diagnosis HONDA CR-V 1999 RD1-RD3 / 1.G Owner's Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1999, Model line: CR-V, Model: HONDA CR-V 1999 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 960 of 1395

Kickback'1. The motor operates when the ABS is functioning. and the fluid in the reservoir is forced out to the master cylinder,

causing kickback at the brake pedal.

2. The ABS control unit operates the solenoid valve when the brake pedal is released after the initial diagnosis You may

hear the solenoid valve operate at this time, but it is normal

Pumo Motol

1. The pump motor operates when the ABS is functioning

2. The ABS control unit checks the pump motor operation during acceleration. You may hear the motor operate at this

time, but it is normal.

Brake Fluid Replacement/Ail Bleeding

L Brake fluid replacement and air bleeding procedures are the same as for vehicles without ABS To ease bleeding, start

with the front wheels.

Troubleshooting

1. The troubleshooting flowchart procedures assume that the cause of the problem is still present and the ABS indicator

is still on. Following the flowchart when the ABS indicator does not come on can result in incorrect diagnosis.

2. Ouestion the customer about the conditions when the problem occurred, and try to reproduce the same conditions

for troubleshooting.

Self-diagnosis is made at various times such as the initial diagnosis, except ABS control, during ABS control, during

acceleration, during the specified vehicle speed, etc. Therefore, the symptom canngt be checked unless the check

conditions match with the problem conditjons

3. When the ABS jndicator does not come on during the test-drive. but troubleshooting is performed based on the DTC,

check lor loose connectors, poor contact of the terminals, etc., before you start troubleshooting.

4. After troubleshooting, erase the DTC and test-drive the vehicle. Be sure the ABS indicator does not come on.

5. The connector illustratjons show the female terminals with a single outline and the male terminals with a double out-

l ne.

ABS Function Test

To simulate ABS operation and activate the solenoid valves and pump, use the Honda PGM Tester.

Connect the PGM Tester to the 16P Data Link Connector (DLC). When the System Select menu is displayed, select the ABS

Test Mode menu, and follow the tester's prompts.

19-37

www.emanualpro.com

Page 963 of 1395

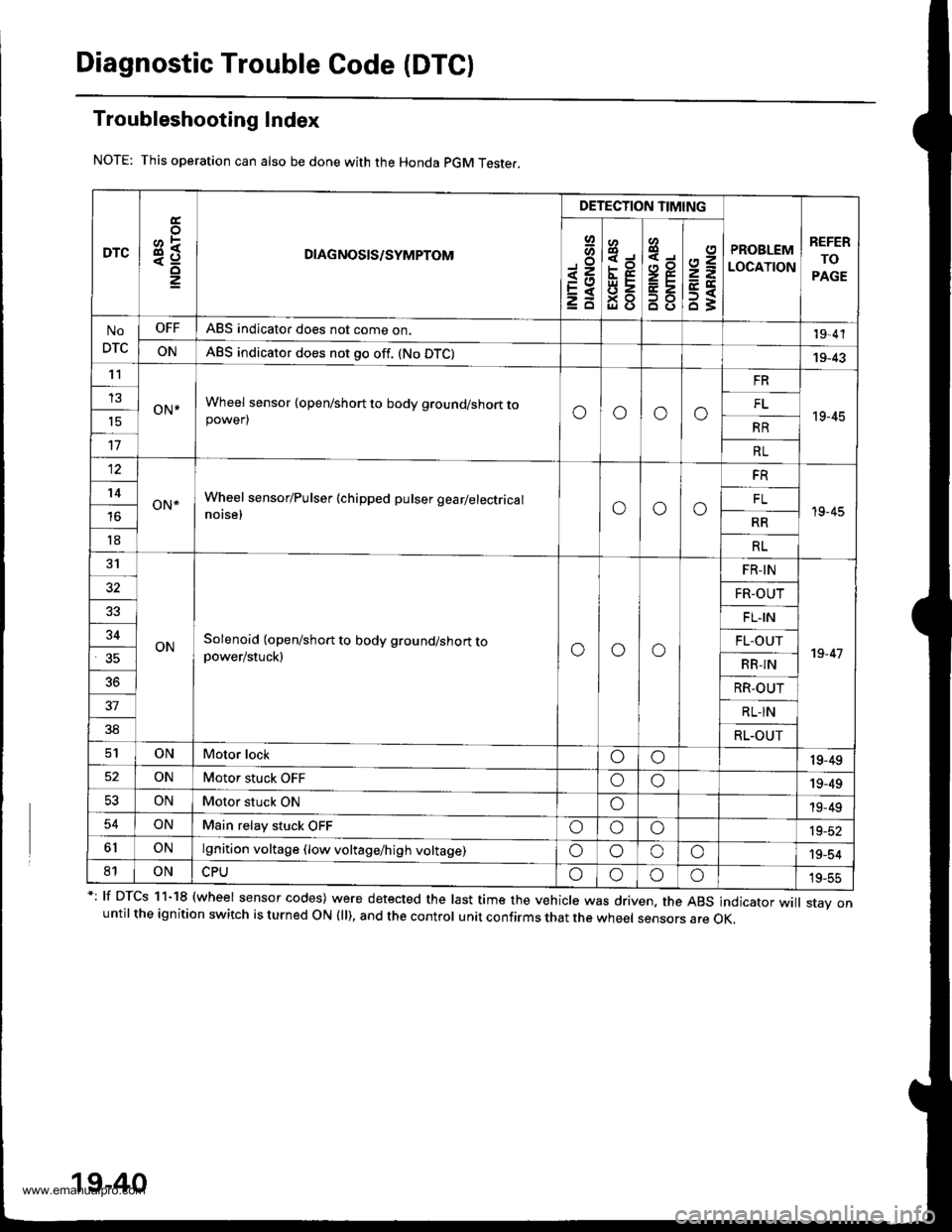

Diagnostic Trouble Code (DTC)

Troubleshooting Index

This operation can also be done with the Honda pGM Teste..

