 through C605

lnterior wire harnessC701 through C703

Rear bumper wire harnessC641 through C643

Heater sub-harnessC731 through C740

Secondary heated oxygen sensor

sub-harness

C721 through C722

Combination switch sub-harnessC751 through C760

Driver's door wire harnessC661 through C667

Front passenger's door wire harnessC6Tl through C676

Left rear door wire harnessC681 through C684

Right rear door wire harnessC69'l through C694

Rear wire harnessC611 through C520

Tailgate wire harnessC631 through C634

G631

SRS main harnessC801 through C808

G801

High mount brake light sub-harnessC651 through C653

Fuel tank oressure sensor sub-harnessC645 through C647

www.emanualpro.com

Page 1172 of 1395

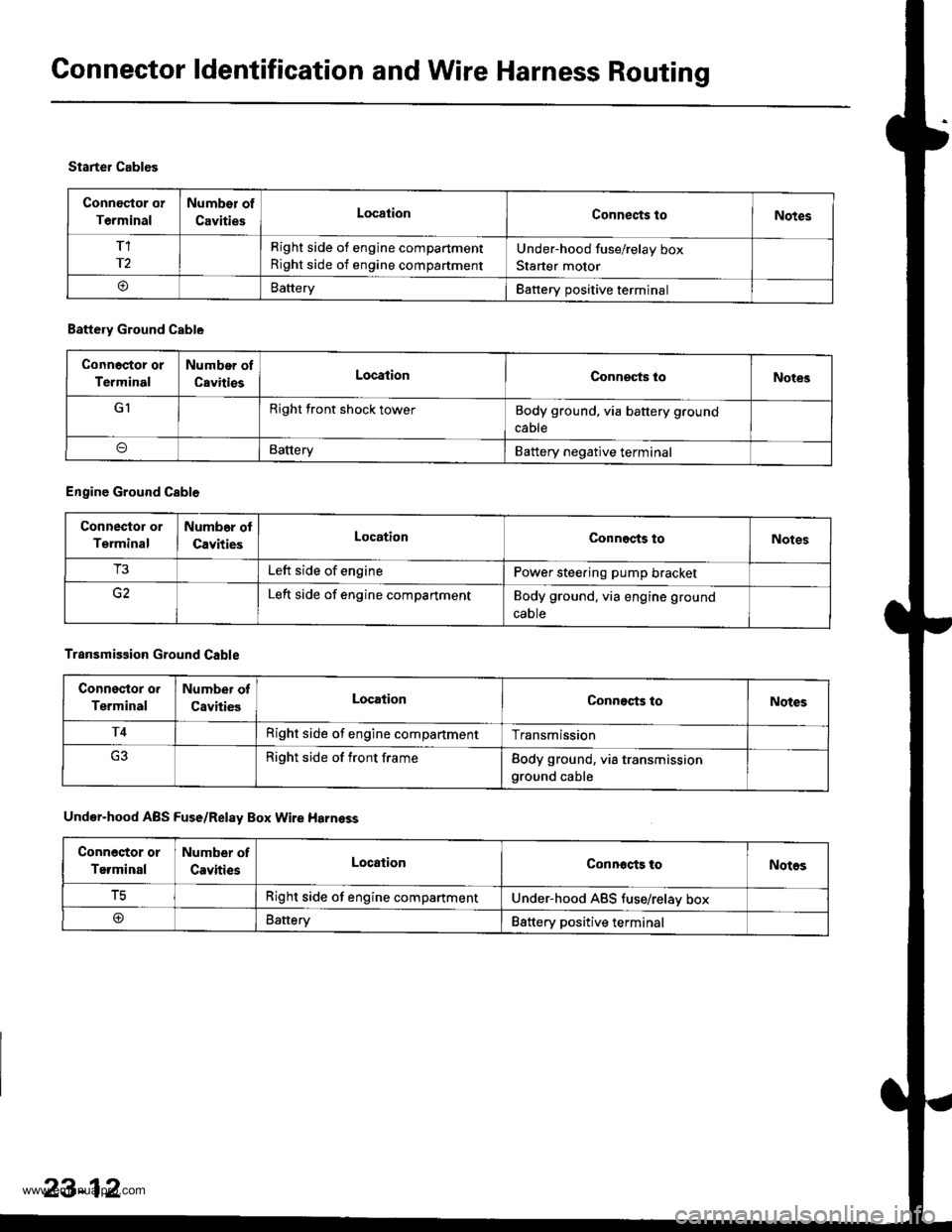

Connector ldentification and Wire Harness Routing

Connoctor or

Terminal

Number of

CavitiesLocationConnects toNotes

T1

r2

Right side of engine compartment

Right side of engine compartment

Under-hood fuse/relay box

Starter motor

oBatteryBattery positive terminal

Starter Cables

Battery Ground Cable

Connoctor or

Terminal

Number of

CavitiesLocationConneqts loNotes

GIRight front shock towerBody ground, via battery ground

cable

BatteryBattery negative terminal

Engine Ground Cable

Connector or

Terminal

Numb6r ol

CavitiesLocationConnects toNotes

T3Left side of enginePower steering pump bracket

Left side of engine compartmentBody ground. via engine ground

caote

Transmission Ground Cable

Connsstor o.

Terminal

Number of

CavitiesLocationConnects toNotes

T4Right side of engine compartmentTransmission

Right side of front frameBody ground, via transmissionground cable

Under-hood ABS Fuse/Relay Box Wire Harnsss

Conn6stor or

Terminal

Number of

CavitiesLocationConnocts toNotos

tcRight side of engine compartmentUnder-hood ABS tuse/relav box

@Battery88ttery positive terminal

23-12

www.emanualpro.com