*: lf DTcs 11-18 {wheel sensor codes) were detected the last time the vehicle was driven, the ABs indicator wi

stav onuntil the ignition switch is turned ON (ll), and the control unit confirms that the wheel sensors are OK,

19-40

DTC3R

DETECTION TIMING

PROBLEM

LOCATION

REFER

TO

PAGE

Io

<=EXzd

8

93gl (J

4,,to

B8

2=

ET63

No

DTC

OFFABS indicator does not come on.19,4'l

ONABS indicator does not go off. (No DTC)19-43't1

oN*Wheel sensor {open/short to body ground/short topower)oooo

FR

19-45

13FL't5RR

17RL

12

oN*Wheel sensor/Pulser (chipped pulser gearlelectrical

notse,ooo

FR

19-45

't4FL

RR

18RL

31

ONSolenoid (open/short to body ground/short topower/stuck)ooo

FR-IN

19-47

32FR-OUT

FL.IN

34FL-OUT

RB-IN

36RR-OUT

37RL-IN

38RL.OUT

ONMotor lockoo19-49

ONMotor stuck OFFoo19-49

53ONMotor stuck ONo19-49

54ONMain relay stuck OFFoooia_at

6lONlgnition voltage (low voltage/high voltage)oooo'19-54

81ONoooo19-55

www.emanualpro.com

Page 1101 of 1395

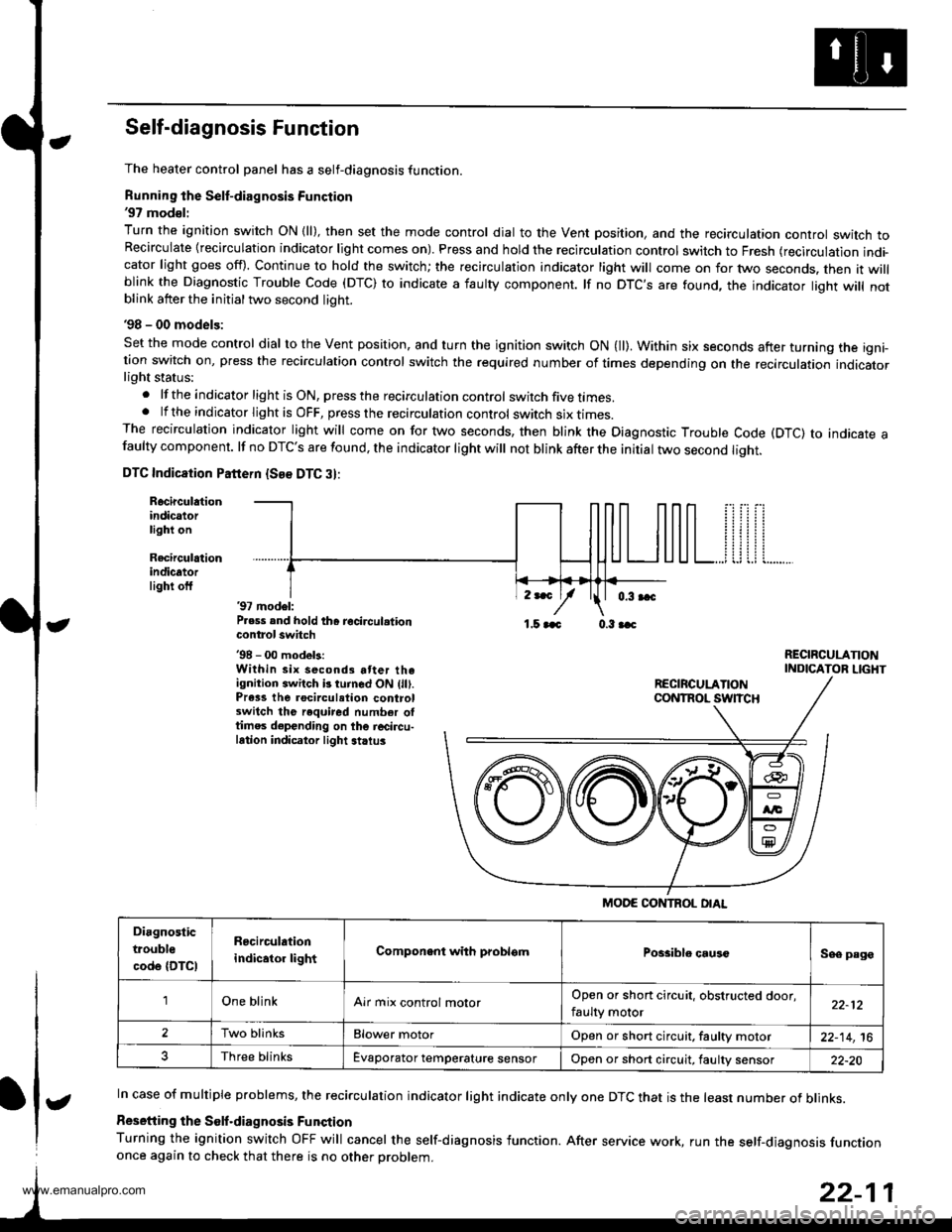

Self-diagnosis Function

The heater control panel has a self-diagnosis function.

Running the Self-diagnosis Function'97 mod€l:

Turn the ignition switch ON {ll), then set the mode control dial to the Vent position, and the recirculation controt switch toRecirculate {recirculation indicator light comes on). Press and hold the recirculation control switch to Fresh (recirculation indi-cator light goes off). Continue to hold the switch; the recirculation indicator light will come on for two seconds. then it willblink the Diagnostic Trouble Code (DTC) to indicate a iaulty component. lf no DTC'S are found, the indicator liqht will notblink atter the initial two second light.

'98 - 00 models:

Set the mode control dial to the Vent position, and turn the ignition switch ON (ll). Within six seconds after turning the igni-tion switch on, press the recirculation control switch the required number of times depending on the recirculation indicatorlight status:

.lftheindicatorlightisON,presstherecirculationcontrol switch five times..lftheindicatorlightisOFF,presstherecirculationcontrol switch six I|mes.The recirculation indicator light will come on for two seconds, then blink the Diagnostic Trouble Code (DTC) to indicate afaulty component. lf no DTC'S are found, the indicator light will not blink after the initial two second liqht.

DTC Indicaiion Pattern {See DTC 3}:

Rocirculationindicatorlight on

Recirculrtionindicatorlighi off'97 model:P.ess and hold th6 recircul.tioncontrol switch'98 - 00 modek:Within six second3 atter theignition switch b turned ON (lll.Prass the rocirculation controlswitch the required number oltimes depending on the r6circu-lation indicator light striu3

,r*

/1.5 aaa 0.3 aac

RECIRCULANONINDICATOR LIGHT

In case of multiple problems, the recirculation indicator light indicate only one DTC that is the least number of blinks.

Resetiing the Solf.diagnosis Funqtion

Turning the ignition switch OFF will cancel the self-diagnosis function. After service work, run the self-diaqnosis functiononce again to check that there is no other Droblem.

MODE CONTROL OIAL

Diagnostic

trouble

code {DTCI

R6circulation

indicator lightComponent with problsmPossiblo causcSee page

'lOne blinkAir mix control molorOpen or short circuit, obstructed door,

faulty motor22-12

2Two blinksElower motorOpen or short circuit, faultv motor22-14,16

Three blinksEvaporator temperature sensorOpon or short circuit, faulty sensor22-20

t

www.emanualpro.com

Page 1102 of 1395

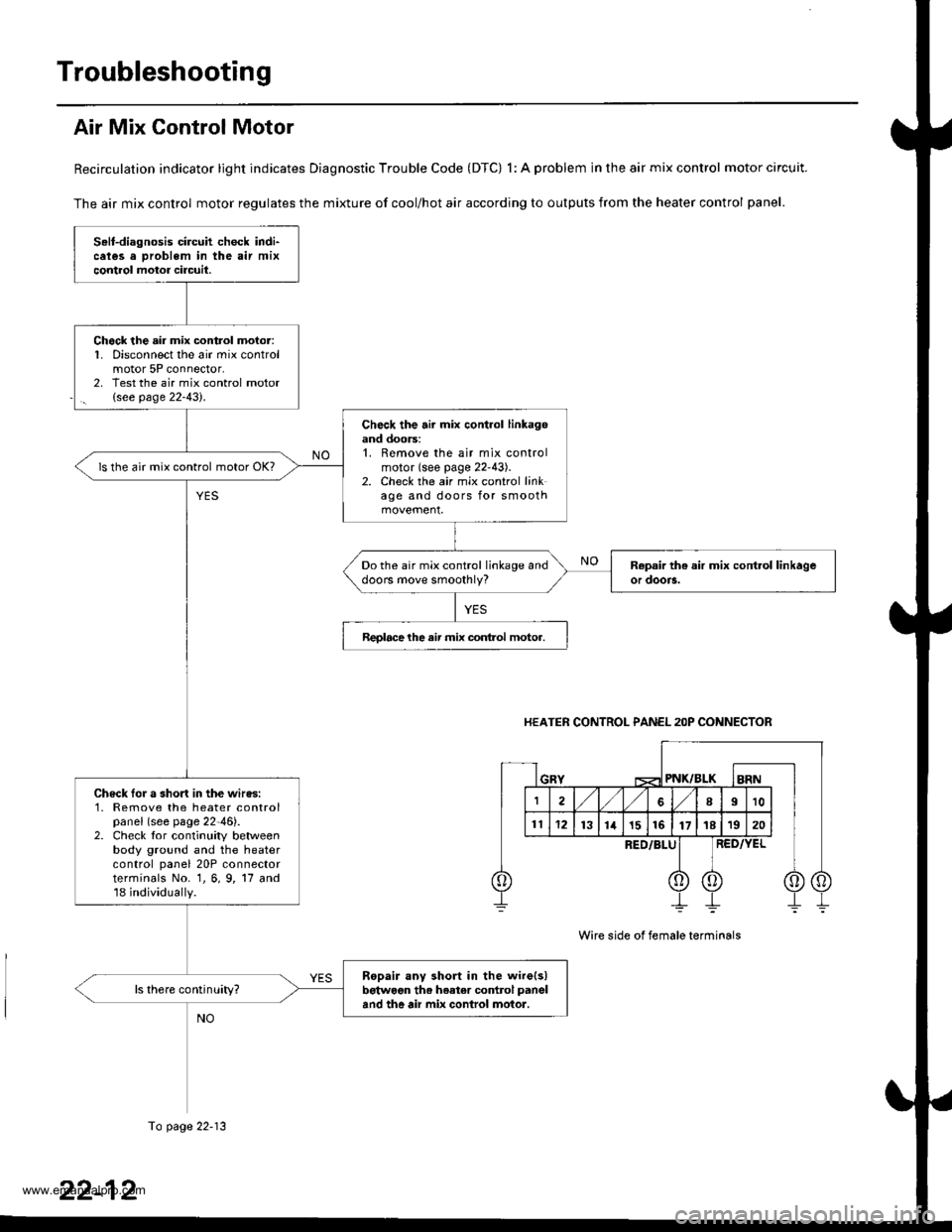

Troubleshooting

Air Mix Control Motor

Recirculation indicator light indicates Diagnostic Trouble Code (DTC) 1: A problem in the air mix control motor circuit.

The air mix control motor regulates the mixture of cool/hot air according to outputs from the heater control panel.

Selt-diagnosis circuit check indi-cates a Droblem in the air mixcontrol motor circuil.

Chock the air mix control moior:1. Disconnect the air mix controlmotor 5P connector,2, Test the air mix control motor(see page 22-43).

Check the air mix control linkagoand doors:1. Remove the air mix controlmotor (see page 22'43).2. Check the air mix control linkage and doors for smooth

ls the air mix control motor OK?

Do the air mix control linkage anddoors move smoothly?

Reolacelhe air mix conlrol motor.

Check Ior a short in the wires:1- Remove the heater controlpanel (see page 22-46).2. Check tor continuity betweenbody ground and the heatercontrol panel 20P connectorterminals No. 1, 6, 9, 17 and18 individually.

Ropair any short in the wire(s)betwoon th. heater co.rtrol panel

and the air mix conlrol motor.

HEATER CONTROL PANEL 2OP CONNECTOR

PNK/BLK

RED/BLU

Wire side of female terminals

To page 22-13

www.emanualpro.com

Page 1104 of 1395

Troubleshooting

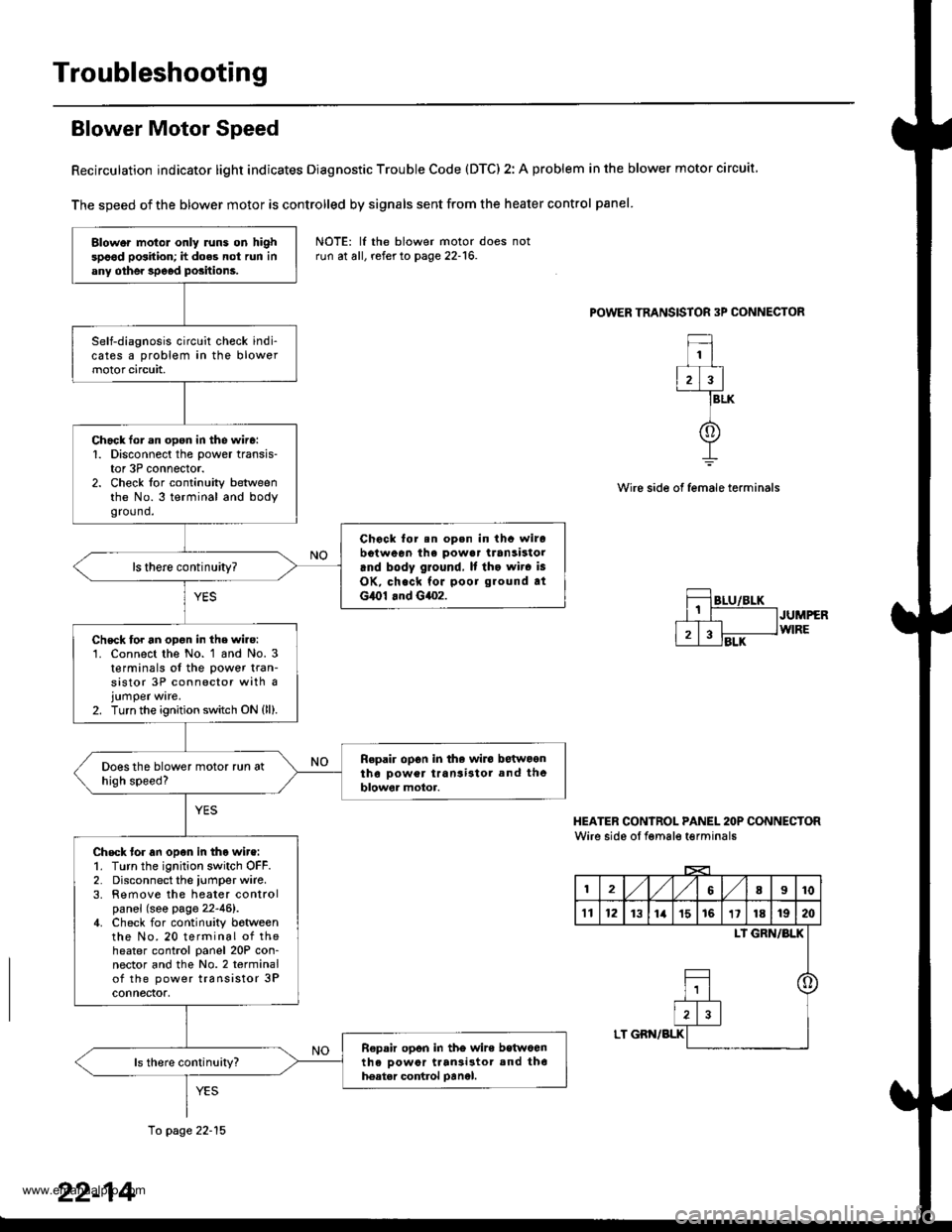

Blower Motor Speed

Recirculation indicator light indicates Diagnostic Trouble Code (DTC) 2: A problem in the blower motor circuit

The speed of the blower motor is controlled by signals sent from the heater control panel

POWER TRANSISTOR 3P CONNECTOR

1

2)3

f

BLK

Wire side of female terminals

JUMPERWIRE

HEATER CONIROL PANEL 2OP CONNECTORWire side oI fgmale t€rminals

12,/1,/68I10

't112131ia't51611181920

LI GRN/BLK

o

LT GBN/BLK

Blower motol only runs on highspood position; h does not run inany othe. speod positions.

Self-diagnosis circuit check indi-cates a problem in the blowermotor circuit,

Chack lor.n open in the wire:1. Disconnect the power transis-tor 3P connector.2. Check for continuity betweenthe No.3 terminal and bodygro(1nd.

Chock for.n op.n in thc wirobotween ihe powa. transistorrnd body ground, It tho wir. is

OK, check for poor ground atG,O1 .nd G4o2.

ls there continuity?

Chsck for an opon in the wire:'1. Connect the No. 1 and No. 3t€rminals of the power tran-sistor 3P connector with ajumper ware.2. Turn the ignition switch ON {ll).

Repair op6n in the wiro betwoontho Dower transi3tol and theblowor motor.

Check tor an open in tho wire:1. Turn the ignition switch OFF.2. Disconnect the iumper wire.3. Remove the heater controlpanel (see page 22-46).4. Check for continuity botweenthe No. 20 terminal of theheater control panel 20P con-nector and the No.2 terminalof the power transistor 3Pconnectof,

R€pair opon in tho wire betwoenth6 oowor ttan3i3tor and th6hoatar control oanel.

NOTE: lf the blower motor doesrun at all, refer to page 22-16.

10 page 22-15

22-14

www.emanualpro.com

Page 1106 of 1395

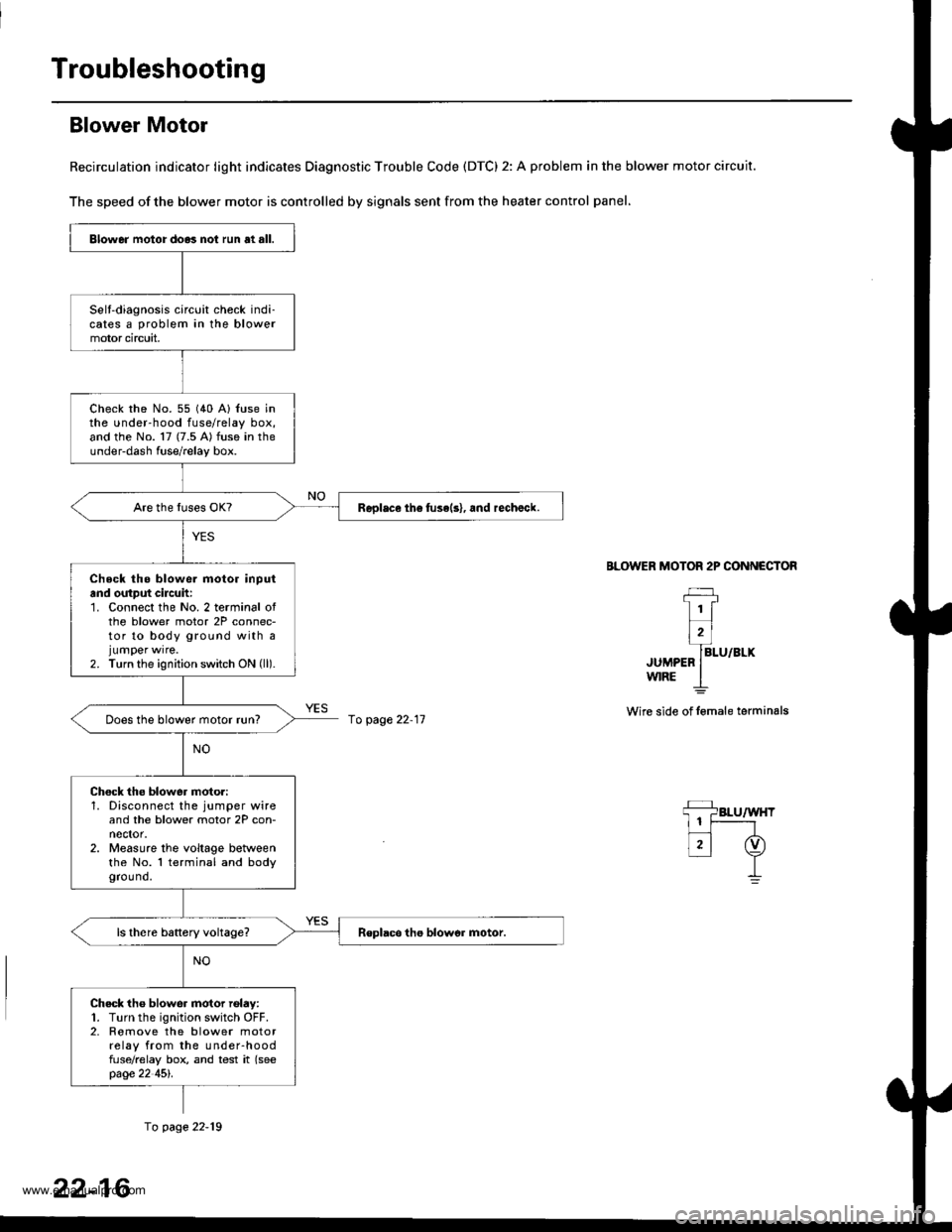

Troubleshooting

Blower Motor

Recirculation indicator light indicates Diagnostic Trouble Code (DTC) 2: A problem in the blower motor circuit.

The speed of the blower motor is controlled by signals sent from the heater control panel,

BLOWER MOTOR 2P CONNECTOR

JUMPEFw|RE

Wire side of lemale terminals

Blower motor do.3 not run at all.

Selt-diagnosis circuit check indi-cates a problem in the blowermotor circuit,

check rhe No. 55 (40 A) {use inthe under-hood fuse/relay box,and the No. 17 (7.5 A) fuse in theunder-dash fuse/relay box.

Replace th6 fuse(s), and rechalck.

Check tho blowe. motor inputand output cilcuh:1. Connect the No. 2 terminal ofthe blower motor 2P connec-tor to body ground with ajumper wrre.2. Turn the ignition switch ON (ll).

Does the blower motor run?

Chock the blower moto.:1. Disconnect the jumper wireand the blower motor 2P con-nector.2. Measure the voltage betweenthe No. l terminal and bodygrou nd.

Check tho blower motor rolay:1. Turn the ignition switch OFF.2. Romove the blower motorrelay from the under-hoodfuse/relay box, and test it (seepage 22 45l'.

fo page 22-11

fo page 22-19

22-16

www.emanualpro.com

Page 1110 of 1395

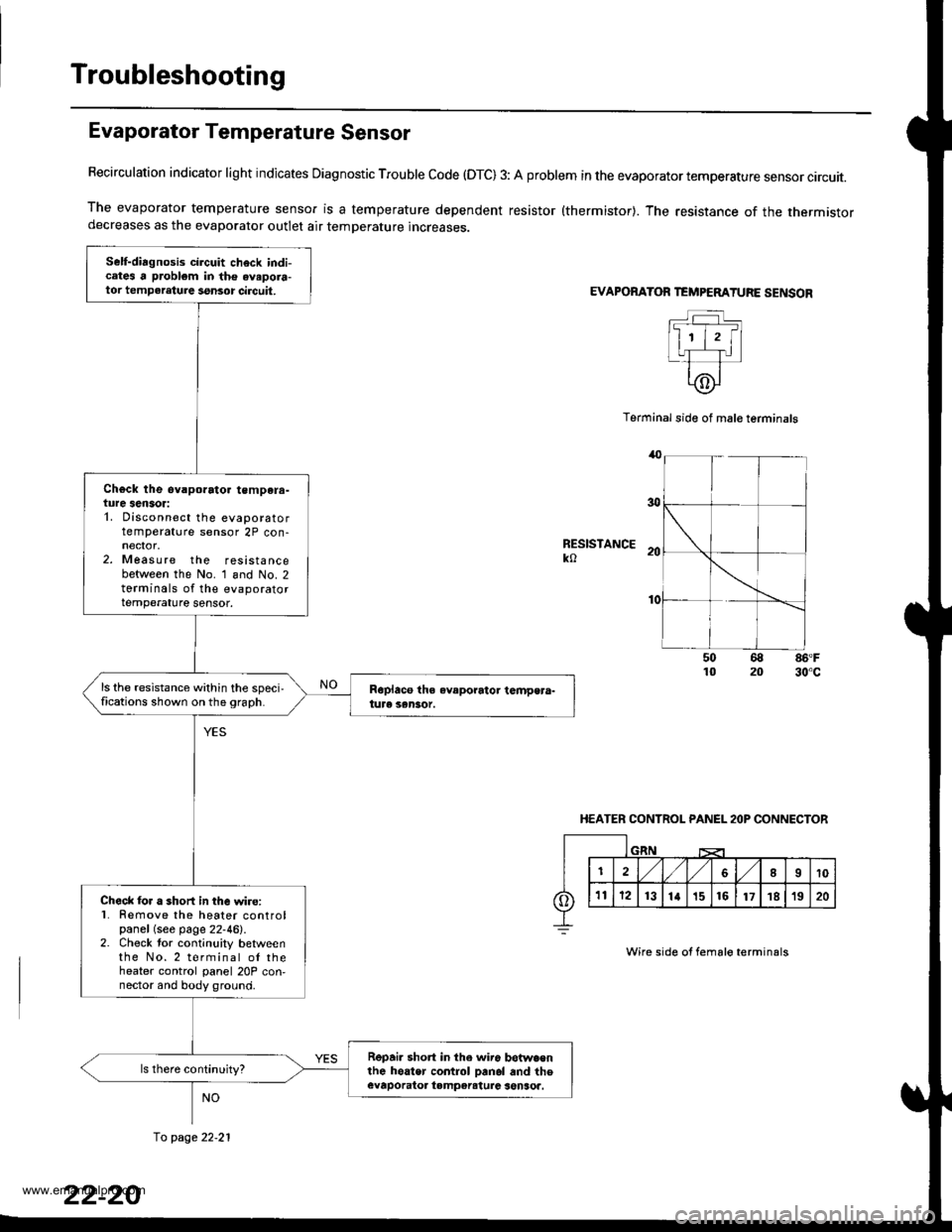

Troubleshooting

Evaporator Temperature Sensor

Recirculation indicator light indicates Diagnostic Trouble code (OTC) 3: A problem in the evaporator temperature sensor circuit.

The evaporator temperature sensor is a temperature dependent resistor {thermistor}. The resistance of the thermistordecreases as the evaporator outlet air temperature increases.

EVAPORATOR TEMPEMTURE SENSOR

Terminal side of mal€ terminals

RESISTANCEko

86'F30"c

HEATER CONTROL PANEL 2OP CONNECTOR

Wire side of fema16 terminals

Self-diagnosis circuit check indicates a problem in the avapora-tor tempeleture ssnsor circuit,

Ch€ck the ev.porato. tempera-ture sensor:1. Disconnect the evaporatortemperature sensor 2P con-

2. Measure the resistancebetween the No. 1 and No. 2torminals of the evaporatortemperature sensor.

ls the resistance within the speci,fications shown on the 9raph.

Check lor a short in the wire:l� Remove the heater controlpanel (see page 22-46).2. Check tor continuity betweenthe No.2 terminal ol theheater control panel 20P con,nector and body ground.

Repai. short in the wir6 betwa€nlhe hoater control Danol and theevaporatoa tampereturc senSoa.

fo page 22.21

www.emanualpro.com

Page 1165 of 1395

Five-step Troubleshooting

1.

3.

Verify The Complaint

Turn on all the components in the problem circuit to

verify the customer complaint. Note the symptoms.

Do not begin disassembly or testing until you have

narrowed down the problem area.

Analyze The Schematic

Look up the schematic for the problem circuit.

Determine how the circuit is supposed to work by

tracing the current paths from the power feed

through the circuit components to ground. lf several

circuits fail at the same time, the fuse or ground is a

likely cause,

Based on the symptoms and your understanding of

the circuit operation, identify one or more possible

causes of the problem.

lsolate The Problem By Testing The Circuit

Make circuit tests to check the diagnosis you made

in step 2. Keep jn mind that a logical, simple proce-

dure is the key to efficient troubleshooting. Test for

the most likely cause of failure first. Try to make

tests at points that are easily accessible,

Fix The Problem

Once the specific problem is identified, make the

repair. Be sure to use proper tools and safe proce-

dures.

Make Sure The Circuit Works

Turn on all components in the repaired circuit in all

modes to make sure you've fixed the entire prob-

lem. lf the problem was a blown fuse, be sure to

test all of the circuits on the fuse. lvlake sure no new

problems turn up and the original problem does nol

recur.

4.

O

Wire Color Codes

The following abbreviations are used to identify wire

colors in the circuit schematics:

WHT ............................. White

YEL,.............................. Yellow

BLK ..........,................... Black

BLU .............................. Blue

GRN .............................Green

RED .............................. Red

ORN .............................Oran9e

PNK.....,........................ Pink

BRN .............................. Brown

GRY .............................. Gray

PUR .........,.................... Purple

LT BLU ..................,...... Light Blue

LT GRN ........................ Light Green

The wire insulation has one color or one color with

another color stripe. The second color is the stripe.

WHT/BLK

www.emanualpro.com

Page 1314 of 1395

Description

J)

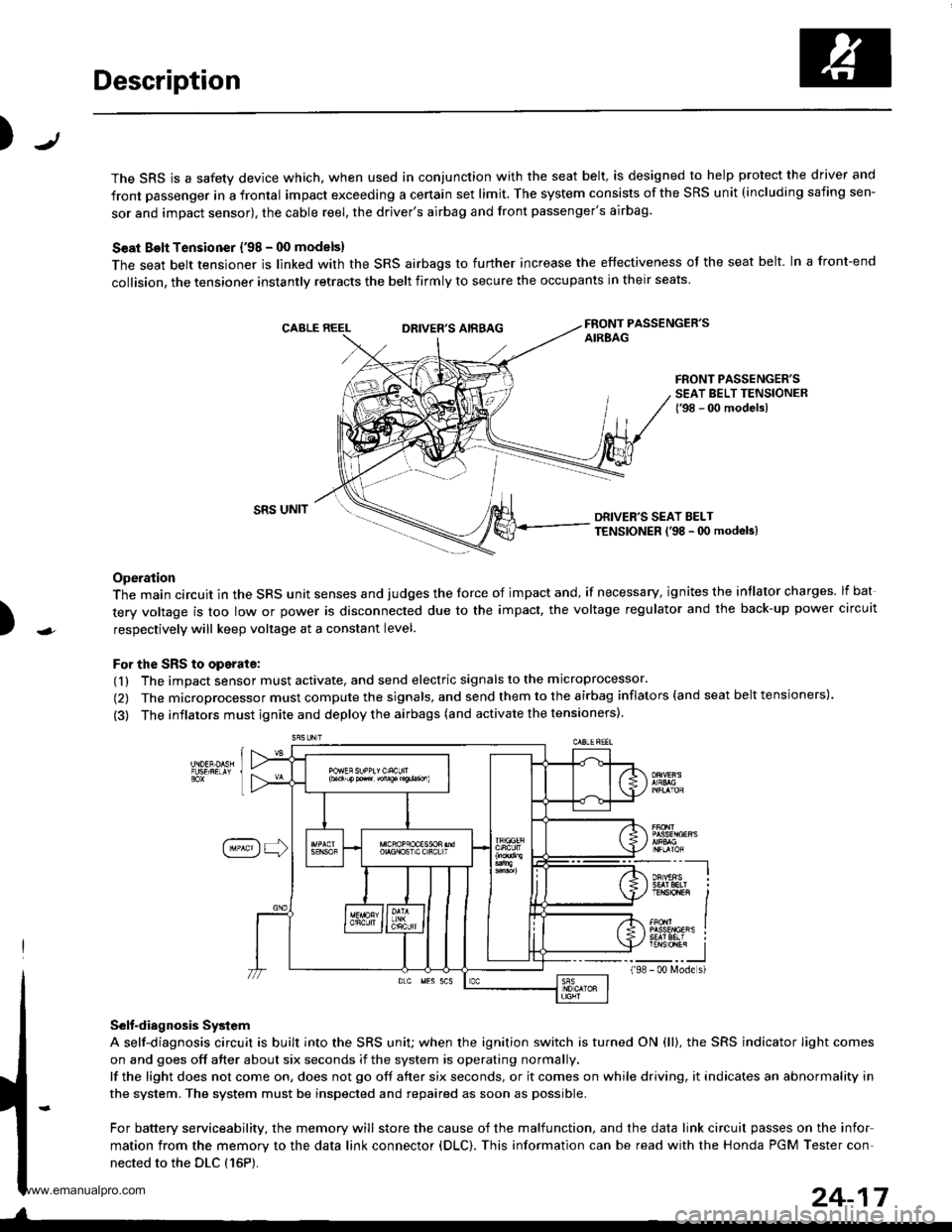

The SRS is a safety device which, when used in conjunction with the seat belt, is designed to help protect the driver and

front passenger in a frontal impact exceeding a certain set limit. The system consists of the SRS unit (including safing sen-

sor and impact sensor), the cable reel, the driver's airbag and front passenger's airbag.

Seat Bolt Tensioner {'98 - 00 models}

The seat belt tensioner is linked with the SRS airbags to further increase the effectiveness of the seat belt. In a front-end

collision, the tensioner instantly retracts the belt firmly to secure the occupants in their seats

FRONT PASSENGER'SAIREAGDRIVER'S AIRBAG

FRONT PASSENGER'SSEAT BELT TENSIONER{'98 - 00 modelsl

)

SRS UNITDRIVER'S SEAT BELTTENSIONER l'98 - 0O modeb)

Operation

The main circuit in the SRS unit senses and judges the force of impact and, if necessary, ignites the intlator charges. lf bat

tery voltage is too low or power is disconnected due to the impact, the voltage regulator and the back-up power circuit

respectively will keep voltage at a constant level.

For the SRS to operate:

(1) The impact sensor must activate, and send electric signals to the microprocessor.

(2) The microprocessor must compute the signals, and send them to the airbag inflators (and seat belt tensioners).

(3) The inflators must ignite and deploy the airbags (and activate the tensioners).

Selt-diagnosis System

A self-diagnosis circuit is built into the SRS uniU when the ignition switch is turned ON (ll), the SRS indicator Iight comes

on and goes off after about six seconds if the system is operating normally.

lf the light does not come on, does not go off after six seconds, or it comes on while driving, it indicates an abnormality in

the system. The system must be inspected and repaired as soon as possible.

For battery serviceability, the memory will store the cause of the malfunction, and the data link circuit passes on the infor

mation from the memory to the data link connector (DLC). This information can be read with the Honda PGM Tester con-

nected to the DLC {16P).

198

---__-l

TENSTO1En II

_-___J- 00 N4ode s)

24-17

www.emanualpro.com

Page 1328 of 1395

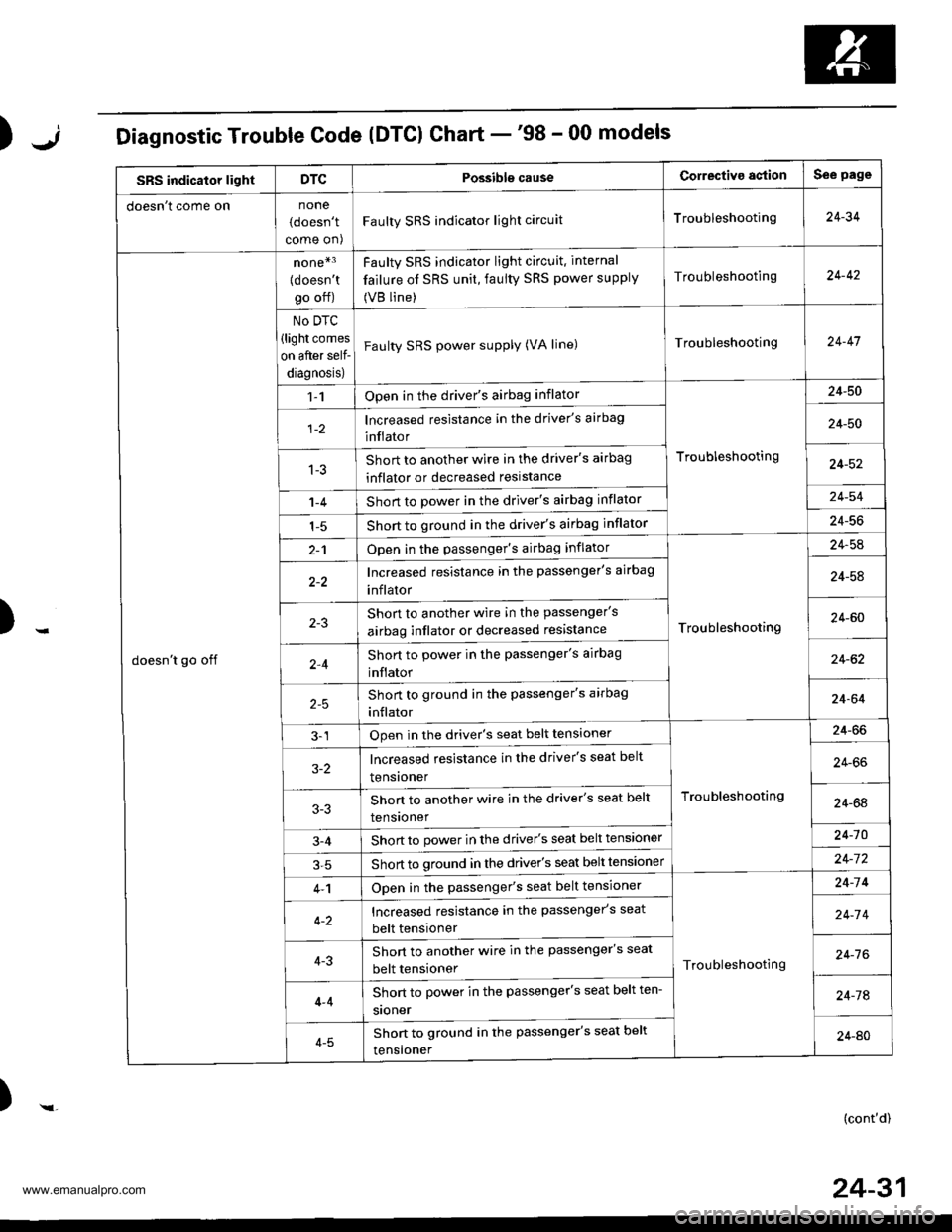

);Diagnostic Trouble Code (DTCI Chart -'98 - 00 models

SRS indicator lightDTCPossibls causeCorrectiva agtionSee page

doesn t come onnone

(doesn't

come on)

Faulty SRS indicator light circuitTroubleshooting24-34

doesn't go off

none*3

{doesn'tgo off)

No DTC

(light comes

on after self-

diagnosis)

Faulty SRS indicator light circuit. internal

failure of SRS unit, faulty SRS power supply

(VB line)

Troubleshooting24-42

Faulty SRS power supply (VA line)Troubleshooting24-47

1-1Open in the driver's airbag inflator

Troubleshooting

24-50

lncreased resistance in the driver's airbag

inflator24-50

1-3Short to another wire in the driver's airbag

inflator or decreased reslstance24-52

1-4Short to power in the driver's airbag inflator24-54

1-5Short to ground in the driver's airbag inflator24-56

2-1Open in the passenger's airbag inflator

Troubleshooting

24-54

Increased resistance in the passenger's airbag

inflator24-58

Shon to another wire in the passenger's

airbag inflator or decreased resistance24-60

2,4Short to power in the passenger's airbag

inflator24-62

Short to ground in the passenger's arrbag

inflator24-64

3-1Open in the driver's seat belt tensioner

Troubleshooting

24-66

3-2lncreased resistance in the driver's seat belt

tensroner24-66

Shon to another wire in the driver's seat belt

tensroner24-64

3-4Short to power in the driver's seat belt tensioner24-10

Short to ground in the driver's seat belt tensloner24-7 2

4-1Open in the passenger's seat belt tensioner

Troubleshooting

24-14

Increased resistance in the passenger's seat

belt tensioner24-7 4

4-3Short to another wire in the passenger's seat

belt tensioner24-7 6

4-4

4-5

Short to power in the passenger's seat belt ten-

sroner24-74

Shon to ground in the passenger's seat belt

tensroner24-AO

)-(cont'd)

24-31

www.emanualpro.com